1. Introduction

Mineral oil-based lubrication is still the leading choice in reduction of friction and wear for most industrial and commercial applications. However, due to their ecology-related challenges, such as toxicity and non-biodegradability, they represent a high risk for environmental pollution. Therefore, the research is nowadays focusing towards suitable substitutes for mineral oils [

1]. It has been shown that vegetable oil lubrication represents the competitive substitute to mineral-oil lubrication due to their renewable, environmentally friendly and cost-effective nature [

2]. In addition, their effectiveness is also reflected in high viscosity index, good lubricity and low volatility [

1,

2].

Lately, several studies have focused on introduction of specific lubricant additives to additionally reduce friction and wear during lubrication [

3]. It has been shown that the efficiency of lubrication is related to the size, shape and concentration of additives [

3]. Various organic and inorganic nanomaterials, such as graphene, ionic liquids, hydrogels, hexagonal BN, different metallic oxides, Cu and MoS

2 have been considered for improvement of sliding efficiency and durability [

2,

4,

5].

A step forward in the tribological response represents the capability of the base material for lubricant retention [

6]. The performance of the base material can be improved by surface modification via introduction of micro/nanoscale topographies that are a result of micro/nanoscale fabrication techniques. Lee et al. [

7] reported on electrochemical etching of 304 stainless steel resulting in porous hierarchical structures with noticeable oil retention. Hao et al. [

8] studied the improvement of tribological properties after surface micro texturing by chemical solutions. It was also shown theoretically that biomimetic texture morphologies significantly improve tribological response through increased oil retention [

9,

10,

11]. In the past decade, surface laser texturing has been recognized as effective technique in enhancing the tribological performance of materials [

12,

13,

14,

15] due to the short processing times, good control over the process and friendliness to the environment. It was already shown that the texturing geometry and direction of texturing with regard to sliding during application significantly influence the lubrication efficiency and wear behaviour [

16,

17]. Various texturing geometries, such as micro-channels and dimples of different sizes and depths, have already been established as traps for wear debris and lubricant reservoirs, leading to reduced abrasion [

15,

18]. The added value of such modified surfaces is attributed to the possibility of continuous lubrication due to the lubricant retention on the textured surface, the generation of micro-hydrodynamic effects, reducing the abrasive wear due to the entrapment of wear debris and the minimisation of the contact area [

19].

In this paper we investigated and compared the friction and wear response of two different laser-textured AISI 316L morphologies, crosshatch and dimples, in vegetable oils (jojoba and sunflower) upon addition of solid lubricant, MoS2 nanotubes. In connection to the tribological analysis we also analysed the surface wettability, oil spreadability and oil retention capacity. The obtained results offer a comprehensive insight into the friction and wear behaviour of laser-textured surfaces under oil lubrication with or without MoS2 nanotubes addition.

2. Materials and Methods

Materials.― The steel sheet, AISI 316L, with a thickness of 1.5 mm was cut into discs of 25 mm diameter. Prior the laser texturing, the steel discs were hand-ground, using grinding paper of 600 grit to remove the surface oxide layer. They were then cleaned using cotton wool and isopropanol to remove surface impurities. The average surface roughness of the prepared steel discs was Sa = (0.19 ± 0,01) µm.

The sunflower and jojoba oil (supplier Tovarna Organika Ltd.) were used for lubricated tribological testing. The kinematic viscosity measured at 20 oC is 50,5 mPa.s for the sunflower oil is and 33,6 mPa.s for the jojoba oil.

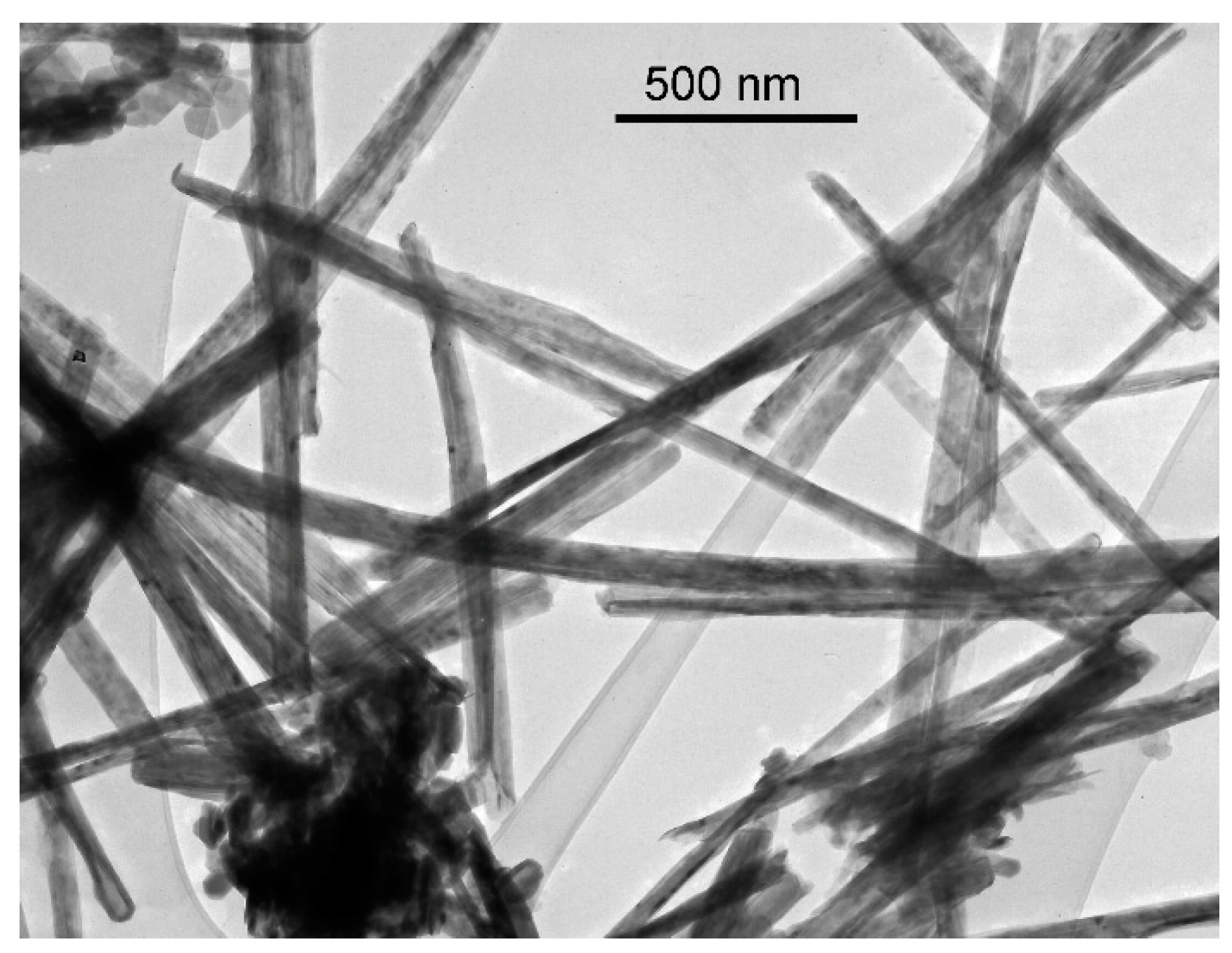

The MoS

2 nanotubes were synthesised by Nanotul Ltd. following the procedure described in [

