1. Introduction

In the last years, a great amount of concern was paid to isolation of bioactive compounds from natural sources due to their antioxidant properties. In particular, the interest was directed to the examination and use of products obtained from the transformation processes of vegetable raw materials [

1,

2]. Cereal-based products, especially pasta and bread, are well suited for nutrient supply through fortification. Furthermore, the development of new functional products based on fortified breads and flours may have an impact on the influence of metabolism and other health conditions [

3]. Unfortunately, fortification often affects the quality of cereal-based products, in relation to texture, color, cooking quality and sensory properties. One the main challenges faced by the food industry is to improve the healthfulness of foods without compromising their sensory attributes [

4].

Bakery products, such as bread and pasta, are foods based on simple ingredients such as wheat flour, yeast, water and salt. Nevertheless, bread is one of the basic food products in the human diet, constituting a valuable source of many important nutrients necessary for the proper functioning of the body. Just because of its simpleness and its wide consumption, bread is appropriate to be enriched and fortified with healthy bioactive compounds [

5,

6].

Industrial

Cannabis sativa L. plants, with a low level of d-9-tetrahydrocannabinol (THC, < 0.2%), are grown to obtain fiber, seeds and their derivatives, such as oil [

7]. It is important agricultural commodity in Canada [

6,

8], USA [

9] and China [

10]. Hemp fiber is widely used in the modern production of paper and fabrics in these countries. The edible part of Cannabis sativa is the seeds, which have become an attractive by-product for the production of hemp seed food products that have become available to consumers. In China toasted hemp seeds are sold in the markets, although most seeds are exported (untoasted) as bird seeds. In Eastern European countries, hemp seeds oil has been used as a butter substitute, typically by those who could not afford dairy products [

11].

Hemp seeds have a high nutritional value thanks to their high content of easily and quickly digestible proteins, essential amino acids, and a good ratio between omega-6 and omega-3 polyunsaturated fatty acids (PUFA) [

12,

13]. Prociuk et al. studied the effects of a hempseed enriched diet on cholesterol levels. They observed a reduction in plasma cholesterol probably related to increased levels of plasma γ-linolenic acid [

14]. Other authors investigated the beneficial effects of hemp seeds to improve pain symptoms in patients with osteoarthritis [

15].

As evidenced by previous analyses [

16,

17,

18], from seeds is obtained an oil rich in fatty acids, mainly linoleic and α-linolenic acids.

After oil extraction, seeds can be ground to obtain edible flours. Hemp seeds flour is an example of promising bio-sustainability waste raw material with a high nutritional value that can be obtained from industrial by-products.

Foods fortified with these “non-wheat flours” would have an additional supply of fiber, minerals, proteins, and polyphenols. Therefore, food fortification increases the nutritional and potential beneficial properties of the final product, and enhances by-products of agri-food industries, as new sources of bioactive components, from the perspective of a circular economy and a biorefinery approach both for environmental and economic reasons. In this regard, many authors have already investigated the impact of hemp seed flour enrichment on technological, nutritional, and sensorial characteristics of bakery products [

19,

20] and pasta [

21,

22,

23].

One of the objectives of this study was to reuse hemp seed processing waste after oil extraction. In particular, the technological and nutritional characteristics of bread samples obtained with "Cyclops" durum wheat semolina were evaluated, compared to those of breads fortified with 5%, 7.5% and 10% hemp seed flour.

2. Materials and Methods

2.1. Raw materials

The Ciclope durum wheat variety, registered in the National Register of Varieties in 2006, was established by researchers from the former Experimental Institute for Cereal crops in Catania, today the Cereal and Industrial Crops Research Center of CREA, in Acireale (Catania - Sicily). Its qualitative and technological properties, in particular the high gluten index, make the Ciclope variety particularly suitable for industrial transformation processes. In this work, the first transformation involved the grinding of the kernels performed with an experimental mill Bona Labormill 4RB. The semolina obtained had a granulometry of about 250 µm and the extraction yield stood at 55-60%. Instead, the hemp flours were obtained from the milling waste of the hemp seeds, for the purpose of oil extraction; the entire transformation process took place at the Molino Crisafulli Soc. Coop. RL, Caltagirone - Sicily. Based on the type of sieve used, two types of flour were obtained, differing in particle size: 530 µm, namely Hemp 1 and 236 µm, namely Hemp 2.

