1. Introduction

The Korean livestock industry has experienced rapid growth, leading to a significant increase in both the number of livestock and meat consumption. However, this growth has also resulted in a decrease in the number of livestock farms and a shift towards large-scale and intensive operations. To manage productivity and control environmental factors such as temperature, humidity, and ventilation, the majority of farms now adopted closed-type livestock pens. While these closed spaces allow for effective management, they also present challenges such as increased livestock manure and odor, as well as higher levels of fine dust. Consequently, there is an elevated risk of workers and animals being exposed to harmful gases and organic dust within these facilities [

1,

2]. In light of the increasing number of occupational accidents among farmers, ensuring the working safety and welfare of workers has become a paramount concern [

3]. Farmers may not possess a complete understanding of the potential hazards and safety risks associated with agricultural work, leading to a lack of adequate precautions.

Livestock facilities commonly generate harmful gases, including ammonia and hydrogen sulfide. Among these, hydrogen sulfide is highly toxic, and exposure to high concentrations can even result in fatalities. When highly concentrated hydrogen sulfide disperses from livestock excrement or slurry due to pig movement and rapid changes in internal airflow, there is a significant risk of workers being exposed to these dangerous gases[

4]. Ammonia is a colorless and irritating toxic gas. Even at low concentrations, ammonia can cause irritation to the eyes and lungs, resulting in inflammation, sneezing, and excessive salivation. Inhaling harmful gases and organic dust can cause acute and chronic poisoning, as well as various serious health issues such as bronchitis, pneumonia, asthma, coughing, allergies, headaches, and dizziness[

5,

6,

7,

8,

9,

10,

11].

Among the methods available for reducing harmful gases, the ventilation system offers both technical and economic advantages. It has the capability to directly remove harmful gases by discharging them outside and can be implemented using the existing infrastructure. However, the introduction of outside air through ventilation can cause rapid temperature changes in the livestock breeding environment, which can negatively impact the immune system, respiratory health, and overall productivity of the animals[

12,

13,

14]. Therefore, when implementing ventilation, it is essential to analyze the resulting thermal environment changes.

There has been limited research on strategies for operating ventilation systems to enhance the working environment in the agricultural field. Moreover, studies that simultaneously consider both the breeding environment and the working environment are even scarcer. Therefore, there is a need for monitoring the internal environment and conducting simulation-based research that takes into account the working environment for workers as well as the animal-centric breeding environment. To improve the working environment, it is common practice to increase the ventilation volume to expel more harmful gases. However, increasing the ventilation volume also leads to greater temperature variations within the livestock breeding area, potentially causing issues in the breeding environment. Additionally, it is crucial to analyze the working and breeding environments concurrently since the ventilation volume and temperature inside the facility are highly correlated. Monitoring the working environment and breeding environment simultaneously poses challenges, as workers enter and exit the area periodically while the pigs remain relatively constant. Therefore, utilizing simulation techniques becomes an effective approach to gather diverse environmental data, such as temperature and location variations within the facility.

Relying solely on field experiments to gather data on the breeding and working environments presents several challenges, including limitations related to time, space, the ability to maintain stable experimental conditions, and restricted measurement points. However, by combining field measurements with computational fluid dynamics (CFD), it becomes possible to overcome these challenges and acquire a substantial amount of qualitative and quantitative data. Such data can be utilized for research purposes, such as investigating automatic environmental control within smart farms and developing management algorithms. Previous studies employing computational fluid dynamics have primarily focused on assessing the breeding environment, but their findings can be extended to encompass other relevant areas as well[

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28].

This research aims to propose a ventilation control standard that considers both the working environment and the breeding environment in a pig house simultaneously by efficiently reducing the concentration of harmful gases at the workers’ height. The study involves measuring and identifying the concentration levels of harmful gases to which workers are exposed during specific tasks in the pig house. The ventilation efficiency by combination of inlet and outlet systems is evaluated using computational fluid dynamics (CFD).

2. Materials and Methods

2.1. Experimental pig house

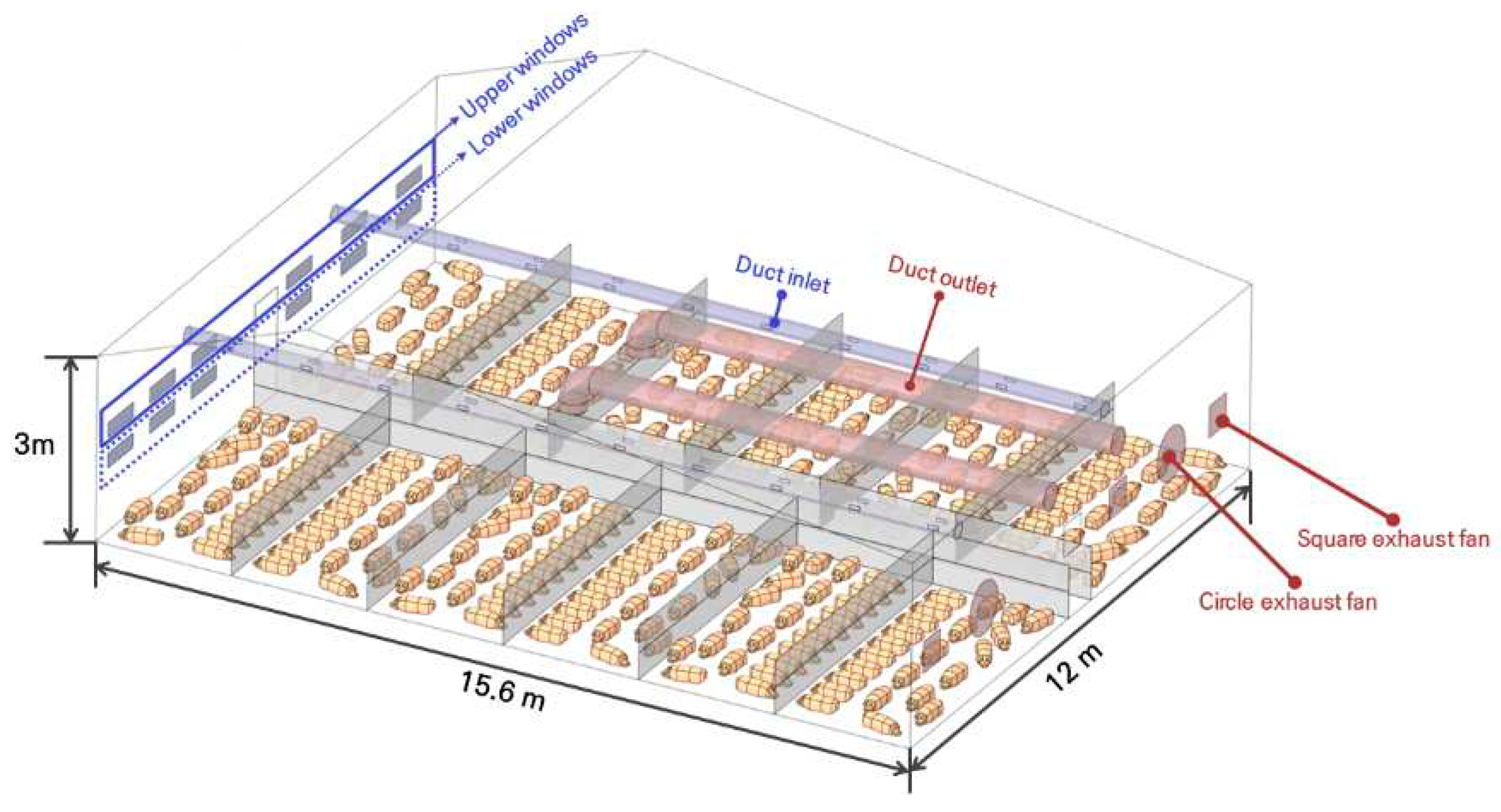

The experiment was conducted in a commercial pig house with a capacity of 15,000 pigs, located in Yeonggwang-gun, Jeollanam-do, Korea. A pigpen that had a relatively high mortality rate was chosen based on interviews with the farm manager. The dimensions of the selected pigpen are 12 meters in width, 15.6 meters in length, and 3.2 meters in height. Inside the pigpen, there is a central corridor that is 0.8 meters wide, and the pigpen is divided into 12 compartments by 1-meter-high walls. Each compartment can accommodate around 18 to 25 fattening pigs. The pigpen has a total capacity for 300 pigs. There are 12 windows (6 upper and 6 lower) that allow outside air to flow into the pigpen through the corridor. Additionally, two duct inlets, each with a diameter of 0.94 meters, are installed on the left and right sides of the pigpen to distribute air evenly throughout (

Figure 1). On the outer wall, there are two circular exhaust fans with a diameter of 1 meter each, as well as three square fans with a length of 0.6 meters per side. These fans are used for extracting air from the pigpen. Furthermore, two 1.5-meter diameter ducts (duct outlets) are installed on the left and right sides, extending from the outside to the center of the pigpen. These ducts serve the purpose of both removing harmful gases to the outside and allowing fresh air to enter (

Figure 2). The ventilation system is operated by utilizing different combinations of inlets and outlets based on the season and internal temperature and humidity conditions.

2.2. Computatinal fluid dynamics

Computational fluid dynamics (CFD) encompasses three main steps: pre-processing, main computational processing, and post-processing. In the pre-processing step, the outer shape of the experimental object and the grid of the target area are designed. In the main computational processing step, the target area is analyzed using numerical analysis techniques, employing equations such as the Navier-Stokes equations. Finally, in the post-processing step, the results of the analysis are qualitatively and quantitatively evaluated. To begin the CFD analysis, the object is designed as a 3D model. Grid design and boundary conditions are then specified. The calculations are conducted using FLUENT software (version 18.1., ANSYS Inc., USA)[

29], employing the principles of mass conservation, energy generation and movement, and the law of momentum conservation on each grid. The model utilizes specific boundary conditions, which are outlined in

Table 1.

2.3. Tracer gas decay method

Tracer gas decay (TGD) method was used to compute regional ventilation efficiency using CFD simulation[

30,

31,

32,

33]. The conventional method used for calculating the internal ventilation rate was based on the mass flow rate calculation. This determines the air replacements per unit hour, assuming that all the air entering the pig house was used to replace the air by ventilation. While the mass flow rate calculation method offers the advantage of a straightforward calculation for determining the ventilation volume of the entire facility, it does not allow for the analysis of regional ventilation effects. Consequently, it is not suitable for evaluating the ventilation volume of individual compartments within the pig house or the dilution effect of harmful gases. It does not provide insights into the flow behavior inside the facility, which can vary based on the combination of ventilation structures.

