1. Introduction

Germinated brown rice (GBR) have better texture, nutritional and nutraceutical quality compared to brown rice [

1,

2,

3,

4]. The water is absorbed rapidly during soaking process and a series of biochemical processes occur, and result in the softening texture, degradation of polymers, and enhancing the synthesis and accumulation of some phytochemical compounds [

1,

5,

6,

7]. Example of production process of GBR in commercial small manufacturing from rough rice was soaked in water at room temperature for 48 h. The water was changed every 4 h and drained at the end of soaking to prevent the fermentation of the rice. The rice was kept in polypropylene sag for incubating at 24 h to obtain the germinated rough rice (GRR). The GRR was dried using fluidized bed technique by superheated steam which would reduce the moisture content of the rice to around 19%wb. Then the rice was spread on screen for 3 h at room temperature and the moisture content would reduce to about 13-14%wb. After that the GRR sample was dehusked to obtain GBR. In addition, RD31 rough rice's initial soaking resulted in a moisture content increase of 12.39-13.42% (dry basis) to 24.95-35.63% (dry basis), although the moisture content only increased with time [

8].

Due to slight flavor, hence the texture properties of cooked rice including cooked GBR is dominant to indicate the eating quality. Texture and aroma are two important attributes for the eating quality of cooked rice. Wang et al. [

9] reported a large variance of textural attributes and a total number of 39 major volatile organic components were observed for Yueguang cooked rice varieties. Pearson correlation showed that the hardness of cooked rice was positively correlated with the content of E-2-hexenal, 2-hexanol-monomer, 1-propanol, and E-2-pentenal, while stickiness was positively correlated with 5-methyl-2-furanmethanol and dimethyl trisulfide. Possible mechanisms were discussed for these relations in this report. These results could help the rice industry to develop rice products with both desirable texture and aroma property. There were change of cooked GBR texture effected by different process reported in several publication. The softer texture of brown rice, about 32% lower, could be achieved by germination and 46% by harvesting early [

10]. The germ of GRB during soaking in water produces substances from the physiological action and enzymes to improve nutrition and the texture of brown rice [

11,

12]. Zhu et al. [

13] investigated the effects of hydrogen-rich water (HRW) on the germination efficiency and texture of GBR where the results showed that HRW (1.5 mg L−1) treatment significantly increased the germination efficiency of GBR by changing the migration of water during soaking and improved the texture of GBR due to the changes in the ultrastructure of the bran layer and the decrease in insoluble dietary fibre. Additionally treated germinated brown rice by microwave precooking and freeze-drying made the brown rice softer (hardness is reduced by about 54.78% after treatment) and simpler to chew, the chewiness of the precooked brown rice is lowered [

14].

Cheevitsopon et al. [

15] reported Asian Institute of Technology research group developed and used Back extrusion (BE) test [

16,

17] for measuring hardness of cooked rice while the rice cooking followed Reyes and Jindal [

16]; Srisawas and Jindal [

18]; Parnsakhorn and Noomhorm [

19]. BE sample holder is consisted of a stainless steel cylinder 80 mm in length with an internal diameter of 15 mm and a stainless steel spherical probe of 12.7 mm in diameter. There is a 1.15 mm gap between the spherical probe with the wall of the cylinder. Cooked rice of 3 g was put into the cylinder without exerted pressure. Then the spherical probe moved down and pressed the rice sample in the cylinder at a speed of 1 mm s-1 until the spherical probe is 1 mm from the bottom of the cylinder and it stopped moving and returned to initial position. BE followed Sirisoontaralak and Noomhorm [

17] where hardness, adhesiveness and stickiness were measured. The texture of cooked rice was measured under various measurement conditions using extrusion test which better predict sensory texture characteristic values and the Pearson correlation test between the maximum force and the gradient value or the maximum force and the area value under each measurement condition, showed a high correlation of 0.90 or more [

20]. The maximum force indicated hardness, gradient value indicated firmness and the area value indicated stickiness. Parnsakhorn & Langkapin [

21] used the BE test for measuring the hardness of Zongzi products cooked by white glutinous rice, black sticky rice and rice berry rice as an ingredient divided into the first sample 100% white glutinous rice, the second sample: white glutinous rice mixed with black sticky rice50% each, the third sample white glutinous rice mixed with rice berry rice 50% each and the fourth sample black glutinous rice mixed with rice berry rice50% each.

Germinated brown rice is more popular for consumption because of its high nutritional value. The texture quality of germinated brown rice is important for consumers, therefore, the rice industry. Rice aging is a complicated process, which involves changes in physical and chemical properties of the rice grain. Starch, protein and lipids are the main rice grain components which affect cooking and eating quality [

22]. In addition, rice aging commences during pre-harvest and continues with the postharvest storage. It dramatically involves the changes in physical and physicochemical properties of the rice grain such as cooking, pasting, and thermal properties [

23].

