Submitted:

20 July 2023

Posted:

20 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Synthesis of graphene and transfer to glass substrate

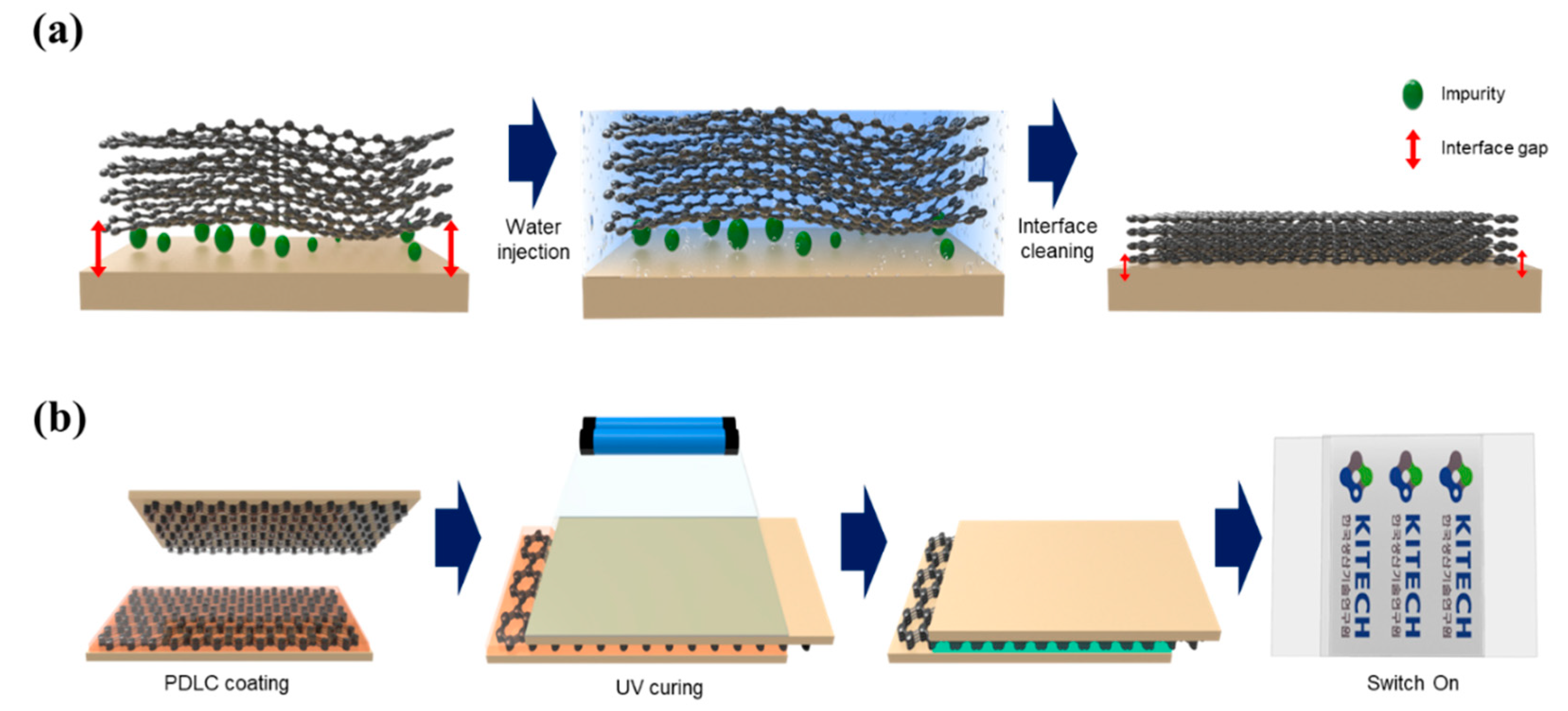

2.2. Water-Induced Interface Cleaning (WIIC) process

2.3. Fabrication of PDLC device

