Submitted:

17 July 2023

Posted:

18 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Key definitions

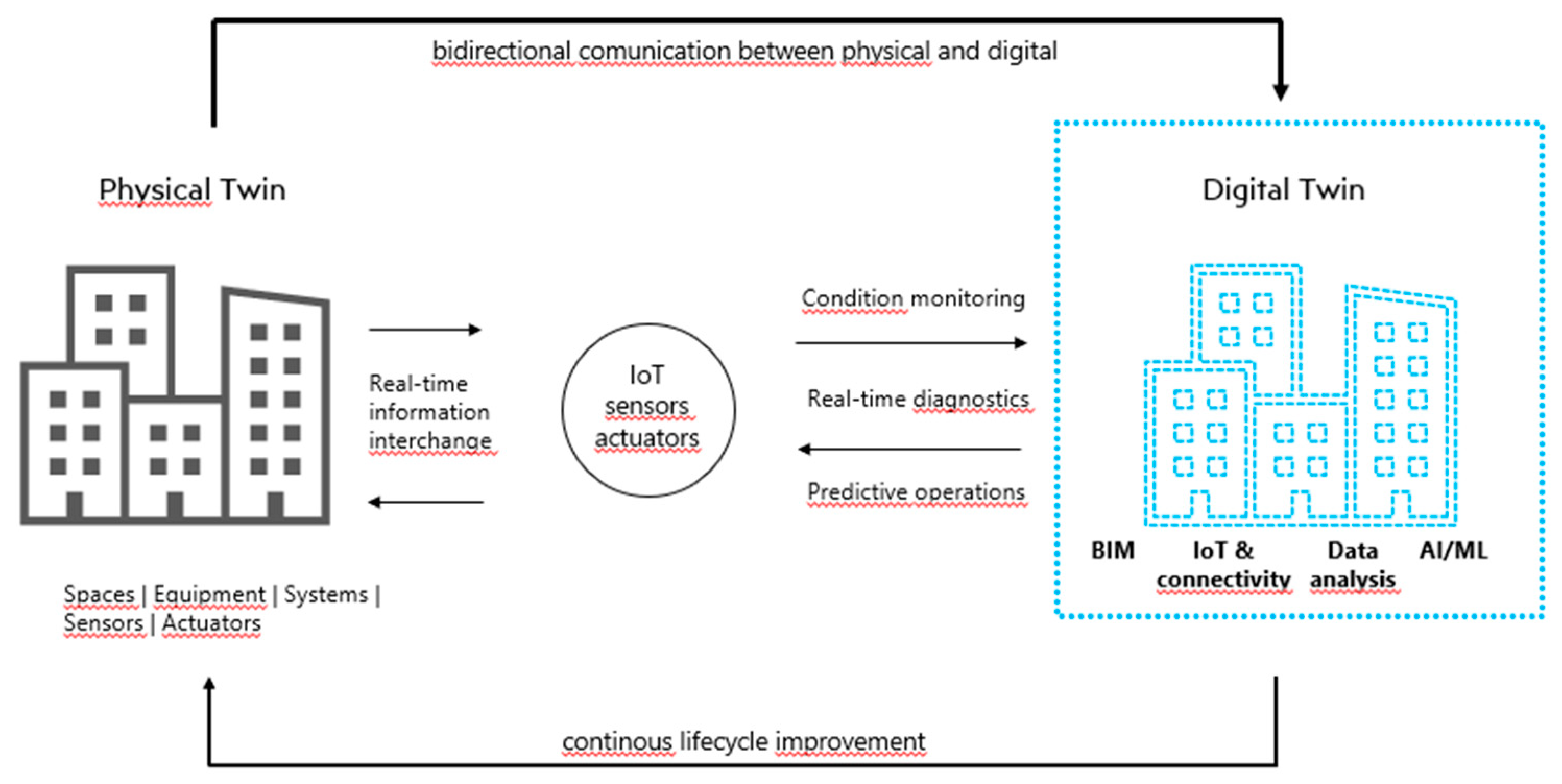

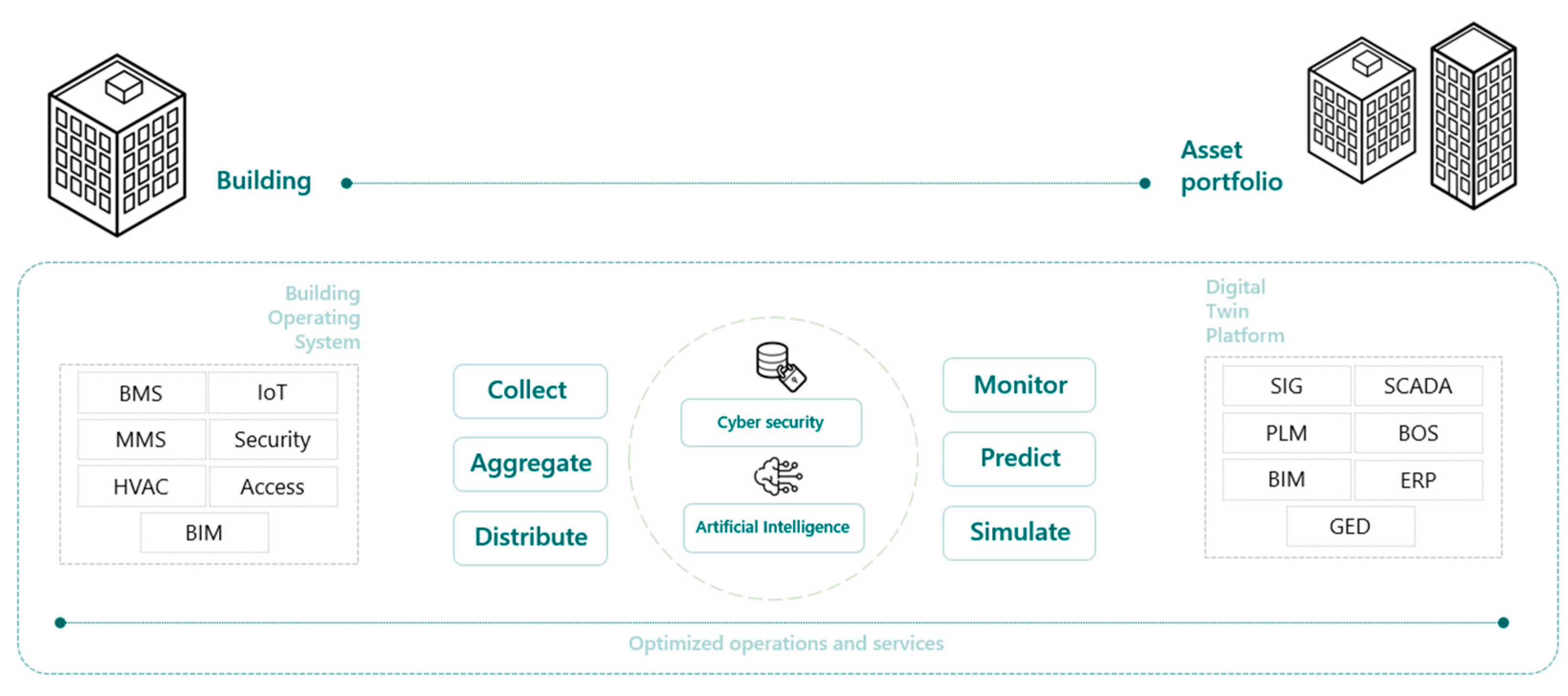

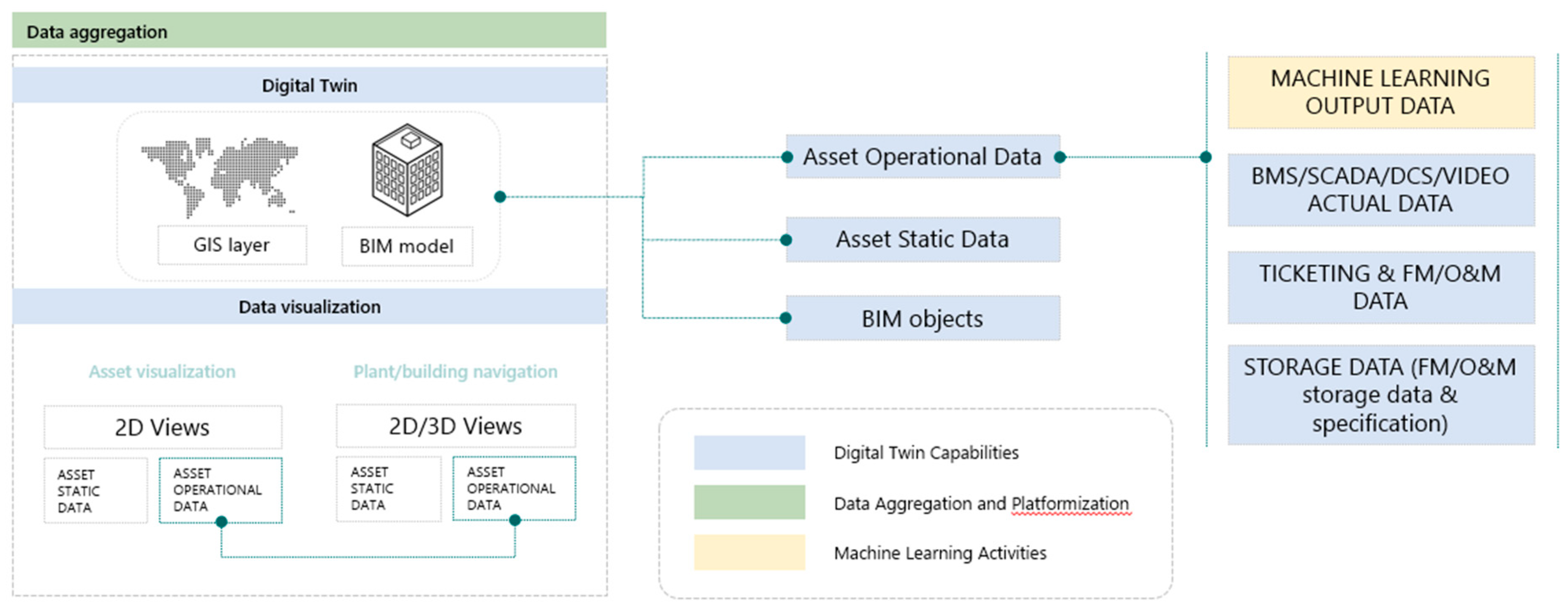

3. Primary components and system architecture

4. Digital Twin in the AECO industry

4.1. Enabling technologies use cases

4.1.1. IoT and lighting systems

4.1.2. Computer vision

4.1.2. Building Information Modelling (BIM)

4.1.3. Systems and data integration

4.1.4. GIS and BIM integration

5. Digital Twins and Smart Cities

6. Other Industries DT Applications

6.1. Aerospace

6.2. Industry and Manufacturing

6.3. Energy

8. Conclusions

Author Contributions

References

- UN Environment, “Global status report for buildings and construction 2018. Available online: https://www.worldgbc.org/sites/default/files/UNEP%20188_GABC_en%20%28web%29.pdf.

- P. N. Negroponte, Being Digital. New York: Random House Incorporated. New York, NY, 1995.

- Lamagna, M.; Groppi, D.; Nezhad, M.M.; Piras, G. A comprehensive review on digital twins for smart energy management system. Int. J. Energy Prod. Manag. 2021, 6, 323–334. [Google Scholar] [CrossRef]

- Lamagna, M.; Groppi, D.; Nezhad, M.M.; Piras, G. A comprehensive review on digital twins for smart energy management system. Int. J. Energy Prod. Manag. 2021, 6, 323–334. [Google Scholar] [CrossRef]

- Carrasco, C.A.; Lombillo, I.; Sánchez-Espeso, J.M.; Balbás, F.J. Quantitative and Qualitative Analysis on the Integration of Geographic Information Systems and Building Information Modeling for the Generation and Management of 3D Models. Buildings 2022, 12, 1672. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, W.; Dutta, B.; Wu, Z.; Goh, M. Digital Twinning for Productivity Improvement Opportunities with Robotic Process Automation: Case of Greenfield Hospital. Int. J. Mech. Eng. Robot. Res. 2020. [Google Scholar] [CrossRef]

- S. P. A. Datta, “Emergence of Digital Twins,” Oct. 2016.

- Rosen, R.; Boschert, S.; Sohr, A. Next Generation Digital Twin. atp Mag. 2018, 60, 86–96. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Michael Grieves, “Digital Twin: Manufacturing Excellence through Virtual Factory Replication,” 2014.

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital Twin Data Modeling with AutomationML and a Communication Methodology for Data Exchange. IFAC-PapersOnLine 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Grieves, M.W. Product lifecycle management: the new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71. [Google Scholar] [CrossRef]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- S. Flumerfelt, “Transdisciplinary Perspectives on Complex Systems_ New Findings and Approaches,” 2017.