The objective of this work was to evaluate the effect of different soaking and aging duration in the production of Khao Dawk Mali 105 (KDML 105) GBR on cooked GBR texture measured by BE test and to determine the precision and sensitivity of BE test on texture properties of 32 brands of cooked GBR rice in Thailand produced by varieties of rough rice, therefore, the original protocol for determination of precision and sensitivity of food texture measurement is proposed.

2. Materials and Methods

2.1. Samples

The GBR samples were prepared by a factory of P.J. Brand germinated rough rice in Chonburi Province, Thailand and purchased from local markets in Thailand. The rough rice of Oryza sativa L., cultivar Khao Dawk Mali 105 (KDML 105) was collected from a field of P.J. Brand germinated rough rice factory in Chonburi Province, Thailand. The GBR was produced by method of the company reported by Kaewsorn and Sirisomboon (2014) while 32 commercial types and brands of germinated brown rice of some different varieties and some same varieties indicated in Kaewsorn and Sirisomboon [

24] were purchased from local department stores in Bangkok, Thailand and stored in the laboratory at room temperature.

2.2. Rice Cooking Method

Rice cooking method followed Sirisomboon et al. [

25] where home electronic rice cookers (RC-10 MM, Toshiba, Thailand) were used to cook 200 g of GBR sample using water to rice ratios as recommended by rice producers i.e. 1.6:1 for GBR. The recommended water-to-rice ratio were used to obtain a typical texture of cooked rice consumed by consumers. The cooked GBR was put into plastic cup consisting of approximately 5 g. In total, 5 cups per sample were prepared.

2.3. Back Extrusion Test

The cooked GBR samples were then subjected to the back extrusion test using 3 g of cooked rice putting into back extrusion test rig (BE) (

Figure 1) which was compressed from top opening of the rice container by stainless ball for 99 mm of the total height of 100 mm with the ball probe speed of 1mm/s. The mean of each sample was obtained from 5 replicate measurements. The hardness, toughness, stickiness and adhesiveness of cooked GBR is determined by observe in the force-time curve the maximum compression force (N) (point H), the area under curve AHB (Nmm), the negative force (N) (point C) and area BCD (Nmm) respectively. The hardness of cooked GBR illustrate how hard or oppositely how soft the rice is. This is measured when the ball probe passes through 3 g of cooked rice and reaches 1 mm above the bottom of cylinder where the cooked rice grains is maximum crushed while the texture meter still in safe mode. The toughness of cooked GBR is the texture parameter indicating how tough the cooked rice to resist the stress applied on the rice by the ball probe to deform the cooked GBR from the beginning of the compression till the probe reaches the bottom of the cylinder as in case of the hardness measurement. The toughness is the value of the area under curve from the beginning of the compression till the probe is withdrawn out of the cooked rice which is the value of energy used for 3 g cooked rice deformation. The stickiness of cooked GBR indicating how sticky of the cooked rice is measured by detect the maximum negative force occurred when the ball probe is being withdrawn but the deformed sticky cooked rice is attached to the probe where the rice exerts the pulling force (opposite to compressing force, therefore, the negative force) to the probe. The adhesiveness of cooked GBR is measured by calculate the negative value of area occurred during withdrawal of the probe where the deformed sticky cooked rice is attached to the probe and the rice exerts the pulling force to the probe until the probe leave the rice. Ninety-two samples were subjected to the back extrusion test, and the average of each sample was to be determined using 5 replications.

2.4. The Repeatability and Reproducibility of the Measurement of Texture Properties

The repeatability and reproducibility of the measurement of texture properties were determined by measuring four duplicates (four pairs) that were randomly subjected during the experiment at different times. The reproducibility is defined as the standard deviation of the differences observed between the blind duplicate values. In addition, the repeatability of the reference test was determined as the standard deviation of the differences between the values obtained from four duplicates (four pairs) that were not blind samples. The repeatability indicates the precision of nature of measurement methods by analyst and the reproducibility indicate the precision of nature of the analyst on the measurement methods.

3. Results and Discussion

3.1. The Repeatability and Reproducibility of the Measurement of Texture Properties

Table 1,

Table 2,

Table 3 and

Table 4 show the results of precision of reference test of texture properties including hardness, toughness, stickiness and adhesiveness, respectively, of cooked GBR. It was obvious for the reproducibility was higher than repeatability due to the blind samples were in the reproducibility test. The repeatability and reproducibility of hardness, toughness and stickiness tests were small different compared to adhesiveness tests indicating the lower precision of the method and analyst of adhesiveness test which might lead to the high fluctuation and scatter of the values. The high precision of hardness, toughness and stickiness tests by BE might lead to the high correlation with sensory properties found by Jindal and Limpisut [

26] and Cheevitsopon et al. [

15] and with aging time in this study. The characteristics of brown rice that has germinated are influenced by the incubation time. According to Cho et al. [

27] reported the effect of germination on the physicochemical and textural properties of brown rice (BR) was investigated in different rice varieties (Samkwang, Misomi, Chindeul, and Hyeonpum). The results showed hardness and toughness were decreased by germination, whereas stickiness and adhesiveness increased significantly. These results revealed that germination leads to improvements in the cooking and eating properties of BR.

