1. Introduction

The Food and Agriculture Organization has projected that aquaculture products will account for 53% of the global seafood consumption by 2030 [

1]. With an increase in the significance of the aquaculture industry, several countries are now striving to develop it into a vital national sector [

2]. Consequently, the traditional labor-intensive aquaculture industry is rapidly evolving into a technology-intensive industry driven by advances in automation, water treatment, and biotechnology. With this, technologies automating the aquaculture process are increasingly being developed to save labor, stabilize aquaculture production, and reduce operating costs [

3].

A representative example of such technology is automatic feeding. Feeding is a repetitive task in aquaculture that is labor intensive and exerts a direct impact on the growth of aquaculture organisms. Moreover, considering that the cost of feed procurement accounts for a large proportion of the operational costs, it is crucial to supply the appropriate amount of feed according to growth stages and feeding activities of fish to prevent feed loss [4, 5]. In particular, in land-based tank farming, excessive feeding can increase mortality rates owing to water pollution caused by increased excreta and feed loss [

6]. In cage farming, lost feed contributes to marine environmental pollution [7, 8].

Previous studies have developed methods to supply appropriate amounts of feed by analyzing feeding behavior; these methods employ mathematical models and image processing techniques to address existing problems in the feeding process [

9]. Moreover, image processing techniques are increasingly being applied to determine the amount of feed supply based on quantifications of fish feeding activities in recirculating aquaculture systems [

10]. However, assessing the fish feeding activity using images presents challenges owing to the low-light conditions inside farms and complex backgrounds of the objects to be observed. Therefore, recent research has attempted to recognize feeding behavior using underwater acoustics and deep learning technology [

11,

12,

13].

In this paper, we present an edge-computing-based intelligent feeding system that observes the depth-specific feeding behavior of red sea bream to automate feeding. The feeding algorithm is designed to observe the depth-specific feeding behavior of red seabream during the feeding process and determine whether the feed supply must be continued. We evaluate the performance of the intelligent feeding system by analyzing the feeding quantity and speed according to the feed diameter. To compare the feeding algorithm with the conventional manual feeding method, we analyzed the feed loss rate based on the total amount of feed supplied and the amount of lost feed measured in a feeding experiment conducted at a red seabream sea cage farm.

2. Materials and Methods

2.1. Design of the Intelligent Feeding System

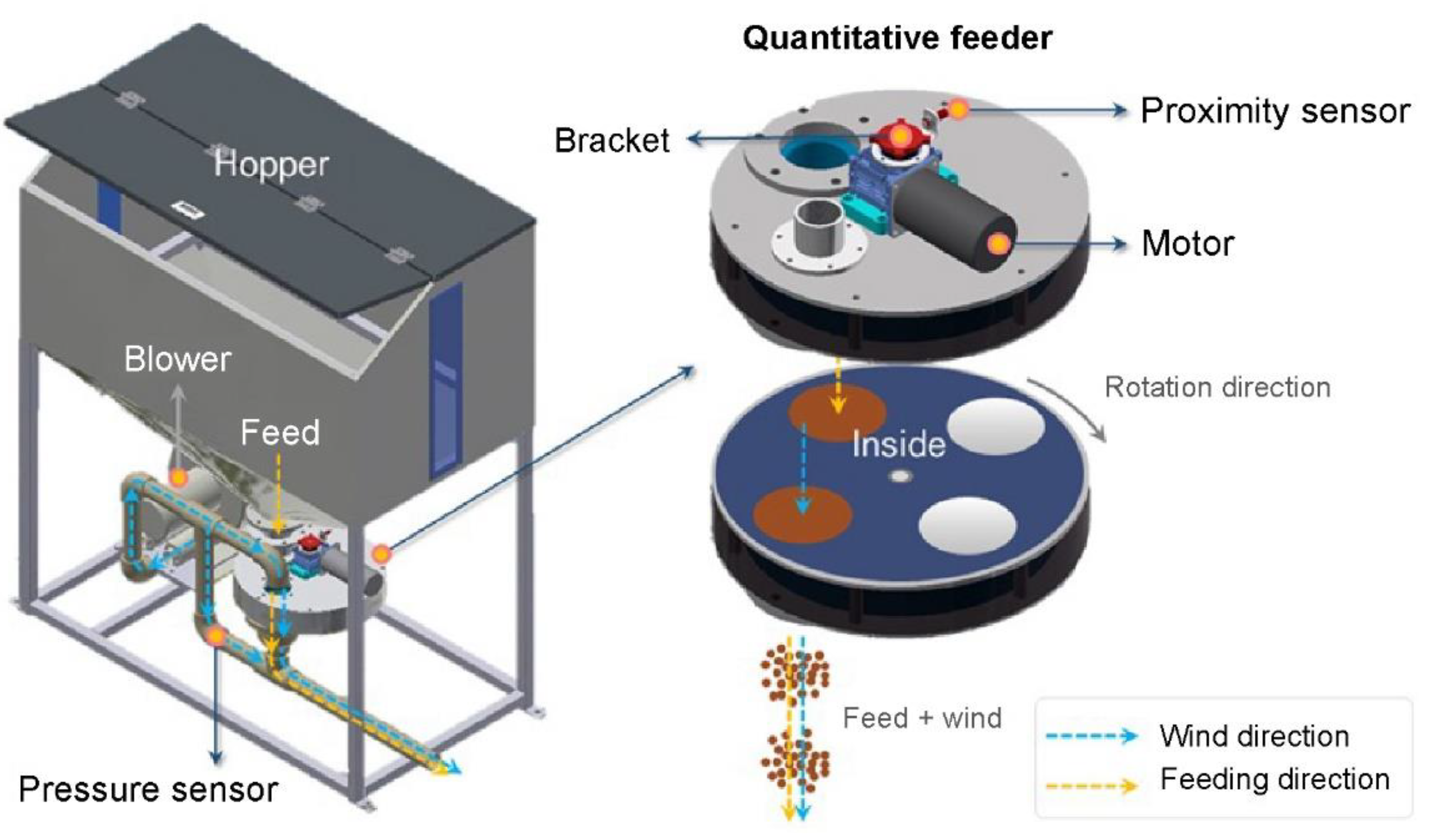

The developed intelligent feeding system is designed to supply feed using the wind force generated by a blower, as shown in

Figure 1. The system consists of a hopper, blower, quantitative feeder, and programmable logic controller (PLC) that controls each component. The quantitative feeder comprises a feed measuring disk and motor that rotates the disk. The feed measuring disk is designed with circular grooves (diameter: 79.49 mm, height: 79.20 mm) with the same volume at 90

intervals to ensure that the feed is evenly loaded. Moreover, the quantitative feeder is designed to measure the rotation of the feed measuring groove. This is achieved by installing a bracket with protrusions along the same direction as the measuring groove on the motor shaft, enabling the rotating protrusion to be detected by the proximity sensor.