- Liu, Z.; Meyendorf, N.; Mrad, N. The Role of Data Fusion in Predictive Maintenance Using Digital Twin. In Proceedings of the 44th Annual Review of Progress in Quantitative Nondestructive Evaluation, Provo, Utah, USA, 16–21 July 2017; 2018; p. 020023. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- O. A. N. C. B. and D. B. V. Martinez, “Service business model innovation: the digital twin technology,” Cambridge Serv. Alliance, 2019.

- Abramovici, M.; Göbel, J.C.; Dang, H.B. Semantic data management for the development and continuous reconfiguration of smart products and systems. CIRP Ann. 2016, 65, 185–188. [Google Scholar] [CrossRef]

- S., F. Y. S., F. Y., & H. W. Chen, “Augmented reality visualization of building energy performance data based on BIM and IoT,”. Autom Constr 2018. [Google Scholar]

- S., H. W. S., H. W., & F. Y. Chen, “Digital twin technology for building energy management: A review. Appl Energy 2020. [Google Scholar]

- J., L. J., L. S., & K. J. Lee, “A review of digital twin technology for sustainable building management. J Clean Prod 2020.

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and U. In S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hl, USA, 23–26 April 2012. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Y. P. A. B. and H.-G. M. I. Brilakis, “Built Environment Digital Twinning,” 2019.

- Identity Management Institute, “Digital twin technology benefits and challenges.

- Research and Markets, “Digital Twin Market Research Report: By Type, Technology, Enterprise, Application, Industry - Global Industry Analysis and Growth Forecast to 2030. Available online: https://www.researchandmarkets.com/reports/5128896/digital-twin-market-research-report-by-type.

- Gartner, “Market Guide for Digital Twin Portfolios and Enabling Technologies,” 2022. Available online: https://www.gartner.com/en/newsroom/press-releases/2019-02-20-gartner-survey-reveals-digital-twins-are-entering-mai.

- Digital Twin Market. Global Forecast to 2027. Available online: https://www.marketsandmarkets.com/Market-Reports/digital-twin-market-225269522.html.

- Siemens, “Digital twin - Driving business value throughout the building life cycle,” 2020.

- Agostinelli, S.; Cumo, F.; Nezhad, M.M.; Orsini, G.; Piras, G. Renewable Energy System Controlled by Open-Source Tools and Digital Twin Model: Zero Energy Port Area in Italy. Energies 2022, 15, 1817. [Google Scholar] [CrossRef]

- Juntunen, E.; Sarjanoja, E.-M.; Eskeli, J.; Pihlajaniemi, H.; Österlund, T. Smart and dynamic route lighting control based on movement tracking. Build. Environ. 2018, 142, 472–483. [Google Scholar] [CrossRef]

- Roisin, B.; Bodart, M.; Deneyer, A.; D’herdt, P. Lighting energy savings in offices using different control systems and their real consumption. Energy Build. 2008, 40, 514–523. [Google Scholar] [CrossRef]

- Gao, Y.; Lin, Y.; Sun, Y. A wireless sensor network based on the novel concept of an I-matrix to achieve high-precision lighting control. Build. Environ. 2013, 70, 223–231. [Google Scholar] [CrossRef]

- van de Meugheuvel, N.; Pandharipande, A.; Caicedo, D.; Hof, P.v.D. Distributed lighting control with daylight and occupancy adaptation. Energy Build. 2014, 75, 321–329. [Google Scholar] [CrossRef]

- Wagiman, K.R.; Abdullah, M.N.; Hassan, M.Y.; Radzi, N.H.M. A new optimal light sensor placement method of an indoor lighting control system for improving energy performance and visual comfort. J. Build. Eng. 2020, 30, 101295. [Google Scholar] [CrossRef]

- Sun, F.; Yu, J. Indoor intelligent lighting control method based on distributed multi-agent framework. Optik 2020, 213. [Google Scholar] [CrossRef]

- Wei, W.; Wu, J.; Zhu, C. Special issue on role of computer vision in smart cities. Image Vis. Comput. 2021, 107, 104113. [Google Scholar] [CrossRef]

- Ramanathan, S.S.K.; Basha, R.F.K.; Banu, A. A novel face recognition technology to enhance health and safety measures in hospitals using SBC in pandemic prone areas. Mater. Today: Proc. 2021, 45, 2584–2588. [Google Scholar] [CrossRef]

- Zhu, Z.; Cheng, Y. Application of attitude tracking algorithm for face recognition based on OpenCV in the intelligent door lock. Comput. Commun. 2020, 154, 390–397. [Google Scholar] [CrossRef]

- Seelam, V.; Penugonda, A.K.; Kalyan, B.P.; Priya, M.B.; Prakash, M.D. Smart attendance using deep learning and computer vision. Mater. Today: Proc. 2021, 46, 4091–4094. [Google Scholar] [CrossRef]

- Wei, S.; Tien, P.W.; Calautit, J.K.; Wu, Y.; Boukhanouf, R. Vision-based detection and prediction of equipment heat gains in commercial office buildings using a deep learning method. Appl. Energy 2020, 277, 115506. [Google Scholar] [CrossRef]

- Despotovic, M.; Koch, D.; Leiber, S.; Döller, M.; Sakeena, M.; Zeppelzauer, M. Prediction and analysis of heating energy demand for detached houses by computer vision. Energy Build. 2019, 193, 29–35. [Google Scholar] [CrossRef]

- Zawadzki, A. Lighting Fitting Controller Using Image Processing System. IFAC Proc. Vol. 2009, 42, 133–136. [Google Scholar] [CrossRef]

- Carrillo, C.; Diaz-Dorado, E.; Cidrás, J.; Bouza-Pregal, A.; Falcón, P.; Fernández, A.; Álvarez-Sánchez, A. Lighting control system based on digital camera for energy saving in shop windows. Energy Build. 2013, 59, 143–151. [Google Scholar] [CrossRef]

- Wu, Y.; Këmpf, J.H.; Scartezzini, J.-L. Characterization of a quasi-real-time lighting computing system based on HDR imaging. Energy Procedia 2017, 122, 649–654. [Google Scholar] [CrossRef]

- Motamed, A.; Deschamps, L.; Scartezzini, J.-L. On-site monitoring and subjective comfort assessment of a sun shadings and electric lighting controller based on novel High Dynamic Range vision sensors. Energy Build. 2017, 149, 58–72. [Google Scholar] [CrossRef]

