Submitted:

20 July 2023

Posted:

21 July 2023

You are already at the latest version

Abstract

Keywords:

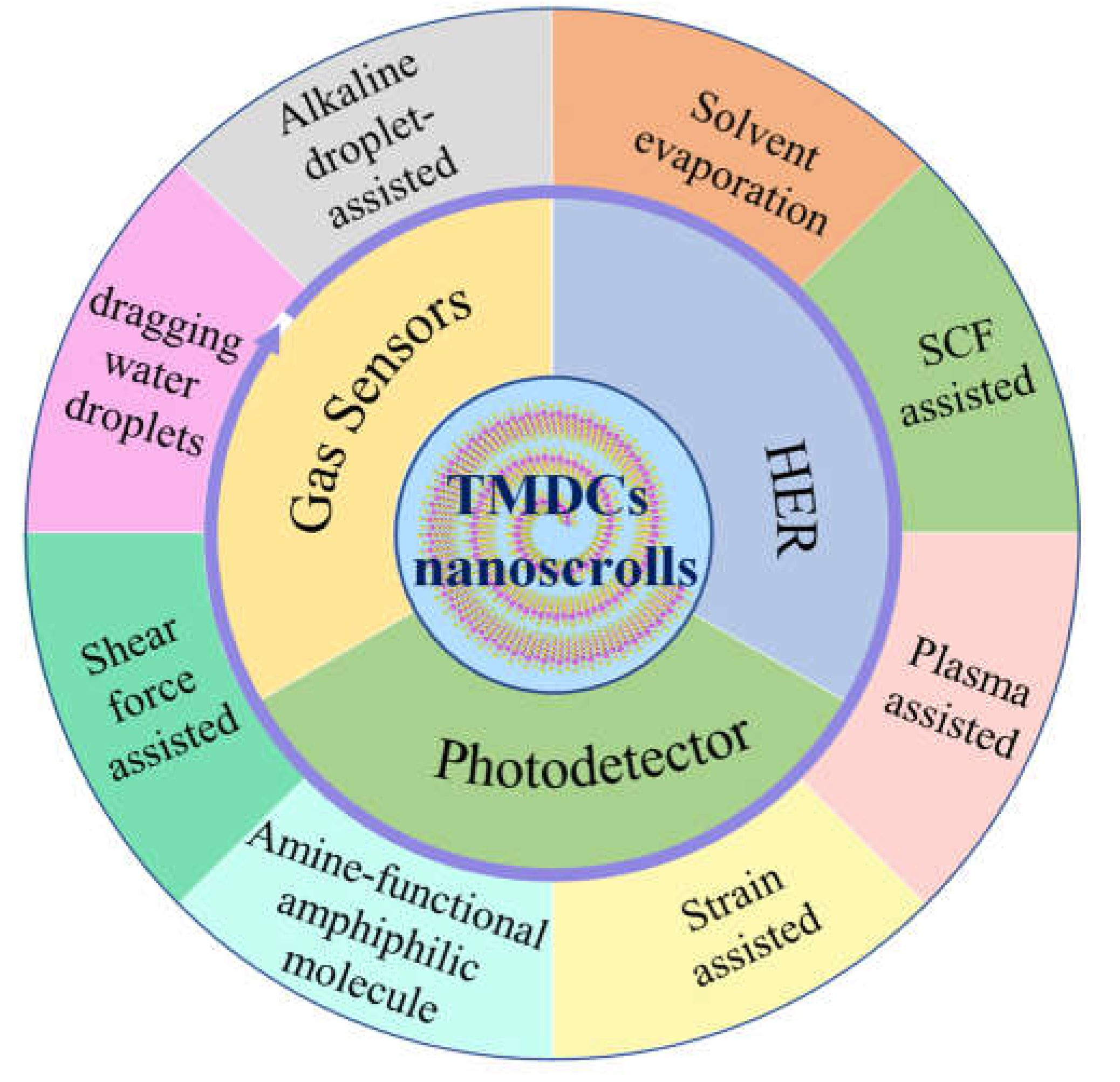

1. Introduction

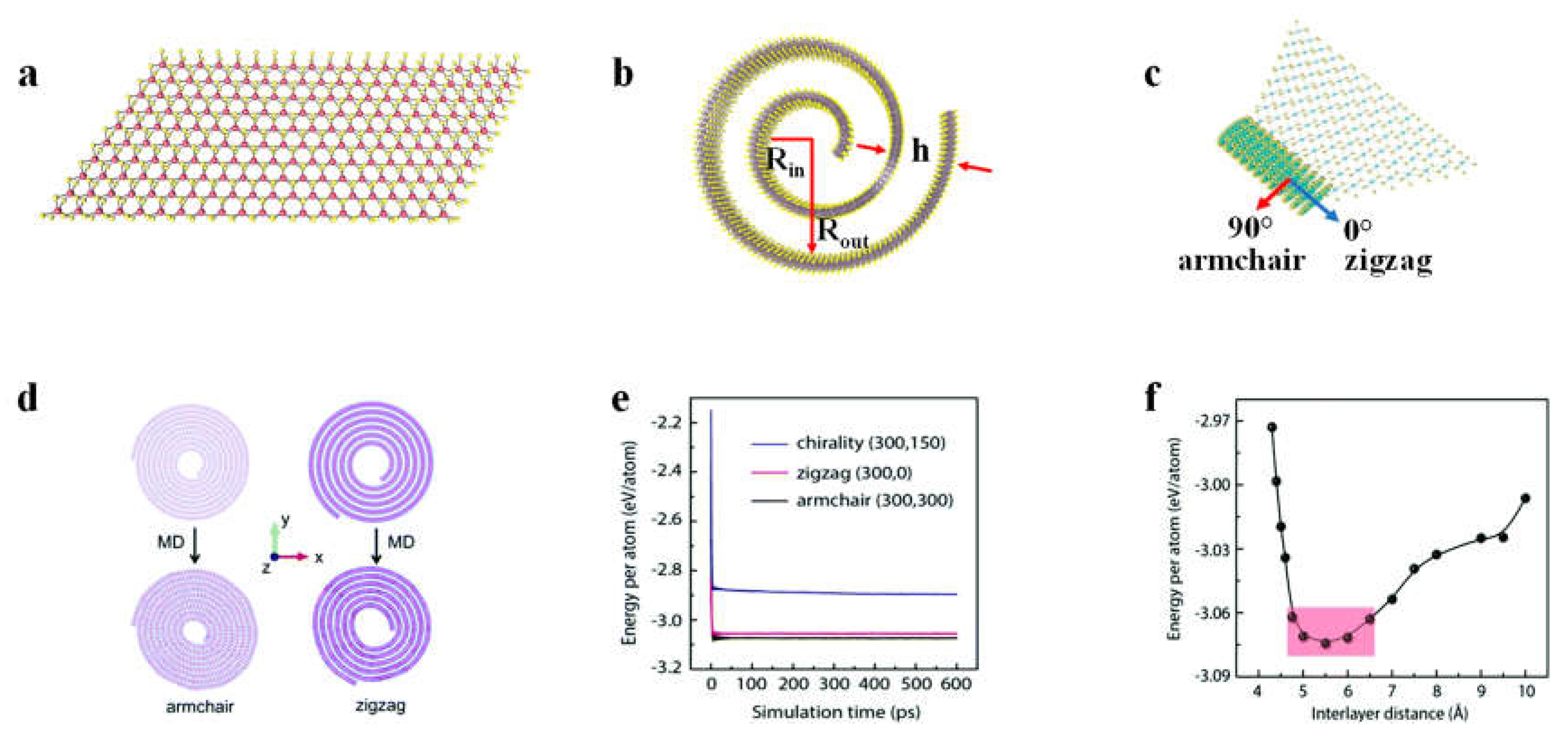

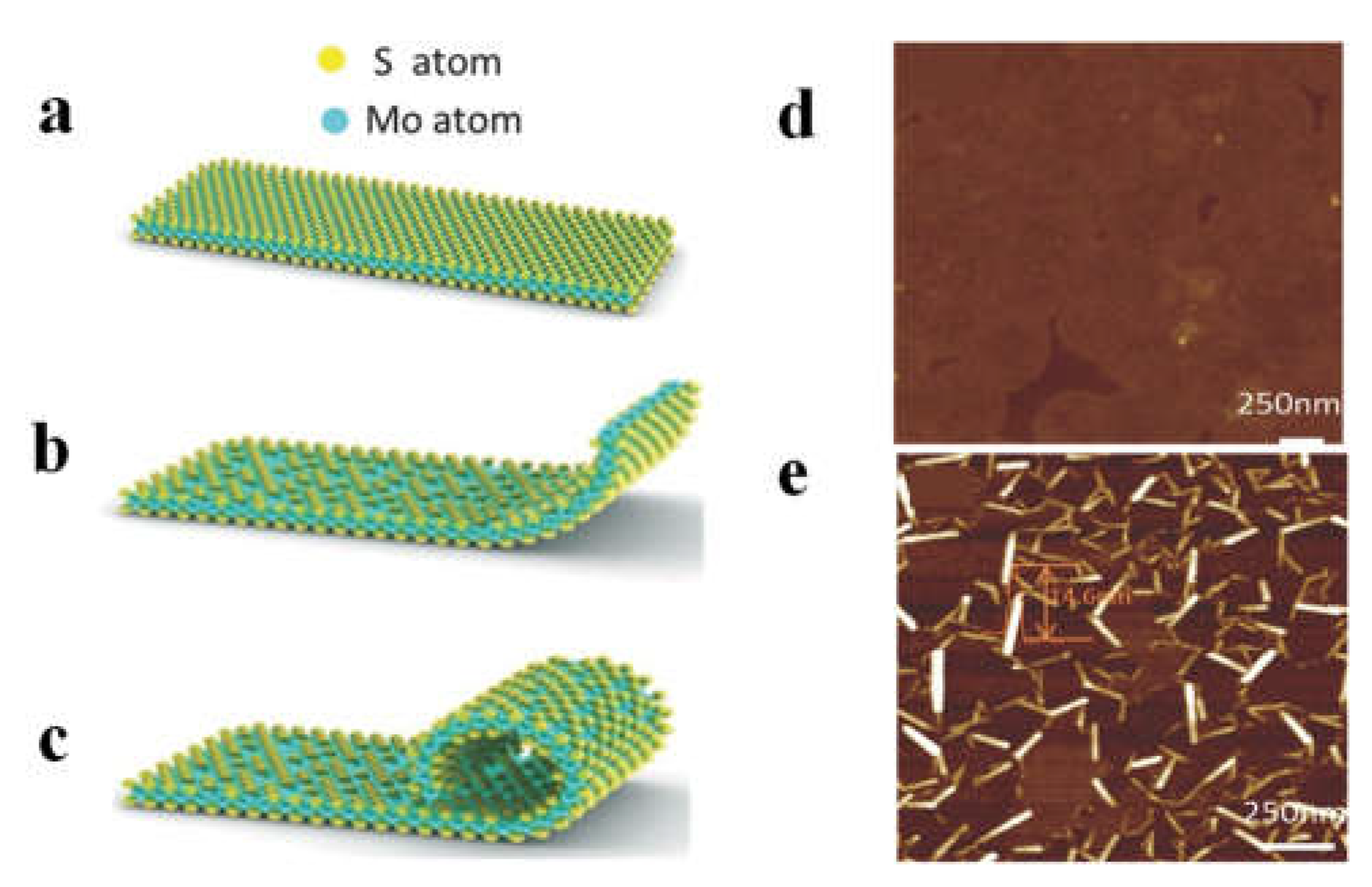

2. Structure of TMDCs-NS

3. Preparation of TMDCs nanoscrolls

3.1. Fabrication of TMDCs nanoscrolls in liquid

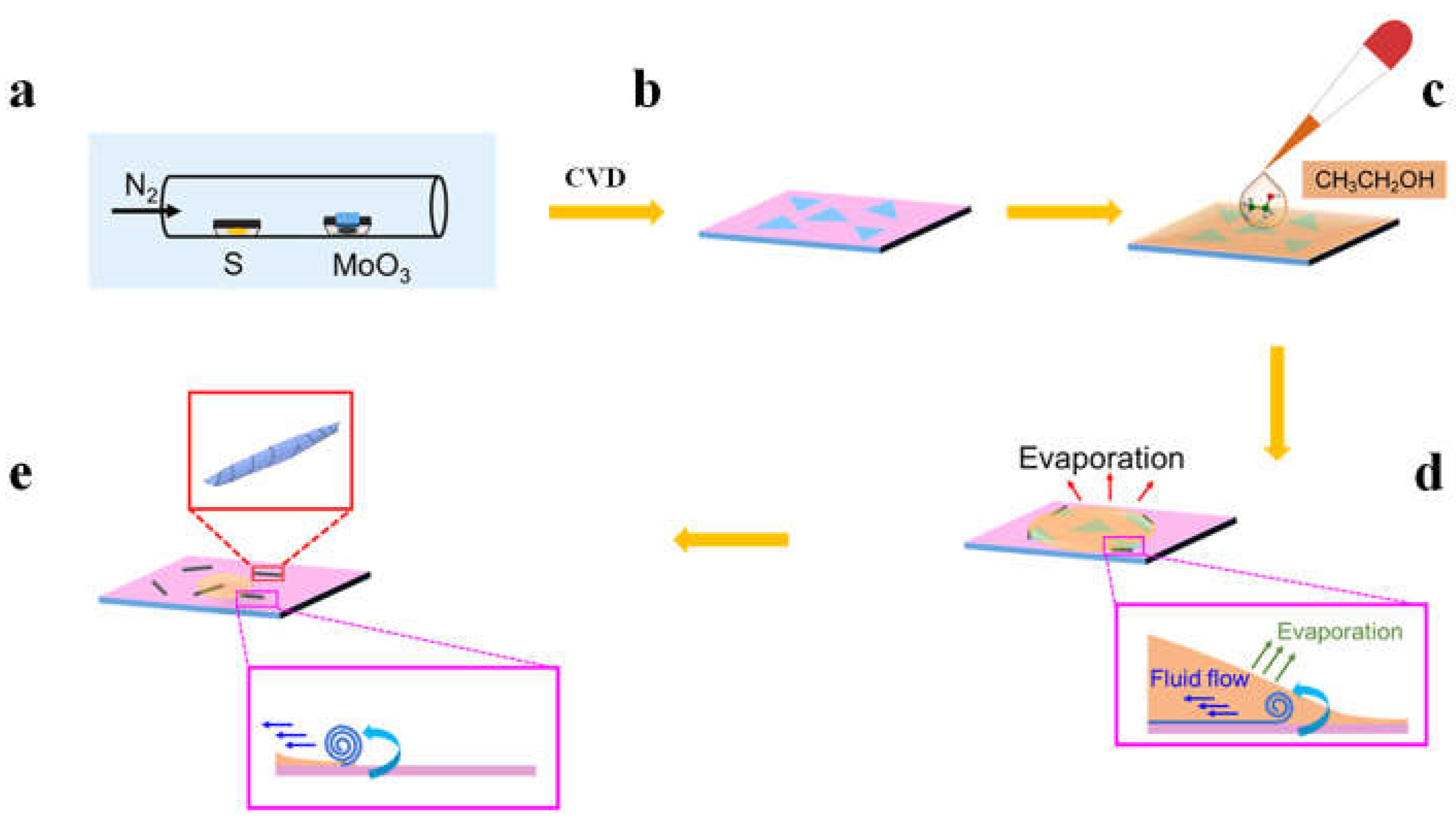