2.2. Bread Rheological Characteristics

Moisture content was determined according to the AACC 08-01 methods (AACC, 2000) [

24]. The farinograph indices were determined according to the AACC 54- 21 method (AACC, 2000) by a farinograph (Brabender instrument, Duisburg, Germany), equipped with the software Farinograph® (Brabender instrument, Duisburg, Germany). According to the standard procedure, the following farinograph indices were determined: water absorption needed to achieve the dough consistency of 500 ± 20 Brabender Units (B.U.) (WA), dough development time (DT) and dough stability (S) were measured. The alveographic test was used to analyze the effect of additions on the dough rheological behavior performed by Chopin alveograph (Chopin,Villeneuve La Garenne, France) according to the standard alveographic (UNI n° 10453 method) (a). Each sample was analyzed in five repetitions and deformation energy W (strength) and P/L (tenacity/extensibility ratio) were calculated. Wet and dry gluten and gluten index were determined using a Glutomatic System (Glutomatic 2200, Centrifuge 2015, Glutork 2020; Perten Instruments AB, Huddinge, Sweden), according to the UNI 10690 method (UNI, 1979).

2.3. Technological and qualitative analysis for fortified bread

2.3.1. Bread-Making Test

In order to determine the optimal development of the doughs, an experimental bread-making test was performed, using the AACC 10.10 method [

24], modified for durum wheat. Three different percentages of hemp flour integration were considered (5%, 7.5% and 10% w/w), in addition to the Ciclope durum wheat semolina. Bread made from 100% Ciclope durum wheat semolina was used as a control (CTRL) (

Table 1). The bread-making process was carried out in the laboratory, at a constant temperature (25 °C). The production of each fortified bread sample involved the use of 200 g of flour (xg of Ciclope durum wheat + xg of hemp flour), brewer's yeast (3%), sugar (6%), NaCl (2%), ascorbic acid (80 p.p.m) and shortening (3%) to distilled water. The quantity of water to be added to obtain the mixtures was calculated through farinographic analysis. The entire bread-making process involved four leavening phases, for a total time of 4.20 hours. The leavening process took place in a leavening chamber with controlled temperature and humidity, respectively at 29 ± 1.41 ◦C and 82.5% ± 3.54%. During the first phase, lasting 2.15 hours, the doughs were placed in the leavening compartment. The second phase, lasting 50 minutes, concerned the samples subjected to the first rolling. After the set time, the dough was rolled out a second time and then left to rise for another 25 minutes. The last leavening phase, which lasted 50 minutes, involved the dough rolled up manually and placed in individual metal molds. Then, the loaves were baked for 18 minutes at 215–220 ◦C., in a continuous oven (Pavailler Engineering S.r.l., Galliate, Italy). On the breads, the following properties were tested for each bread sample: volume (BV) (determined according to the rapeseed displacement in a loaf volume meter, AACC 10.05.01 method), height (BH) (DigiMaxTM digital caliper, Scienceware, N.J., USA), and weight (BW) were measured.

2.3.2. Sensorial Analysis of Bread

Once the transformation process was completed, sensory analysis was carried out on the bread samples obtained. The different types of breads (CTRL and 5%, 7.5% and 10% of bread fortified with Hemp 1 and Hemp 2 flour) were evaluated by 10 previously trained tasters, aged between 25 and 62 years old. The loaves were cut into slices, one centimeter thick, and placed in containers previously labeled with numbers. The thickness of the crust, the elasticity, the hardness, the friability, the apparent softness were evaluated. Regarding the crumb, the elasticity, friability, cohesion and humidity were evaluated and the crumb porosity was estimated using the Mohs scale. In order to determine a general evaluation, a scale of values ranging from 1 to 10 was used, where 6 represents the minimum threshold of acceptability.

2.3.3. Bread Colour Estimate

The crust and crumb color data of the loaves were measured through the use of a Minolta CR-300 colorimeter (Osaka, Japan), in the L∗, a∗, b∗ color space with the illuminant D65. The Brown index was calculated as 100 − L∗ [

25].

2.4. Chemical characterization

2.4.1. Chemicals and reagents

DPPH, 6-hydroxy-2.5.7.8-tetramethylchroman-2-carboxylic acid (Trolox), gallic acid, heptylamine 99%, Folin–Ciocalteu reagent, methanol, chloroform, hydrochloric acid, sodium hydroxide, formic acid, potassium hydroxide, toluene, hexane were purchased from Sigma-Aldrich (Steinheim, Germany). Supelco 37 Component FAMEs Mix, a mix of 17 Amino acid standards containing L-alanine, L-arginine, L-aspartic acid, L-cystine, L-glutamic acid, L-glycine, L-histidine, L-isoleucine, L-leucine, L-lysine, L-methionine L-phenylalanine, L-proline, L-serine, L-threonine. L-tyrosine and L-valine (0.5 μmole ml-1 except for L-cystine at 0.25 μmole ml-1) (Supelco Bellefonte, PA, USA) were used. L-Tryptophan, L-asparagine and L-glutamine pure standards were acquired from Merck (Darmstadt. Germany). Purified water was obtained through a Milli-Q Integral 5 system (Millipore. Merck KGaA. Darmstadt. Germany).