20]. Their diameter is 100 – 200 nm and length up to 5 µm. Transmission electron microscopy (TEM) image of MoS

2 nanotubes is presented in

Figure 1.

Prior to tribological testing, 2 wt. % of MoS2 nanotubes were dispersed in both media, sunflower and jojoba oil. The mixture was alternately put into ultrasound for 20 min and then manually shaken prior use.

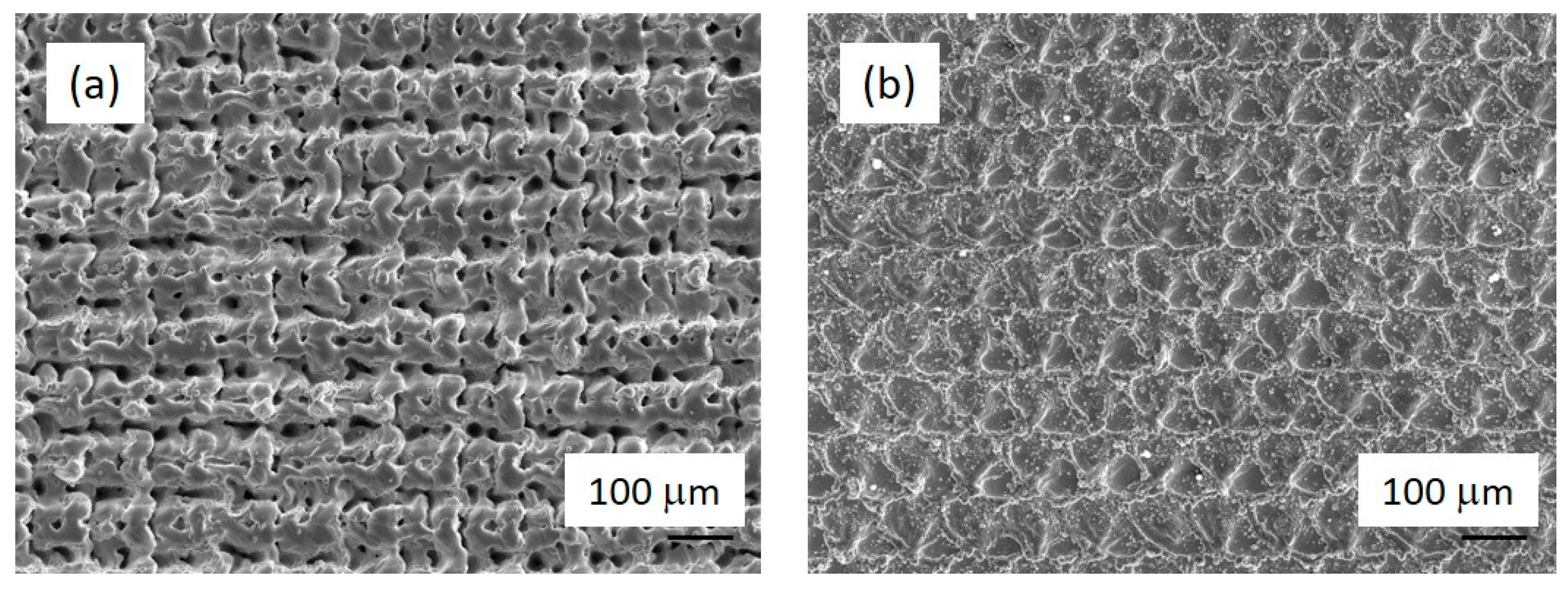

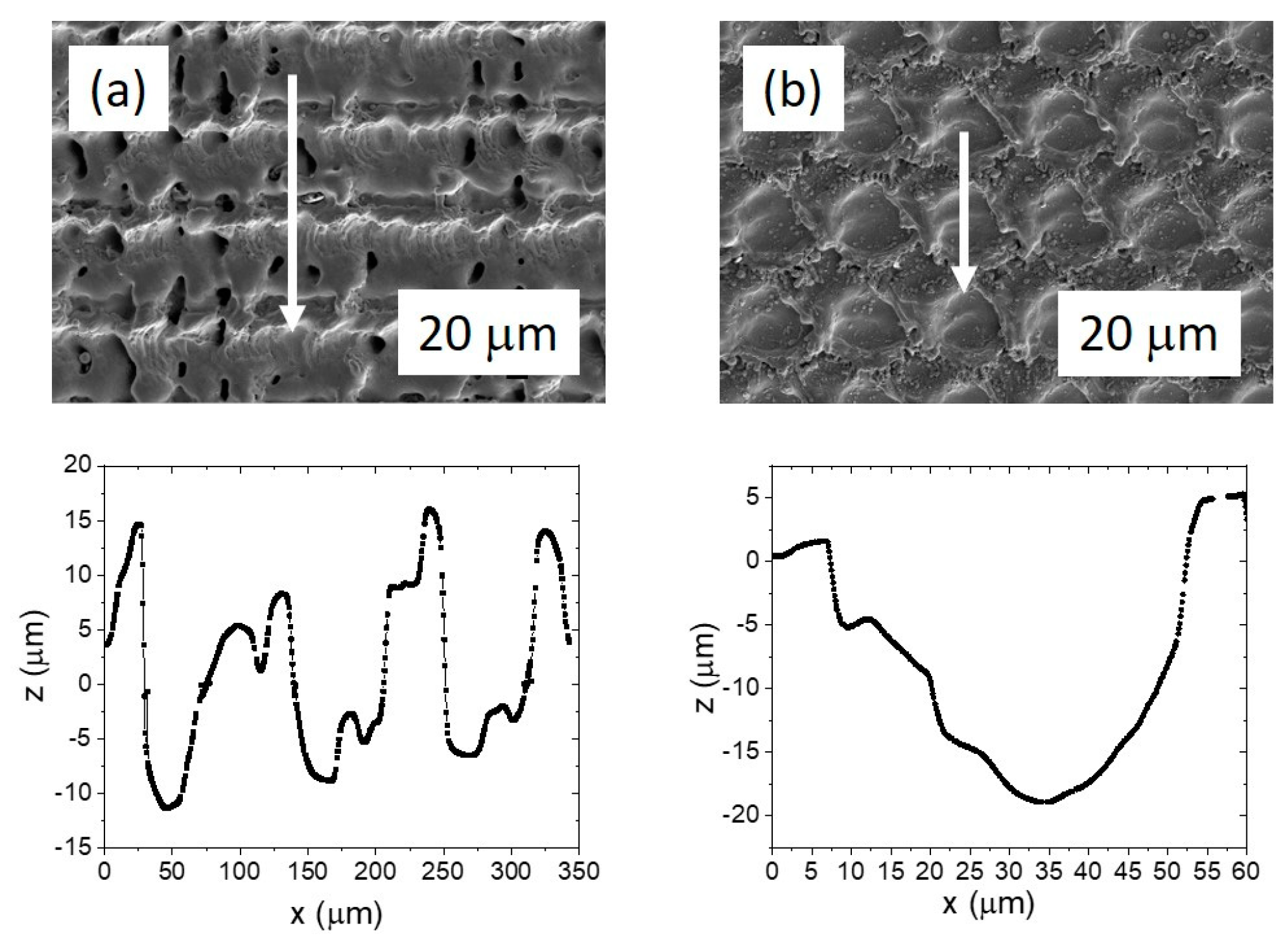

Surface laser texturing.― A Starmark laser texturing machine was used for the production of AISI 316L test coupons. A Rofin SMD 50 W II Nd-YAG laser power source equipped with F-Theta-Ronar lens with a focusing length of 160 mm were used for texturing. The laser’s focal point was set on the surface of the test coupons. Programming of shapes was done using Rofin LaserCAD software, where a set of crosshatch pattern and dimples were processed (

Figure 2). The lines in the crosshatch texture were 15 µm deep and 50 µm wide with the spacing of 100 µm. The dimples with diameter 50 µm were 20 µm deep and were arranged in a pattern with centre-to-centre distance 100 µm. The laser texturing of dimples was done in pulsed mode using: a pulse length of 0.06 ms, pulse frequency of 500 Hz, and an electrical current of 48.0 A. Each dimple was processed with 10 pulses. The laser texturing of lines and crosshatch pattern was done in CW mode with the speed of 10 mm/s and an electrical current of 42.0 A. Crosshatch pattern was done at wobble frequency of 10 kHz in one run. The texturing times of test coupons were 45 minutes for dimples, 14 minutes for line pattern and 30 min for crosshatch pattern.

Prior to laser texturing, we assured the removal of the surface oxide layer from the surfaces of test samples with hand grinding using grinding paper of 600 grit. After grinding, the surface impurities were cleaned using cotton wool and isopropanol. The laser-texturing was done in an air atmosphere at room temperature.

Surface characterization.― JEOL JSM-6500F scanning electron microscope (SEM) using field emission was employed to investigate the morphology of the laser-textured surfaces. Optical 3D metrology system, model Alicona Infinite Focus (Alicona Imaging GmbH) and IF-MeasureSuite (Version 5.1) software were used to analyse the surface-topography.

Wettability, spreadability and oil retention test.― Wettability of the laser textured AISI 316L surface was evaluated with sunflower oil contact angle measurements. Droplets of oil with V = 5 µL were deposited on at least three different spots on the surface to avoid the influence of roughness and gravity on the shape of the droplet. Advex Instruments s.r.o. was used to analyse the droplets and determine the contact angles. Spreadability was further analysed after 60 s by measuring the spreading area of the droplet. Oil retention capacity was determined by application of 500 µL oil droplet on the surface using the rotational motion of a spin coater (Laurell technologies corporation, model WS-650MZ-23NPPB). We compared the weight of the sample before and after the application of the oil droplet and calculated the oil retention capacity via [