3.1.1. Solvent evaporation to make nanoscrolls

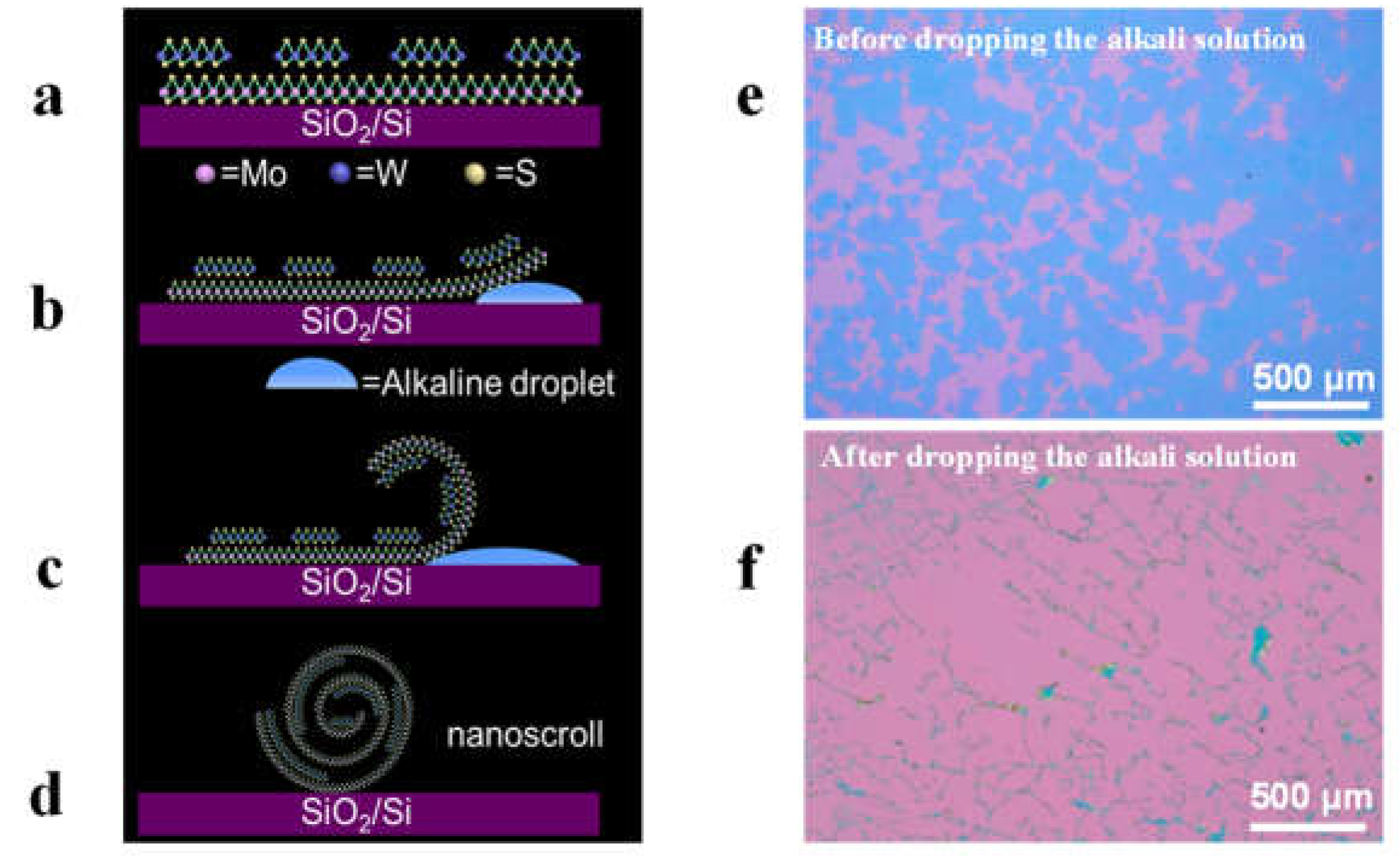

3.1.2. Alkaline droplet-assisted fabrication of nanoscrolls

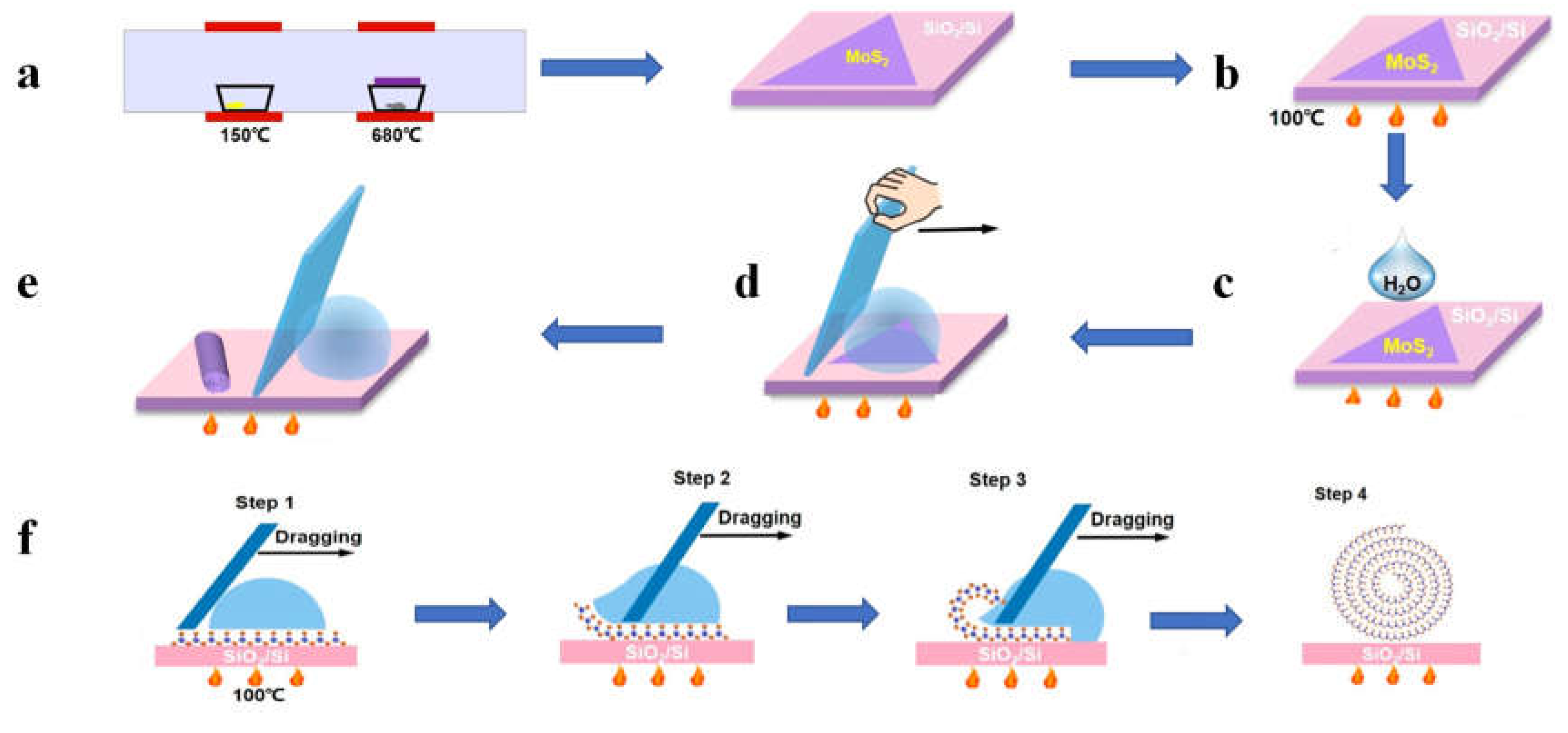

3.1.3. Fabrication of TMDCs nanoscrolls by dragging water droplets

3.1.4. Amine-functional amphiphilic molecule assisted fabrication of TMDCs nanoscrolls

3.1.5. Supercritical fluid assisted fabrication of nanoscrolls