3.2. Effect of Different Soaking and Aging Duration in the Production of Khao Dawk Mali 105 (KDML 105) GBR on Cooked GBR Texture

Soaking time of 24 hr had no correlation between aging times and texture properties tested by BE test including hardness, toughness, stickiness and adhesiveness which coefficient of determination (R2) value were 0.0357, 0.0087, 0.0064 and 0.1452, respectively. This indicated the soaking time is too less to make linear variation in texture even the aging time had wide range from 0 to 36 hr. However, the texture of cooked GBR was softer which corresponding to the study of Chao et al. [

28] show that the hardness of grain soaked for 12 hr and germinated for 30 hr was on average 24 N (39%) lower than brown rice. Paddy soaked in water at ambient temperature (20-30°C) will take 36 to 48 hours to reach 30% moisture content. Soaking time less than specified may not affect texture properties.

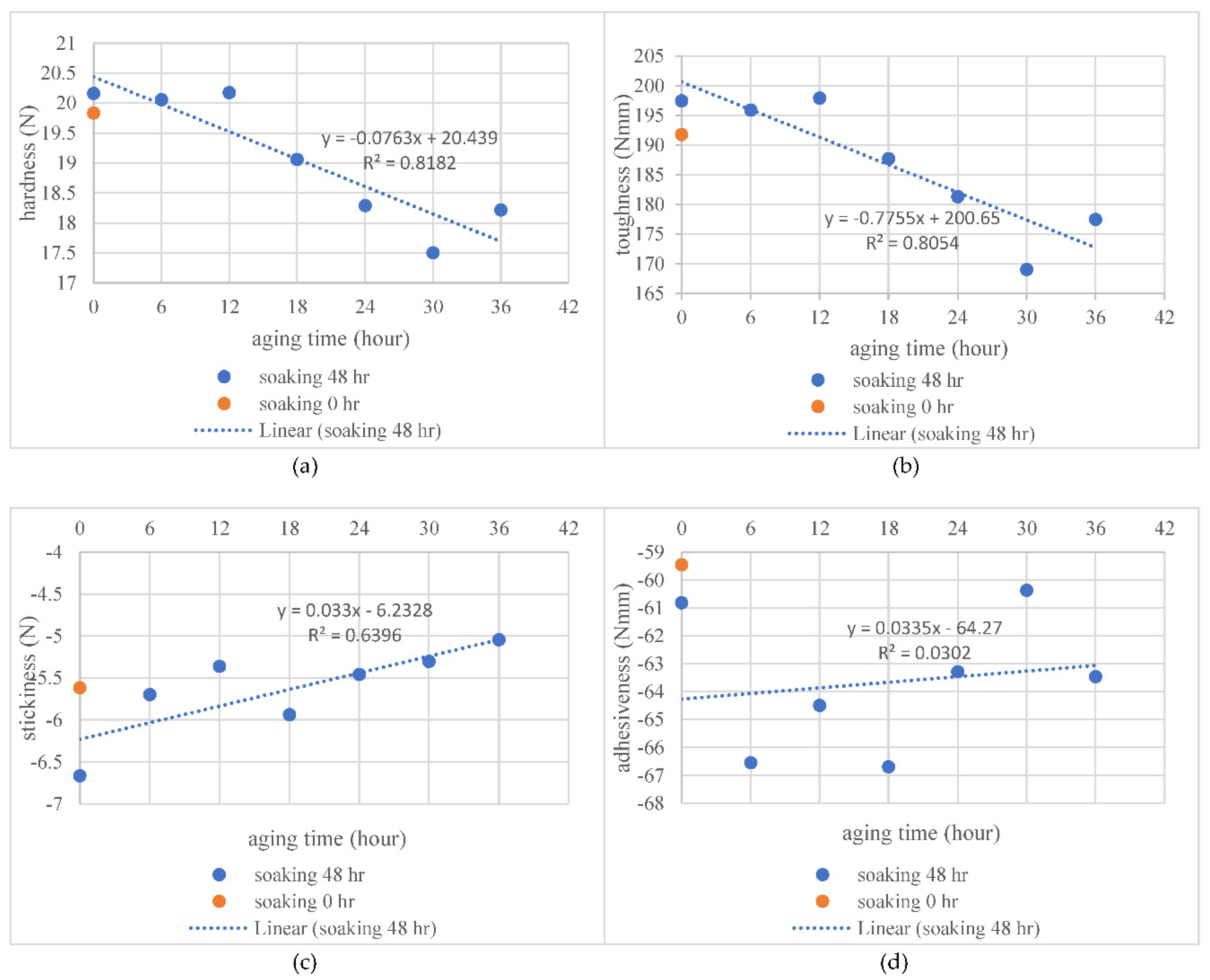

Relationship indicated by R2 between aging times with hardness, toughness, stickiness and adhesiveness when soaking time was 48 hr were 0.8182, 0.8054, 0.6396 and 0.0312, respectively (

Figure 2). The characteristics would be defined by the ratio of starch constituents, amylose and amylopectin. Jiamjariyatam et al. [

29] reported that the higher amylose content and aging time resulted in higher hardness in the puffed products made by rice starch. This might applicable to cooked rice of KDML 105 in this experiment.

Hardness and toughness decreased with aging times, but stickiness increased with aging times. Jindal and Limpisut [

26] reported corresponded to our finding the reliable empirical models developed for estimating sensory hardness and stickiness with R2=0.96, and overall acceptability with R2>0.71 from BE force (hardness by BE) and water-to-rice ratio as independent variables. From Cheevitsopon et al. [

