1. Introduction

Tooth movements and changes in orthodontic appliances result from force systems and a tissue response to them. An ideal force produces tooth movement without damaging teeth or tissues. Factors including tooth size and type of movement need to be considered when applying force during orthodontic treatment. However, it is difficult to determine an ideal force [

1,

2]. Hence, a sound knowledge of the mechanical behaviour of orthodontic archwires is required to select the most suitable size and material to achieve optimal and predictable treatment results [

3].

Orthodontic treatment begins with levelling and aligning the teeth with nickel-titanium (NiTi) archwires, which deliver light and continuous forces for efficient tooth movement. [

4,

5,

6]. NiTi archwires, introduced by Andreasen and Hillman in the 1970s, deliver an optimal constant force over an extended range of deflection in order to enable a smooth transformation into and from a martensitic phase [

1,

7,

8]. This phase transformation may occur through variations in temperature and stress changes in the oral cavity [

1,

9].

The shape memory of NiTi archwires is incorporated in the production phases by establishing a shape at approximately 482ºC [

1]. It has been suggested that nickel-titanium alloys become ductile and may be plastically deformed at temperatures below the transition temperature range (TTR). Another property of NiTi archwires is their superelasticity or pseudoelasticity, which is produced by reversible phase transformation from the body-centred cubic structure (austenitic) to a martensitic structure (monoclinic) by applying stress during activation and deactivation [

6]. During transformation, the stress remains stable even as it increases, preventing undesirable side effects such as hyalinization, pain, and root resorption [

10,

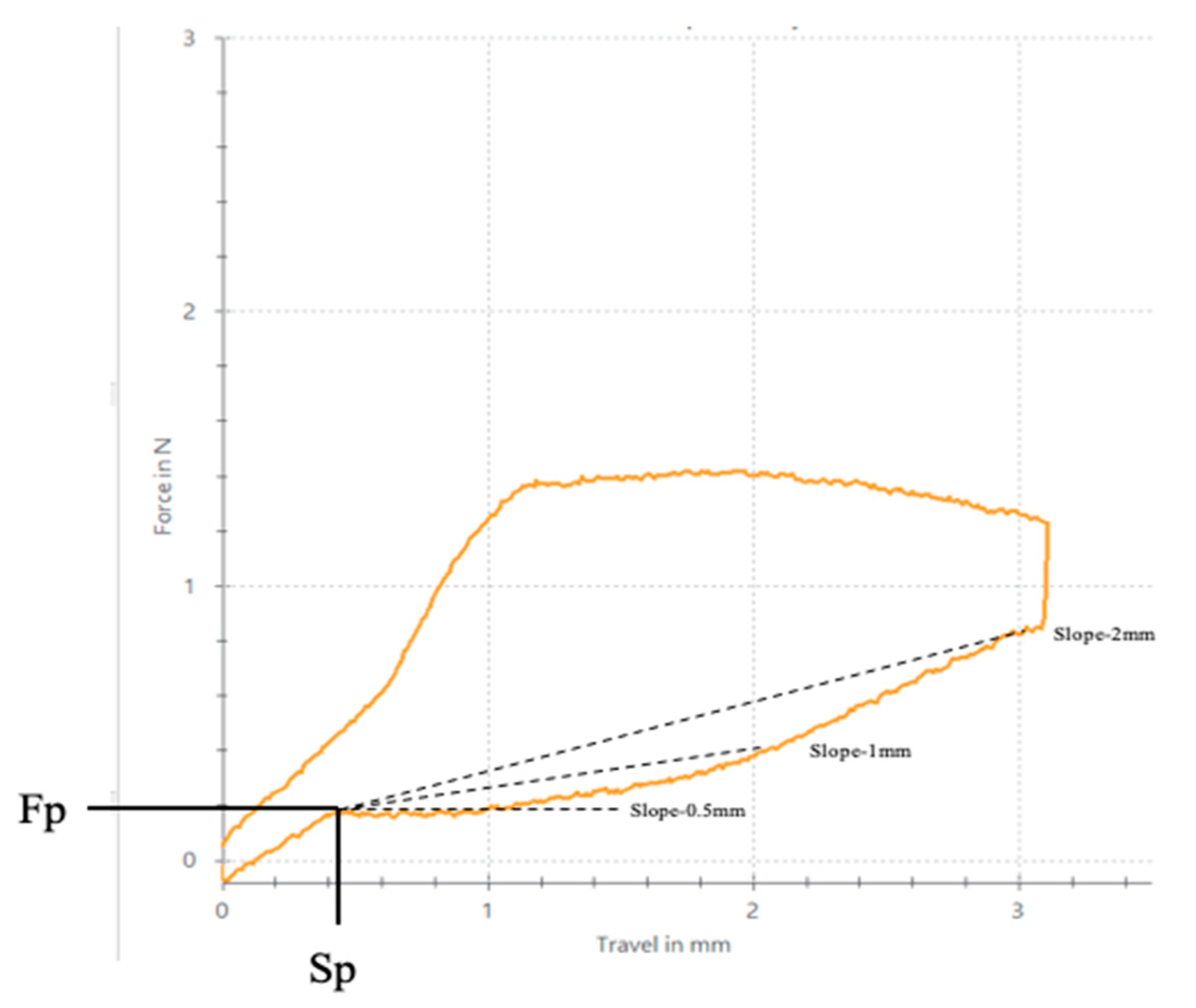

11]. As shown in the load/deflection diagram (

Figure 2), Superelasticity is characterized by the plateau, indicating that the force exerted is relatively constant in the range of tooth movement.

The first NiTi archwires wires in orthodontic treatments are usually used for at least two or three months, during which they undergo mechanical stress and chemical exposure in the patient’s mouth. Furthermore, studies indicate that 52% of clinicians recycle these wires [

12]. During sterilization, recycled wires endure further stress [

3,

12,

13]. Hence, repeated exposure and sterilization may induce changes in the mechanical properties and surface conditions of NiTi archwires that may not be clinically adequate for tooth movement [

12].