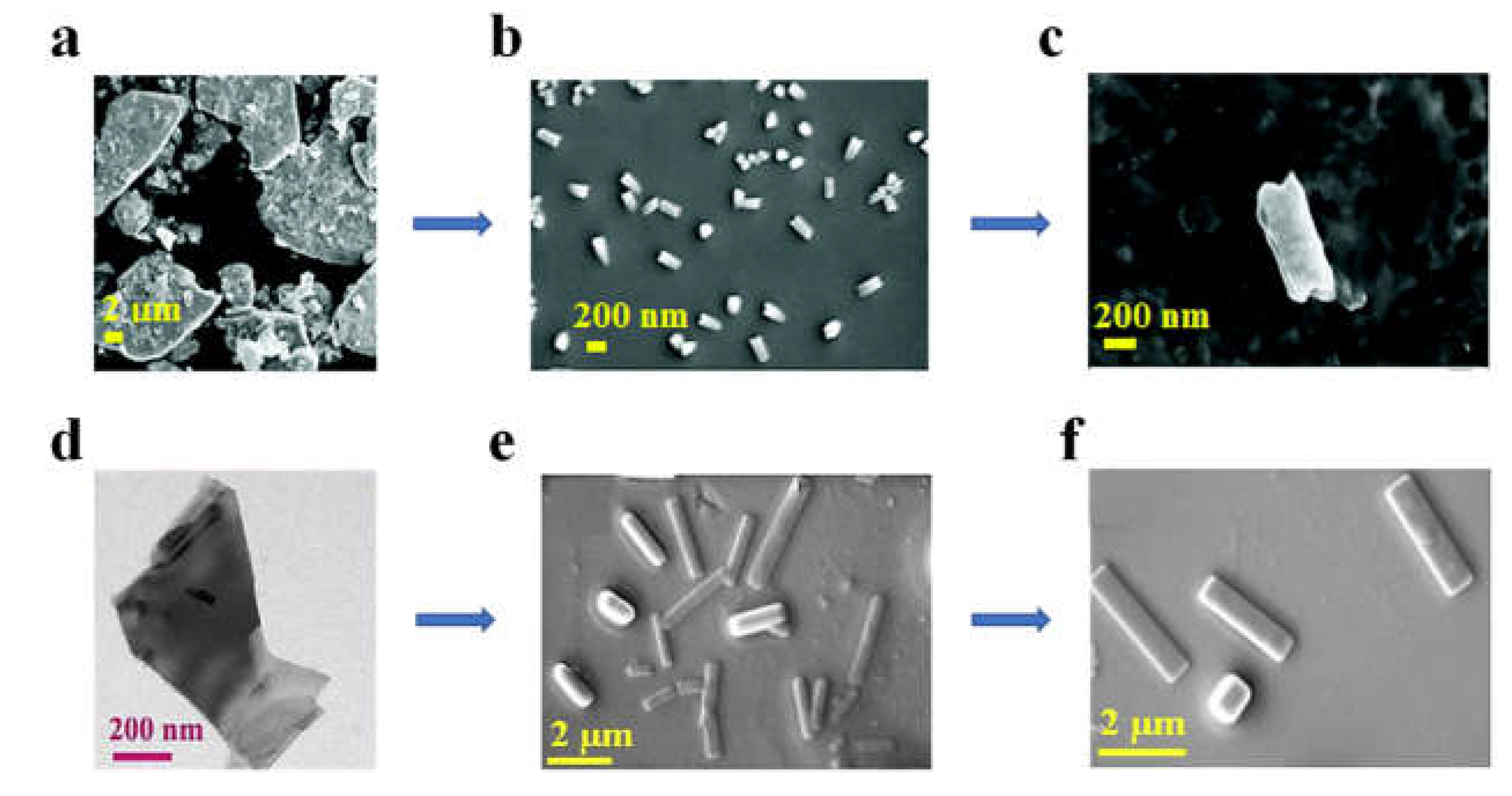

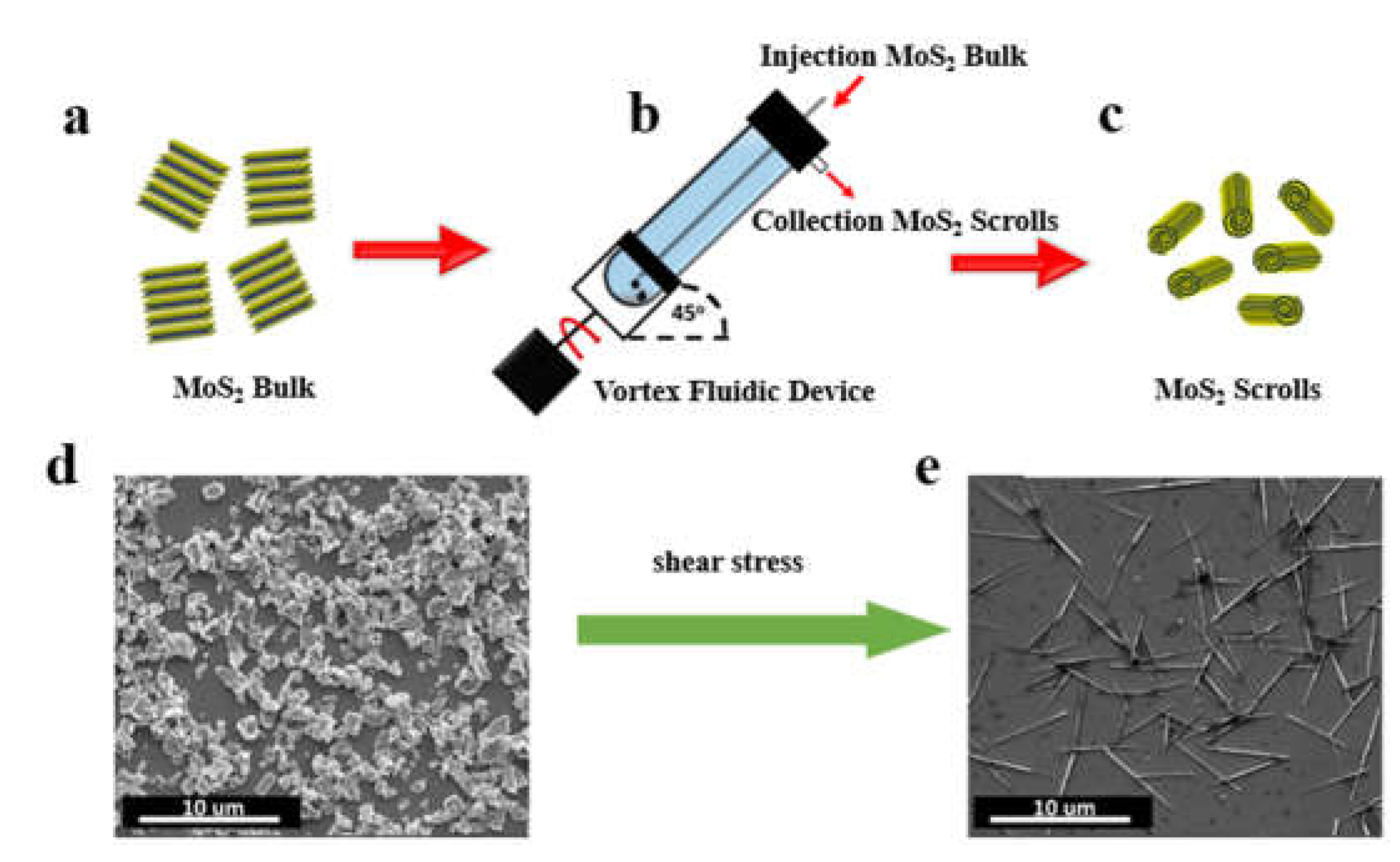

3.1.6. Shear force assisted fabrication of nanoscrolls

3.2. Fabrication of TMDCs nanoscrolls in air

3.2.1. Plasma-assisted fabrication of MoS2 nanoscrolls

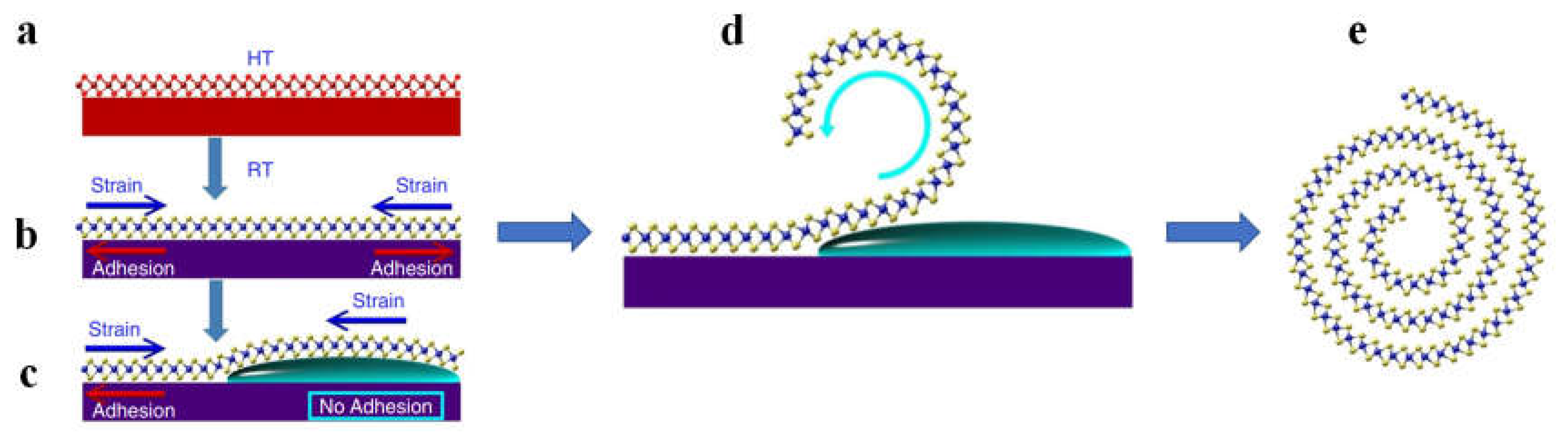

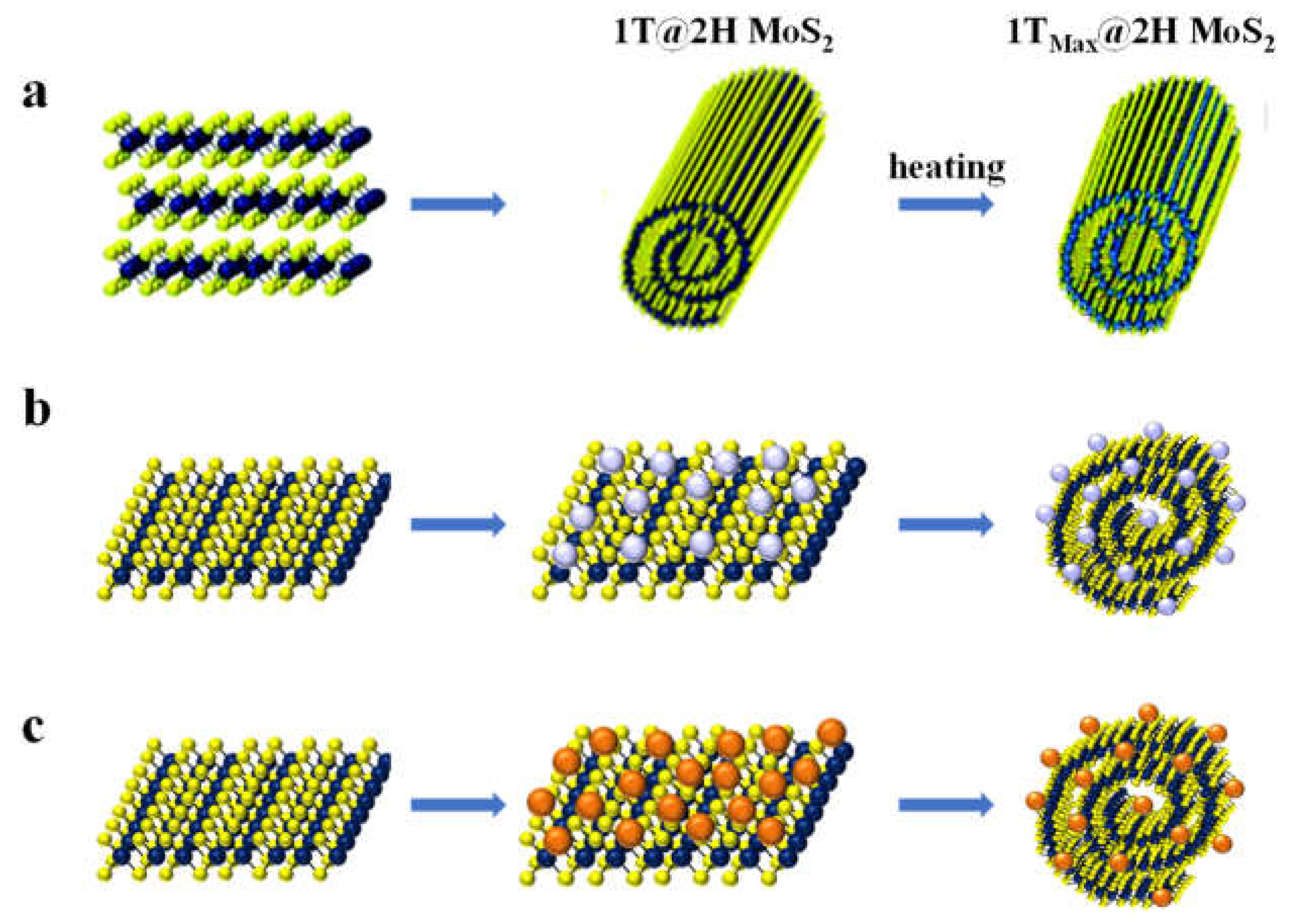

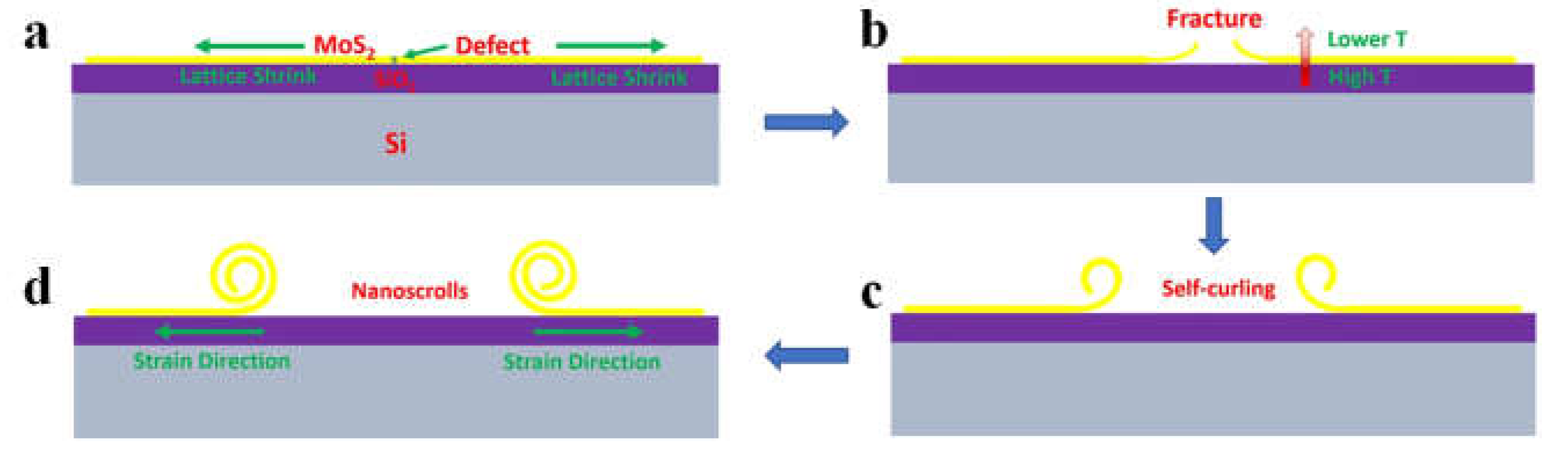