15], correlation coefficient (R) of hardness-softness of cooked rice by sensory test and hardness by BE was -0.856 which confirmed our findings. There had no relationship between adhesiveness and aging time.

Munarko et al. [

30] reported the 5 varieties of Indonesia GBR in experienced the decline of peak viscosity, trough viscosity, breakdown, setback, and final viscosity where the decrease of peak viscosity was attributed to the presence of endogenous hydrolytic enzymes activity such as amylase enzyme, which hydrolyzed starch to smaller molecules [

31]. The α-amylase, as well as β-amylase enzymes, increased as germination progressing, thus, leading to a decrease in peak viscosity [

30,

32] [

33]. GBR peak of viscosity might related to the stickiness of cooked GBR which increased (more viscous) with the germination progressing i.e., aging time increased (increased of peak viscosity). According to Li et al. [

34] reported that germination led to decrease in amylose content, while molecular weights of the germinated starches showed no significant changes, however, relative crystallinity of grain starches decreased significantly during germination and brown rice starches exhibited marginal increases in peak viscosities during germination. But Cho et al. [

35] reported that the viscosity of germinated brown rice decreased and germination percentage was linearly associated with reduced pasting characteristics (final, peak and setback viscosities), and varieties with faster germination speed tended to have lower viscosities. These results suggested that the germination of certain varieties greatly reduced the final viscosity of flour and hardness of cooked brown rice. According to Chao et al [

36] reported early harvest and germination decreased pasting viscosities and cooked grain hardness. The reduction of setback value indicates that GBR is more stable against retrogradation [

30]. These indicated the reasons why the hardness of cooked GBR decreased (softer) might be due to longer aging duration caused the retrogradation of cooked GBR decreased respectively.