It should be noted that the properties of NiTi orthodontic wires may depend on various aspects; chief among them are consistent chemical composition [

14,

17], grain size [

15,

16], mechanical and thermal cycling [

18], residual stresses [

19], and whether the surface treatment of wires improves friction coefficients. In addition, possible heat treatments of wires for flexibility, loops, or soldering to obtain different forces in the molar or canine areas produce substantial changes in the transformation temperatures and, therefore, in the superelastic curves [

19,

20]. Numerous studies have demonstrated that changes in temperature cause precipitation of precipitates rich in nickel or titanium, depending on the chemical composition of the wire, lead to a loss of the superelastic properties, rendering the wires useless for orthodontic therapy [

21,

22,

23]. There appears to be limited evidence on the intraoral aging sequence and associated changes in NiTi archwire properties. Some studies have reported that heat sterilization has detrimental effects on the elastic and tensile properties of these wires [

24], but more studies tend to focus on the corrosion resistance and other effects on mechanotherapy. However, no reports on changes in superelastic properties have been found [

1,

7].

The aim of the present study was to determine changes in the superelastic properties of NiTi archwires after clinical use and sterilization and identify possible differences among the different archwire brands.

2. Materials and Methods

The sample comprised preformed NiTi wires from five manufacturers (GC Orthodontics Europe GmbH, Germany; Unitek, Monrovia, CA USA; Ods Kisdorf, Germany; Forestadent Pforzheim, Germany; and GAC, Grenoble, France) commercialized as superelastic with a 0.016inch round section, as shown in

Table 1. The archwires were randomly distributed among orthodontic patients of the clinic at Universitat Internacional de Catalunya (UIC Barcelona, Barcelona, Spain). The study was approved by the Clinical Research Ethics Committee of the Universitat Internacional de Catalunya (ORT-ELM-2019-01). The sample was divided in three groups of archwires per brand at the following time points: 10 archwires before clinical use (T0); 10 after three months in the mouth (T1); and 10 after sterilization (T2). Each archwire was cut in to two samples to test 20 segments in each group. Each of the five brands was tested 60 times, totalling 300 specimens.

Accepting an alpha risk of 0.05 and a beta risk of 0.2 in a two-sided test, twenty specimens were necessary to recognize a difference greater than or equal to 0.05 units as statistically significant. The standard deviation was assumed to be 0.309, as in previous studies [

1,

7].

The three-point elastic bending test was used to assess the mechanical properties using a 10 mm beam length. The distance between the penetrator point and the two supporting points of each archwire was identical. The radius of these two points measured 0.10 ± 0.05 mm, in accordance with the ISO14841:2006 [

25].

Each wire segment was tested once using the TestXpert III (Z005 Test Control II, Universal Testing Machine, Zwick Roell, Kennesaw, Ga, USA). The middle portion of the wire was deflected at a crosshead speed of 7.5mm/min under the pressure of the penetrator point. The middle portion of each segment was loaded to 3.1mm of deflection, similar to what is usually produced in clinical situations when teeth are levelled and aligned. The wire segments were unloaded at the same crosshead speed until the released force reached zero. Subsequently, the unloading curve and the superelasticity of each wire segment were evaluated using the nine following parameters:

Force level delivered in Newtons (N) with deflection at 3.0 mm, 2.0 mm, 1.0 mm, 0.5 mm (Fdef-3mm, Fdef-2mm, Fdef-1mm, Fdef-0.5mm, respectively).

Deflection at the end of plateau in mm (Sp).

Minimum force level at the end of superelastic plateau in N (Fp).