11]:

where m

0 is the weight of the laser-textured specimen, m

1 is the weight of the specimen and the oil droplet before rotation and m

2 is the weight of the specimen and the oil after rotation

Tribological testing.― Tribological testing using a ball-on-flat contact configuration was performed under a reciprocating sliding motion on a TRIBOtechnic friction testing tribometer. Experiments were carried out in room conditions (RH = 50%, T = 20°C), a normal load of 5 N, corresponding to a nominal contact pressure of 1.2 GPa, an average sliding speed of 5 mm/s (frequency 0.25 Hz and amplitude 10 mm). The same sliding distance of 1 m was kept for all the tests for the purposes of a relative wear comparison between the different texturing parameters and the orientation. A 100Cr6 bearing steel ball with a diameter of 5 mm (Ra = 0.05 μm, 58 HRC) was used as a stationary counter-body and loaded against the as-textured AISI 316L disc without any post-polishing or additional processing. The relatively small ball diameter of 5 mm was selected to simulate the most critical contact situations with very small contact areas (edges) and high-pressure spikes and to examine whether the texturing type, spacing and orientation still influence the tribological behaviour or is it overwhelmed by the small contact size. The CoF was measured continuously during the tests, with the steady-state coefficient of friction being determined as the average value of the last 100 seconds. The wear volume of textured surfaces could not be measured, therefore wear tracks of the counter body were analysed.

3. Results

3.1. Surface Morphology

The AISI 316L samples were hand ground with 600-grit grinding paper and textured using a LPKF nanosecond Nd-YAG marking laser to modify the surface with crosshatch and dimples patterns.

Figure 3 shows SEM images of the details of the laser texturing patterns and the corresponding height profiles that define the morphological details the crosshatch texture and the dimples. The width of the channels in the crosshatch-textured samples is approximately 50 µm and the depth is approximately 10 µm. We can also observe that the laser produces a certain amount of ejected material on both sides of the laser channel, with the height of the bulges extending up to 15 μm. The diameter of the dimples is approximately 50 μm, while the maximum depth of dimples is around 20 µm. The bulges of the ejected material are also observed at the edge of the circle, however not as high as in case of the crosshatching-textured samples, extending up to 5 μm.

Furthermore, the laser texturing not only affects the surface morphology, but also the microstructural-crystallographic characteristics. Significant surface hardening (~310-315 HV0.01) is observed for melted and re-solidified surface of both laser textured samples in comparison to the base material with surface hardness ~240 HV0.01.