2.4.2. Total Phenolic Content (TPC)

Folin–Ciocalteu method was used in order to determine total phenolic content (TPC) as previously described [

23]. A calibration curve was obtained with gallic acid standard solutions [0.001 to 0.25 mg/mL] (y=10.955x+0.1405, R2 = 0.992). Results were expressed as mg gallic acid equivalents per g (mg GAE g−1) of sample. The method used a methanolic/water (80:20) extraction of samples. The TPC was measured four times for each sample.

2.4.3. Fatty Acid Composition

The fatty acid composition was performed according to previous procedure [

25,

26]. ISQ™ 9000 Quadrupole GC-MS System (Thermo Fisher Scientific, Waltham, MA, USA) gas chromatography-mass spectrometry (GC/MS) was used for the determination of fatty acid methyl esters (FAMEs) after methylation. Analyses were performed in triplicate and FAMEs were identified by comparing their retention times with the external standard mix solution (Supelco 37 Component FAME Mix). Amount of individual fatty acid methyl esters was expressed as relative percentage (%).

2.4.4. Amino Acids (AAs) quantification by HPLC-FLD method

As already reported [

23], the procedure for quali-quantitative determination in dried bread samples involves the preventive acid hydrolysis at 110°C for 24 hours of the proteins. Following that, derivation of amino acids using FMOC-Cl (9 fluorenyl-methyl chloroformate) was required before the HPLC-FLD analysis. Analyses of the derivatized amino acids were performed using an Agilent 1100 series HPLC chromatography system, equipped with a fluorescence FLD detector. Derivatized amino acids were quantified using calibration curves of commercial AAs standard solutions in a range from 0.025 mM to 0.4 mM (

Table S1). The results were expressed in grams of amino acids per 100 grams of sample.

2.4.5. Antiradical properties of bread

The antiradical activity of samples was measured by using the DPPH method previously reported [

27,

28,

29,

30]. The DPPH is an assay for the study of in vitro anti-radical activity and is commonly used for the evaluation of the scavenger activity towards free radicals. Scavenging activity can be monitored by spectrophotometric analysis of the absorbance at a wavelength of 517 nm using a UV-Vis spectrophotometer (Varian Cary® 50) and methanol as the blank. The results were also reported as TEAC (Trolox equivalent antioxidant activity) and expressed as mmol Trolox equivalent (TE)/100g of sample. As standard was used Trolox in a range of 5 to 400 μM (y = 0.0037x + 0.1655 and R

2 = 0.987). All experimental procedures were replicated three times.

2.5. Data analysis

Data were submitted to Bartlett’s test for the homogeneity of variance and then analyzed using one or two-way analysis of variance (ANOVA). Means were statistically separated on the basis of the Student-Newmann-Kewls test. when the ‘F’ test of ANOVA for treatment was significant at least at the 0.05 probability (CoHort Software, CoStat version 6.451).

3. Results

3.1. Bread quality

3.1.1. Rheological Characteristics

As already highlighted in a previous work [

25], the qualitative characteristics of gluten influence the technological properties of doughs. In fact, the two protein subunits that make up gluten, glutenins and gliadins, respectively give dough toughness and extensibility. In this study, the results of the rheological characteristics obtained on the doughs (

Table 2) show that the addition of hemp flour positively influenced its qualitative and technological properties. In fact, the different percentages of substitution of the Ciclope durum wheat semolina with the two types of hemp flour led to significant differences in the doughs highlighted through the determination of the alveographic and farinographic indices. It is known that the alveographic indices W and P/L provide important indications regarding the gluten qualitative characteristics. In particular, the value of the P/L ratio shows the correspondence between toughness and extensibility. A P/L value close to unity gives indications about the bread-making aptitude of a flour [

31].

Table 2 shows the significant variations that occurred in the dough following the integration of Ciclope semolina with hemp flour. These variations were highlighted by the rheological analyzes by determining the alveographic (W and P/L) and farinographic (WA, DT, S) parameters. Comparing the CTRL sample (100% Ciclope semolina) and those enriched with hemp flour, different behavior of the Hemp 1 and Hemp 2 flours was observed. As regards the alveographic parameter W, it is possible to detect a decrease in its value in all samples. In particular, in the replacement of Hemp 2_5 bread, the W value decreased by about 15%. In Hemp 1, a decrease in the value of W is observed up to a maximum of 10% in Hemp_1 10. As far as the P/L alvographic parameter is concerned, an increase in its value is observed in all samples, in particular up to 40% on the Hemp 1_10 sample. In Hemp 2, its value only increases up to 15% in Hemp_2 10.

