Submitted:

19 July 2023

Posted:

24 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

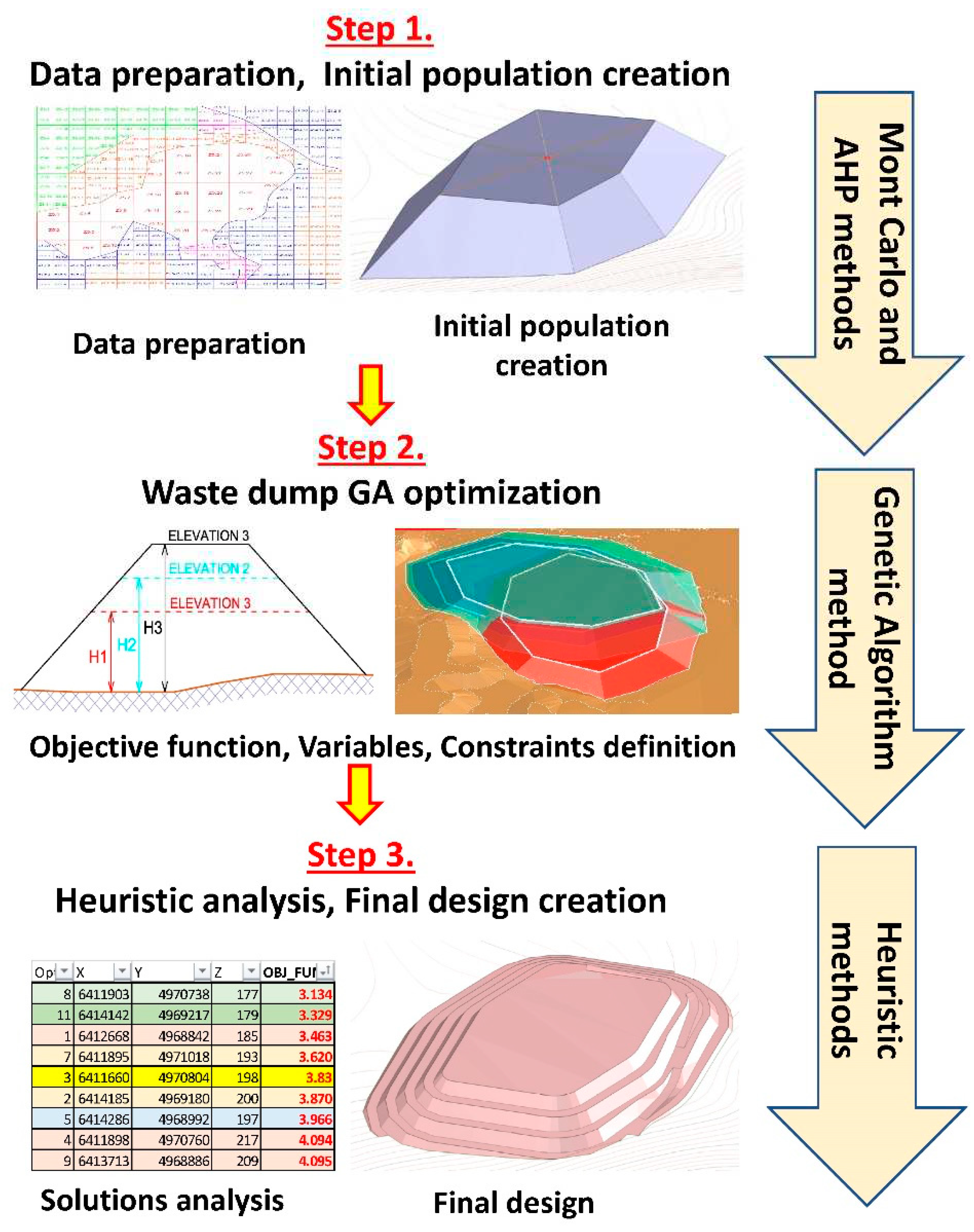

2. Hybrid model Development

2.1. Methods

- Random selection (Monte Carlo simulation) - to simulate the geometry of potential solutions,

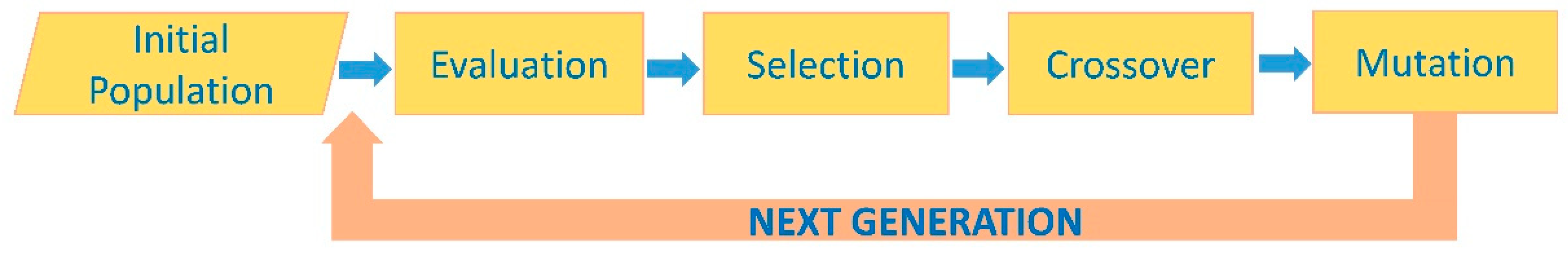

- Genetic algorithm - to optimise solutions,

- Multi-criteria decision making - AHP method - for defining variable values,

- Heuristic method - for expert interpretation and finalisation of solutions

- Generation of a static model (process functions),

- Defining input parameters through probability distribution functions,

- Generation of random variables from the set of distribution of input parameters,

- Analysis of the obtained results.