The feeding amount (

) can be calculated using the volume (

) of the feed measuring groove, density (

) of the feed, and rotation count (

) of the feed measuring groove, as expressed in Equation 1. However, the feeding quantity varies owing to the empty space between feed grains, depending on the diameter of the feed loaded into the feed measuring groove. Therefore, the feeding quantity must be calculated by considering the volume rate (

), which is represented by the volume (

) of the empty space in the volume of the measuring groove, as expressed in Equation 2.

2.2. Edge Computing System

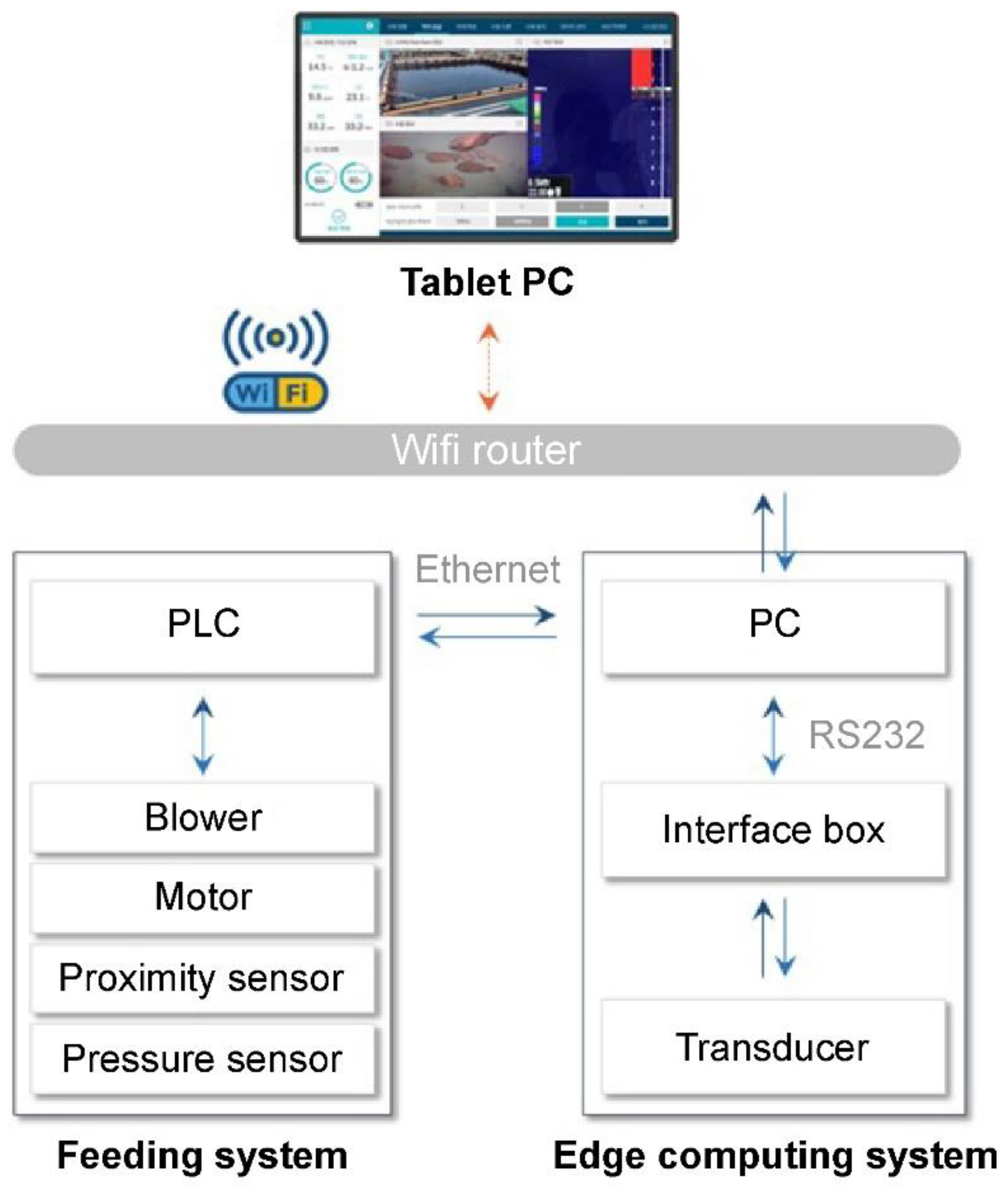

As shown in

Figure 2, the hardware of the edge computing system is composed of a CruzPro Fishfinder (PCFF80) transducer and interface box, a mini PC, and a Wi-Fi router to observe the depth-specific feeding behavior of red seabream and establish a link with the intelligent feeding system.

The specifications of the Fishfinder are listed in

Table 1. The Fishfinder and PC use the RS232 communication method, and the PLC of the intelligent feeding system communicates with the PC via Ethernet. Additionally, an app for mobile devices based on the Android operating system was developed to remotely set the feeding time of the intelligent feeding system, monitor the swimming depth of the fish school, and check the operating status.

The PC software of the edge computing system was designed to collect and analyze the data output in ASCII code from the Fishfinder, reflecting the target strength (

)—the reflected signal (

) from the target according to the incident signal (

)—at different depths, as expressed in Equation 3. The data processing flow of the PC software is illustrated in

Figure 3. To visualize the swimming depth of the fish school, the PC software was designed to convert the ASCII code of the Fishfinder into eight bits, divide it into 16 sections, and then map the color information of each section to reconstruct it into a pixel line format.