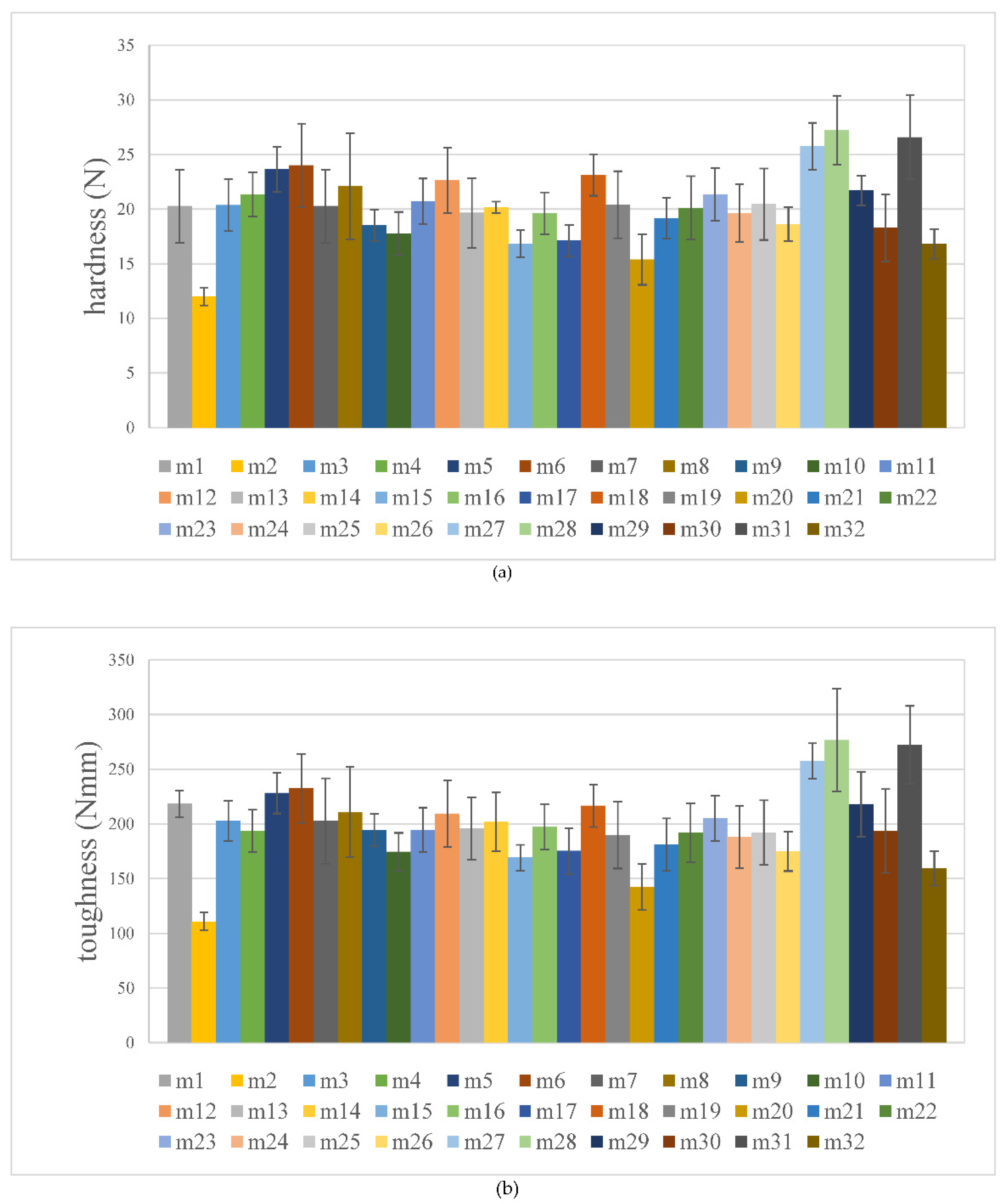

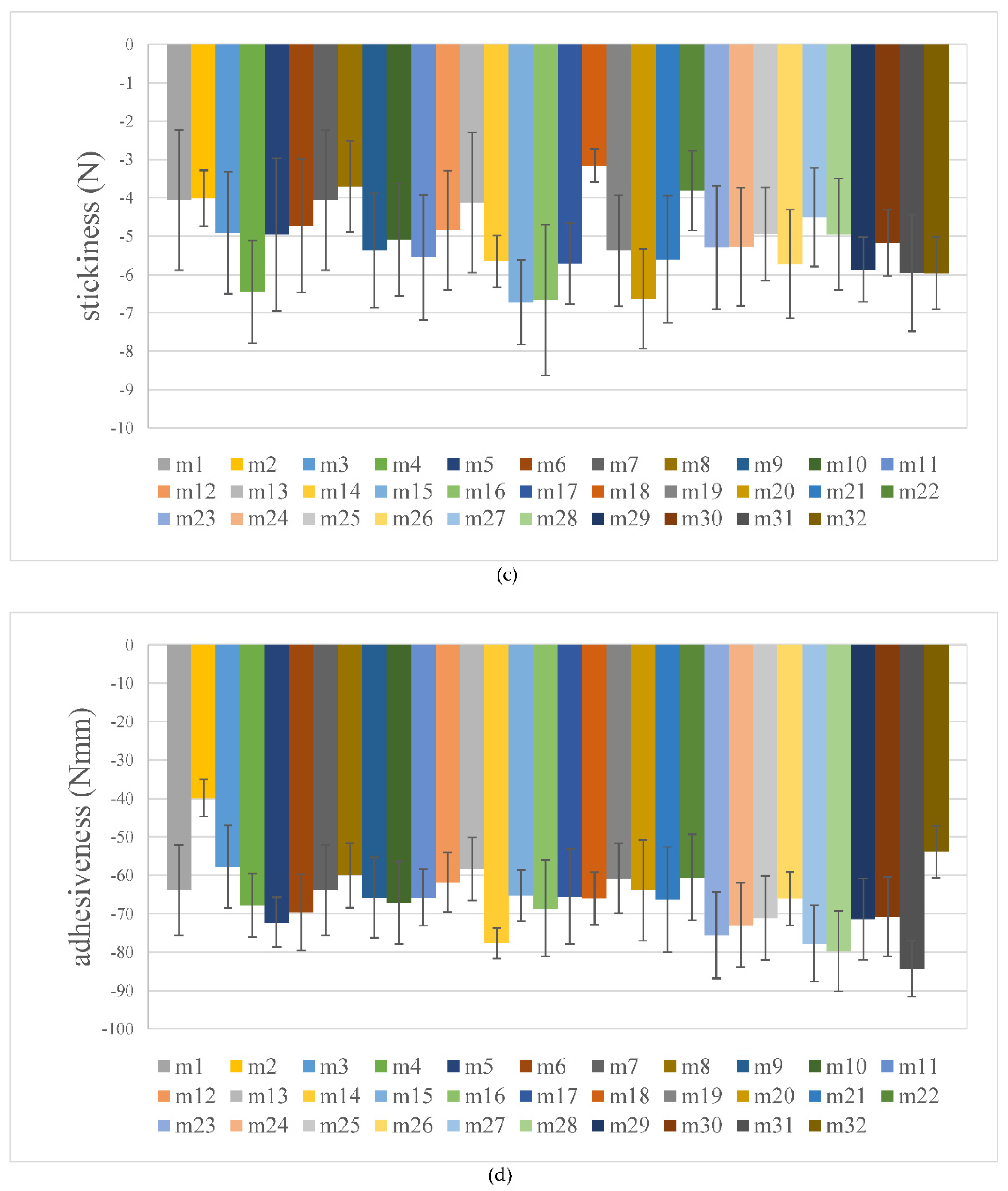

3.3 The Sensitivity of BE Test on Texture Properties of Cooked GBR Rice

Figure 3 shows the texture properties including hardness, toughness, stickiness and adhesiveness of cooked GBR of 32 different commercial brands in Thailand using some different varieties and some same varieties where the range of the values, mean, standard deviation and coefficient of variation is shown in

Table 5. The coefficient of variation shows the degree of variation of the properties which can show the variation relativity of different sets of data even mean is drastically different. The BE measurement methods of hardness, toughness, stickiness and adhesiveness of cooked GBR gave different degree of variation though the same sample set indicating different sensitivity of the method on the properties. High coefficient of variation where the relative wide variation of the absolute value of the property can be detected indicate high sensitivity which even small resolution can be detected or vice versa. The sensitivity of BE test of stickiness, toughness and hardness were higher in order when compared to the sensitivity of the method for adhesiveness which was the lowest. This implies the BE is sensitive for measurement of stickiness, toughness and hardness, respectively.

Table 6 shows the correlation between texture parameters of commercial GBR in Thailand which indicate the highest correlation coefficient between hardness and toughness and the parameters fairly correlated with adhesiveness while stickiness was not correlated well with other parameters. The result confirms the coefficient of variation (sensitivity) and the correlation between the properties have no relation.

4. Conclusions