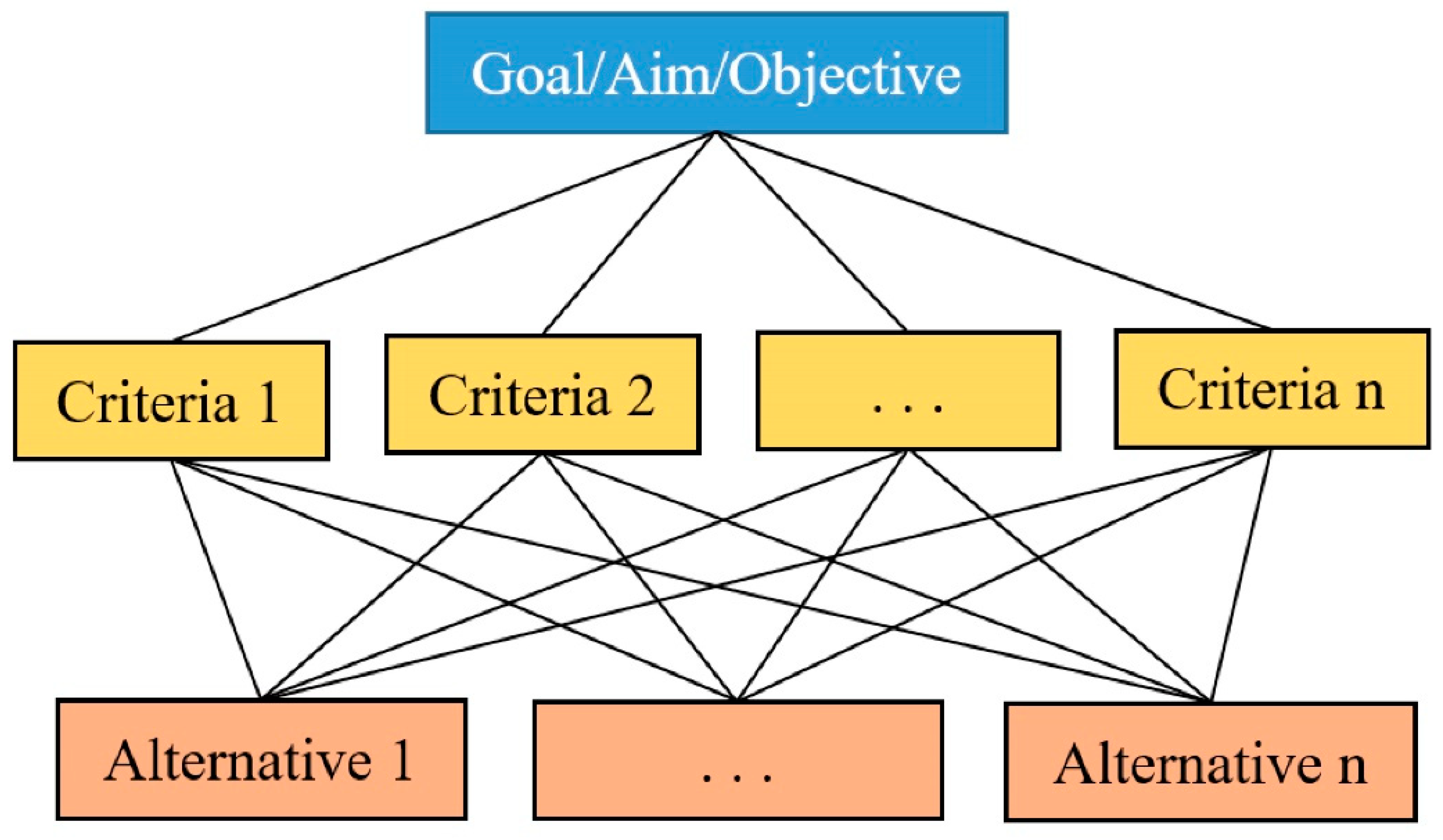

- Define the unstructured problem and clearly state the objectives and outcomes.

- Decompose the complex problem into a hierarchical structure with decision elements (criteria, detailed criteria and alternatives).

- Pairwise comparisons - assess the relative importance of criteria and alternatives through pairwise comparisons (using a scale that reflects their relative preference or importance).

- Derive priority weights - based on the pairwise comparisons, the AHP calculates priority weights for each element in the hierarchy (these weights quantify the relative importance of each element in achieving the goal).

- Consistency check - evaluates the consistency of the pairwise comparisons to ensure their reliability.

- Aggregation and ranking - combine the priority weights to obtain a comprehensive ranking of the alternatives.