- Shanmugam, M.; Aravind, S.; Yuvashree, K.; JaiVignesh, M.; Shrinivasan, R.J.; Santhanam, V. Energy efficient intelligent light control with security system for materials handling warehouse. Mater. Today: Proc. 2020, 37, 1884–1886. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, L.; Wei, F.; Cao, B. The Application of Digital Twin on Power Industry. IOP Conf. Series: Earth Environ. Sci. 2021, 647, 012015. [Google Scholar] [CrossRef]

- Shahzad, M.; Shafiq, M.T.; Douglas, D.; Kassem, M. Digital Twins in Built Environments: An Investigation of the Characteristics, Applications, and Challenges. Buildings 2022, 12, 120. [Google Scholar] [CrossRef]

- Fan, C.; Jiang, Y.; Mostafavi, A. Social Sensing in Disaster City Digital Twin: Integrated Textual–Visual–Geo Framework for Situational Awareness during Built Environment Disruptions. J. Manag. Eng. 2020, 36. [Google Scholar] [CrossRef]

- Ham, Y.; Kim, J. Participatory Sensing and Digital Twin City: Updating Virtual City Models for Enhanced Risk-Informed Decision-Making. J. Manag. Eng. 2020, 36. [Google Scholar] [CrossRef]

- Dutta, S.; Cai, Y.; Huang, L.; Zheng, J. Automatic re-planning of lifting paths for robotized tower cranes in dynamic BIM environments. Autom. Constr. 2020, 110. [Google Scholar] [CrossRef]

- Alves, M.; Carreira, P.; Costa, A.A. BIMSL: A generic approach to the integration of building information models with real-time sensor data. Autom. Constr. 2017, 84, 304–314. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Bagchi, A.; Salem, A. Development of an IoT and BIM-based automated alert system for thermal comfort monitoring in buildings. Sustain. Cities Soc. 2020, 66, 102602. [Google Scholar] [CrossRef]

- Srinivasan, R.S.; Rinker, M.; Thakur, S.; Parmar, M.; Akhmed, I. Towards the implementation of a 3D heat transfer analysis in dynamic-bim (dynamic building information modeling) workbench. 2014, 3224–3235. In Proceedings of the Winter Simulation Conference 2014; pp. 3224–3235. [CrossRef]

- Edmondson, V.; Cerny, M.; Lim, M.; Gledson, B.; Lockley, S.; Woodward, J. A smart sewer asset information model to enable an ‘Internet of Things’ for operational wastewater management. Autom. Constr. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Chen, X.-S.; Liu, C.-C.; Wu, I.-C. A BIM-based visualization and warning system for fire rescue. Adv. Eng. Informatics 2018, 37, 42–53. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- B. B. Atkin, Total Facility Management. 2021.

- Jamil, S.; Rahman, M. ; Fawad A Comprehensive Survey of Digital Twins and Federated Learning for Industrial Internet of Things (IIoT), Internet of Vehicles (IoV) and Internet of Drones (IoD). Appl. Syst. Innov. 2022, 5, 56. [Google Scholar] [CrossRef]

- Khallaf, R.; Khallaf, L.; Anumba, C.J.; Madubuike, O.C. Review of Digital Twins for Constructed Facilities. Buildings 2022, 12, 2029. [Google Scholar] [CrossRef]

- Nasab, S.N.; Azeri, A.R.K.; Mirbazel, S. Ideal physical features of environmental design in children’s hospital. Facilities 2020, 38, 445–466. [Google Scholar] [CrossRef]

- Parsanezhad, P.; Dimyadi, J. Effective Facility Management and Operations via a BIM-based Integrated Information System. [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings — Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- R. De Silva, “Related papers The Need for an Integrated Cost Modelling Framework for Building Information Modelling (BIM),” 2008.

- Deng, Y.; Cheng, J.C.; Anumba, C. Mapping between BIM and 3D GIS in different levels of detail using schema mediation and instance comparison. Autom. Constr. 2016, 67, 1–21. [Google Scholar] [CrossRef]

- Nastasi, B.; Nezhad, M.M. GIS and Remote Sensing for Renewable Energy Assessment and Maps. Energies 2021, 15, 14. [Google Scholar] [CrossRef]

- Xia, H.; Liu, Z.; Maria, E.; Liu, X.; Lin, C. Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic information system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Rong, Y.; Zhang, T.; Zheng, Y.; Hu, C.; Peng, L.; Feng, P. Three-dimensional urban flood inundation simulation based on digital aerial photogrammetry. J. Hydrol. 2019, 584, 124308. [Google Scholar] [CrossRef]

- Lochhead, I.; Hedley, N. Mixed reality emergency management: bringing virtual evacuation simulations into real-world built environments. Int. J. Digit. Earth 2018, 12, 190–208. [Google Scholar] [CrossRef]

- Olfat, H.; Atazadeh, B.; Shojaei, D.; Rajabifard, A. The Feasibility of a BIM-Driven Approach to Support Building Subdivision Workflows—Case Study of Victoria, Australia. ISPRS Int. J. Geo-Information 2019, 8, 499. [Google Scholar] [CrossRef]

- Shahi, K.; McCabe, B.Y.; Shahi, A. Framework for Automated Model-Based e-Permitting System for Municipal Jurisdictions. J. Manag. Eng. 2019, 35. [Google Scholar] [CrossRef]

- Sun, J.; Mi, S.; Olsson, P.-O.; Paulsson, J.; Harrie, L. Utilizing BIM and GIS for Representation and Visualization of 3D Cadastre. ISPRS Int. J. Geo-Information 2019, 8, 503. [Google Scholar] [CrossRef]

- Giuffrida, D.; Nardo, V.M.; Neri, D.; Cucinotta, G.; Calabrò, I.V.; Pace, L.; Ponterio, R.C. A Multi-Analytical Study for the Enhancement and Accessibility of Archaeological Heritage: The Churches of San Nicola and San Basilio in Motta Sant’Agata (RC, Italy). Remote Sens. 2021, 13, 3738. [Google Scholar] [CrossRef]

- Gotlib, D.; Wyszomirski, M.; Gnat, M. A Simplified Method of Cartographic Visualisation of Buildings’ Interiors (2D+) for Navigation Applications. ISPRS Int. J. Geo-Information 2020, 9, 407. [Google Scholar] [CrossRef]