3.2. Tribological Analysis

3.2.1. Coefficient of Friction

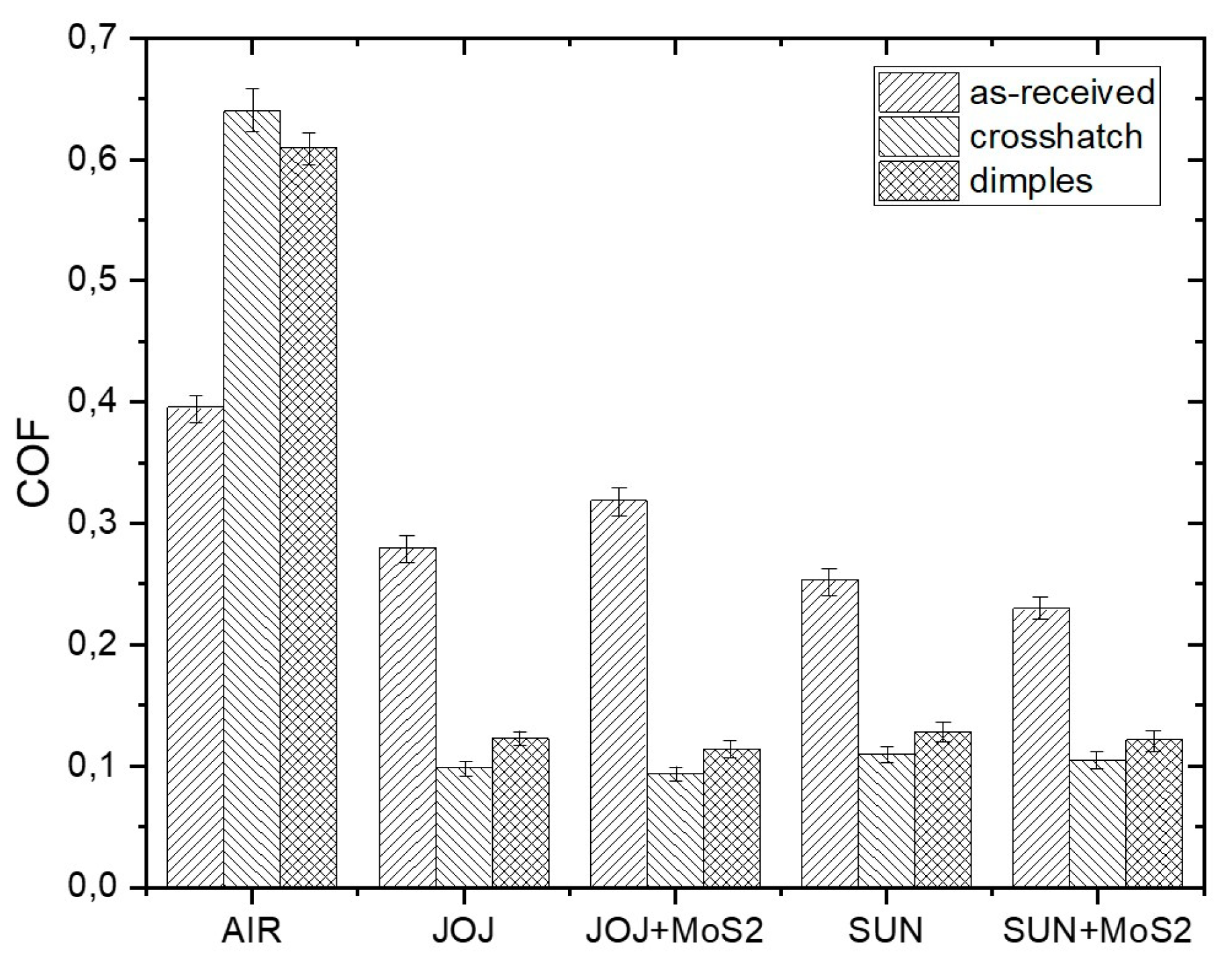

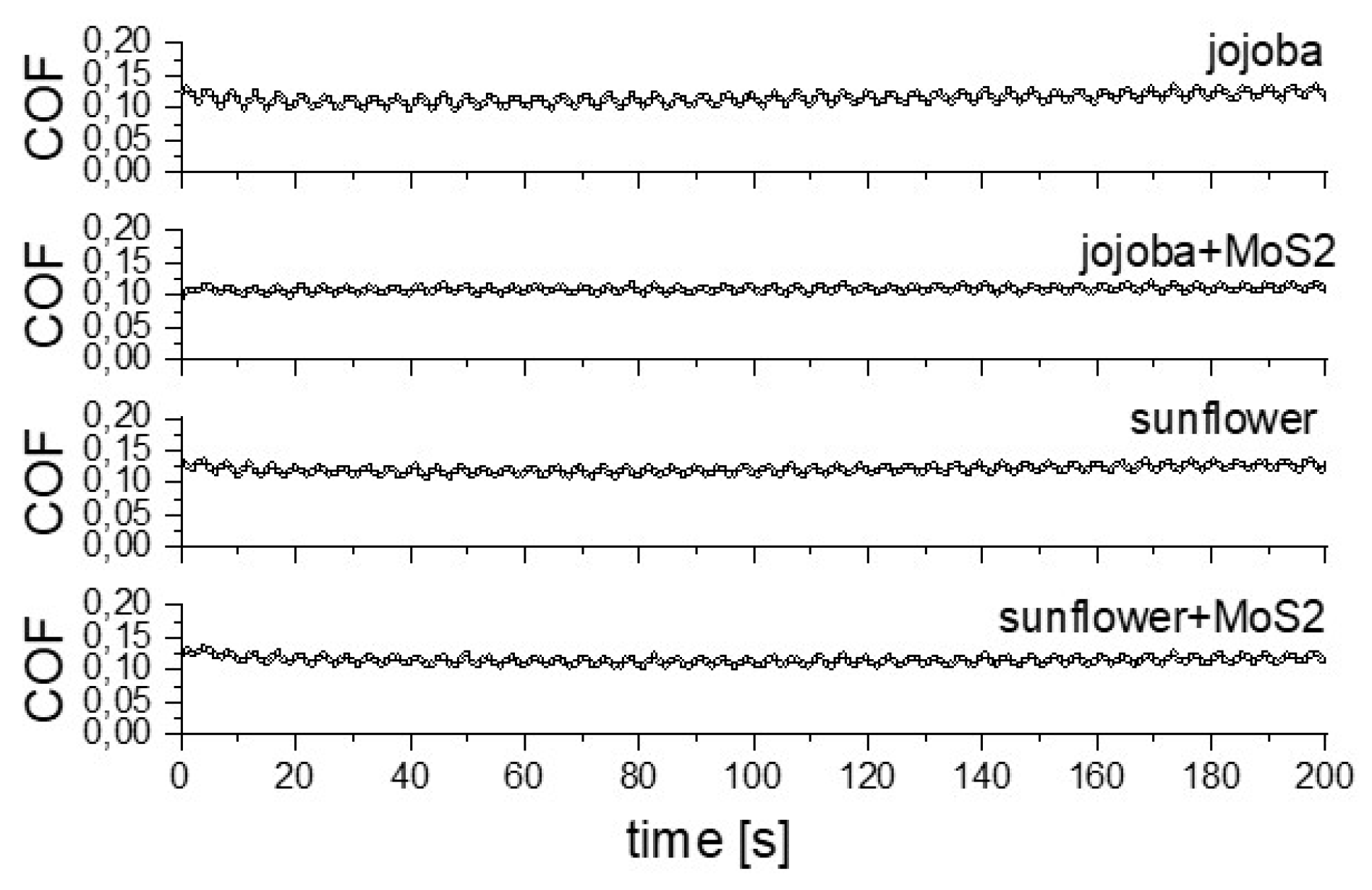

Steady-state coefficient of friction (COF) values are shown in

Figure 4. In the case of dry sliding in air, texturing results in increased steady-state COF, increasing it from 0.4 to about 0.6, with crosshatch pattern showing slightly higher values. Increase in friction can be attributed to reduced contact area and abrasive action of hard bulges formed around the textured patterns, being more pronounced for crosshatch pattern. However, in the case of lubricated contact, laser texturing provides more than 50% lower friction with respect to the surfaces without laser texturing. Texturing provides micro-hydrodynamic effects, with the lubrication regime changing from boundary/mixed into hydrodynamic, as indicated by the level of coefficient of friction [

21]. For reference, un-textured surface steady-state COF is between 0.25 and 0.3 and for the textured ones around 0.1. Regardless of the oil used, crosshatch pattern shows 10-20 % lower friction, while the addition of MoS

