Submitted:

18 July 2023

Posted:

19 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. The constitutive model

2.1. State variables

2.2. System Hamiltonian

2.3. The Poisson and dissipation brackets

2.4. The Matrices L and Λ

2.5. Thermodynamic admissibility

2.6. Conformation tensor evolution equation

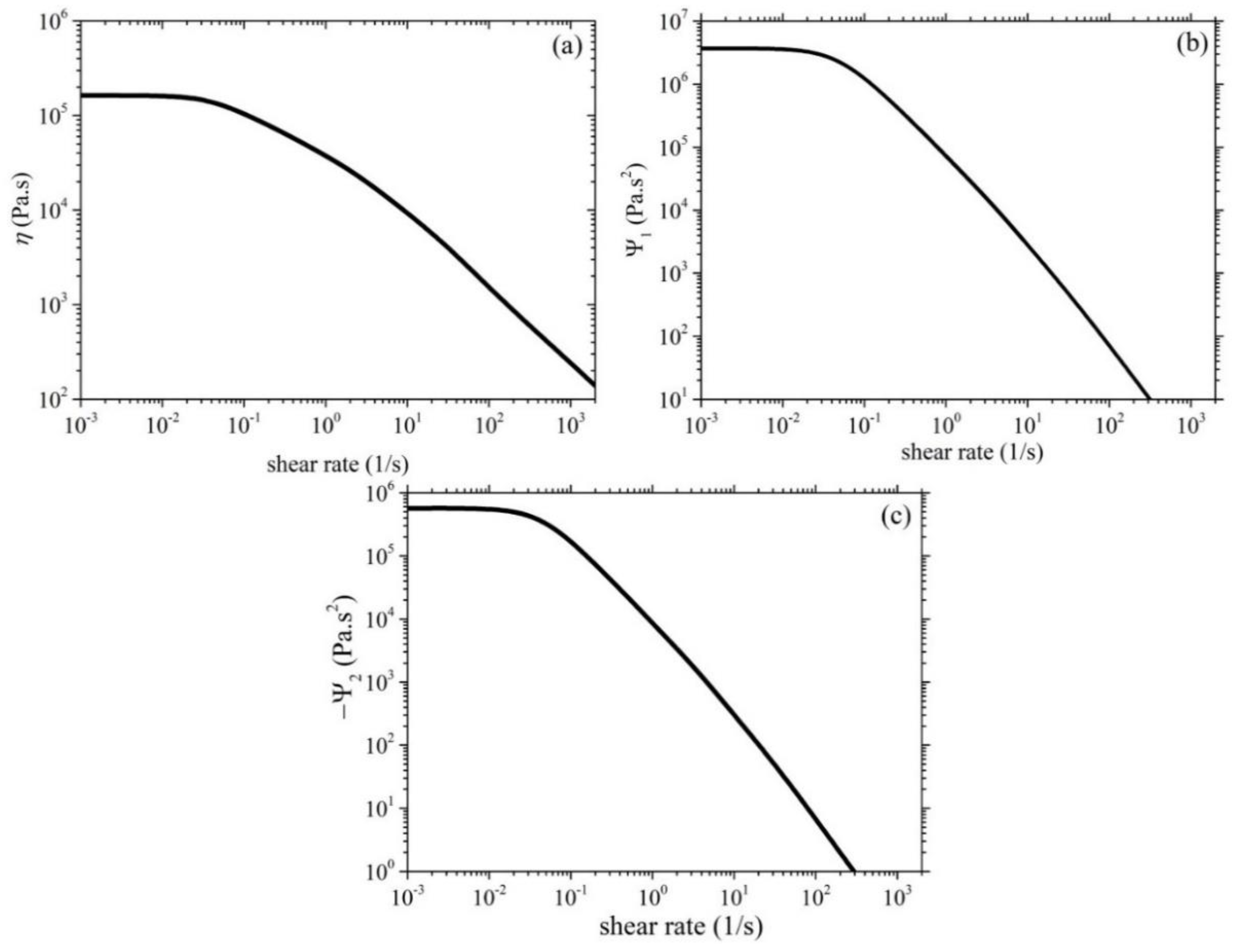

3. Asymptotic behavior of the model in steady state shear

4. Results and Discussion

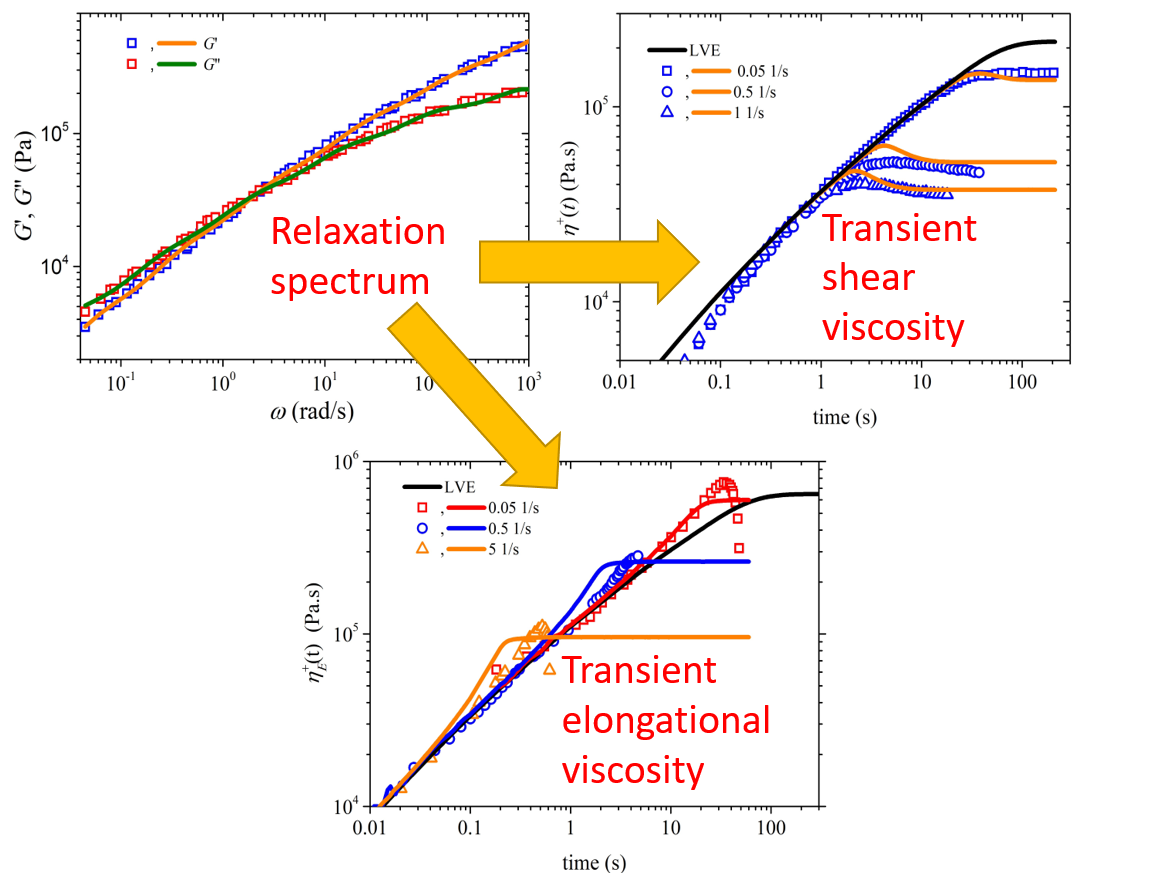