2.3. Feeding Algorithm

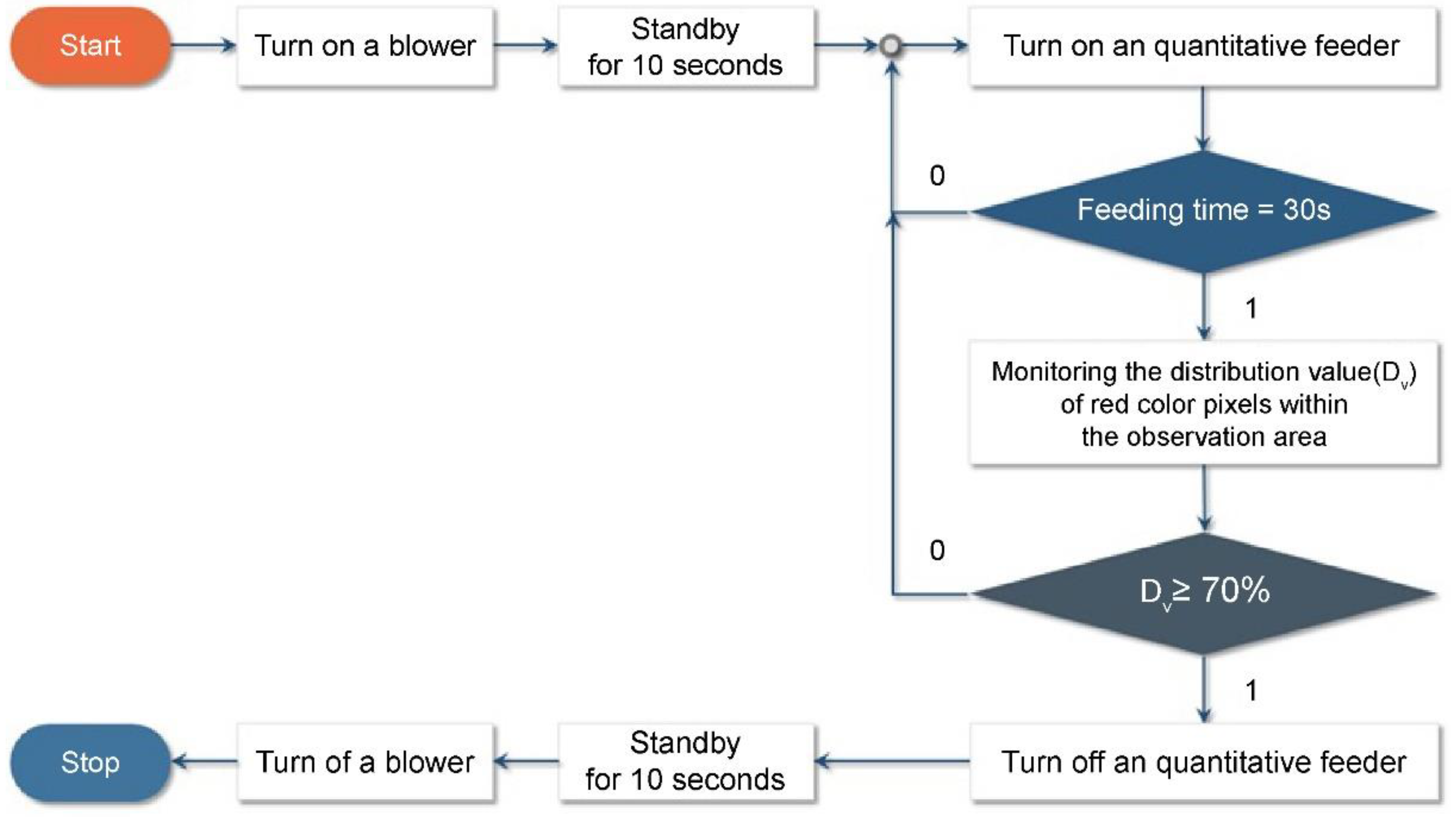

Generally, the feeding behavior of red seabream being farmed in sea cages involves the movement of the fish from deeper waters to the surface of the sea when feed is supplied, consuming sufficient feed in a school, followed by their movement back to deeper waters. Utilizing this characteristic, we developed a feeding algorithm that determines whether the feed supply must be continued based on the depth-specific feeding behavior observations of the red seabream from the feed supply time, as illustrated in

Figure 4.

The observation results of the depth-specific feeding behavior of red seabream are illustrated by the number of pixels shown in red in

Figure 3, which represents the acoustic intensity value of the fish school in the set observation area. The system determines whether the feed supply must be continued by observing the proportion (

) of red pixels in the set observation area from the time feed is supplied. However, the proportion of red pixels in the set observation area is high in both cases, i.e., when the red seabream school rises to the sea surface to consume feed and when it descends to deeper waters after adequate feed consumption. Therefore, the feeding algorithm was designed to stand by for the duration the red seabream ascends to the sea surface from the time feed is supplied and to cease feed supply upon detecting their descent after sufficient feed consumption. The standby time from the time feed is supplied until the red seabream ascends to the sea surface and the distribution value of red pixels (

) in the observation area were set to 30 s and 70%, respectively, reflecting the field experiment results.

2.4. Performance Evaluation Method

The performance of the intelligent feeding system was evaluated by measuring and analyzing the difference in feeding quantity according to the diameter of the feed and the maximum feeding speed. The difference in feeding quantity was analyzed through 50 repeated experiments that involved measuring the weight of the feed filled to the brim in the measuring grooves of the quantitative feeder according to the diameter of the feed. The maximum feeding speed was determined based on the feeding time and quantity. The feeding time was measured based on the pressure signals from the pressure gauge during feed spray and time, and the feeding quantity was determined by referring to the weight data of the feeding amount according to the diameter.

The performance of the feeding algorithm was evaluated by comparing its results with those of the traditional manual feeding method in a feeding experiment at a red seabream sea cage farm. In the feeding experiment, we categorized the traditional manual method and the feeding algorithm as the control group and experimental group, respectively.

Table 2 presents the aquaculture information. The sea cage farm sizes (12 × 12 × 6 m) of the control and experimental groups are identical.