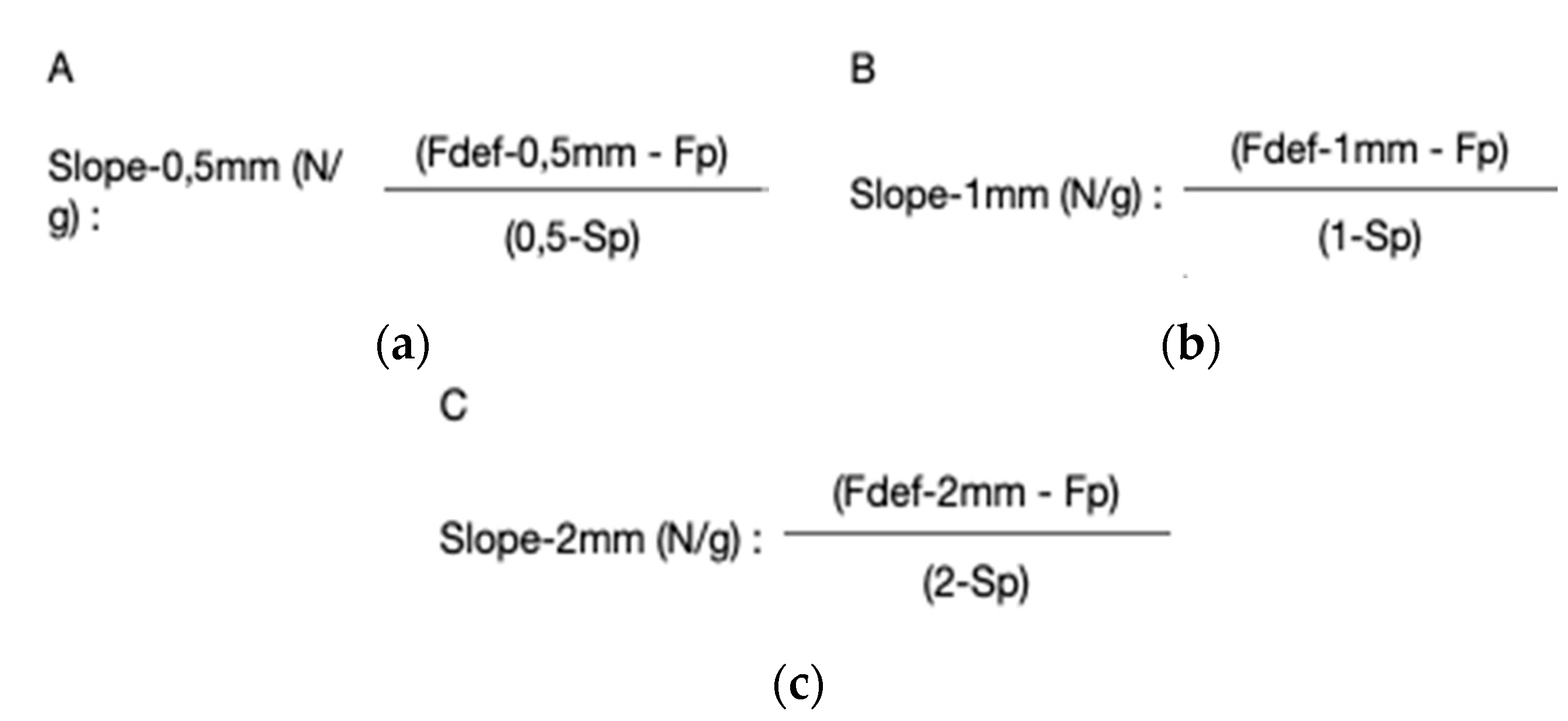

Plateau slopes; between 0.5mm and Sp (Slope-0.5mm), between 1mm and Sp (Slope-1mm) and between 2mm and Sp (Slope-2mm) of deflection expressed in N/mm.

The plateau slope value, obtained using the following equations show in

Figure 1: A. Slope at 0.5 mm, B. Slope at 1 mm, C. Slope at 1 mm measures the degree of plateau flatness; thus, the closer the slope is to zero, the more constant the force.

Figure 2 shows the loading and unloading curve of the archwire segments and all the evaluated parameters.

The results were analyzed with R software version 4.2.1 (1989, 1991 Free Software Foundation, Inc.Temple Place, Boston, USA). The variables of interest were first described by mean and standard deviation. Normality was tested with the Shapiro Wilk test. The groups were compared with ANOVA. All tests were considered significant for a p-value of less than 0.05. Statistically significant differences were set at a p-value <0.001.

