1. Introduction

Onions, scientifically known as Allium cepa L, have been grown for over 4000 years and belong to the Liliaceae family [

1,

2]. The top five onion producers include European countries, Asia, China, India and the United States [

1]. In recent years, the world production of onions has increased by more than 25% and now reaching about 44 million tons, the second most important crop after tomatoes [

2]. They are an essential ingredient in cooking traditions of many countries and are widely consumed worldwide due to their distinctive flavor and numerous health benefits [

3].

Onions are considered a medicinal plant that can alleviate or prevent several common illnesses such as atherosclerosis, asthma, bronchitis, and cough. They are also a rich source of biologically active phytomolecules [

4]. Onions may exhibit various activities such as antimicrobial, antifungal, antiviral, antioxidant, antidiabetic, antitumor, anti-inflammatory, antihypertensive, antiallergic, and hypolipidemic properties [

3,

5].

Preedy has reported that the anti-inflammatory activity of onion is responsible for its anti-asthma effectiveness, which is considered one of its most extensively studied effects. Moreover, a pharmaceutical or veterinary combination of onion and coconut (Cocos nucifera) has been developed to manage brain parasites (nematodes) and/or tapeworms (Platyhelminthes) in humans or animals [

2].

More and more researchers are becoming interested in the bioactivity of onions, specifically their oil. However, the low oil yield and high water content of onions make extracting the oil a delicate process. [

3].

To address this issue, researchers are turning to extracting oil from onion seeds, which have been described in the literature in relation to different onion cultivars. However, studies on the chemical and functional properties of onion seeds are rare, especially those that use environmentally-friendly extraction techniques such as supercritical CO2 extraction. The neglect of onion seeds is due to a common misconception that they are merely a part of the onion vegetable. In fact, onion seeds are a plant with flowers, and herbalists and users claim that they have various benefits such as preventing hair loss, improving digestive system function, and treating wounds.

Recently, there has been a surge in research efforts to identify new sources of edible oils, particularly plant seeds, due to their nutritional, industrial, and medicinal benefits. Consumers are increasingly seeking seed oils with bioactive properties that can enhance human health and protect against diseases [

4].

Although onion seeds are a viable source of edible oil, their commercial availability is currently limited. However, if consumers were more informed about the health, nutritional, and functional attributes of onion seeds, their consumption would likely increase, making them a profitable oil crop [

2].

Dini et al. (2008b) showed the advantageous effectiveness of onion seed oil, highlighting its significance in managing obesity. The study revealed that the oil can enhance blood sugar control, reduce food intake, and promote fat tissue cell death, thereby underscoring its potential for treating obesity [

4].

Onion seeds have considerable oil content, with high percentages of linoleic, oleic, and palmitic acids, proteins, alcohols, acids, and esters, as well as sulfur compounds, which aid in controlling cholesterol, diabetes, and cancer. Additionally, onion seeds contain free amino acids and antioxidants[

1].

Alliaceae plants, including onions, are part of a group of plants that accumulate secondary selenium. Onion seeds with a moderate concentration of selenium have potent natural antioxidant properties, protecting plants against various types of stress such as salinity, drought, UV radiation, heavy metals, and herbivore attacks. Genetic, environmental, and agricultural factors affect the accumulation of selenium in seeds and their fatty acid composition, resulting in differences in the oil composition between countries and extraction methods. According to a study by Dini et al., onion seeds may contain up to 24.8% crude protein, 20.4% oil and 10.5% moisture [

4]. Additionally, it has been shown that onion seeds oil with a high content of polyunsaturated fatty acids can be obtained through cold-pressed extraction [

2].

The cold-pressed onion seed oil showed antioxidant properties with a total phenolic content (TPC) of 3.35 mg GAE/g, a higher value compared to those of seed oils from cold-pressed black raspberry, parsley and milk thistle. Furthermore, the cold-pressed onion seed oil yield was found to be 21.1%, higher than the yield shown by Soxhlet extraction [6 ,7]. However in the present study an even higher extraction yield of up to 24.5% was achieved by supercritical CO2 extraction, under specific operating conditions.

The selection of supercritical CO2 extraction for this study was primarily influenced by its environmentally friendly nature, which involves minimizing the utilization and generation of harmful substances while extracting oils from natural plants. This process is categorized as a green chemistry approach.

Supercritical fluids are often regarded as eco-friendly, and their supercritical phase can be viewed as an intermediary state that is almost as dense as a liquid and with transport properties, such as viscosity and diffusion, comparable to those of a gas [

7].

Among the extraction solvents, supercritical carbon dioxide is commonly favored, especially for oxidation-sensitive, thermolabile, high-value, or minor components, owing to its advantageous blend of mild critical conditions regarding temperature (304.13 K) and pressure (7.38 MPa) [

8].

The present work concerns the extraction of oil from local onion seeds and the objectives are to carry a comprehensive study on the impact of four parameters, namely pressure, temperature, diameter, and flowrate of supercritical CO2 into the extractor, and to optimize the extraction yield and quality of oil and highlight the significance of onion seed oil in various industries, including pharmaceuticals, parapharmaceuticals, cosmetics and food.