2.2. Model algorithm

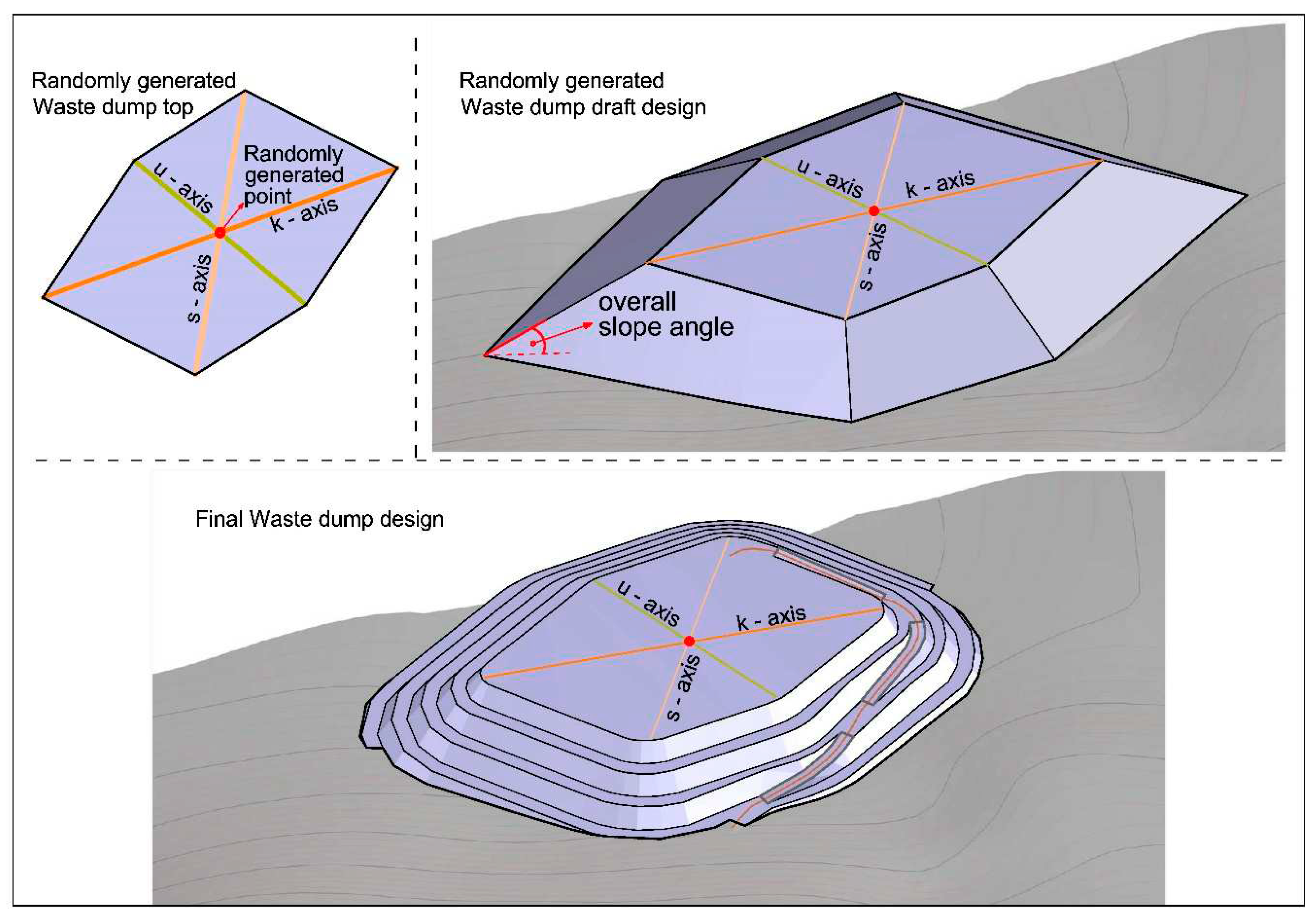

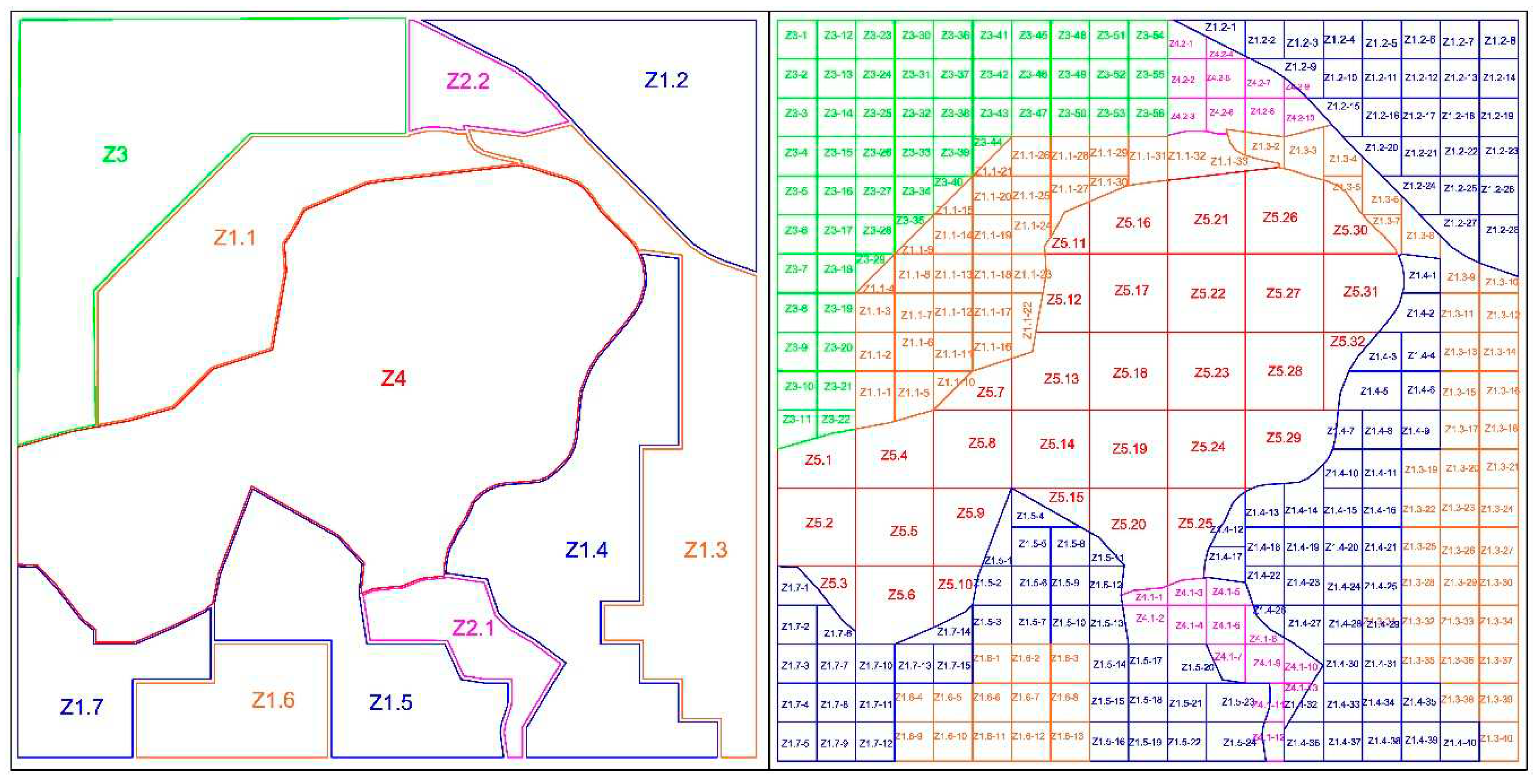

2.2.1. Step 1 – Data preparation and initial population creation

- Waste dump capacity,

- Overall slope angle of waste dump,

- Basic geometry (shape) and elevation of waste dump top area,

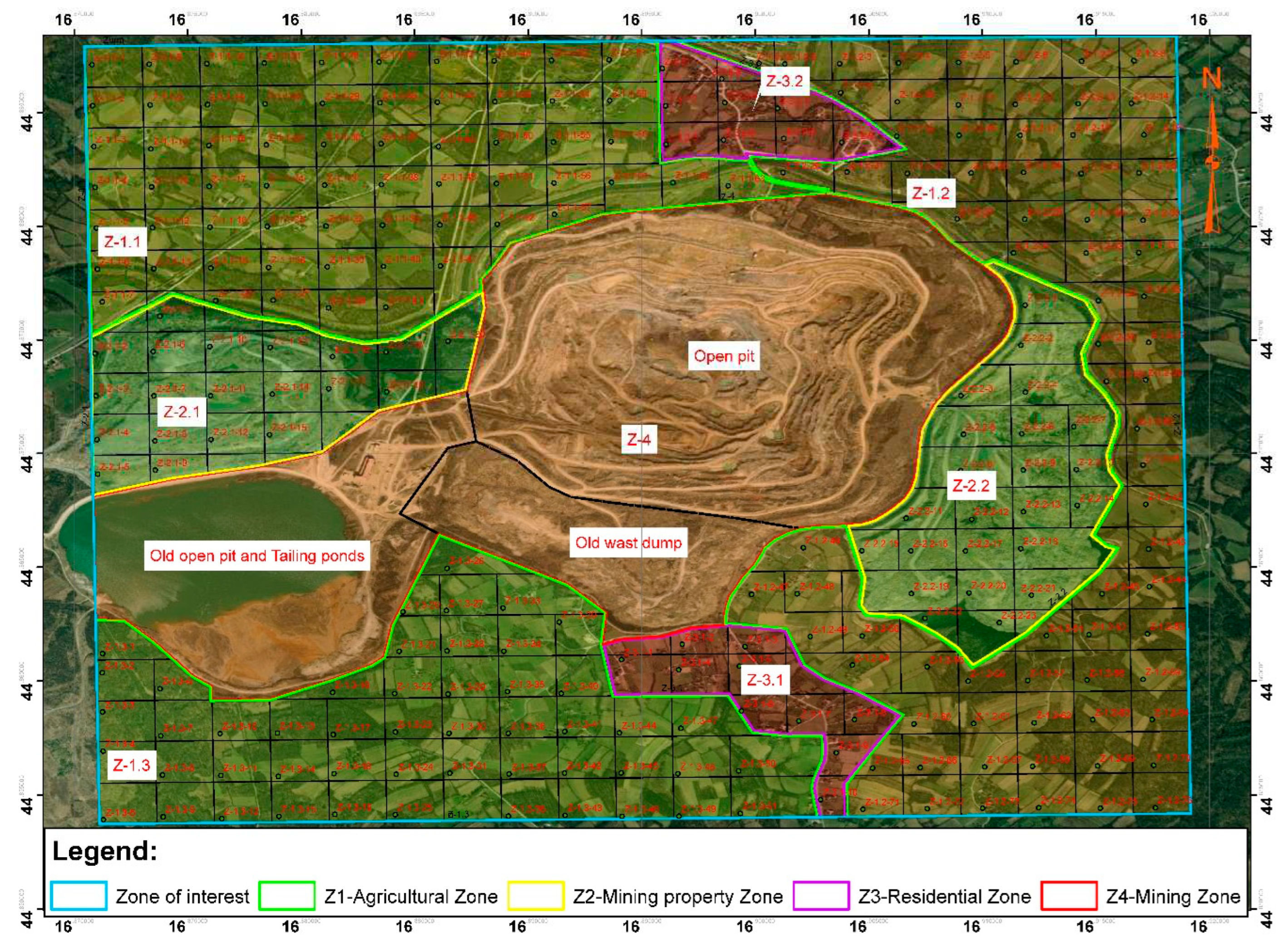

- Definition of terrain zones to be analysed by the model and zone evaluation.

2.2.2. Step_2 – Waste dump optimization - objective function, constraints and variables

- Costs related to the value of the land on which the waste dump is built; and

- Haulage costs.

- waste dump capacity (volume),

- waste dump elevation,

- waste dump position in XY plane.