3. Results

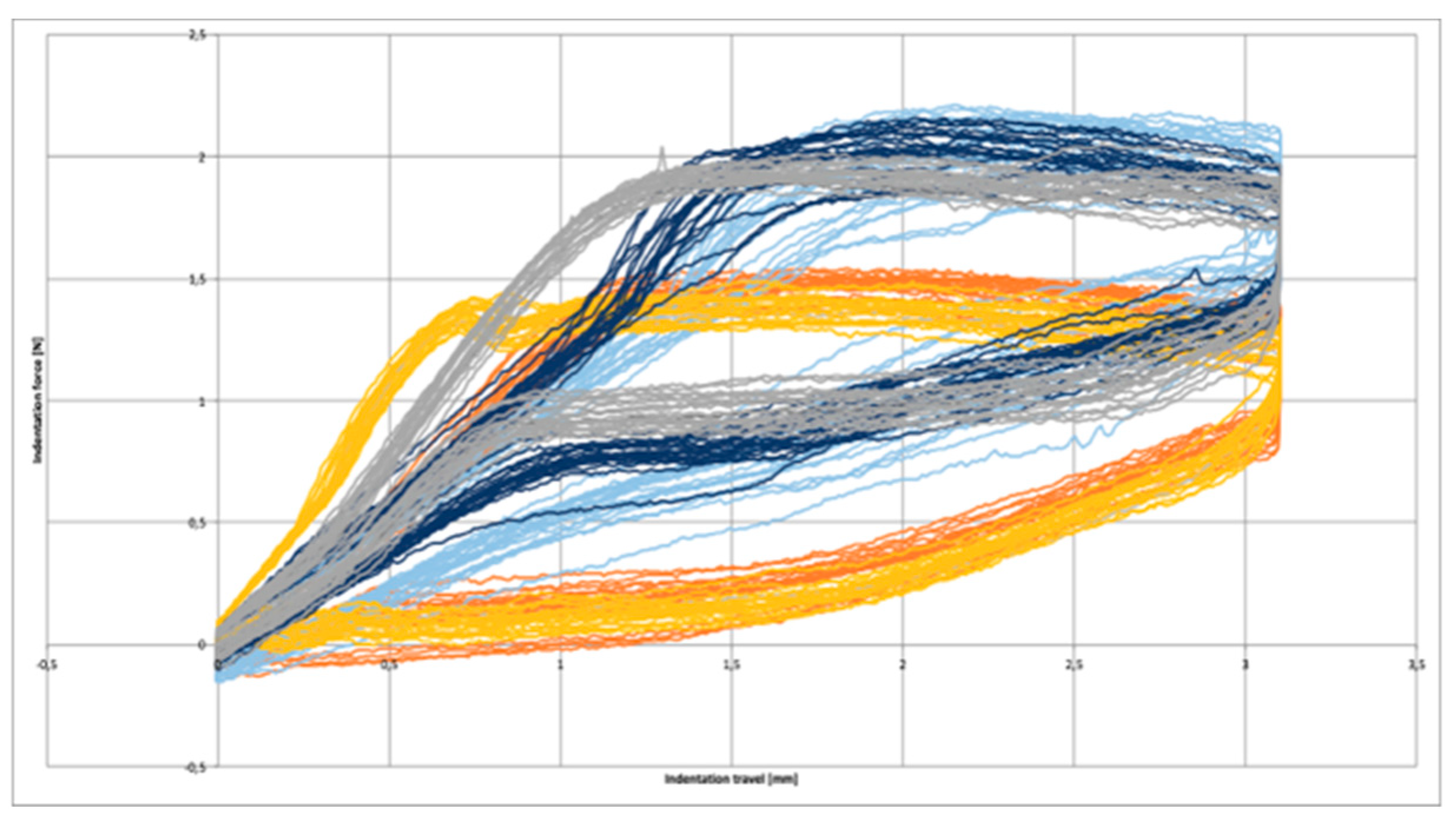

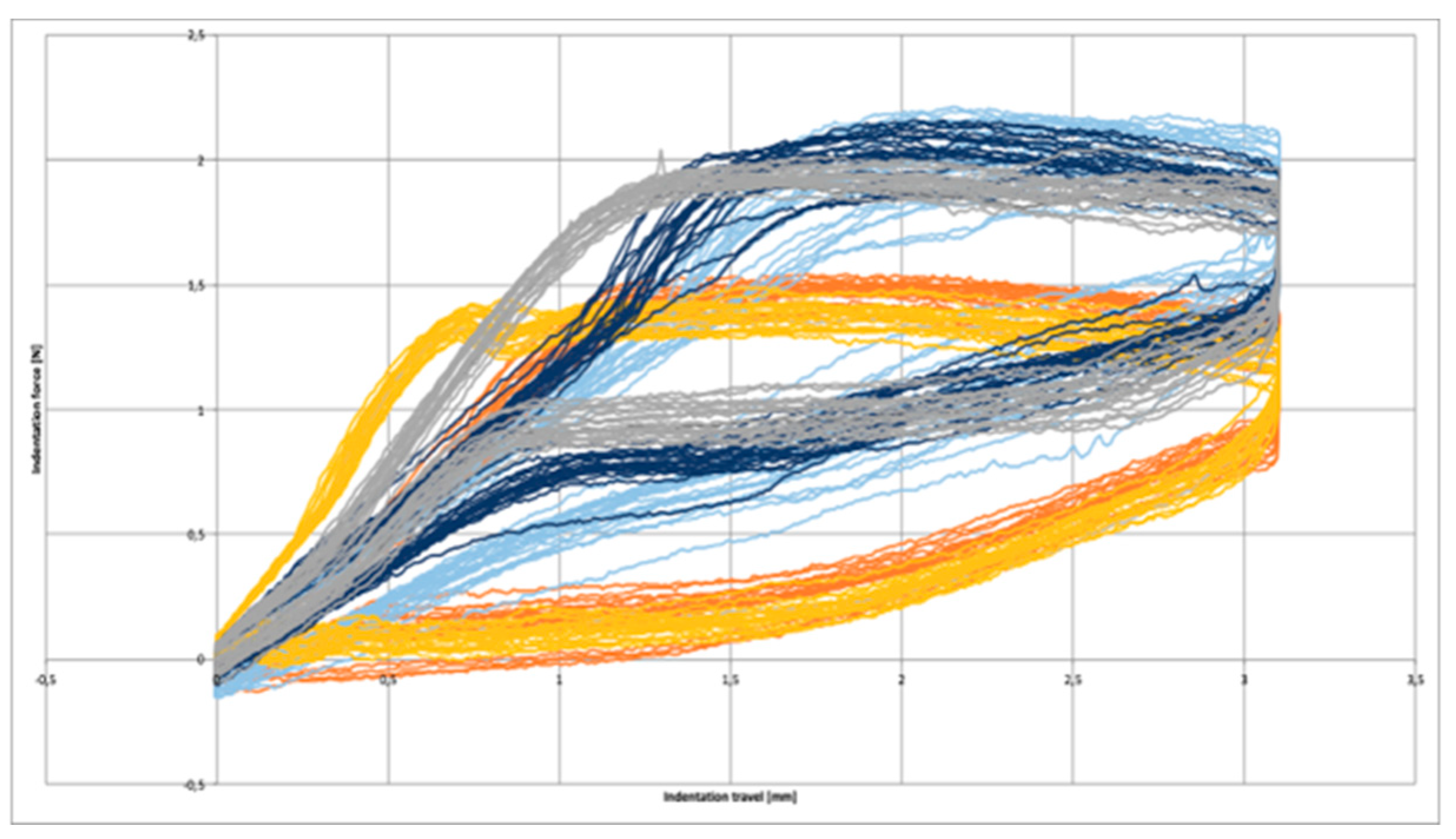

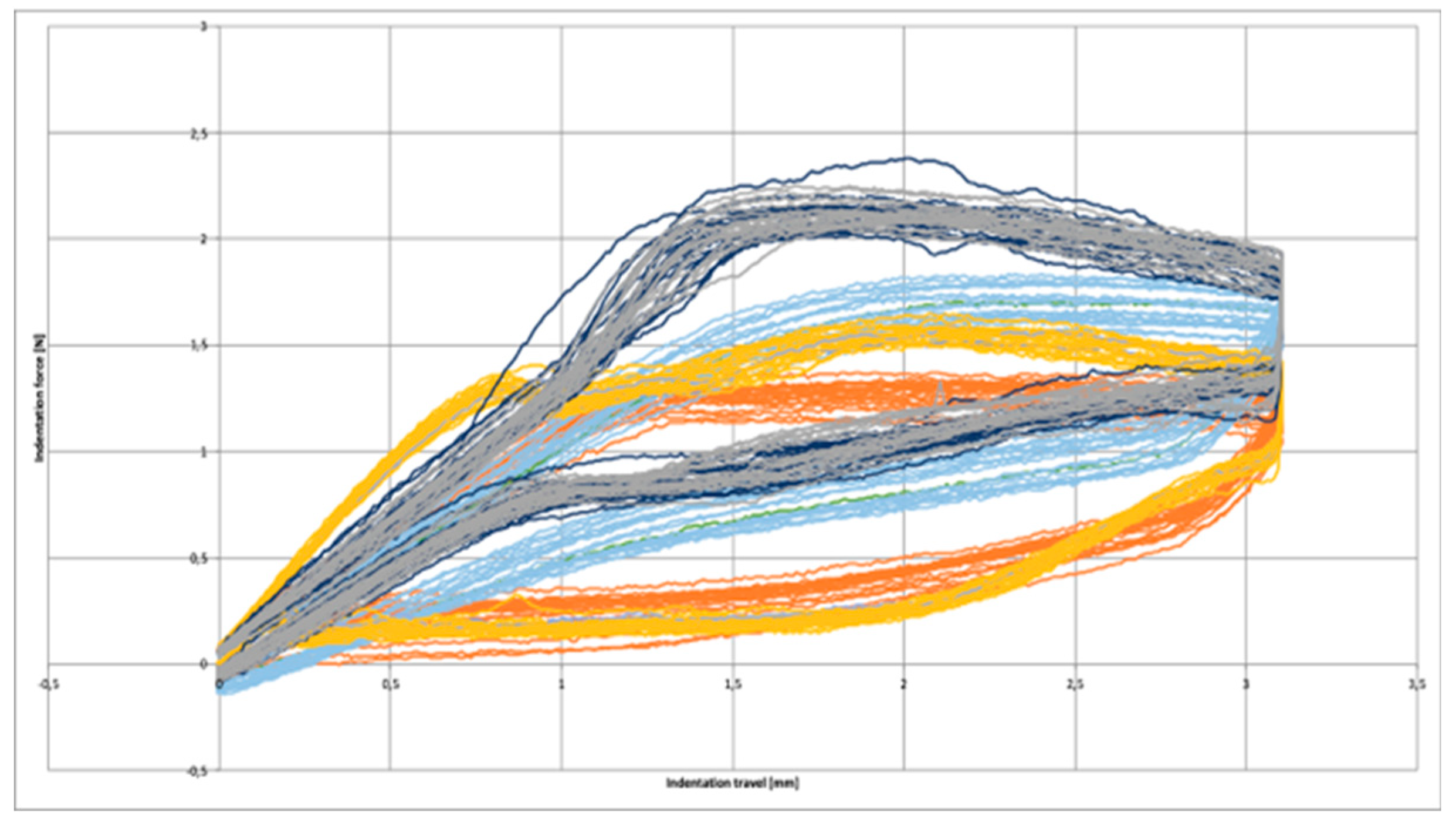

Graphs were made showing the behaviour of each wire at the three time points (

Figure 3,

Figure 4 and

Figure 5). Note the comparable shape and an apparent superelastic

plateau, albeit an apparent discrepancy in the loading and unloading curve.

Table 2 and

Table 3 show the Plateau Slopes at 0.5mm, 1mm and 2mm of deactivation and the mean delivered force at 3, 2, 1 and 0.5mm deflection respectively. The variations in properties of wire segments before clinical use (T0) and after three months (T1) were compared; changes among T1, T2 and T0 were also analyzed.

4. Discussion

The present study has a twofold aim: to analyze the superelastic properties of NiTi wires at three time points; and to determine the changes in the mechanical properties after recycling the wires used in patients and non in-vitro simulation processes (thermocycling, cyclic loading). There appear to be limited clinical studies and a notorious inability of in-vitro research to simulate in vivo conditions [

26,

27,

28] since the multiplicity of factors present in the oral cavity cannot be simulated [

28,

29,

30,

31]. Due to its reproducibility, the three-point bending test is the standard method for testing and comparing flexural properties [

3,

5,

32,

33]. However, studies show wide variability in this method, indicating no established consensus about how testing should be undertaken [

3,

5,

9,

34]. Currently, this bending test is regulated by two standards: the European National Standard and the American National Standard (ANSI / ADA), which are identical to ISO 15841: 2006 23 [

25,

35]. Thus, it is recommended to follow the same standard procedure with equally adjusted parameters to accurately compare archwire properties. Archwire manufacturers are required to indicate the properties of their product according to the three-point bending test, as set out in the European National Standard [

25,

36]. The testing procedure used in the present study was conducted according to ISO 15841: 2006 [

25]. However, most previous studies have not followed these criteria [

6,

13,

32,

37,

38,

39,

40]. As a result, only two articles have been found in which testing was performed according to ISO 15841: 2006 [

14,

34].

Nine parameters were studied for the three groups of NiTi archwires supplied by five brands. The plateau slopes calculated to determine the superelastic properties of each wire revealed great variability [