3. Results and discussion

3.1. BBD analysis results

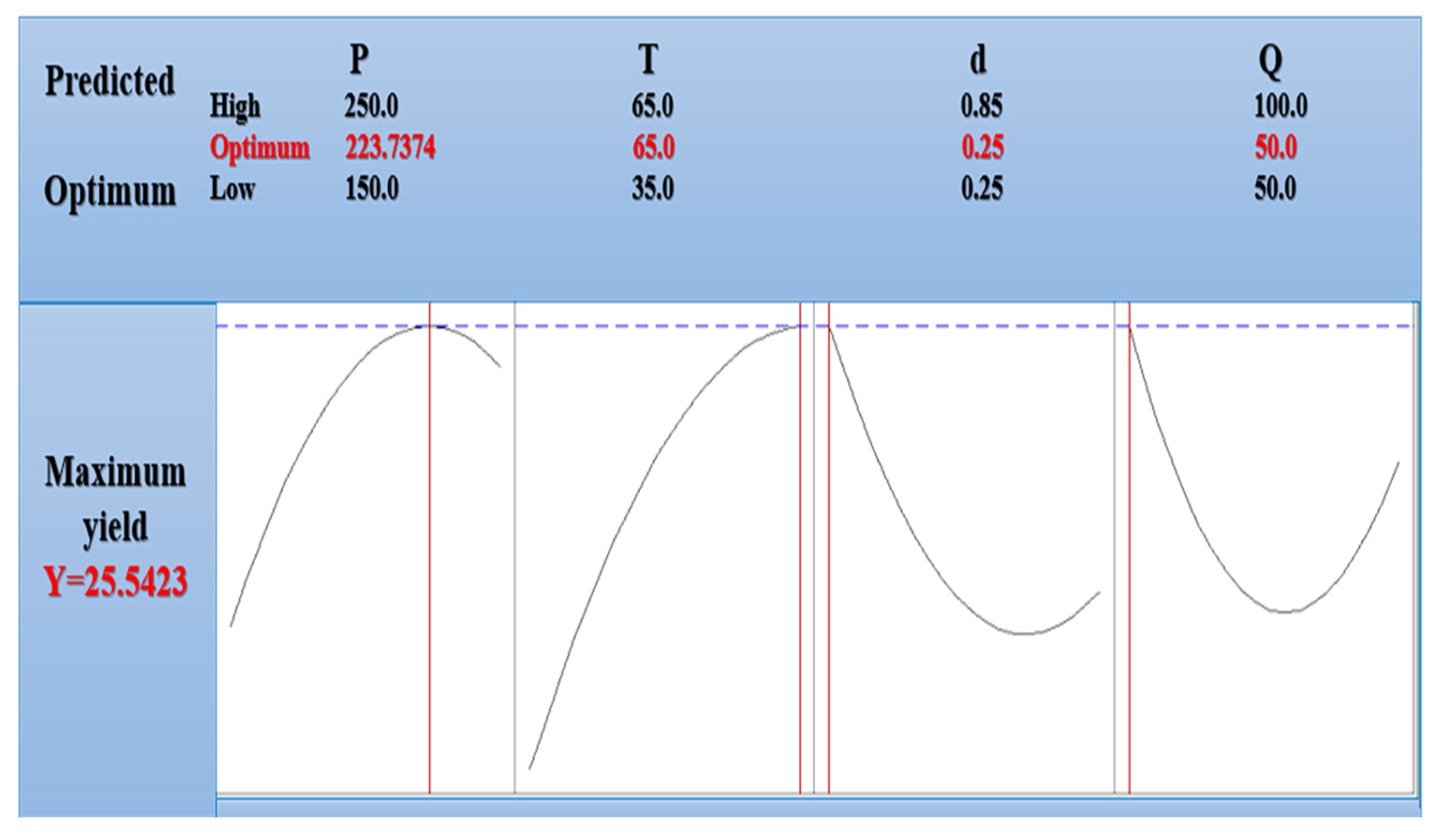

The process was optimized using the Box-Behnken method that involved a set of 27 experiments. The obtained results showed that the onion seeds oil extraction yield was influenced by the four considered key parameters: temperature, pressure, particle diameter and CO

2 flow rate. The obtained yield values ranged from 11.6 to 24.36%, indicating the significance of examining these parameters. A detailed experimental design matrix in terms of the four factors, each at three levels was generated using the BBD approach and the results are shown in

Table 3. The response (extraction yield) is expressed as second-order polynomial function of the four independent variables as follows:

Where y is the predicted response for oil extraction yield (%), , , and are the coded independent variables, T(°C), P (bar), d(mm) and Q (g/min), respectively.

ANOVA analyses showed that the determined model was weak with a coefficient of determination (R2) equal to 81.37%. The first analysis included the Fisher test, hence the comparison the F values calculated by Minitab software with an F (critical) obtained from the Fisher-Snedecor table using (p-1) and (n-p) degrees of freedom, for a pre-defined level of significance (0.05). The present model had 15 coefficients, with p-1 = 14 and n=27 experiments, resulting in n-p =12 degrees of freedom. The tabulated F value was 2.62. However, the obtained F value was higher than the tabulated one of 3.74. This confirms the reliability of the proposed model and its predictive capability.

To ensure the validity of the factors in the model, their p-values should be examined and indicate significance when less than 0.05. Upon evaluation, it was discovered that all the terms in the full quadratic model were significant except for the flowrate term, which was found to be insignificant with a p-value of 0.213. The model p-value was calculated as 0.014, while the p-values for temperature, pressure, and particle diameter were 0.024, 0.005, and 0.005, respectively [

12].

Several studies have been carried out on extracting onion seed oil through conventional methods. Results showed that cold-pressed onion seed oil had a higher yield of 21.1% compared to Soxhlet extraction with 13.5% only [

2]. However, at the considered conditions a significantly higher yield of up to 24.36%., could be achieved. This confirmed the ability of the BBD model in selecting the appropriate range for each parameter.

