Submitted:

20 July 2023

Posted:

21 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature review

2.1. Foreign object detection methods based on image processing

2.2. Foreign object detection method based on deep learning

2.3. Discussion

3. The proposed foreign object detection method

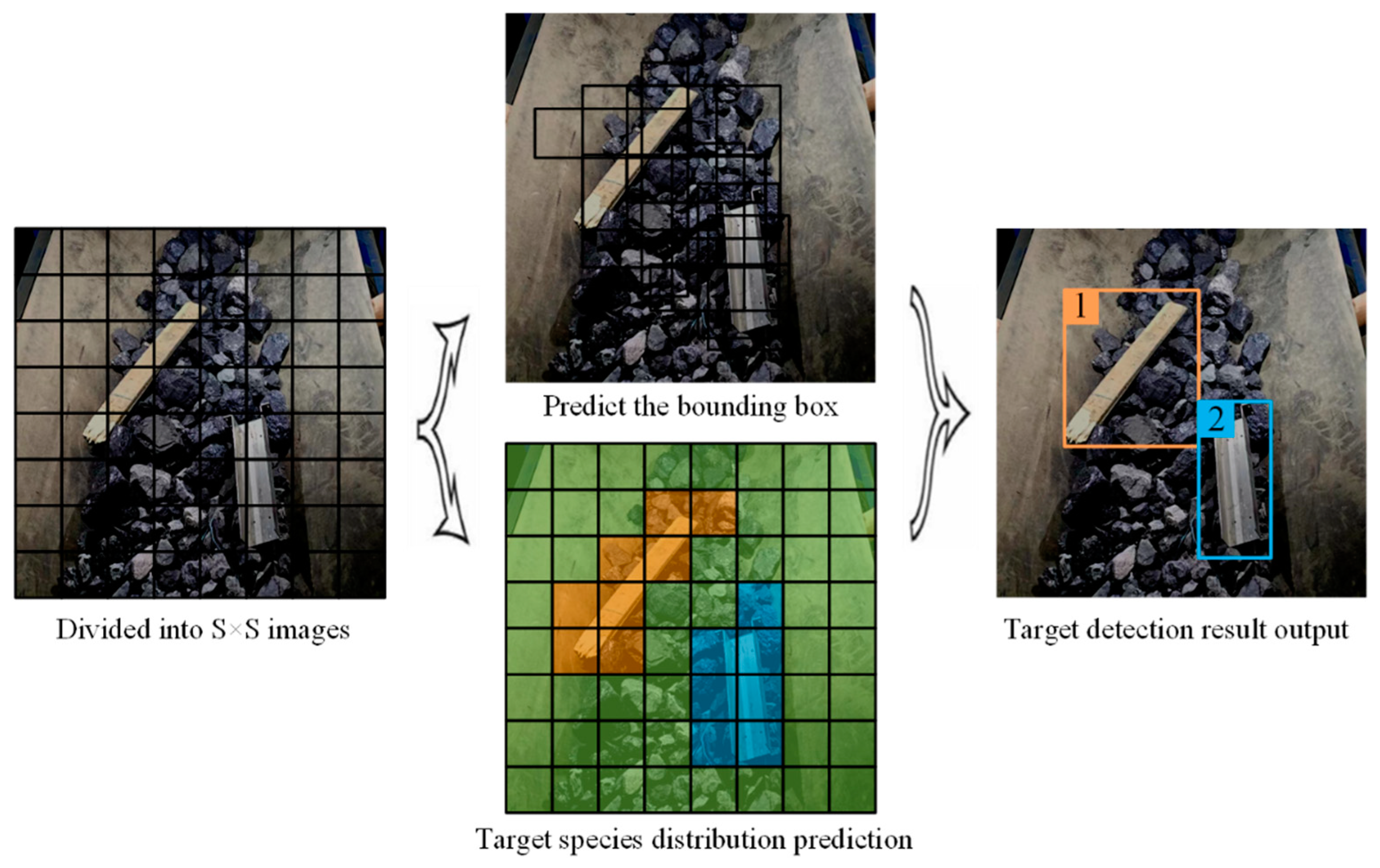

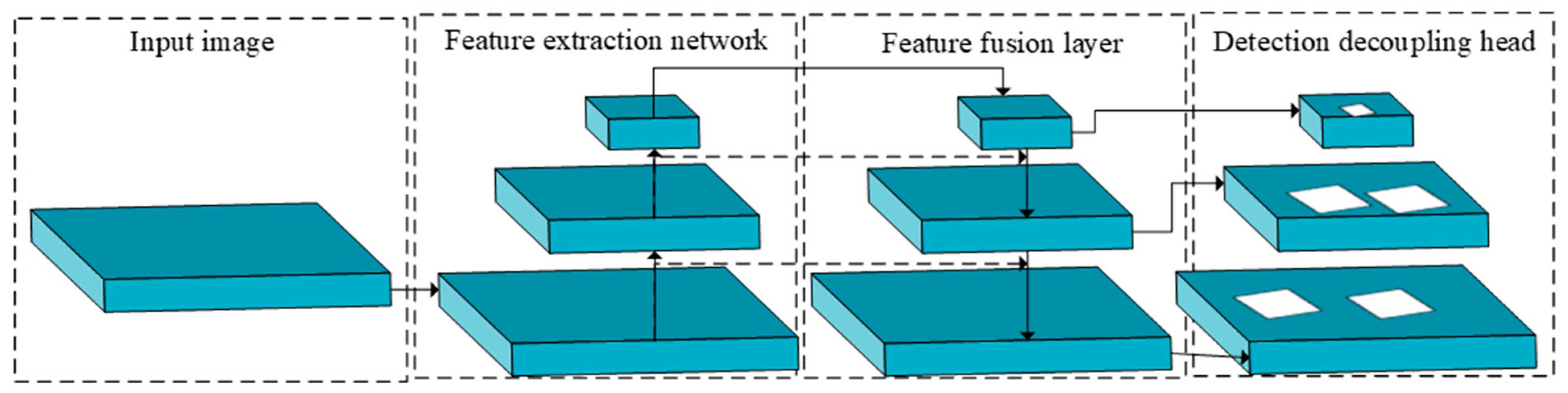

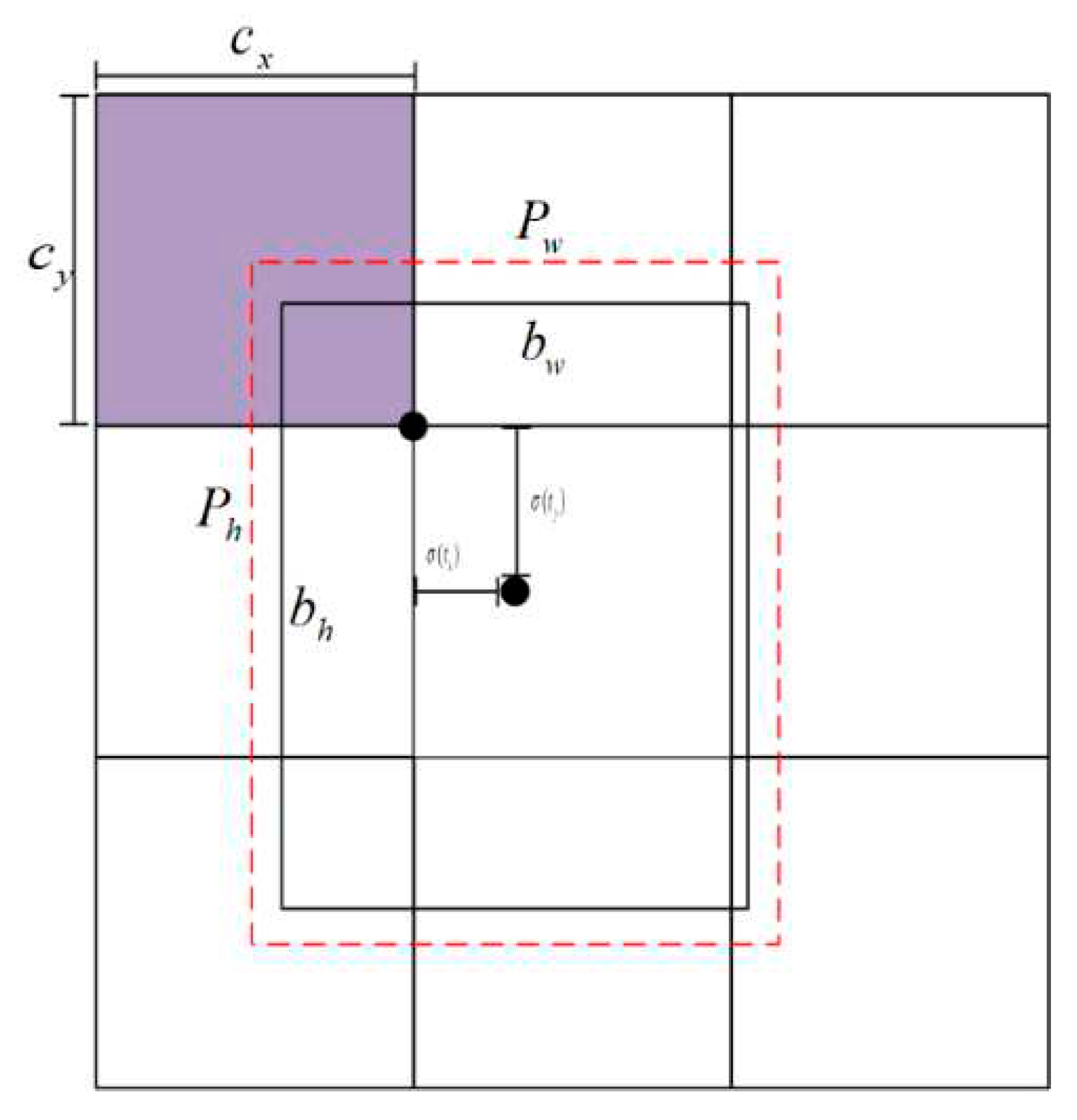