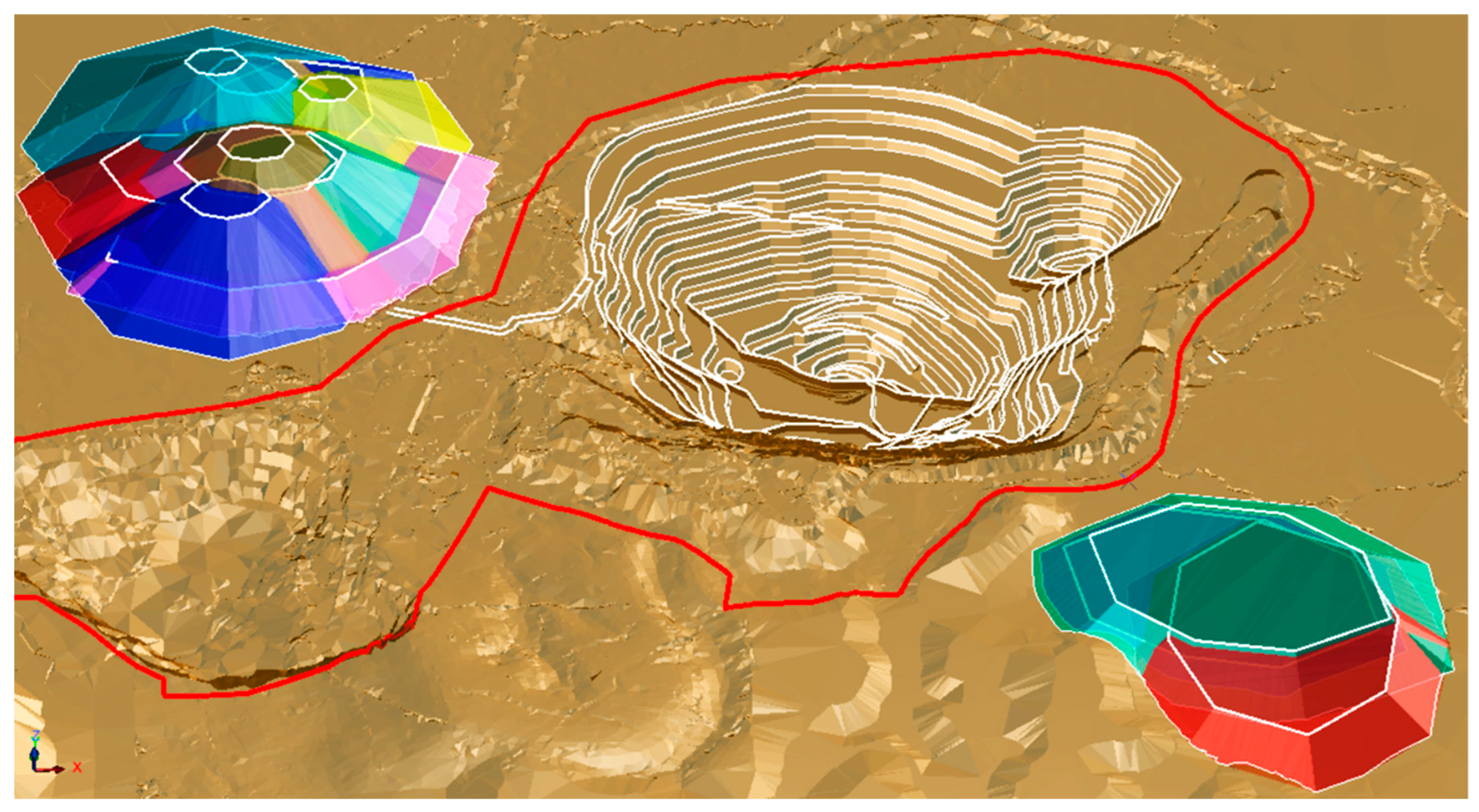

2.2.3. Step 3 – Heuristic analysis of optimization results and final waste dump design

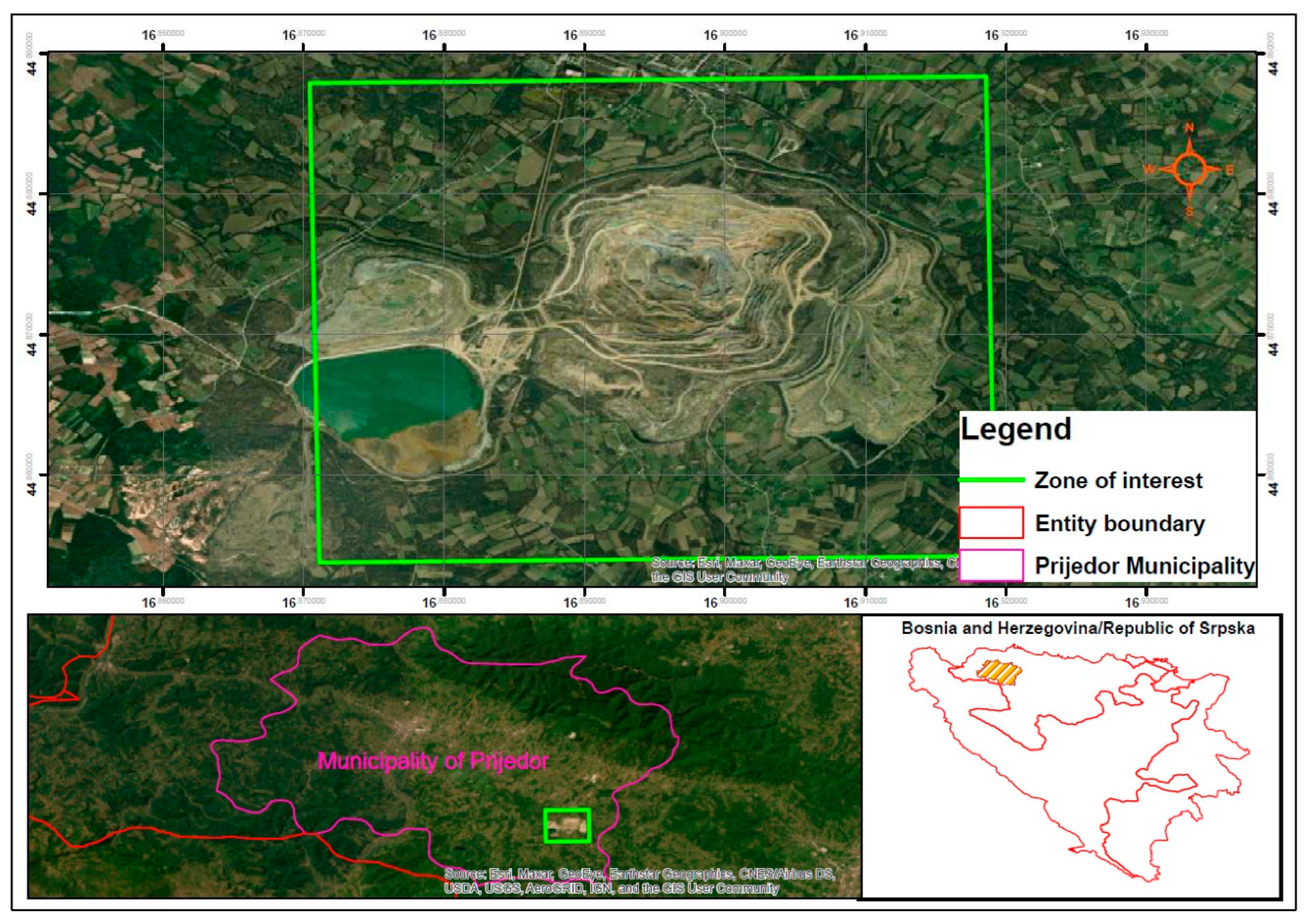

3. Case study

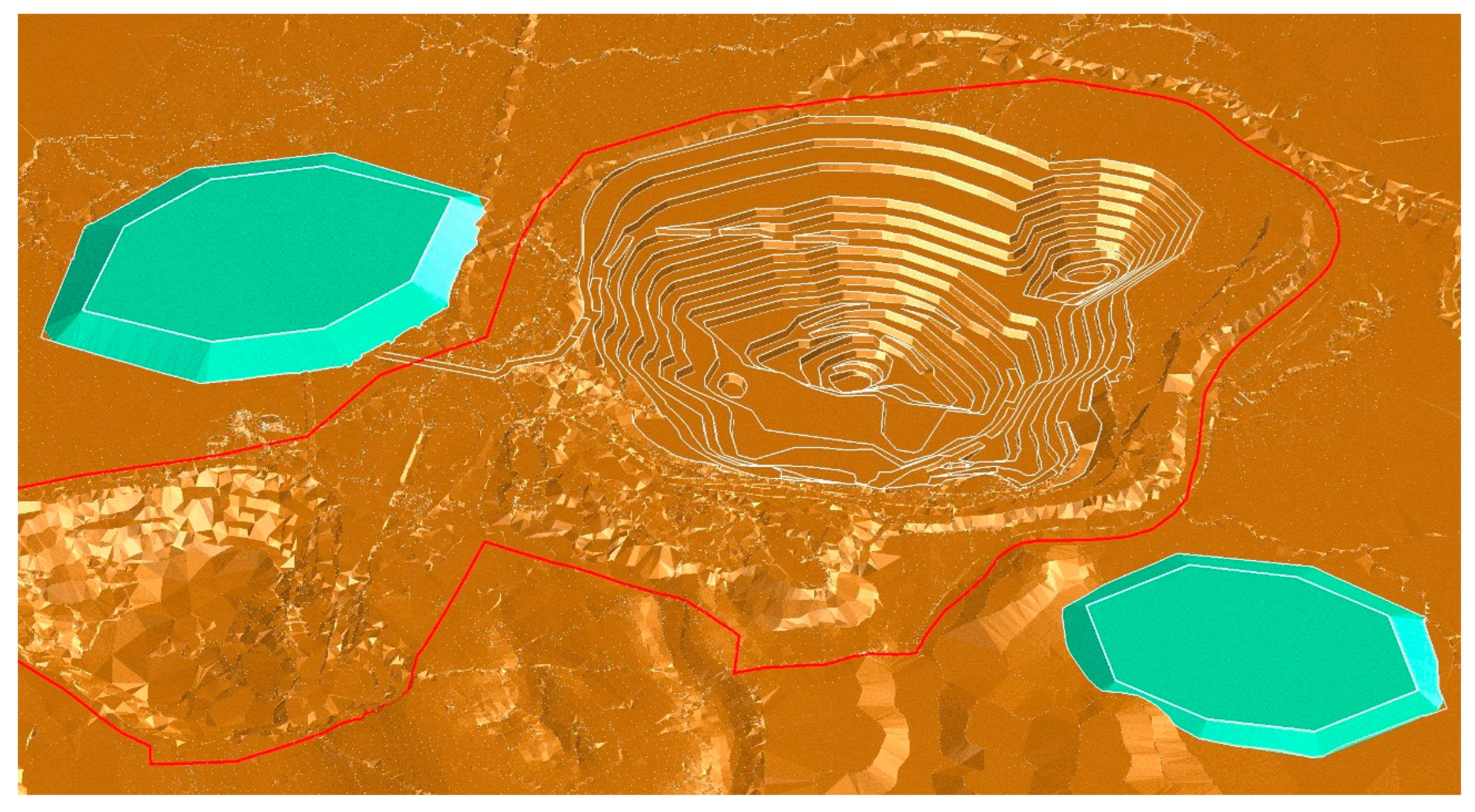

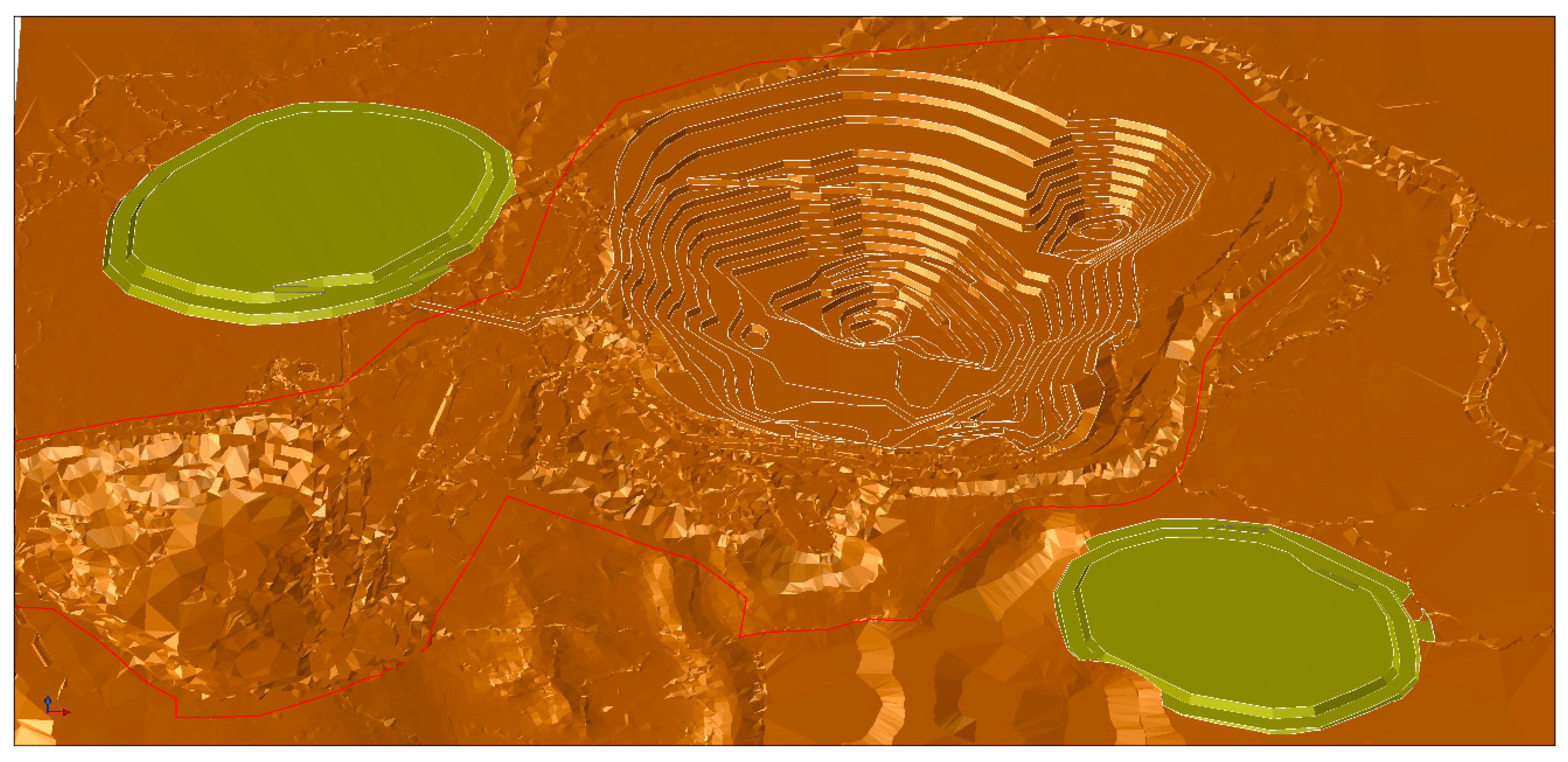

3.1. Buvac waste dump optimization

4. Analysis of results and discussion

| Compered Options | Option 1 (solution - rang number 6) |

Option 2 (combination of solutions with rang number 1 and 2) |

|

|---|---|---|---|

| solution with rang number 1 | solution with rang number 2 | ||

| Top elevation | 200 m | 177 m | 179 m |

| Volume | 21.48 mil.m3 | 13.05 | 8.12 |

| Volume sum = 13.41+8.74= 21.2 mil. m3 | |||

| Objective function | 3.87 | 3.13 | 3.33 |

| 3.21 (mean value weighted by volume) | |||

- Bench height is 10 m, Bench angle is 33°, Berm width is 40 m,

- Ramp gradient is 8%, Ramp width is 25 m.

Author Contributions

Funding

Conflicts of Interest

References

- Dincer, T. Application pit optimization algorithms beyond open pit limits. In Proceedings of the seventeenth International Mining Congress and Exhibition of Turkey: IMCET 2001, Ankara, Turkey, 19-22 June 2001; pp. 549–556. [Google Scholar]