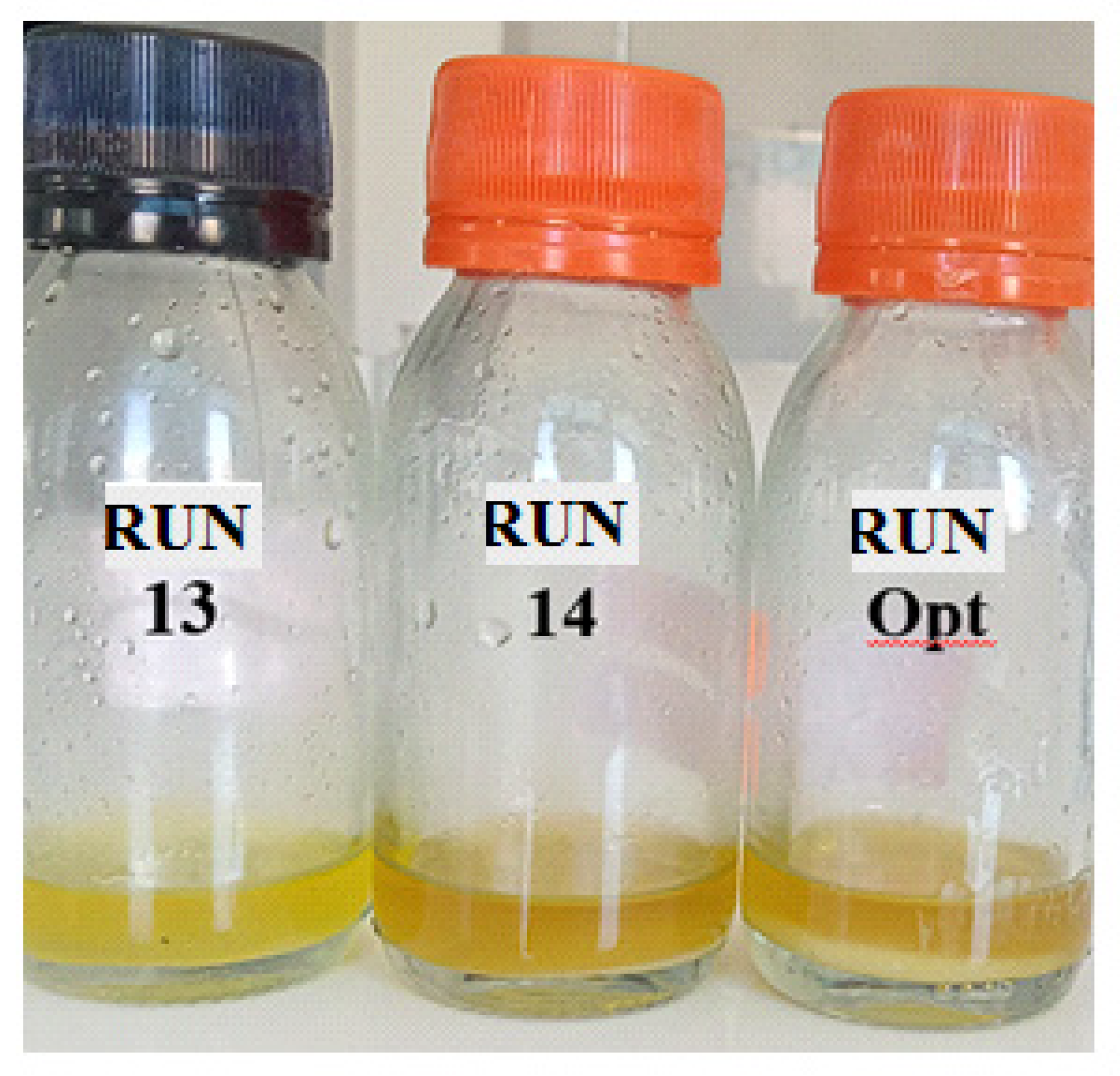

Generally the composition of extracts obtained through supercritical CO

2 extraction is influenced by various factors, such as the plant species and the adopted operating conditions like temperature, pressure, seed size and CO

2 flowrate, for the present study. This influence can be seen through the obtained extract properties like their nature, color, viscosity, density, etc. This is confirmed by the three samples of onion seeds oil extracts where the differences can easily be seen.

Figure 1.

Different extracts of onion seeds by supercritical CO2 extraction according to the operating parameters.

Figure 1.

Different extracts of onion seeds by supercritical CO2 extraction according to the operating parameters.

3.2. The influence of the four selected parameters on the oil yield of onion seeds

The solid matrix consisting of onion seeds underwent a mass transfer in contact with the supercritical fluid in the extractor. This transfer occurred through molecular diffusion due to concentration gradients.

