1. Introduction

Concrete is a building material usually reinforced with steel rebars, which confer a good tensile strength to a structural element. This makes reinforced concrete one of the most versatile materials in building and civil engineering works. Nevertheless, in the last decades, fibres have become an interesting complement to steel rebars as reinforcement and there are a wide variety of fibres that can be added, depending on the properties that need to be enhanced.

When strength needs to be improved, steel fibres have been traditionally employed and there is a solid experience on their usage [

1,

2,

3,

4]. Nevertheless, in more recent times, polymer fibres have arisen as a competitive alternative to steel fibres, since they overcome some limitations inherent to these, such as corrosion and other durability issues [

5]. Recent standards have included guidelines for using fibres in structural concrete [

6,

7,

8,

9] and provide good guidance for steel-fibre reinforced concrete, but apparently not so good for polymer fibres [

10].

On another note, the influence of high temperatures on the mechanical properties of concrete is also of paramount importance in some applications. The use of reinforced concrete in nuclear reactors boosted the interest in how high temperatures and fire affect concrete mechanical performance [

11]. This interest has naturally extended to fibre-reinforced concrete and has produced interesting findings depending on the fibres employed. For example, using polypropylene fibres in certain dosages reduces the risk of explosive spalling in concrete [

12,

13]. These fibres melt at high temperatures and generate a capillary network that relieves inner pressure inside concrete and prevent spalling. This effect has also been recently observed with recycled tyre polymer fibres [

14]. Regarding the enhancement of concrete tensile strength, steel fibres have traditionally proven to provide good results in structural applications [

15], in fact, if certain requirements are met, some standards permit to reduce, or even eliminate, reinforcing steel rebars. However, steel-fibre reinforced structural elements exhibit explosive spalling under high temperatures, even with low fibre dosages. The use of mixed dosages, combining steel and polypropylene fibres, have successfully overcome this problem [

16,

17].

Regarding other types of fibres, polyolefin macro-fibres have proven to provide remarkable structural properties to concrete. Polyolefin-fibre reinforced concrete (PFRC) has been extensively studied in recent times and their performance in vibrated or self-compacting concrete, as well as the influence of many parameters on the PFRC mechanical properties or their performance under shear stresses are already well known [

18,

19,

20,

21]. Nevertheless, if polyolefin fibres are to be widely employed as structural reinforcement, their performance under high temperature must be understood; this has been recently analysed and the mechanical behaviour of PFRC specimens subjected to high temperatures has been experimentally identified [

22].

From the numerical point of view, concrete fracture has long been successfully simulated using cohesive formulations, which relies on a softening diagram that drives the fracture process by progressively reducing cohesive forces between both cracking surfaces as they move apart from each other. PFRC fracture has been successfully reproduced using this approach by means of an embedded fracture model that had been used in the past with concrete and masonry [

23,

24]. To adapt the cohesive formulation to fibre-reinforced concrete, the traditional concrete softening diagram, usually expressed by a stress-crack opening relation matematically expressed by exponential, linear or bilinear functions [

25], was turned into a trilinear diagram that could reproduce the effect of fibres, extending the mechanical behaviour of the material and also correctly reproducing the load increase after cracking due to the action of fibres. The points of the trilinear diagram can be obtained with measurable values such as the volume of fibres in the mix, the fibre orientation factor or the ultimate tensile strength of the fibres [

26]. This model has proved to correctly reproduce fracture under Mode I conditions and under mixed-mode (Modes I+II) conditions [

27], also capturing the size effect [

28].

The present study seeks to adapt the trilinear softening cohesive model to account for high-temperature exposure of the PFRC elements. To do this, the results obtained in [

22] are used as benchmark. These results correspond to PFRC mixes of two fibre dosages (3 and 10 kg/m

) exposed to increasing temperatures ranging from 20°C to 200°C and tested with a three-point bending flexural test. Firstly, the experimental benchmark is briefly described, secondly, the numerical simulation is presented by shortly outlining the embedded cohesive formulation employed and the finite element model used. Then, the numerical results are compared with the experimental benchmark and, finally, a modification of the trilinear diagram obtained for room temperature (20°C) is proposed for high temperature exposure.

2. PFRC performance at high temperature

The experimental results used here as reference correspond to an experimental campaign that can be consulted in [

22]. Two sets of specimens are compared, all of them manufactured with the same concrete formulation, only modifying the fibre content, with one of the sets containing a fibre dosage of 3 kg/m

(HF3) and the other one containing 10 kg/m

(HF10). The formulation of each mix can be consulted in

Table 1.