- Siahboomy, M.A.; Sarvari, H.; Chan, D.W.M.; Nassereddine, H.; Chen, Z. A multi-criteria optimization study for locating industrial warehouses with the integration of BIM and GIS data. Arch. Eng. Des. Manag. 2021, 17, 478–495. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, P. Implementation of BIM + WebGIS Based on Extended IFC and Batched 3D Tiles Data: An Application in RCC Gravity Dam for Republication of Design Change Model. KSCE J. Civ. Eng. 2021, 25, 4045–4064. [Google Scholar] [CrossRef]

- Zhang, S.; Hou, D.; Wang, C.; Pan, F.; Yan, L. Integrating and managing BIM in 3D web-based GIS for hydraulic and hydropower engineering projects. Autom. Constr. 2020, 112, 103114. [Google Scholar] [CrossRef]

- Borrmann, A.; Kolbe, T.; Donaubauer, A.; Steuer, H.; Jubierre, J.; Flurl, M. Multi-Scale Geometric-Semantic Modeling of Shield Tunnels for GIS and BIM Applications. Comput. Civ. Infrastruct. Eng. 2014, 30, 263–281. [Google Scholar] [CrossRef]

- Carrasco, C.A.; Lombillo, I.; Sánchez-Espeso, J.M.; Balbás, F.J. Quantitative and Qualitative Analysis on the Integration of Geographic Information Systems and Building Information Modeling for the Generation and Management of 3D Models. Buildings 2022, 12, 1672. [Google Scholar] [CrossRef]

- Ali, K.N.; Alhajlah, H.H.; Kassem, M.A. Collaboration and Risk in Building Information Modelling (BIM): A Systematic Literature Review. Buildings 2022, 12, 571. [Google Scholar] [CrossRef]

- Miller, C.; Abdelrahman, M.; Chong, A.; Biljecki, F.; Quintana, M.; Frei, M.; Chew, M.; Wong, D. The Internet-of-Buildings (IoB) — Digital twin convergence of wearable and IoT data with GIS/BIM. J. Physics: Conf. Ser. 2021, 2042. [Google Scholar] [CrossRef]

- Sammartano, G.; Avena, M.; Cappellazzo, M.; Spanò, A. Hybrid gis-bim approach for the torino digital-twin: the implementation of a floor-level 3d city geodatabase. ISPRS - Int. Arch. Photogramm. Remote. Sens. Spat. Inf. Sci. -2. [CrossRef]

- Zhu, J.; Wu, P. A Common Approach to Geo-Referencing Building Models in Industry Foundation Classes for BIM/GIS Integration. ISPRS Int. J. Geo-Information 2021, 10, 362. [Google Scholar] [CrossRef]

- Diakite, A.A.; Zlatanova, S. Automatic geo-referencing of BIM in GIS environments using building footprints. Comput. Environ. Urban Syst. 2019, 80, 101453. [Google Scholar] [CrossRef]

- Pan, Z.; Shi, J.; Jiang, L. A Novel HDF-Based Data Compression and Integration Approach to Support BIM-GIS Practical Applications. Adv. Civ. Eng. 2020, 2020, 1–22. [Google Scholar] [CrossRef]

- Pan, Z.; Shi, J.; Jiang, L. A Novel HDF-Based Data Compression and Integration Approach to Support BIM-GIS Practical Applications. Adv. Civ. Eng. 2020, 2020, 1–22. [Google Scholar] [CrossRef]

- Razmjoo, A.; Mirjalili, S.; Aliehyaei, M.; Østergaard, P.A.; Ahmadi, A.; Nezhad, M.M. Development of smart energy systems for communities: technologies, policies and applications. Energy 2022, 248, 123540. [Google Scholar] [CrossRef]

- Janoskova, P.; Stofkova, K.R.; Kovacikova, M.; Stofkova, J.; Kovacikova, K. The Concept of a Smart City Communication in the Form of an Urban Mobile Application. Sustainability 2021, 13, 9703. [Google Scholar] [CrossRef]

- Persson, “The Digital Twin — Unsung Hero in F1 and in the Smart City,”. Available online: https://sensative.com/thedigital- twin-unsung-hero-in-f1-and-in-the-smart-city/.

- N. R. Foundation, “Virtual Singapore,”. Available online: https://www.nrf.gov.sg/programmes/virtual-singapore.

- Amaravati Smart City,”. Available online: https://cityzenith.com/customers/amaravati-smart- city.

- SmartCitiesWorld, “Digital Twin Created for New Indian Smart City, 2018. Available online: https://www.smartcitiesworld.net/news/news/digitaltwin- created-for-new-indian-smart-city-3674.

- Fishermans Bend Digital Twin,” https://www.delwp.vic.gov.au/maps/digital-twin. 2020. Available online: https://www.delwp.vic.gov.au/maps/digital-twin.

- Ford, D.N.; Wolf, C.M. Smart Cities with Digital Twin Systems for Disaster Management. J. Manag. Eng. 2020, 36. [Google Scholar] [CrossRef]

- White, G.; Zink, A.; Codecá, L.; Clarke, S. A digital twin smart city for citizen feedback. Cities 2021, 110, 103064. [Google Scholar] [CrossRef]

- Hämäläinen, M. Smart city dvelopment with digital twin technology. 2020. [CrossRef]

- Deren, L.; Wenbo, Y.; Zhenfeng, S. Smart city based on digital twins. Comput. Urban Sci. 2021, 1. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Zeng, W. Development and application of digital twin technology for integrated regional energy systems in smart cities. Sustain. Comput. Informatics Syst. 2022, 36. [Google Scholar] [CrossRef]

- J. Grübel et al., “The Hitchhiker’s Guide to Fused Twins -- A Conceptualization to Access Digital Twins in situ in Smart Cities,” Remote Sens (Basel), vol. 14, pp. 1–54, 2022.