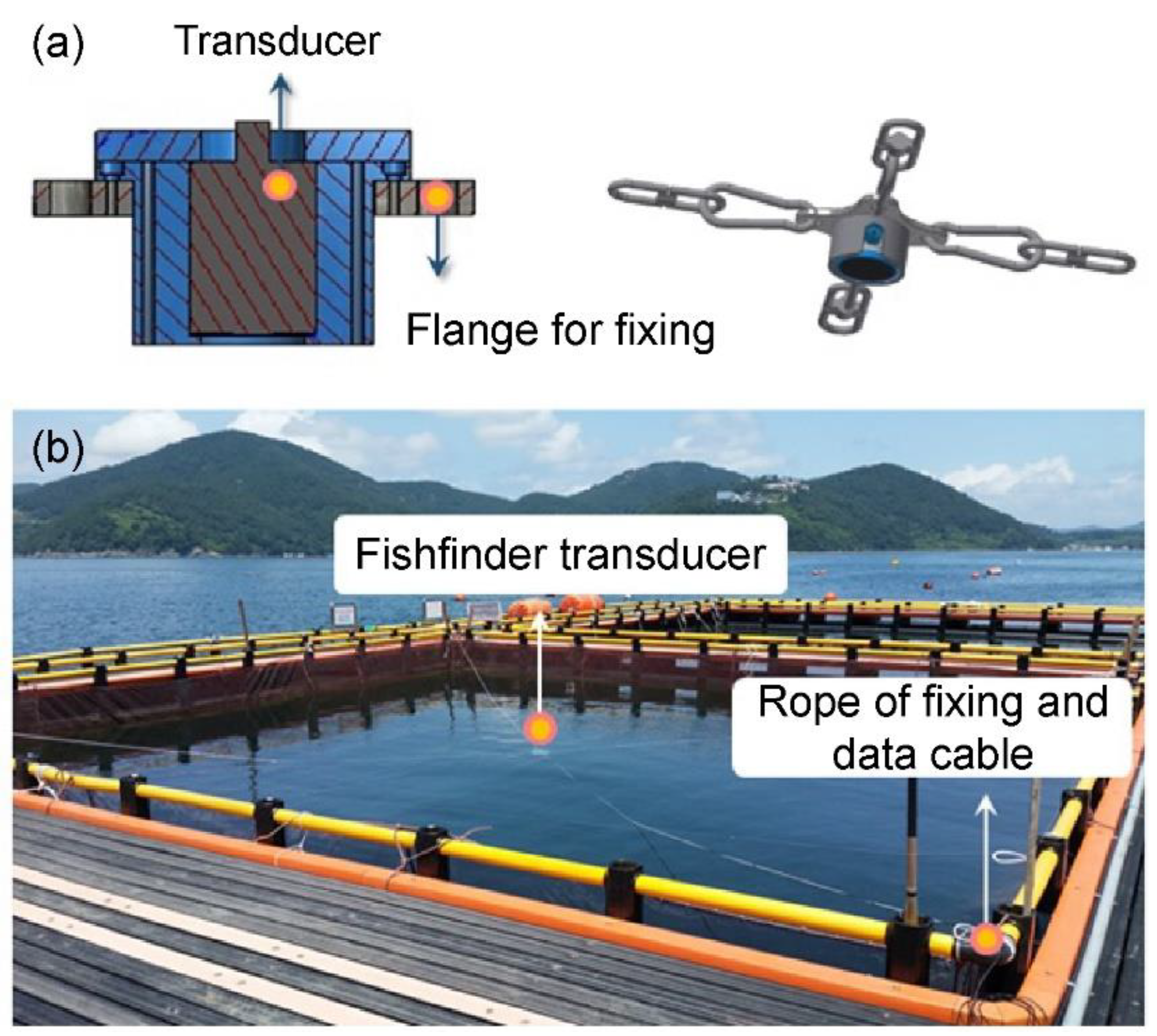

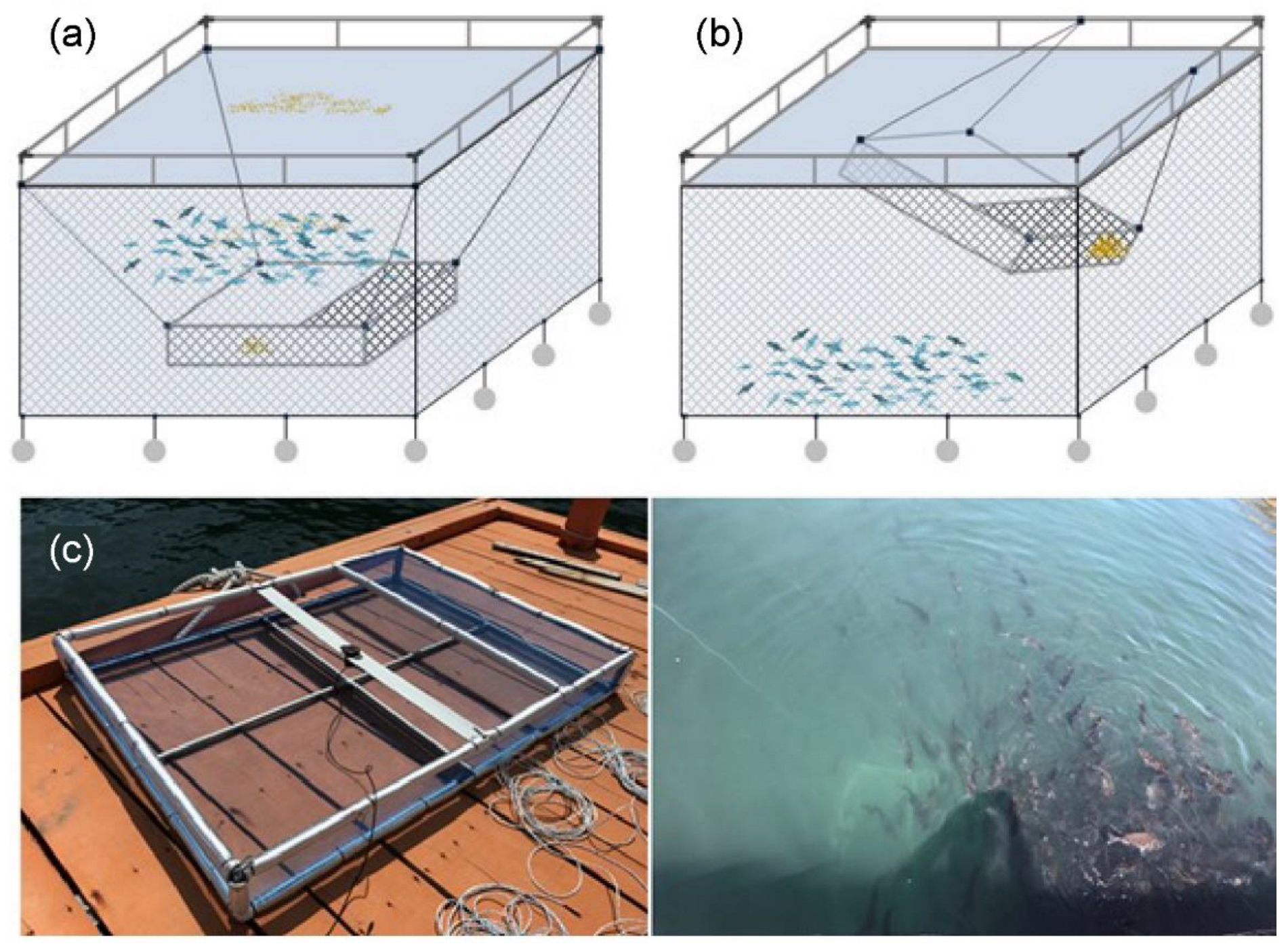

For the sea cage farm of the experimental group, we fixed the Fishfinder transducer and the developed edge computing-based intelligent feeding system by creating an installation bracket, as shown in

Figure 5 (a). The transducer was installed at the exact center of the cage where the feed was sprayed, as shown in

Figure 5(b). Additionally, the transmitter and receiver of the transducer were installed to face the bottom of the ocean from the surface, making it easier to observe the depth-specific feeding activity of the red seabream. The settings of the Fishfinder are listed in

Table 3.

The performance of the feeding algorithm was evaluated by conducting a comparative analysis of the results of 30 repeated feeding experiments involving both the control and experimental groups. The evaluation considered the total feeding time, amount of feed supplied, amount of feed lost, and loss rate. Here, the lost feed refers to the amount of feed that the red seabream did not consume and was subsequently lost. The weight of the lost feed was measured by installing a feed collection net (size: 1,500 × 2,000 × 200 mm) under the point where feed was supplied and collecting it, as shown in

Figure 6.

The feed loss rate can be calculated using Equation 4, which uses the total weight (

) of the feed supplied in the feeding experiment and the weight of the feed collected by the feed collection net (

).