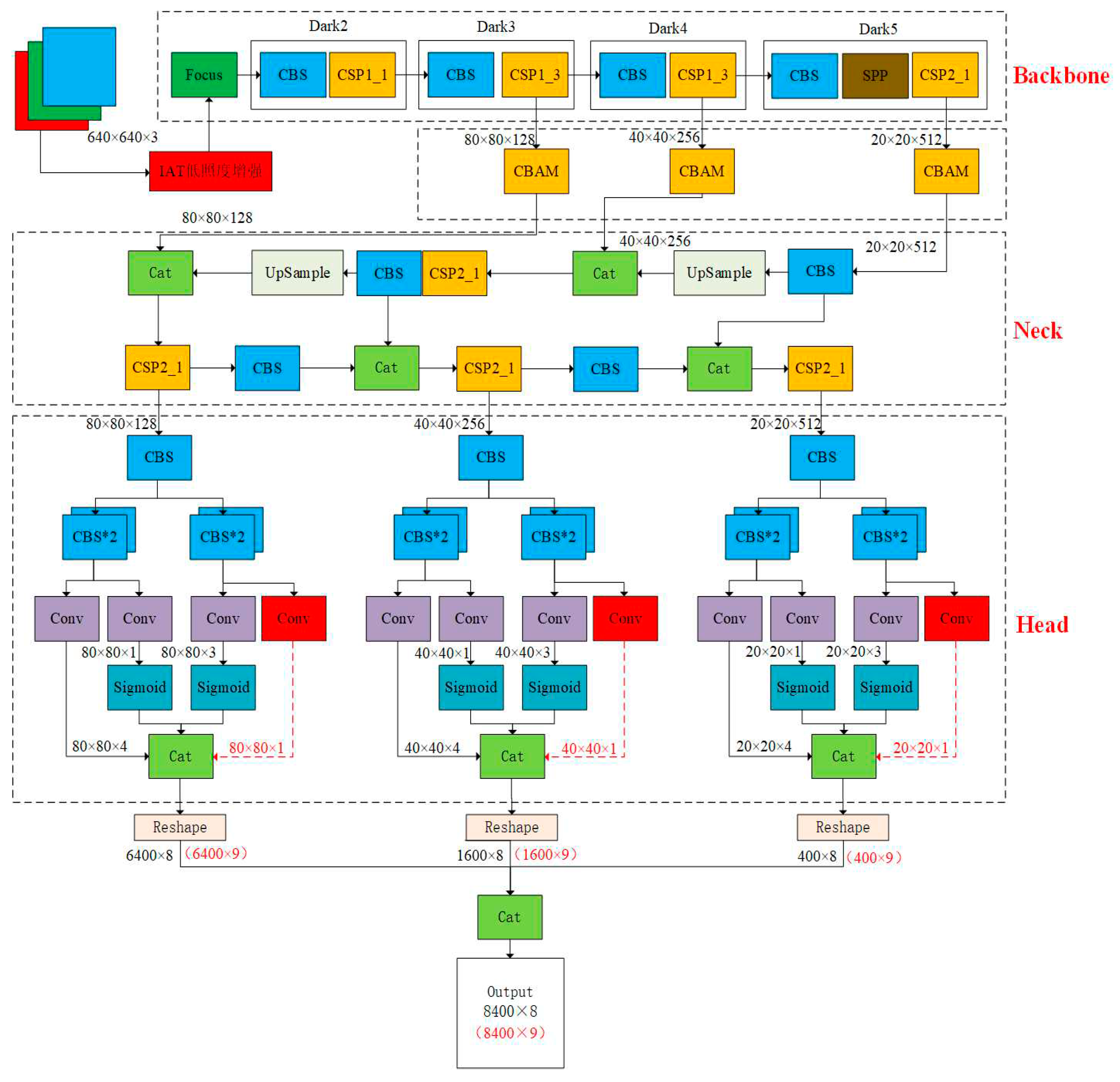

3.1. Target detection of YOLO model

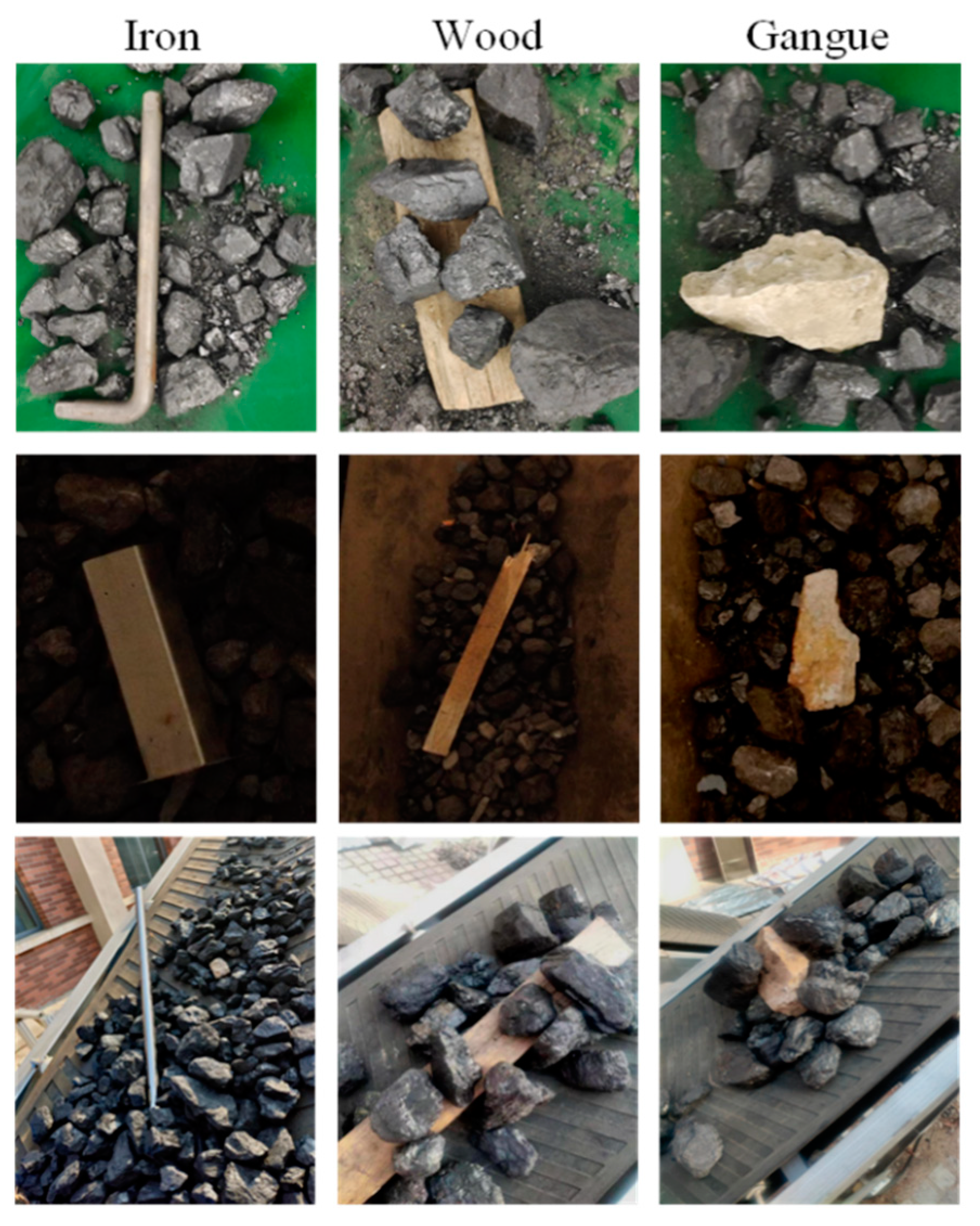

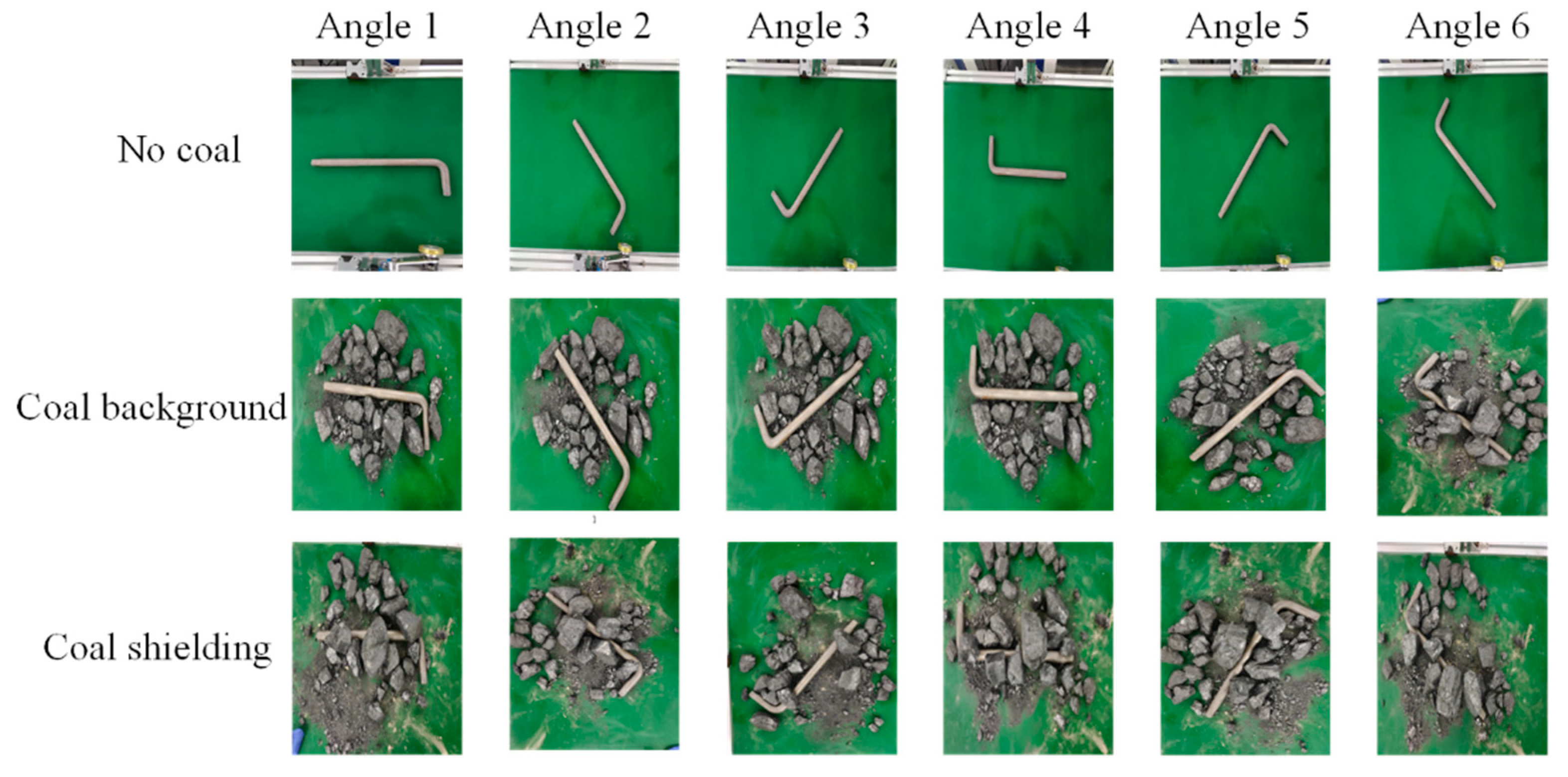

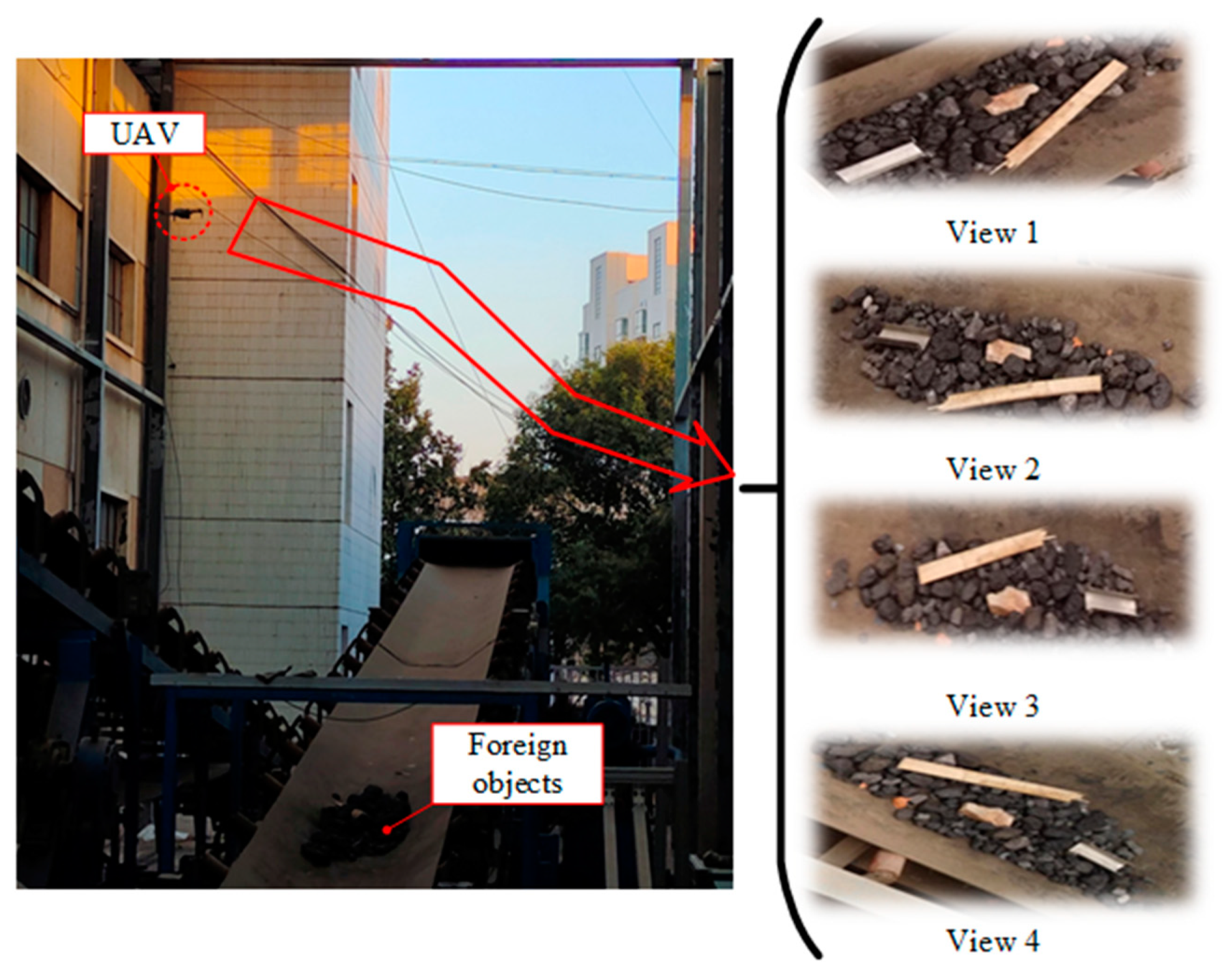

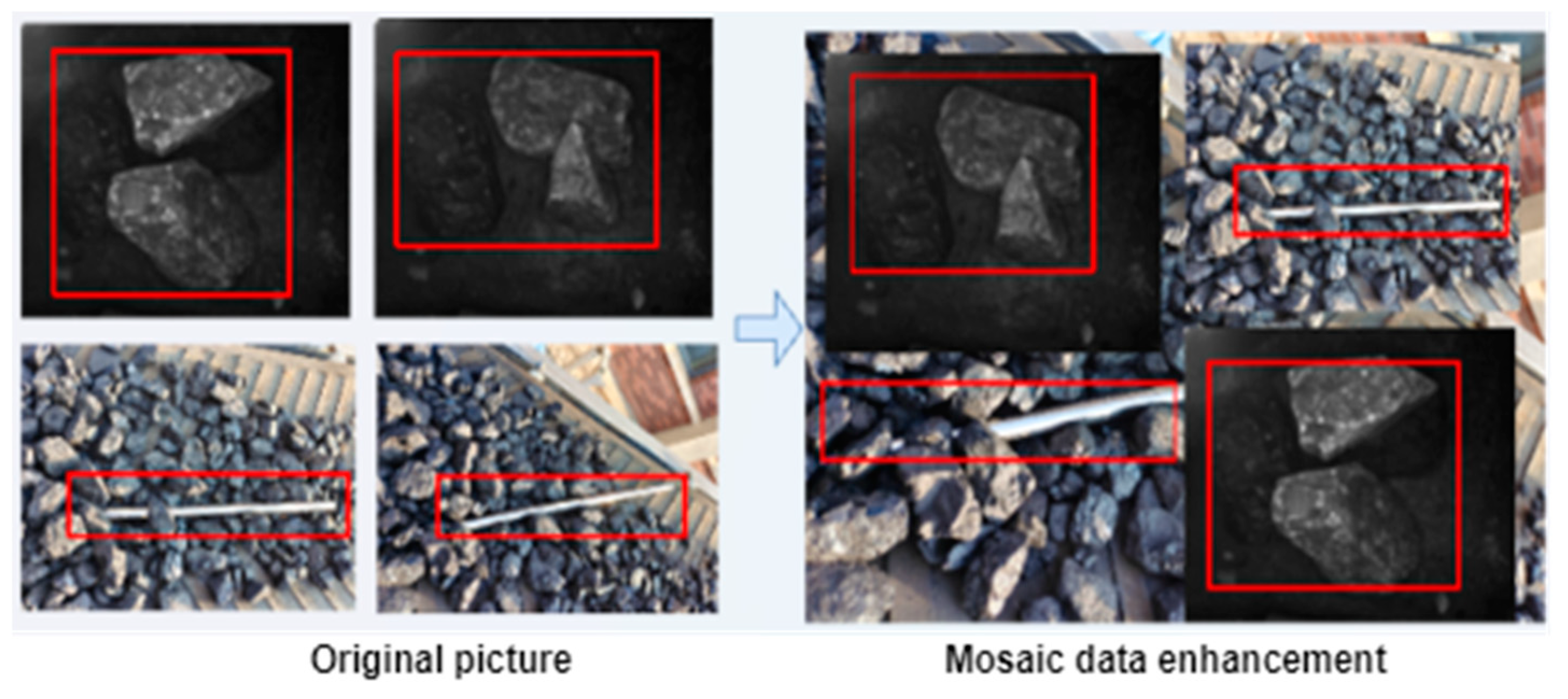

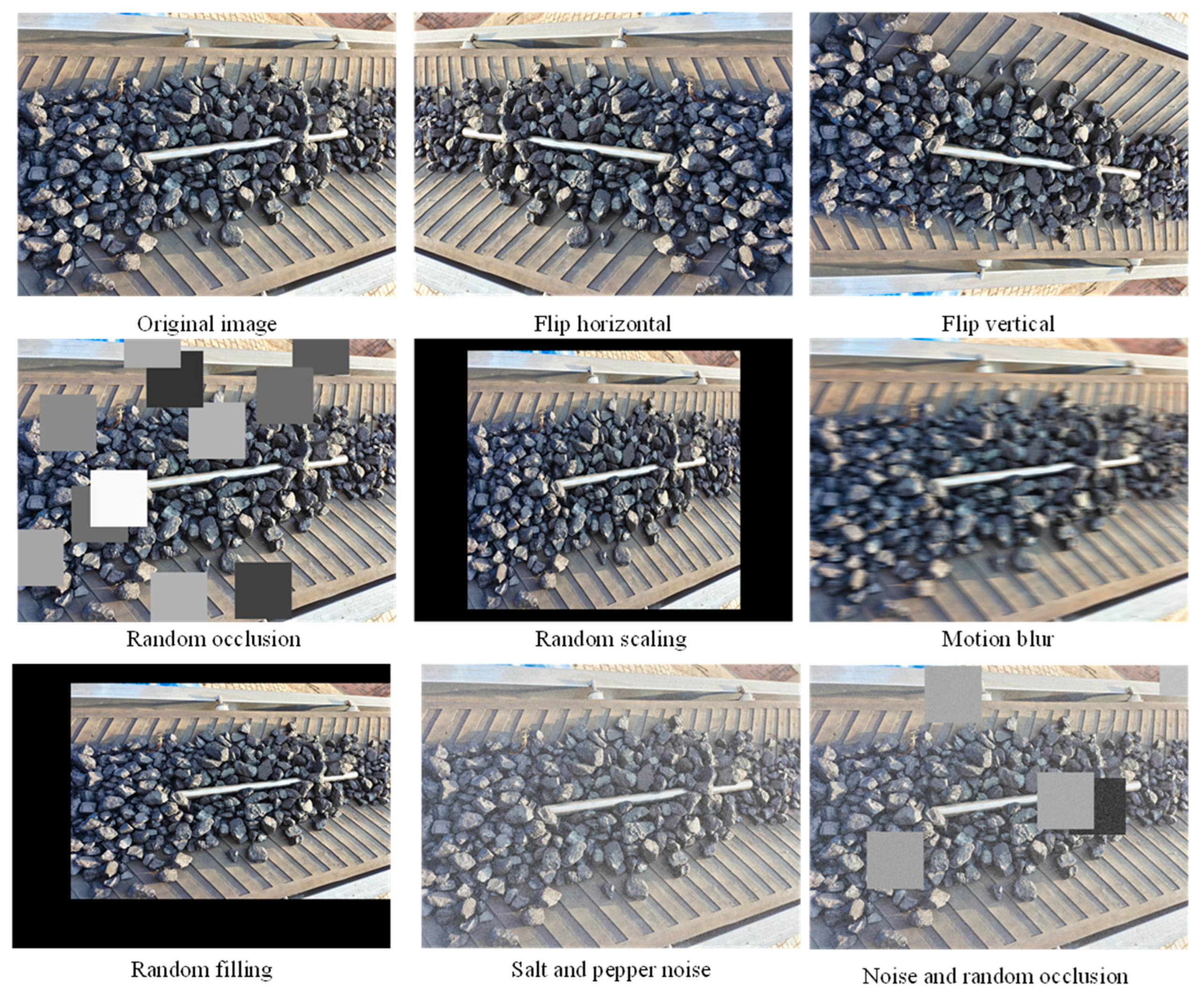

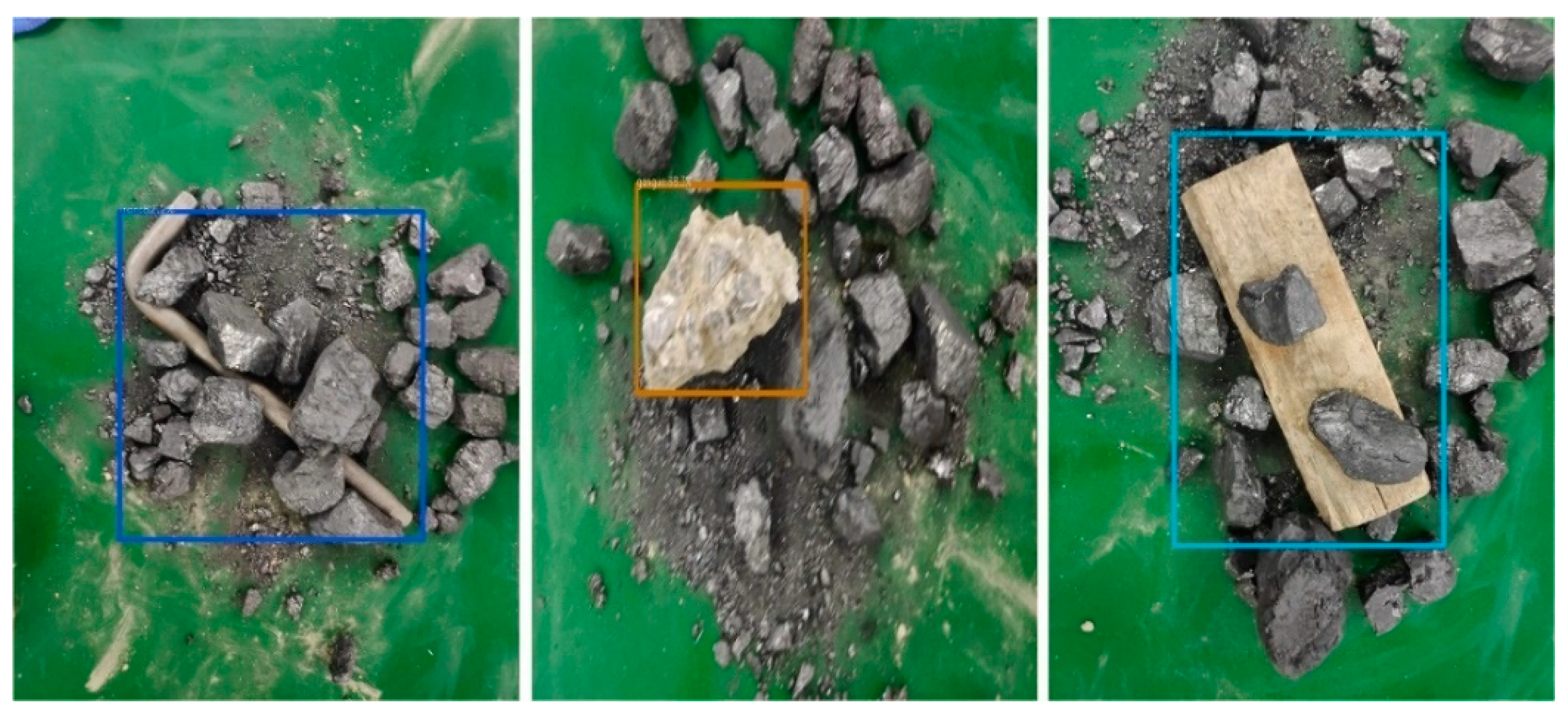

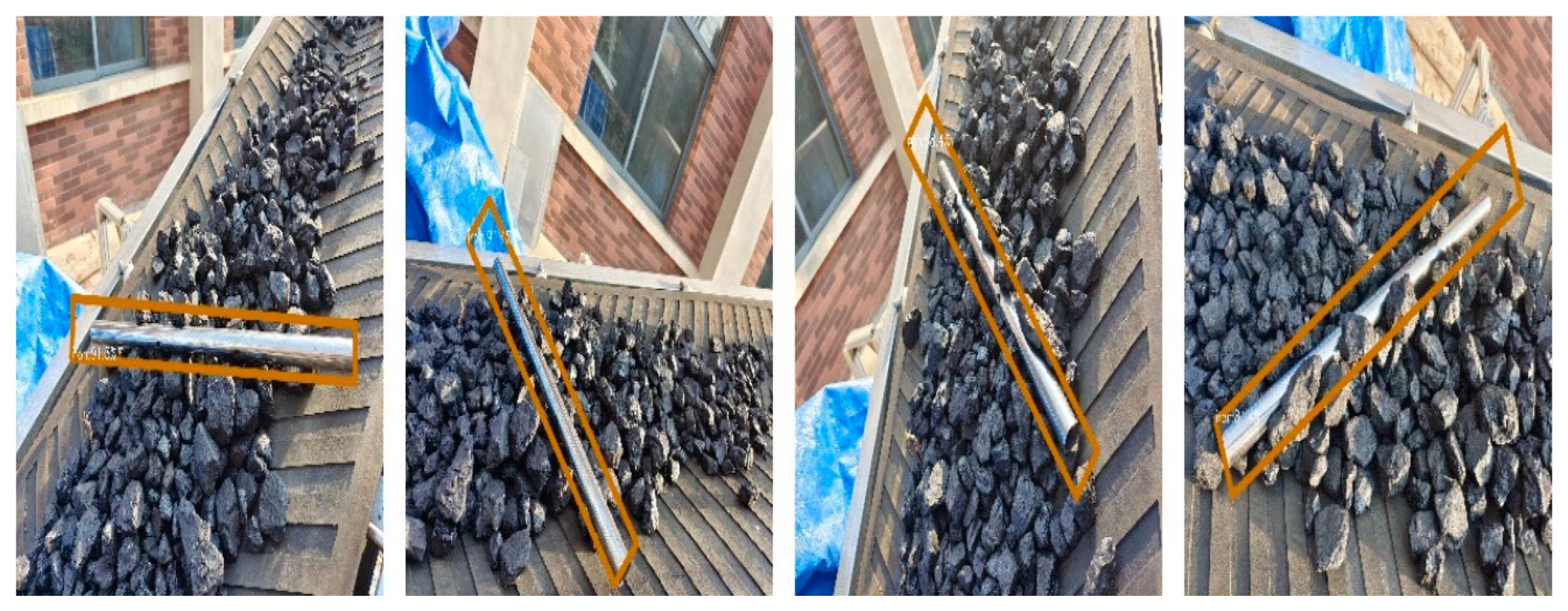

3.2. Established foreign object image dataset