2.4. Characterization

3. Results

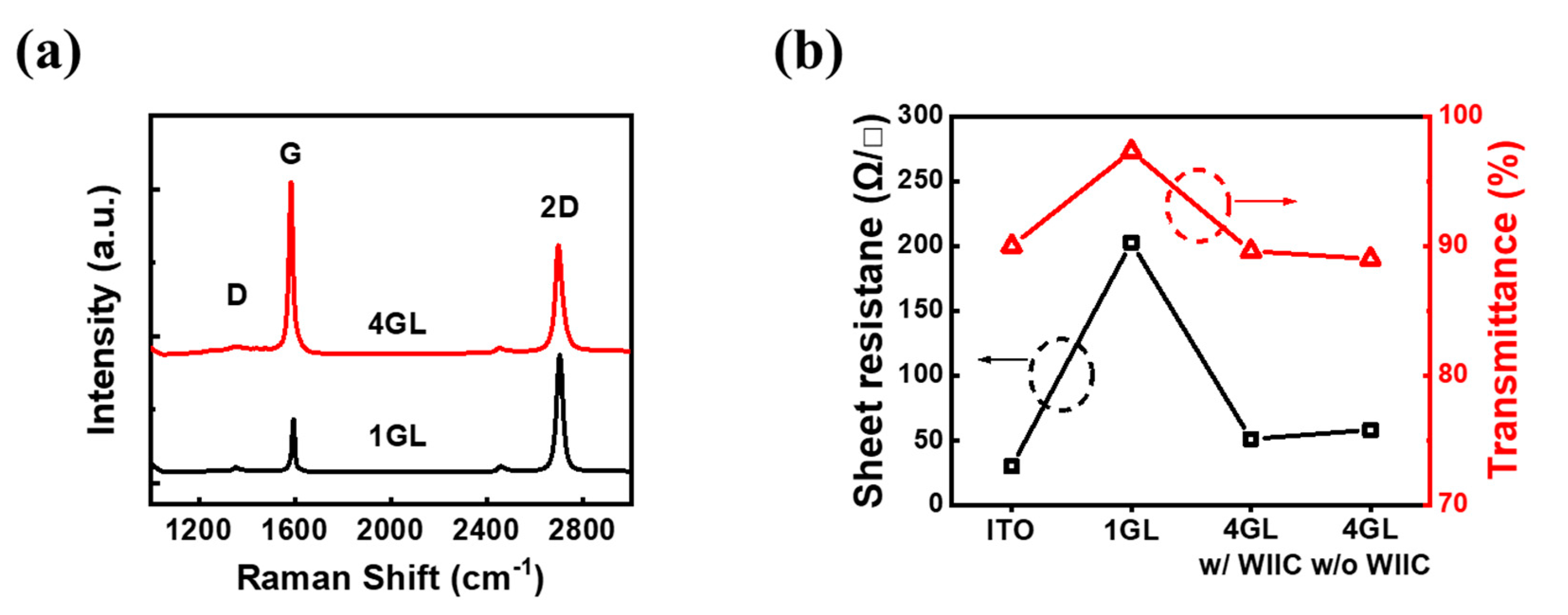

3.1. Number of graphene layer

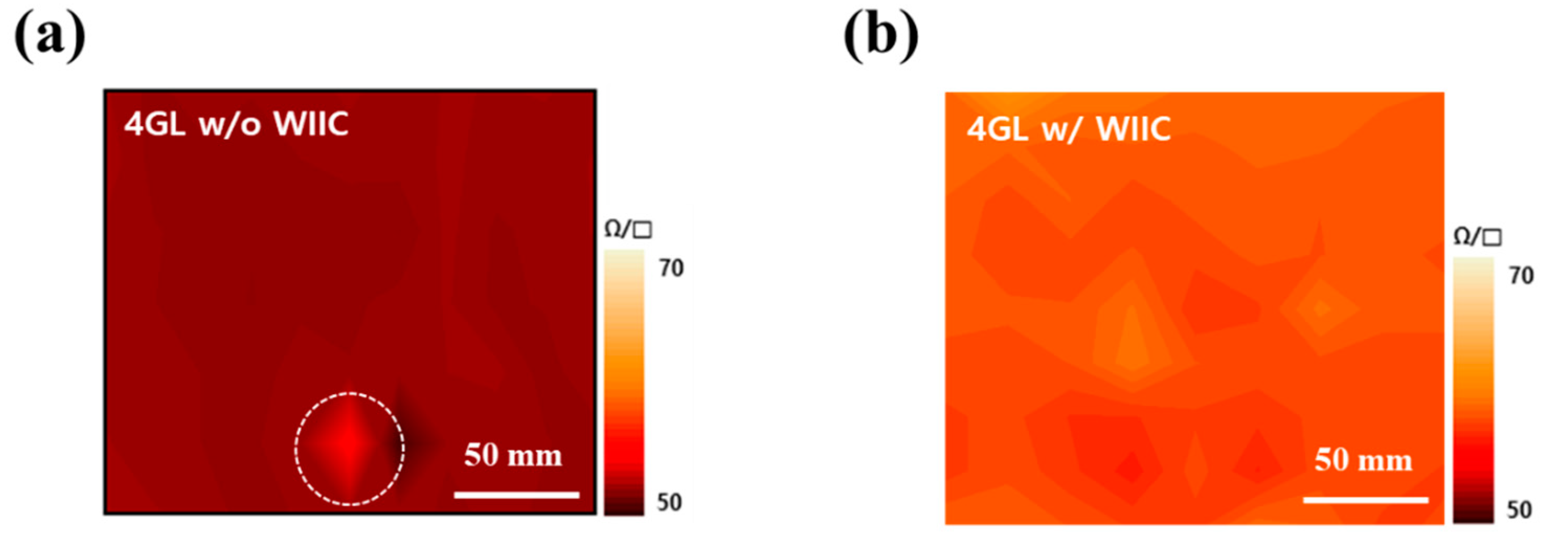

3.2. Effect of WIIC

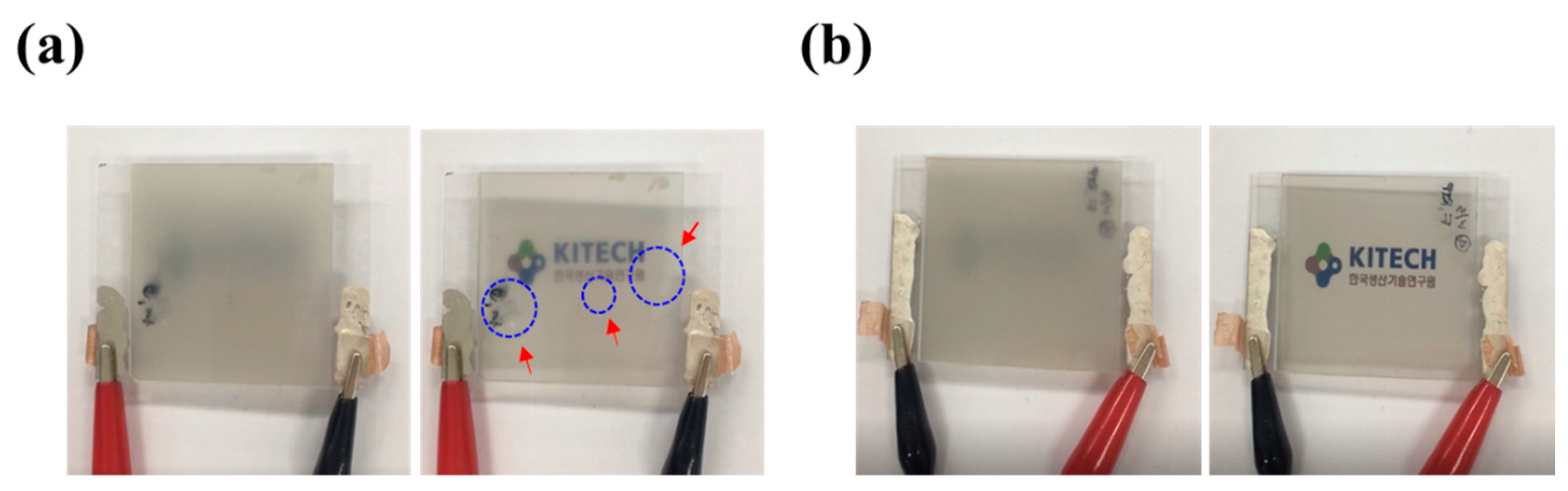

3.3. Performance of PDLC device

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marszal, A.J.; Heiselberg, P.; Bourrelle, J.S.; Musall, E.; Voss, K.; Sartori, I.; Napolitano, A. Zero Energy Building – A review of definitions and calculation methodologies. Energy Build. 2011, 43, 971–979. [Google Scholar] [CrossRef]