Among air age theories, the tracer gas decay method (TGD method) is utilized to calculate the regional ventilation efficiency by analyzing the change in tracer gas concentration over time. This study employs the TGD method to analyze the regional ventilation efficiency of the pig house. This method quantitatively determines the ventilation amount by analyzing the reduction in concentration over time after initiating ventilation, after patching a tracer gas having a uniform concentration. The Air Exchange Rate (AER, min⁻¹) is used as a unit to denote the amount of ventilation, representing the number of times the incoming air from outside replaces the entire indoor air. In the CFD simulation, carbon dioxide was uniformly distributed at a concentration of 2000 ppm inside the pig house, while the air entering from outside contained 400 ppm of carbon dioxide.

Where

is air exchange rate of mass flow (min

-1),

is air exchange rate of tracer gas decay(min-1), V is volume of pig house (m

3),

is velocity at inlet and outlet (m·s

-1),

is vent area of inlet and outlet (m

2),

is concentration of tracer gas at

time (ppm)

2.4. Experimental procedure

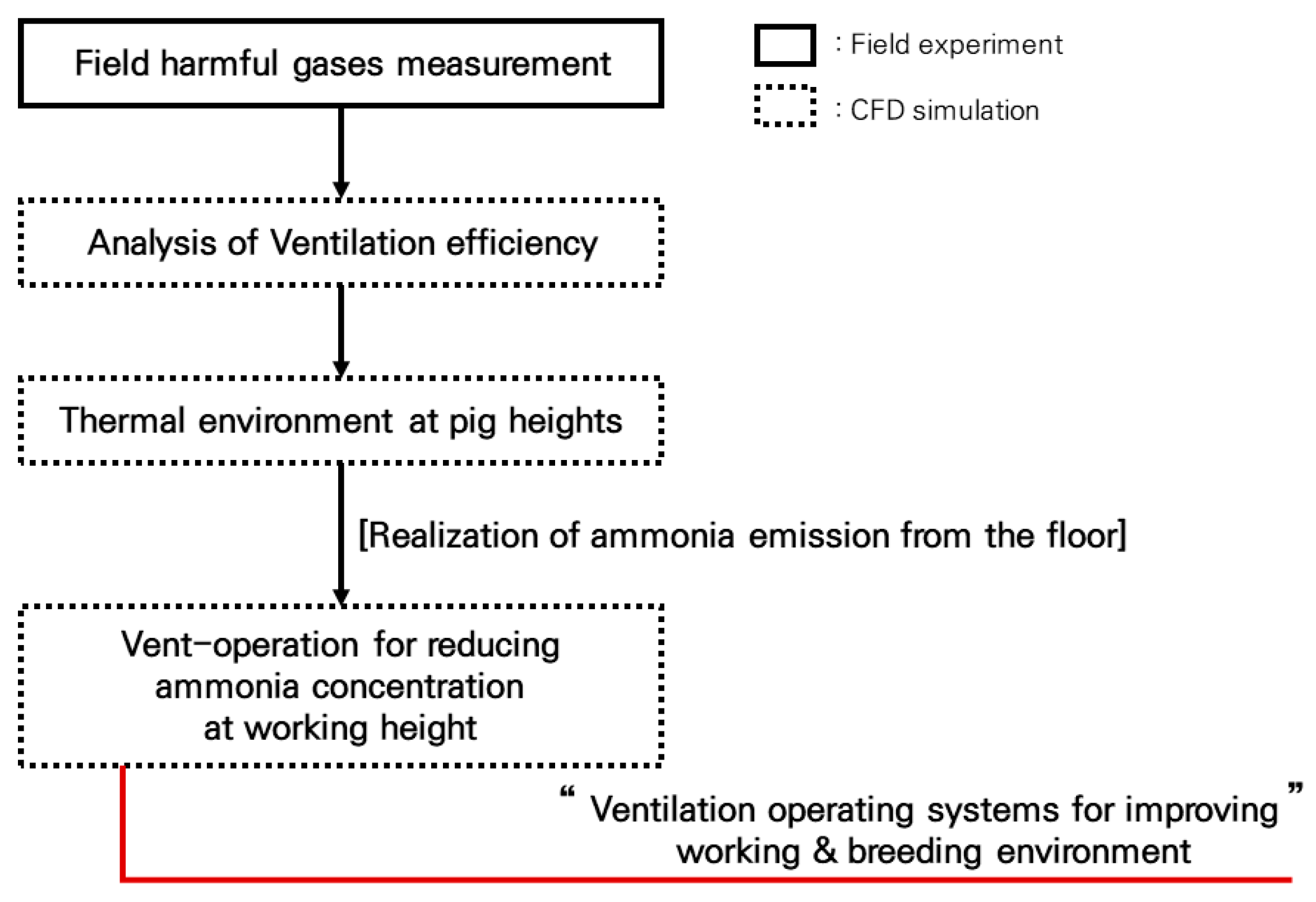

Ventilation operating standard was suggested based on field monitoring of gas concentration and CFD modelling according to various combinations of ventilation systems as shown in

Figure 3. The first step involves measuring the concentration of harmful gases to which workers were exposed during various tasks performed in the pig house. Using this model, the ventilation efficiency was analyzed for different combinations of ventilation openings within the pigpen to select an upgraded ventilation operation method that effectively reduces harmful gases at the workers’ height. To enhance the accuracy of the analysis, the selected ventilation system considered the ammonia emission from the floor. The analysis takes into account the changes over time during ventilation, as well as the thermal environment of the pig herd. This is important because sudden temperature changes can impact the breeding environment for the pigs. By implementing the ventilation operation plan, which aims to reduce harmful gases such as ammonia concentration, the extent of harmful gas removal by the ventilation system for improving the working environment is analyzed. Additionally, the thermal environment of the pig herd were utilized to develop the ventilation operation standardtable that aims to enhance both the working and breeding environments.

2.4.1. Field monitoring of harmful gas concentrations

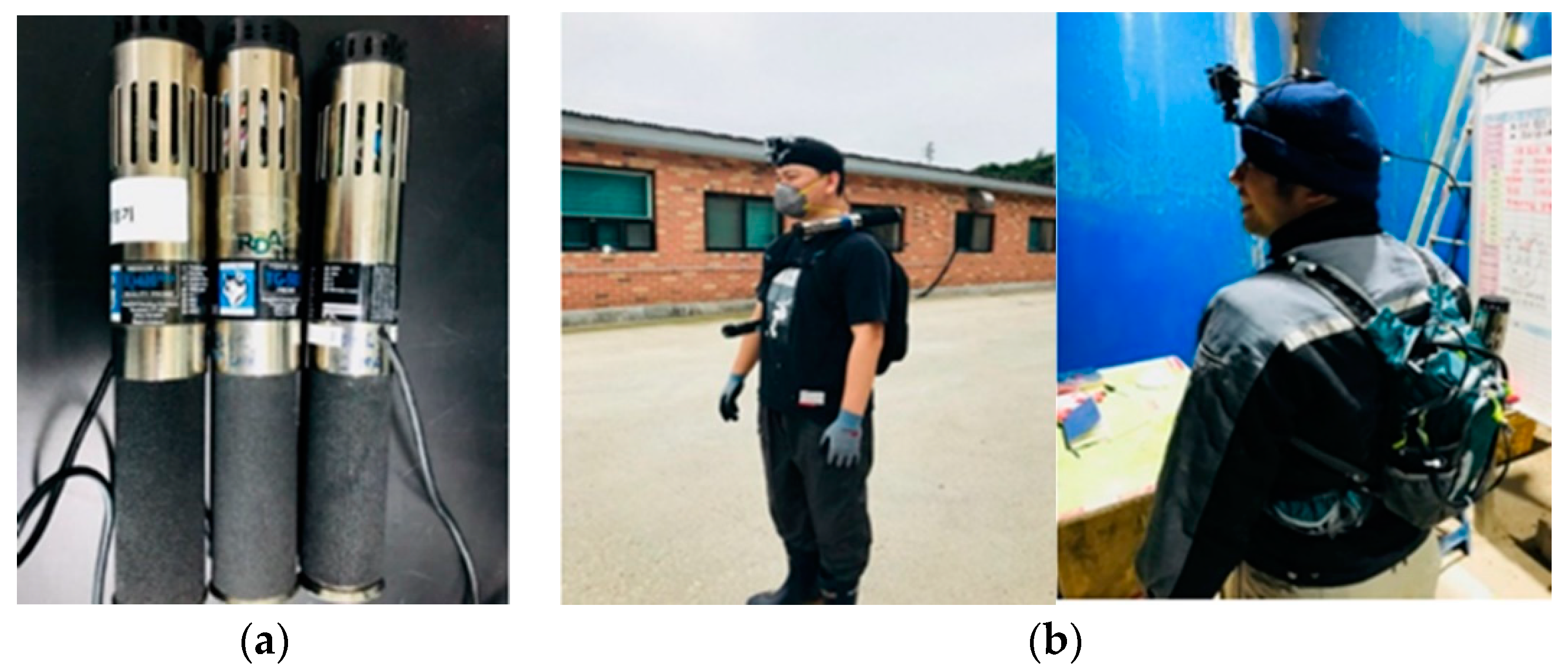

The concentration of harmful gases to which workers are directly exposed is measured at the height of their respiratory system during different types of work performed inside the pigpen. The measurements were conducted for both morning and afternoon daily working routines, with break time between 12 pm and 1 pm. To assess the exposure level for workers, ammonia and hydrogen sulfide sensors were attached at shoulder height, which is approximately the same height as the worker’s respiratory tract (

Figure 4). The working tasks were categorized as either contact work or non-contact work, depending on their interaction with the pigs. During contact work with pigs, more gases were dispersed from the floor due to animal movements. The concentrations of harmful gases were analyzed by considering the characteristics of each working tasks.

2.4.2. CFD analysis for ventilation efficiency and thermal environment

The ventilation system in the experimental pigpen was characterized by combination of vent openings with multiple inlets and outlets that can be operated in various configurations to assess the ventilation efficiency. The outlet ventilation system was comprised with 3 small square-shaped fans (SF) measuring 0.6 x 0.6 m, 2 circular fans (CF) with a diameter of 1.0 m, and a large duct located on the upper right side of the pigpen (RBD, right big duct). These outlet components are labeled alphabetically from A to H. The inlet ventilation system consisted of a large duct on the left-hand side (LBD, left big duct), two small elongated ducts positioned on the upper side of the pigpen (SD, small duct), and a total of 12 windows (UW/LW, upper windows and lower windows) located at the end of the pigpen. These inlet components are grouped numerically from 1 to 5. The ventilation efficiency of a total of 42 ventilation systems, comprising different combinations of the exhaust structures (outlets) and inflowing structures (inlets), is evaluated and presented in

Table 2.

