Submitted:

13 July 2023

Posted:

13 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Raw materials

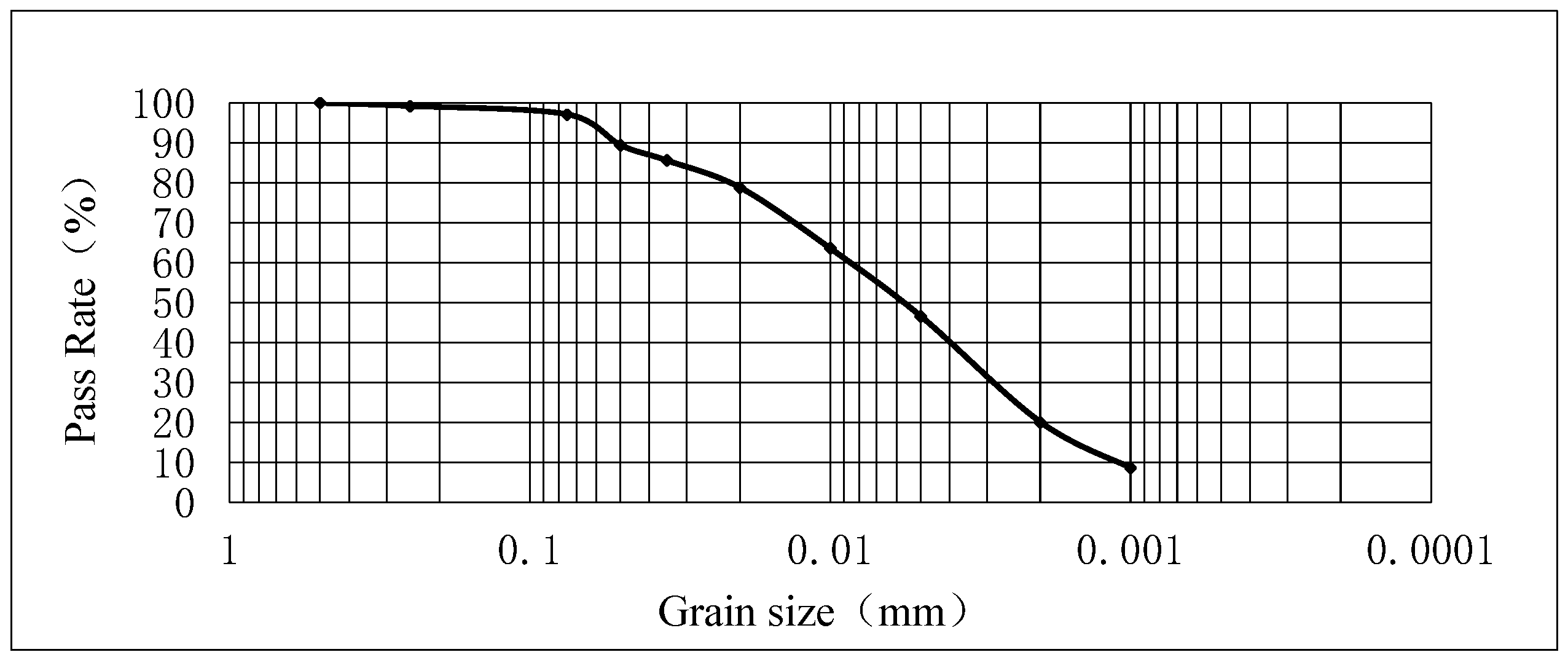

2.1.1. Red mud

2.1.2. Nano-SiO2

2.1.3. Cement

2.1.4. Gypsum

2.2. Experimental design

- ①

- Adding cement alone to dry red mud and testing the effect of the individual admixture of cement on the strength of the specimen;

- ②

- The nano-SiO2 dosing of 1% was selected to test the effect of different cement dosing on the unconfined compressive strength of specimens under the synergistic effect of nano-SiO2;

- ③

- The optimum dose of 3% cement and 6% gypsum was selected from both strength and economic considerations, and different mass ratios of nano-SiO2 were added on this basis to test the synergistic effects of the three modified materials on strength control, and to determine the optimum nano-SiO2 dosage.