3.2.2. Strain-assisted fabrication of TMDCs nanoscrolls

4. Applications of TMDCs-NS

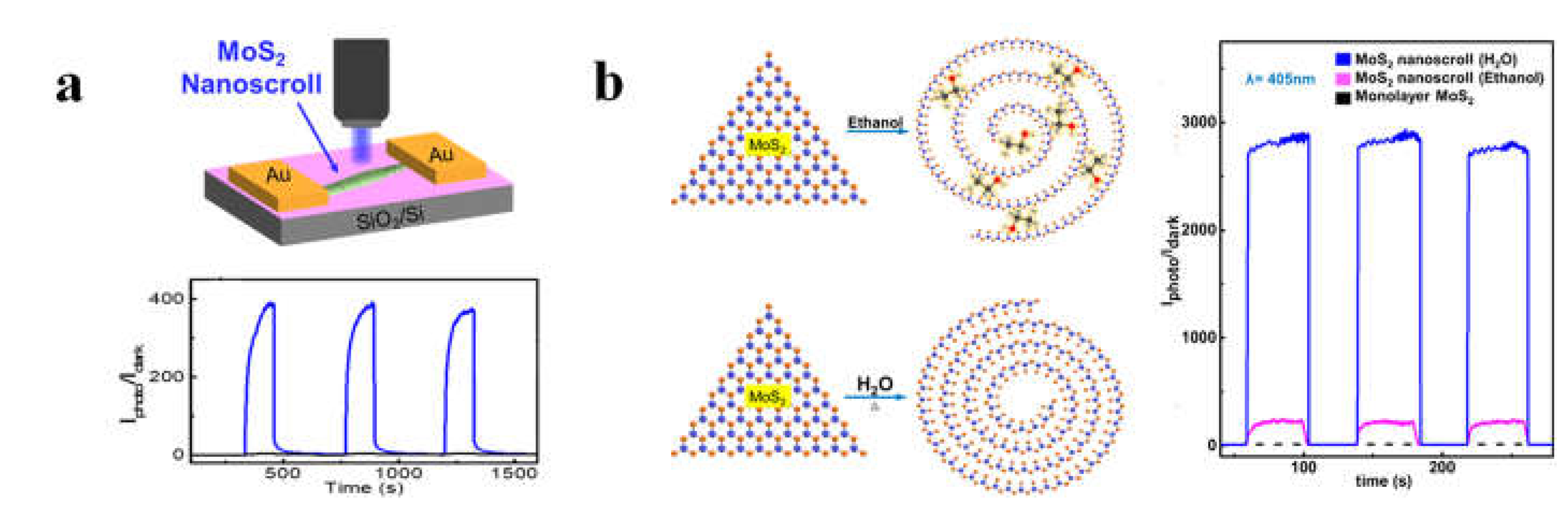

4.1. Photodetector based on TMDCs-NS

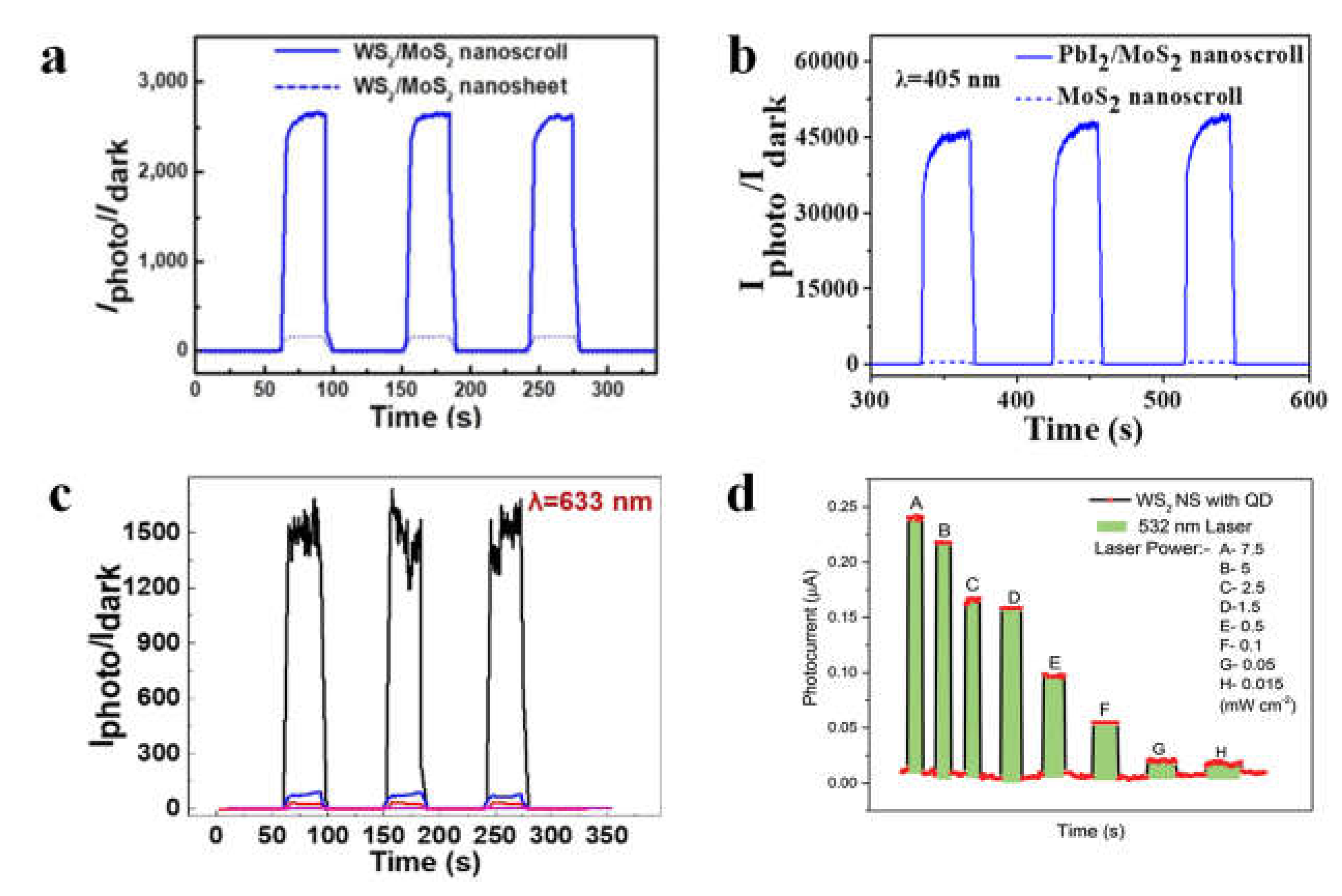

4.2. Photodetector based on TMDCs-NS composite

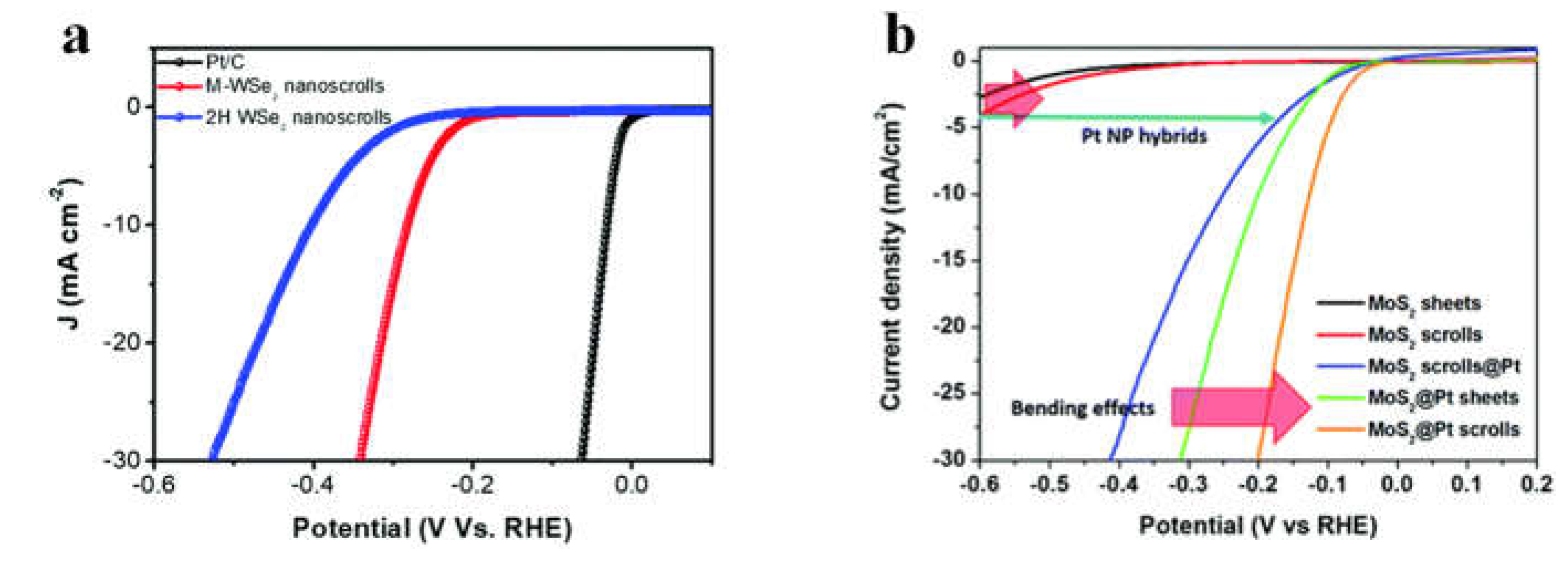

4.3. Hydrogen Evolution Reaction

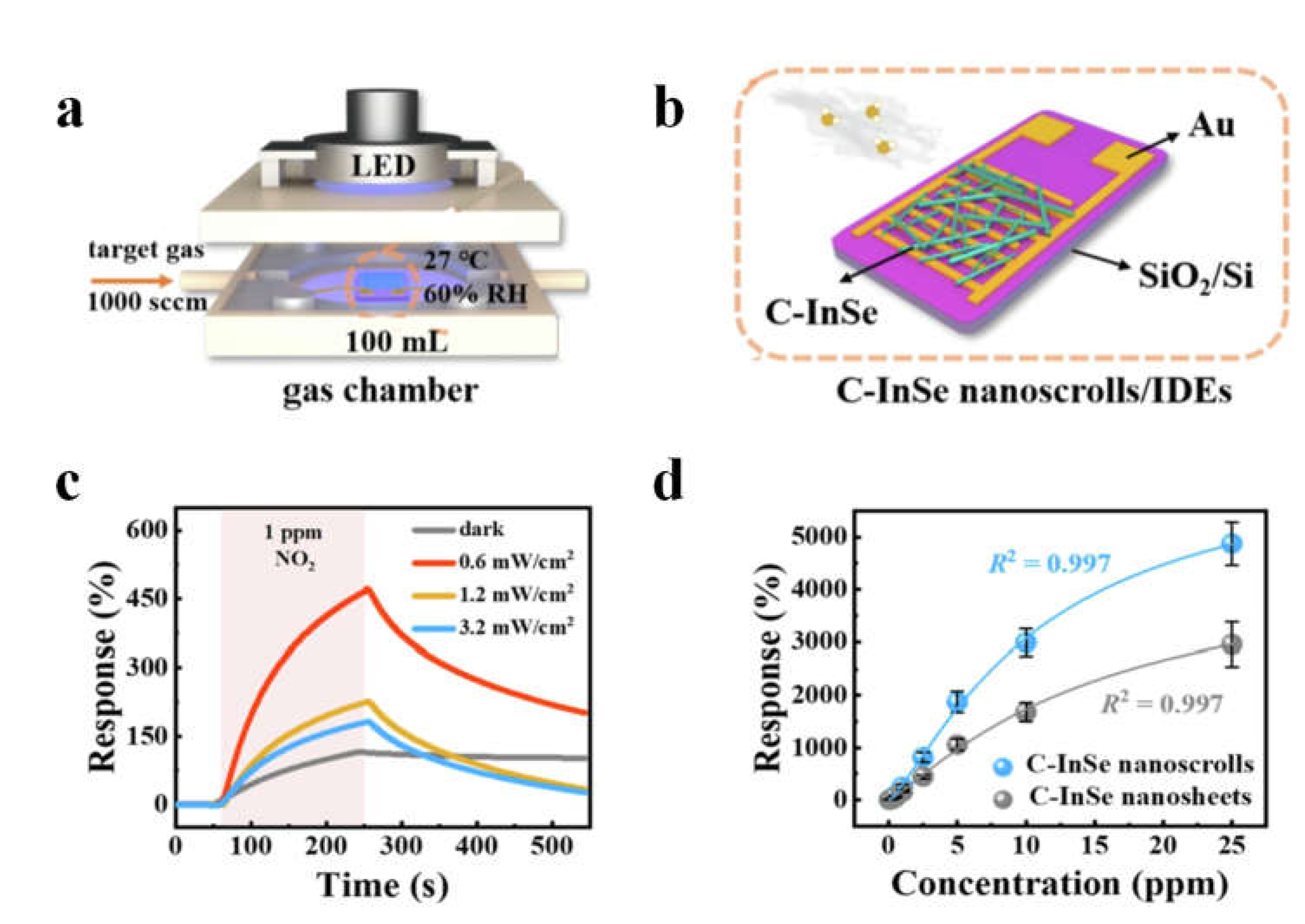

4.4. Gas sensor

5. Conclusion

Acknowledgments

References

- Xuefei Zhou; Ziao Tian; Hyuk Jin Kim; Yang Wang; Borui Xu; Ruobing Pan; Young Jun Chang; Zengfeng Di; Peng Zhou; Mei, Y. Rolling up MoSe2 nanomembranes as a sensitive tubular photodetector. Small 2019, 15, 1902528–1902535. [CrossRef]

- Meng, J.; Wang G; Li X; Lu X; Zhang J; Yu H; Chen W; Du L; Liao M; J., Z.; et al. Rolling up a monolayer MoS2 Sheet. Small 2016, 12, 3770–3774. [CrossRef]