In order to improve the working environment and minimize the impact to the pig, an analysis of the thermal condition was conducted based on the ventilation period. An optimal ventilation level was identified to provide suitable breeding environment while ensuring the removal of harmful gases inside the pigpen. When ventilation started, outside air enters into the pigpen resulting in sudden change in the thermal environment which can lead to respiratory diseases or decreased immunity. Therefore, it is crucial to analyze both ventilation efficiency reducing gases and thermal condition for pig breeding environment. The height of the pig herd was set at 0.5 m where the pigs breathe.

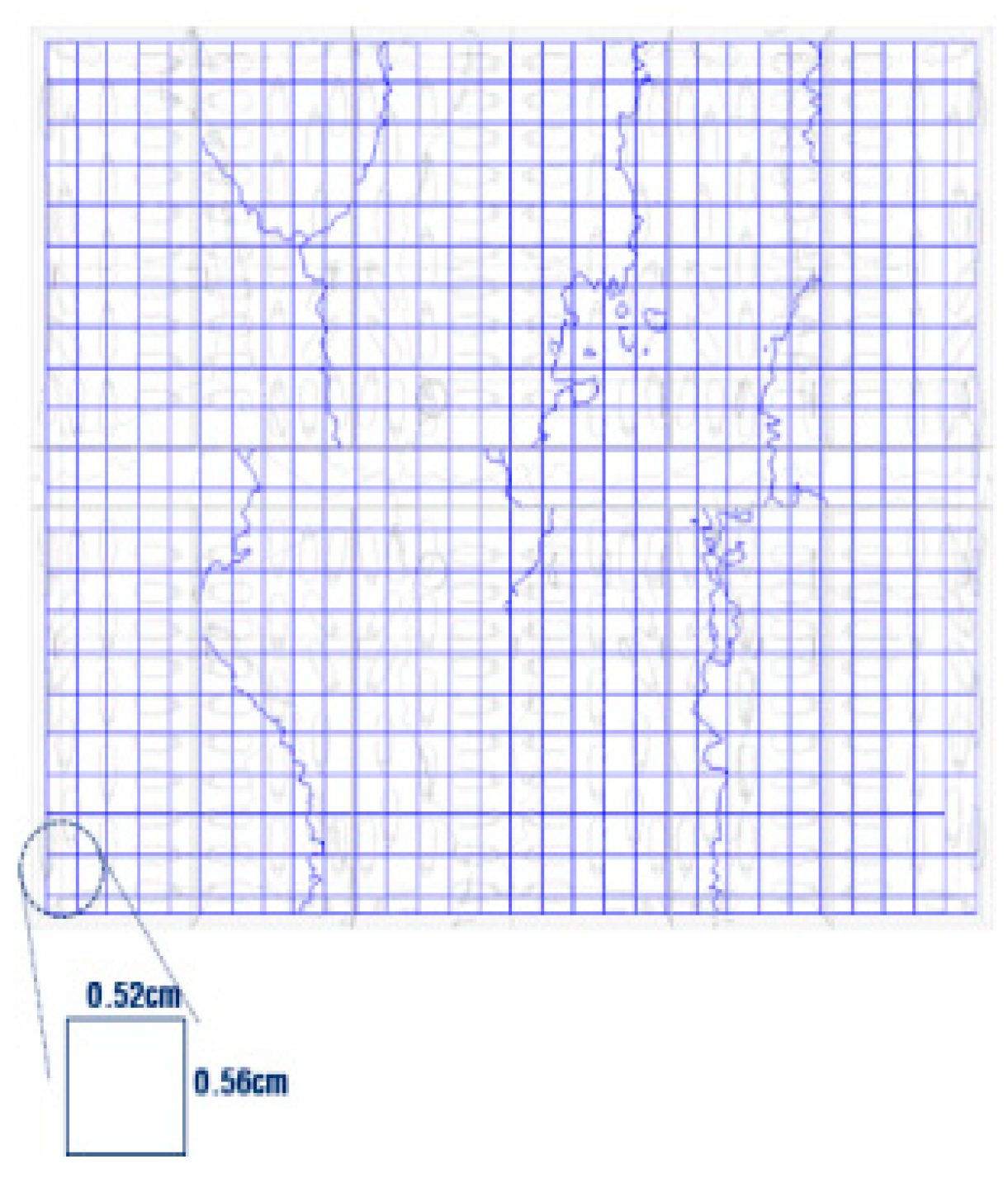

The CFD model was designed with a combination of regular tetrahedron, triangular-shaped tetrahedron, grids, regular hexahedron, and square-shaped hex-dominant grids to represent the complex shapes found in the pigpen following the previous validated modelling approaches[

17,

34,

35]. Dense meshes were used for aerodynamically importance areas of the pigpen, such as inlets, outlets, or regions near complex structures to enhance model accuracy. The calculation area was subdivided into smaller sections, for analyzing the ventilation efficiency and thermal condition. Frequency analysis was performed by dividing the height of the breeding environment into a total of 630 compartments, each with a consistent size of 0.52 × 0.56 cm (

Figure 5). When the temperature difference compared to the average temperature of the pigpen is less than 3℃, it is considered a suitable temperature. Temperature difference levels were categorized into three levels: the warning level, caution level, and normal level were defined based on the proportions of compartments representing suitable temperatures, with less than 60% of the total area, less than 70%, and more than 70%, respectively.

The ventilation efficiency of each region was analyzed for 42 different combinations of ventilation system in order to identify which system can efficiently ventilate harmful gases at the worker’s height. When the outlets remain the same, the ventilation efficiency was high by increasing inlet area by additionally opening the 6 lower windows located on the corridor wall. Replacing exhaust vents from three square-shaped fans to two larger circular fans installed for summer season leads to increased ventilation efficiency at the worker’s height. As high ventilation efficiency is crucial for effectively diluting harmful gases, these two ventilation schemes were selected for improving the working environment.

2.4.3. CFD analysis for ventilation efficiency and thermal environment

To develop a ventilation operation standard that simultaneously considers the work environment and breeding environment based on CFD-computed results, it is essential to analyze the combination of ventilation system, ventilation efficiency which can reduce harmful gas over ventilation time, and temperature difference affecting to pigs. Considering easy accessibility for farmers in the field, a single sheet visualized, simplified, and presented for ventilation operation standard was suggested by combining the multiple analyzes from the CFD model need. By utilizing the double linear interpolation method through polynomial regression analysis, the reduction rate of harmful gases in the working environment and the results of thermal environment analysis for the breeding environment were presented together for each ventilation system.

3. Results & Discussion

3.1. Field monitoring for harmful gas concentrations

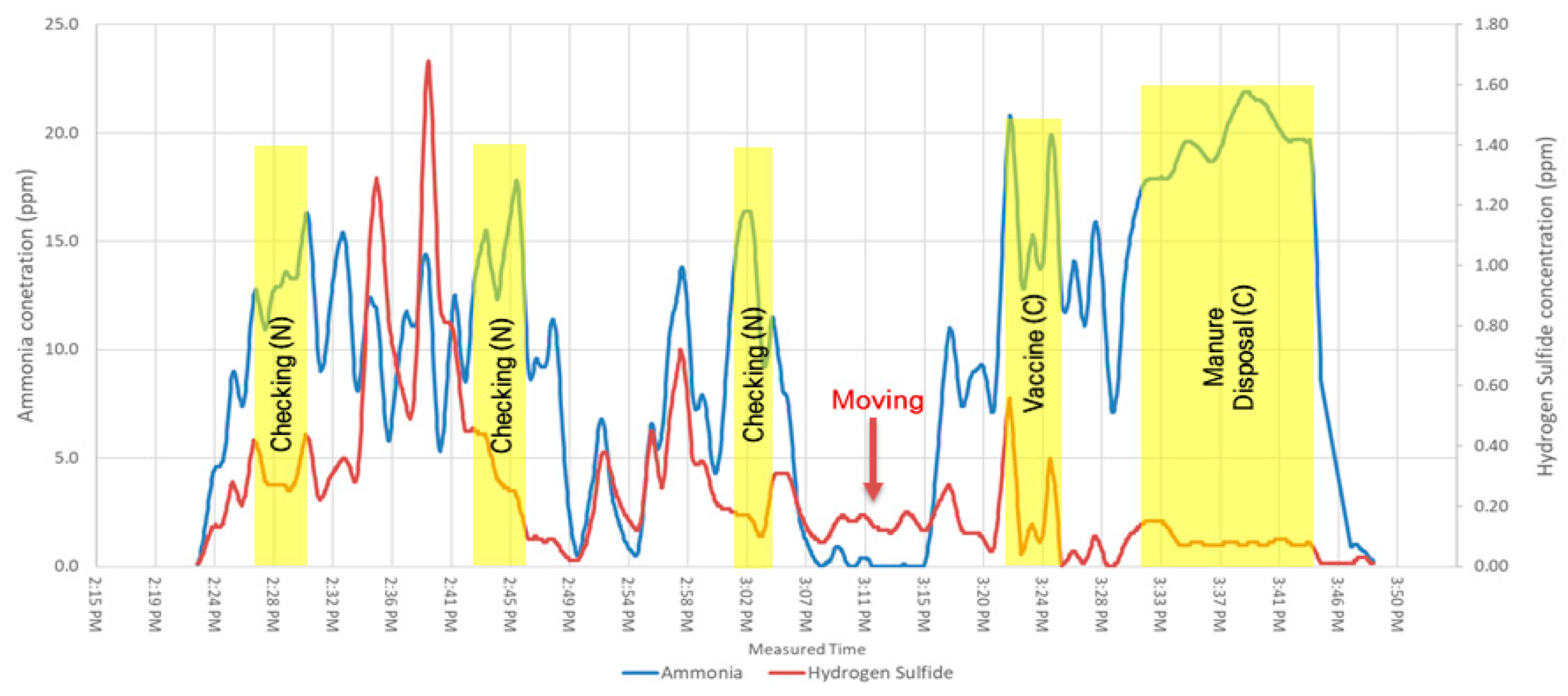

To analyze the exposure of workers to gas concentration inside the pigpen, comprehensive analysis was conducted using measured data by gas detectors attached at the height of the worker’s shoulder and image data captured during the measurements. The works performed in the pig house were categorized into morning and afternoon works including shipment, animal manure treatment, vaccine administration, condition checking, cleaning, and marking. During continuous monitoring of gas concentration including ammonia and hydrogen sulfide, each data was obtained based on the average concentrations during each task performed as shown in

Figure 6. Each work is further classified as either a “contact” work if the worker directly contacts the pigs or a “non-contact” work if there is no direct contact with the pigs.