Table 2 shows that the value of the water absorption farinographic index decreases as the percentages of substitution increase, only in Hemp 1_7.5 and in Hemp 1_10. In Hemp 2 bread the values remain almost unchanged compared to the CTRL. Regarding the development time, all the added samples showed a decrease in values up to 40%. As regards the stability parameter, the value rises up to 50% in Hemp 1, but drops from 15% (Hemp 2_5) to 50% in Hemp 2_10.

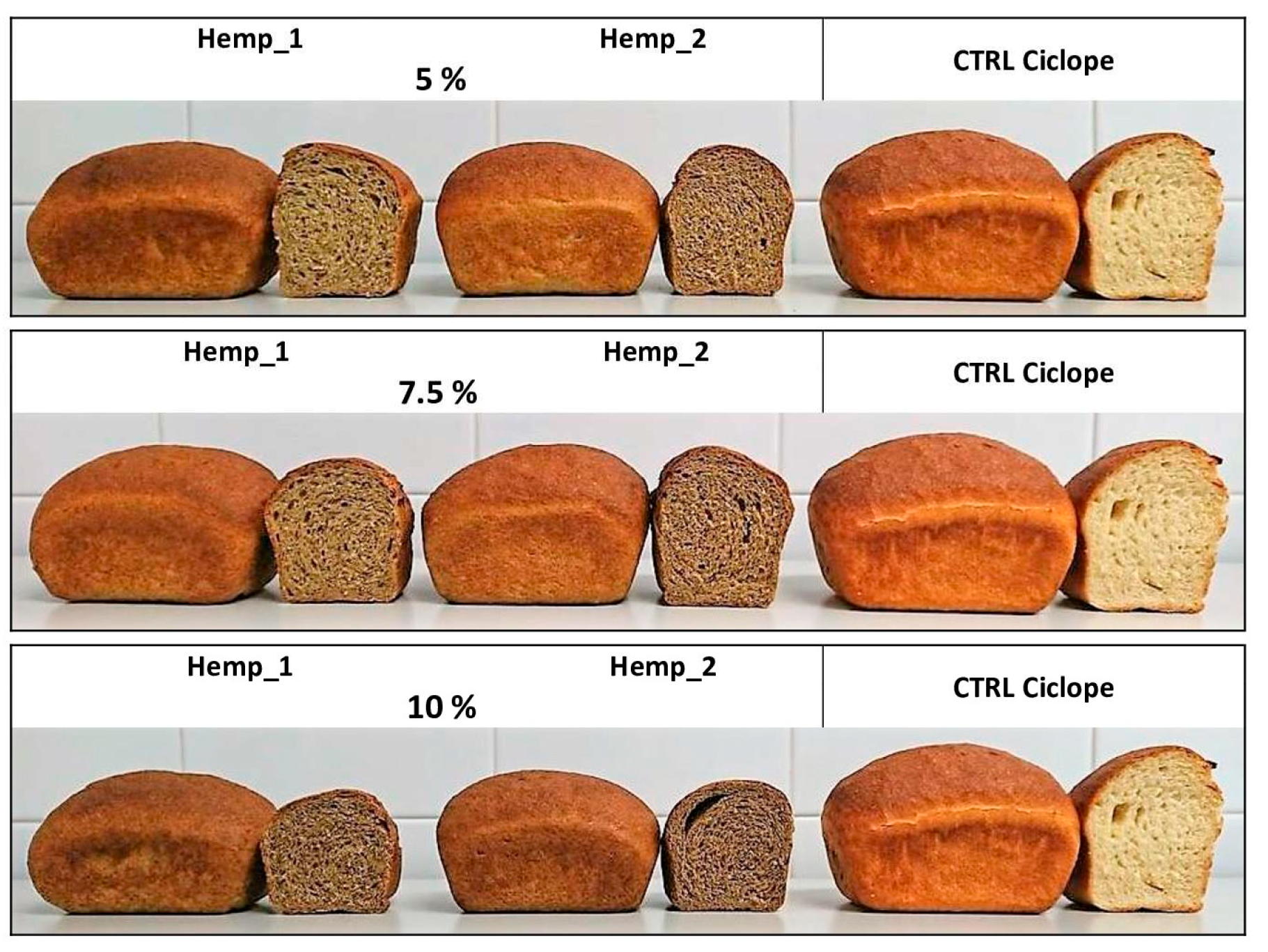

3.2. Color, Form, and Organoleptic Characteristics of the Fortified Breads

The first parameter of quality evaluated by consumers is the color of the food. The objective values of CIELAB, on crust and crumb, the height, and the volume of the bread samples are reported in