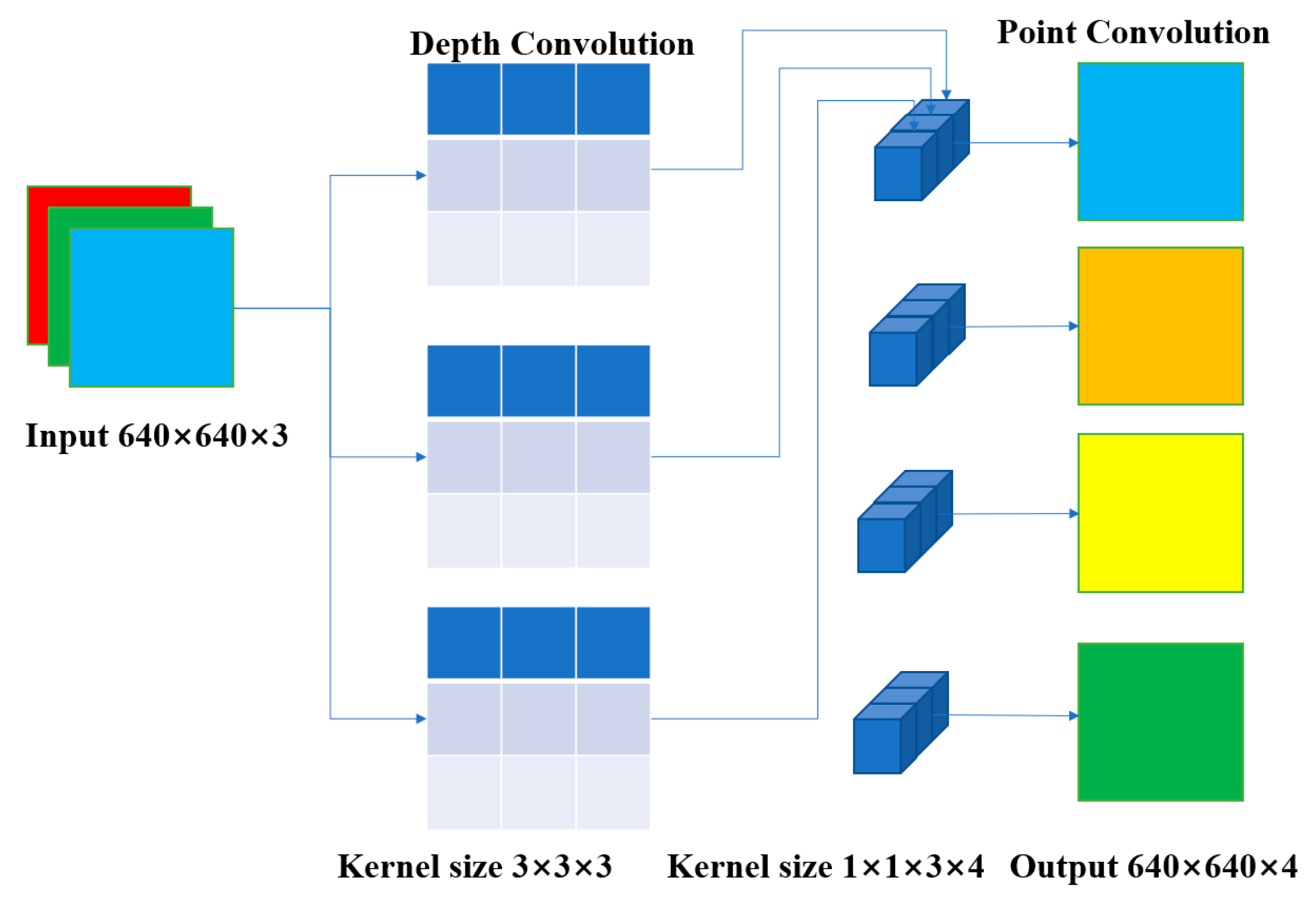

3.3. Improved depthwise separable convolution block

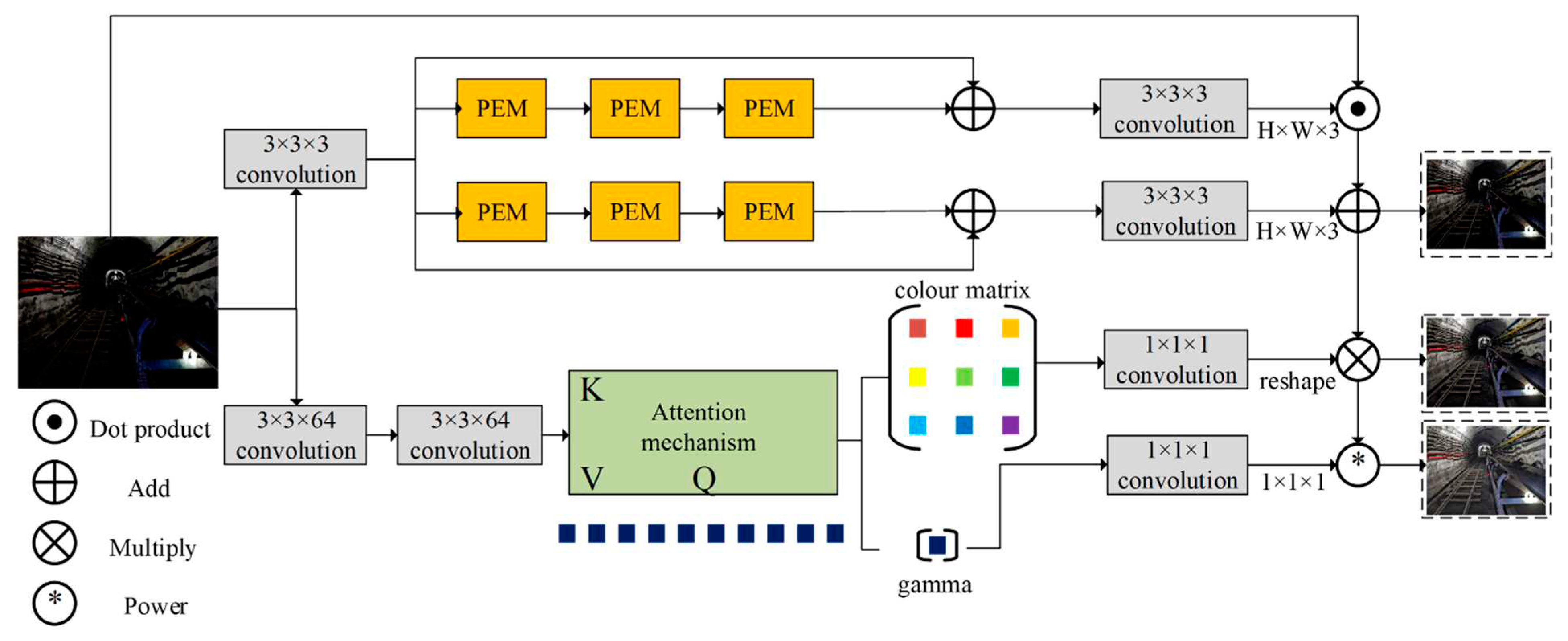

3.4. IAT image enhancement module

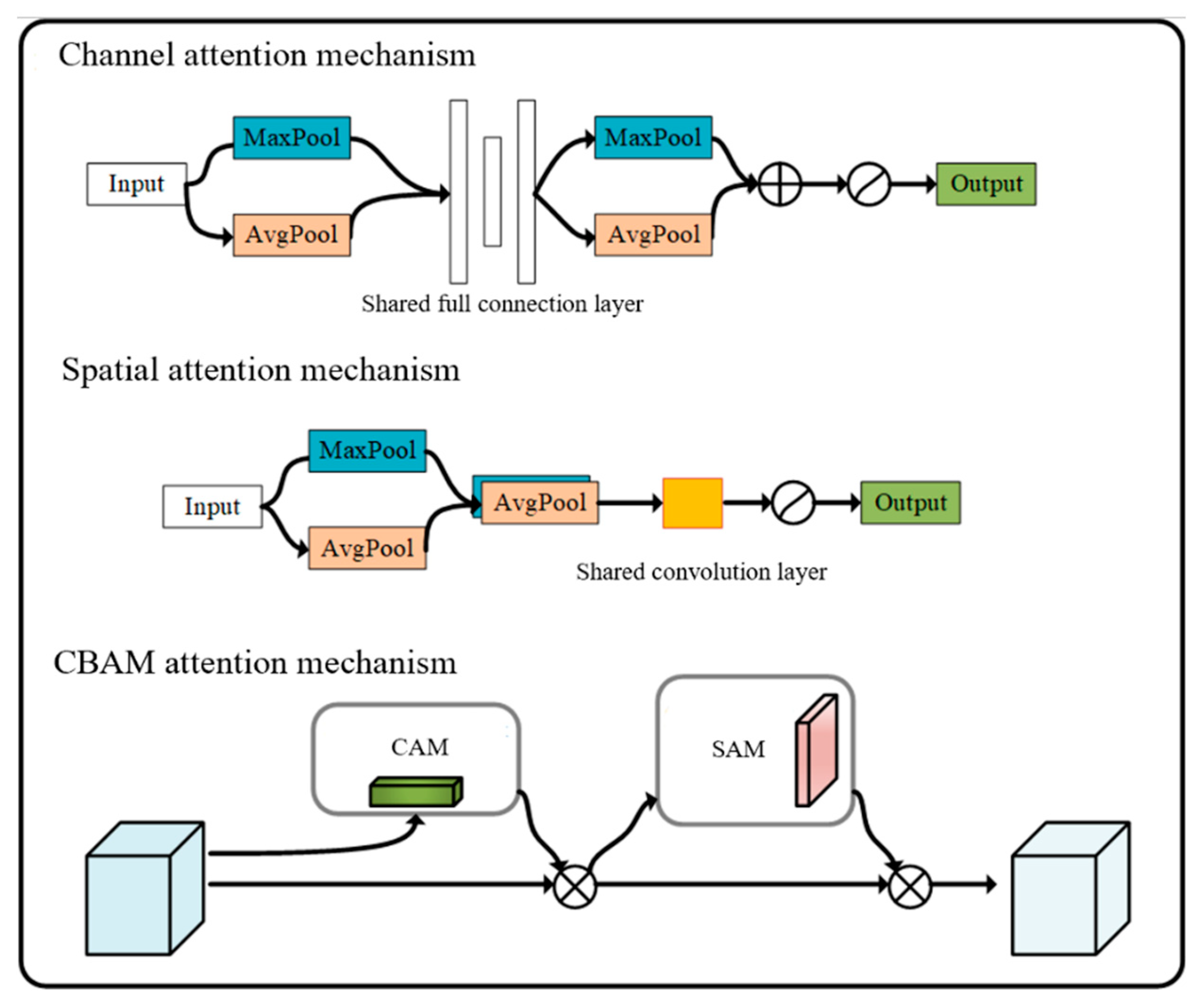

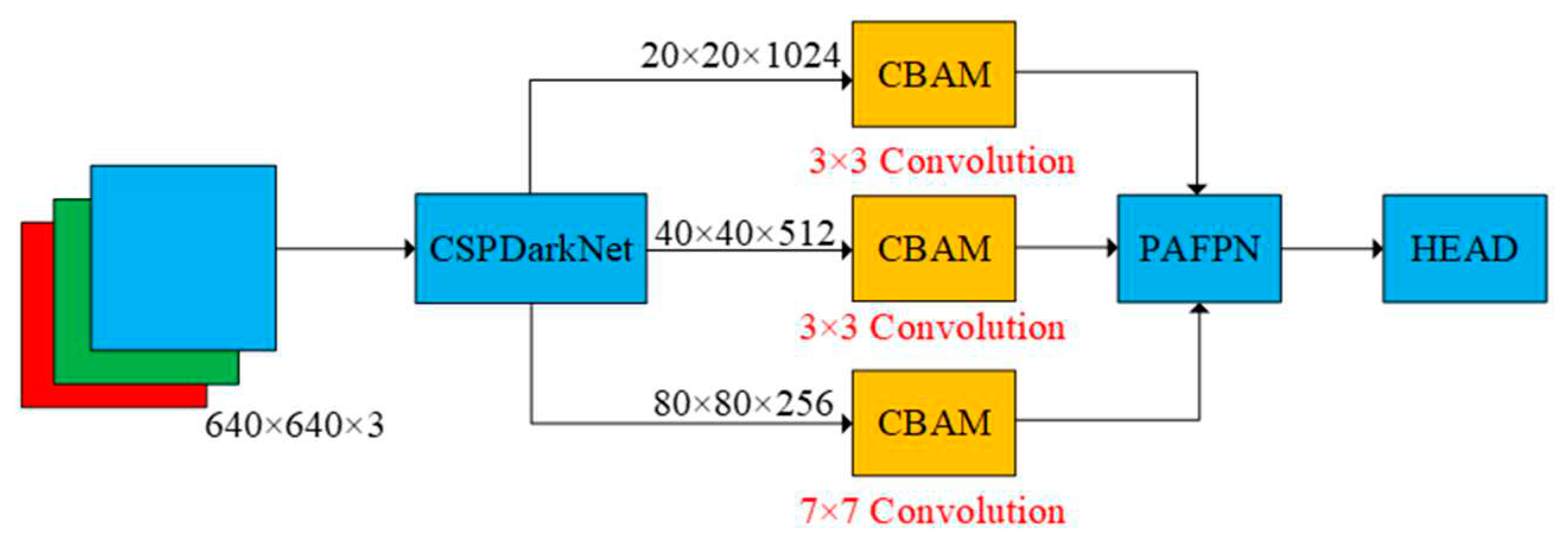

3.5. Improved CBAM attention block

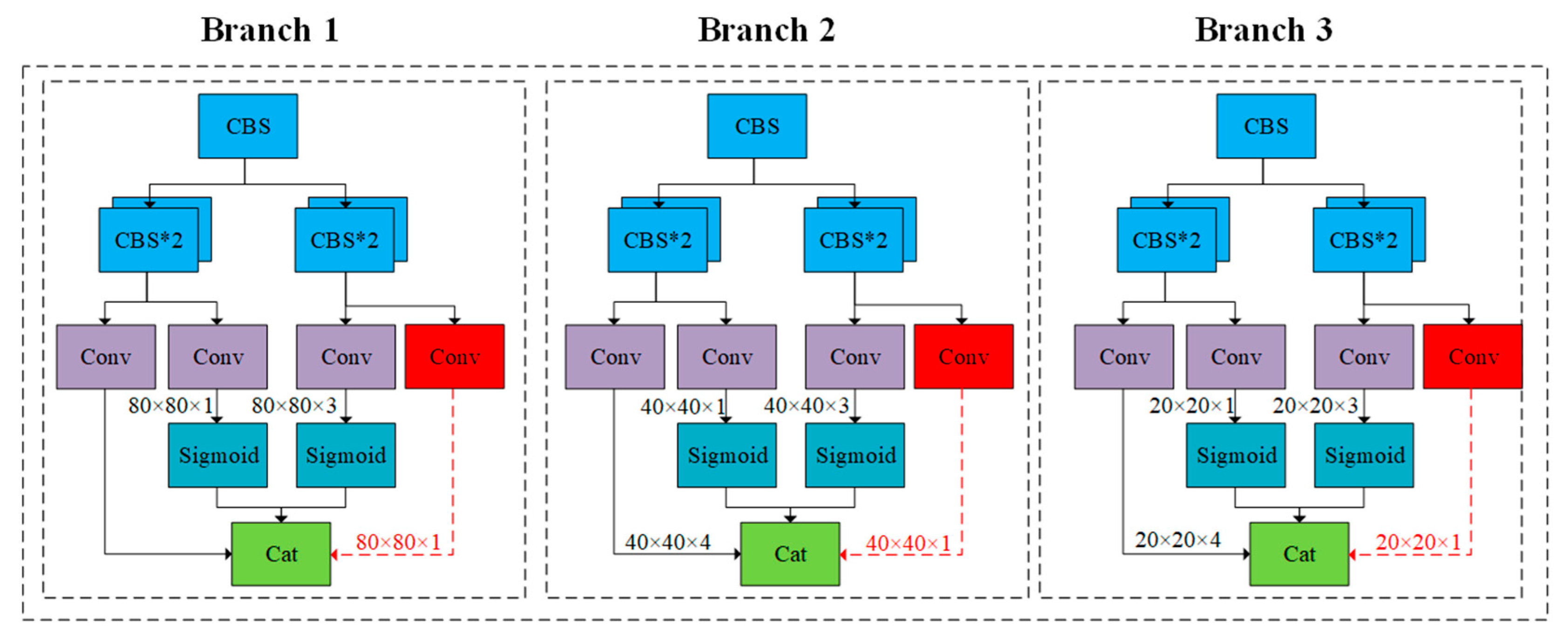

3.6. Designed rotating decoupling head and MO-YOLOX network

4. Experimental example and discussion