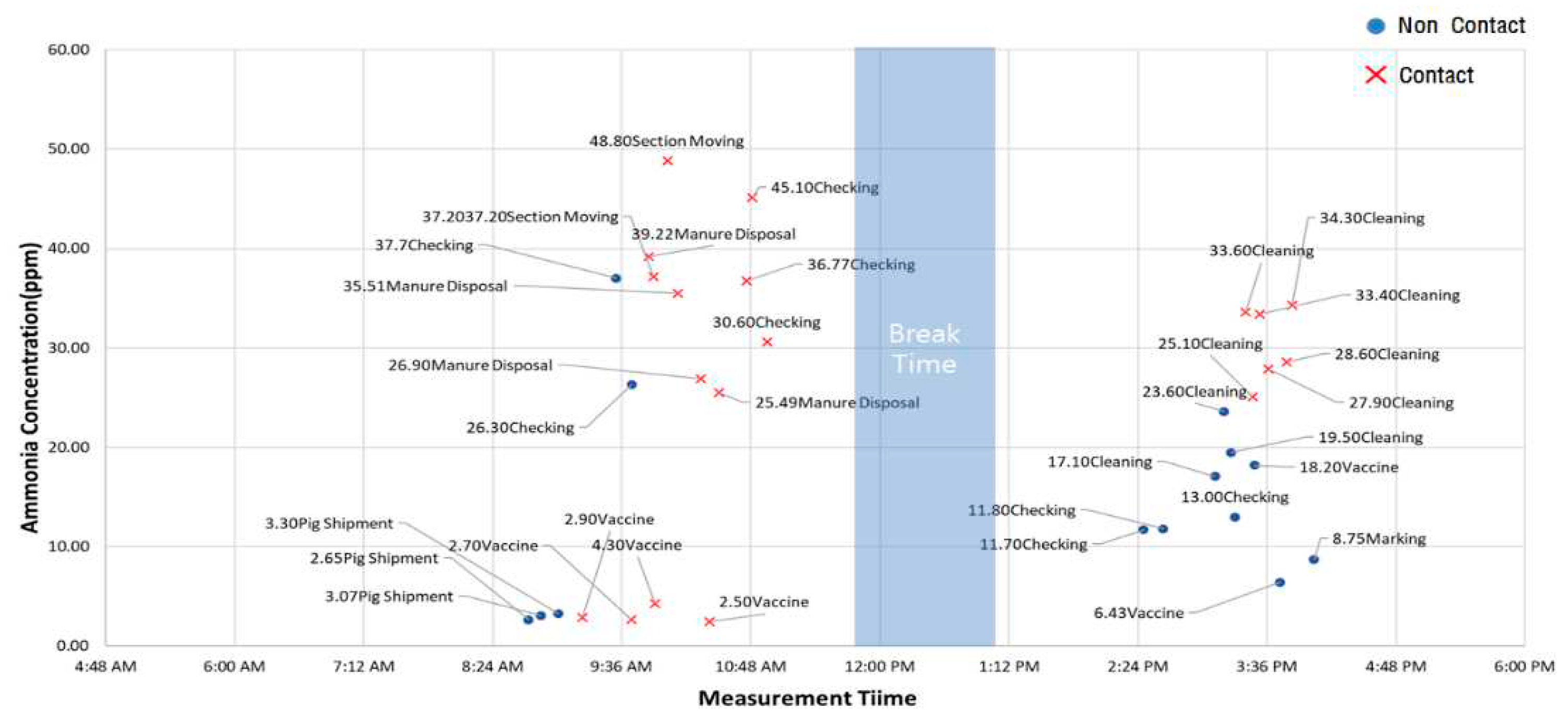

Each data point in

Figure 7 and

Figure 8 represents the average ammonia and hydrogen sulfide concentrations monitored at the worker’s height during the working time. During contact works such as general checking, manure treatment, and cleaning tasks, ammonia concentrations was higher compared to non-contact works. Generally, workers were exposed to ammonia concentrations ranging from the late 20 ppm to 40 ppm during contact works. During the shipment task of pigs, workers are exposed to low ammonia concentrations of 5 ppm or lower due to increment of ventilation by opening whole doors in the pigpen. The average exposure to ammonia is further analyzed by the type of work. The highest ammonia concentration was observed when workers moved pigs between compartments within the pigpen, with an average exposure of 43.0 ppm. Other tasks associated with relatively high ammonia concentrations included manure treatment (31.8 ppm), condition checking (26.5 ppm), and cleaning (27.0 ppm). On the other hand, marking (8.8 ppm) and vaccine injection (6.2 ppm) resulted in relatively low ammonia exposure. The average ammonia concentration during the shipment of pigs was 3.0 ppm, indicating a low exposure level despite the direct contact with pigs. This can be attributed to the fact that the task is mainly performed in the corridor outside the pigpen. The average levels of ammonia exposure are compared between contact works and non-contact works. Contact works have an average ammonia concentration of 24.7 ppm, which is 1.58 times higher than the average concentration of 15.6 ppm observed in non-contact works.

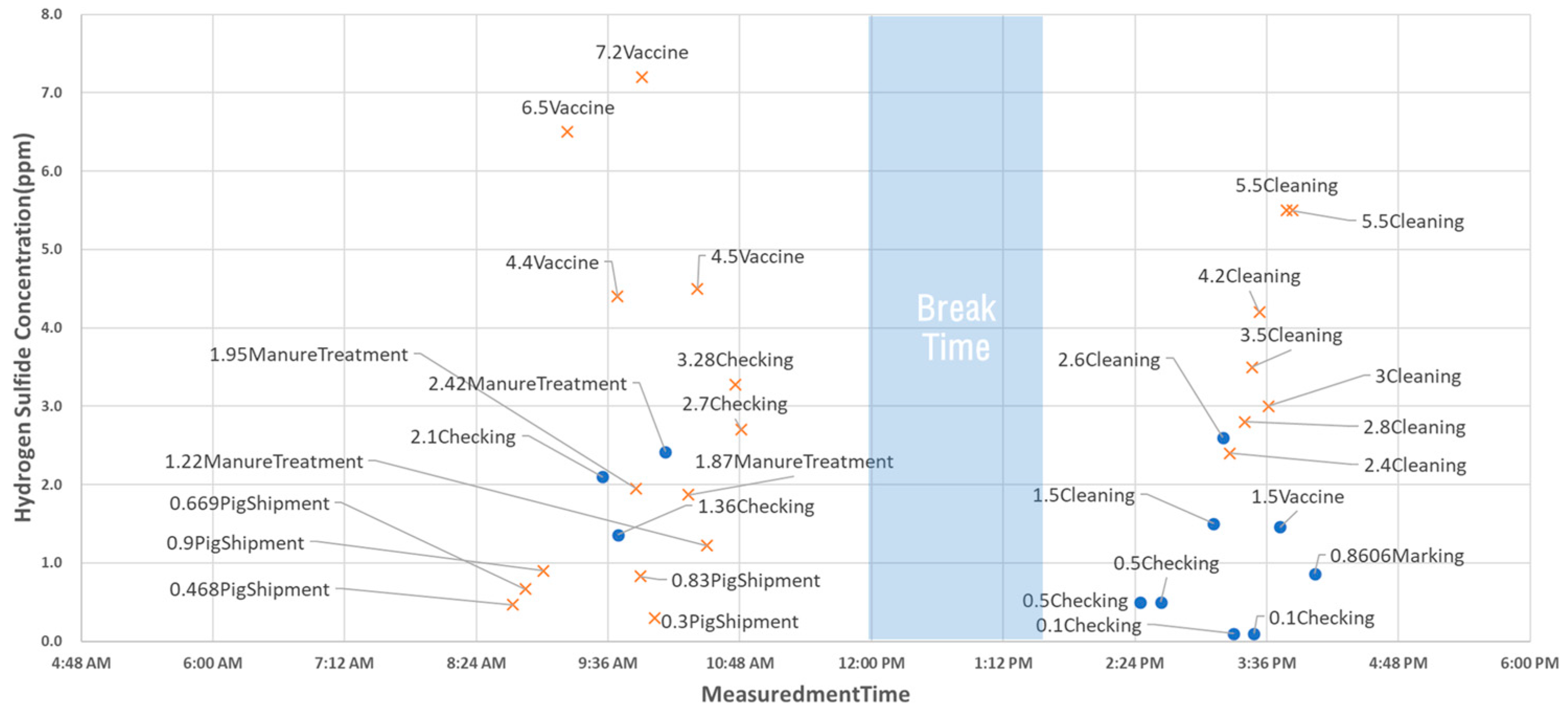

The average exposure to hydrogen sulfide by working types was also analyzed (

Figure 8). The highest hydrogen sulfide concentration was observed during the vaccine injection task, with an average exposure of 4.0 ppm. Internal cleaning, manure treatment, and condition checking tasks resulted in average exposures of 3.4 ppm, 1.9 ppm, and 1.5 ppm, respectively. The average levels of hydrogen sulfide exposure were compared between contact works and non-contact works. Non-contact works have an average exposure of 1.1 ppm, while direct contact works have an average exposure of 3.0 ppm, indicating approximately 2.73 times higher concentration in contact works. It should be noted that while hydrogen sulfide tends to be concentrated on the floor of the pigpen, the measurements in our experiment were taken at the worker’s shoulder height, which corresponds to the height of the worker’s respiratory system.

3.2. CFD analysis for ventilation efficiency and termal environment

The ventilation efficiency analysis was conducted through CFD simulation for a total of 42 ventilation systems in the experimental pigpen at a height of 1.5 m (representing the worker’s respiratory tract location) and 0.5 m (representing the pig’s respiratory tract location).