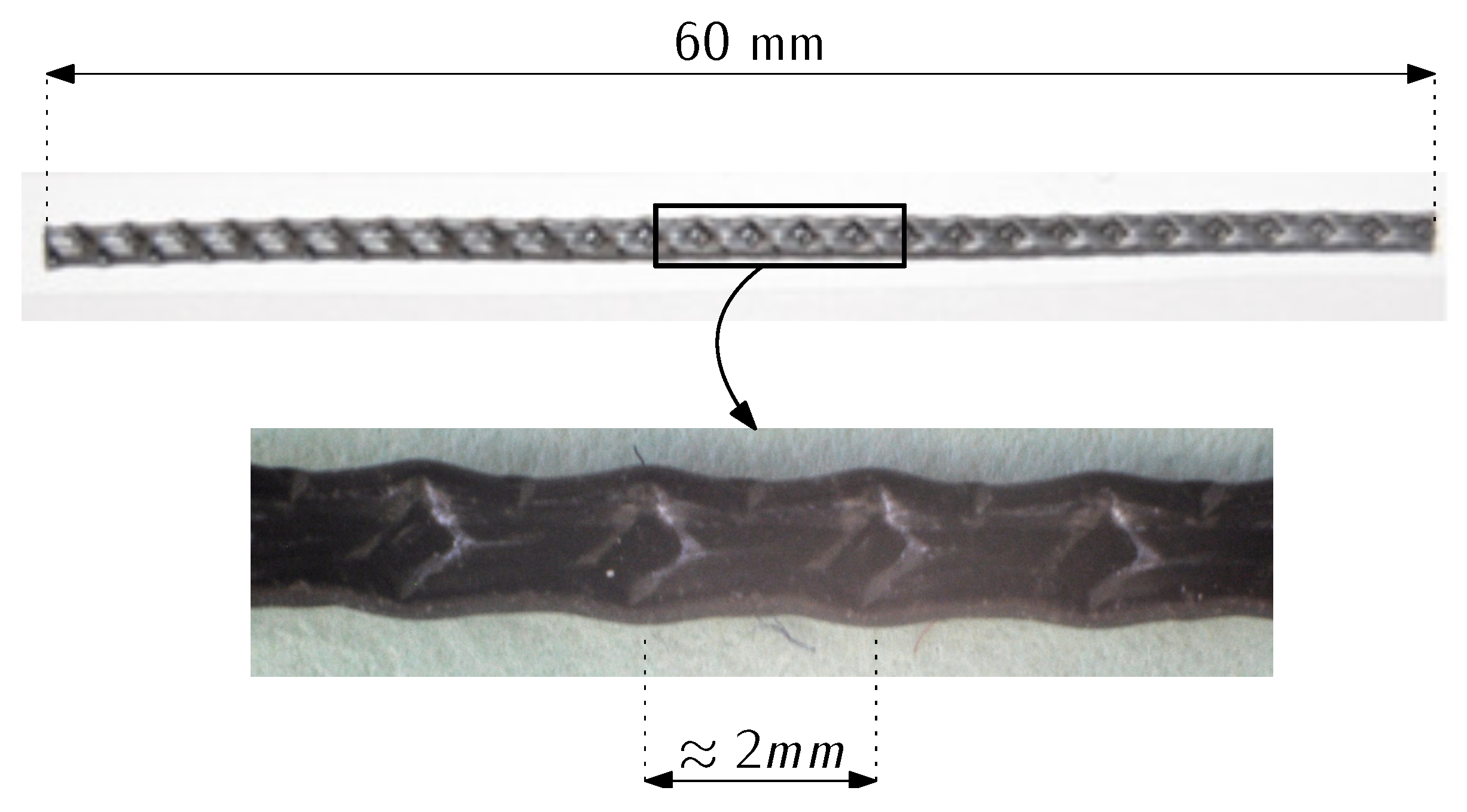

All specimens were manufactured with 60 mm long fibres, the appearance of these fibres as well as their properties can be consulted in

Figure 1 and

Table 2.

After manufacturing, all the specimens were introduced in a convection oven at a heating rate of 2.80 °C/min, remaining at the desired temperature for 3 hours before progressively cooling during 7 hours inside the oven. The bending tests were performed once the cooling process was over.

In the case of HF3 specimens, three temperatures were used for characterisation: room temperature (20°C), 150°C and 200°C, while in the case of HF10 specimens, six temperatures were chosen: room temperature (20°C), 150°C, 165°C, 175°C, 185°C and 200°C. Temperatures over 150°C correspond to values at which fibres showed progressive degradation due to heating (see [

22]).