Evaluation of back extrusion (BE) test precision and sensitivity for cooked germinated brown rice texture in production process was investigated in this study. The first findings for the objective to evaluate the effect of different soaking and aging duration in the production of Khao Dawk Mali 105 (KDML 105) GBR on cooked GBR texture measured by BE test was the 24 h soaking time was too less to make linear variation in texture even the aging time had wide range from 0 to 36 hr but the soaking time of 48 hr showed the hardness and toughness decreased with aging times but stickiness increased with aging times. There had no relationship between adhesiveness and aging time. For the objective to determine the precision and sensitivity of BE test on texture properties of cooked GBR rice show high precision of measurement of hardness, toughness and stickiness tests by BE which is proofed by the repeatability and reproductivity test, and high sensitivity of BE test of stickiness, toughness and hardness, respectively, proofed by coefficient of variation of the texture properties measured by BE test. These might be the rational why these texture properties by BE correlated well with the aging time during soaking for producing of GBR and with the texture properties by sensory test indicated by other researchers previously. But the correlation coefficient among the texture properties by BE were not related to the precision or sensitivity of the test. By this study the original protocol for determination of precision and sensitivity of food texture measurement was proposed and the results of the study verified the usabilty of the protocol.

Author Contributions

Conceptualization, K.K., P.S. and M.T.; validation, P.P., W.K. and T.K.; formal analysis, K.K. and P.M.; investigation, K.K.; writing—original draft preparation, K.K. and P.M.; writing—review and editing, P.S., P.P., W.K. and M.T.; visualization, M.T. and T.K.; supervision, M.T. and T.K.; funding acquisition, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the NIRS research center for agricultural product and food, King Mongkut’s Institute of Technology Ladkrabang, BANGKOK, Thailand