Table 3 provides the minimum, average, and maximum ventilation efficiencies at the corresponding heights, along with the individual analysis of ventilation efficiencies on the corridor side. Among the 50 ventilation combinations, the top 20% structures that exhibit the highest ventilation efficiency at both the worker’s height and the pig’s height commonly utilize both upper and lower windows as inlets. These combinations demonstrate an average airflow exchange rate (AER, m-1) of 0.34 at the worker’s height and 0.4 AER(m-1) at the pig’s height. Comparing these values with the average value of 0.28 AER(m-1) for the previously operated ventilation system, which represents the 24% improvement in ventilation efficiency at the worker’s height and a 43% improvement at the pig’s height are observed at the same ventilation capacity with changing the combinations of vents.

In cases where a single-floor window inlet structure is used, the analysis reveals higher ventilation efficiency when the upper windows are employed rather than the lower windows. Specifically, when only the upper windows are utilized, the average ventilation efficiency is 10.7% higher at the worker’s height and 17.8% higher at the pig’s height compared to using only the lower windows. Conversely, when both upper and lower windows are utilized, the overall ventilation efficiency improves compared to using a single-floor window. This shows an average improvement of 25% at the worker’s height and an average improvement of 45% at the pig’s height. The larger improvement at the pig’s height is attributed to the height of the inlet windows. Regarding the exhaust structure, analysis results demonstrate that ventilation efficiency improved in all ventilation structure combinations when two circular fans, which were previously only used in summer, are utilized instead of the three square-exhaust fans. On average, the efficiency improvement is 10.8% at the worker’s height ’nd 12% at the pig’s height. While the three square-fans are located on the walls of the left and right sides of the pigpen and in the center close to the corridors, the two circular fans are positioned in the center of the pigpen where the pigs are reared, resulting in higher ventilation efficiencies. Based on the ventilation efficiency analysis mentioned above, the air flow pattern based on inlet and outlet combinations significantly affects to the levels of ventilation efficiency at both the worker’s and the pig’s heights for reducing harmful gases.

Table 4 presents the thermal distribution analysis for uniformity and stability during ventilation period. The temperature difference levels are indicated by different colors: white for normal, gray for caution, and black for warning. When the exhaust system was changed from the [B+LW] case to the [B+LW-CF] case, there was an increase in the proportion of sections representing small temperature changes of less than 3℃. This increase was particularly significant in the case of a ventilation efficiency of 0.75 AER. The analysis indicates that while increasing the inlets by opening the lower windows has an impact on the ammonia reduction rate. The change in the ventilation system using larger exhausting fans may lead to temperature drops affecting the breeding environment of the pigs.

3.3. Ventilation operating standard for improving working and breeding environment

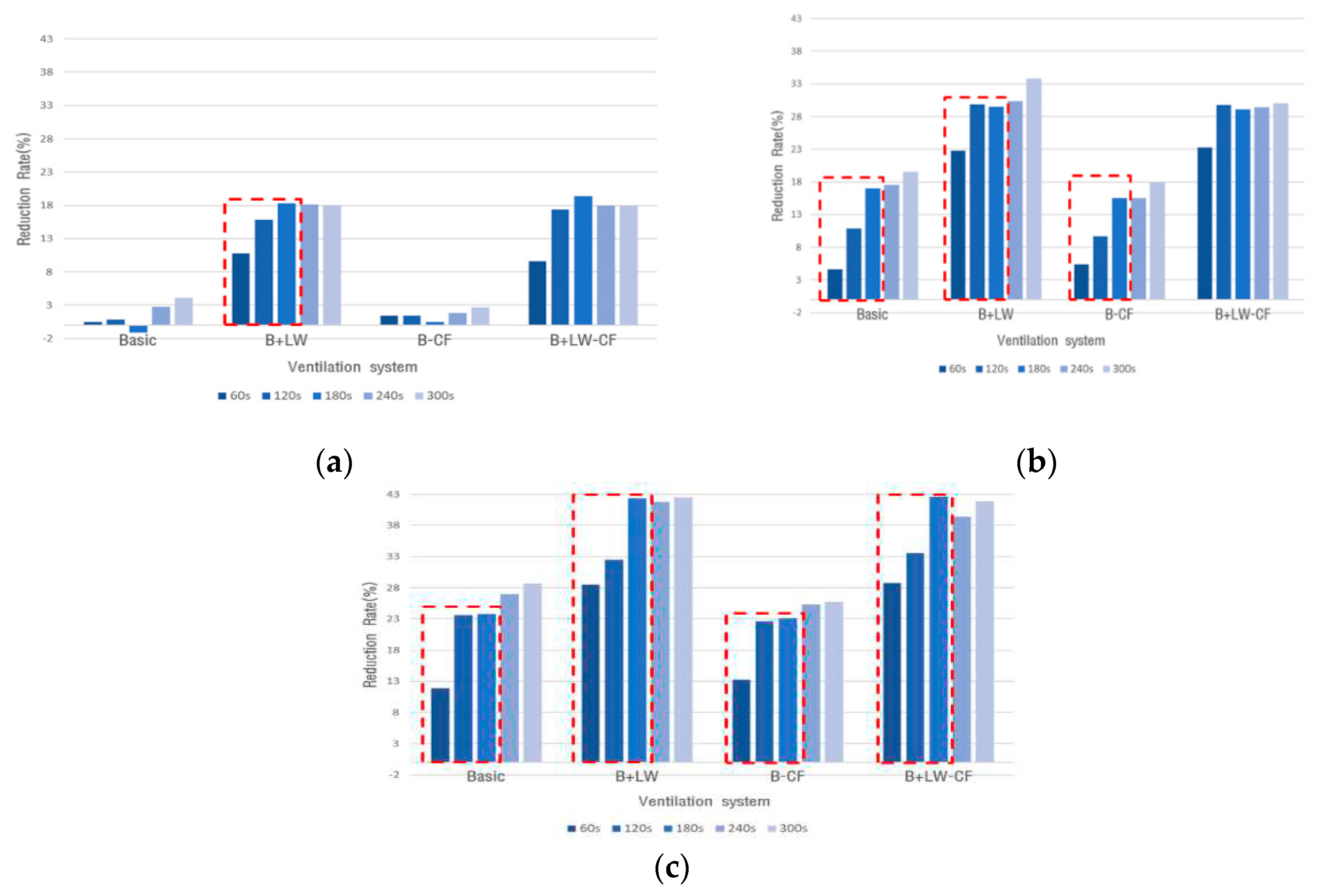

When the ventilation was continuously operated for a long duration, it can lead to temperature drops affecting the thermal environment in the pigpen. The ventilation time is one of important factor not only for removing harmful gas but also for controlling internal thermal conditions.

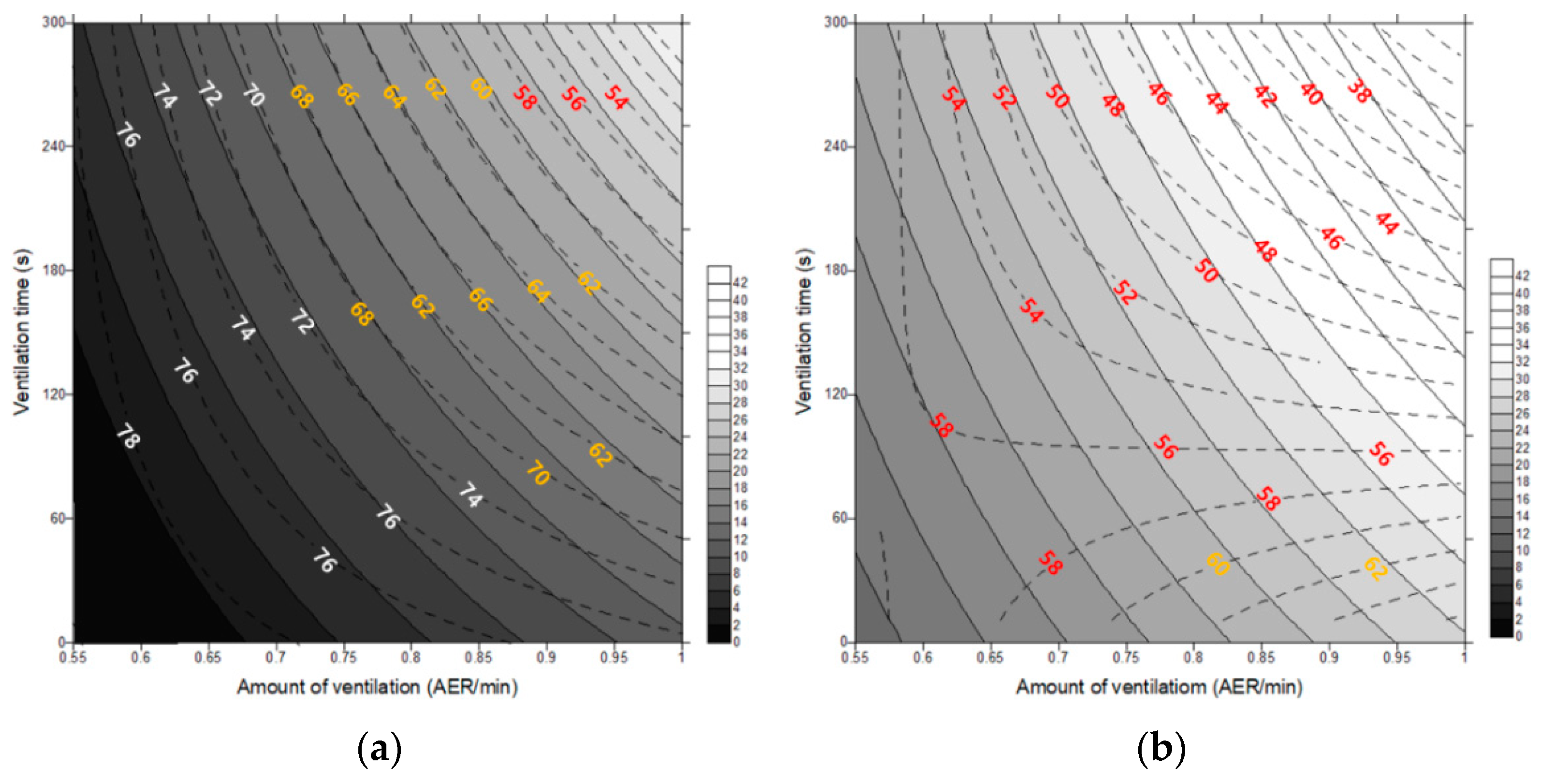

Figure 9 illustrates the ammonia reduction rate based on ventilation capacity and time for each system. The maximum ammonia reduction rate increases significantly from 28.8% at a ventilation time of 60 seconds to 42.6% at a ventilation time of 180 seconds. However, there is no significant increase beyond 180 seconds, with the reduction rate remaining at 42.5% at a ventilation time of 300 seconds. Additionally, as the ventilation time increases, the level of temperature dropped in the herd of pigs progresses from Caution to Warning. Therefore, the most efficient ventilation time for reducing ammonia gas can be determined to be up to 3 minutes considering the balance between ammonia reduction and thermal stability.