- Ke, Y.; Zhou, C.; Zhou, Y.; Wang, S.; Chan, S.H.; Long, Y. Emerging Thermal-Responsive Materials and Integrated Techniques Targeting the Energy-Efficient Smart Window Application. Adv. Funct. Mater. 2018, 28, 1800113. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells. 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Jung, D.; Choi, W.; Park, J.Y.; Kim, K.B.; Lee, N.; Seo, Y.; Kim, H.S.; Kong, N.K. Inorganic gel and liquid crystal based smart window using silica sol-gel process. Sol. Energy Mater. Sol. Cells. 2017, 159, 488–495. [Google Scholar] [CrossRef]

- Park, J.Y.; Kim, H.K. Highly stretchable polymer-dispersed liquid crystal-based smart windows with transparent and stretchable hybrid electrodes. RSC Adv. 2018, 8, 36549–36557. [Google Scholar] [CrossRef]

- Huang, J.; Li, J.; Xu, J.; Wang, Z.; Sheng, W.; Li, H.; Yang, Y.; Song, W. Simultaneous achievement of high visible transmission and near-infrared heat shielding in flexible liquid crystal-based smart windows via electrode design. Sol. Energy. 2019, 188, 857–864. [Google Scholar] [CrossRef]

- Na, S.I.; Kim, S.S.; Jo, J.; Kim, D.Y. Efficient and Flexible ITO-Free Organic Solar Cells Using Highly Conductive Polymer Anodes. Adv. Mater. 2008, 20, 4061–4067. [Google Scholar] [CrossRef]

- Wang, X.; Zhi, L.; Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 2008, 8, 323–327. [Google Scholar] [CrossRef]

- Kumar, A.; Zhou, C. The race to replace tin-doped indium oxide: which material will win? ACS Nano. 2010, 4, 11–14. [Google Scholar] [CrossRef]

- Wu, H.; Kong, D.; Ruan, Z.; Hsu, P.C.; Wang, S.; Yu, Z.; Carney, T.J.; Hu, L.; Fan, S.; Cui, Y. A transparent electrode based on a metal nanotrough network. Nat. Nanotechnol. 2013, 8, 421–425. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, X.D.; Wang, H.; Li, X.; Lin, L.; Chen, K.; Ci, H.; Wu, X.; Zhang, Y.; Liu, Z. One-Step Growth of Graphene/Carbon Nanotube Hybrid Films on Soda-Lime Glass for Transparent Conducting Applications. Adv. Electron. Mater. 2017, 3, 1700212. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, K.; Kim, K.B.; Park, J.Y.; Lee, N.; Seo, Y. Flexible polymer dispersed liquid crystal film with graphene transparent electrodes. Curr. Appl. Phys. 2016, 16, 409–414. [Google Scholar] [CrossRef]

- Liu, F.; Wang, G.; Pal, K.; Zhan, B.; Liu, S.; Wen, D.; Ye, S. Flexible Polymer Dispersed Liquid Crystal Module with Graphene Electrode. J. Nanosci. Nanotechnol. 2015, 15, 9829–9833. [Google Scholar] [CrossRef] [PubMed]

- Chung, S.H.; Noh, H.Y. Polymer-dispersed liquid crystal devices with graphene electrodes. Opt. Express. 2015, 23, 32149–32157. [Google Scholar] [CrossRef]

- Marinova, V.; Petrov, S.; Napoleonov, B.; Mickovski, J.; Petrova, D.; Dimitrov, D.; Hsu, K.Y.; Lin, S.H. Multilayer Graphene for Flexible Optoelectronic Devices. Mater. Proc. 2021, 65(4), 1–6. [Google Scholar] [CrossRef]

- Kim, Y.B.; Park, S.; Hong, J.W. Fabrication of flexible polymer dispersed liquid crystal films using conducting polymer thin films as the driving electrodes. Thin Solid Films. 2009, 517, 3066–3069. [Google Scholar] [CrossRef]

- Wang, P.C.; MacDiarmid, A.G. Integration of polymer-dispersed liquid crystal composites with conducting polymer thin films toward the fabrication of flexible display devices. Displays. 2007, 28, 101–104. [Google Scholar] [CrossRef]

- Khaligh, H.H.; Liew, K.; Han, Y.; Abukhdeir, N.M.; Goldthorpe, I.A. Silver nanowire transparent electrodes for liquid crystal-based smart windows. Sol. Energy Mater. Sol. Cells. 2015, 132, 337–341. [Google Scholar] [CrossRef]