2 nanotubes has no effect under the contact conditions investigated. For all oils used similar friction trend was observed, with the initial coefficient of friction being in the range of 0.15 and then reaching the steady-state conditions in 100 s (

Figure 5). This indicates that all the friction reducing effect comes from the texturing and not from the oil or additive used.

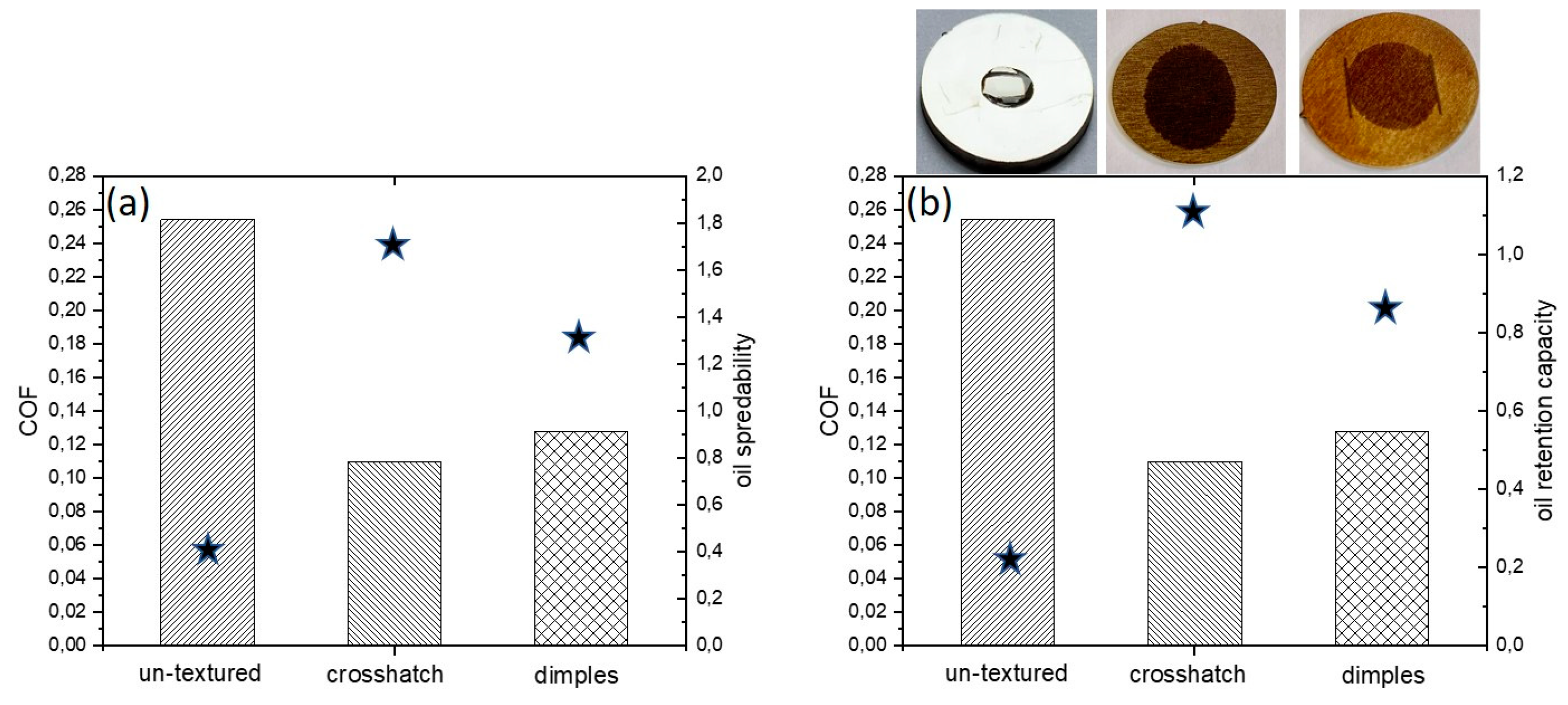

We also evaluated the static contact angles of the sunflower oil and sunflower oil+MoS

2 on un-textured and laser textured samples. For sunflower oil we observed that for both textures, crosshatch and dimples, the contact angles were below 8o ± 2o, while for un-textured sample was 10o ± 2o. The spreadability test was performed after 60 s. We observed circular-shaped spreading area of the droplet on the un-textured and dimple-textured surface, sized around 0.4 cm2 and 1.3 cm2, respectively. On the other hand, elliptical-shaped spreading area of the droplet was observed on the crosshatch-textured surface, sized 1.7 cm2 (