- Scoble, M.; Klein, B.; Dunbar, W.S. Mining waste: Transforming mining system for waste management. Int. j. surf. min. reclam. environ. 2003, 17, 123–135. [Google Scholar] [CrossRef]

- Alarie, S.; Gamache, M. Overview of solution strategies used in truck dispatching systems for open pit mines. Int. j. surf. min. reclam. environ. 2002, 16, 59–76. [Google Scholar] [CrossRef]

- Ozdemir, B.; Kumral, M. A system-wide approach to minimize the operational cost of bench production in open-cast mining operations. Int J Coal Sci Technol 2019, 6, 84–94. [Google Scholar] [CrossRef]

- Lizotte, Y.; Bonates, E. Truck and shovel dispatching rules assessment using simulation. Min. Sci. Technol. 1987, 5, 45–58. [Google Scholar] [CrossRef]

- Subtil, R. F.; Silva, D. M.; Alves, J. C. A practical approach to truck dispatch for open pit mines. In Proceedings of the 35th APCOM Symposium, Wollongong, Australia, 24-30 September 2011; pp. 765–778. [Google Scholar]

- Li, Y.; Topal, E.; Williams, D. Waste rock dumping optimization using mixed integer programming (MIP). Int. J. Min. Reclam. Environ. 2013, 27, 425–436. [Google Scholar] [CrossRef]