- Xia, H.; Liu, Z.; Maria, E.; Liu, X.; Lin, C. Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic information system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Ramu, S.P.; Boopalan, P.; Pham, Q.-V.; Maddikunta, P.K.R.; Huynh-The, T.; Alazab, M.; Nguyen, T.T.; Gadekallu, T.R. Federated learning enabled digital twins for smart cities: Concepts, recent advances, and future directions. Sustain. Cities Soc. 2022, 79, 103663. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Wang, W.; Zheng, Y.; Lv, H.; Lv, Z. Big data analysis of the Internet of Things in the digital twins of smart city based on deep learning. Futur. Gener. Comput. Syst. 2021, 128, 167–177. [Google Scholar] [CrossRef]

- Bujari, A.; Calvio, A.; Foschini, L.; Sabbioni, A.; Corradi, A. A Digital Twin Decision Support System for the Urban Facility Management Process. Sensors 2021, 21, 8460. [Google Scholar] [CrossRef]

- Ana, R.R.S.; Escoto, J.E. ; Jr., D.F.; Panlilio, K.; Jerez, M.; Sarmiento, C.J. Development of a digital twin for the monitoring of smart cities using open-source software. ISPRS - Int. Arch. Photogramm. Remote. Sens. Spat. Inf. Sci. [CrossRef]

- Deng, T.; Zhang, K.; Shen, Z.-J.M. A systematic review of a digital twin city: A new pattern of urban governance toward smart cities. J. Manag. Sci. Eng. 2021, 6, 125–134. [Google Scholar] [CrossRef]

- Mylonas, G.; Kalogeras, A.; Kalogeras, G.; Anagnostopoulos, C.; Alexakos, C.; Munoz, L. Digital Twins From Smart Manufacturing to Smart Cities: A Survey. IEEE Access 2021, 9, 143222–143249. [Google Scholar] [CrossRef]

- Mylonas, G.; Kalogeras, A.; Kalogeras, G.; Anagnostopoulos, C.; Alexakos, C.; Munoz, L. Digital Twins From Smart Manufacturing to Smart Cities: A Survey. IEEE Access 2021, 9, 143222–143249. [Google Scholar] [CrossRef]

- Parrott and, L. Warshaw, “Industry 4.0 and the digital twin,” Deloitte Univ. Press, 2017.

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 1–14. [Google Scholar] [CrossRef]

- West, T.D.; Pyster, A. Untangling the Digital Thread: The Challenge and Promise of Model-Based Engineering in Defense Acquisition. INSIGHT 2015, 18, 45–55. [Google Scholar] [CrossRef]

- Seshadri, B.R.; Krishnamurthy, T. Structural Health Management of Damaged Aircraft Structures Using Digital Twin Concept. In Proceedings of the 25th AIAA/AHS Adaptive Structures Conference, Reston, Grapevine, TX, USA, 9–13 January 2017., Virginia: American Institute of Aeronautics and Astronautics.

- Zhuang, C.; Liu, Z.; Liu, J.; Ma, H.; Zhai, S.; Wu, Y. Digital Twin-based Quality Management Method for the Assembly Process of Aerospace Products with the Grey-Markov Model and Apriori Algorithm. Chin. J. Mech. Eng. 2022, 35, 1–21. [Google Scholar] [CrossRef]

- Conde, J.; Munoz-Arcentales, A.; Romero, M.; Rojo, J.; Salvachúa, J.; Huecas, G.; Alonso. Applying digital twins for the management of information in turnaround event operations in commercial airports. Adv. Eng. Informatics 2022, 54. [Google Scholar] [CrossRef]

- Hultman, H.; Cedergren, S.; Wärmefjord, K.; Söderberg, R. Predicting Geometrical Variation in Fabricated Assemblies Using a Digital Twin Approach Including a Novel Non-Nominal Welding Simulation. Aerospace 2022, 9, 512. [Google Scholar] [CrossRef]

- Candon, M.; Esposito, M.; Fayek, H.; Levinski, O.; Koschel, S.; Joseph, N.; Carrese, R.; Marzocca, P. Advanced multi-input system identification for next generation aircraft loads monitoring using linear regression, neural networks and deep learning. Mech. Syst. Signal Process. 2022, 171, 108809. [Google Scholar] [CrossRef]

- Medina, F.G.; Umpierrez, A.W.; Martinez, V.; Fromm, H. A Maturity Model for Digital Twin Implementations in the Commercial Aerospace OEM Industry. 2021, 149–156. [CrossRef]

- Borgen, K.B.; Ropp, T.D.; Weldon, W.T. Assessment of Augmented Reality Technology’s Impact on Speed of Learning and Task Performance in Aeronautical Engineering Technology Education. Int. J. Aerosp. Psychol. 2021, 31, 219–229. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital twin modeling method based on biomimicry for machining aerospace components. J. Manuf. Syst. 2020, 58, 180–195. [Google Scholar] [CrossRef]

- Ezhilarasu, C.M.; Skaf, Z.; Jennions, I.K. A Generalised Methodology for the Diagnosis of Aircraft Systems. IEEE Access 2021, 9, 11437–11454. [Google Scholar] [CrossRef]

- Z, H.Y.; Wang, L. Application and Development Prospect of Digital Twin Technology in Aerospace. IFAC-PapersOnLine 2020, 53, 732–737. [Google Scholar] [CrossRef]

- Z, H.Y.; Wang, L. Application and Development Prospect of Digital Twin Technology in Aerospace. IFAC-PapersOnLine 2020, 53, 732–737. [Google Scholar] [CrossRef]

- N. Lahoti, “How is digital twin technology impacting the automotive industry? Available online: http://mobisoftinfotech.com/resources/blog/digital-twin-technology- impacting-automotive-industry/.

- Mourtzis, D.; Vlachou, E.; Milas, N. Industrial Big Data as a Result of IoT Adoption in Manufacturing. Procedia CIRP 2016, 55, 290–295. [Google Scholar] [CrossRef]

- Henrichs, E.; Noack, T.; Piedrahita, A.M.P.; Salem, M.A.; Stolz, J.; Krupitzer, C. Can a Byte Improve Our Bite? An Analysis of Digital Twins in the Food Industry. Sensors 2021, 22, 115. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Rodrigues, R.N.; Henriques, R.V.B.; Rettberg, A.; Pereira, C.E. A Methodology for Digital Twin Modeling and Deployment for Industry 4.0. Proc. IEEE 2020, 109, 556–567. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, L.; Wei, F.; Cao, B. The Application of Digital Twin on Power Industry. IOP Conf. Series: Earth Environ. Sci. 2021, 647, 012015. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.I.; Warrian, P.J. Digital twin for the oil and gas industry: Overview, research trends, opportunities, and challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An approach to develop a digital twin for industry 4.0 systems: manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Yu, J.; Liu, P.; Li, Z. Hybrid modelling and digital twin development of a steam turbine control stage for online performance monitoring. Renew. Sustain. Energy Rev. 2020, 133, 110077. [Google Scholar] [CrossRef]