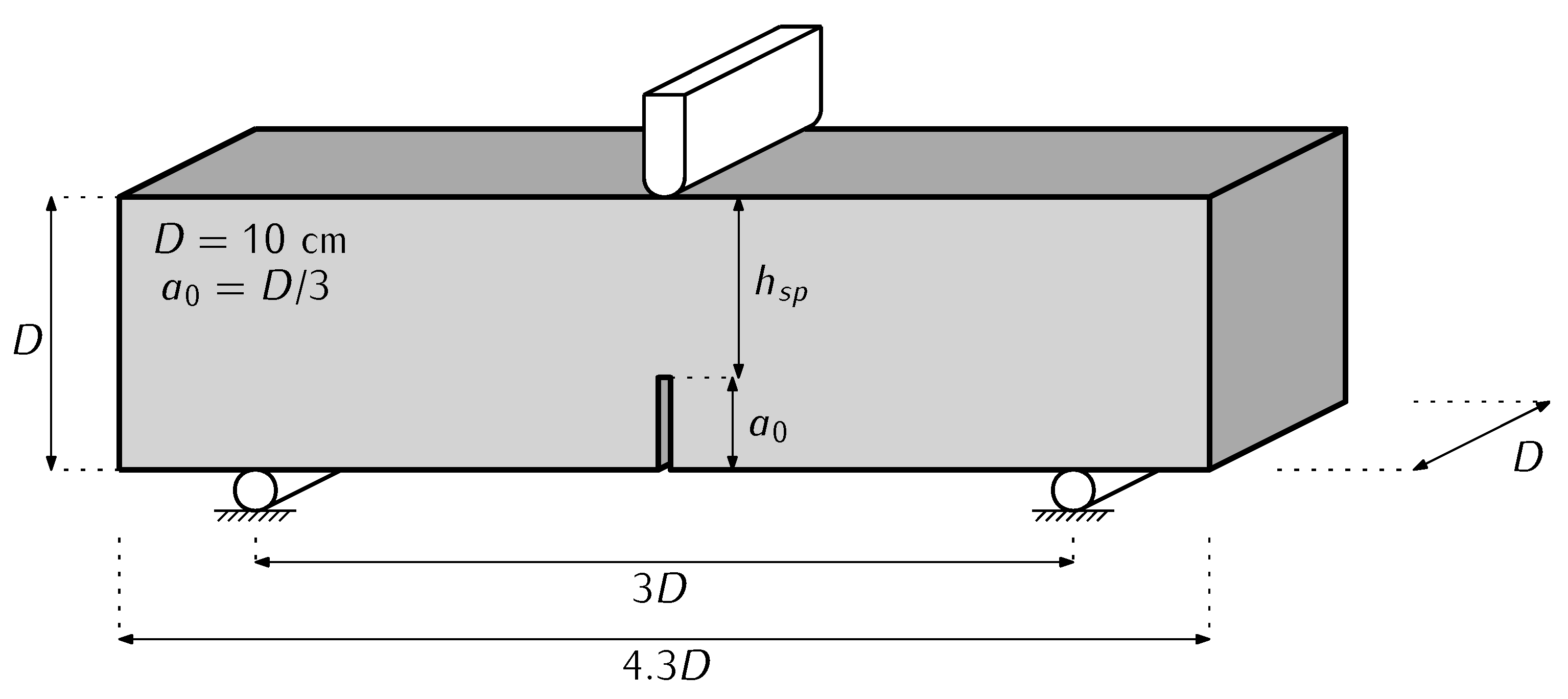

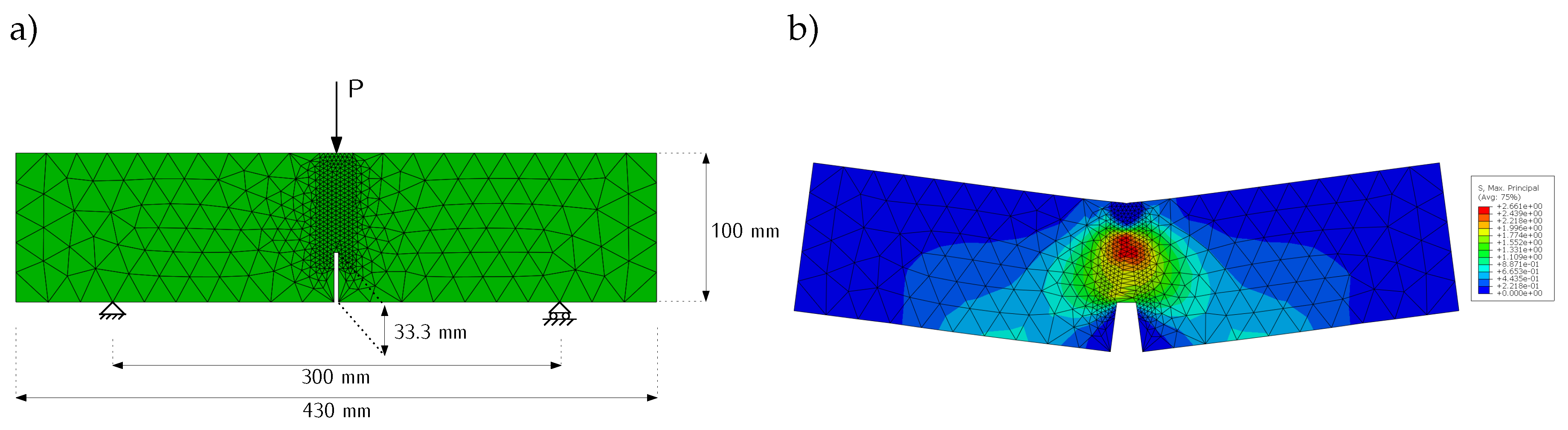

The mechanical behavior of the specimens was analysed with a three point bending test as described by the standard RILEM TC-187-SOC [

29] with notched specimens, the proportions of this specimens are shown in

Figure 2.

3. Numerical simulation of fracture

This section presents the numerical work carried out to reproduce the experimental diagrams obtained for HF3 and HF10 specimens. These simulations use an embedded crack model that is briefly described in the first subsection, then, in the second part, the finite element models are presented. Given that the model is not new, the fracture model is very concisely described, the interested reader can find a more detailed description in [

23,

24,

30].

3.1. Embedded crack model

Fracture is reproduced with the finite element method (FEM) using an element formulation that is based on the cohesive zone concept developed by Hillerborg [

31]. This formulation constitutes a strong discontinuity approach that, although initially designed for concrete [

23,

30], has also been adapted for other types of materials [

24], including the PFRC [

32]. This model is usually described as a central forces model, given that it assumes that the cohesive stress vector

is parallel to the crack displacement vector

:

with

representing the material softening function, that is described in terms of an equivalent crack opening,

, which identifies the maximum value of the crack opening up to that instant, which allows accounting for loading-unloading scenarios.