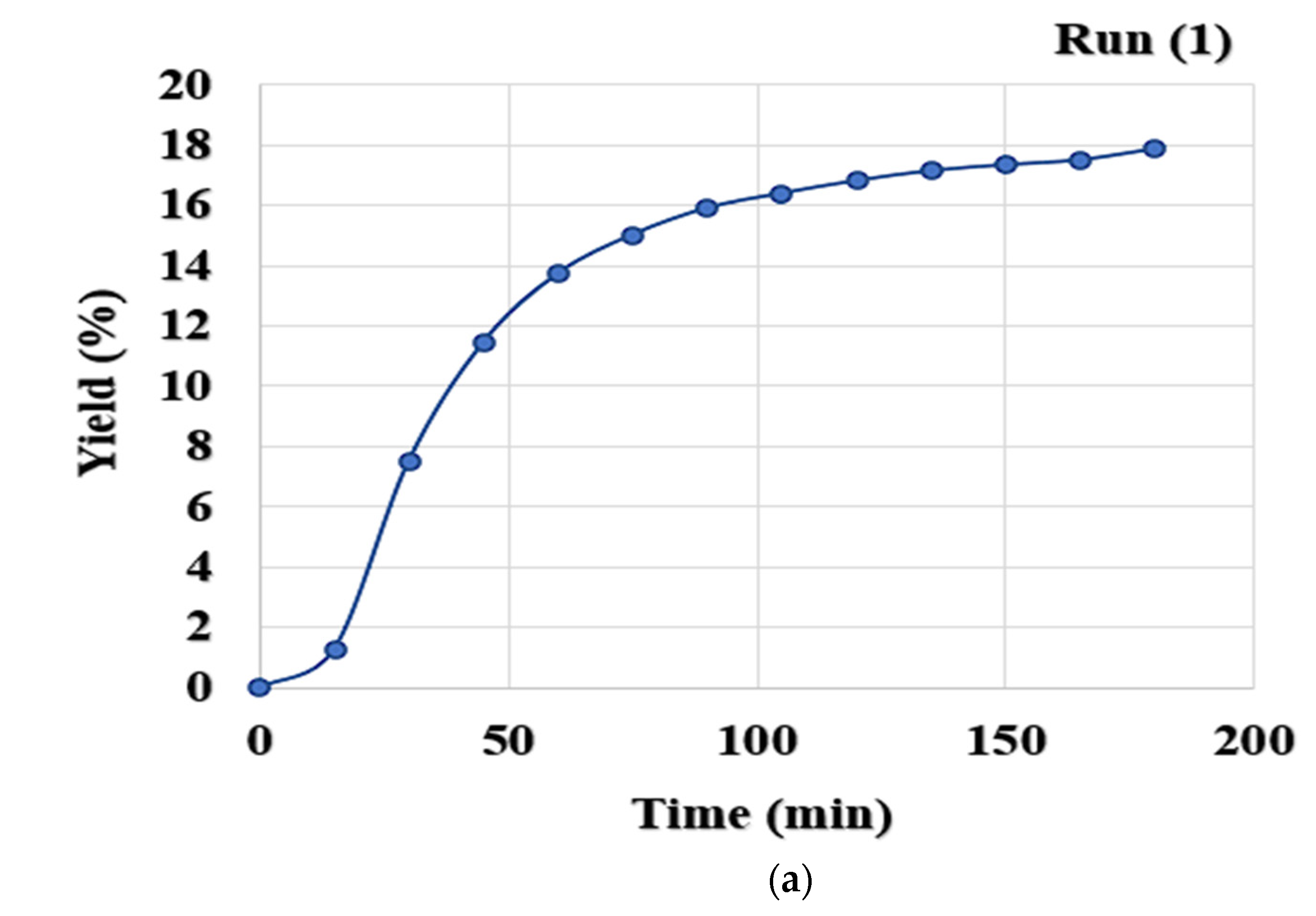

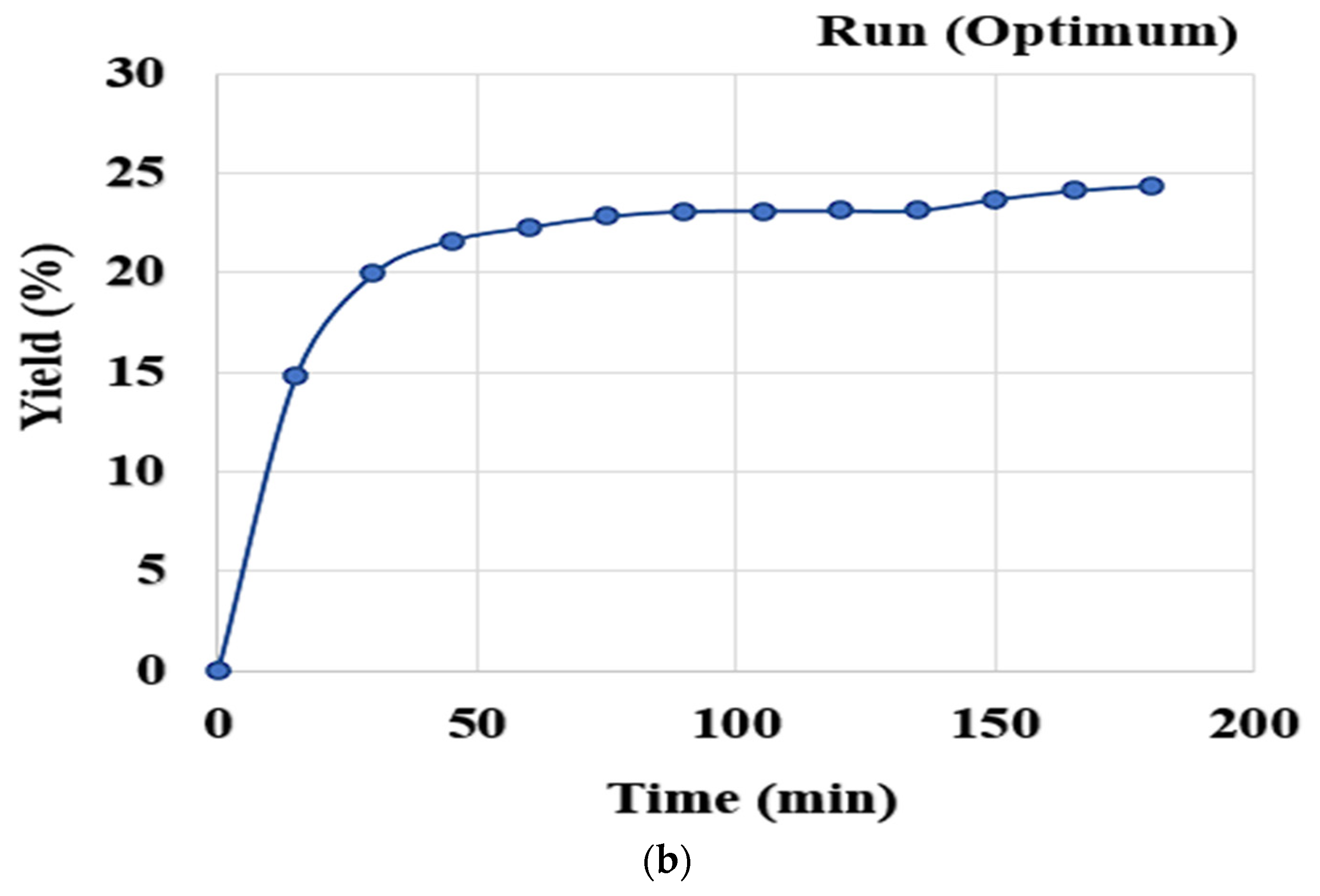

Figure 2 shows the oil extraction yield variations with time at given and optimal operating conditions.

The performance of any supercritical fluid extraction process depends upon the operating parameters mainly temperature, pressure, particle size and solvent flowrate. The present study is mainly concerned by two performance criteria: the oil extraction yield and the composition. Therefore it is important to investigate the effect of each parameter on these two criteria and determine operating ranges corresponding to high yield and quality of extracts via the composition.