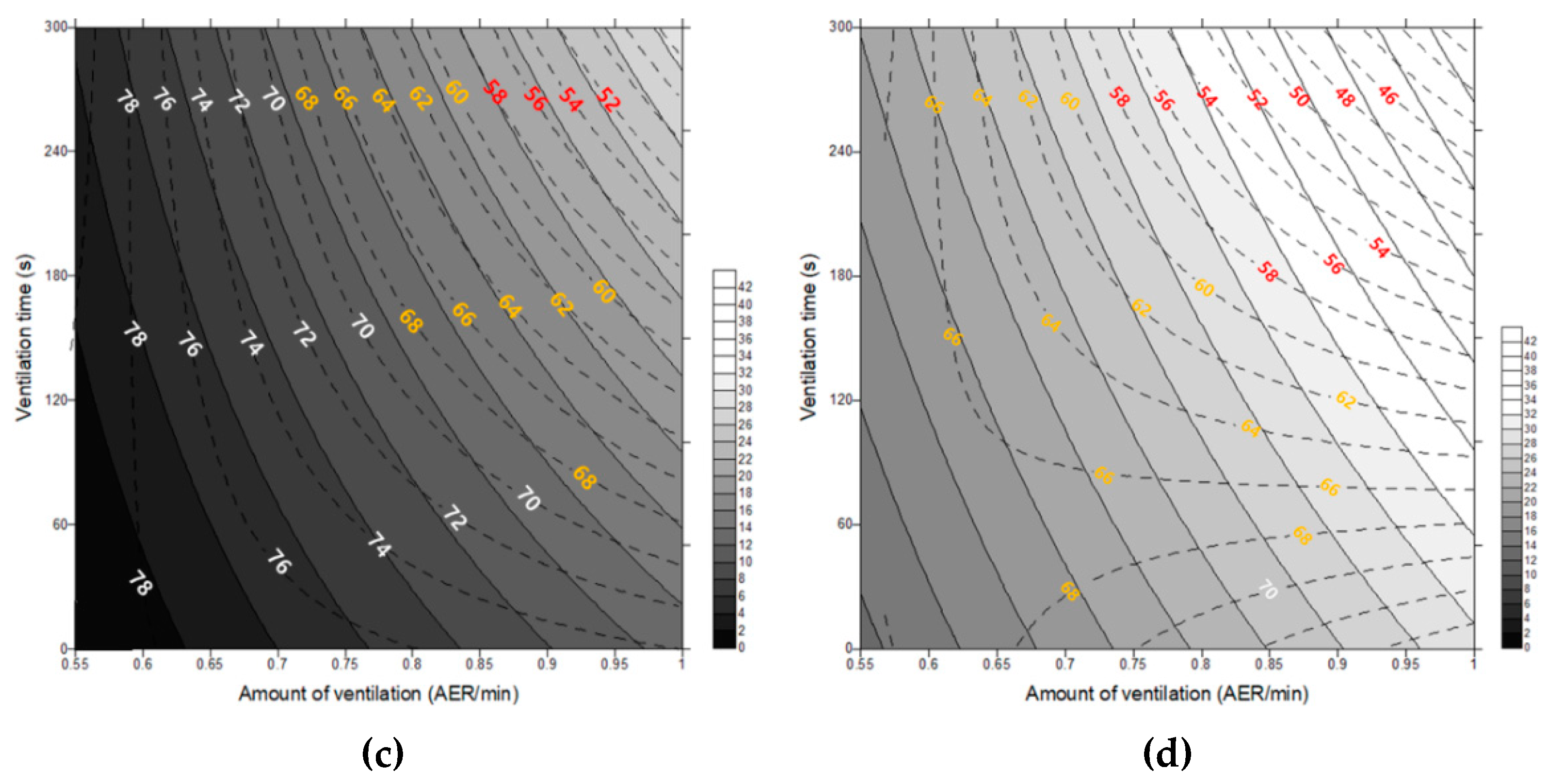

Figure 10 illustrates the ventilation operating standard for the experimental pigpen considering different ventilation structures on reducing harmful gases and controlling breeding environment. When the ventilation rate was maximum, the reduction rate of harmful gases was the highest for all cases. However, it is important to consider that the maximum ventilation rate can lead to sudden temperature drops, which can be problematic for the breeding environment. In the case of the existing ventilation system, the reduction rates of harmful gases are relatively low: 1.4% at 0.55 AER, 13.9% at 0.75 AER, and 23% at 1.0 AER. As the ventilation rate increased, the breeding environment deteriorated to the level of Caution and Warning on thermal stability. This indicates that it is necessary to consider a balance between reducing harmful gases and maintaining a stable breeding environment when selecting the appropriate ventilation system.

Among the upgraded ventilation system, the increased inlet area with the lower windows shows that the highest ammonia gas reduction rate, averaging 27.7%, while the average reduction rates for different ventilation volumes are 16.2% at 0.55 AER, 29.3% at 0.75 AER, and 37.5% at 1.0 AER. When the ventilation efficiency was only considered to achieve the highest performance in reducing harmful gases, it also leads to sudden temperature drops in the pig height. In most cases, temperature differences were reached to Warning levels within 1 minute of ventilation time. Consequently, this ventilation system can make problems for the breeding conditions during removing harmful gases for the working environment (

Figure 10b). When more exhaust fans were used with two large circular fans, the results showed a relatively low improvement in the working environment, averaging 12.1%. Specifically, this system has achieved working environment improvement effects of 1.6% at 0.55 AER, 12.8% at 0.75 AER, and 22% at 1.0 AER (Figure 15c).

The ventilation system with the increased inlets is effective in improving the working environment due to its successful reduction of harmful gases, while the system with the increased outlets has minimized the adverse effects on the breeding environment. When both upgraded measures are applied together, an overall improvement effect of 27.3% is achieved; ammonia reduction rates of 16.5% at 0.5 AER, 28.3% at 0.75 AER, and 37.2% at 1.0 AER(min-1). As for temperature differences, the level has not exceeded the Warning threshold in most cases. By applying both upgraded ventilation structures, a high level of working environment improvement (27.3% improvement for workers) and temperature stability for the herd of pigs have been achieved (Figure 15d).

4. Conclusions

This study has comprehensively analyzed the ammonia gas reduction rates and the thermal environment at the pig level by using various combinations of ventilation system. As a result of the analysis, the optimized ventilation operation standard has been developed to simultaneously enhance the working environment and the breeding environment. Field measurements have shown that workers had been exposed to high ammonia concentrations of 43 ppm on average when moving pigs inside the pigpen. When the worker performs a task that involves direct contact with pigs, they were exposed to 1.58 times higher ammonia concentration compared with that of non-contact work. CFD (computational fluid dynamics) were used to make the optimal ventilation operation standard for improving both the working and breeding environment at the same time in a pig house. Among 50 combinations of ventilation systems, the upgraded ventilation system was chosen considering gas reduction rate and thermal stability.

As suggested in this study, the working and the breeding environment should be considered simultaneously to improve the ventilation system, and the ventilation operation standard was sugges ted by consideration of ventilation time, gas reduction rate, and thermal stability for workers and pigs. The results can be used to make a livestock environment management algorithm for using IoT-based automatic precision control in the future and making precision agricultural system considering upgraded working and breeding environment, simultaneously.

Acknowledgments

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry(IPET) through 2025 Livestock Industrialization Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs(MAFRA) (321085053SB010)

References

- Thorne, P.S.; Ansley, A.C.; Perry, S.S. Concentrations of bioaerosols, odors, and hydrogen sulfide inside and downwind from two types of swine livestock operations. Journal of occupational and environmental hygiene 2009, 6, 211–220. [Google Scholar] [CrossRef]

- Gautam, R.; Heo, Y.; Lim, G.; Song, E.; Roque, K.; Lee, J.; Kim, Y.; Cho, A.; Shin, S.; Kim, C. Altered immune responses in broiler chicken husbandry workers and their association with endotoxin exposure. Industrial health 2017. [Google Scholar] [CrossRef]

- Park, K.-H.; Jeong, B.-Y. Characteristics and causes of musculoskeletal disorders for employees aged 50 years or older. Journal of the Ergonomics Society of Korea 2009, 28, 139–145. [Google Scholar] [CrossRef]

- Chapin, A.; Boulind, C.; Moore, A. Controlling odor and gaseous emission problems from industrial Swine facilities. Yale Environmental Protection Clinic Handbook 1998. [Google Scholar]

- Bruce, J. Ventilation and Temperature Control Criteria for Pigs in Environmental. 1981.

- Donham, K.J.; Scallon, L.J.; Popendorf, W.; Treuhaft, M.W.; Roberts, R.C. Characterization of dusts collected from swine confinement buildings. American Industrial Hygiene Association Journal 1986, 47, 404–410. [Google Scholar] [CrossRef]

- Kim, C.-B.; Won, J.-U.; Roh, J.-H.; Lee, K.-H.; Lee, H.-J.; Lee, H.-S.; Lee, H.-J. Study on manifestation of allergic symptoms by cultivation of Cyperus exaltatus & manufacture of hwamunsok. Journal of agricultural medicine and community health 1995, 20, 187–195. [Google Scholar]

- Dutkiewicz, J. Bacteria and fungi in organic dust as potential health hazard. Annals of Agricultural and Environmental Medicine 1997, 4, 11–16. [Google Scholar]

- KIM, G.S.; Kim, E.A.; Lee, S.H.; Pakr, H.S. A Study on Risk Factors of Grain Dust-Induced Occupational Asthma in Grain Feedmill Workers. 1997.