5,

41]. The statistical differences among manufacturers for the means of each variable were measured at T0 (before clinical use). The GC archwires exerted the highest forces at all deflection points, although the FOR and 3M archwires behaved similarly. Thus, at T1 (after three months of use in the mouth), the FOR group exerted the highest forces at all deflection points, except at 2mm, where GC and 3M wires performed similarly to the FOR. At T2 (after sterilizing the used archwires), the GC group exerted the highest force at three deflection points, except at 3mm, where the 3M archwires behaved identically to the GC. Despite the differences observed at T0, all the archwires exerted almost the same force after three months of use. Some authors point out that force increases as crowding is resolved but then recovers baseline properties once teeth are aligned [

24,

32].

Plateau slope values show the degree of superelasticity. If these values remain stable over time, superelastic properties remain stable. A constant force over a wide range allows the orthodontist to use the archwire even on teeth far from their correct position in the arches. The present study found significant differences in plateau slope values across the studied groups. Regarding lower deformations (0.5-1mm), GAC and 3M archwires did not remain stable after three months, lowering values and becoming more superelastic, after which sterilization plateau values remained constant. As for lower deformations, EURO, GC and FOR at the plateau increase, making the archwires gradually lose their superelasticity after three months in the oral cavity. After sterilization, the plateau slope values also increased, compromising superelasticity. In contrast, the FOR wires showed no decrease in plateau values, thus recovering superelastic properties [

9].

Despite these differences among the archwire brands at the different time points, we found that all the groups released almost the same force as before clinical use at all deflection points. This may be due to the fact that as crowding resolves, as observed in other studies [

7,

9], the force initially increases but subsequently recovers its baseline properties. These results suggest that the wire is subjected to continuous deformations due to crowding. Once crowding is resolved, the archwire stops receiving continuous activation forces as it recovers its initial properties [

9].