3.2.1. The effect of pressure on the extraction yield

The effect of pressure on oil extraction yield was considered leading to the observation of various findings. First, at a low temperature of 35 °C, increasing the pressure from 150 to 250 bar, respectively, resulted in a nearly constant yield of 17.876-18.047%, corresponding to experimental Runs 1 and 3. However, at a higher temperature of 65 °C, increasing pressure from 150 to 250 bar in experimental runs 2 and 4, respectively, resulted in a yield increase from 11.604% to 18.253%.

Second, in experimental Runs 13 and 14 at a temperature of 50°C, a pressure increase from 150 to 250 bar, respectively led to a remarkable increase in oil extraction yield from 19.854% to 24.350% while maintaining a flow rate of 75 g/min and a pressure of 0.25 mm.

Clearly this result shows the great dependency of the solvent power of supercritical CO2 on its density which increases with pressure at constant temperature.

3.2.2. The effect of temperature on the extraction yield

At fixed parameters at [150 bar, 0.55 mm, 75 g/min] for experimental Runs 1 and 2, it was observed that an increase in temperature from 35 to 65°C led to a decrease in the oil extraction yield from 17.876 to 11.604%, respectively. Similar results were obtained for experimental Runs 17 and 18 at fixed operating conditions of [200 bar, 0.25 mm, 75 g/min] and for experimental Runs 19 and 20 under the conditions of [200 bar, 0.85 mm, 75 g/min], indicating that an increase in temperature had negatively affected the extracted oil mass at pressures of 150 and 200 bar.

Contrary to the previous case, when the pressure increased to 250 bar (experimental Runs 3 and 4 at operating conditions of [250 bar, 0.55 mm, 75 g/min]), the increase of temperature from 35 to 65°C had no adverse impact on the yield with just a slight yield increase of 0.206%. This indicates that temperature did not affect the oil extracting yield at a the fixed pressure of 250 bar along with other fixed parameters, similarly to the reported supercritical CO

2 extraction of Syzygium aromaticum [

13].

The impact of temperature on extraction effectiveness relies on the extraction pressure, with a negative effect seen at low pressure. This suggests that the density of CO

2 takes precedence over the vapor pressure of the solute. Conversely, at higher pressure, this phenomenon is reversed. Thus, predicting the influence of temperature on the solubility of a substance in a supercritical fluid is more challenging than that of pressure. However, the relationship between temperature and extraction yield is not always simple, and an optimal temperature range may exist before yield drops at higher temperatures. This is due to possible degradation or denaturation of the targeted compound or induced changes to the solvent or solid matrix properties, which can reduce the extraction yield [

14].

Finally from the obtained results it can be confirmed that: the solvent power of supercritical CO

2 depends mainly on its density which increases with pressure at constant temperature conditions and decreases with temperature at constant pressure conditions. Similar behavior was also observed by Frohlich et al. for the supercritical CO

2 extraction of Syzygium aromaticum [

13].

3.2.3. Effect of diameter on the extraction yield

For experimental Runs 5 and 6 the considered conditions were [50°C, 200 bar, 50 g/min] with two particle diameters of 0.25 and 0.85 mm. A decrease in the oil extraction yields from 24.32 to 21.20% for 0.25 and 0.85 mm diameter values, respectively, was observed. This is simply explained by the greater mass transfer area for the smaller diameter. This was also observed for other experimental Runs like, 7, 8, 13, 14, 15 and 16. Therefore the size of particles can be regarded as a key factor that can greatly influence the supercritical fluid extraction yield and the smaller are the particle sizes the higher is the mass transfer area, hence an increase of the diffusion rate and a decrease in the diffusion path, resulting in a better extraction [

15].

3.2.4. The effect of flowrate on extraction yield

The oil extraction yield can be affected by the flowrate of CO2 passing through the solid matrix. An increase in fluid flowrate can reduce resistance to mass transfer and the fluid may be saturated when leaving the solid matrix. This leads to a solute solubility equilibrium, hence a maximum yield.

In terms of the seed morphology, raising the flowrate did not lead to an increase in yield, except for experimental experimental Runs 9 and 10, carried out under identical conditions of [35°C, 200 bar, 0.55 mm] but with different solvent flowrates. A yield increase from 22.017 to 23.161% was observed with an increase in flowrate, confirming the results reported in previous works [15, 16].

The change in CO

2 flowrate induced noticeable changes in the viscosity and the color of the extracts. Therefore iIn terms of the overall interpretation of the experimental design and identification of the effects of each parameter, qualitative analyses were needed to confirm its impact on oil composition, as shown in