3. Results and Discussion

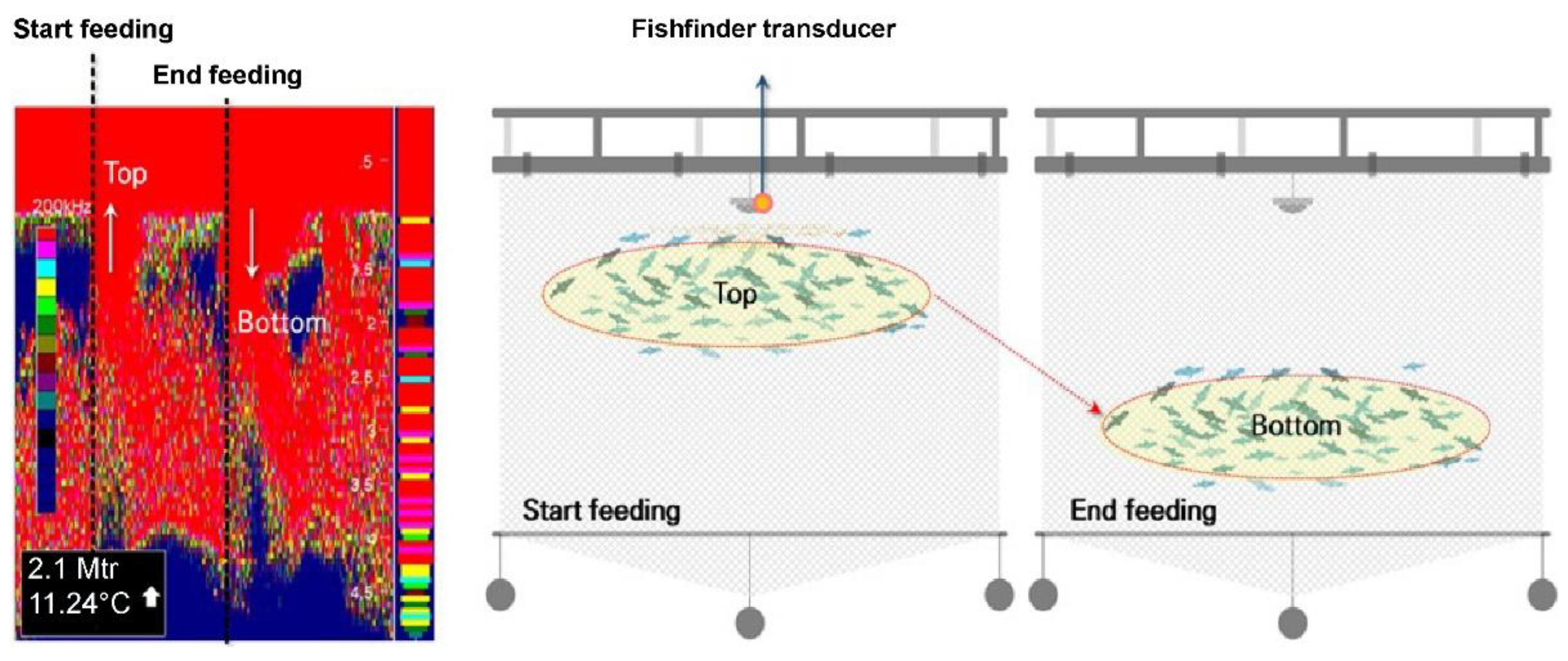

3.1. Feeding Behavior Characteristics of Red Seabream

The feeding behavior characteristics of the red seabream were identified by observing the swimming depth of the fish school using the Fishfinder while manually supplying the feed, as depicted in

Figure 7. These observations demonstrated that when feed is supplied, the red seabream rises from the net at the bottom of the sea cage to the sea surface to consume the feed, and once they have consumed enough feed, they descend back to the net at the bottom of the sea cage. Notably, this phenomenon was consistent for adult fish rather than juveniles and when the water temperature was at least 11 °C.

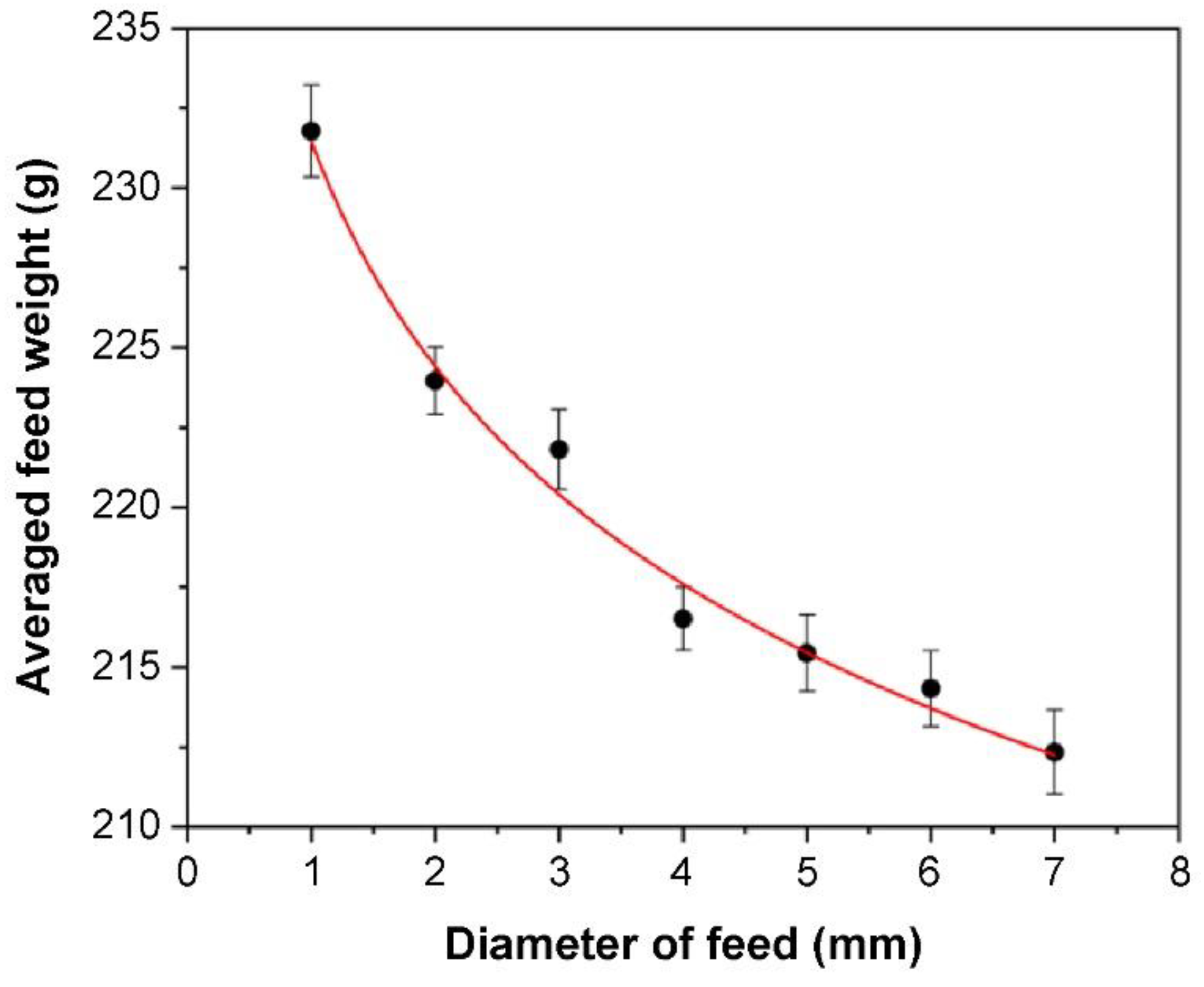

3.2. Performance of the Intelligent Feeding System

Figure 8 illustrates a plot of the average weight of the feed supplied and measured according to the diameter of the feed. From the experimental results, it can be observed that the weight of the feed supplied by the intelligent feeding system differs owing to the volume of the empty space based on the diameter of the feed. The regression analysis results listed in

Table 4 indicate that as the diameter of the feed increases, the supply amount decreases as a power function.