Table 3. The color indices were affected by Hemp flour and levels of fortification. Except for Hemp 1 at 5% substitution, all samples have L* values lower than CTRL both for crust and crumb. The a* value represents the green-red spectrum and negative values go towards green. For the crust, the values ranged from 10.63 (Hemp 2_10) to 12.68 (Hemp 1_5), while for the crumb the values ranged from 2.04 (Hemp 2 _10) to 0.26 (Hemp 1_5). Concerning the blue-yellow spectrum (b*), for the crust, the bread sample Hemp 2 at 10% substitution, shows a decrease in the yellow index of 12,3%, while the bread sample Hemp_2 at 5% substitution gives darker crumb. The CTRL shows values of L* 43.06, a* 14.34, and b* 23.0 for the crust, while L* 73.12, a* −2 and b* 18.24 are recorded on the crumb. For the control bread sample, prepared with Ciclope semolina, the average volume of 427 cm

3 and the height of 8.1 cm represent a good bread-making quality. Regarding the bread samples fortified, the baking test results showed that the partial volumes were diminishing namely from 427 cm

3 for CTRL bread to 300 cm

3 in Hemp_1 10. The reason for this phenomenon can be seen in the change in the gluten protein content in this bread, after replacing part of the wheat flour with hemp flour, which does not have it, as well as in the increased content of fiber which reduced the ability to retain fermentation gases [

32]. Regarding the height of the enriched bread samples, in comparison with the CTRL, the values showed a decrease of about 30%, in particular for Hemp 1_10. As regards the pitting of the crumb, no significant variations in the size of the pits were observed following the addition of hemp flour. (

Figure 1).

Sensory parameters were evaluated in bread two hours after baking and self-cooling.

As shown in

Table 4, the amount of fiber and protein present in the two types of hemp flour influenced the quality of the finished product, also in terms of a decrease in the elasticity values of both the crust and the crumb. Crust thickness decreased with respect to CTRL (5.0), but was still higher than 4.0 in all samples, except Hemp 2_10. The decrease in crust hardness values, as the integration percentages increase, is justified by the presence of the oil content in the hemp flour, which can improve the consistency of the finished product [

20]. All bread samples had good elasticity, thickness, crispness and apparent softness with very little variation between the two hemp flours. The overall judgment has always been higher than 6 (threshold of acceptability).

3.3. Chemical characterization of bread samples

Chemical characterization of raw material was discussed in a published research [

23] (

Table S2). Antioxidant activity of the bread samples and the antiradical activity were measured; in particular, as shown in

Table 5, a high total phenolic content (TPC) was mostly highlighted in bread Hemp 1_10 and in bread Hemp 2_10 samples (1.73±0.029-1.64±0.222 mgGAE/g, respectively). The analysis shown in these samples also high values of antiradical activity (3.18±0.071- 2.72 ± 0.018 mmol TE/100g, respectively) and % Scavenging (46.27 and 42.08). The lipid profile (

Table 6) was evaluated by GC-MS analysis and linoleic acid, palmitic acid and oleic acid were mostly found in all samples.

Table 7 highlights also the amino acids content in bread samples and a majority of tyrosine, glutamine, proline and isoleucine was identified, with increasing concentration in essential AAs according to fortification percentage.

4. Discussion

The study of the technological properties of the Ciclope durum wheat doughs enriched with hemp flour has provided important indications regarding the qualitative and functional characteristics of the breads obtained. The most significant difference found in the different types of dough bread concerned their decrease in terms of extensibility, as the integration percentages increased. In fact, it was possible to detect an increase in the values of the alveographic P/L, in all samples, up to 40% on the Hemp 1_10 sample. The farinographic stability index highlighted how the addition of the three different additions of hemp flour led to an increase in its values, especially in Hemp 1_5 and in Hemp 1_10 bread samples. In general, considering all the rheological and technological parameters, the inclusion of bioactive compounds in durum wheat semolina has certainly given the fortified bread good potential in relation to health benefits.

Chemical analyses showed that the bread fortification using hemp flour at different percentages increased the antiradical and antioxidant activity, and also improved amino acid and lipidic profiles and sensory and good cooking qualities. The Folin–Ciocalteau method was used for the evaluation of total phenolic content.