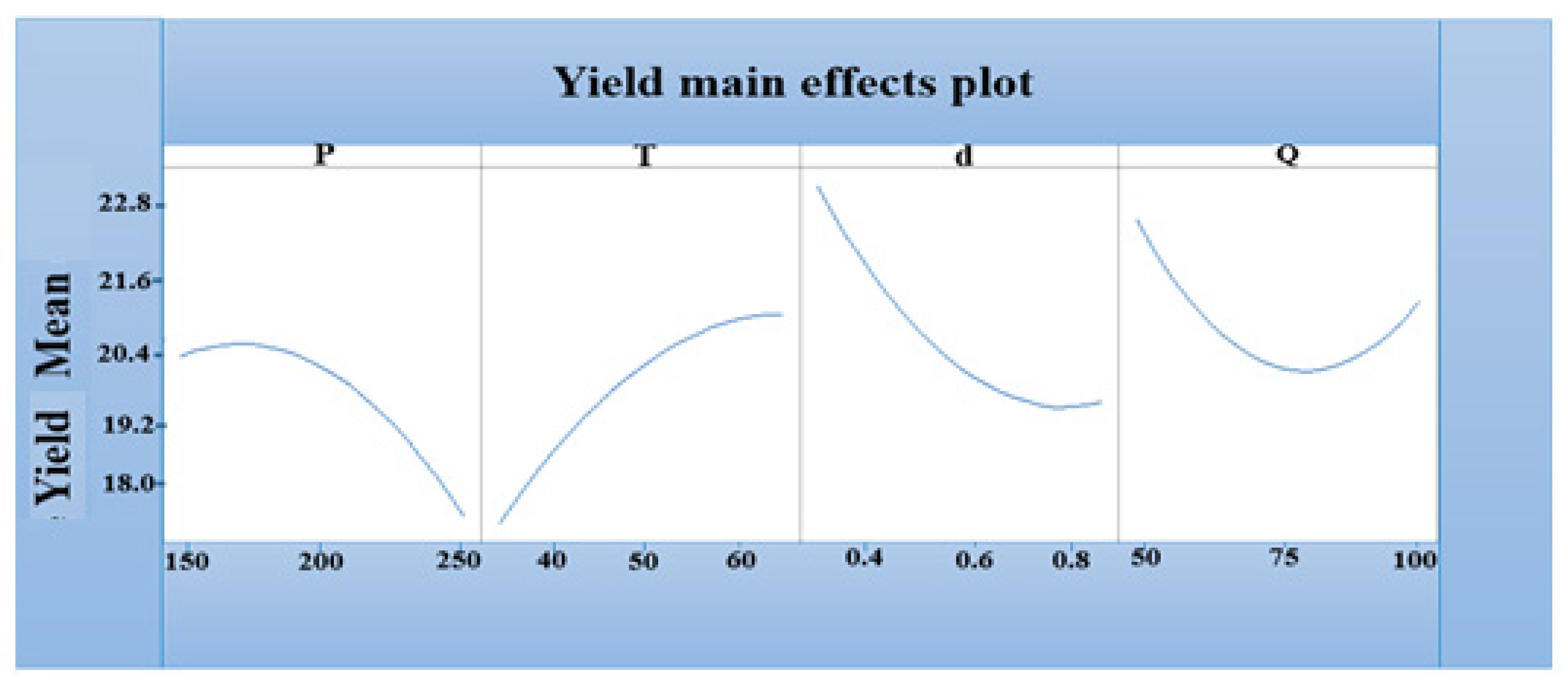

Figure 3. In terms of the effect on the extraction process,

Figure 4 demonstrates that the yield increased with a decrease in temperature from 65 to 35°C, an increase in pressure from 150 to 250 bar, a decrease in diameter from 0.85 to 0.25 mm and an increase/decrease in flowrate from 75 to 100 g/min and 75 to 50 g/min, respectively. The lowest yield was observed at a flow rate of 75 g/min, while the highest ones were achieved at 50 and 100 g/min.

Furthermore, the accuracy of this interpretation can be checked through the requirements derived for conducting the most efficient experiment, easing the retrieval of the highest possible yield.

3.3. Qualitative and quantitative analyses

Gas chromatography-mass spectrometry (GC-MS) is a powerful analytical technique that combines two separate methods, gas chromatography and mass spectrometry, to efficiently separate and identify qualitatively and quantitatively complex chemical compound mixtures. [

17].

This method has found widespread applications in the pharmaceutical industry for various purposes, including analytical research and development, quality control, quality insurance, production, bulk drugs, and formulations.[

18].

The separation of compounds according to their physical and chemical characteristics is demonstrated in the chromatogram, whereas the molecular weight and structure of the compounds are revealed through information provided by the mass spectrum[

19,

20].