- Mudd, G.M. The Sustainability of Mining in Australia: Key Production Trends and Environmental Implications for the Future, Research Report No. RR5; Department of Civil Engineering, Monash University and Mineral Policy Institute, Melbourne, Australia, 2009.

- Northey, S.; Mohr, S.; Mudd, G.M.; Weng, Z.; Giurco, D. Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining. Resour. Conserv. Recycl. 2014, 83, 190–201. [Google Scholar] [CrossRef]

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef]

- Calvo, G.; Palacios, J. L.; Valero, A. The influence of ore grade decline on energy consumption and GhG emissions: The case of gold. Environ. Dev. 2022, 41, 100683. [Google Scholar] [CrossRef]

- Li, Y.; Topal, E.; Williams, D.J. Optimisation of waste rock placement using mixed integer programming. Min. Tech. 2014, 123, 220–229. [Google Scholar] [CrossRef]

- Li, Y.; Topal, E.; Ramazan, S. Optimising the long-term mine waste management and truck schedule in a large-scale open pit mine. Mining Technology 2016, 125, 35–46. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Topal, E.; Williams D., J. A new tool for optimisation of mine waste management in potential acid forming conditions. In Proceedings of the Tailings and mine waste management for the 21st century, Sydney, Australia, 27-28. July 2015. [Google Scholar]