High values of TPC in bread samples fortified with a higher percentage of hemp flour (bread Hemp 1_10 and bread Hemp 2_10), and lower values in the CTRL bread sample (0.54±0.028 mg GAE/g) were highlighted. The supplementation of hemp flour in bread enhanced also the antiradical and antioxidant activity. The highest increase in antiradical activity was observed in bread samples containing 10% of Hemp 1 flour fortification (3.18±0.071 mmol TEAC/100g) while the lowest was recorded for the CTRL bread sample (0.32±0.018 mmol TEAC/100g).

This study also focused on the aminoacidic composition of studied samples. The contents of some amino acids considered essential in the human diet can be low in wheat proteins, especially lysine and threonine. Enriching the functional bread with different proportions of hemp flour has the potential to boost the content of essential amino acids. Aminoacidic analysis revealed an increase in the amino acid content of the fortified bread compared to CTRL (100% Ciclope flour). In particular, the analyzes showed higher content of lysine and threonine usually deficient in products based on cereals. The lysine content was found to be 0.03 g/100 g in the CTRL, a lower value than those found in bread samples added to 10% of hemp flour (0.95-1.61 g/100g in bread Hemp 1_10 and in bread Hemp 2_10 respectively); while higher values of threonine were found in bread Hemp 1_10 (1.83 g/100g) compared to the CTRL (1.1 g/100g). High levels of total essential amino acids were found in the samples of fortified bread, respectively 4.09 and 4.68 g/100 g in bread Hemp 1_10 and in Bread Hemp 2_10, compared to values found in durum wheat bread (1.71 g/100 g). This increase in amino acid values shows how much fortification can improve the protein characteristics of a fortified bakery product compared to one made only of durum wheat.

An increase in mono and polyunsaturated fatty acids was also observed in fortified bread samples respect to CTRL. The total ω 3 contents varied between 8.1 and 9.99% in bread Hemp 2 samples and between 6.7-8.9% in bread Hemp 1 samples. Linoleic, palmitic and oleic were the fatty acids present in the largest amount in bread Hemp 1_10 sample (59.18% - 14.03% - 14.8% respectively). The CTRL sample had a lower amount of total ω 3 (3.4%).

5. Conclusions

This study demonstrates that incorporating hemp seed flour into bread enhances its nutritional properties and aligns with the increasing demand for fortified products and the growing interest in utilizing agrifood waste in the food chain.

Through the fortification process, a notable increase in proteins and essential amino acids, lipids, unsaturated fatty acids, fiber, and minerals has been achieved, without significantly impacting the rheological effects of the final product. Despite consumers' growing interest in these fortified products, their development and design must balance the percentage of plants/extracts or byproducts and the sensory attributes to ensure consumer satisfaction. Enriching durum wheat flour with 10% hemp flour yielded favorable results, striking a balance to maintain excellent rheological characteristics in breads, while simultaneously increasing the omega-3 essential fatty acid content and enhancing antioxidant properties. Since traditional bread in Sicilian and Mediterranean cultures is primarily made from durum wheat, incorporating 10% hemp flour represents a valuable strategy to increase its nutritional properties, to the advantage of human health benefits.

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org. Table S1: Retention time (min.), coefficient of determination (R2) and linear regression model of external standards used for amino acids quantification; Table S2: Chemical characterization of raw materials

Author Contributions

Conceptualization F.S; N.V. and M.G.M.; methodology F.S, N.V. and M.G.M.; formal analysis. F.S., V.D.S., C.B. and M.G.M.; investigation, S. B., F. S., N.V, N.P; resources. N.V.; data curation. F.S, V.D.S., C.B., M.G.M.; writing—original draft preparation. F.S., M.G.M and V.D.S.; writing-review and editing F.S., N.V., N.P., V.D.S., C.B. and M.G.M..; supervision. N.V., F.S., N.P., V.D.S and M.G.M.; project administration. F.S. and M.G.M..; All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported for 50% by the FEASR - PSR Sicilia 2014-2020 (Rural Development Programme of Sicilia) within Project “NUTRAGE (Nutrizione, Alimentazione e Invecchiamento Attivo DBA.AD005.225 (FOE 2021).

Acknowledgments

The authors would like to thank the “National Biodiversity Future Center” (identification code CN00000033, CUP B73C22000790001) on ‘Biodiversity’, financed under the National Recovery and Resilience Plan (NRRP).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Branca, F.; Arena, D.; Argento, S.; Frustaci, F.; Ciccarello, L.; Melilli, M.G. Recovery of healthy compounds in waste bracts of globe artichoke heads. Acta Hortic. 2022, 361–366. [Google Scholar] [CrossRef]

- Del Gatto, A.; Mengarelli, C.; Foppa Pedretti, E.; Duca, D.; Pieri, S.; Mangoni, L.; Signor, M.; Raccuia, S.A.; Melilli, M.G. Adaptability of Sunflower (Helianthus Annuus L). High Oleic Hybrids to Different Italian Areas for Biodiesel Production. Ind. Crops Prod. 2015, 75, 108–117. [Google Scholar] [CrossRef]