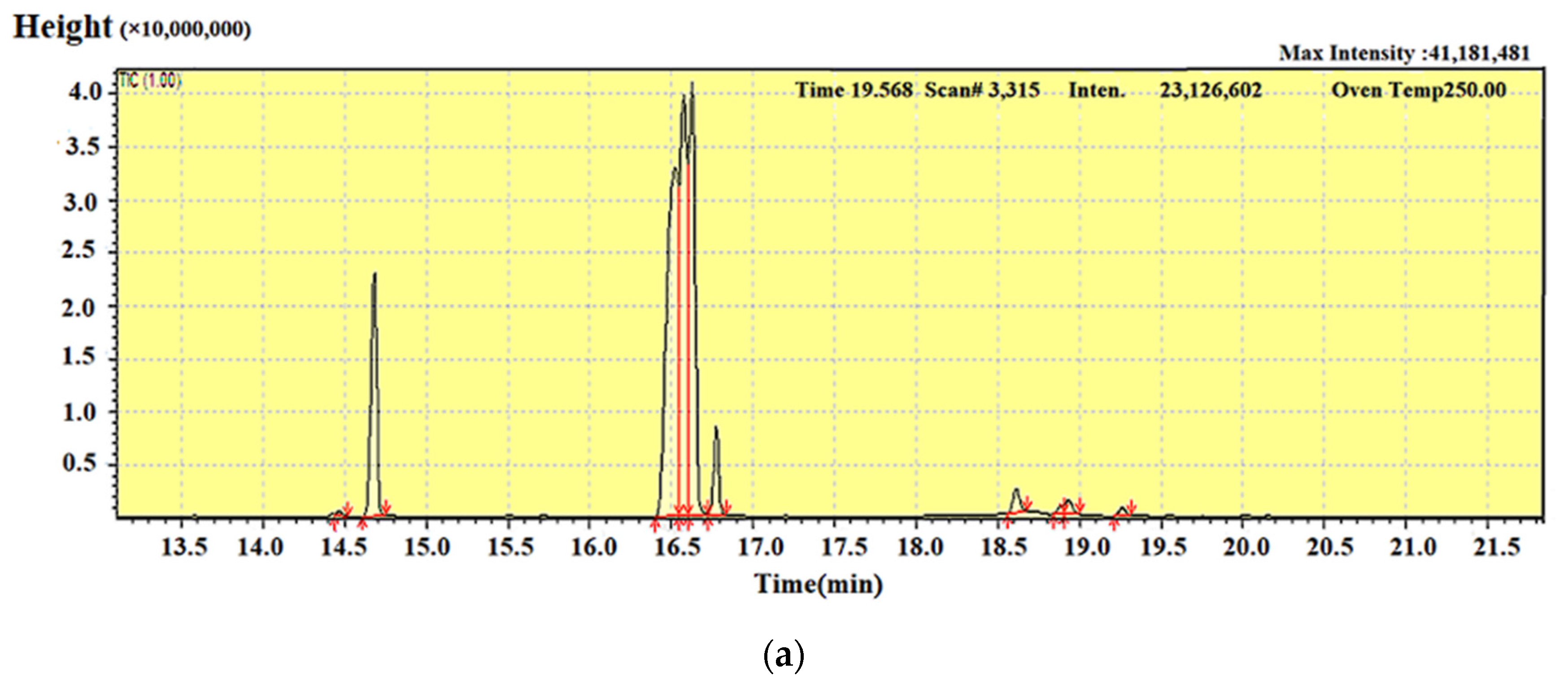

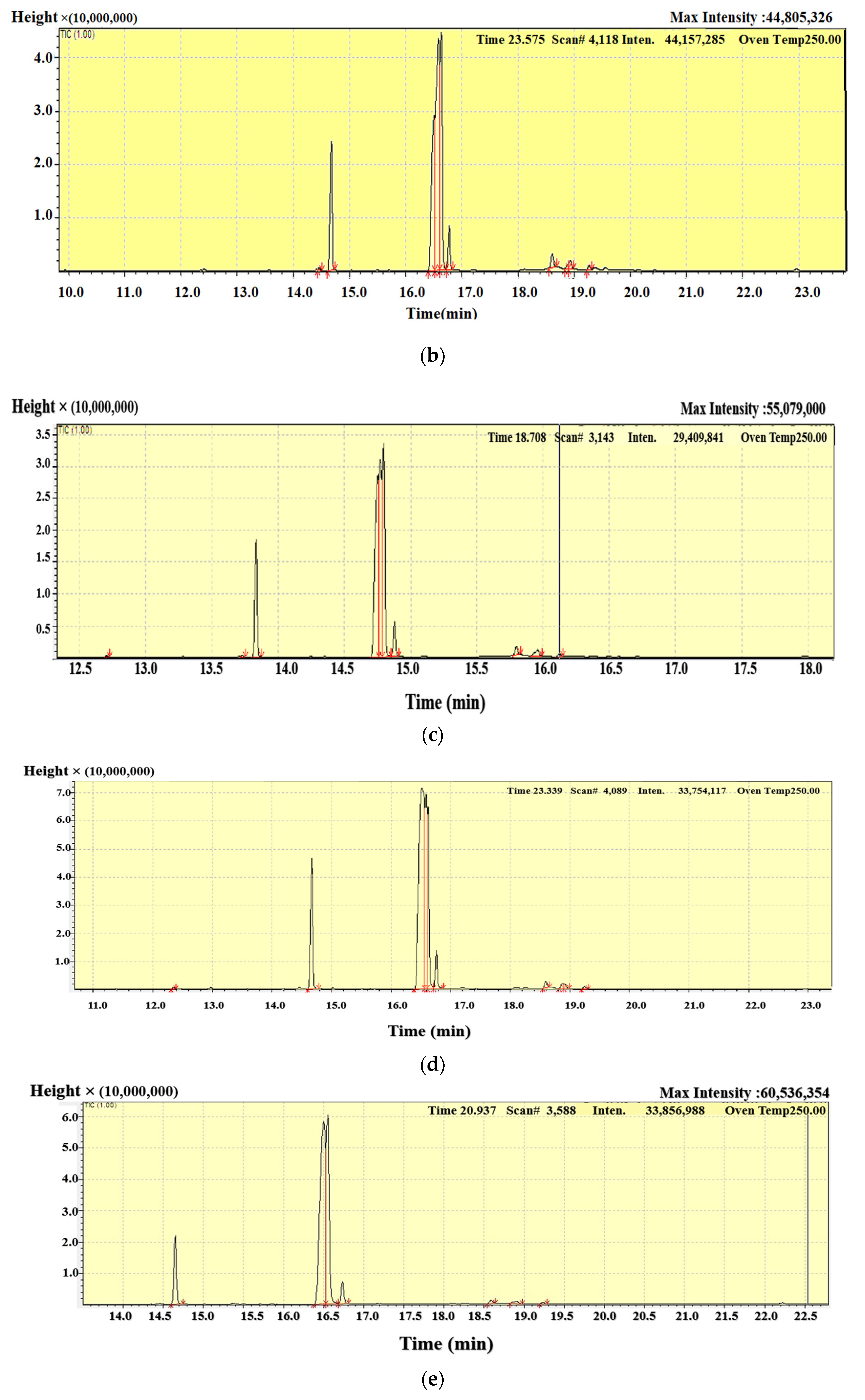

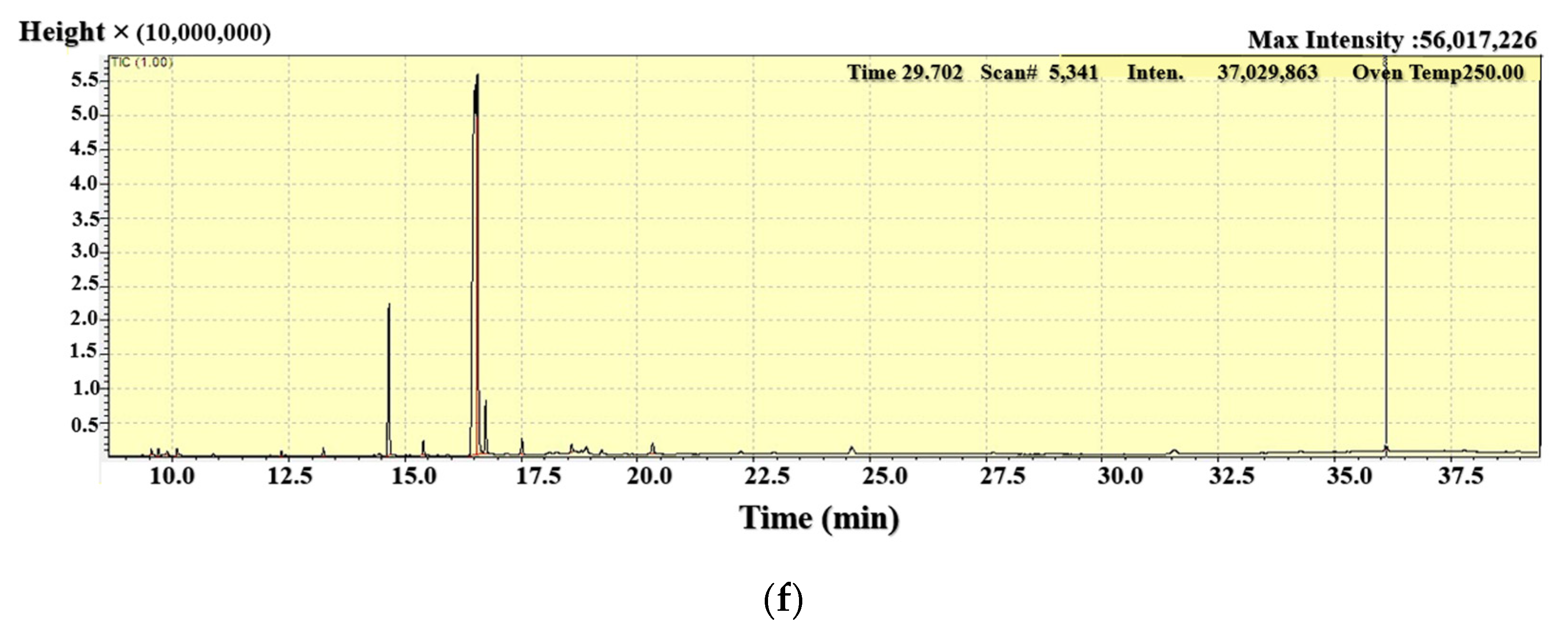

To obtain significant insights from the data, one must carefully interpret the intricate set of information resulting from GCMS analysis. In order to begin the process of interpreting the results, it is important to first comprehend the chromatogram. Chromatograms concerning extracts obtained in different experimental runs are shown in

Figure 5a- f. These are used to find the respective compositions of each extract and where the observed peaks in the chromatogram represent individual compounds detected in the sample.

Then the pattern of mass fragmentation of the detected elutants molecule ions, as illustrated in the above figures, can be observed in the spectra. To achieve this, one can compare the retention times which depict sequential peaks of separated analyte components at different times, and the mass spectra of unknown compounds with those of known compounds in a reference library or database [

17].

Table 4 shows the analyses results concerning three distinct samples extracted at different operating conditions. In total ten major components were identified.

Based on the GCMS analysis results, it has been discovered that among the 10 components obtained, the following four primary components were present in significant percentages in all extracts obtained under varying conditions:

9,12-Octadecadienoic acid ,methyl ester.

9,12-Octadecadienoic acid (Z,Z)-, methyl ester.

9-Octadecadienoic acid (Z)-, methyl ester.

Hexadecanoic acid, methyl ester.

By changing the pressure applied during the extraction process, both chemical and physical characteristics of the oil could be modified. For instance, when the pressure was raised from 150 to 250 bar, the primary compounds remained present at both pressures, but at different percentages. For example, 9, 12-Octadecadienoic acid, methyl ester was present at 24.78% at 150 bar, but increased to 37.98% at 250 bar. This was also valid for the compositions of the secondary compounds.

By increasing the flow rate from 50 to 75 g/min, the quality of the extract was impacted. This was evident from the increase in the mass percentage of compound 9-octadecadienoic acid (Z)-, methyl ester from 3.62 to 21.37%. Therefore CO2 flow rate had a more significant impact on the quality of the extract than the on the quantity.