4.1. Experimental platform

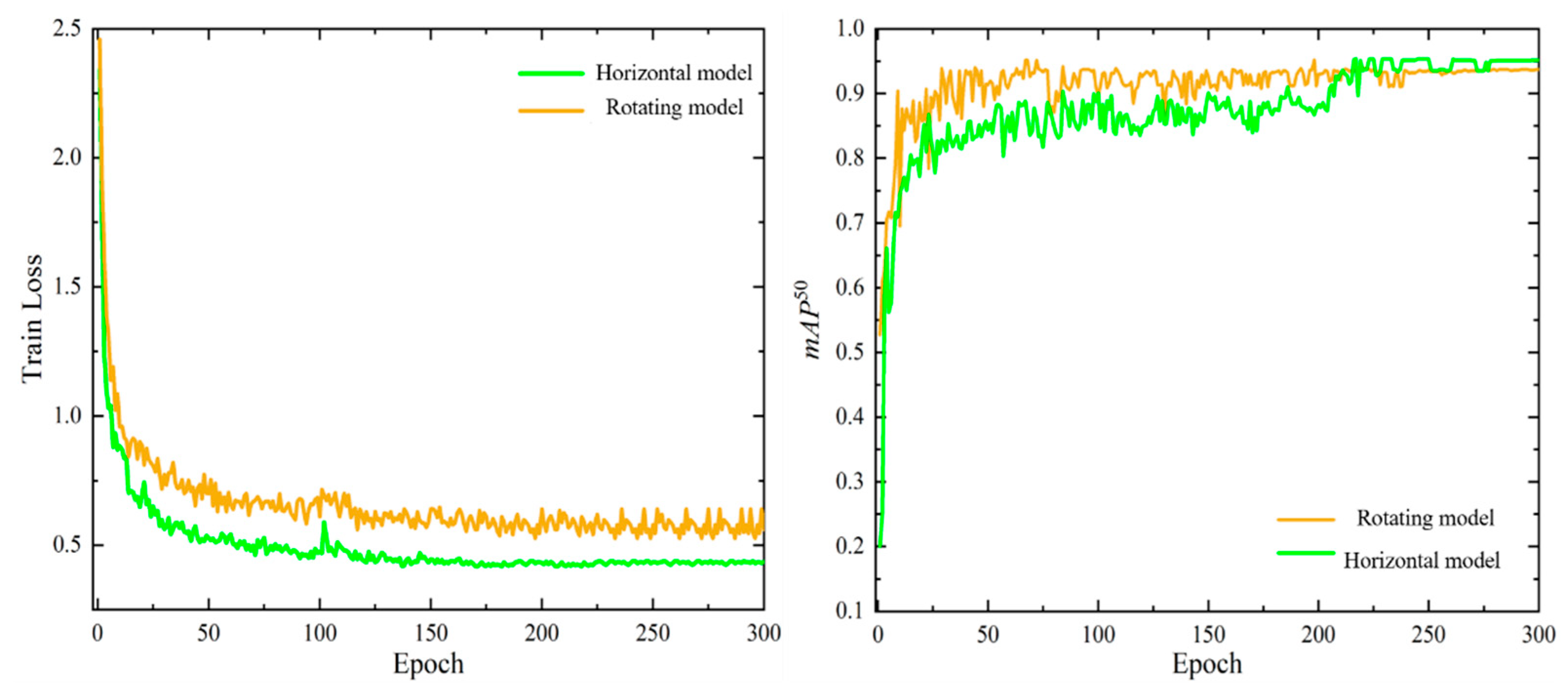

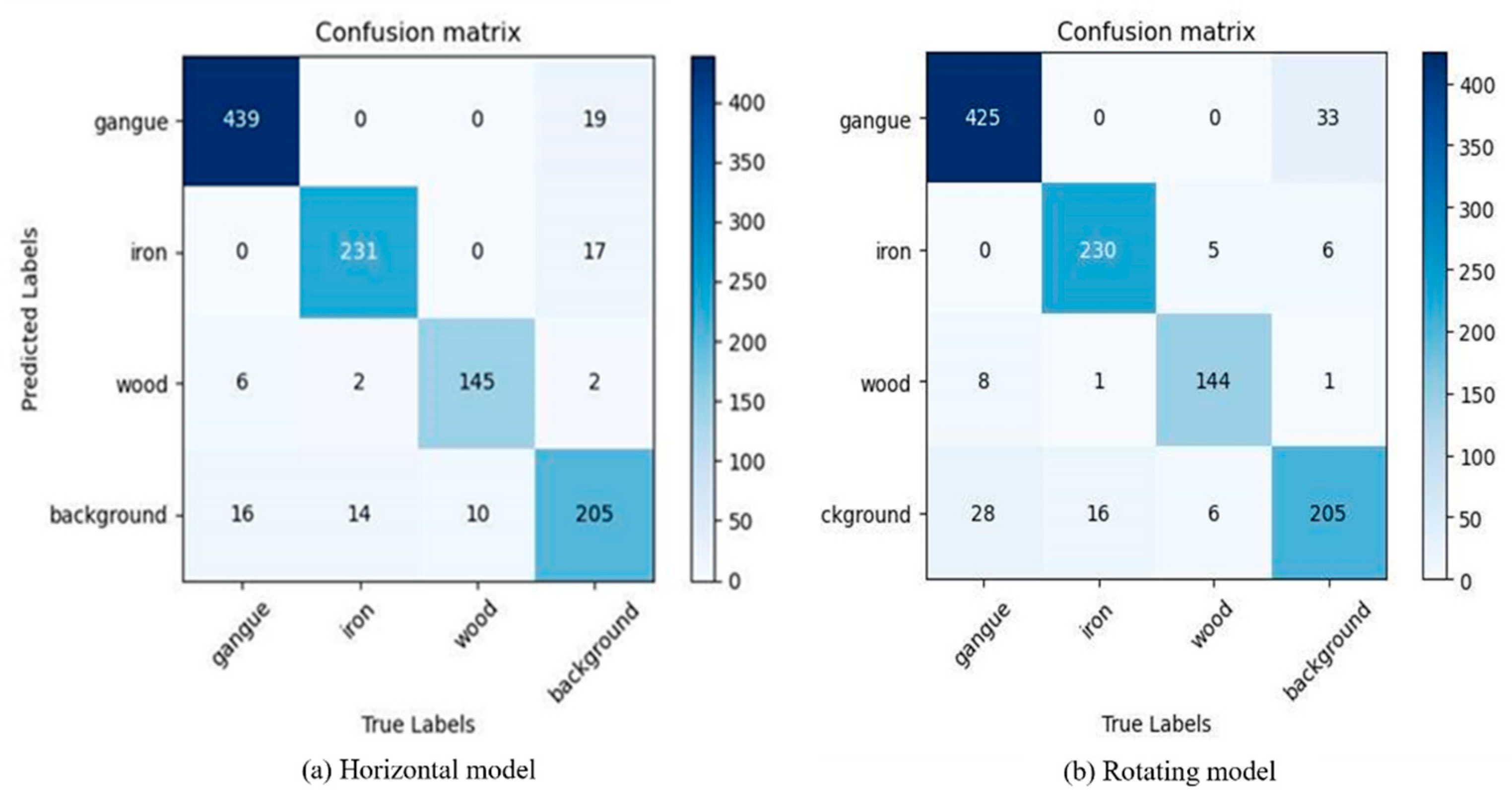

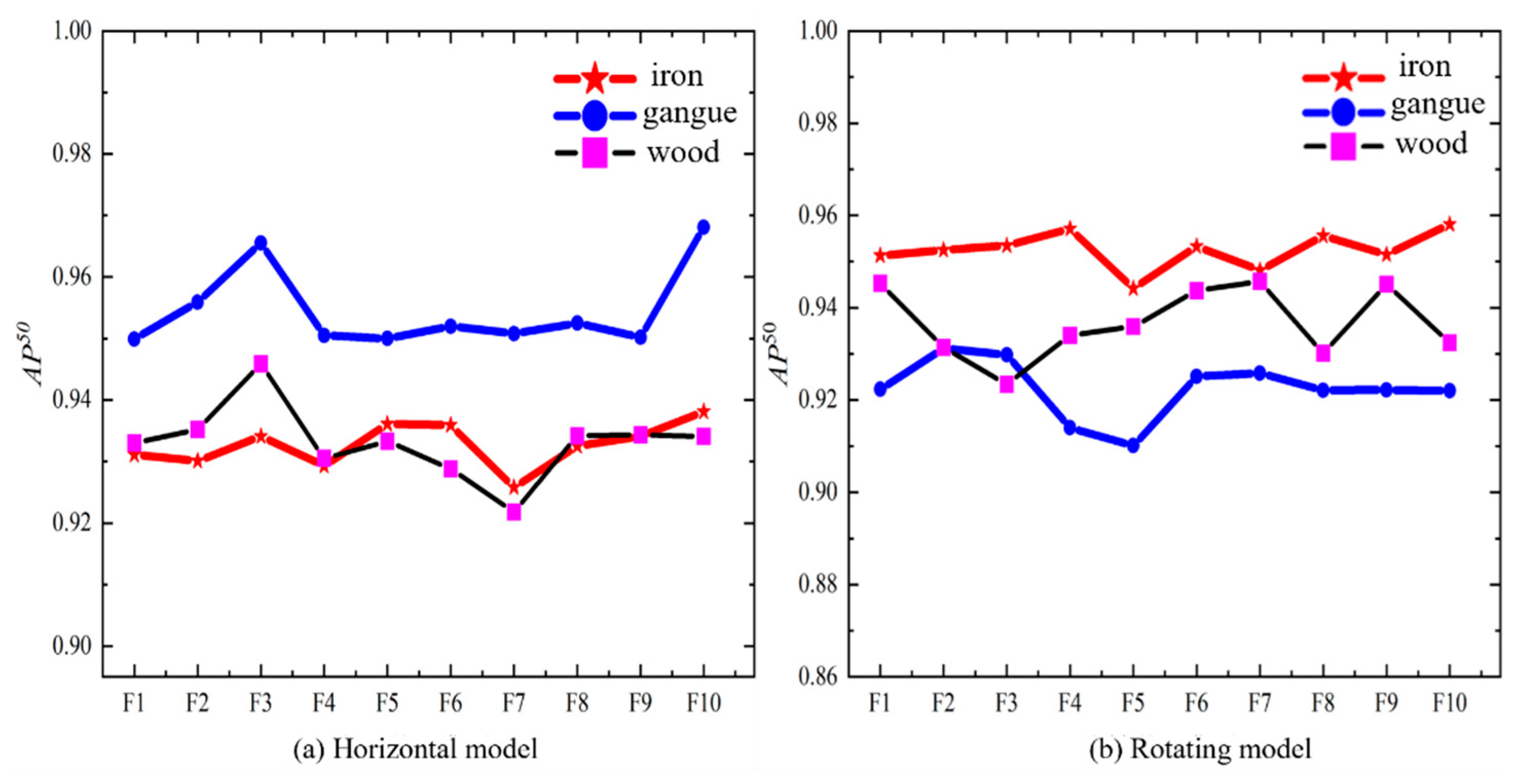

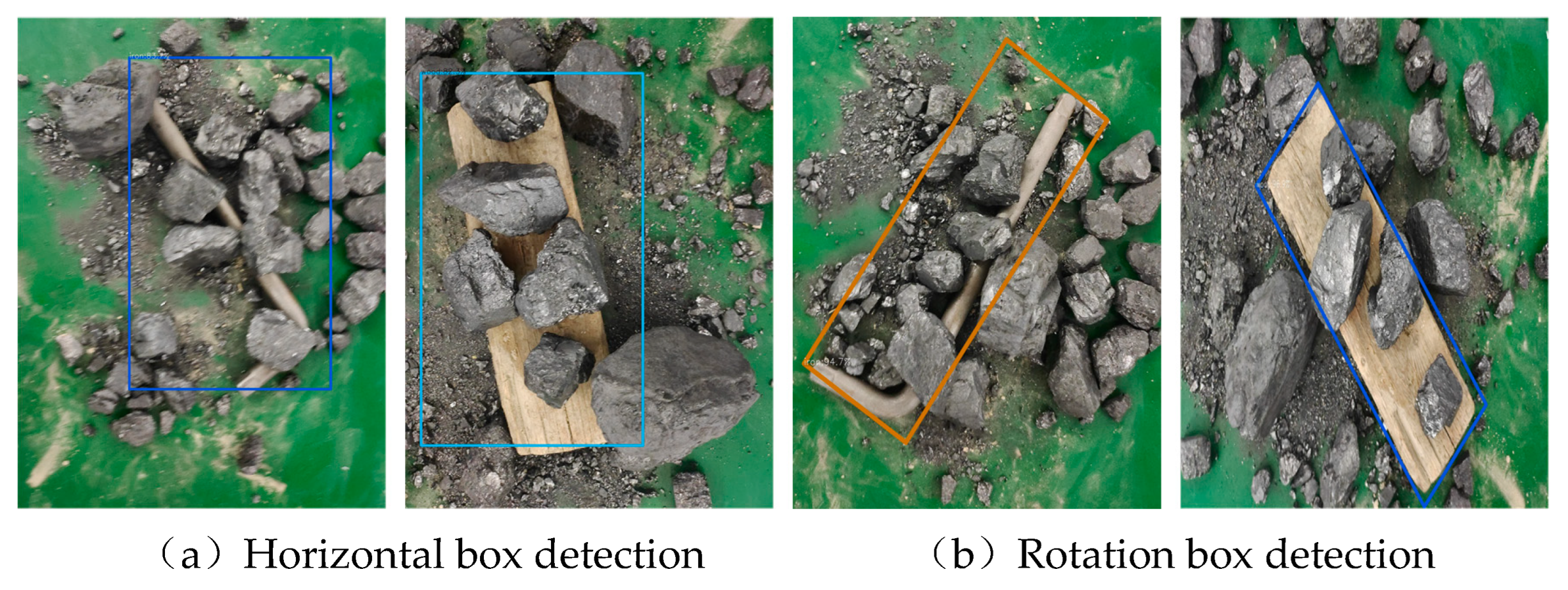

4.2. Experimental tests

5. Conclusions and future works

Acknowledgments

Data access statement

Conflicts of Interest

Ethics statement

References

- Petrikova, I.; Marvalova, B.; Samal, S.; et al. Digital image correlation as a measurement