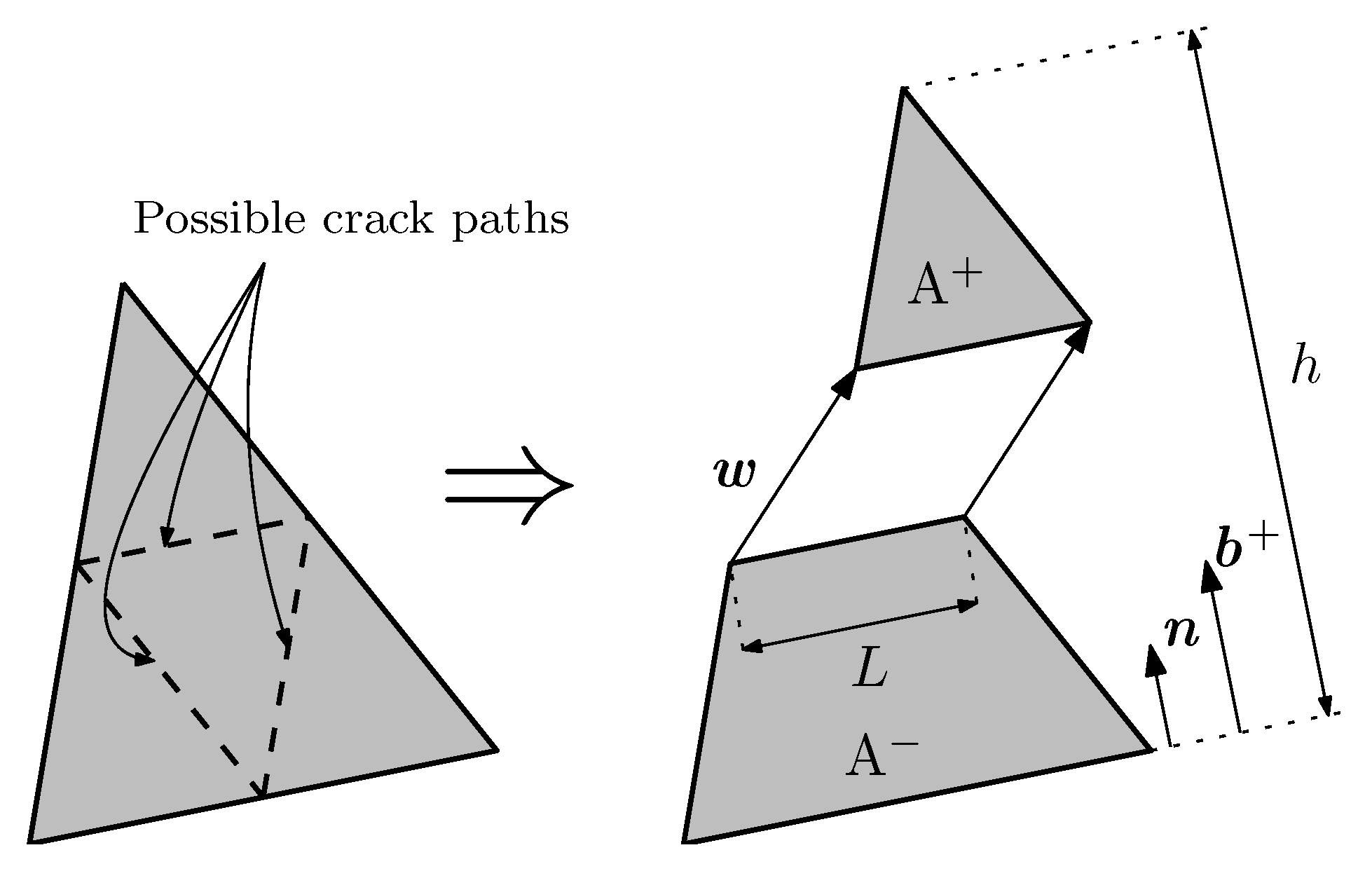

This formulation can only be used in constant strain triangular elements, which implies using a single integration point per element, and only allows three crack orientations, which are parallel to the sides of the element (see

Figure 3).

At the onset of fracture, the element is divided into parts

and

, as shown in

Figure 3. The stress vector

is obtained with (

2), where

A stands for the element surface area,

h for the height of the triangle with respect to the opposite side of the solitary node,

is the stress tensor,

L is the crack length and

is the unit vector perpendicular to the crack. In order to satisfy both, global and local equilibrium, the crack must be placed at mid height and must be parallel to one of the sides of the triangle, thus (

2) becoming

. A more detailed description of this formulation can be found in [

30].

The crack displacement vector

is obtained by an iterative process through the Newton-Raphson’s method with given nodal displacements using expression (

3). To do this, the elastic prediction of the stress tensor (

) is corrected by an inelastic stress (

). In this expression,

represents elastic tangent tensor,

the strain vector that is obtained with given nodal displacements under elastic assumptions and

is the gradient vector that identifies the shape function of the node at

(the solitary node), which is obtained with (

4). Superscript

S denotes the symmetric part of the resulting tensor.

By using the expression of

(

1) and the expression of

(

3), the following equality can be written:

which can be also expressed as

where

represents the identity tensor.