- Bortolini, R.; Rodrigues, R.; Alavi, H.; Vecchia, L.F.D.; Forcada, N. Digital Twins’ Applications for Building Energy Efficiency: A Review. Energies 2022, 15, 7002. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Xu, B.; Wang, J.; Wang, X.; Liang, Z.; Cui, L.; Liu, X.; Ku, A.Y. A case study of digital-twin-modelling analysis on power-plant-performance optimizations. Clean Energy 2019, 3, 227–234. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A Digital Twin-Based Approach for Designing and Multi-Objective Optimization of Hollow Glass Production Line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Blume, C.; Blume, S.; Thiede, S.; Herrmann, C. Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study. J. Manuf. Mater. Process. 2020, 4, 97. [Google Scholar] [CrossRef]

- Pimenta, F.; Pacheco, J.; Branco, C.M.; Teixeira, C.M.; Magalhães, F. Development of a digital twin of an onshore wind turbine using monitoring data. J. Physics: Conf. Ser. 2020, 1618. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic Digital Twin Architecture for Industrial Energy Systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Yu, J.; Liu, P.; Li, Z. Hybrid modelling and digital twin development of a steam turbine control stage for online performance monitoring. Renew. Sustain. Energy Rev. 2020, 133, 110077. [Google Scholar] [CrossRef]

- Prawiranto, K.; Carmeliet, J.; Defraeye, T. Physics-Based Digital Twin Identifies Trade-Offs Between Drying Time, Fruit Quality, and Energy Use for Solar Drying. Front. Sustain. Food Syst. 2021, 4. [Google Scholar] [CrossRef]

| Lifecycle stage | DT outcome |

|---|---|

| Design | Model, simulate and conduct what-if scenarios. Improve and optimize their design. Environmental impacts analysis. Individual asset scale, district or city level analysis. Design informed by data, information and connected ecosystems. Improve the built environment’s operational efficiency (traffic flow, occupancy, energy etc). |

| Construction | Site-based process enhancement (sensors, drones, laser scanning). Supply chain allowing real-time inventory tracking. Prefabrication and industrialised construction. Benefits in production management, work performance, health, safety and wellbeing of workers, materials, equipment tracking. Streamline the management of data and information during construction. |

| Operation and maintenance | Predictive maintenance (monitoring of health of building systems and equip-ment in real-time, enabling predictive maintenance and reducing downtime and repair costs). Improved energy efficiency optimizing building systems and operations. Better asset management (track the location, condition, and performance of building assets). Enhanced safety and security (simulation of emergency scenarios, identifica-tion of potential safety and security risks, proactive measures). Reduced operational costs (identification of inefficiencies and areas of waste). Improved occupant experience (tracking occupant behavior). Increased sustainability (track and reduce the environmental impact of build-ings). |

| Decommissioning | Planning and executing the decommissioning process safely and efficiently. Simulate and optimize different decommissioning scenarios and identify potential risks. Reducing the likelihood of unexpected delays or complications. Facilitate collaboration and communication between different stakeholders. Progress tracking and monitoring. Improved sustainability and resource efficiency. |

| Author(s) | Year | Methodology | Aims | Reference |

|---|---|---|---|---|

| Carrasco et al, | 2022 | A review: BIM and GIS integration. | The research objective is to identify the most significant technological developments and potential applications integration. To these aims, after a bibliographic consultation, two analyses are carried out, one quantitative and the other qualitative. | [83] |

| Xia et al, | 2022 | A review: the BIM, GIS, data value, and ontology-based data integration. | Keyword analysis, co-country analysis, and co-citation and pairwise analyzes are performed using CiteSpace. The GIS and BIM integration has attracted much attention. The professional disconnection and fragmented composition create challenges for GIS and BIM integration. | [79] |

| Nita Ali et al, | 2022 | A review: BIM and GIS integration. The current status and future trends in BIM from the Web of Science database. | Focus on the following topics: collaboration in BIM, integration of BIM, GIS and IoT, barriers to the BIM, sustainability and BIM, and risk assessment and uncertainty integration. | [84] |

| Miller et al, | 2021 | A DT case study of the data intersection from systems are described. | Preliminary insights are discussed for an experiment with participants focused on residents' feedback collection to characterize indoor comfort. | [85] |

| Sammartano et al, | 2021 | Based on the actual scenario to address the advantage of the BIM-GIS models dataset, test availability at a different scale, with different potential and bottlenecks. The proposed methodology tries to elaborate rules on shared language parameters by combining parametric modeller software (Revit) and visual programming language (Dynamo). |

A preliminary work into geo-spatial management of public administration assets thanks to interoperability of BIM-GIS models related to urban scale scenarios. | [86] |

| Zhu et al, | 2021 | A systematic and thorough investigation into the IFC standard was conducted to assess the IFC geo-referencing capability. | The study aims to clarify the meaning of geo-referencing in the context of BIM/GIS data integration and develop a common geo-referencing approach for IFC. | [87] |

| Diakite et al, | 2020 | The GIS data geo-referencing comes from the BIM domain and the Computer-Aided Design (CAD) world. |

The paper aims to create an automatic framework to transform the BIM model's local coordinates into real-world geographic coordinates. | [88] |

| Pan et al, | 2020 | An HDF- (Hierarchical Data Format-) based and synthesized scheme with three (IFC-SPF (IFC STEP Physical File) and XML-encoded CityGML (City Geography Markup Language), bidirectional transformation methods and data aggregation enhances the integrated model bond and heterogeneous data resources from the transformed HDF files) significant technical processes. | The case studies show that the approach proposed to reach high efficiency for the BIM + GIS integration model practicability. This lightweight integration method can further improve the front-end service responsiveness in DT applications. | [89] |

| Author(s) | Year | Methodology | Aims | Reference |

|---|---|---|---|---|

| Deren et al, | 2021 | Using digital twins and DT cities concepts. | The relationship between digital twins and smart cities analyzes the smart cities' characteristics based on digital twins and focuses on the smart cities' five main applications based on digital twins. | [101] |

| Wolf et al, | 2022 | A fundamental concept of the digital twin and gives the construction method and possible applications of the energy internet digital twin. | The development and application of DT technology in the integrated regional energy system of smart cities. | [102] |

| Grübel et al, | 2022 | A review | Situated Analytics, and Smart Cities as the foundations of Physical Twins. | [103] |

| Xia et al, | 2022 | A review and bibliometric analysis of geographic information system and building information modeling integration. | Study on city DT technologies for sustainable smart city design. | [104] |

| Priya Ramu et al, | 2022 | Present an extensive survey on the various smart city-based applications of Federated Learning (FL) models in DTs. The Deep Learning (DL) algorithm uses BDA and puts forward the distributed parallelism strategy of the Convolutional Neural Net (CNN). | The integration of Artificial Intelligence (AI) and the IoT promising technologies for adoption in real-time and life-critical scenarios for ease of governance in smart city-based applications. | [105] |