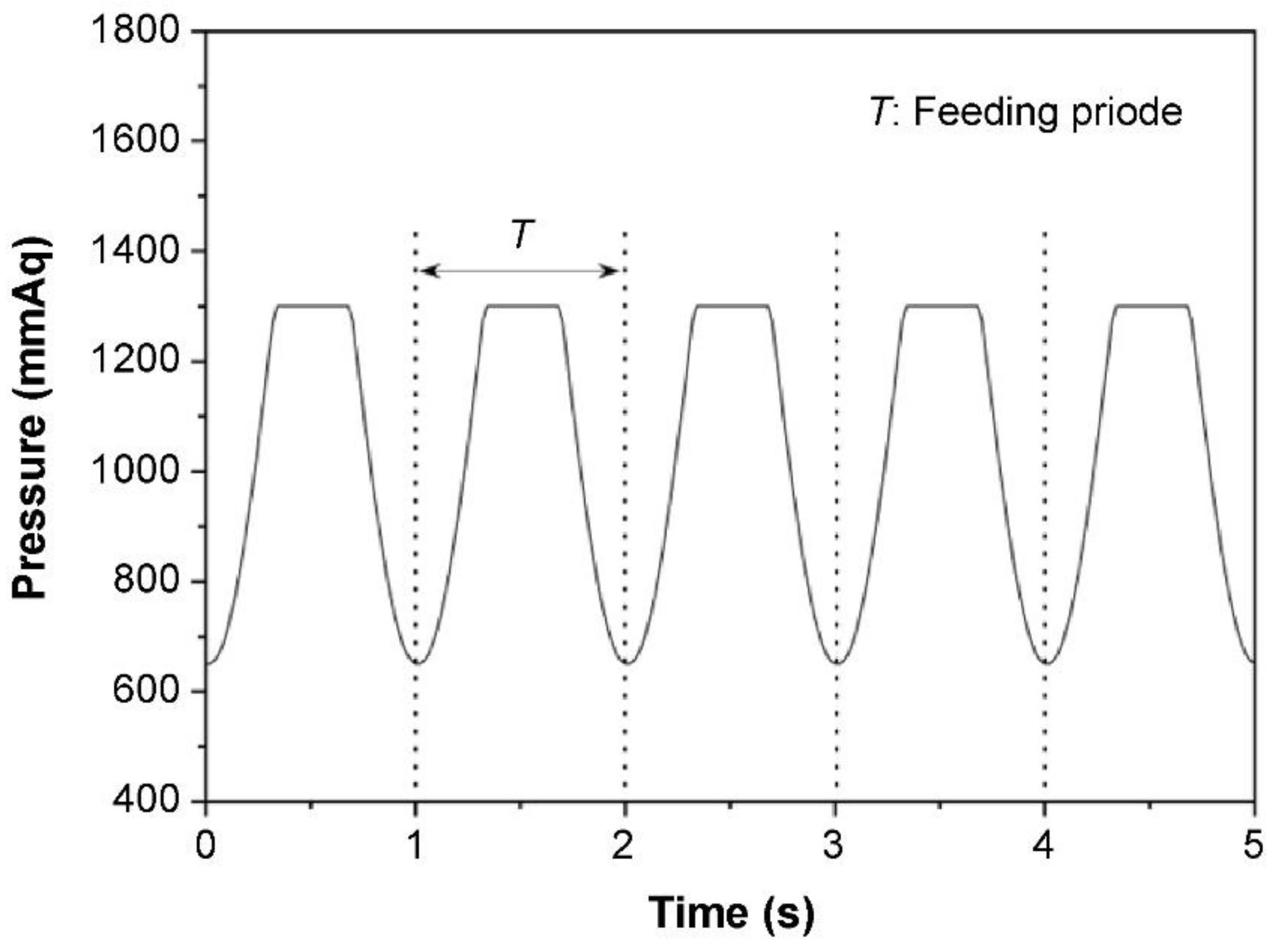

In the feeding experiment, the maximum supply distance and feeding speed were analyzed by measuring the spray pressure of the feed and the rotation count and time of the feed measuring grooves using a proximity sensor. The experimental conditions were as follows: feed with a diameter of 7 mm, motor designed with a reduction ratio of 100:1 set at the maximum speed of the inverter, 60 Hz.

According to the experimental results, as shown in

Figure 9, the feed was sprayed up to approximately 8.1 m, which is the central position of the sea cage, with a maximum pressure of 1,300 mm Aq at 1 s intervals. Therefore, the maximum feeding speed is determined by the time per second, and the average weight of the feed is determined by its diameter, as shown in

Figure 8. When using feed with a diameter of 7 mm, as in this feeding experiment, the maximum supply speed averages at 213.21 g/s.

3.3. Analysis of the Feed Loss Rate

We performed experiments in designated areas divided into the control and experimental groups, each using the manual method and feeding algorithm, respectively. In the experimental group, feed with a diameter of 7 mm was supplied at an average rate of 213.21 g per session at 3 s intervals. To facilitate a fair comparison, the control group was also supplied with feed under the same conditions.

The feeding time was recorded from the time that feed was supplied. The control group was analyzed until the termination of feeding activity as a result of the red seabream adequately consuming the feed, while the experimental group was analyzed until feeding was automatically stopped by the algorithm. The amount of feed supplied was calculated by weight as the total amount of feed supplied during the feeding time.