- Wang, L.; Yue, Q.; Pei, C.; Fan, H.; Dai, J.; Huang, X.; Li, H.; Huang, W. Scrolling bilayer WS2/MoS2 heterostructures for high-performance photo-detection. Nano Res. 2020, 13, 959–966. [Google Scholar] [CrossRef]

- Chu, X.S.; Li, D.O.; Green, A.A.; Wang, Q.H. Formation of MoO3 and WO3 nanoscrolls from MoS2 and WS2 with atmospheric air plasma. J. Mater. Chem. C 2017, 5, 11301–11309. [Google Scholar] [CrossRef]

- Zhao, B.; Wan, Z.; Liu, Y.; Xu, J.; Yang, X.; Shen, D.; Zhang, Z.; Guo, C.; Qian, Q.; Li, J.; et al. High-order superlattices by rolling up van der Waals heterostructures. Nature 2021, 591, 385–390. [Google Scholar] [CrossRef]

- Ghosh, R.; Lin, H.-I.; Chen, Y.-S.; Hofmann, M.; Hsieh, Y.-P.; Chen, Y.-F. Efficient light-confinement in heterostructured transition metal dichalcogenide-based nanoscrolls for high-performance photonic devices. J. Mater. Res. 2022, 37, 660–669. [Google Scholar] [CrossRef]

- Fang, X.; Wei, P.; Wang, L.; Wang, X.; Chen, B.; He, Q.; Yue, Q.; Zhang, J.; Zhao, W.; Wang, J.; et al. Transforming monolayer transition-metal dichalcogenide nanosheets into one-dimensional nanoscrolls with high photosensitivity. ACS Appl. Mater. Interfaces 2018, 10, 13011–13018. [Google Scholar] [CrossRef]

- Cui, X.; Kong, Z.; Gao, E.; Huang, D.; Hao, Y.; Shen, H.; Di, C.A.; Xu, Z.; Zheng, J.; Zhu, D. Rolling up transition metal dichalcogenide nanoscrolls via one drop of ethanol. Nat. Commun. 2018, 9, 1301–1308. [Google Scholar] [CrossRef]

- Deng, W.; You, C.; Chen, X.; Wang, Y.; Li, Y.; Feng, B.; Shi, K.; Chen, Y.; Sun, L.; Zhang, Y. High-performance photodiode based on atomically thin WSe2 /MoS2 nanoscroll integration. Small 2019, 15, 1901544–1901550. [Google Scholar] [CrossRef]

- Ji, E.; Son, J.; Kim, J.H.; Lee, G.-H. Rolling up two-dimensional sheets into nanoscrolls. FlatChem 2018, 7, 26–33. [Google Scholar] [CrossRef]

- Su, J.; Li, X.; Xu, M.; Zhang, J.; Liu, X.; Zheng, X.; Shi, Y.; Zhang, Q. Enhancing photodetection ability of MoS2 nanoscrolls via interface engineering. ACS Appl. Mater. Interfaces 2023, 15, 3307–3316. [Google Scholar] [CrossRef] [PubMed]

- Du, L.; Hasan, T.; Castellanos-Gomez, A.; Liu, G.-B.; Yao, Y.; Lau, C.N.; Sun, Z. Engineering symmetry breaking in 2D layered materials. Nat. Rev. Phys. 2021, 3, 193–206. [Google Scholar] [CrossRef]

- Lai, Z.; Chen, Y.; Tan, C.; Zhang, X.; Zhang, H. Self-assembly of two-dimensional nanosheets into one-dimensional nanostructures. Chem. 2016, 1, 59–77. [Google Scholar] [CrossRef]

- Koppens, F.H.; Mueller, T.; Avouris, P.; Ferrari, A.C.; Vitiello, M.S.; Polini, M. Photodetectors based on graphene, other two-dimensional materials and hybrid systems. Nat. Nanotechnol. 2014, 9, 780–793. [Google Scholar] [CrossRef]

- Long, M.; Wang, P.; Fang, H.; Hu, W. Progress, challenges, and opportunities for 2D material based photodetectors. Adv. Funct. Mater. 2018, 29, 1803807–1803835. [Google Scholar] [CrossRef]

- Huo, N.; Konstantatos, G. Recent progress and future prospects of 2D-based photodetectors. Adv. Mater. 2018, 30, 1801164–1081181. [Google Scholar] [CrossRef]

- Deng, W.; Chen, X.; Li, Y.; You, C.; Chu, F.; Li, S.; An, B.; Ma, Y.; Liao, L.; Zhang, Y. Strain effect enhanced ultrasensitive MoS2 nanoscroll avalanche photodetector. J. Phys. Chem. Lett. 2020, 11, 4490–4497. [Google Scholar] [CrossRef]

- Chaoliang Tan; Xiehong Cao; Xue-Jun Wu; Qiyuan He; Jian Yang; Xiao Zhang; Junze Chen; Wei Zhao; Shikui Han; Gwang-Hyeon Nam; et al. Recent advances in ultrathin two-dimensional nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [CrossRef]

- Yue, Q.; Wang, L.; Fan, H.; Zhao, Y.; Wei, C.; Pei, C.; Song, Q.; Huang, X.; Li, H. Wrapping plasmonic silver nanoparticles inside one-dimensional nanoscrolls of transition-metal dichalcogenides for enhanced photoresponse. Inorg. Chem. 2021, 60, 4226–4235. [Google Scholar] [CrossRef]

- Da Young Hwang; Suh, D.H. Universal surface modification of transition metal dichalcogenide decorated with metal nanoparticles for surface enhanced Raman scattering. Mater. Res. Bull. 2017, 90, 73–80. [CrossRef]

- Perim, E.; Machado, L.D.; Galvao, D.S. A brief review on syntheses, structures, and applications of nanoscrolls. Front. Mater. 2014, 1, 31–38. [Google Scholar] [CrossRef]

- Mariana C.F. Costa; Pei Rou Ng ; Sergey Grebenchuck ; Jun You Tan ; Gavin K.W. Koon ; Hui Li Tan; Colin R. Woods; Ricardo K. Donato; Kostya S. Novoselov; Neto, A.H.C. Colossal enhancement of electrical and mechanical properties of graphene nanoscrolls. Carbon 2023, 208, 140–147. [CrossRef]

- Muschi, M.; Lalitha, A.; Sene, S.; Aureau, D.; Fregnaux, M.; Esteve, I.; Rivier, L.; Ramsahye, N.; Devautour-Vinot, S.; Sicard, C.; et al. Formation of a single-crystal aluminum-based MOF nanowire with graphene oxide nanoscrolls as structure-directing agents. Angew. Chem. Int. Ed. Engl. 2020, 59, 10353–10358. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Jiang, C.; Chen, Q.; Zhou, Q.; Wang, H.; Wan, J.; Ma, L.; Wang, J. Highly promoted carrier mobility and intrinsic stability by rolling up monolayer black phosphorus into nanoscrolls. J Phys. Chem. Lett. 2018, 9, 6847–6852. [Google Scholar] [CrossRef] [PubMed]

- Yitian Wang; Xuehao Tang; Qionghua Zhou; Xinyu Chen; Qian Chen ; Xu, Y. Blue phosphorus nanoscrolls. Phys. Rev. B 2020, 102, 165428–165434. [CrossRef]

- Miranti, R.; Qayyum, M.S.; Sharma, A.; Einarsrud, M.-A.; Mestres, N.; Benelmekki, M. Spectroscopic study of partially oxidized BN nanoscrolls induced by low frequency ultrasonic irradiation. Appl. Surf. Sci. 2020, 515, 146055–146062. [Google Scholar] [CrossRef]

- Bacon, R. Growth, ctructure, and properties of graphite whiskers. J. Appl. Phys. 1960, 31, 283–290. [Google Scholar] [CrossRef]

- V. P. Dravid; X. Lin; Y. Wang; X. K. Wang; A. Yee; J. B. Ketterson; Chang, R.P.H. Buckytubes and derivatives their growth and implications for buckyball formation. Science 1993, 259, 1601–1604. [Google Scholar] [CrossRef]

- H Shioyama; Akita, T. A new route to carbon nanotubes. Carbon 2003, 41, 179–198. [CrossRef]

- Lisa M., Viculis; Julia J., Mack; Kaner, R.B. A chemical route to carbon nanoscrolls. Science 2003, 299, 1361. [Google Scholar]

- Scheila F., Braga; Vitor R., Coluci; Sergio, B. Legoas; Ronaldo Giro; Douglas S. Galvão; Baughman, R.H. Structure and dynamics of carbon nanoscrolls. Nano Lett. 2004, 4, 881–884. [Google Scholar]

- Hwang, D.Y.; Choi, K.H.; Park, J.E.; Suh, D.H. Highly efficient hydrogen evolution reaction by strain and phase engineering in composites of Pt and MoS2 nano-scrolls. Phys. Chem. Chem. Phys. 2017, 19, 18356–18365. [Google Scholar] [CrossRef] [PubMed]

- Hwang, D.Y.; Choi, K.H.; Park, J.E.; Suh, D.H. Highly thermal-stable paramagnetism by rolling up MoS2 nanosheets. Nanoscale 2017, 9, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, T.M.D.; Elmas, S.; Alotabi, A.S.; Andersson, M.R.; Raston, C.L. Continuous flow fabrication of MoS2 scrolls for electrocatalytic hydrogen evolution. ACS Sustain. Chem. Eng. 2022, 10, 9325–9333. [Google Scholar] [CrossRef]

- Wu, Z.; Li, F.; Ye, H.; Huang, X.; Li, H. Decorating MoS2 nanoscrolls with solution-processed PbI2 nanocrystals for improved photosensitivity. ACS Appl. Nano Mater. 2022, 5, 15892–15901. [Google Scholar] [CrossRef]

- Zhao, Y.; You, H.; Li, X.; Pei, C.; Huang, X.; Li, H. Solvent-free preparation of closely packed MoS2 nanoscrolls for improved photosensitivity. ACS Appl. Mater. Interfaces 2022, 14, 9515–9524. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, H.H.; Li, Q.; Besenbacher, F.; Zeng, X.C.; Dong, M. Self-scrolling MoS2 metallic wires. Nanoscale 2018, 10, 18178–18185. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, J.; Zhang, G.; Cheng, Y.; Zhang, Y.W. From two-dimensional nano-sheets to roll-up structures: expanding the family of nanoscroll. Nanotechnology 2017, 28, 385704. [Google Scholar] [CrossRef]

- Wang, R.; Guo, S.; Li, Z.; Weller, D.; Quan, S.; Yu, J.; Wu, M.; Jiang, J.; Wang, Y.; Liu, R. Strong anisotropic optical properties by rolling up MoS2 nanoflake. J Phys. Chem. Lett. 2022, 13, 8409–8415. [Google Scholar] [CrossRef]