- Kumral, M.; Dimitrakopoulos, R. Selection of waste dump sites using a tabu search algorithm. J. South. Afr. Inst. Min. Metall. 2008, 108, 9–13. [Google Scholar]

- Hajarian, A.; Osanloo, M. A New Developed Model to Determine Waste Dump Site Selection in Open Pit Mines: An Approach to Minimize Haul Road Construction Cost. Int. J. Eng. (IJE) 2020, 33, 1413–1422. [Google Scholar] [CrossRef]

- Shahba, S.; Arjmandi, R.; Monavari, M.; Ghodusi, J. Application of multi-attribute decision-making methods in SWOT analysis of mine waste management (case study: Sirjan's Golgohar iron mine, Iran). Resour. Policy 2017, 51, 67–76. [Google Scholar] [CrossRef]

- Osanloo, M.; Ataei, M. Factors affecting the selection of site for arrangement of pit rock-dumps. J. Min. Sci. 2003, 39, 148–153. [Google Scholar] [CrossRef]

- Hekmat, A.; Osanloo, M.; Shirazi, A. M. New approach for selection of waste dump sites in open pit mines. Min. Tech. 2008, 117, 24–31. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Ahmadi, Z.; Oraee, K.; Basiri, M. H. Waste Dump Site Selection by Using Fuzzy VIKOR. In Proceedings of the 5th Conference of Applied Geology and the Environment, Eslamshahr, Iran, 07. March 2011. [Google Scholar]

- Mensah, F. Integrating Global Positioning Systems and Geographic Information Systems in Mine Waste disposal: The Case of Goldfields Ghana Limited. MSc Thesis, University of Mines and Technology, Tarkwa, 2007. [Google Scholar]

- Suleman, H. A.; Baffoe, P. E. Selecting suitable sites for mine waste dumps using GIS techniques at Goldfields, Damang Mine. Ghana Min. J. 2017, 17, 9–17. [Google Scholar] [CrossRef]

- Liu, Y. Y.; Bao, J. J.; Liu, Y. J. Discussion on the safety distance between the bottom of the inner dump and the stope. Surface Coal Mining Technology 2003, 2, 11–13. [Google Scholar]

- Verma, D.; Kainthola, A.; Gupte, S. S.; Singh, T. N. A finite element approach of stability analysis of internal dump slope in Wardha valley coal field, India, Maharashtra. American Journal of Mining and Metallurgy 2013, 1, 1–6. [Google Scholar]

- Cheskidov, V. I.; Norri, V. K. Stripping with direct dumping in Kuzbass open pit mines: The current state and prospects. J. Min. Sci. 2016, 52, 725–731. [Google Scholar] [CrossRef]

- Stevanović, D.; Banković, M.; Rupar, V.; Milisavljević, V.; Cvjetić, A.; Kržanović, D. Waste Dump Design Optimization, Case Study Open Pit Drmno. In Proceedings of the 6th International Symposium Mining and Environmental Protection, MEP 17, Vrdnik, Serbia, 21-24. June 2017; pp. 282–286. [Google Scholar]

- Sari, Y. A.; Kumral, M. A landfill based approach to surface mine design. J. Cent. South Univ. 2018, 25, 159–168. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, D. Research on Inpit Dumping Height during Tracing Mining Period between Two Adjacent Surface Coal Mines. Adv. Civ. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Kaykov, D.; Koprev, I. Rationalising The Location And Design Of The Waste Dump In The Case Of Open-Pit Mining. Sustainable Extraction and Processing of Raw Materials 2020, 1, 42–46. [Google Scholar] [CrossRef]

- Williams, D.J.; Scott, P.; Johnston, D.; Lee, G. Rock Dump Design to Limit Potential Acid Drainage. In Proceedings of the First International Seminar on the Management of Rock Dumps, Stockpiles and Heap Leach Pads, Perth, Western Australia, 5-6 March 2008. Australian Centre for Geomechanics (ACG); pp. 207–217. [Google Scholar]

- Ozturk, C.A.; Ercelebi, S.; Onsel, I.E.; Ozkan, M. Open pit mine waste dump area design based on stability principles. In Proceedings of the 24th International Mining Congress and Exhibition of Turkey, IMCET'15, Antalya, Turkey, 14-17. April 2015; pp. 570–578.

- Puell Ortiz, J. Methodology for a dump design optimization in large-scale open pit mines. Cogent Eng. 2017, 4, 1387955. [Google Scholar] [CrossRef]

- Metropolis, N.; Ulam, S. The Monte Carlo Method. J. Am. Stat. Assoc. 1949, 44, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Anderson, H. L. Metropolis, Monte Carlo and the MANIAC. Los Alamos Science 1986, 14, 96–108. [Google Scholar]

- Vujić, S.; Ivić, A. Mathematical methods in mining and geology, Faculty of Mining and Geology, University of Belgrade, Serbia, 1991.

- Stevanović, D. Open pit mine optimization and planning with stochastic models. PhD dissertation, Faculty of Mining and Geology, University of Belgrade, Serbia, 2015.

- Sauvageau, M.; Kumral, M. Cash flow at risk valuation of mining project using Monte Carlo simulations with stochastic processes calibrated on historical data. The Engineering Economist 2018, 63, 171–187. [Google Scholar] [CrossRef]

- Wei, J.; Jian, Z.; Jianglan, L. Mining Investment Risk Analysis Based on Monte Carlo Simulation. In Proceedings of the 5th International Conference on Management of e-Commerce and e-Government, Wuhan, China, 5-6. November 2011; pp. 72–75. [Google Scholar] [CrossRef]

- Kopacz, M.; Kryzia, D.; Kryzia, K. Assessment of sustainable development of hard coal mining industry in Poland with use of bootstrap sampling and copula-based Monte Carlo simulation. J. Clean. Prod. 2017, 159, 359–373. [Google Scholar] [CrossRef]

- Holland, J. H. Adaptation in Natural and Artificial Systems, The University of Michigan Press, Ann Arbor, 1975.

- Еckhardt, R. Stan Ulam, John von Neumann, and the Monte Carlo method. Los Alamos Science Special Issue 1987, 15, 131–141. [Google Scholar]

- Katoch, S.; Chauhan, S. S.; Kumar, V. A review on genetic algorithm: past, present, and future. Multimed. Tools. Appl. 2020, 80, 8091–8126. [Google Scholar] [CrossRef]

- Stanković, R.; Lilić, N.; Obradović, I. Prediction of air pollution by coupling neural networks and genetic algorithms. In Proceedings of the Informatics, ecology and management in surface mining of mineral resources, Aranđelovac, Serbia, June 1997; pp. 211–220. [Google Scholar]

- Chang, P. C.; Huang, W. H.; Ting, C. J. Dynamic diversity control in genetic algorithm for mining unsearched solution space in TSP problems. Expert Syst. Appl. 2010, 37, 1863–1878. [Google Scholar] [CrossRef]

- Pham, D. T.; Karaboga, D. Intelligent optimisation techniques: genetic algorithms, tabu search, simulated annealing and neural networks, Springer, London, 2012. [CrossRef]