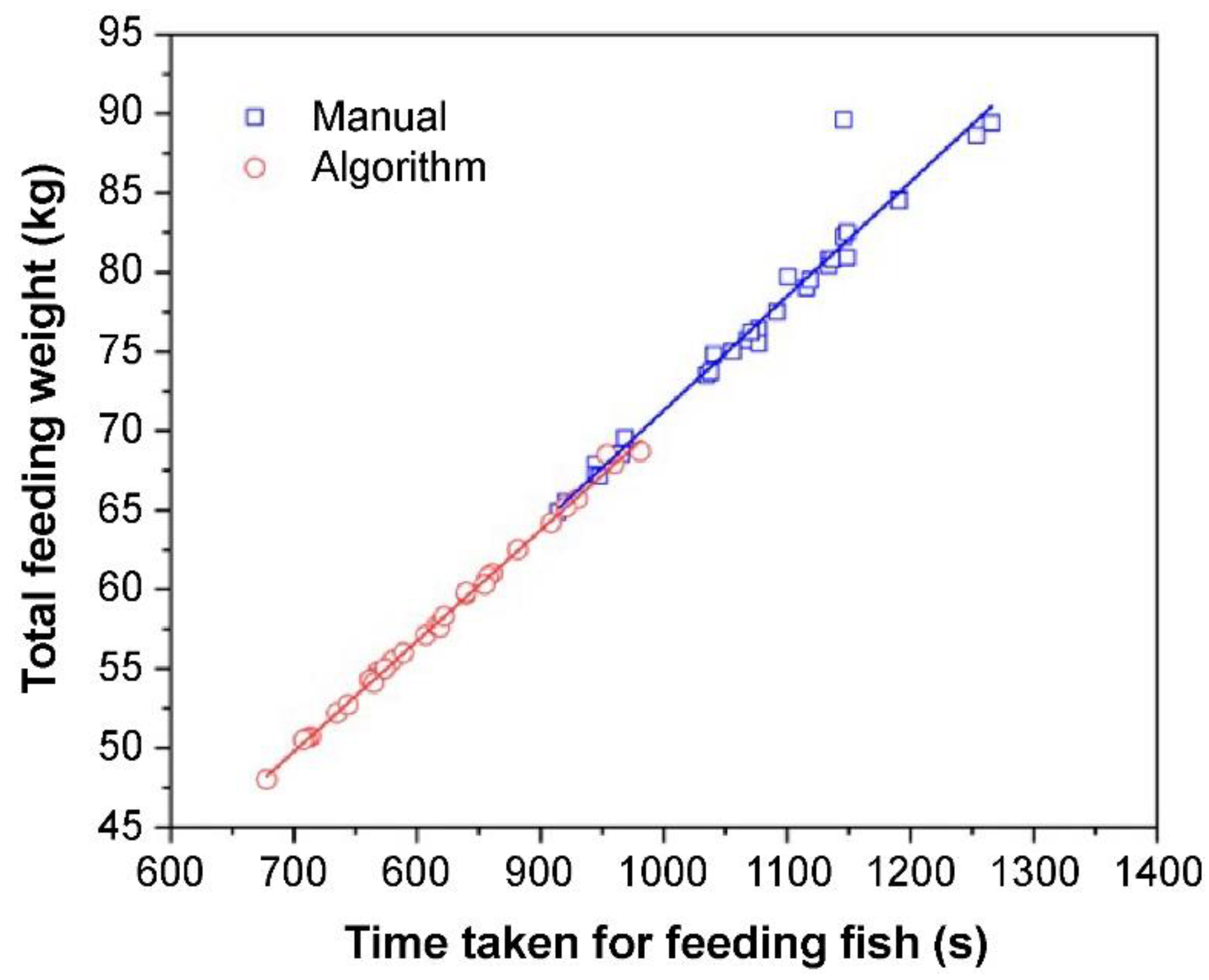

Figure 10 illustrates the total feeding amount and time measured during the 30 repetitions of the feeding experiment, for each feeding method of the control and experimental groups.

Table 5 presents the sum of the measured feeding amount and supply time during the feeding experiment period, value converted to the feeding amount per unit time, and results of the regression analysis.

Based on the experimental results, the control group had a relatively larger and longer feed supply compared to the experimental group, but there was no difference in the amount of feed supplied per unit of time. Additionally, the regression analysis shows that the supply amount relative to supply time has a linear relationship, (a) the slopes of the control and experimental groups are the same, and (b) the error in the feeding amount is negligible. These results indicate that the difference in feeding amount and time between the control and experimental groups arises because the average weight per red seabream in the control group is 32 g larger, and there were 3,000 more fish farmed. Moreover, for farmed fish like red seabream, the feed consumption and feeding activity may vary with changes in the farming environment, such as water temperature and dissolved oxygen, so differences can be expected in the feeding amount and time [14, 15].

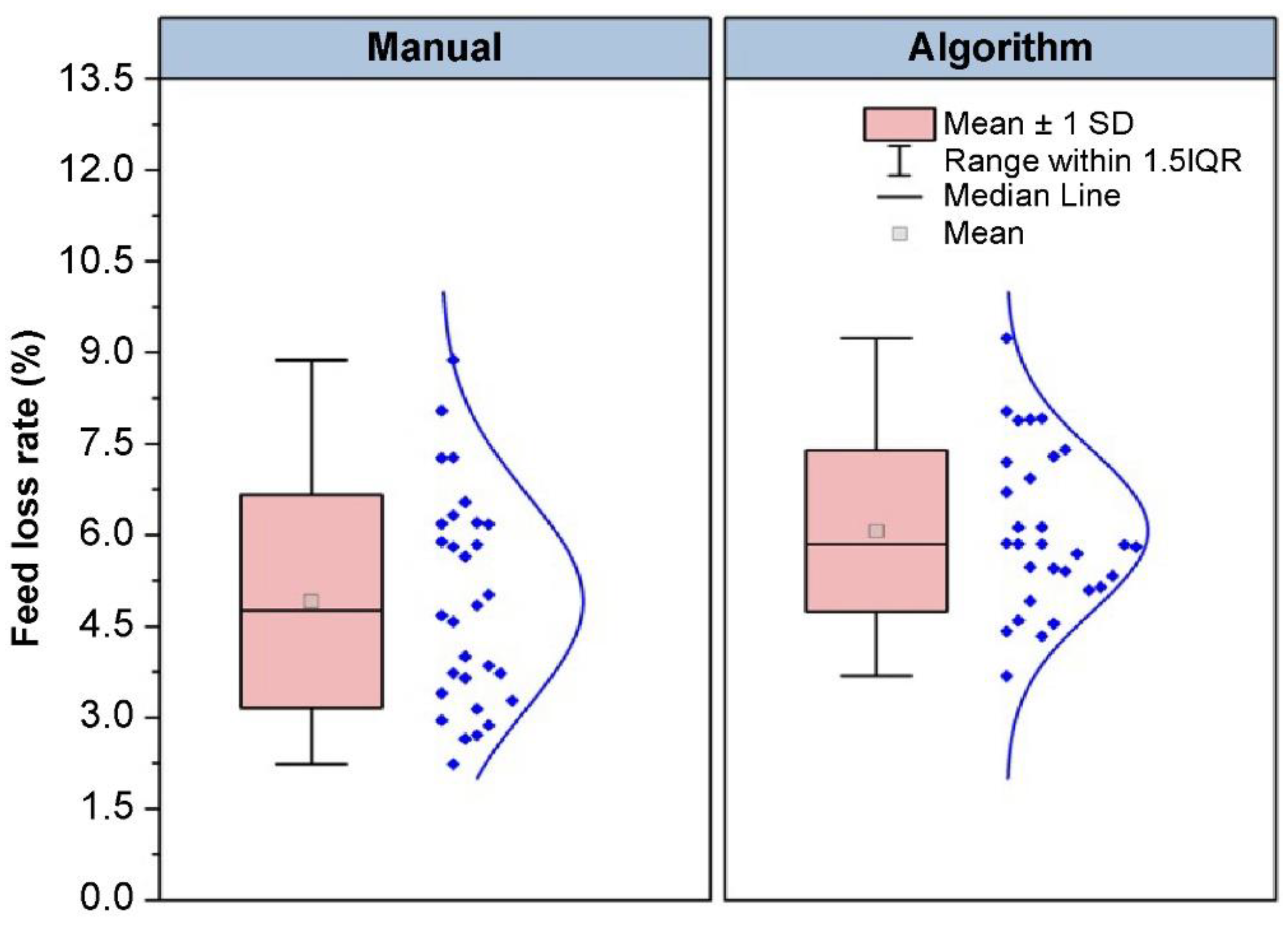

Feed loss according to the feeding method was measured by collecting the feed from the feed collection net installed for the control and experimental groups after feeding was stopped, and then weighing the feed using a digital scale.