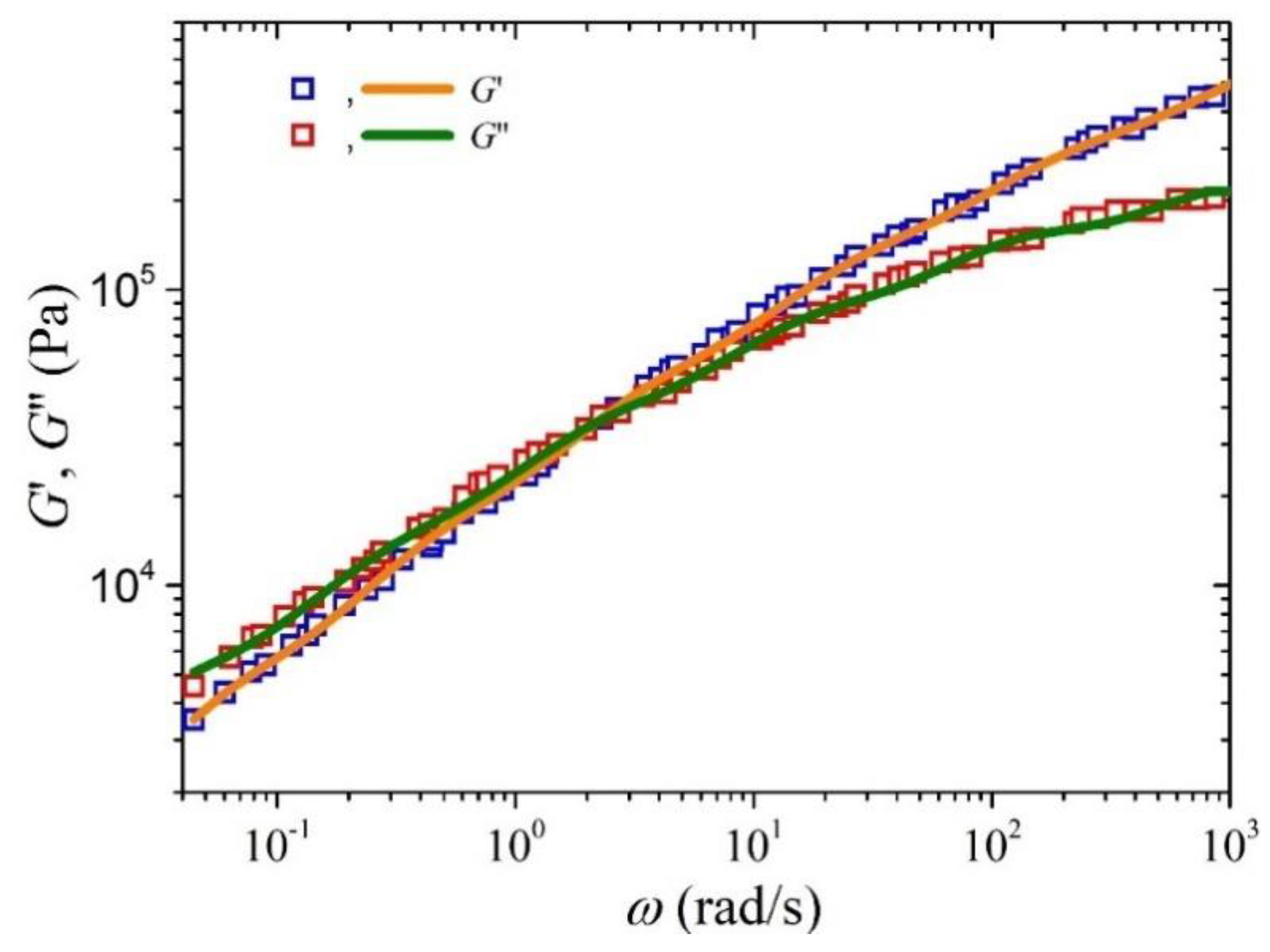

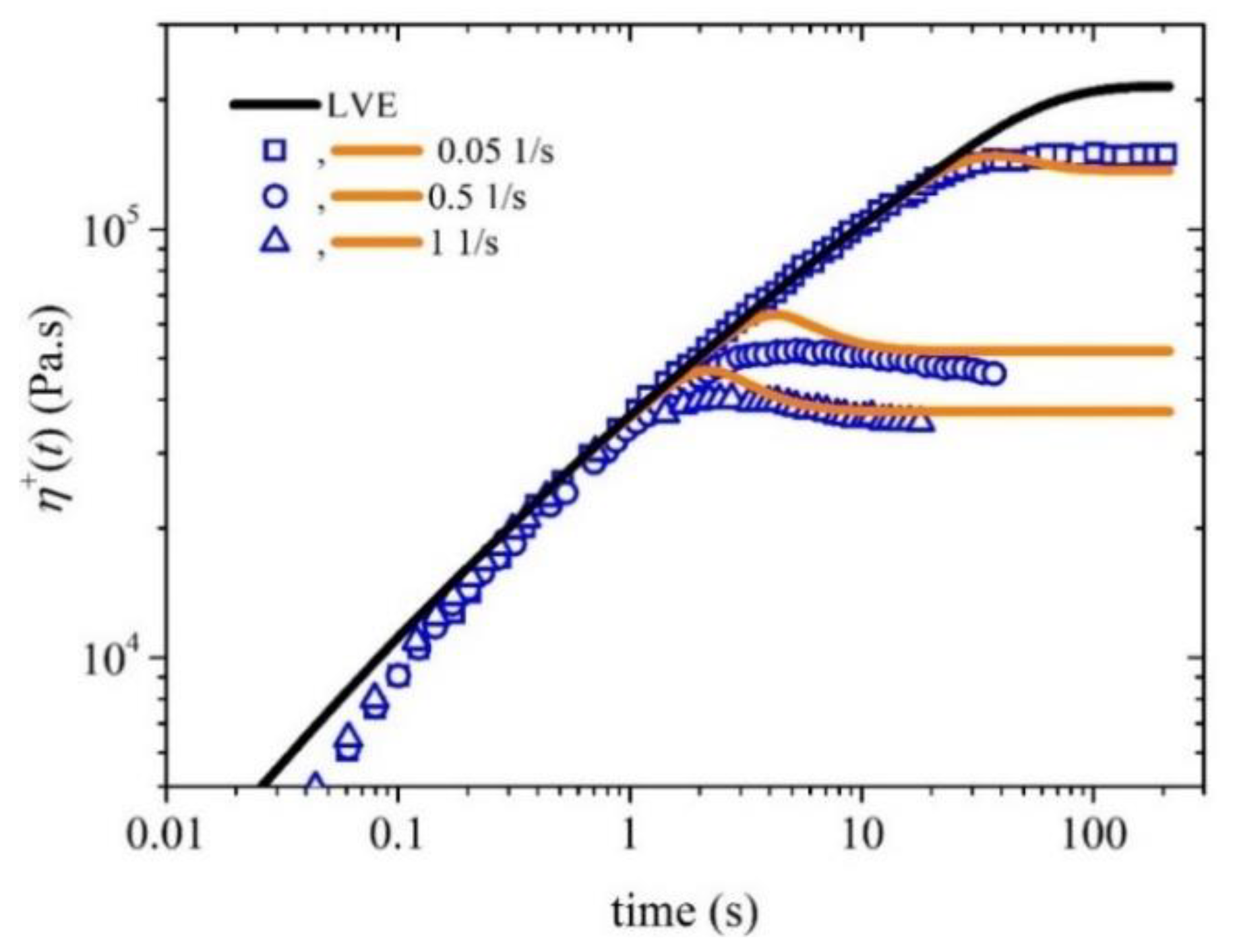

4.1. Comparison with start-up shear flow data

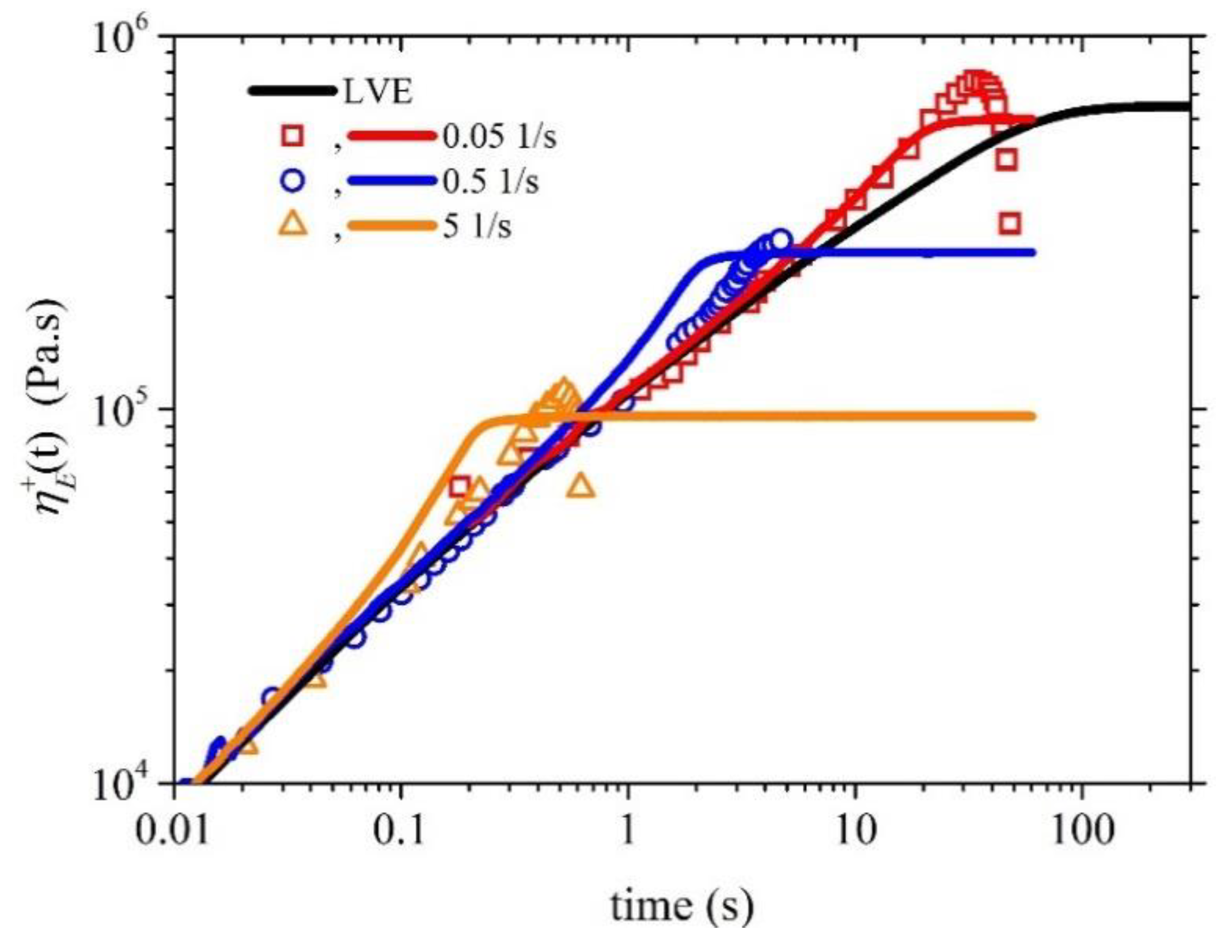

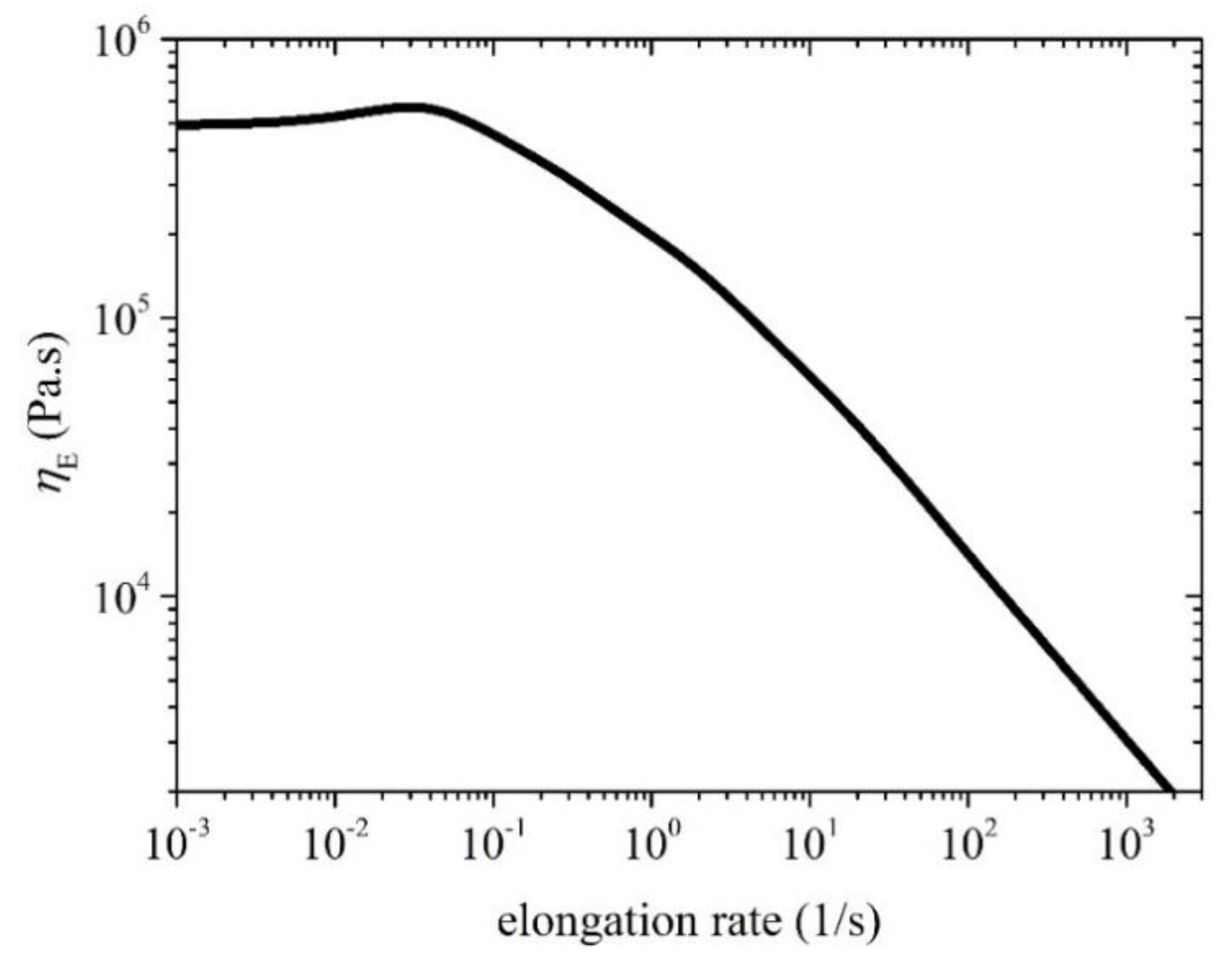

4.2. Comparison with start-up uniaxial elongational flow data

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

| 1 |

https://www.plasticstoday.com/packaging/global-plastic-packaging-market-worth-2696-billion-2025. Accessed 19 June 2023. |

References