- Alipour, A.; Khodaiari, A.A.; Jafari, A.J.; Tavakkoli-Moghaddam, R. Production scheduling of open-pit mines using genetic algorithm: a case study. Int. J. Manag. Sci. Eng. Manag. 2020, 15, 176–183. [Google Scholar] [CrossRef]

- Noriega, R.; Pourrahimian, Y. A systematic review of artificial intelligence and data-driven approaches in strategic open-pit mine planning. Resour. Policy 2022, 77, 102727. [Google Scholar] [CrossRef]

- Gu, Z.; Cao, M.; Wang, C.; Yu, N.; Qing, H. Research On Mining Maximum Subsidence Prediction Based On Genetic Algorithm Combined with Xgboost Model. Sustainability 2022, 14, 10421. [Google Scholar] [CrossRef]

- Ahmadi, M.R.; Shahabi, R.S. Cutoff grade optimization in open pit mines using genetic algorithm. Resour. Policy 2018, 55, 184–191. [Google Scholar] [CrossRef]

- Paithankar, A.; Chatterjee, S.; Goodfellow, R. Open-pit mining complex optimization under uncertainty with integrated cut-off grade based destination policies. Resour. Policy 2021, 70, 101875. [Google Scholar] [CrossRef]

- Williams, J.; Singh, J.; Kumral, M.; Ramirez Ruiseco, J. Exploring Deep Learning for Dig-Limit Optimization in Open-Pit Mines. Nat. Resour. Res. 2021, 30, 2085–2101. [Google Scholar] [CrossRef]

- Banković, M.; Stevanović, D.; Pešić, M.; Tomašević, A.; Kolonja, Lj. Improving efficiency of thermal power plants through mine coal quality planning and control, Therm. Sci. 2018, 22, 721–733. [Google Scholar] [CrossRef]

- Saaty, T. The Analytical Hierarchy Process, Mc-Graw-Hill, New York, NY, USA, 1980.

- Pessoa, I. C.; Trojan, F.; Oliveira, G. A.; Setti, D. The statistical sampling about levels of utilization of multi-criteria methods to solve problems in POM. In POMS 26th Annual Conference - Production and Operations Management Society, Wasington DC, USA, 8-11 May 2015.

- Saaty, T. Decision-making with the AHP: Why is the principal eigenvector necessary. Eur. J. Oper. Res. 2003, 145, 85–91. [Google Scholar] [CrossRef]

- Lee, A. H. I.; Chen, W. C.; Chang, C. J. A fuzzy AHP and BSC approach for evaluating performance of IT department in manufacturing industry in Taiwan. Expert Syst. Appl. 2008, 34, 96–107. [Google Scholar] [CrossRef]

- Petković, D.; Radovanović, M. Primena genetskog algoritma za optimizaciju obradnih procesa na primeru struganja. IMK-14-Istraživanje i razvoj 2011, 17, 11–16. [Google Scholar]

- Hustrulid, W. A.; Kuchta, M.; Martin, R. K. Open pit mine planning and design, two volume set & CD-ROM pack, 3rd ed., CRC Press, London, 2013. [CrossRef]

- Li, Y.; Topal, E.; Williams, D. Waste rock dumping optimisation using mixed integer programming (MIP). Int. J. Min. Reclam. Environ. 2013, 27, 425–436. [Google Scholar] [CrossRef]

- Matlab, MathWorks, additional information. Available online: https://www.mathworks.com/products/matlab.

- Excel, Microsoft, additional information. Available online: https://www.microsoft.com/en-us/microsoft-365/excel.

- Geovia Surpac, Dessault Systemes, additional information. Available online: https://www.3ds.com/products-services/geovia/products/surpac/.

| Factor | Coefficient | Rang | Index |

|---|---|---|---|

| Potential open pit expansion | 0.657 | 1 | K1 |

| Potential administrative obstacles | 0.105 | 3 | K2 |

| Increased environmental impact | 0.238 | 2 | K3 |

| Model operational mod |

Volume range (m3) |

Number of Initial population members | Number of optimizations | Generations number |

|---|---|---|---|---|

| Mod 2 | 6x106 - 22x106 | 2,250 | 15 | 5 |

| Solution Rang Number |

Point Coordinates | Haul Distance Component (m) | Costs (mil. €) |

Waste Dump Volume (mil. m3) | Objective Function (€/m3) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | Horiz. | Verti. | C1 | C2 | C3 | |||

| 1. | 6,411,903 | 4,970,738 | 177 | 1,288 | 1,740 | 13.82 | 28.02 | 0.19 | 13.05 | 3.13 |

| 2. | 6,414,142 | 4,969,217 | 179 | 1,459 | 1,786 | 10.21 | 18.75 | 0.14 | 8.12 | 3.33 |

| 3. | 6,411,895 | 4,971,018 | 193 | 1,430 | 2,053 | 13.68 | 29.46 | 0.14 | 11.96 | 3.62 |

| 4. | 6,412,230 | 4,971,409 | 192 | 1,465 | 2,048 | 21.05 | 44.15 | 0.20 | 17.97 | 3.64 |

| 5. | 6,411,660 | 4,970,804 | 198 | 1,537 | 2,158 | 12.23 | 25.76 | 0.14 | 9.95 | 3.83 |

| 6. | 6,414,185 | 4,969,180 | 200 | 1,516 | 2,207 | 24.22 | 52.90 | 0.18 | 20.48 | 3.87 |

| 7. | 6,414,286 | 4,968,992 | 197 | 1,719 | 2,150 | 24.70 | 46.32 | 0.20 | 17.96 | 3.97 |

| 8. | 6,411,898 | 4,970,760 | 217 | 1,301 | 2,537 | 16.43 | 48.06 | 0.15 | 15.79 | 4.09 |

| 9. | 6,411,834 | 4,971,128 | 209 | 1,543 | 2,374 | 10.63 | 24.53 | 0.11 | 8.61 | 4.10 |

| 10. | 6,412,016 | 4,971,044 | 216 | 1,348 | 2,520 | 9.36 | 26.26 | 0.12 | 8.68 | 4.12 |

| 11. | 6,411,836 | 4,970,765 | 216 | 1,359 | 2,524 | 20.39 | 56.78 | 0.16 | 18.75 | 4.12 |

| 12. | 6,411,942 | 4,970,816 | 220 | 1,286 | 2,598 | 19.81 | 60.04 | 0.16 | 19.26 | 4.15 |

| 13. | 6,411,761 | 4,970,614 | 220 | 1,378 | 2,606 | 14.70 | 41.73 | 0.12 | 13.34 | 4.24 |

| 14. | 6,411,836 | 4,970,765 | 236 | 1,359 | 2,912 | 21.73 | 69.84 | 0.17 | 19.98 | 4.59 |

| 15. | 6,411,745 | 4,971,070 | 238 | 1,584 | 2,963 | 25.19 | 70.69 | 0.18 | 19.88 | 4.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).