Figure 11 shows the feed loss rate measured through 30 repeated trials of feed supply experiments, each conducted using different feed supply methods in the control and experimental groups. The feed loss rate was calculated as the proportion of the lost feed amount to the total feed supplied, as expressed in Equation 3.

The experimental results indicate that the average feed loss rates of the control and experimental groups are 4.91% and 6.07%, respectively. A t-test was conducted to compare the averages between the two groups. The resulting p-value was significantly below the threshold at 0.0027 (p<0.05), demonstrating a 1.16% difference in the average feed loss rates between the control and experimental groups. These findings suggest that the control group, with a lower feed loss rate, exhibits better feed supply performance than the experimental group.

However, feed loss rates can vary depending on the amount of feed lost due to the flow rate of water during the feed capture process. Consequently, to compare the feed supply performance of the control and experimental groups more accurately, it is deemed necessary to either perfectly measure the feed lost underwater or devise a method to collect it.

4. Conclusions

In this study, we developed an intelligent feeding system that determines whether the feed supply must be continued or terminated by observing the depth-specific feeding behavior of red seabream. We compared the feeding performance of the system with that of traditional manual feeding by conducting a field experiment to investigate the per-unit-time feed supply amount and loss rate. The experimental results show that while the per-unit-time feed supply of both the manual method and the intelligent feed supply system was at an equivalent level, the intelligent feed supply system yielded a feed loss rate 1.16% higher than the manual method. This negligible difference in feed loss underscores the feasibility and effectiveness of the feeding method, as confirmed through observation of the depth-specific feeding behavior of the red seabream.

However, continuous follow-up research is deemed necessary to improve the performance of the developed technology and assure reliability. Moreover, the developed intelligent feeding system requires measures against malfunctions, such as failures in the edge computing system and Fishfinder, that can cause the system to continue or stop feeding. Accordingly, in future research, we plan to analyze the correlations between farming environment data (e.g., water temperature and dissolved oxygen) and depth-specific feeding behavior data of red seabream collected in the feeding experiment to predict the appropriate amount of feed according to the farming environment using the edge computing system.

Such research is expected to help improve the operating environment of aquaculture sites, ensure appropriate feed supply, stabilize fish production, ensure the health of fish, and reduce overall operational costs. Moreover, we expect that the developed system can contribute to shifting from traditional labor-intensive farming methods to a technology-intensive aquaculture industry by automating the farming process using intelligent techniques.

Author Contributions

Conceptualization, D.L.; methodology, D.L. and K.L.; software, D.L.; validation, D.L. and K.L.; formal analysis, D.L. and J.B.; investigation, D.L. and K.L.; resources, D.L.; data curation, D.L. and K.L.; writing—original draft preparation, D.L.; writing—review and editing, D.L., K.L. and J.B.; visualization, D.L.; supervision, D.L.; project administration, D.L.; funding acquisition, J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Institute of Fisheries Science, Korea, under grant number R2023033.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to express our gratitude to the red seabream sea cage farmers for their kind support during our on-site feeding experiments in evaluating the performance of the intelligent feed supply system developed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Food and Agriculture Organization. The State of World Fisheries and Aquaculture 2020: Sustainability in Action. 2020, 165. Available online: http://www.fao.org/3/ca9229en/CA9229EN.pdf.

- Naylor, R.L.; Hardy, R.W.; Buschmann, A.H.; Bush, S.R.; Cao, L.; Klinger, D.H.; Little, D.C.; Lubchenco, J.; Shumway, S.E.; Troell, M. A 20-year retrospective review of global aquaculture. Nature 2021, 591(7851), 551–563. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Zhang, S.; Liu, J.; Wang, H.; Zhu, J.; Li, D.; Zhao, R. Application of machine learning in intelligent fish aquaculture: A review. Aquaculture 2021, 540, 736724. [Google Scholar] [CrossRef]

- Chang, C.M.; Fang, W.; Jao, R.C.; Shyu, C.Z.; Liao, I.C. Development of an intelligent feeding controller for indoor intensive culturing of eel. Aquac. Eng. 2005, 32, 343–353. [Google Scholar] [CrossRef]

- El-Ebiary, El-S. H.; Rearing sharp-snout seabream (Diplodus Puntazzo) fingerlings at varying dietary protein and lipid levels. Egypt. J. Aquat. Res. 2005, 31, 443–452. [Google Scholar]

- Varadi, L.; Mechanized feeding in aquaculture. Inland Aquaculture Engineering, ADCP/REP/84/21, Food and Agriculture Organization (FAO).

- Daoliang, L.; et al. Automatic recognition methods of fish feeding behavior in aquaculture: A review. Aquaculture 2020, 528, 735508. [Google Scholar] [CrossRef]

- Persson, G. ; Eutrophication resulting from salmonid fish culture in fresh and salt waters: Scandinavian experiences . Nutritional Strategies & Aquaculture Waste. In Proceedings of the First International Symposium on Nutritional Strategies in Ma. (1991).

- Chao, Z.; et al. Intelligent feeding control methods in aquaculture with an emphasis on fish: a review. Rev Aquac. 2018, 10.4, 975–993. [Google Scholar] [CrossRef]

- Ziyi, L.; et al. Measuring feeding activity of fish in RAS using computer vision. Aquac. Eng. 2014, 60, 20–27. [Google Scholar] [CrossRef]

- Yuhao, Z.; et al. Fish school feeding behavior quantification using acoustic signal and improved Swin Transformer. Comput Electron Agric. 2023, 204, 107580. [Google Scholar] [CrossRef]

- Mallekh, R.; Lagard`ere, J.P.; Eneau, J.P.; Cloutour, C. An acoustic detector of turbot feeding activity. Aquaculture 2003, 221, 481–489. [Google Scholar] [CrossRef]

- Xinting, Y.; et al. Deep learning for smart fish farming: Applications, opportunities and challenges. Rev Aquac. 2021, 13.1, 66–90. [Google Scholar] [CrossRef]

- Daniel, A.; et al. Fish feed intake, feeding behavior, and the physiological response of apelin to fasting and refeeding. Front. Endocrinol. 2021, 12, 798903. [Google Scholar] [CrossRef]

- Yoon, S. Critical low temperature and response of behavioral tolerance in red seabream pagrus major fingerlings exposed to cold shock. Journal of the Korea Academia-Industrial cooperation Society 2021, 22, 575–584. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).