- Sciacca F.; Palumbo M.; Pagliaro A.; Di Stefano V.; Scandurra S.; Virzì N.; Melilli M. G. Opuntia cladodes as functional ingredient in durum wheat bread: rheological, sensory, and chemical characterization. CyTA – J Food, 2021, 19:1, 96-104. [CrossRef]

- Garbetta, A.; D’Antuono, I.; Melilli, M.G.; Sillitti, C.; Linsalata, V.; Scandurra, S.; Cardinali, A. Inulin enriched durum wheat spaghetti: Effect of polymerization degree on technological and nutritional characteristics. J. Funct. Foods, 2020, 71, 104004. [Google Scholar] [CrossRef]

- Dewettinck, K.; Van Bockstaele, F.; Kühne, B.; Van de Walle, D.; Courtens, T.M.; . Gellynck, X. Nutritional value of bread: Influence of processing, food interaction and consumer perception. J Cereal Sci, 2008, 48, 243e257. [Google Scholar] [CrossRef]

- Callaway J.C. Hempseed as a nutritional resource: An overview. Euphytica, 2004, 140: 65–72. [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients, 2020, 12(7), 1935. [CrossRef]

- Oomah, B.D.; Busson, M.; Godfrey, D.V.; Drover, J.C.G.; Characteristics of hemp (Cannabis sativa L.) seed oil. Food Chem, 2022, 76(1), 33–43. [CrossRef]

- Alden, D.M.; Proops, J.L.R.; Gay, P.W. Industrial hemp’s double dividend: A study for the USA. Ecol Econ, 1998, 25, 291–301 ISSN: 0921. [Google Scholar] [CrossRef]

- Tang, C.H.; Ten, Z.; Wang, X.S.; Yang, X.Q. Physicochemical and functional properties of hemp (Cannabis sativa L.) protein isolate. J AGR FOOD CHEM, 2006, 54(23), 8945–8950. [CrossRef]

- Aluko, R.E. Chapter 7 - Hemp Seed (Cannabis sativa L.) Proteins: Composition, Structure, Enzymatic Modification, and Functional or Bioactive Properties. Sustainable Protein Source, 2017, 121-132. [CrossRef]

- Krüger, M.; van Eeden, T.; Beswa, D. Cannabis sativa Cannabinoids as Functional Ingredients in Snack Foods-Historical and Developments Aspects. Plants 2022, 11, 3330. [Google Scholar] [CrossRef]

- Montero, L.; Ballesteros-Vivas, D.; Gonzalez-Barrios, A.F.; Sánchez-Camargo, A.D.P. Hemp seeds: Nutritional value, associated bioactivities and the potential food applications in the Colombian context. Front Nutr 2023, 9, 1039180. [Google Scholar] [CrossRef]

- Prociuk, M.A.; Edel, A.L.; Richard, M.N.; Gavel, N.T.; Ander, B.P.; Dupasquier, C.M.; Pierce, G.N. Cholesterol-induced stimulation of platelet aggregation is prevented by a hempseed-enriched diet. Can J Physiol Pharmacol, 2008;86(4):153-159. [CrossRef]

- Maurotti, S.; Mare, R.; Pujia, R.; Ferro, Y.; Mazza, E.; Romeo, S.; Pujia, A.; Montalcini, T. Hemp Seeds in Post-Arthroplasty Rehabilitation: A Pilot Clinical Study and an In Vitro Investigation. Nutrients 2021, 13, 4330. [Google Scholar] [CrossRef] [PubMed]

- Mikulcová, V.; Kašpárková, V.; Humpolíček, P.; Buňková, L. Formulation, Characterization and Properties of Hemp Seed Oil and Its Emulsions. Molecules, 2017, 22(5):700. [CrossRef]

- Kriese, U.; Schumann, E.; Weber, W.E.; Beyer, M.; Brühl, L.; Matthäus, B. Oil content, tocopherol composition and fatty acid patterns of the seeds of 51 Cannabis sativa L. genotypes. Euphytica 2004, 137, 339–351. [Google Scholar] [CrossRef]

- Siano, F.; Moccia, S.; Picariello, G.; Russo, G.; Sorrentino, G.; Di Stasio, M.; La Cara, F.; Volpe, M. Comparative Study of Chemical, Biochemical Characteristic and ATR-FTIR Analysis of Seeds, Oil and Flour of the Edible Fedora Cultivar Hemp (Cannabis sativa L). Molecules 2018, 24, 83. [Google Scholar] [CrossRef]