- Z. Tadmor and C. G. Gogos, Principles of Polymer Processing, 2nd Edition. 2006. [Online]. Available: https://books.google.ca/books?id=TUdmBk1_mlAC.

- Graham, M.D. The sharkskin instability of polymer melt flows. Chaos: Interdiscip. J. Nonlinear Sci. 1999, 9, 154–163, . [CrossRef]

- Barone, J.R.; Plucktaveesak, N.; Wang, S.Q. Interfacial molecular instability mechanism for sharkskin phenomenon in capillary extrusion of linear polyethylenes. J. Rheol. 1998, 42, 813–832, . [CrossRef]

- Baig, C.; Stephanou, P.S.; Tsolou, G.; Mavrantzas, V.G.; Kröger, M. Understanding Dynamics in Binary Mixtures of Entangled cis-1,4-Polybutadiene Melts at the Level of Primitive Path Segments by Mapping Atomistic Simulation Data onto the Tube Model. Macromolecules 2010, 43, 8239–8250, . [CrossRef]

- Stephanou, P.S.; Baig, C.; Tsolou, G.; Mavrantzas, V.G.; Kröger, M. Quantifying chain reptation in entangled polymer melts: Topological and dynamical mapping of atomistic simulation results onto the tube model. J. Chem. Phys. 2010, 132, 124904, . [CrossRef]

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. Projection of atomistic simulation data for the dynamics of entangled polymers onto the tube theory: calculation of the segment survival probability function and comparison with modern tube models. Soft Matter 2011, 7, 380–395, . [CrossRef]

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. Toward an Improved Description of Constraint Release and Contour Length Fluctuations in Tube Models for Entangled Polymer Melts Guided by Atomistic Simulations. Macromol. Theory Simulations 2011, 20, 752–768, . [CrossRef]

- Stephanou, P.S.; Mavrantzas, V.G. Accurate prediction of the linear viscoelastic properties of highly entangled mono and bidisperse polymer melts. J. Chem. Phys. 2014, 140, 214903, . [CrossRef]

- V. Nassehi, Practical Aspects of Finite Element Modelling of Polymer Processing. 2002.