| Li et al, | 2022 | Present an extensive survey on the various smart city-based applications of Federated Learning (FL) models in DTs. The Deep Learning (DL) algorithm uses BDA and puts forward the distributed parallelism strategy of the Convolutional Neural Net (CNN). | Big Data Analysis (BDA) on the massive data generated in the smart city IoT. | [106] |

| Bujari et al, | 2021 | The Interactive Planning Platform for City District Adaptive Maintenance Operations (IPPODAMO). | Presenting a detailed proof-of-concept implementation of a DT solution for the Urban Facility Management (UFM) process. | [107] |

| Sta. Ana et al, | 2021 | Unity3D, QGIS2threejs, and TerriaMap. | A DT development for the smart cities monitoring. | [108] |

| Deng et al, | 2021 | A review | A DT city concept | [109] |

| Mylonas et al, | 2021 | A review | The current research landscape regards DTs in the field of smart cities, while also attempting to draw parallels with the DTs application. | [110] |

| Author(s) | Year | Methodology | Aims | Reference |

|---|---|---|---|---|

| Zhuang et al, | 2022 | Quality management (Using the Grey-Markov Model and Apriori Algorithm). | The aerospace products assembly process. | [116] |

| Conde et al, | 2022 | Reference Conceptualisations and data model based on FIWARE Generic Enablers and the Next Generation Service Interfaces-Linked Data standard. | Information management in turnaround event operations in commercial airports. | [117] |

| Hultman et al, | 2022 | A Novel Non-Nominal Welding Simulation. | Predicting Geometrical Variation in Fabricated Assemblies. | [118] |

| Candon et al, | 2022 | linear regression, neural networks and deep learning. | Advanced multi-input system identification for next generation aircraft loads monitoring. | [119] |

| Gomez Medina et al, | 2021 | The Design Science Research (DSR) framework has been used to structure the maturity model development. | Implementations in the Commercial Aerospace OEM Industry. | [120] |

| B. Borgen et al, | 2021 | The university undergraduate students enrolled in a university aeronautical engineering technology program were divided into AR and paper-based groups and compared on first-time task execution times for starting an aircraft Auxiliary Power Unit (APU). | Assessment of Augmented Reality Technology’s Impact on Learning Speed and Task Performance. | [121] |

| Liu et al, | 2021 | Based on biomimicry for machining aerospace components. | Fusing multi-dimensional in-context machining process data, such as changes in geometry, material properties and machining parameters. | [122] |

| Ezhilarasu et al, | 2021 | Based on OSA-CBM (Open System Architecture for Condition Based Maintenance). | Efficiently informing aircraft maintenance to the Original Equipment Manufacturers, the operators /airlines, and the Maintenance, Repair, and Overhaul organizations. |

[123] |

| Yin Z H et al, | 2020 | Compared modelling simulations, the advantages of shorting design cycle, high reliability, less frequent overhaul and low maintenance cost. | Focusing on the DT application's current situation in aerospace. | [124] |

| Author(s) | Year | Method | Aims | Reference |

|---|---|---|---|---|

| Henrichs et al, | 2021 | Overview | The DT applications in the food industry and analyze their challenges and potentials. | [128] |

| Schroeder et al, | 2021 | Model Driven Engineering (MDE). | This article focuses on DT and proposes a methodology for DT design using model-driven engineering (MDE) that strives to be flexible and generic. | [129] |

| Tao et al, | 2019 | A review | A Correlation and Comparison of DTs and Cyber-Physical Systems toward Smart Manufacturing and Industry. | [130] |

| Min et al, | 2019 | A machine learning-based approach is proposed to form a mathematical DT model that simulates the control inputs and outputs. | A framework and approaches for constructing a DT based on the petrochemical industrial IoT, machine learning and a practice loop for information exchange between the physical factory and a virtual DT model to realize production control optimization. | [131] |

| Singh et al, | 2022 | A review | Covering the DT applications in different industries. | [132] |

| Huang et al, | 2021 | Real-time situational awareness uses real-time virtual deduction as a cognitive means and real-time feedback from virtual to real space as an iterative method. | Develop a smarter new generation of Smart Power Systems (SPS). | [133] |

| Wanasighe et al, | 2020 | A review | The Oil and Gas Industry: Overview, Research Trends, Opportunities, and Challenges. |

[134] |

| Guerra-Zubiaga et al, | 2021 | Digital Manufacturing Tools (DMT). | Develop a DT of production systems to optimize the planning and commissioning process. | [135] |

| Leng et al, | 2021 | A review | To reduce the vast time and cost of physical commissioning/reconfiguration by the Smart Manufacturing System (SMS) design errors/flaws early detection. | [136] |

| Author(s) | Year | Method | Aims | Reference |

|---|---|---|---|---|

| Yu et al, | 2022 | A review. | To accelerate the understanding, classification, and application of energy DT technology. | [140] |

| Xu et al, | 2019 | Optimization solutions and their cost effectiveness have been evaluated using DT modeling analysis. | Using a PPSM case study in a 320 MW coal-fired thermal power plant unit, it examines how DT technology can be used to explore and analyze optimization solutions. | [141] |

| Zhang et al, | 2017 | The DT merges physics-based system modeling and distributed real-time process data to generate a traditional digital system design at the pre-production phase. | Approach for rapid individualized designing of the hollow glass production line. | [142] |

| Blume et al, | 2020 | Comprises seven consecutive steps in a broadly applicable workflow based on the CRISP-DM paradigm. | Improve system understanding and performance prediction as essentials for successful operations management. | [143] |

| Pimenta et al, | 2020 | FAST software and ANSYS Fluent. | To create a DT of an onshore wind turbine tool for continuous tracking of accumulated fatigue damage and evaluation of alternative operation strategies and to perform the first tasks for creating a reliable numerical of a floating wind turbine to simulate experimental data. | [144] |

| Steindl et al, | 2020 | Analyzed concepts, architectures, and frameworks for DTs in the literature | To develop a technology-independent Generic Digital Twin Architecture (GDTA), which is aligned with the information technology layers of the Reference Architecture Model Industry 4.0 (RAMI4.0). | [145] |

| Yu et al, | 2020 | A hybrid modelling method based on operation data and first-principal mechanism. | Performance monitoring of control stage systems. | [146] |

| Prawiranto et al, | 2021 | Combine a mechanistic fruit drying model, quality models and weather data. | Evaluate apple fruit's drying characteristics and quality evolution with and without the improvement above strategies. | [147] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).