- Rusu, I.E.; Marc Vlaic, R.A.; Mureşan, C.C.; Mureşan, A.E.; Mureşan, V.; Pop, C.R.; Chiş, M.S.; Man, S.M.; Filip, M.R.; Onica, B.M.; Alexa, E.; Vişan, V.G.; Muste, S. Hemp (Cannabis sativa L.) Flour-Based Wheat Bread as Fortified Bakery Product. Plants, 2021, 10(8), 1558. [CrossRef]

- Poji´c, M.; Hadnadev, T.D.; Hadna ¯ dev, M.; Rakita, S.; Brlek, T. Bread Supplementation with Hemp Seed Cake: A By-Product of ¯ Hemp Oil Processing. J. Food Qual. 2015, 38, 431–440. [Google Scholar] [CrossRef]

- Merlino, M.; Tripodi, G.; Cincotta, F.; Prestia, O.; Miller, A.; Gattuso, A.; Verzera, A.; Condurso, C. Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour. Foods 2022, 11, 2783. [Google Scholar] [CrossRef]

- Teterycz, D.; Sobota, A.; Przygodzka, D.; Lysakowska, P. Hemp seed (Cannabis sativa L.) enriched pasta: Physicochemical properties and quality evaluation. PLoS One 2021, 16, 1–14. [Google Scholar] [CrossRef]

- Bonacci S, Di Stefano V, Sciacca F, et al. Hemp Flour Particle Size Affects the Quality and Nutritional Profile of the Enriched Functional Pasta. Foods, 2023;12(4):774. [CrossRef]

- AACC. Approved Methods of Analysis, 11th Edition. Cereals & Grains Association. Available online: https://www.cerealsgrains. org/resources/Methods/Pages/54PhysicalDoughTests.aspx (accessed on 23 June 2022).

- Melilli, M.G.; Di Stefano, V.; Sciacca, F.; Pagliaro, A.; Bognanni, R.; Scandurra, S.; Virzì, N.; Gentile, C.; Palumbo, M. Improvement of Fatty Acid Profile in Durum Wheat Breads Supplemented with Portulaca oleracea L. Quality Traits of Purslane-Fortified Bread. Foods, 2020, 9. [Google Scholar] [CrossRef] [PubMed]

- Di Stefano, V., Bongiorno, D., Buzzanca, C., Indelicato, S., Santini, A., Lucarini, M., ... & Durazzo, A. (2021). Fatty acids and triacylglycerols profiles from Sicilian (cold pressed vs. soxhlet) grape seed oils. Sustainability, 13(23), 13038. [CrossRef]

- Di Stefano, V.; Pitonzo, R.; Novara, M.E.; Bongiorno, D.; Indelicato, S.; Gentile, C.; Avellone, G.; Bognanni, R.; Scandurra, S.; Melilli, M.G. Antioxidant activity and phenolic composition in pomegranate (Punica granatum L.) genotypes from south Italy by UHPLC-Orbitrap-MS approach. J Sci Food Agric. 2019; 99(3):1038-1045. [CrossRef]

- Melilli, M.G.; Pagliaro, A.; Bognanni, R.; Scandurra, S.; Di Stefano, V. Antioxidant activity and fatty acids quantification in Sicilian purslane germplasm. Nat. Prod. Res. 2019, 1–8. [Google Scholar] [CrossRef]

- Cardullo, N.; Muccilli, V.; Di Stefano, V.; Bonacci, S.; Sollima, L.; Melilli, M.G. Spaghetti Enriched with Inulin: Effect of Polymerization Degree on Quality Traits and α-Amylase Inhibition. Molecules, 2022; 27(8):2482. [CrossRef]

- Di Stefano, V.; Buzzanca, C.; Melilli, M.G.; Indelicato, S.; Mauro, M.; Vazzana, M.; Arizza, V.; Lucarini, M.; Durazzo, A.; Bongiorno, D. Polyphenol Characterization and Antioxidant Activity of Grape Seeds and Skins from Sicily: A Preliminary Study. Sustainability 2022, 14, 6702. [Google Scholar] [CrossRef]

- Palumbo, M.; Spina, A.; Boggini, G. Bread-making quality of Italian durum wheat. Ital. J. Food Sci. 2002, 14, 2. ID: 99474574.

- Gavurníková, S.; Havrlentová, M.; Mendel, Ľ.; Čičová, I.; Bieliková, M.; Kraic, J. Parameters of Wheat Flour, Dough, and Bread Fortified by Buckwheat and Millet Flours. Agriculture (Pol'nohospodárstvo), 2011, 57(4) 144-153. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).