- R. G. Larson, Constitutive Equations for Polymer Melts and Solutions, 1st ed. Butterworth-Heinemann, 1988.

- R. B. Bird, R. C. Armstrong, and O. Hassager, Dynamics of polymeric liquids. Volume 1. Fluid mechanics., 2nd Editio. Wiley-Interscience, 1987.

- J. D. Ferry, Viscoelastic properties of polymers, 1st ed. John Wiley & Sons, Ltd, 1980.

- X. -L Luo and R. I. Tanner, “Finite element simulation of long and short circular die extrusion experiments using integral models,” Int. J. Numer. Methods Eng., 25, 9–22, (1988),.

- Konaganti, V.K.; Ansari, M.; Mitsoulis, E.; Hatzikiriakos, S.G. Extrudate swell of a high-density polyethylene melt: II. Modeling using integral and differential constitutive equations. J. Non-Newtonian Fluid Mech. 2015, 225, 94–105, . [CrossRef]

- Langouche, F.; Debbaut, B. Rheological characterisation of a high-density polyethylene with a multi-mode differential viscoelastic model and numerical simulation of transient elongational recovery experiments. Rheol. Acta 1999, 38, 48–64, . [CrossRef]

- Shiromoto, S.; Masutani, Y.; Tsutsubuchi, M.; Togawa, Y.; Kajiwara, T. The effect of viscoelasticity on the extrusion drawing in film-casting process. Rheol. Acta 2010, 49, 757–767, . [CrossRef]

- Khan, S.A.; Larson, R.G. Comparison of Simple Constitutive Equations for Polymer Melts in Shear and Biaxial and Uniaxial Extensions. J. Rheol. 1987, 31, 207–234, . [CrossRef]

- M. (Masao) Doi and S. F. (Samuel F. Edwards, The theory of polymer dynamics, 1st ed. Clarendon Press, 1988. Accessed: May 17, 2023. [Online]. Available: https://global.oup.com/academic/product/the-theory-of-polymer-dynamics-9780198520337.

- Ianniruberto, G.; Marrucci, G. On compatibility of the Cox-Merz rule with the model of Doi and Edwards. J. Non-Newtonian Fluid Mech. 1996, 65, 241–246, . [CrossRef]

- Marrucci, G. Dynamics of entanglements: A nonlinear model consistent with the Cox-Merz rule. J. Non-Newtonian Fluid Mech. 1996, 62, 279–289, . [CrossRef]

- Baig, C.; Mavrantzas, V.G.; Kröger, M. Flow Effects on Melt Structure and Entanglement Network of Linear Polymers: Results from a Nonequilibrium Molecular Dynamics Simulation Study of a Polyethylene Melt in Steady Shear. Macromolecules 2010, 43, 6886–6902, . [CrossRef]

- Stephanou, P.S.; Tsimouri, I.C.; Mavrantzas, V.G. Simple, Accurate and User-Friendly Differential Constitutive Model for the Rheology of Entangled Polymer Melts and Solutions from Nonequilibrium Thermodynamics. Materials 2020, 13, 2867, . [CrossRef]

- Stephanou, P.S.; Schweizer, T.; Kröger, M. Communication: Appearance of undershoots in start-up shear: Experimental findings captured by tumbling-snake dynamics. J. Chem. Phys. 2017, 146, 161101, . [CrossRef]

- Costanzo, S.; Huang, Q.; Ianniruberto, G.; Marrucci, G.; Hassager, O.; Vlassopoulos, D. Shear and Extensional Rheology of Polystyrene Melts and Solutions with the Same Number of Entanglements. Macromolecules 2016, 49, 3925–3935, . [CrossRef]

- Stephanou, P.S.; Kröger, M. Non-constant link tension coefficient in the tumbling-snake model subjected to simple shear. J. Chem. Phys. 2017, 147, 174903, . [CrossRef]

- T. C. B. Mcleish, ; R G Larson, and R. G. Larson, “Molecular constitutive equations for a class of branched polymers: The pom-pom polymer,” J. Rheol., 42, 81–110, (1998),.