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors thank to the laboratory of physical and engineering properties of agricultural product and food in department of agricultural engineering, school of engineering, King Mongkut’s Institute of Technology Ladkrabang, Bangkok, Thailand for the instrument support and to P.J. Brand germinated rough rice in Chonburi Province, Thailand for germinated brown rice production methodology.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Yodpitak, S.; Mahatheeranont, S.; Boonyawan, D.; Sookwong, P.; Roytrakul, S.; Norkaew, O. Cold plasma treatment to improve germination and enhance the bioactive phytochemical content of germinated brown rice. Food Chem 2019, 289, 328–339. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, B.C.Q.; Shahinozzaman, M.; Tien, N.T.K.; Thach, T.N.; Tawata, S. Effect of sucrose on antioxidant activities and other health-related micronutrients in gamma-aminobutyric acid (GABA)-enriched sprouting Southern Vietnam brown rice. J. Cereal Sci 2020, 93, 102985. [Google Scholar] [CrossRef]

- Ren, C.; Hong, B.; Zheng, X.; Wang, L.; Zhang, Y.; Guan, L.; Yao, X.; Huang, W.; Zhou, Y.; Lu, S. Improvement of germinated brown rice quality with autoclaving treatment. Food Sci. Nutr 2020, 8, 1709–1717. [Google Scholar] [CrossRef]

- Munarko, H.; Sitanggang, A.B.; Kusnandar, F.; Budijanto, S. Germination of five Indonesian brown rice: evaluation of antioxidant, bioactive compounds, fatty acids and pasting properties. Food Sci. Technol 2021, 42, e19721. [Google Scholar] [CrossRef]

- Cho, D.H.; Lim, S.T. Germinated brown rice and its bio-functional compounds. Food Chem 2016, 196, 259–271. [Google Scholar] [CrossRef] [PubMed]

- Ca ́ceres, P.J.; Pen ̃as, E.; Martinez-Villaluenga, C.; Amigo, L.; Frias, J. Enhancement of biologically active compounds in germinated brown rice and the effect of sun-drying. J. Cereal Sci 2017, 73, 1–9. [Google Scholar] [CrossRef]

- Techo, J.; Soponronnarit, S.; Devahastin, S.; Wattanasiritham, L.S.; Thuwapanichayanan, R.; Prachayawarakorn, S. Effects of heating method and temperature in combination with hypoxic treatment on γ-aminobutyric acid, phenolics content and antioxidant activity of germinated rice. Int. J. Food Sci. Technol 2018, 54, 1330–1341. [Google Scholar] [CrossRef]

- Neamsorn, N.; Inprasit, C.; Terdwongworakul, A. Water absorption of RD31 paddy during soaking in parboiling process. TSAE Journal 2017, 23, 1–8. [Google Scholar]

- Wang, Z.; Wang, J.; Chen, X.; Li, E.; Li, S.; Li, C. Mutual relations between texture and aroma of cooked rice-a pilot study. Foods 2022, 11, 3738. [Google Scholar] [CrossRef]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effects of variety, early harvest, and germination on pasting properties and cooked grain texture of brown rice. J. Texture Stud 2022, 53, 503–516. [Google Scholar] [CrossRef]

- Kaosa-ard, T.; Songsermpong, S. Influence of germination time on the GABA content and physical properties of germinated brown rice. As. J. Food Ag-Ind 2012, 5, 270–283. [Google Scholar]

- Singh, K.; Simapisan, P.; Decharatanangkoon, S.; Utama-ang, N. Effect of soaking temperature and time on GABA and total phenolic content of germinated brown rice (Phitsanulok 2). Curr. J. Appl. Sci. Technol 2017, 17, 224–232. [Google Scholar]

- Zhu, C.; Yang, L.; Nie, P.; Zhong, L.; Wu, Y.; Sun, X.; Song, L. Effects of hydrogen-rich water on the nutritional properties, volatile profile and texture of germinated brown rice. Int. J. Food Sci. Technol 2022, 57, 7666–7680. [Google Scholar] [CrossRef]

- Guan, H.; Wu, Y.; Liu, X. ; Effect of microwave precooking and freeze-drying on the quality of the germinated brown rice. J. Food Process. Preserv 2023, 2023, 3610644. [Google Scholar] [CrossRef]

- Cheevitsopon, E.; Klakankhai, T.; Kladsuk, S.; Sonsanguan, N.; Phanomsophon, T.; Sirisomboon, P.; Pornchaloempong, P. Texture properties of cooked rice evaluated by sensory test interpreted by instrument tests. Proceedings of The XX CIGR World Congress 2022, Sustainable Agricultural Production-Water, Land, Energy and Food, Kyoto International Conference Center, Kyoto, Japan, 5th - 9th December 2022. [Google Scholar]

- Reyes, V.G.; Jindal, V.K. A small sample back extrusion test for measuring texture of cooked rice. J. Food Qual 1990, 13, 109–118. [Google Scholar] [CrossRef]