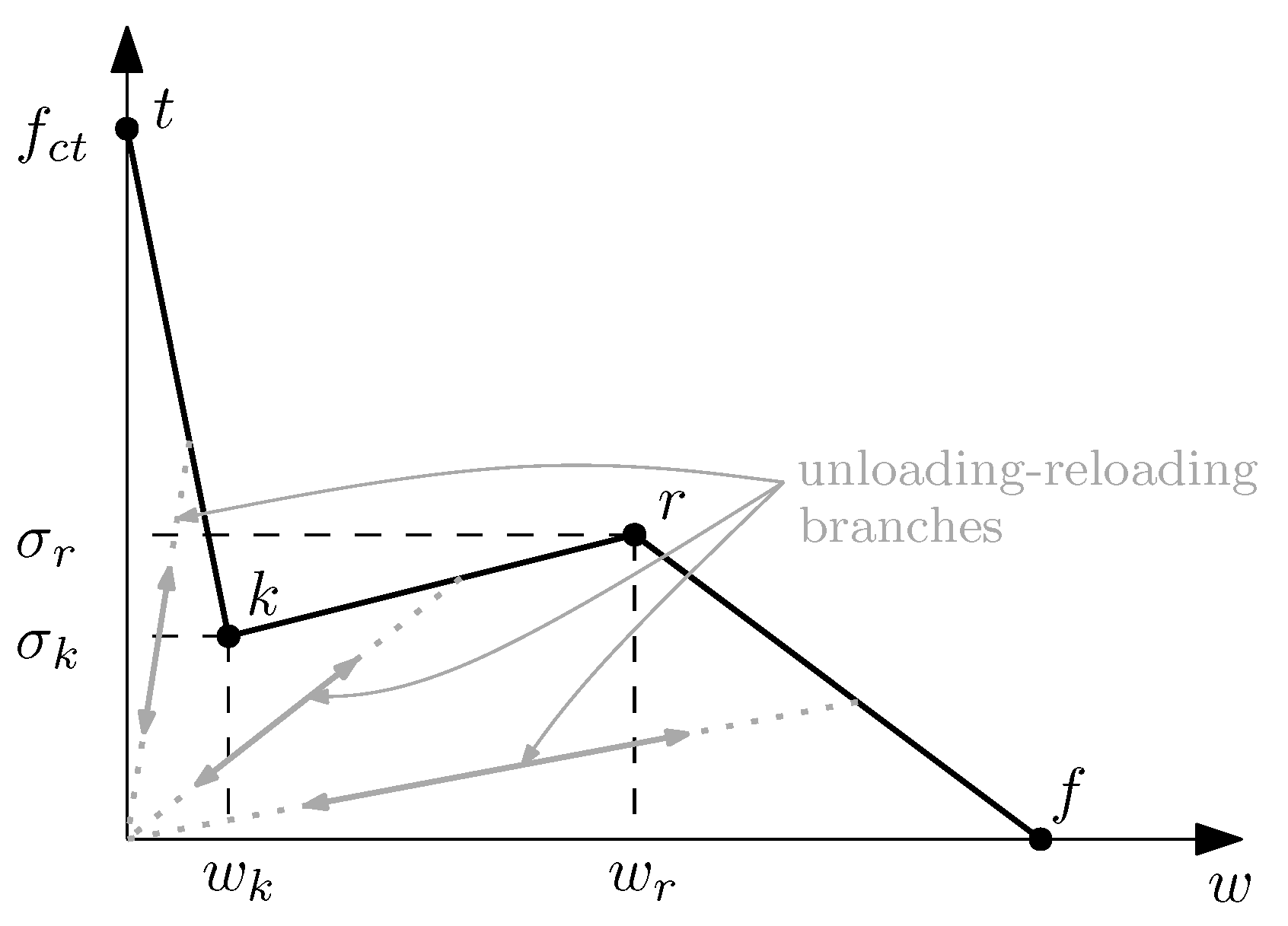

3.2. Trilinear softening diagram

As proved in previous works [

27,

28,

32] the above described model can be adapted to reproduce PFRC behaviour by using a trilinear softening diagram as that presented in

Figure 4. Unloading and reloading branches lead to the origin and the softening function is defined by four points (

t,

k,

r and

f). This trilinear diagram can be expressed with the following equations::

3.3. FEM models

The three-point bending test on notched specimens shown in

Figure 2 is numerically reproduced in 2D using plane stress conditions, thus a bidimensional mesh is employed. This mesh is finer between the notch tip and the applied load, since that is the region where fracture evolves; mesh refinement has been validated in previous works [

27,

28].

Figure 5a shows an image of the finite element mesh used in the models with sizes and boundary conditions.

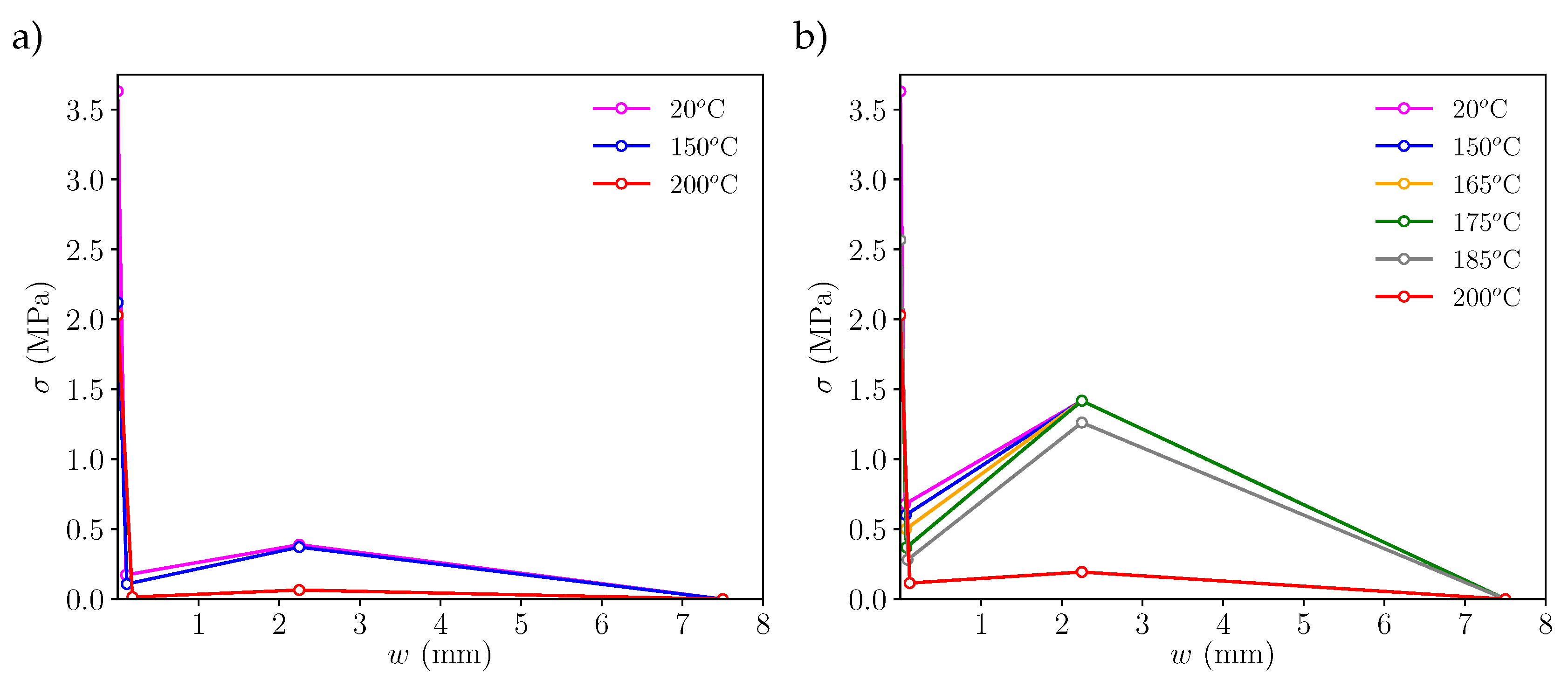

4. Definition of the trilinear softening diagrams and results

In this section, trilinear diagrams for each mix and high-temperature exposure are obtained. To do this, the coordinates of all four points

t,

k,

r and

f observed in

Figure 4 must be defined and, in order to keep a coherent approach as temperature increases, the specific criteria that has been employed is defined here.