- Öttinger, H.C. Thermodynamic admissibility of the pompon model for branched polymers. Rheol. Acta 2001, 40, 317–321, . [CrossRef]

- Inkson, N.J.; McLeish, T.C.B.; Harlen, O.G.; Groves, D.J. Predicting low density polyethylene melt rheology in elongational and shear flows with “pom-pom” constitutive equations. J. Rheol. 1999, 43, 873–896, . [CrossRef]

- Soulages, J.; Schweizer, T.; Venerus, D.; Kröger, M.; Öttinger, H. Lubricated cross-slot flow of a low density polyethylene melt. J. Non-Newtonian Fluid Mech. 2008, 154, 52–64, . [CrossRef]

- W. M. H. Verbeeten, G. W. M. Peters, and F. P. T. Baaijens, “Differential constitutive equations for polymer melts: The extended Pom–Pom model,” J. Rheol., 45, 823–843, (2001),.

- Soulages, J.; Hütter, M.; Öttinger, H.C. Thermodynamic admissibility of the extended Pom-Pom model for branched polymers. J. Non-Newtonian Fluid Mech. 2006, 139, 209–213, . [CrossRef]

- Hoyle, D.M.; Harlen, O.G.; Auhl, D.; McLeish, T.C.B. Non-linear step strain of branched polymer melts. J. Rheol. 2009, 53, 917–942, . [CrossRef]

- Stephanou, P.S.; Tsimouri, I.C.; Mavrantzas, V.G. Flow-Induced Orientation and Stretching of Entangled Polymers in the Framework of Nonequilibrium Thermodynamics. Macromolecules 2016, 49, 3161–3173, . [CrossRef]

- A. N. Beris and B. J. Edwards, Thermodynamics of Flowing Systems: with Internal Microstructure. New York: Oxford University Press, 1994.

- Stephanou, P.S.; Baig, C.; Mavrantzas, V.G. A generalized differential constitutive equation for polymer melts based on principles of nonequilibrium thermodynamics. J. Rheol. 2009, 53, 309–337, . [CrossRef]

- Öttinger, H.C. Beyond Equilibrium Thermodynamics; Wiley: Hoboken, NJ, United States, 2005; ISBN: 9780471666585.

- Marrucci, G.; Ianniruberto, G. Flow-induced orientation and stretching of entangled polymers. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2003, 361, 677–688, . [CrossRef]

- R. G. Larson, The Structure and Rheology of Complex Fluids. New York, United States: Oxford University Press, 1999.

- E. Behzadfar, M. Ansari, V. K. Konaganti, and S. G. Hatzikiriakos, “Extrudate swell of HDPE melts: I. Experimental,” J. Nonnewton. Fluid Mech., 225, 86–93, (2015),.

- Wood-Adams, P.M. The effect of long chain branches on the shear flow behavior of polyethylene. J. Rheol. 2001, 45, 203–210, . [CrossRef]

- Rogošić, M.; Mencer, H.; Gomzi, Z. Polydispersity index and molecular weight distributions of polymers. Eur. Polym. J. 1996, 32, 1337–1344, . [CrossRef]

- Schieber, J.D. Kinetic theory of polymer melts. VIII. Rheological properties of polydisperse mixtures. J. Chem. Phys. 1987, 87, 4917–4927, . [CrossRef]

- J. D. Schieber, “Kinetic theory of polymer melts. IX. Comparisons with experimental data,” The Journal of Chemical Physics, 87. 4928–4936, 1987.

| Mode | (Pa) | (s) |

| 1 | 387,808 | 0.00086 |

| 2 | 185,307 | 0.0075 |

| 3 | 93,338 | 0.0548 |

| 4 | 37,766 | 0.403 |

| 5 | 12,934 | 2.99 |

| 6 | 5,025 | 30.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).