2.3. Specimen preparation

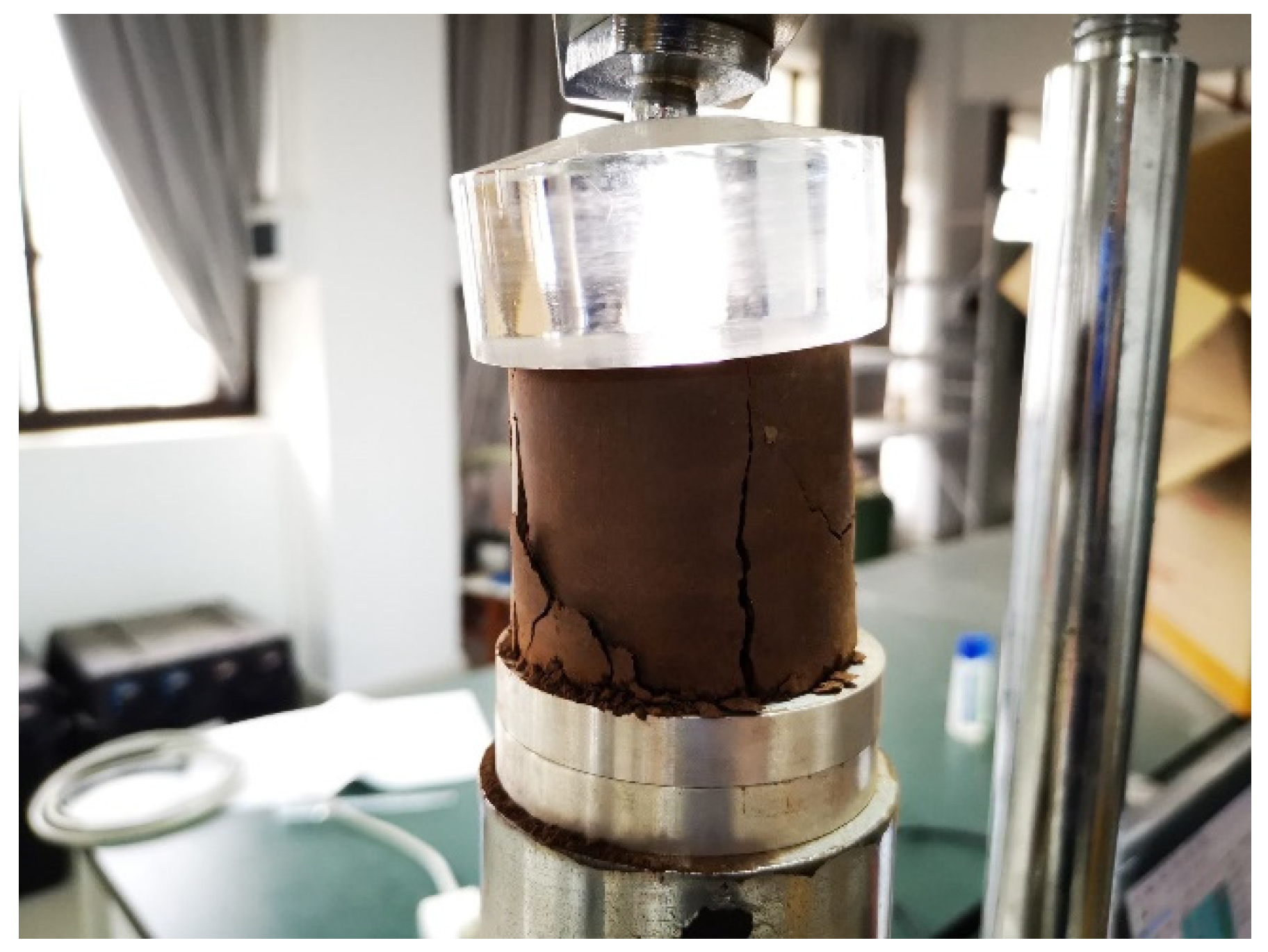

2.4. Unconfined compressive strength test

3. Results and analysis

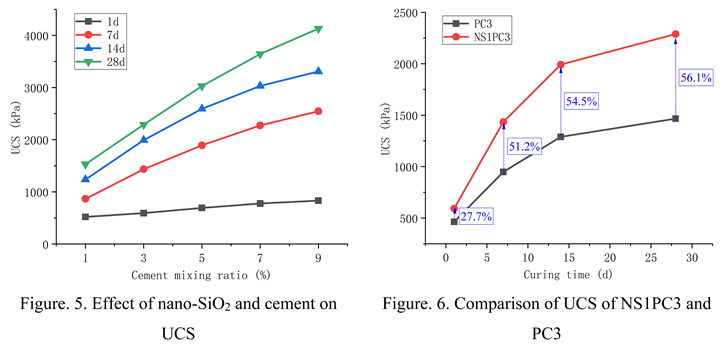

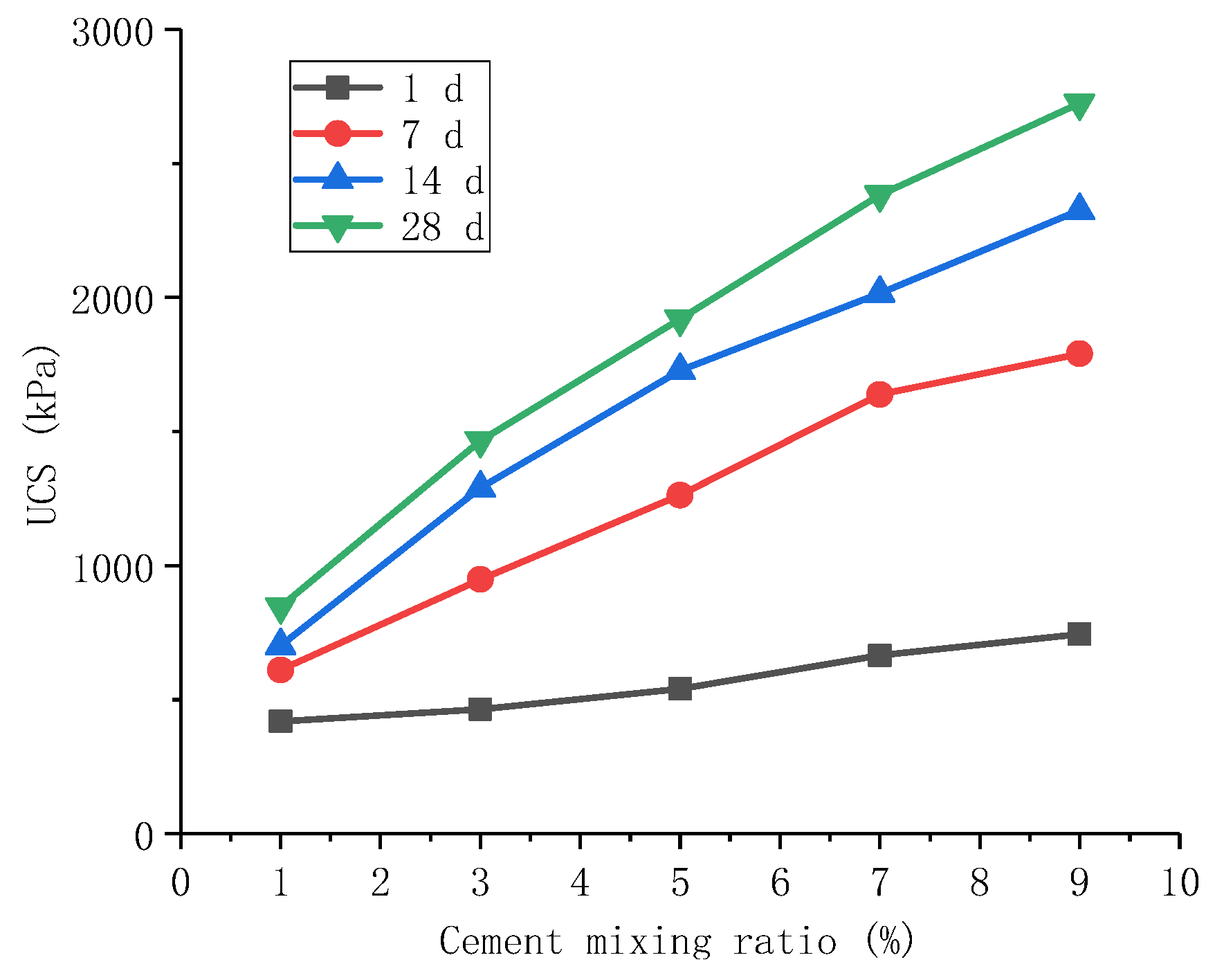

3.1. Effect of cement

3.2. Effect of synergistic modification

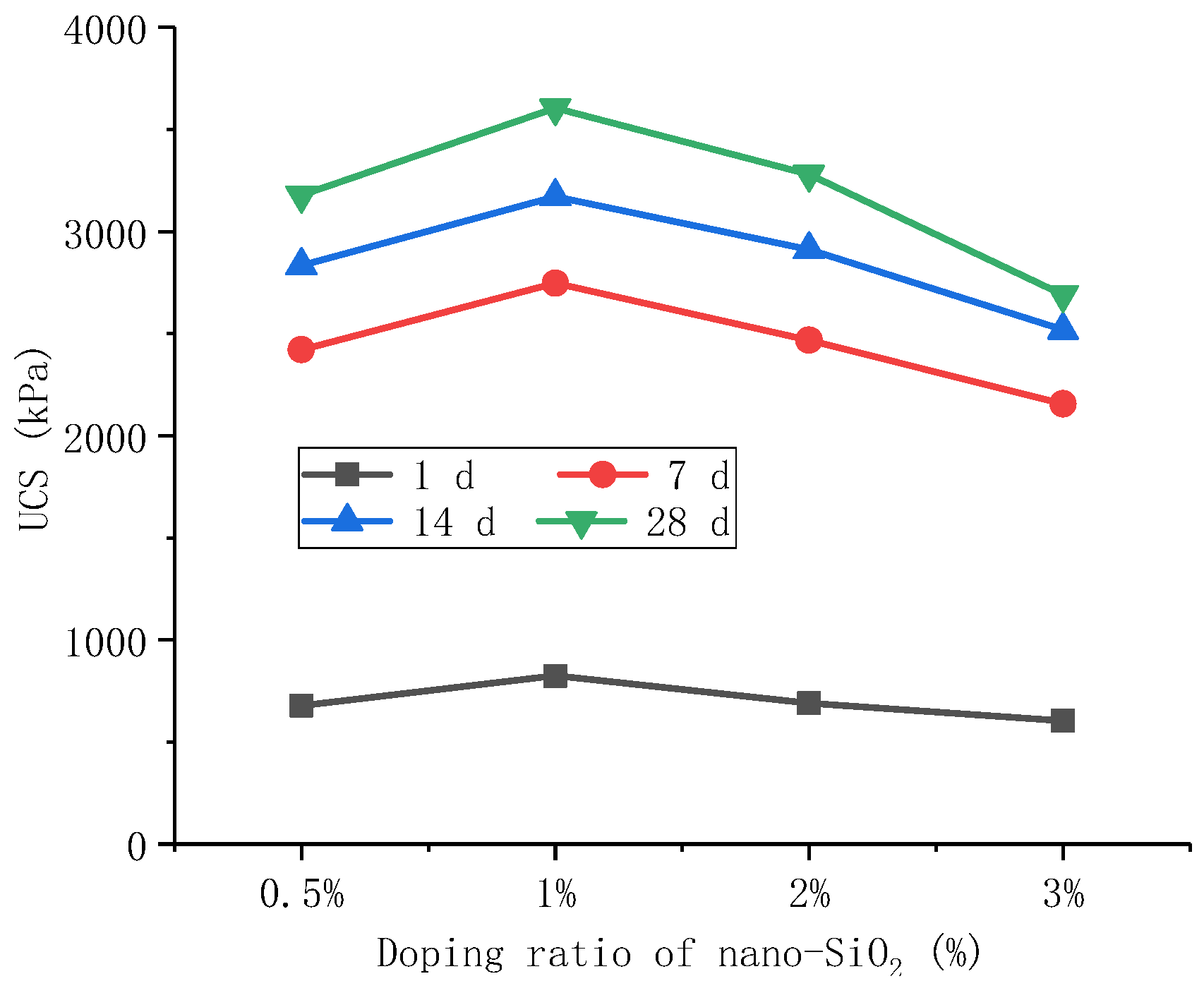

3.2.1. Effect of nano-SiO2 and cement co-modification

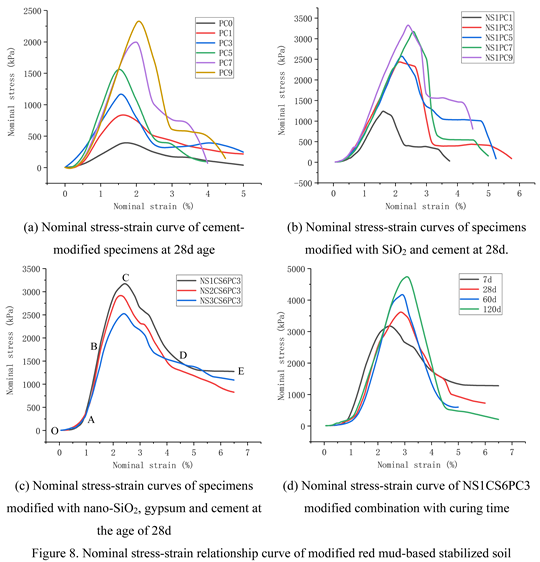

3.2.2. Effect of nano-SiO2 co-modification with cement and gypsum

3.2.3. Analysis of the synergistic effect of nano-SiO2

3.3. Compressive damage characteristics of red mud-based stabilized soil

3.3.1. Nominal stress-strain relationship

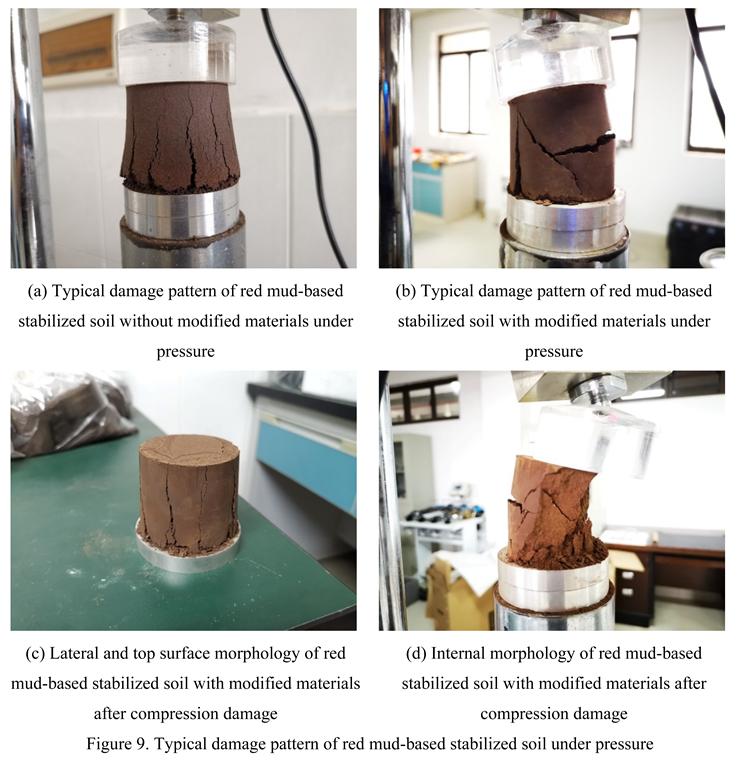