Figure 6 a). Oil retention capacity in correlation to COF is shown in

Figure 6 b. We can observe the highest ORC, 1.10 % for crosshatch-textured surface compared to 0.86 % for dimple-textured surface and to un-textured surface with the lowest ORC 0.21 %. Much better oil spreadability and oil retention capacity of textured surfaces also result in considerably lower coefficient of friction (0.1 vs. 0.3). Furthermore, better oil spreadability and oil retention capacity also indicate better tribological performance of crosshatch- compared to dimple-textured surface, resulting in 10-20% lower steady-state COF for crosshatch-textured surfaces. Similar trend was observed for sunflower oil+MoS

2, showing similar contact angle and spreadability, but 30% reduced ORC for textured surfaces (0,78 % for crosshatch and 0,58 % for dimples), which is compensated by increased viscosity, thus resulting in similar COF values as for pure oil. ORC for un-textured sample under sunflower oil+MoS

2 lubrication is about the same as for pure sunflower oil, 0.22 %, while spreadability is reduced to the circular-shaped area sized around 0.2 cm2. Similar values and trends were observed also for jojoba oil and jojoba oil+MoS

2. However, jojoba oil with lower viscosity shows lower ORC but slightly better oil spreadability, thus resulting in about 10% lower steady-state friction.