Regarding point

t, since the elastic modulus of concrete is much higher than the elastic modulus of the fibres, and given that the volume of fibres is almost negligible if compared with concrete, this point is defined as the tensile strength of concrete. Following the experimental observations, this value will be gradually reduced as temperature increases, thus reproducing a gradual material degradation. Point

k is related to the crack opening value at which fibres start to transmit meaningful stresses across the fracture plane. The reinforcing action of fibres stops the load drop and can even lead to a load recovery. Both coordinates of point

k have been estimated considering that the contribution of fibres is negligible up to this instant, therefore, they have been obtained with the softening diagram of a plain concrete (without fibres). Reinforcing capacity of fibres decays when a certain crack opening is reached, which is related to point

r in the trilinear diagram. On the one hand, the abscissa

is defined as a fixed value equal to 2.25 mm, based on previous experiences [

27,

28], on the other hand, the ordinate of this point,

, is assumed to decay as temperature increases, since the experimental observations prove that high temperatures degrade the fibres material and their bonding with concrete. Point

f identifies the crack opening value at which fibre reinforcement is negligible, this point depends on the length of the fibres and, in this case, using previous experineces, has been fixed with a value of 7.5 mm for all temperatures.

Following these criteria, the initial softening diagram, adjusted for room temperature (20°C), was modified so that the load-deflection diagrams fitted the experimental results.

Figure 6 shows the resulting trilinear softening diagrams obtained for each set of specimens and temperature (the coordinates of these points for each trilinear diagram can be consulted in

Table 3).