tool for large deformations of a Conveyor Belt. Applied Mechanics and Materials 2015, 732, 77–80. [Google Scholar] [CrossRef]

- Zimroz, R.; Stefaniak, P.K.; Bartelmus, W.; et al. Novel techniques of diagnostic data processing for belt conveyor maintenance. In Proceedings of the 12th International Symposium Continuous Surface Mining-Aachen 2014; Springer International Publishing, 2015; pp. 31–40. [Google Scholar]

- Chen, W.; Wang, X. Coal mine safety intelligent monitoring based on wireless sensor network. IEEE sensors journal 2020, 21, 25465–25471. [Google Scholar] [CrossRef]

- Gao, D.; Li, W.; Dai, K. Design of coal mine intelligent monitoring system based on ZigBee wireless sensor network. In Proceedings of the International Conference on Mechanics, Materials and Structural Engineering (ICMMSE 2016); Atlantis Press, 2016; pp. 182–187. [Google Scholar]

- Norkobil Saydirasulovich, S.; Abdusalomov, A.; Jamil, M.K.; et al. A YOLOv6-based improved fire detection approach for smart city environments. Sensors 2023, 23, 3161. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Zhou, Z.; Geng, Z. Safety monitoring method of moving target in underground coal mine based on computer vision processing. Scientific reports 2022, 12, 17899. [Google Scholar] [CrossRef]