- Chithaiah, P.; Ghosh, S.; Idelevich, A.; Rovinsky, L.; Livneh, T.; Zak, A. Solving the “MoS2 nanotubes” synthetic enigma and elucidating the route for their catalyst-free and scalable production. ACS Nano 2020, 14, 3004–3016. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, J.; Dong, J. Electronic and magnetic properties of MoS2 nanoribbons with sulfur line vacancy defects. Appl. Surf. Sci. 2015, 346, 470–476. [Google Scholar] [CrossRef]

- Jiao, Y.; Hafez, A.M.; Cao, D.; Mukhopadhyay, A.; Ma, Y.; Zhu, H. Metallic MoS2 for high performance energy storage and energy conversion. Small 2018, 14, 1800640–1800660. [Google Scholar] [CrossRef] [PubMed]

- Kotekar-Patil, D.; Deng, J.; Wong, S.L.; Lau, C.S.; Goh, K.E.J. Single layer MoS2 nanoribbon field effect transistor. Appl. Phys. Lett. 2019, 114, 13508–13513. [Google Scholar] [CrossRef]

- Li, H.; Yin, Z.; He, Q.; Li, H.; Huang, X.; Lu, G.; Fam, D.W.; Tok, A.I.; Zhang, Q.; Zhang, H. Fabrication of single- and multilayer MoS2 film-based field-effect transistors for sensing NO at room temperature. Small 2012, 8, 63–67. [Google Scholar] [CrossRef]

- Ali Mehdizadeh ; Mahdieh Zeynali ; Karimi, M. Engineering of MoS2 nanoribbons as high-performance materials for biosensing applications. Appl. Surf. Sci. 2021, 540, 148349–148359. [CrossRef]

- Seravalli, L.; Bosi, M.; Fiorenza, P.; Panasci, S.E.; Orsi, D.; Rotunno, E.; Cristofolini, L.; Rossi, F.; Giannazzo, F.; Fabbri, F. Gold nanoparticle assisted synthesis of MoS2 monolayers by chemical vapor deposition. Nanoscale Advances 2021, 3, 4826–4833. [Google Scholar] [CrossRef]

- Wang, Q.; Sang, P.; Wei, W.; Li, Y.; Chen, J. Functionalized MoS2 nanoribbons for intrinsic cold-source transistors: a computational study. ACS Appl. Nano Mater. 2022, 5, 1178–1184. [Google Scholar] [CrossRef]

- Wu, Z.; Li, F.; Li, X.; Yang, Y.; Huang, X.; Li, H. Direct synthesis of MoS2 nanosheets in reduced graphene oxide nanoscroll for enhanced photodetection. Nanomaterials (Basel) 2022, 12, 1581–1591. [Google Scholar] [CrossRef]

- Yi, J.-D.; Liu, T.-T.; Huang, Y.-B.; Cao, R. Solid-state synthesis of MoS2 nanorod from molybdenum-organic framework for efficient hydrogen evolution reaction. Sci. China Mater. 2019, 62, 965–972. [Google Scholar] [CrossRef]

- Jeong, Y.; Shin, J.; Hong, Y.; Wu, M.; Hong, S.; Kwon, K.C.; Choi, S.; Lee, T.; Jang, H.W.; Lee, J.-H. Gas sensing characteristics of the FET-type gas sensor having inkjet-printed WS2 sensing layer. Solid State Electron. 2019, 153, 27–32. [Google Scholar] [CrossRef]

- John, M. Woods; Yeonwoong Jung; Yujun Xie; Wen Liu; Yanhui Liu; Hailiang Wang; Cha, J.J. One-step synthesis of MoS2/WS2 layered heterostructures and catalytic activity of defective transition metal dichalcogenide films. ACS Nano 2016, 10, 2004–2009. [Google Scholar] [CrossRef]

- Lin, C.; Cai, L.; Fu, J.H.; Sattar, S.; Wang, Q.X.; Wan, Y.; Tseng, C.C.; Yang, C.W.; Aljarb, A.; Jiang, K.; et al. Direct band gap in multilayer transition metal dichalcogenide nanoscrolls with enhanced photoluminescence. Acs Mater Lett 2022, 4, 1547–1555. [Google Scholar] [CrossRef]

- Pitchai Thangasamy; Jeyaraman Anandha Raj; Sathish, M. Transformation of multilayer WS2 nanosheets to 1D luminescent WS2 nanostructures by one-pot supercritical fluid processing for hydrogen evolution reaction. Mater. Sci. Semicond. Process. 2020, 119, 105167–105174. [CrossRef]

- Zhou, X.; Tian, Z.; Kim, H.J.; Wang, Y.; Xu, B.; Pan, R.; Chang, Y.J.; Di, Z.; Zhou, P.; Mei, Y. Rolling up MoSe2 nanomembranes as a sensitive tubular photodetector. Small 2019, 15, 1902528–1902535. [Google Scholar] [CrossRef]

- Sathish, M.; Mitani, S.; Tomai, T.; Honma, I. Supercritical fluid assisted synthesis of N-doped graphene nanosheets and their capacitance behavior in ionic liquid and aqueous electrolytes. J. Mater. Chem. A 2014, 2, 4731–4738. [Google Scholar] [CrossRef]

- Zhang, S.; Gao, F.; Feng, W.; Yang, H.; Hu, Y.; Zhang, J.; Xiao, H.; Li, Z.; Hu, P. High-responsivity photodetector based on scrolling monolayer MoS2 hybridized with carbon quantum dots. Nanotechnology 2021, 33, 105301–105309. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Jiang, H.; Shen, Y.; Li, X.Z.; Wang, E.G.; Meng, S. Transparent proton transport through a two-dimensional nanomesh material. Nat. Commun. 2019, 10, 3971–3979. [Google Scholar] [CrossRef] [PubMed]

- Graba, M.; Mamala, J.; Bieniek, A.; Sroka, Z. Impact of the acceleration intensity of a passenger car in a road test on energy consumption. Energy 2021, 226, 120429–120445. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, Z.; Kang, J.; Betzler, S.; Czarnik, C.; Zhang, X.; Ophus, C.; Yu, C.; Bustillo, K.; Pan, M.; et al. Formation of two-dimensional transition metal oxide nanosheets with nanoparticles as intermediates. Nat. Mater. 2019, 18, 970–976. [Google Scholar] [CrossRef]

- Gentile, P.; Cuoco, M.; Volkov, O.M.; Ying, Z.-J.; Vera-Marun, I.J.; Makarov, D.; Ortix, C. Electronic materials with nanoscale curved geometries. Nat. Electron. 2022, 5, 551–563. [Google Scholar] [CrossRef]

- Xu, C.; Wu, X.; Huang, G.; Mei, Y. Rolled-up nanotechnology: materials issue and geometry capability. Adv. Mater. Technol. 2018, 4, 1800486–1800512. [Google Scholar] [CrossRef]

- Cho, J.H.; Azam, A.; Gracias, D.H. Three dimensional nanofabrication using surface forces. Langmuir 2010, 26, 16534–16539. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, J.; Gao, W.; Huang, G.; Di, Z.; Liu, R.; Wang, J.; Mei, Y. Dry-released nanotubes and nanoengines by particle-assisted rolling. Adv. Mater. 2013, 25, 3715–3721. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Huang, Z.; Liu, Q.; Zhou, A.a.; Ma, Y.; Wang, J.; Qiu, H.; Bai, H. Organic solvent-assisted lyophilization: a universal method of preparing two-dimensional material nanoscrolls. ACS Omega 2019, 4, 7420–7427. [Google Scholar] [CrossRef]

- Ghosh, R.; Lin, H.I.; Chen, Y.S.; Singh, M.; Yen, Z.L.; Chiu, S.; Lin, H.Y.; Bera, K.P.; Liao, Y.M.; Hofmann, M.; et al. QD/2D hybrid nanoscrolls: a new class of materials for high-performance polarized photodetection and ultralow threshold laser action. Small 2020, 16, 2003944–2003953. [Google Scholar] [CrossRef]

- Jeonghyeon Na; Changyeon Park ; Chang Hoi Lee; Won Ryeol Choi; Sooho Choi; Jae-Ung Lee; Woochul Yang ; Hyeonsik Cheong; B., E.E.; Jhang, C.a.S.H. Indirect band gap in scrolled MoS2 monolayers. Nanomaterials 2022, 12, 3353. [CrossRef]

- Hwang, D.Y.; Choi, K.H.; Suh, D.H. A vacancy-driven phase transition in MoX2 (X: S, Se and Te) nanoscrolls. Nanoscale 2018, 10, 7918–7926. [Google Scholar] [CrossRef]

- Hwang, D.Y.; Suh, D.H. Evolution of a high local strain in rolling up MoS2 sheets decorated with Ag and Au nanoparticles for surface-enhanced Raman scattering. Nanotechnology 2017, 28, 25603–25614. [Google Scholar] [CrossRef]

- Janardhana Reddy ; G Basha, H.; Venkata Narayanan, N.S. Heat flow visualization of a chemical compound isobutane (C4H10) past a vertical cylinder in the subcritical, near critical and supercritical regions. J. Mol. Struct. 2018, 259, 209–219. [CrossRef]

- L. El Khouri; Carle`s, P. Supercritical fluids as experimental models for geophysical flows. Int J Thermophys 2003, 24, 683–693. [CrossRef]

- Parag, S. Shah; Tobias Hanrath; Keith P. Johnston; Korgel, B.A. Nanocrystal and nanowire synthesis and dispersibility in supercritical fluids. J. Phys. Chem. B 2004, 108, 9574–9587. [Google Scholar]

- Schienbein, P.; Marx, D. Assessing the properties of supercritical water in terms of structural dynamics and electronic polarization effects. Phys. Chem. Chem. Phys. 2020, 22, 10462–10479. [Google Scholar] [CrossRef]

- Pitchai Thangasamy; Sathish, M. Rapid, one-pot synthesis of luminescent MoS2 nanoscrolls using supercritical fluid processing. J. Mater. Chem. C 2016, 4, 1165–1169. [CrossRef]

- Thangasamy, P.; Sathish, M. Supercritical fluid processing: a rapid, one-pot exfoliation process for the production of surfactant-free hexagonal boron nitride nanosheets. CrystEngComm 2015, 17, 5895–5899. [Google Scholar] [CrossRef]

- Wang, W.; Gai, Y.; Xiao, D.; Zhao, Y. A facile and general approach for production of nanoscrolls with high-yield from two-dimensional nanosheets. Sci. Rep. 2018, 8, 15262–15268. [Google Scholar] [CrossRef] [PubMed]

- Rangappa, D.; Sone, K.; Wang, M.; Gautam, U.K.; Golberg, D.; Itoh, H.; Ichihara, M.; Honma, I. Rapid and direct conversion of graphite crystals into high-yielding, good-quality graphene by supercritical fluid exfoliation. Chem. Eur. J. 2010, 16, 6488–6494. [Google Scholar] [CrossRef]