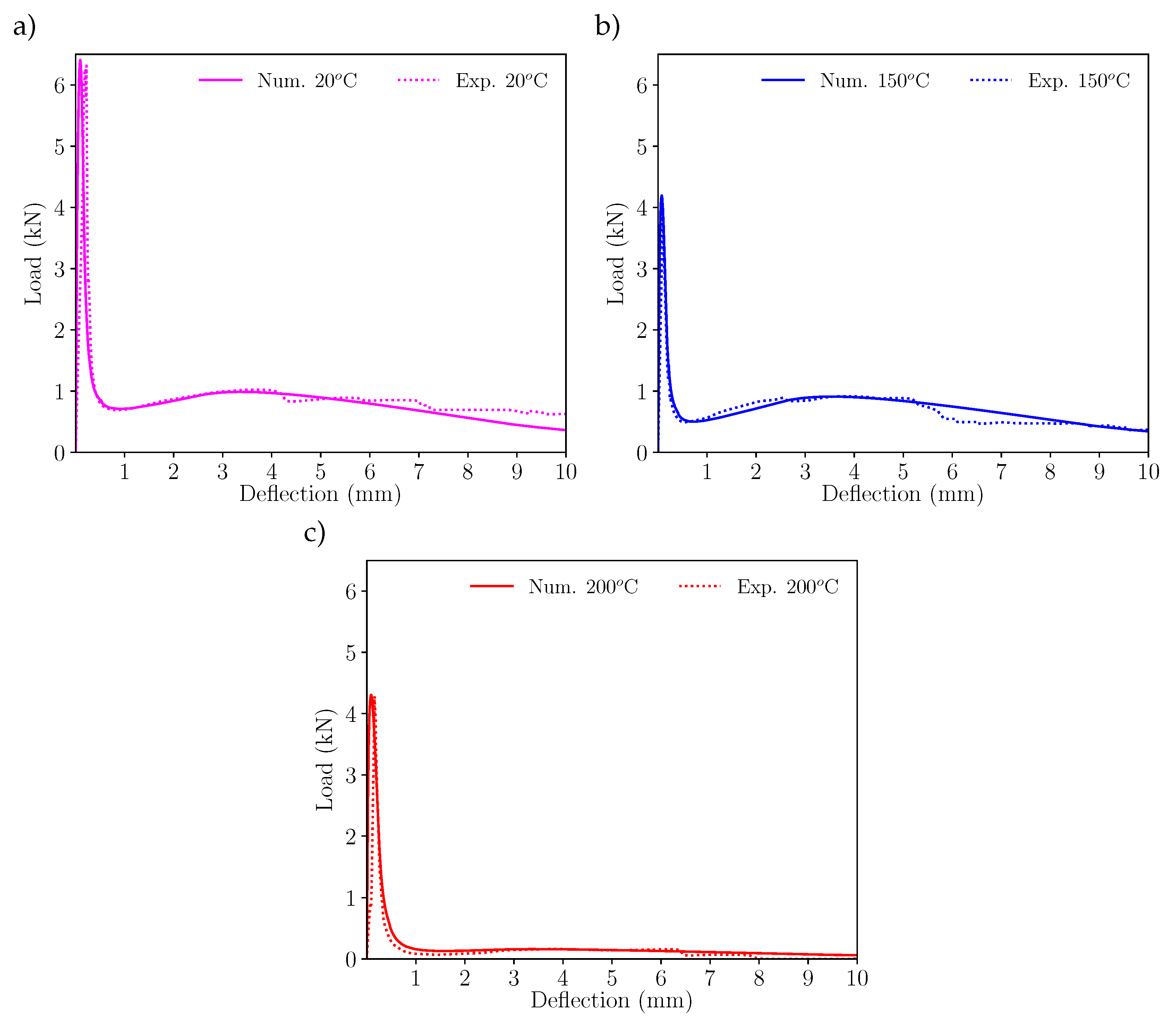

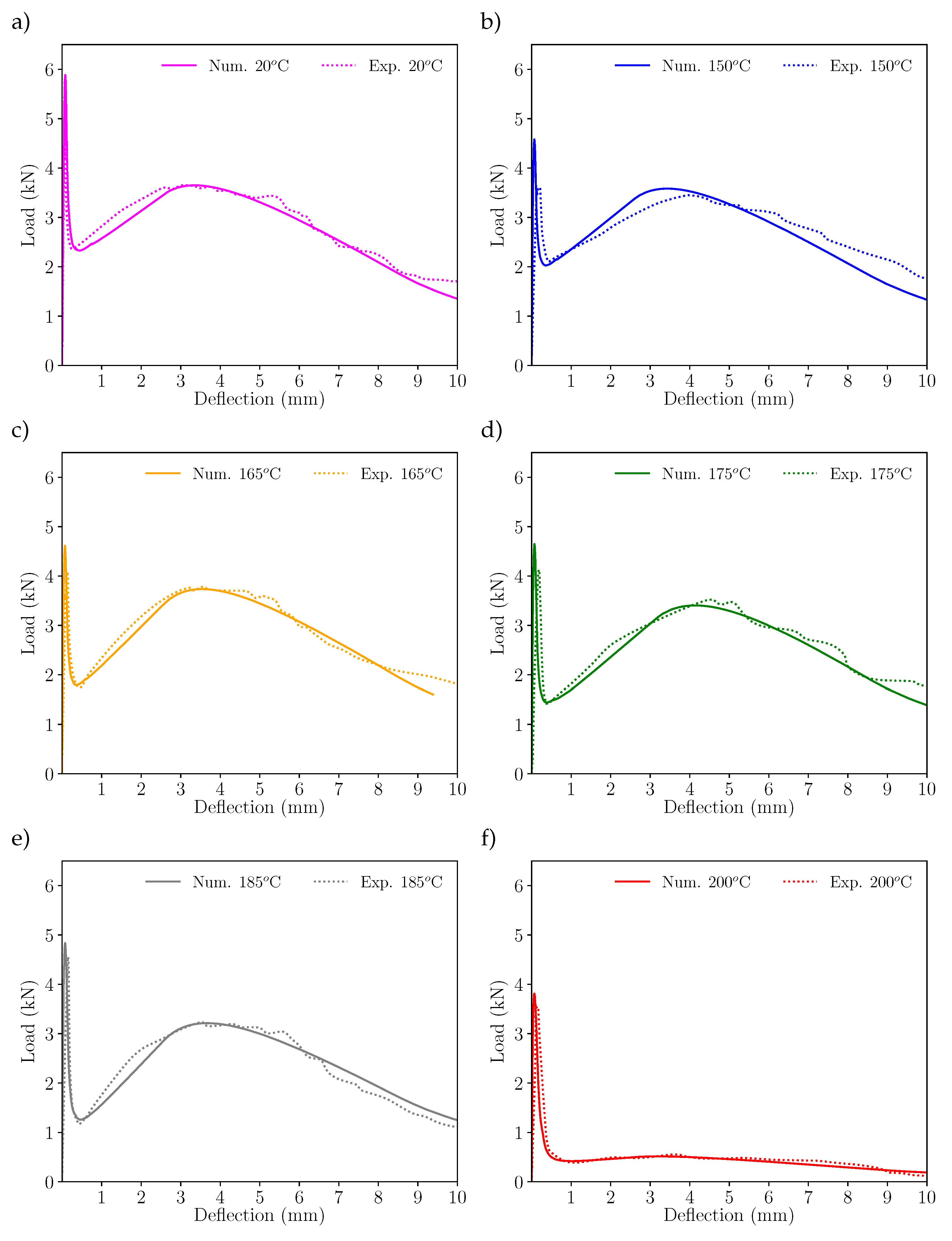

Figure 7 and

Figure 8 presents the resulting load-deflection diagrams obtained in each case, compared with the experimental results. These diagrams are plotted with the same colour scheme used in

Figure 6 for each temperature and compare the numerical results (solid lines) with the experimental curves (dotted lines).

Table 3.

Coordinates of

t,

k,

r and

f points of the trilinear softening diagrams shown in

Figure 6.

Table 3.

Coordinates of

t,

k,

r and

f points of the trilinear softening diagrams shown in

Figure 6.

| HF3 |

|

HF10 |

| |

20°C |

150°C |

200°C |

|

|

20°C |

150°C |

165°C |

175°C |

185°C |

200°C |

|

0.000 |

0.000 |

0.000 |

|

|

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

|

3.630 |

2.120 |

2.030 |

|

|

3.630 |

2.567 |

2.567 |

2.567 |

2.567 |

2.030 |

|

0.102 |

0.113 |

0.182 |

|

|

0.058 |

0.067 |

0.070 |

0.074 |

0.090 |

0.116 |

|

0.173 |

0.108 |

0.015 |

|

|

0.679 |

0.601 |

0.501 |

0.369 |

0.281 |

0.115 |

|

2.250 |

2.250 |

2.250 |

|

|

2.250 |

2.250 |

2.250 |

2.250 |

2.250 |

2.250 |

|

0.389 |

0.372 |

0.065 |

|

|

1.418 |

1.418 |

1.418 |

1.418 |

1.262 |

0.194 |

|

7.500 |

7.500 |

7.500 |

|

|

7.500 |

7.500 |

7.500 |

7.500 |

7.500 |

7.500 |

|

0.000 |

0.000 |

0.000 |

|

|

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

0.000 |

In the case of HF3, the initial peak load is correctly reproduced for all three temperatures. The same can be pointed out in regards to the minimum load after peak and the subsequent remnant peak load that takes place around a deflection of 4 mm for all temperatures.

In the case of HF10, the minimum load after peak and the subsequent remnant peak load are well reproduced for all temperatures. In some cases, especially in the case of T=150°C, the peak load in the numerical model takes place at a slightly earlier deflection than in the experimental curve. Nevertheless, in the authors’ opinion this does not make the numerical simulation inaccurate, since only one experimental value for each temperature is available and, as past experience shows, if a higher number of specimens had been tested for each case, the experimental envelopes would fit all numerical results.