3.3.2. Typical damage characteristics

4. Conclusions

References

- Ahmed S, Meng T, Taha M. Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening [J]. Nanotechnology Reviews, 2020, 9(1):396-409. [CrossRef]

- Atan E, Sutcu M, Cam A S. Combined effects of bayer process bauxite waste (red mud) and agricultural waste on technological properties of fired clay bricks [J]. Journal of Building Engineering, 2021, 43(3):103194. [CrossRef]

- Bombik E, Bombik A, Rymuza K.The influence of environmental pollution with fluorine compounds on the level of fluoride in soil, feed and eggs of laying hens in Central Pomerania, Poland[J].Environmental Monitoring and Assessment, 2020, 192(3). [CrossRef]

- Gayathiri K, Praveenkumar S. Influence of Nano Silica on Fresh and Hardened Properties of Cement-based Materials – A Review [J]. 2022, Silicon:1-31. [CrossRef]

- GB/T50123-2019, Standard for soil test method [S]. Beijing:China Planning Press, 2019.

- JTG/T F20-2015, Technical Guidelines for Construction of Highway Roadbases [S]. Beijing:Ministry of Transport of the People's Republic of China, 2015.

- JTG E51-2009, Test Method of Materials Stabilized whit Inorganic Binders for Highway Engineering [S]. Beijing:People's Traffic Publishing House, 2009.

- Kumar D P, Amit S, Chand M. Influence of various nano-size materials on fresh and hardened state of fast setting high early strength concrete [FSHESC]: A state-of-the-art review [J]. Construction and Building Materials, 2021, 277(1):122299. [CrossRef]

- Liao S Z, Yang J L, Ma S J, et al. Research Progress in the Comprehensive Utilization of Red Mud [J]. Conservation and Utilization of Mineral Resources, 2019. [CrossRef]

- Li X F, Guo Y, Zhu F, et al. Alkalinity stabilization behavior of bauxite residue: Ca-driving regulation characteristics of gypsum [J]. Journal of Central South University, 2019, 26(2):383-392. [CrossRef]

- Li Z F, Gao Y F, Zhang M, et al. The enhancement effect of Ca-bentonite on the working performance of red mud-slag based geopolymeric grout [J]. Materials Chemistry and Physics, 2022, Volume 276(35): 125311. [CrossRef]