Fatty acids are critical molecules of essential components for the human body. They not only do serve as a primary source of energy, but they also have crucial roles in the building and operation of cell membranes, and in the production of hormones and other signal molecules. Saturated fats are typically solid at room temperature and commonly found in animal-based products whereas unsaturated fatty acids are usually as liquid at room temperature and are present in plant-based foods like nuts, seeds, and vegetable oils. They are widely acknowledged to be more beneficial for health than saturated fats, as studies have linked them with a reduced risk of heart disease and other chronic conditions. According to the result obtained in the present study, it is important to note that the onion seed extracts contain a remarkably high proportion of these unsaturated fatty acids. Knowing that 9, 12-Octadecadienoic acid (Z, Z), also known as Omega 6, is considered to be the most significant among the various fatty acids due to its numerous biological functions which induce its impact on the inflammatory cascade, its ability to reduce oxidative stress, as well as its role in providing neuro and cardio-vascular protections.

4. Conclusion

The present study had clearly shown that many natural plants, vegetables, fruits, etc. may be great sources of valuable substances with important applications in sensitive fields like pharmaceutical, cosmetic and food industries. This is the major stimulating factor to carry out the exploration, identification and test of these natural species. However in order to obtain the valuable substances from these natural sources, performing fluid based extraction techniques are required. One of these non conventional techniques is the supercritical fluid extraction which was used in the present work to extract oil from onion seed with important yields and composition.

The results did put into evidence one of the important features of the supercritical fluid extraction consisting of manipulating the operating parameters in order to achieve extracts with a high purity and a targeted composition, confirming the merit of fluids at supercritical state.

The effectiveness of this method was conditioned by several parameters, including temperature, pressure, particle size, and CO2 flow rate. Although the CO2 flow rate did not have a significant impact on the oil yield of onion seeds, it had a notable influence on the oil composition. Using the most commonly used analytical method to identify essential components in our extract, it was found that onion seeds contain a significant proportion of fatty acids, which are important constituents of the human body and play a crucial role in maintaining health and well-being.