The superelastic properties observed after months of treatment can be attributed to the presence of martensite that is stabilized by mechanical stress. When the clinician inserts an orthodontic wire, the wire is in the initial phase known as the austenitic phase. However, due to the tension caused by the misalignment of the teeth, the wire exerts a corrective force to realign the dental position. This force exerted by the wire on the teeth results from a martensitic transformation induced by the stress in the region of maximum tension [

41,

42,

43].

The martensitic phase induced by the tension is not stable at the oral cavity temperature of 37ºC. Consequently, under mechanical tensions, it tends to revert back to the original phase and restore the initial arch shape, which is considered optimal for each patient.

These transformations are known as thermoelastic martensitic transformations, as they do not result in plastic deformations like those observed in steel. Instead, they allow for wires with superelastic behaviour that can withstand deformations exceeding 20%. However, when the wires remain in service for an extended period or experience high loads, dislocations occur that anchor the martensite plates. These plates, once stablized, no longer return to their initial phase at 37º C. To unanchor these plates, significanly higer temperatures are required, typically ranging from 400-500 ºC, as indicated by several authors. The stabilisation of the martensite inhibits superelasticity and dimishes the effectiveness of the orthodontic wire, a phenomenon referred to as NiTi wire amnesia [

42].

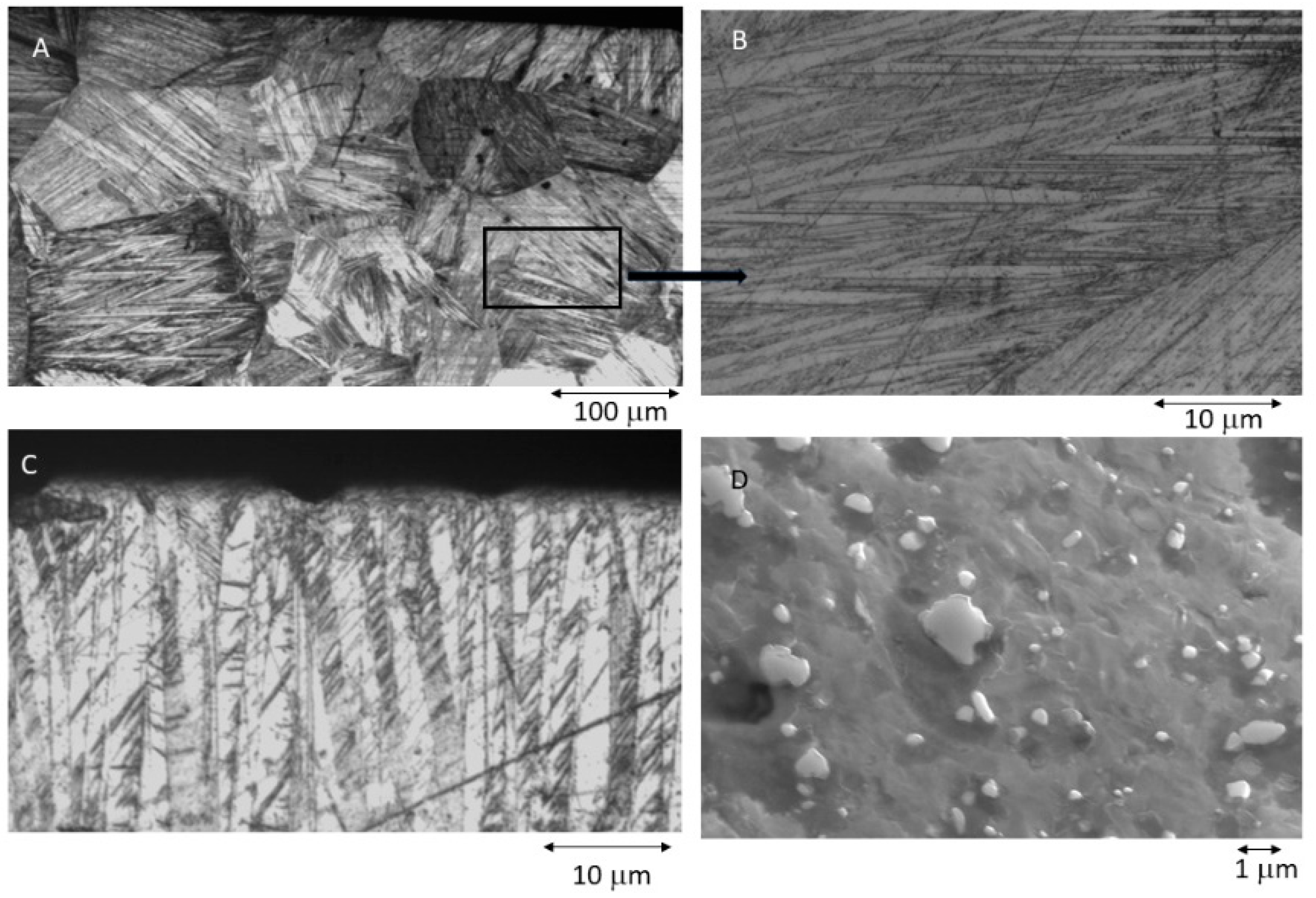

Figure 6A shows self-accomodating martensite plates resulting from wire cooling, while

Figure 6B shows marestintic plates with various orientations.

Figure 6C illustratrates matensite plates induced by mechanical stress, revealing that these stress-indcued plates allign with the direction of mechanical stress. Unlike temperature, which is not a vectorial property, stress is a vectorial parameter, thereby influencing the direction of the plates.

Figure 6C shows the martensitic plates that have stabilized within a wire, which was initially ausenitic at room temperature. However, after a stress period of 3 months, it is evident that a part of the martensitic plates did not transform back to the austenitic phase.

When the chemical composition of NiTi deviates from an equiatomioc ratio of nickel and titanium, cyclic or static mechanical loading over time can lead to the formation of precipitates enriched in nickel or titanium, as shown in

Figure 6D,. These precipitaes inhibit the superelasticity of the NiTi archwire.

Figure 6D shows Ti-rich precipitates within the austenitic matrix.