3.2.2. Wear

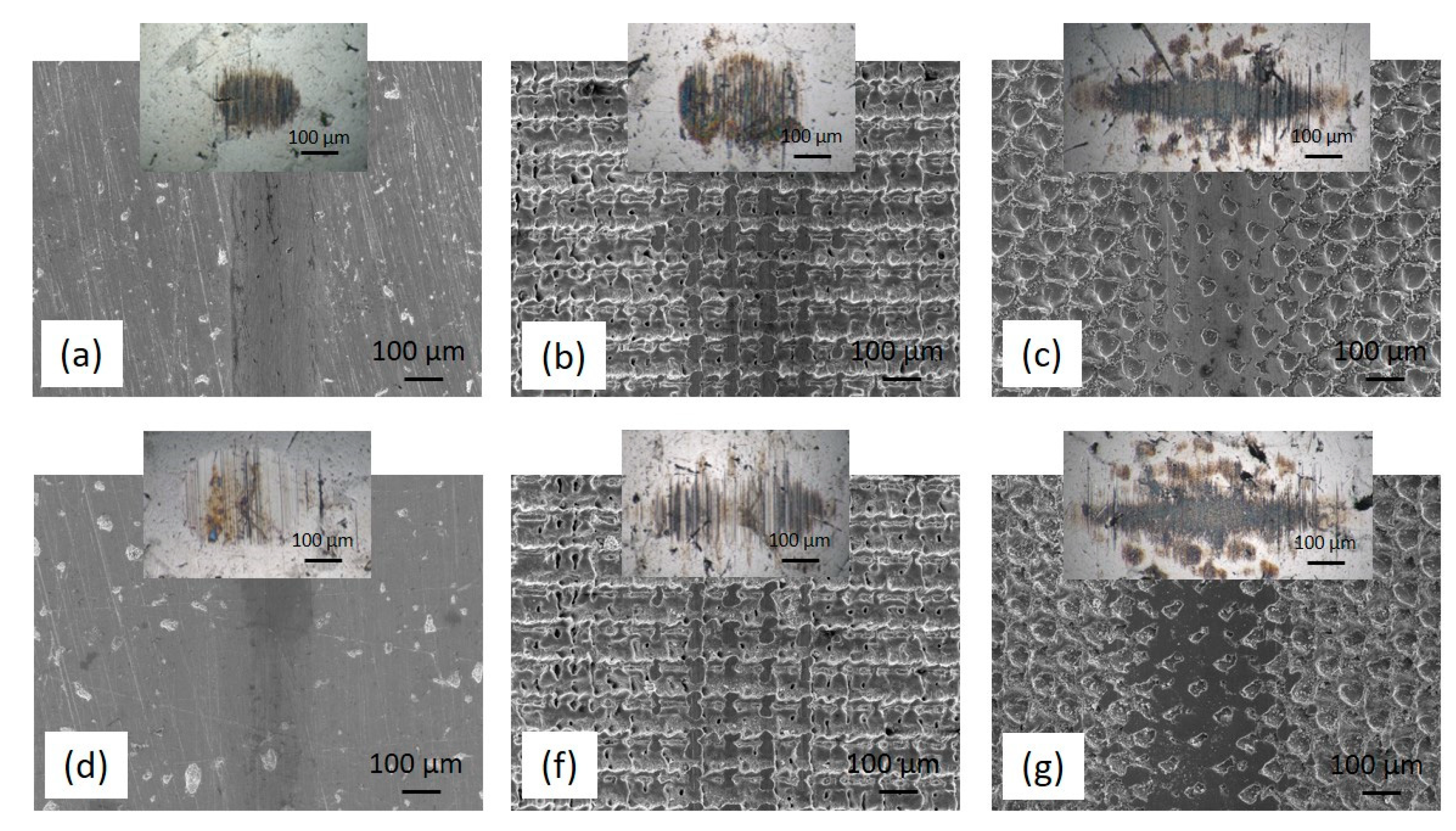

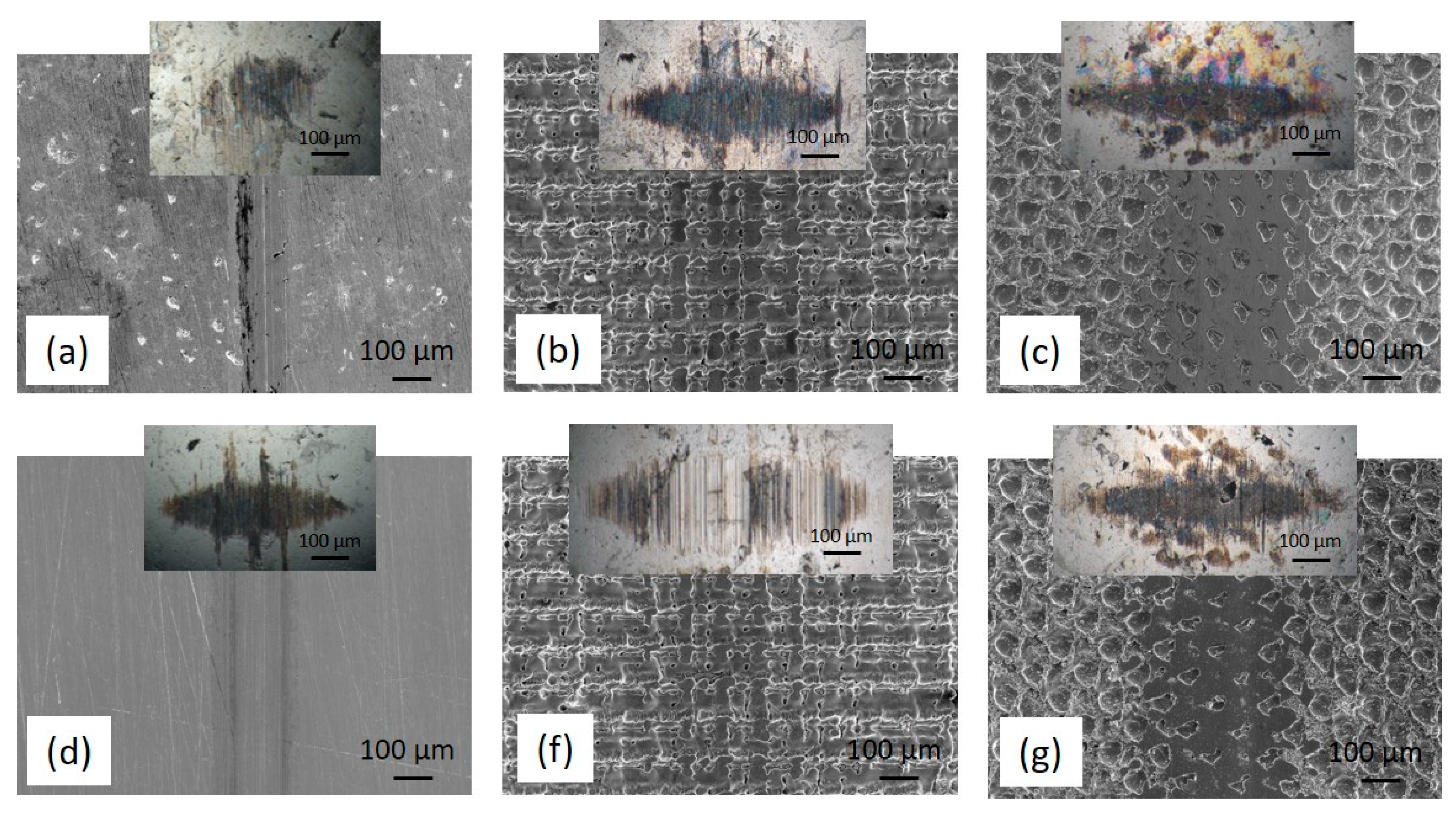

Wear volume of the textured stainless steel disc samples could not be determined, therefore wear volume of the 100Cr6 steel counter-ball was analysed, being determined as the volume of the removed spherical section. As shown in

Figure 7 and

Figure 8, texturing reduces wear of the stainless steel disc, but due to hard bulges formed around the textured pattern results in about one order of magnitude larger wear of the counter-body (

Table 1 and

Table 2). In general, for all contact surfaces (un-textured and textured) use of jojoba oil in general results in lower counter-body wear, which can be related to better oil spreadability of the jojoba oil as compared to sunflower oil. However, addition of MoS

2 nanotubes has the opposite effect, reducing oil retention capacity (30% lower) of both oils, thus resulting in increased counter-body wear. This effect is even more pronounced for textured contact, with nanotubes reducing micro-hydrodynamic effects of the textured pattern. Comparison of crosshatch- and dimple-textured pattern reveals increased counter-body wear for crosshatch pattern. Although crosshatch pattern shows better oil retention capacity it is characterized by denser and more pronounced bulges, thus causing intensified counter-body wear.

Table 1.

Counter-body wear track dimensions – jojoba oil.

Table 1.

Counter-body wear track dimensions – jojoba oil.

| |

long axis [µm] |

short axis [µm] |

Wear volume [mm3] |

| as-received jojoba |

226.6 |

164.0 |

0.28·10-4

|

| as-received jojoba+MoS2

|

246.6 |

212.0 |

0.54·10-4

|

| crosshatch jojoba |

335.7 |

250.0 |

1.44·10-4

|

| crosshatch jojoba+MoS2

|

460.6 |

205.3 |

2.27·10-4

|

| dimples jojoba |

656.6 |

150.6 |

5.22·10-4

|

| dimples jojoba+MoS2

|

698.7 |

145.0 |

6.25·10-4

|

Table 2.

Counter-body wear track dimensions – sunflower oil.

Table 2.

Counter-body wear track dimensions – sunflower oil.

| |

long axis [µm] |

short axis [µm] |

Wear volume [mm3] |

| as-received sunflower |

240.0 |

178.1 |

0.37·10-4

|

| as-received sunflower+MoS2

|

577.0 |

176.2 |

3.95·10-4

|

| crosshatch sunflower |

650.6 |

198.6 |

6.39·10-4

|

| crosshatch sunflower+MoS2

|

718.6 |

241.3 |

10.45·10-4

|

| dimples sunflower |

654.6 |

150.6 |

5.17·10-4

|

| dimples sunflower+MoS2

|

694.6 |

148.7 |

6.22·10-4

|

4. Conclusions

The surface morphology of the AISI 316L samples was modified through laser surface texturing, resulting in the creation of crosshatch and dimples patterns with characteristic bulges of the surface-hardened ejected material around the textures.

Within tribological analysis we compared lubricated sliding behaviour in two vegetable oils, jojoba and sunflower with or without addition of MoS2 nanotubes. Under lubricated conditions the textured surfaces demonstrate more than 50% lower friction as compared to untextured ones, indicating micro-hydrodynamic effects and a shift towards hydrodynamic lubrication regime. Overall, the crosshatch pattern generally exhibited lower friction than the dimples pattern (10-20% lower COF), with the addition of MoS2 nanotubes not having any significant effect on the COF under the investigated contact conditions. The possible reason is a relatively short length of the MoS2 nanotubes in comparison with deepness of the laser-texturing channels, which limits their contribution to the friction contact. Improved friction behaviour of crosshatch pattern was supported with better oil spreadability and oil retention capacity results. Furthermore, lubrication under jojoba oil with lower viscosity, lower ORC but better spreadability also results in lower COF than for sunflower oil.