- Kim, D.J.; Hwang, D.Y.; Park, J.Y.; Kim, H.K. Liquid crystal–Based flexible smart windows on roll-to-roll slot die–Coated Ag nanowire network films. J. Alloys Compd. 2018, 765, 1090–1098. [Google Scholar] [CrossRef]

- Jiang, T.; Zhu, Y. Measuring graphene adhesion using atomic force microscopy with a microsphere tip. Nanoscale. 2015, 7, 10760–10766. [Google Scholar] [CrossRef]

- Cho, D.H.; Wang, L.; Kim, J.S.; Lee, G.H.; Kim, E.S.; Lee, S.; Lee, S.Y.; Hone, J.; Lee, C. Effect of surface morphology on friction of graphene on various substrates. Nanoscale. 2013, 5, 3063–3069. [Google Scholar] [CrossRef] [PubMed]

- Hammad, M.; Adjizian, J.J.; Sacré, C.H.; Huet, B.; Charlier, J.C.; Raskin, J.P.; Pardoen, T. Adhesionless and near-ideal contact behavior of graphene on Cu thin film. Carbon. 2017, 122, 446–450. [Google Scholar] [CrossRef]

- Seo, T.H.; Lee, S.; Cho, H.; Chandramohan, S.; Suh, E.K.; Lee, H.S.; Bae, S.K.; Kim, S.M.; Park, M.; Lee. J.K.; Kim, M.J. Tailored CVD graphene coating as a transparent and flexible gas barrier. Sci. Rep. 2016, 6, 24143. [Google Scholar] [CrossRef] [PubMed]

- Leenaerts, O.; Partoens, B.; Peeters, F.M. Graphene: A perfect nanoballoon. Appl. Phys. Lett. 2008, 93, 193107. [Google Scholar] [CrossRef]

- Bunch, J.S.; Verbridge, S.S.; Alden, J.S.; van der Zande, A.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Impermeable atomic membranes from graphene sheets. Nano Lett. 2008, 8, 2458–2462. [Google Scholar] [CrossRef]

- Karpan, V.M.; Giovannetti, G.; Khomyakov, P.A.; Talanana, M.; Starikov, A.A.; Zwierzycki, M.; van den Brink, J.; Brocks, G.; Kelly, P.J. Graphite and graphene as perfect spin filters. Phys. Rev. Lett. 2007, 99, 176602. [Google Scholar] [CrossRef]

- Gadipelli, S.; Guo, Z.X. Graphene-based materials: Synthesis and gas sorption, storage and separation. Prog. Mater. Sci. 2015, 69, 1–60. [Google Scholar] [CrossRef]

- Wang, T.Y.; Ni, Zh.; Yu, T.; Shen, Z.X.; Wang, H.M.; Wu, Y.H.; Chen, W.; Wee, A.T.S. Raman Studies of Monolayer Graphene: The Substrate Effect. J. Phys. Chem. C. 2008, 112, 10637–10640. [Google Scholar] [CrossRef]

- Graf, D.; Molitor, F.; Ensslin, K.; Stampfer, C.; Jungen, A.; Hierold, C.; Wirtz, L. Spatially resolved Raman spectroscopy of single- and few-layer graphene. Nano Lett. 2007, 7, 238–242. [Google Scholar] [CrossRef]

- Kim, B.J.; Lee, C.M.; Jung, Y.H.; Baik, K.H.; Mastro, M.A.; Hite, J.K.; Eddy, C.R.; Kim, J.H. Large-area transparent conductive few-layer graphene electrode in GaN-based ultra-violet light-emitting diodes. Appl. Phys. Lett. 2011, 99, 143101. [Google Scholar] [CrossRef]

- Seo, T.H.; Kim, B.K.; Shin, G.U.; Lee, C.H.; Kim, M.J.; Kim, H.; Suh, E.K. Graphene-silver nanowire hybrid structure as a transparent and current spreading electrode in ultraviolet light emitting diodes. Appl. Phys. Lett. 2013, 103, 051105. [Google Scholar] [CrossRef]

- Kim, Y.J.; Seo, T.H.; Kim, Y.H.; Suh, E.K.; Bae, S.K.; Hwang, J.Y.; Kim, J.W.; Kang, Y.J.; Kim, M.J.; Ahn, S.H. Two-Dimensional Stacked Composites of Self-Assembled Alkane Layers and Graphene for Transparent Gas Barrier Films with Low Permeability. Nano. lett. 2022, 22, 286–293. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).