- Lin R S, Seokhoon Oh, Du W, et al. Strengthening the performance of limestone-calcined clay cement (LC3) using nano silic [J]. Construction and Building Materials, 2022, 340:127723. [CrossRef]

- Liu S, Li Z, Li Y, et al. Strength properties of Bayer red mud stabilized by lime-fly ash using orthogonal experiments [J]. Construction and Building Materials, 2018, 166:554-563. [CrossRef]

- Lockwood, C.L.; Stewart, D.I.; Mortimer, R.; Mayes, W.M.; Jarvis, A.P.; Gruiz, K.; Burke, I.T. Leaching of copper and nickel in soil-water systems contaminated by bauxite residue (red mud) from Ajka, Hungary: The importance of soil organic matter. Environ. Sci. Pollut. Res. 2015, 22, 10800–10810. [CrossRef]

- Ma Q W, Duan W, Liu X F, et al. Engineering Performance Evaluation of Recycled Red Mud Stabilized Loessial Silt as a Sustainable Subgrade Material [J]. Materials, 2022, 9:3391. [CrossRef]

- Mukiza E, Zhang L L, Liu X, et al. Utilization of red mud in road base and subgrade materials: A review [J]. Resources, Conservation and Recycling, 2019, 141:187-199. [CrossRef]

- Nandhini K, Ponmalar V. Effect of Blending Micro and Nano Silica on the Mechanical and Durability Properties of Self-Compacting Concrete [J]. Silicon, 2021, 13(3):687–695. [CrossRef]

- Ou X D, Chen S J, Jiang J, et al. Reuse of Red Mud and Bauxite Tailings Mud as Subgrade Materials from the Perspective of Mechanical Properties [J]. Materials, 2022, 15(3):1123. [CrossRef]

- Wang J B, Du P, Zhou H Z, et al. Effect of nano-silica on hydration, microstructure of alkali-activated slag [J]. Construction and Building Materials, 2019, 220(30):110-118. [CrossRef]

- Wang S, Jin H, Deng Y, et al. Comprehensive utilization status of red mud in China: A critical review [J]. Journal of Cleaner Production, 2020, 289(11):125136. [CrossRef]

- Wang Y G, Geng Y F, Zhang HM, et al. Effect of nano-silica on alkaline slag cement flooding[J]. Silicate Bulletin, 2020, 39(05):1451-1456+1465. (In Chinese).

- Xue S G, Kong X F, Zhu F, et al. 2016a. Proposal for management and alkalinity transformation of bauxite residue in China [J].Environmental Science and Pollution Research, 23 (13): 12822-12834. [CrossRef]

- Xie W, Zhou F, Liu J, et al. Synergistic reutilization of red mud and spent pot lining for recovering valuable components and stabilizing harmful element [J]. Journal of Cleaner Production, 2020, 243(Jan.10):118624.1-118624.12. [CrossRef]

- Zhao H, Gou H. Unfired bricks prepared with red mud and calcium sulfoaluminate cement: Properties and environmental impact [J]. Journal of Building Engineering, 2021, 38(7):102238. [CrossRef]

- Zhu F,Li Y B,Xue S G,et al. 2016a. Effects of iron-aluminium oxides and organic carbon on aggregate stability of bauxite residues [J].Environmental Science and Pollution Research,23 ( 9) : 9073-9081. [CrossRef]

| Projects | Synergistic Solution Portfolio | ||||

| Program 1 | Program 2 | Program 3 | Program 4 | Program 5 | |

| RM unmodified | RM | ||||

| PC individually modified | PC1 | PC3 | PC5 | PC7 | PC9 |

| NS+PC synergistic modification | NS1PC1 | NS1PC3 | NS1PC5 | NS1PC7 | NS1PC9 |

| NS+CS6+PC3 synergistic modification | NS0.5CS6PC3 | NS1CS6PC3 | NS2CS6PC3 | NS3CS6PC3 | |

| Projects | NS doping | Remarks | ||||||

| 0 | 0.5% | 1% | 1.5% | 2% | 2.5% | 3% | ||

| RM unmodified | 388 | Control test | ||||||

| PC3 separately modified | 948 | |||||||

| NS1+PC3 synergistic modification | 1434 | |||||||

| NS+CS6+PC3 synergistic modification | 2421 | 2748 | 2467 | 2156 | ||||

| Curing period (d) | 0 | 14 | 28 | 60 | 120 |

| Residual stress/peak stress | 0.53 | 0.44 | 0.24 | 0.16 | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).