- Sirisoontaralak, P.; Noomhorm, A. Changes to physicochemical properties and aroma of irradiated rice. J. Stored Prod. Res 2006, 42, 264–276. [Google Scholar] [CrossRef]

- Srisawas, W.; Jindal, V. Sensory evaluation of cooked rice in relation to water-to-rice ratio and physicochemical properties. J. Texture Stud 2007, 38, 21–41. [Google Scholar] [CrossRef]

- Parnsakhorn, S.; Noomhorm, A. Changes in physicochemical properties of parboiled brown rice during heat treatment. Agric. Eng. Int 2008, 10, 1–20. [Google Scholar]

- Shin, S.H.; Choi, W.S. Analysis of the texture characteristics of cooked rice using extrusion tests under various measurement conditions. Journal of the Korean Society of Food Science and Nutrition 2022, 51(6), 627–631. [Google Scholar] [CrossRef]

- Parnsakhorn, S.; Langkapin, J. Effect of different rice varieties on changes in anthocyanin content and physical properties of Zongzi products. J. Eng. Rmutt 2022, 20, 59–70. (in Thai). [Google Scholar]

- Zhou, Z.; Robards, K.; Helliwell, S.; Blanchard, C. Ageing of stored rice: changes in chemical and physical attributes. J. Cereal Sci 2002, 35, 65–78. [Google Scholar] [CrossRef]

- Keawpeng, I.; Venkatachalam, K. Effect of aging on changes in rice physical qualities. Int. Food Res. J 2015, 22, 2180–2187. [Google Scholar]

- Kaewsorn, K.; Sirisomboon, P. Study on evaluation of gamma oryzanol of germinated brown rice by near infrared spectroscopy. J. Innovative Opt. Health Sci 2014, 7, 1450002. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Kaewsorn, K.; Thanimkarn, S.; Phetpan, K. ; Non-linear viscoelastic behavior of cooked white, brown, and germinated brown Thai jasmine rice by large deformation relaxation test. Int. J. Food Prop 2017, 20, 1547–1557. [Google Scholar] [CrossRef]

- Jindal, V.K.; Limpisut, P. Back extrusion testing of cooked rice texture, Chicago, USA, ASAE Annual Meeting 2002, No. 02 6068.

- Cho, D.H.; Park, H.Y.; Lee, S.K.; Park, J.; Choi, H.S.; Woo, K.S.; Kim, H.J.; Sim, E.Y.; Won, Y.J.; Lee, D.H.; Oh, S.K. Differences in physiochemical and textural properties of germinated brown rice in various rice varieties. The Korean Journal of Crop Science 2017, 62, 172–183. [Google Scholar] [CrossRef]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effect of germination level on properties of flour paste and cooked brown rice texture of diverse varieties. J. Cereal Sci 2021, 102, 103345. [Google Scholar] [CrossRef]

- Jiamjariyatam, R.; Kongpensook, V.; Pradipasena, P. Effects of amylose content, cooling rate and aging time on properties and characteristics of rice starch gels and puffed products. J. Cereal Sci 2015, 61, 16–25. [Google Scholar] [CrossRef]

- Munarko, H.; Sitanggang, A.B.; Kusnandar, F.; Budijanto, S. Effect of different soaking and germination methods on bioactive compounds of germinated brown rice. Int. J. Food Sci. Technol 2021, 56, 4540–4548. [Google Scholar] [CrossRef]

- Wichamanee, Y.; Teerarat, I. Production of germinated red jasmine brown rice and its physicochemical properties. Int. Food Res. J 2012, 19, 1649–1654. [Google Scholar]

- Mohan, B.H.; Malleshi, N.G.; Koseki, T. Physico-chemical characteristics and non-starch polysaccharide contents of Indica and Japonica brown rice and their malts. LWT--Food Sci. Technol 2010, 43, 784–791. [Google Scholar] [CrossRef]

- Pinkaew, H.; Thongngam, M.; Wang, Y.J.; Naivikul, O. Isolated rice starch fine structures and pasting properties changes during pre-germination of three Thai paddy (Oryza sativa L.) cultivars. J. Cereal Sci 2016, 70, 116–122. [Google Scholar] [CrossRef]

- Li, C.; Oh, S.G.; Lee, D.H.; Baik, H.W.; Chung, H.J. Effect of germination on the structures and physicochemical properties of starches from brown rice, oat, sorghum, and millet. Int. J. Biol. Macromol 2017, 105, 931–939. [Google Scholar] [CrossRef] [PubMed]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effect of germination level on properties of flour paste and cooked brown rice texture of diverse varieties. J. Cereal Sci 2021, 102, 103345. [Google Scholar] [CrossRef]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effects of variety, early harvest, and germination on pasting properties and cooked grain texture of brown rice. J. Texture Stud 2022, 53, 503–516. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).