Before starting orthodontic treatment, it is crucial to consider the changes in mechanical properties of each brand, in particular superelasticity and delivered forces, which affect crowding resolution and periodontal conditions. It is also relevant that some archwires recover their initial properties after sterilization, allowing them to be reused.

5. Conclusions

Significant differences in exerted forces, both during three months of activation (T1) and after sterilization (T2), were found among the brands.

GC, EURO and FOR appeared to lose their superelastic properties during three months of clinical use (T1).

As for lower deformations (<2mm), GAC, 3M and FOR wires recovered their properties after sterilization (T2), while EURO archwires appeared to lose their superelasticity.

Superelastic properties and released forces were found to differ significantly among all groups studied (T0, T1, and T2).

Conflicts of Interest. The authors declare no conflict of interest.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, J.M, I.gA, A.P1. and A.P2.; methodology, I.A, J.M, A.P1 and G.R.; software, I.A, G.R, J.M and A.P1.; validation, J.M, I.A, A.P1 and G.R.; formal analysis J.M, A.P2, M.A and J.G; investigation, I.A, A.P1 and .; resources, X.X.; data curation, X.X.; writing—original draft preparation, J.M, I.A, A.P1 and G.R; writing, I.A, J.M—review and editing, I.A, J.M, A.P2, M.A, J.G; visualization, J.M, A.P2; supervision, J.M, A.P2, M.A and J.G; project administration, J.M, A.P2, M.A.; funding acquisition, A.P2 and J.G. All authors have read and agreed to the published version of the manuscript.”

Institutional Review Board Statement

The study was approved by the Clinical Research Ethics Committee of the Universitat Internacional de Catalunya (ORT-ELM-2019-01).

Informed Consent Statement

“Not applicable.”

Data Availability Statement

We encourage all authors of articles published in MDPI journals to share their research data. In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Where no new data were created, or where data is unavailable due to privacy or ethical restrictions, a statement is still required. Suggested Data Availability Statements are available in section “MDPI Research Data Policies” at

https://www.mdpi.com/ethics.

Acknowledgments

This study was supported by the above-mentioned funds.

References

- Mohammed RSK. An Overview of Orthodontic Wires. Trends Biomater Artif Organs 2014; 28:32–6.

- Farnaz Parvizi, W. P. Rock. The load/deflection characteristics of thermally activated orthodontic archwires, European Journal of Orthodontics, 2003; 25: 417–421.

- Juvvadi SR, Kailasam V, Padmanabhan S, Chitharanjan AB. Physical, mechanical, and flexural properties of 3 orthodontic wires: An in-vitro study. American Journal of Orthodontics and Dentofacial Orthopedics 2010; 138:623–30. [CrossRef]

- Hurst CL, Duncanson MG, Nanda RS, Angolkar P V. An evaluation of the shape-memory phenomenon of nickel-titanium orthodontic wires. American Journal of Orthodontics and Dentofacial Orthopedics 1990; 98:72–6. [CrossRef]

- Nakano H, Satoh K, Norris R, Jin T, Kamegai T, Ishikawa F, et al. Mechanical properties of several nickel-titanium alloy wires in three-point bending tests. Am J Orthod Dentofacial Orthop 1999; 115:390–5. [CrossRef]

- Bartzela TN, Senn C, Wichelhaus A. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthodontist 2007; 77:991–8. [CrossRef]

- Tonner RIM, Waters NE. The characteristics of super-elastic Ni-Ti wires in three-point bending. Part l: The effect of temperature. Eur J Orthod 1994; 16:409–19. [CrossRef]

- Dechkunakorn S, Isarapatanapong R, Anuwongnukroh N, Chiranavanit N, Kajorchaiyakul J, Khantachawana A. Mechanical properties of several NiTi alloy wires in three-point bending tests. Applied Mechanics and Materials 2011; 87:14–9. [CrossRef]

- Luca Lombardo, Giorgia Toni, Valentina Mazzanti, Francesco Mollica GAS and GSiciliani. The mechanical behaviour of as received and retrieved nickel titanium orthodontic archwires. Progress in Orthodontics 2019; 20: 1. [CrossRef]

- Segner D, Ibe D. Properties of superelastic wires and their relevance to orthodontic treatment. Eur J Orthod 1995;17:395–402. [CrossRef]

- Pandis N, Bourauel CP. Nickel-Titanium (NiTi) arch wires: The clinical significance of super elasticity. Semin Orthod 2010;16:249–57. [CrossRef]

- Chang Y Il, Lee SH. Effects of recycling on the mechanical properties and the surface topography of nickel-titanium alloy wires. American Journal of Orthodontics and Dentofacial Orthopedics 2001;120:654–63. [CrossRef]

- Bavikati VN, Singaraju GS, Mandava P, Killamsetty SS, Nettam V, Karnati PKR. Evaluation of mechanical and physical properties of clinically used and recycled superelastic NiTi wires. Journal of Clinical and Diagnostic Research 2016;10:ZC35–40. [CrossRef]

- Bellini H, Moyano J., Gil J., Puigdollers A.Comparison of the superelasticity of different nickel–titanium orthodontic archwires and the loss of their properties by heat treatment. J.Mater.Sci. Mater. Med. 2016, 27:158. [CrossRef]

- Gil FJ, Cenizo M., Espinar E., Rodriguez A., Rúperez E., Manero JM. NiTi superelastic orthodontic wires with variable stress obtained by ageing treatments. Mater. Lett. 2013;. 104: 5-7. [CrossRef]

- Gil FJ, Manero JM, Arcas R, Planell JA. Grain growth in austenite NiTi shape memory alloys". Scripta Met. Mater. 1994; 31(4): 483-486. [CrossRef]

- Pastor, F.; Rodriguez, J.C.; Barrera, J.M.; Delgado García-Menocal, J.A.; Brizuela, A.; Espinar, E.; Gil, J. Effect of Fluoride Content of Mouthwashes on Superelastic Properties of NiTi Orthodontic Archwires. Materials 2022, 15, 6592. [CrossRef]