- Alharbi, T.M.D.; Jellicoe, M.; Luo, X.; Vimalanathan, K.; Alsulami, I.K.; Al Harbi, B.S.; Igder, A.; Alrashaidi, F.A.J.; Chen, X.; Stubbs, K.A.; et al. Sub-micron moulding topological mass transport regimes in angled vortex fluidic flow. Nanoscale Adv. 2021, 3, 3064–3075. [Google Scholar] [CrossRef] [PubMed]

- Vimalanathan, K.; Suarez-Martinez, I.; Peiris, M.C.R.; Antonio, J.; de Tomas, C.; Zou, Y.; Zou, J.; Duan, X.; Lamb, R.N.; Harvey, D.P.; et al. Vortex fluidic mediated transformation of graphite into highly conducting graphene scrolls. Nanoscale Adv. 2019, 1, 2495–2501. [Google Scholar] [CrossRef]

- Al-Antaki, A.H.M.; Luo, X.; Alharbi, T.M.D.; Harvey, D.P.; Pye, S.; Zou, J.; Lawrance, W.; Raston, C.L. Inverted vortex fluidic exfoliation and scrolling of hexagonal-boron nitride. RSC. Adv. 2019, 9, 22074–22079. [Google Scholar] [CrossRef]

- Gaoshan Huang ; Mei, Y. Thinning and shaping solid films into functional and integrative nanomembranes. Adv. Mater. 2012, 24, 2517–2546. [CrossRef]

- Song Hao; Bingchu Yang; Gao, Y. Fracture-induced nanoscrolls from CVD-grown monolayer molybdenum disulfide. Phys. Status Solidi Rapid Res. Lett. 2016, 10, 549–553. [CrossRef]

- Qian, Q.; Zu, R.; Ji, Q.; Jung, G.S.; Zhang, K.; Zhang, Y.; Buehler, M.J.; Kong, J.; Gopalan, V.; Huang, S. Chirality-dependent second harmonic generation of MoS2 nanoscroll with enhanced efficiency. ACS Nano 2020, 14, 13333–13342. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Su, L.; Zhang, F.; Huang, D.; Sang, D.K.; Chen, Y.; Li, Y.; Liu, F.; Li, J.; Zhang, H.; et al. Layer-dependent properties of ultrathin ges nanosheets and application in uv–vis photodetectors. ACS Appl. Mater. Interfaces 2019, 11, 47197–47206. [Google Scholar] [CrossRef] [PubMed]

- Carlos, G. Morales-Guio; Lucas-Alexandre Sterna; Hu, X. Nanostructured hydrotreating catalysts for electrochemical hydrogen evolution. Chem. Soc. Rev. 2014, 43, 6555–6569. [Google Scholar] [CrossRef]

- Zhou, X.; Lin, S.H.; Yang, X.; Li, H.; Hedhili, M.N.; Li, L.J.; Zhang, W.; Shi, Y. MoSx-coated NbS2 nanoflakes grown on glass carbon: an advanced electrocatalyst for the hydrogen evolution reaction. Nanoscale 2018, 10, 3444–3450. [Google Scholar] [CrossRef]

- Li, H.; Jia, X.; Zhang, Q.; Wang, X. Metallic transition-metal dichalcogenide nanocatalysts for energy conversion. Chem 2018, 4, 1510–1537. [Google Scholar] [CrossRef]

- Miika Mattinen; Markku Leskelä; Ritala, M. Atomic layer deposition of 2D metal dichalcogenides for electronics, catalysis, energy storage, and beyond. Adv. Mater. Interfaces 2021, 8, 2001677–2001724. [CrossRef]

- Wei Wang; Yutong Li; Mengjia Li; Hailin Shen; Wei Zhang; Jintao Zhang; Tianyu Liu; Kong, X.; Bi, H. Metallic phase WSe2 nanoscrolls for the hydrogen evolution reaction. New J. Chem. 2022, 46, 8381–8384. [CrossRef]

- Berit Hinnemann; Poul Georg Moses; Jacob Bonde; Kristina P. Jørgensen; Jane H. Nielsen; Sebastian Horch; Ib Chorkendorff; Nørskov, J.K. Biomimetic hydrogen evolution: MoS2 nanoparticles as catalyst for hydrogen evolution. J. Am. Chem. Soc. 2005, 127, 5308–5309.

- Wang, F.; Shifa, T.A.; Zhan, X.; Huang, Y.; Liu, K.; Cheng, Z.; Jiang, C.; He, J. Recent advances in transition-metal dichalcogenide based nanomaterials for water splitting. Nanoscale 2015, 7, 19764–19788. [Google Scholar] [CrossRef]

- Thomas F., Jaramillo; Kristina, P. Jørgensen; Jacob Bonde; Jane H. Nielsen; Sebastian Horch; Chorkendorff, I. Identification of active edge sites for electrochemical H2 evolution from MoS2 nanocatalysts. science 2007, 317, 100–102. [Google Scholar]

- Yan, Y.; Xia, B.; Xu, Z.; Wang, X. Recent development of molybdenum sulfides as advanced electrocatalysts for hydrogen evolution reaction. ACS Catal. 2014, 4, 1693–1705. [Google Scholar] [CrossRef]

- Henckel, D.A.; Lenz, O.M.; Krishnan, K.M.; Cossairt, B.M. Improved HER catalysis through facile, aqueous electrochemical activation of nanoscale WSe2. Nano Lett. 2018, 18, 2329–2335. [Google Scholar] [CrossRef]

- Damien Voiry; Jieun Yang; Chhowalla, M. Recent strategies for improving the catalytic activity of 2D TMD nanosheets toward the hydrogen evolution reaction. Adv. Mater. 2016, 28, 6197–6206. [CrossRef]

- Lu, Q.; Yu, Y.; Ma, Q.; Chen, B.; Zhang, H. 2D transition-metal-dichalcogenide-nanosheet-based composites for photocatalytic and electrocatalytic hydrogen evolution reactions. Adv. Mater. 2016, 28, 1917–1933. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Wu, J.; Hardy, W.J.; Loya, P.; Lou, M.; Yang, Y.; Najmaei, S.; Jiang, M.; Qin, F.; Keyshar, K.; et al. Facile synthesis of single crystal vanadium disulfide nanosheets by chemical vapor deposition for efficient hydrogen evolution reaction. Adv. Mater. 2015, 27, 5605–5609. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhou, W.; Hu, C.; Luo, X.; Zeng, W.; Gong, X.; Yang, Y.; Yu, T.; Lei, W.; Yuan, C. Interlayer-confined NiFe dual atoms withinMoS2 electrocatalyst for ultra-efficient acidic overall water splitting. Adv. Mater. 2023, 10, 2300505. [Google Scholar] [CrossRef]

- Rheehyun Kim; Ji-Soo Jang; Dong-Ha Kim; Joon-Young Kang; Hee-Jin Cho; Yong Jin Jeong; Kim, I.-D. A general synthesis of crumpled metal oxide nanosheets as superior chemiresistive. Adv. Funct. Mater. 2019, 29, 1903128. [CrossRef]

- Atanu Bag ; Lee, N.-E. Gas sensing with heterostructures based on two-dimensional nanostructured materials a review. J. Mater. Chem. C 2019, 7, 13367–13383. [CrossRef]

- Kumar, R.; Goel, N.; Hojamberdiev, M.; Kumar, M. Transition metal dichalcogenides-based flexible gas sensors. Sens. Actuator A Phys. 2020, 303, 111875–111902. [Google Scholar] [CrossRef]

- Goswami, P.; Gupta, G. Recent progress of flexible NO2 and NH3 gas sensors based on transition metal dichalcogenides for room temperature sensing. Mater. Today Chem. 2022, 23, 100726–100739. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Z.; Zhang, Y.; Li, H.Y.; Gao, N.; Tian, Z.; Zhou, L.; Zhang, B.; Tang, J.; Zhang, J.; et al. MoS2 nanosheets sensitized with quantum dots for room-temperature gas sensors. Nanomicro Lett 2020, 12, 59–72. [Google Scholar] [CrossRef] [PubMed]

- P. Bharathi; S. Harish, M.; Shimomura; S. Ponnusamy; M. Krishna Mohan; J. Archana; Navaneethan, M. Conductometric NO2 gas sensor based on Co-incorporated MoS2 nanosheets for room temperature applications. Sens. Actuators B Chem. 2022, 360, 131600. [CrossRef]

- Bai, H.; Guo, H.; Feng, C.; Wang, J.; Liu, B.; Xie, Z.; Guo, F.; Chen, D.; Zhang, R.; Zheng, Y. Light-activated ultrasensitive NO2 gas sensor based on heterojunctions of CuO nanospheres/MoS2 nanosheets at room temperature. Sens. Actuators B Chem. 2022, 368, 132131–132146. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, Q.; Liu, J.; Zhou, J.; Zhang, W.; Li, Y. Rolling up of 2D nanosheets into 1D Nanoscrolls: visible-light-activated chemiresistors based on surface modified indium selenide with enhanced sensitivity and stability. Chem. Eng. J. 2022, 446, 136937–136911. [Google Scholar] [CrossRef]

- Park, H.; Park, J.; Kang, S.-W.; Jeong, S.-H. 3D-nanostructured MoS2 nanoscroll with highly active sites for improving NO2 gas detection. Mater. Lett. 2023, 349, 134733–134737. [Google Scholar] [CrossRef]

| Methods | Advantages | Challenges | References | |

|---|---|---|---|---|

| In liquid | Solvent evaporation to make nanoscroll | Large area, large size, high productivity, short time consuming, easy to operate | Solvent residue, loose nanoscrolls | [6,7,8,9,17,37,39,52,56,65,82] |

| Alkaline droplet-assisted fabrication of nanoscroll | High yield, high productivity for thick nanosheet | Substrate etching, solvent residue | [3,5,10,11,19,35] | |

| Fabrication of TMDCs nanoscroll by dragging water droplet | High yield, solvent-free residue, tightly packed nanoscroll | Not suitable for water and oxygen sensitive material | [36] | |

| Amine-functional amphiphilic molecule assisted fabrication of TMDCs nanoscroll | High yield, easy to operate | Small dimension, solvent residue | [32,33,67] | |

| Supercritical fluid assisted fabrication of nanoscroll | Simple, fast | Small dimension, solvent residue | [73] | |

| Shear force assisted fabrication of nanoscroll | High productivity, easy to operate | Low proportion of monolayer nanosheet | [34] | |

| In air | Plasma-assisted fabrication of TMDCs nanoscroll | Simple process, high yield | Small dimension, structure damage | [2,4] |

| Strain-assisted fabrication of TMDCs nanoscroll | Simple and repeatable | Complex process, low productivity, incomplete nanoscroll | [54] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).