Texturing reduced wear of the stainless steel disc but led to approximately one order of magnitude larger wear rate of the steel counter-body, primarily due to the presence of hard bulges around the textured patterns. The use of jojoba oil with better spreadability effect generally resulted in lower counter-body wear compared to sunflower oil. However, the addition of MoS2 nanotubes reduced ORC and increased counter-body wear, mainly by reducing micro-hydrodynamic effects of the textured surface.

In summary, the crosshatch pattern exhibits better oil retention capacity and lower friction in combination with different vegetable oils, thus making it a promising choice for improving tribological performance in various environmentally friendly applications.

Author Contributions

Conceptualization, M.C. and A.K; methodology, M.C., A.K. and D.K..; formal analysis, M.C.; in-vestigation, M.C. and A. K.; writing—original draft preparation, M. C. and A. K.; writing—review and editing, M. C., A. K., B. P. and M. R.; All authors have read and agreed to the published version of the manuscript.

Funding

Slovenian Research Agency, research core funding No. P2-0132 and P2-0050.

Acknowledgments

The authors acknowledge the financial support from the Slovenian Research Agency (research core funding No. P2-0132 and P2-0050). The authors thank Dr Tadeja Kosec, Head of Laboratory for Metals, Corrosion and Anti-Corrosion Protection, for allowing the use of the TRIBOtechnic friction testing tribometer at the Slovenian National Building and Civil Engineering Institute.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Okechukwu, N.N.; Byun, J.; Kim, J.; Park, J.; Kwon, S.; Chung, S.; Kwon, S.; Choi, W. , Friction Assessment of Canola Oil on Contact Bearing Materials, Tribol. Lubr. 36 (2020) 11–17. [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. , Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions, Tribol. Int. 65 (2013) 28–36. [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. , A review of recent advances in tribology, Friction. 8 (2020) 221–300. [CrossRef]

- Sahu, J.; Panda, K.; Gupta, B.; Kumar, N.; Manojkumar, P.A.; Kamruddin, M. , Enhanced tribo-chemical properties of oxygen functionalized mechanically exfoliated hexagonal boron nitride nanolubricant additives, Mater. Chem. Phys. 207 (2018) 412–422. [CrossRef]

- Xu, Y.; Liu, Z.; Dearn, K.D.; Dong, Y.; You, T.; Hu, X. , Thermo-tribological behaviour of microgels for improved aqueous lubrication for steel/UHMWPE contact, Tribol. Int. 130 (2019) 63–73. [CrossRef]

- Wojciechowski, L.; Kubiak, K.J.; Mathia, T.G. , Roughness and wettability of surfaces in boundary lubricated scuffing wear, Tribol. Int. 93 (2016) 593–601. [CrossRef]

- Lee, C.; Kim, A.; Kim, J. , Electrochemically etched porous stainless steel for enhanced oil retention, Surf. Coatings Technol. 264 (2015) 127–131. [CrossRef]

- Hao, X.; Sun, P.; Xiao, S.; Yang, Y.; Li, L. Tribological performance of surface with different wettability under ball-on-disc test, Appl. Surf. Sci. 501 (2020) 144228. [CrossRef]

- Zhang, N.; Yang, F.; Jiang, F.; Zhang, Y.; Liu, G. Investigation of tribological performance of micro-groove textured cemented carbide surfaces, Surf. Eng. 36 (2020) 1190–1199. [CrossRef]

- Quan, S.; Yong, G.; Jun, G.; Liu, X.; Yongping, J.; Shuyi, Y. , Effect of fish scale texture on friction performance for reciprocating pair with high velocity, Ind. Lubr. Tribol. 72 (2020) 497–502. [CrossRef]

- Ma, J.; Yi, P.; Jia, H.; Jiang, Y.; Sun, J.; Zhan, X.; Liu, Y. Effects of oil retention property for sinusoidal textures on tribological characteristics under scarcity oil supply, Tribol. Int. 158 (2021) 106918. [CrossRef]

- Kaur, S.; Ghadirinejad, K.; Oskouei, R.H. , An Overview on the Tribological Performance of Titanium Alloys with Surface Modifications for Biomedical Applications, Lubricants. 7 (2019) 65. [CrossRef]

- Hu, T.; Hu, L. , Tribological Properties of Lubricating Films on the Al-Si Alloy Surface via Laser Surface Texturing, Tribol. Trans. 54 (2011) 800–805. [CrossRef]

- Ye, Y.; Wang, C.; Chen, H.; Wang, Y.; Zhao, W.; Mu, Y. , Micro/Nanotexture Design for Improving Tribological Properties of Cr/GLC Films in Seawater, Tribol. Trans. 60 (2017) 95–105. [CrossRef]

- Conradi, M.; Kocijan, A.; Klobčar, D.; Podgornik, B. Tribological response of laser-textured Ti6Al4V alloy under dry conditions and lubricated with Hank’s solution, Tribol. Int. 160 (2021) 107049. [CrossRef]

- Bhaduri, D.; Batal, A.; Dimov, S.S.; Zhang, Z.; Dong, H.; Fallqvist, M.; M’Saoubi, R. , On Design and Tribological Behaviour of Laser Textured Surfaces, Procedia CIRP. 60 (2017) 20–25. [CrossRef]

- Liang, L.; Yuan, J.; Li, X.; Yang, F.; Jiang, L. , Wear behavior of the micro-grooved texture on WC-Ni3Al cermet prepared by laser surface texturing, Int. J. Refract. Met. Hard Mater. 72 (2018) 211–222. [CrossRef]

- Martinez, J.M.V.; Del Sol Illana, I.; Victoria, P.I.; Salguero, J. , Assessment the Sliding Wear Behavior of Laser Microtexturing Ti6Al4V under Wet Conditions, (n.d.). [CrossRef]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. , Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review, Materials (Basel). 11 (2018) 487. [CrossRef]

- Remškar, M.; Viršek, M.; Mrzel, A. The MoS2 nanotube hybrids, Appl. Phys. Lett. 95 (2009) 133122. [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering tribology / Gwidon Stachowiak, Andrew W. Batchelor, (2014) xxviii, 852 pages ; https://books.google.com.br/books?hl=pt-BR&lr=&id=_wVoTz1pDlwC&oi=fnd&pg=PR1&dq=G.+W.+Stachowiak,+A.W.+Batchelor,+Engineering+tribology,+Butterword+Heineman,+Oxford,+2005.&ots=J2HOjioW2q&sig=CuA64kOpDrvhloa2PVwwfvarj8Q#v=onepage&q&f=false.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).