- Briceño J., Romeu A., Espinar E., Llamas JM, Gil FJ. Influence of the microstructure on electrochemical corrosion and nickel release in NiTi orthodontic archwires. J Materials Science and Engineering C.2013; 33: 4989-4993. [CrossRef]

- Gil FJ., Espinar E, Llamas JM, Manero JM, Ginebra MP. Variation of the superelastic properties and nickel release from original and reused NiTi orthodontic archwires. J. Mech. Beh. Biomed. Mater. 2012; 6: 113-119. [CrossRef]

- Sánchez, P.; Vidi, B.; Mena-Alvarez, J.; Gil, J.; Rico, C.; Aragoneses, J.M. Effect of Stabilized Martensite on the Long-Term Performance of Superelastic NiTi Endodontic Files. Materials 2023, 16, 4089. [CrossRef]

- Gil FJ, Rupérez E., Velasco E., Aparicio C., Manero JM. Mechanism of fracture of NiTi superelastic endodontic rotary instruments. J. Mater. Sci.: Mater. Med. 2018; 29(131): 205. [CrossRef]

- Rúperez E., Manero JM, Bravo-González LA, Espinar E, Gil FJ. Development of biomimetic NiTi alloys: influence of thremo-chemical treatment on the physical, mechanical and biological behavior. Materials 2016; 9: 402. [CrossRef]

- Godoy-Gallardo M., Wang Z., Shen Y., Manero JM., Gil FJ., Rodriguez D., Haapasalo M. Antibacterial Coatings on Titanium Surfaces: A Comparison Study Between in Vitro Single-Species and Multispecies Biofilm. ACS Appl. Mater. Interfaces, 2015, 7 (10):5992–6001. [CrossRef]

- Kusy RP. A review of contemporary archwires: Their properties and characteristics. Angle Orthodontist 1997;67:197–208. [CrossRef]

- Standard I. European Committee for Standarization. Euro Norm EN ISO 158412006. 2006; Dentistry. 2006. [CrossRef]

- Eliades T, Athanasiou AE. In Vivo Aging of Orthodontic Alloys: Implications for Corrosion Potential, Nickel Release, and Biocompatibility. Angle Orthodontist 2002;72:222–37. [CrossRef]

- Perinetti G, Contardo L, Ceschi M, Antoniolli F, Franchi L, Baccetti T, et al. Surface corrosion and fracture resistance of two nickel-titanium-based archwires induced by fluoride, pH, and thermocycling. An in vitro comparative study. Eur J Orthod 2012;34:1–9. [CrossRef]

- Eliades T, Eliades G, Athanasiou AE, Bradley TG. Surface characterization of retrieved NiTi orthodontic archwires. Eur J Orthod 2000;22:317–26. [CrossRef]

- Bourauel C, Scharold W, Jäger A, Eliades T. Fatigue failure of as-received and retrieved NiTi orthodontic archwires. Dental Materials 2008;24:1095–101. [CrossRef]

- Eliades T, Bourauel C. Intraoral aging of orthodontic materials: The picture we miss and its clinical relevance. American Journal of Orthodontics and Dentofacial Orthopedics 2005;127:403–12. [CrossRef]

- Kapila S, Reichhold GW, Anderson RS, Watanabe LG, Francisco S, Valley C. Effects of clinical recycling on mechanical properties of nickel-titanium alloy wires. Am J Orthod 1991;100:428–35. [CrossRef]

- Pop SI, Dudescu M, Merie VV, Pacurar M, Bratu CD. Evaluation of the mechanical properties and surface topography of as-received, immersed and as-retrieved orthodontic archwires. Clujul Medical 2017;90:313–26. [CrossRef]

- Miura F, Mogi M, Ohura Y, Hamanaka H. The wire super-elastic property of the Japanese NiTi alloy for use in orthodontics. vol. 90. 1915.

- Brauchli LM, Keller H, Senn C, Wichelhaus A. Influence of bending mode on the mechanical properties of nickel-titanium archwires and correlation to differential scanning calorimetry measurements. American Journal of Orthodontics and Dentofacial Orthopedics 2011;139:e449–54. [CrossRef]

- American National Standard/ American Dental association (ANSI/ADA). Specif no 32. n.d.

- Deliversky J, Yaneva-Deliverska M, Lyapina M, Kisselova A. EUROPEAN AND INTERNATIONAL STANDARDS ON MEDICAL DEVICES FOR DENTISTRY. Journal of IMAB - Annual Proceeding (Scientific Papers) 2015;21:713–7. [CrossRef]

- Quintão CCA, Cal-Neto JP e., Menezes LM, Elias CN. Force-deflection properties of initial orthodontic archwires. World J Orthod 2009;10:29–32.

- Devaprasad AP, Chandrasekaran T. Effects of Intraoral Ageing on Ultimate Tensile Strength and Surface Topography of Superelastic NiTi Wires from Two Different Manufacturers: A Comparative in vivo Study. J Indian Orthod Soc 2012;46:119–25. [CrossRef]

- Oshagh M, Hematiyan MR, Mohandes Y, Oshagh MR, Pishbin L. Autoclaving and clinical recycling: Effects on mechanical properties of orthodontic wires. Indian Journal of Dental Research 2012;23:638–42. [CrossRef]

- Sernetz F. Standardization of orthodontic products--does it make sense? Journal of Orofacial Orthopedics 2005;66:307–18. [CrossRef]

- Gil FJ, Planell JA. Thermal efficiencies of NiTiCu shape memory alloys.. Thermoch.Acta. 1999; 327: 151-154.

- Gil FJ, Planell JA. In vitro thermomechanical ageing of NiTi alloys”. F.J.Gil and J.A.Planell. J. Biomater.Appl. 1998; 12: 237-248.

- Gil FJ, Manero JM, Planell JA. Effect of grain size on the martensitic transformation in NiTi alloy. J. Mater. Sci. 1995; 30: 2526-2530.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).