- Lim, H.-S.; Bae, G.-R.; Kim, D.-H.; Jun, K.-H. Respiratory symptoms occurring among mushroom farmers. Journal of agricultural medicine and community health 1998, 23, 259–268. [Google Scholar]

- Bottcher, R.W. An environmental nuisance: odor concentrated and transported by dust. Chemical senses 2001, 26, 327–331. [Google Scholar] [CrossRef]

- Eom, H.-J. Beware of swine respiratory diseases in winter. Feed Journal 2006, 4, 106–110. [Google Scholar]

- Oh, B.-W.; Lee, S.-W.; Kim, H.-C.; Seo, I.-H. Analysis of working environment and ventilation efficiency in pig house using computational fluid dynamics. Journal of The Korean Society of Agricultural Engineers 2019, 61, 85–95. [Google Scholar] [CrossRef]

- Lee, S.-W.; Kim, H.-C.; Seo, I.-H. Monitoring of Internal Harmful Factors According to Environmental Factors in Pig Farm. Journal of The Korean Society of Agricultural Engineers 2020, 62, 105–115. [Google Scholar] [CrossRef]

- Bjerg, B.; Svidt, K.; Zhang, G.; Morsing, S.; Johnsen, J.O. Modeling of air inlets in CFD prediction of airflow in ventilated animal houses. Computers and electronics in agriculture 2002, 34, 223–235. [Google Scholar] [CrossRef]

- Seo, I.-H.; Lee, I.-B.; Hong, S.-W.; Hwang, H.-S.; Bitog, J.P.; Yoo, J.-I.; Kwon, K.-S.; Ha, T.-H.; Kim, H.-T. Development of a CFD model to study ventilation efficiency of mechanically ventilated pig house. 2008. [Google Scholar] [CrossRef]

- Seo, I.-h.; Lee, I.-b.; Moon, O.-k.; Hong, S.-w.; Hwang, H.-s.; Bitog, J.P.; Kwon, K.-s.; Ye, Z.; Lee, J.-w. Modelling of internal environmental conditions in a full-scale commercial pig house containing animals. Biosystems engineering 2012, 111, 91–106. [Google Scholar] [CrossRef]

- Bjerg, B.; Cascone, G.; Lee, I.-B.; Bartzanas, T.; Norton, T.; Hong, S.-W.; Seo, I.-H.; Banhazi, T.; Liberati, P.; Marucci, A. Modelling of ammonia emissions from naturally ventilated livestock buildings. Part 3: CFD modelling. Biosystems engineering 2013, 116, 259–275. [Google Scholar] [CrossRef]

- Seo, I.-H.; Lee, I.-B.; Moon, O.-K.; Kwon, K.-S. Aerodynamic approaches for estimation of waste disease spread in pig farm through airborne contaminants. Journal of The Korean Society of Agricultural Engineers 2014, 56, 41–49. [Google Scholar] [CrossRef]

- Wang, K.; Wang, X.; Wu, B. Assessment of hygrothermal conditions in a farrowing room with a wet-pad cooling system based on CFD simulation and field measurements. Transactions of the ASABE 2014, 57, 1493–1500. [Google Scholar] [CrossRef]

- Kwon, K.-s.; Lee, I.-b.; Ha, T. Identification of key factors for dust generation in a nursery pig house and evaluation of dust reduction efficiency using a CFD technique. Biosystems engineering 2016, 151, 28–52. [Google Scholar] [CrossRef]

- Rong, L.; Nielsen, P.V.; Bjerg, B.; Zhang, G. Summary of best guidelines and validation of CFD modeling in livestock buildings to ensure prediction quality. Computers and Electronics in Agriculture 2016, 121, 180–190. [Google Scholar] [CrossRef]

- Berckmans, D. General introduction to precision livestock farming. Animal Frontiers 2017, 7, 6–11. [Google Scholar] [CrossRef]

- Hong, S.-W.; Exadaktylos, V.; Lee, I.-B.; Amon, T.; Youssef, A.; Norton, T.; Berckmans, D. Validation of an open source CFD code to simulate natural ventilation for agricultural buildings. Computers and Electronics in Agriculture 2017, 138, 80–91. [Google Scholar] [CrossRef]

- Kim, D.-W.; Kim, Y.-H.; Kim, K.-S.; Kim, K.-H. Effect of mixing of suckling piglets on change of body surface temperature in sows and piglets. Journal of the Korea Academia-Industrial cooperation Society 2017, 18, 135–140. [Google Scholar] [CrossRef]

- Kim, R.-w.; Lee, I.-b.; Ha, T.-h.; Yeo, U.-h.; Lee, S.-y.; Lee, M.-h.; Park, G.-y.; Kim, J.-g. Development of CFD model for predicting ventilation rate based on age of air theory using thermal distribution data in pig house. Journal of the Korean Society of Agricultural Engineers 2017, 59, 61–71. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zhang, G. Reliability of turbulence models and mesh types for CFD simulations of a mechanically ventilated pig house containing animals. Biosystems Engineering 2017, 161, 37–52. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zhang, G. Numerical study on the convective heat transfer of fattening pig in groups in a mechanical ventilated pig house. Computers and Electronics in Agriculture 2018, 149, 90–100. [Google Scholar] [CrossRef]

- Fluent, A. R2 User’s Guide. (: Available online.

- Seo, I.-H.; Lee, I.-B.; Moon, O.-K.; Kim, H.-T.; Hwang, H.-S.; Hong, S.-W.; Bitog, J.; Yoo, J.-I.; Kwon, K.-S.; Kim, Y.-H. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosystems engineering 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Kwon, K.-S.; Lee, I.-B.; Hwang, H.-S.; Bitog, J.P.; Hong, S.-W.; Seo, I.-H.; Choi, J.-S.; Song, S.-H.; Moon, O.-K. Analysis on the optimum location of an wet air cleaner in a livestock house using CFD technology. Journal of the Korean Society of Agricultural Engineers 2010, 52, 19–29. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, I.-B.; Kwon, K.-S.; Ha, T.-H.; Yeo, U.-H.; Park, S.-J.; Kim, R.-W.; Jo, Y.-S.; Lee, S.-N. Analysis of Natural Ventilation Rates of Venlo-type Greenhouse Built on Reclaimed Lands using CFD. Journal of The Korean Society of Agricultural Engineers 2015, 57, 21–33. [Google Scholar] [CrossRef]

- Lee, S.-y.; Lee, I.-b.; Kim, R.-w. Evaluation of wind-driven natural ventilation of single-span greenhouses built on reclaimed coastal land. Biosystems Engineering 2018, 171, 120–142. [Google Scholar] [CrossRef]

- Sun, H.; Keener, H.M.; Deng, W.; Michel Jr, F.C. Development and validation of 3-d CFD models to simulate airflow and ammonia distribution in a high-rise™ hog building during summer and winter conditions. Agricultural Engineering International: CIGR Journal 2004. [Google Scholar]

- Rong, L.; Aarnink, A. Development of ammonia mass transfer coefficient models for the atmosphere above two types of the slatted floors in a pig house using computational fluid dynamics. Biosystems engineering 2019, 183, 13–25. [Google Scholar] [CrossRef]

Figure 1.

Experimental pigpen with mechanical ventilation systems including five different exhausting fans and duct inlets.

Figure 1.

Experimental pigpen with mechanical ventilation systems including five different exhausting fans and duct inlets.

Figure 2.

Ventilation system operated during spring season with combinations of various outlet(red) and inlet(blue).

Figure 2.

Ventilation system operated during spring season with combinations of various outlet(red) and inlet(blue).

Figure 3.

Research procedure for modeling ventilation efficiency considering regional thermal condition.

Figure 3.

Research procedure for modeling ventilation efficiency considering regional thermal condition.

Figure 4.

Research procedure for modeling ventilation efficiency considering regional thermal condition (a) NH3 & H2S sensors and (b) Installation of sensors at worker’s shoulder.

Figure 4.

Research procedure for modeling ventilation efficiency considering regional thermal condition (a) NH3 & H2S sensors and (b) Installation of sensors at worker’s shoulder.

Figure 5.

Divided sectors for analysis of thermal-environment at 1.5m height.

Figure 5.

Divided sectors for analysis of thermal-environment at 1.5m height.

Figure 6.

Ammonia and hydrogen sulfide concentrations monitored at shoulder height in pig room (yellow section at working time).

Figure 6.

Ammonia and hydrogen sulfide concentrations monitored at shoulder height in pig room (yellow section at working time).

Figure 7.

Average ammonia concentration during contact & non-contact works in pig house.

Figure 7.

Average ammonia concentration during contact & non-contact works in pig house.

Figure 8.

Average ammonia concentration during contact & non-contact works in pig house.

Figure 8.

Average ammonia concentration during contact & non-contact works in pig house.

Figure 9.

NH3 reduction rate to ventilation time each ventilation structure combinations (red box is time of increasing sharply reduction rate) (a) 0.55AER, (b) 0.75AER, (c) 1.0AER.

Figure 9.

NH3 reduction rate to ventilation time each ventilation structure combinations (red box is time of increasing sharply reduction rate) (a) 0.55AER, (b) 0.75AER, (c) 1.0AER.

Figure 10.

Basic;Solid lines represent NH3 reduction rate at working height, dotted lines with numeric values represent thermal suitability ratio at pig height, white=normal, yellow=caution, red=warning) (a) Basic (Standard), (b) Upgrade ① (B+LW), (c) Upgrade ② (B-CF), (d) Upgrade ①+② (B+LW-CF).

Figure 10.

Basic;Solid lines represent NH3 reduction rate at working height, dotted lines with numeric values represent thermal suitability ratio at pig height, white=normal, yellow=caution, red=warning) (a) Basic (Standard), (b) Upgrade ① (B+LW), (c) Upgrade ② (B-CF), (d) Upgrade ①+② (B+LW-CF).

Table 1.

Input & boundary conditions for the CFD simulation model of the experimental pig house.

Table 1.

Input & boundary conditions for the CFD simulation model of the experimental pig house.

| Content |

Value |

| Number of mesh |

about 4.5 million |

| Mesh design |

Tetra-headron |

| Boundary conditions |

Velocity inlet & Pressure outlet |

| Input temperature |

291.8 (K) |

| Output temperature |

289.5 (K) |

| Inside initial temperature |

297.8 (K) |

| Pig heat flux |

210.9 (W·m-1 ) |

| Ventilation rate (air exchanges) |

0.55 (m-1) |

| Velocity at the inlet vent |

3.71 (m·s-1 ) |

| NH3 concentration at work height (1.5m) |

38.7 (ppm) |

Table 2.

Combination of various ventilation systems.

Table 2.