- Dai, L.; Qi, P.; Lu, H.; et al. Image enhancement method in underground coal mines based on an improved particle swarm optimization algorithm. Applied Sciences 2023, 13, 3254. [Google Scholar] [CrossRef]

- Wei, W.; Li, L.; Shi, W.; et al. Ultrasonic imaging recognition of coal-rock interface based on the improved variational mode decomposition. Measurement 2021, 170, 108728. [Google Scholar] [CrossRef]

- Radke, R.J.; Andra, S.; Al-Kofahi, O.; et al. Image change detection algorithms: A systematic survey. IEEE transactions on image processing 2005, 14, 294–307. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Peng, G.; Xu, B.; et al. Foreign object recognition technology for port transportation channel based on automatic image recognition. EURASIP Journal on Image and Video Processing 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Donskoi, E.; Suthers, S.P.; Campbell, J.J.; et al. Modelling and optimization of hydrocyclone for iron ore fines beneficiation-using optical image analysis and iron ore texture classification. International Journal of Mineral Processing 2008, 87, 106–119. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bandopadhyay, S.; Machuca, D. Ore grade prediction using a genetic algorithm and clustering based ensemble neural network model. Mathematical Geosciences 2010, 42, 309–326. [Google Scholar] [CrossRef]

- Zhang, Z.; Su, X.; Ding, L.; et al. Multi-scale image segmentation of coal piles on a belt based on the Hessian matrix. Particuology 2013, 11, 549–555. [Google Scholar] [CrossRef]

- Saran, G.; Ganguly, A.; Tripathi, V.; et al. Multi-modal imaging-based foreign particle detection system on coal conveyor belt. Transactions of the Indian Institute of Metals 2022, 75, 2231–2240. [Google Scholar] [CrossRef]

- Tu, L.; Zhong, S.; Peng, Q. Moving object detection method based on complementary multi resolution background models. Journal of Central South University 2014, 21, 2306–2314. [Google Scholar] [CrossRef]

- Lins, R.G.; Givigi, S.N. Automatic crack detection and measurement based on image analysis. IEEE Transactions on Instrumentation and Measurement 2016, 65, 583–590. [Google Scholar] [CrossRef]

- Ghasemi, Y.; Jeong, H.; Choi, S.H.; et al. Deep learning-based object detection in augmented reality: A systematic review. Computers in Industry 2022, 139, 103661. [Google Scholar] [CrossRef]

- Kaur, J.; Singh, W. Tools, techniques, datasets and application areas for object detection in an image: A review. Multimedia Tools and Applications 2022, 81, 38297–38351. [Google Scholar] [CrossRef] [PubMed]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Pu, Y.; Apel, D.B.; Szmigiel, A.; et al. Image recognition of coal and coal gangue using a convolutional neural network and transfer learning. Energies 2019, 12, 1735. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; et al. Rich feature hierarchies for accurate object detection and semantic segmentation. Proceedings of the IEEE conference on computer vision and pattern recognition. 2014, 580–587. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; et al. Faster r-cnn: Towards real-time object detection with region proposal networks. Advances in neural information processing systems 2015, 28. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Dang, L. Video detection of foreign objects on the surface of belt conveyor underground coal mine based on improved SSD. Journal of Ambient Intelligence and Humanized Computing 2020, 1–10. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, X.; Xu, L.; et al. Application of YOLOv4 algorithm for foreign object detection on a belt conveyor in a low-illumination environment. Sensors 2022, 22, 6851. [Google Scholar] [CrossRef] [PubMed]

- Ma, G.; Wang, X.; Liu, J.; et al. Intelligent detection of foreign matter in coal mine transportation belt based on convolution neural network. Scientific Programming 2022, 2022. [Google Scholar] [CrossRef]

- Xiao, D.; Kang, Z.; Yu, H.; et al. Research on belt foreign body detection method based on deep learning. Transactions of the Institute of Measurement and Control 2022, 44, 2919–2927. [Google Scholar] [CrossRef]

- Ge, Z.; Liu, S.; Wang, F.; et al. Yolox: Exceeding yolo series in 2021. arXiv 2021, arXiv:2107.08430, 2021. [Google Scholar]

- Chollet, F. Xception: Deep learning with depthwise separable convolutions. In Proceedings of the IEEE conference on computer vision and pattern recognition; 2017; pp. 1251–1258. [Google Scholar]

- Cui, Z.; Li, K.; Gu, L.; et al. You Only Need 90K Parameters to Adapt Light: A Light Weight Transformer for Image Enhancement and Exposure Correction. In Proceedings of the BMVC; 2022; p. 238. [Google Scholar]

- Yang, X.; Zhang, G.; Yang, X.; et al. Detecting rotated objects as gaussian distributions and its 3-d generalization. IEEE Transactions on Pattern Analysis and Machine Intelligence 2022, 45, 4335–4354. [Google Scholar] [CrossRef] [PubMed]

| name | parameter |

|---|---|

| CPU | Intel Core i9-10980XE |

| Hard disk | 2T |

| GPU | NVIDIA RTX A4000 |

| Memory Deep learning framework OS Programming Language CUDA |

16G Pytorch1.8.0 Window10 Python3.8 11.2 |

| Training parameters | Setting values |

|---|---|

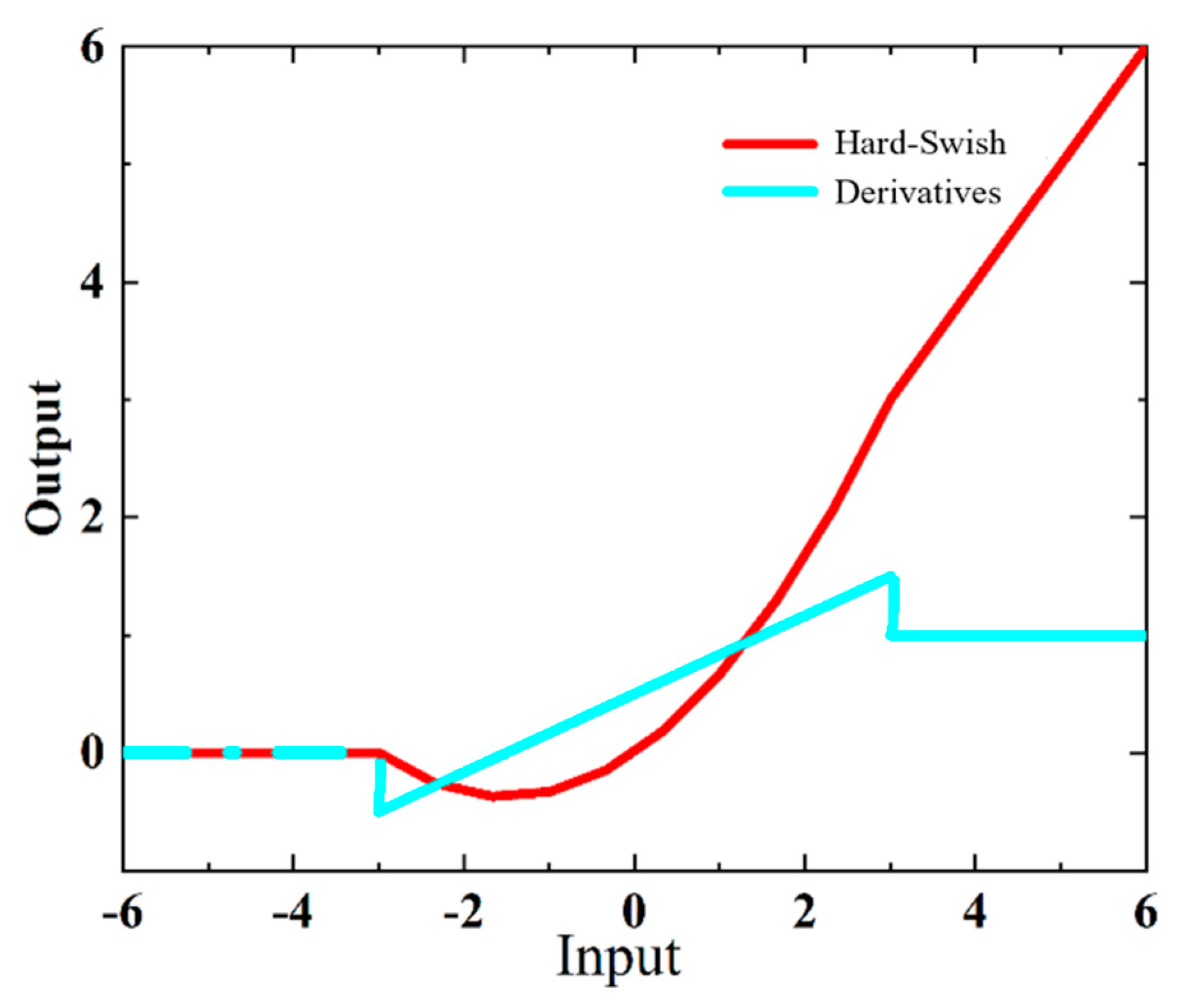

| activation function | Hard-Swish |

| Pooling method | Max-Pooling |

| optimization algorithm | Adams, Batch-size=8, |

| loss function | Cross entropy Loss function, KLD |

| Epoch | 300 |

| data enhancement | Mosaic |

| Learning rate | Initial Learning rate , Nature Index attenuation |

| Dataset partitioning ratio | Training set: Verification set: Test set=0.6:0.3:0.1 |

| Precision | Recall | F2-score | Inference time /ms | ||

|---|---|---|---|---|---|

| iron | 93.71% | 93.20% | 93.27% | 93.30% | 21 |

| wood | 93.12% | 93.62% | 93.30% | 95.80% | 23 |

| Bulk gangue | 95.32% | 95.92% | 95.45% | 93.52% | 22 |

| average value | 94.05% | 94.25% | 94.01% | 94.20% | 22 |

| Precision | Recall | F2-score | Inference time /ms | ||

|---|---|---|---|---|---|

| iron | 93.71% | 93.20% | 93.27% | 95.28% | 28 |

| wood | 93.12% | 93.62% | 93.30% | 93.46% | 26 |

| large gangue | 95.32% | 95.92% | 95.45% | 92.44% | 29 |

| average value | 94.05% | 94.25% | 94.01% | 93.73% | 27.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).