Combination of various ventilation systems.

| Group |

SquareFan |

CircleFan |

RightBig Duct |

LightBig Duct |

SmallDuct |

UpperWindow |

LowerWindow |

| A |

O |

O |

|

|

|

|

|

| B |

O |

|

O |

|

|

|

|

| C |

O |

|

|

|

|

|

|

| D |

|

O |

O |

|

|

|

|

| E |

|

O |

|

|

|

|

|

| F |

O |

I |

|

|

|

|

|

| G |

O |

|

O |

O |

|

|

|

| H |

O |

|

I |

I |

|

|

|

| 1 |

|

|

I |

I |

I |

I |

I |

| 2 |

|

|

|

|

I |

I |

I |

| 3 |

|

|

|

|

|

I |

I |

| 4 |

|

|

|

|

|

I |

|

| 5 |

|

|

|

|

|

|

I |

Table 3.

Result of ventilation efficiency considered various ventilation structure.

Table 3.

Result of ventilation efficiency considered various ventilation structure.

| Case |

Outlet |

Inlet |

Human height (1.5m) |

Pig height (0.5m) |

| Min |

Avg |

Max |

Passage |

Min |

Avg |

Max |

Passage |

| Standard |

-SF-RBD |

+LBD+SD+UW |

0.24 |

0.28 |

0.32 |

0.28 |

0.24 |

0.28 |

0.35 |

0.033 |

| A-1 |

-SF-CF-RBD |

+LBD+SD+UW+DW |

0.25 |

0.35 |

0.45 |

0.35 |

0.25 |

0.35 |

0.47 |

0.080 |

| A-2 |

-SF-CF-RBD |

+SD+UW+DW |

0.25 |

0.35 |

0.41 |

0.43 |

0.23 |

0.41 |

0.47 |

0.074 |

| A-3 |

-SF-CF-RBD |

+UW+DW |

0.24 |

0.35 |

0.39 |

0.44 |

0.23 |

0.40 |

0.47 |

0.070 |

| A-4 |

-SF-CF-RBD |

+UW |

0.26 |

0.31 |

0.34 |

0.28 |

0.26 |

0.28 |

0.34 |

0.028 |

| A-5 |

-SF-CF-RBD |

+DW |

0.25 |

0.25 |

0.31 |

0.28 |

0.24 |

0.24 |

0.37 |

0.042 |

| B-1 |

-SF-RBD |

+LBD+SD+UW+DW |

0.27 |

0.37 |

0.44 |

0.44 |

0.26 |

0.43 |

0.47 |

0.075 |

| B-2 |

-SF-RBD |

+SD+UW+DW |

0.25 |

0.28 |

0.31 |

0.26 |

0.23 |

0.28 |

0.31 |

0.028 |

| B-3 |

-SF-RBD |

+UW+DW |

0.25 |

0.34 |

0.36 |

0.39 |

0.25 |

0.39 |

0.43 |

0.053 |

| B-4 |

-SF-RBD |

+UW |

0.23 |

0.29 |

0.32 |

0.25 |

0.23 |

0.31 |

0.32 |

0.027 |

| B-5 |

-SF-RBD |

+DW |

0.23 |

0.28 |

0.31 |

0.27 |

0.22 |

0.29 |

0.38 |

0.041 |

| C-1 |

-SF |

+LBD+SD+UW+DW |

0.28 |

0.36 |

0.43 |

0.43 |

0.26 |

0.41 |

0.46 |

0.067 |

| C-2 |

-SF |

+SD+UW+DW |

0.26 |

0.35 |

0.42 |

0.42 |

0.26 |

0.40 |

0.47 |

0.068 |

| C-3 |

-SF |

+UW+DW |

0.27 |

0.36 |

0.43 |

0.43 |

0.26 |

0.42 |

0.47 |

0.066 |

| C-4 |

-SF |

+UW |

0.24 |

0.31 |

0.33 |

0.26 |

0.25 |

0.31 |

0.32 |

0.026 |

| C-5 |

-SF |

+DW |

0.26 |

0.25 |

0.31 |

0.29 |

0.25 |

0.22 |

0.37 |

0.041 |

| D-1 |

-CF-RBD |

+LBD+SD+UW+DW |

0.30 |

0.42 |

0.52 |

0.52 |

0.29 |

0.50 |

0.57 |

0.086 |

| D-standard |

-CF-RBD |

+LBD+SD+UW |

0.25 |

0.28 |

0.33 |

0.29 |

0.24 |

0.28 |

0.37 |

0.035 |

| D-2 |

-CF-RBD |

+SD+UW+DW |

0.25 |

0.37 |

0.42 |

0.42 |

0.24 |

0.42 |

0.47 |

0.076 |

| D-3 |

-CF-RBD |

+UW+DW |

0.26 |

0.37 |

0.44 |

0.44 |

0.25 |

0.42 |

0.48 |

0.068 |

| D-4 |

-CF-RBD |

+UW |

0.23 |

0.30 |

0.32 |

0.25 |

0.22 |

0.31 |

0.32 |

0.032 |

| D-5 |

-CF-RBD |

+DW |

0.26 |

0.27 |

0.31 |

0.26 |

0.25 |

0.25 |

0.38 |

0.044 |

| E-1 |

-CF |

+LBD+SD+UW+DW |

0.26 |

0.39 |

0.45 |

0.45 |

0.46 |

0.44 |

0.25 |

0.075 |

| E-2 |

-CF |

+SD+UW+DW |

0.29 |

0.33 |

0.47 |

0.39 |

0.28 |

0.35 |

0.49 |

0.069 |

| E-3 |

-CF |

+UW+DW |

0.27 |

0.37 |

0.43 |

0.43 |

0.25 |

0.42 |

0.48 |

0.066 |

| E-4 |

-CF |

+UW |

0.24 |

0.30 |

0.33 |

0.25 |

0.23 |

0.32 |

0.33 |

0.033 |

| E-5 |

-CF |

+DW |

0.26 |

0.28 |

0.32 |

0.26 |

0.26 |

0.25 |

0.38 |

0.040 |

| F-1 |

-SF |

+CF+RBD+SD |

0.24 |

0.26 |

0.34 |

0.24 |

0.26 |

0.26 |

0.38 |

0.033 |

| F-2 |

-SF |

+CF+RBD+UW+DW |

0.23 |

0.32 |

0.44 |

0.44 |

0.24 |

0.36 |

0.46 |

0.073 |

| F-3 |

-SF |

+CF+RBD+LBD+SD+UW+DW |

0.24 |

0.29 |

0.44 |

0.44 |

0.24 |

0.38 |

0.47 |

0.075 |

| F-4 |

-SF |

+CF+SD |

0.25 |

0.28 |

0.35 |

0.25 |

0.25 |

0.23 |

0.36 |

0.035 |

| F-5 |

-SF |

+CF+UW+DW |

0.21 |

0.33 |

0.55 |

0.50 |

0.22 |

0.49 |

0.60 |

0.125 |

| F-6 |

-SF |

+CF+LBD+SD+UW+DW |

0.22 |

0.31 |

0.46 |

0.46 |

0.21 |

0.37 |

0.47 |

0.084 |

| G-1 |

-SF-RBD-LBD |

+SD+UW+DW |

0.23 |

0.34 |

0.41 |

0.41 |

0.23 |

0.41 |

0.47 |

0.077 |

| G-3 |

SF-RBD-LBD |

+UW+DW |

0.24 |

0.31 |

0.38 |

0.34 |

0.24 |

0.32 |

0.43 |

0.055 |

| G-4 |

-SF-RBD-LBD |

+UW |

0.22 |

0.29 |

0.33 |

0.25 |

0.21 |

0.29 |

0.31 |

0.032 |

| G-5 |

-SF-RBD-LBD |

+DW |

0.25 |

0.26 |

0.31 |

0.27 |

0.25 |

0.24 |

0.38 |

0.040 |

| H-1 |

-SF |

+RBD+LBD+SD+UW+DW |

0.26 |

0.35 |

0.43 |

0.41 |

0.24 |

0.41 |

0.45 |

0.070 |

| H-3 |

-SF |

+RBD+LBD+UW+DW |

0.27 |

0.35 |

0.42 |

0.42 |

0.26 |

0.40 |

0.45 |

0.064 |

| H-4 |

-SF |

+RBD+LBD+UW |

0.23 |

0.27 |

0.32 |

0.24 |

0.21 |

0.26 |

0.35 |

0.037 |

| H-5 |

-SF |

+RBD+LBD+DW |

0.25 |

0.29 |

0.35 |

0.29 |

0.23 |

0.30 |

0.40 |

0.054 |

Table 4.

Temperature analysis at pig height (0.5m) on improving ventilation system cases.

Table 4.

Temperature analysis at pig height (0.5m) on improving ventilation system cases.

| Temperature gap of average temperature (℃) |

x < 3℃ |

3℃ ≤ x < 5℃ |

| Case |

Ventilation Rate (AER·m-1) |

Ventilation Time |

| Basic(Standard) |

0.55 |

60s |

82.9 |

16.5 |

| 180s |

75.9 |

23.7 |

| 300s |

84.6 |

15.4 |

| 0.75 |

60s |

73.3 |

26.3 |

| 180s |

64.6 |

33 |

| 300s |

61 |

34.9 |

| 1.0 |

60s |

69 |

31 |

| 180s |

59.2 |

38.4 |

| 300s |

49.5 |

45.9 |

| Upgrade ①(B+LW) |

0.55 |

60s |

66.3 |

31.6 |

| 180s |

60.8 |

32.2 |

| 300s |

66 |

30 |

| 0.75 |

60s |

44.1 |

49.8 |

| 180s |

39.7 |

53 |

| 300s |

33 |

56.2 |

| 1.0 |

60s |

67.8 |

32.2 |

| 180s |

41.6 |

56 |

| 300s |

39.4 |

58.1 |

| Upgrade (2)(B-CF) |

0.55 |

60s |

80.2 |

17.3 |

| 180s |

81 |

18.9 |

| 300s |

82.7 |

14.6 |

| 0.75 |

60s |

73.8 |

25.9 |

| 180s |

64.9 |

33.7 |

| 300s |

67 |

29.2 |

| 1.0 |

60s |

69.8 |

30.2 |

| 180s |

56.2 |

41 |

| 300s |

44.9 |

50.5 |

| Upgrade (1)+(2)(B+LW-CF) |

0.55 |

60s |

65.2 |

32.1 |

| 180s |

67.1 |

29.4 |

| 300s |

63.5 |

32.5 |

| 0.75 |

60s |

65.7 |

33.3 |

| 180s |

71.4 |

26.7 |

| 300s |

60.6 |

38.7 |

| 1.0 |

60s |

68.7 |

31.3 |

| 180s |

40.5 |

55.7 |

| 300s |

39.4 |

55.4 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).