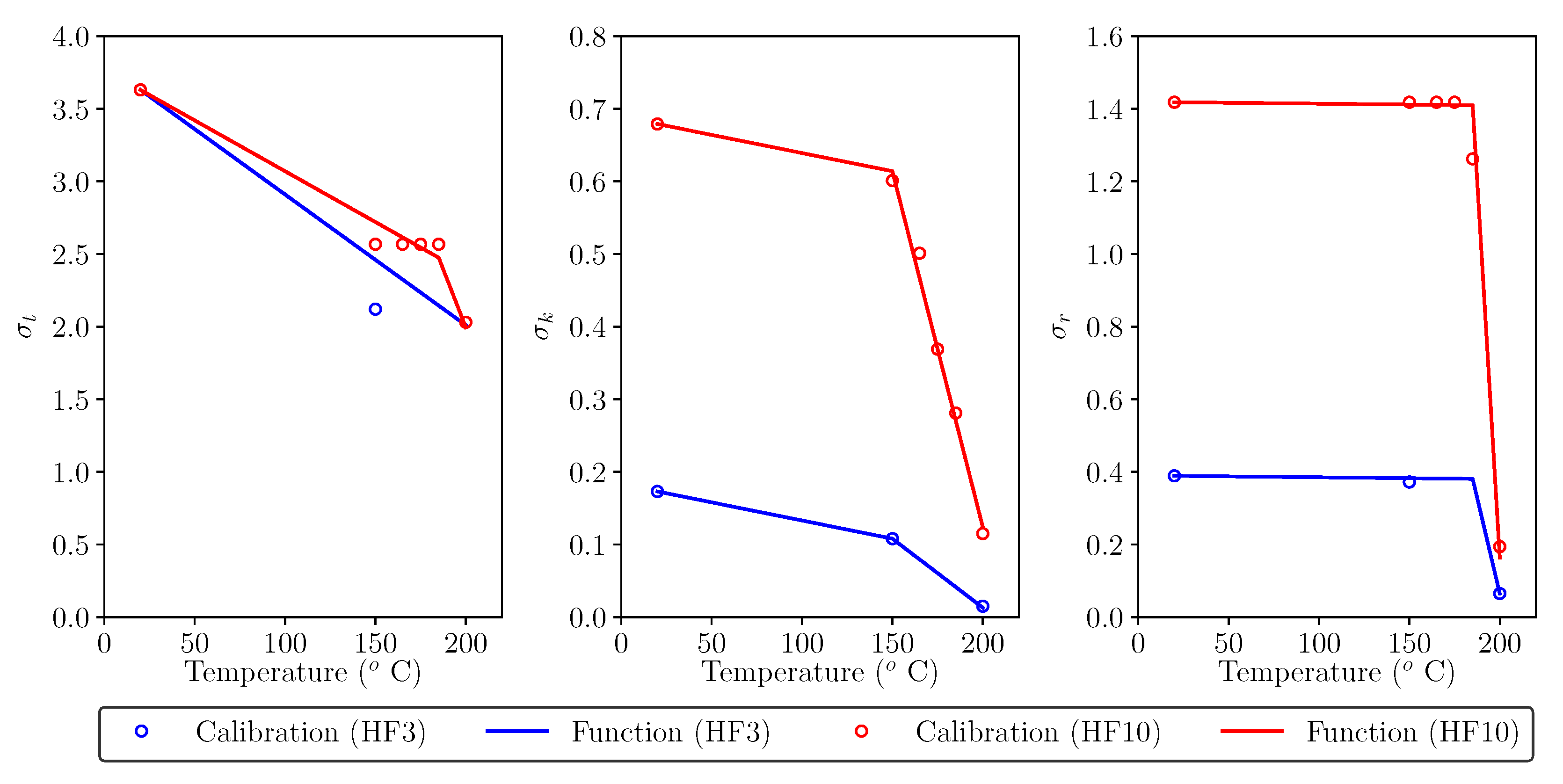

These results show that below 150°C, the softening diagram is not affected by high temperature exposure and, between 150°C and 200°C, , and must be adapted for a good numerical simulation of fracture. In all three cases, points t, k and r reduce their values as temperature increases, which can be a consequence of moderate concrete and fibre degradation. In the case of , all specimens tested after high temperature exposure show smaller values, especially when exposed to higher temperatures, but there is not a clear trend, since in the case of HF10, values of temperatures between 150°C and 200°C present an unclear evolution of the peak load. For example, the peak load experimentally measured at T=150°C is smaller than at T=20°C, which would suggest a decrease as temperature increases, but peak loads at 165°C and 175°C and 185°C are higher than at 150°C. With these results, temperature seems to reduce the peak load, but it is not possible to conclude how temperature affects it; a higher number of experimental results would help to provide a better conclusion. Nevertheless, the material behaviour after the initial peak is what is particularly representative of the fibre reinforcement, which is characterized by points k and r, which show a clear trend as will be discussed hereunder. Since HF3 values are limited to only two high temperature results, HF10 values will be used for the following discussion; observations are equally valid for HF3 results.

If the load drop after peak is analysed, for which

is the most relevant parameter, it becomes higher as temperature increases. As observed in [

22], polyolefin fibres exposed to high temperature become degraded and present lower mechanical properties, especially above 100°C. In this case, these results suggest that high temperature exposure reduce

, especially above 150°C.

If the remnant load is analysed, which is strongly influenced by , high temperature seems to be only relevant at temperatures over 185°C, since a fixed value of provides good numerical representation of fracture up to a temperature exposure of 175°C. For temperature values over 185, rapidly decreases, presenting a dramatic drop at 200°C.

4.1. Proposed modification of the trilinear diagram to include the effect of high temperature exposure

Once the fracture behaviour is correctly captured by a trilinear diagram obtained with specimens manufactured according to the usual standards, their trilinear softening diagram can be adapted for accounting of possible high temperature exposure by modifying

,

and

values with expressions (

7), (

8) and (

9).

where

,

and

stand for the values of

,

and

in the trilinear diagram calibrated at room temperature,

T is the high temperature at which the material is exposed,

,

,

,

,

and

are constant values that depend on the fibre proportion of the PFRC (they are defined for 3 and 10 kg/m

in

Table 4 and could be interpolated for values ranging between 3 and 10) and, finally,

denotes the Macaulay brackets:

Figure 9 compares the diagrams provided by this expressions (solid lines) with the values obtained after calibrating the experimental results with the trilinear diagram (see

Table 3). Values of HF3 specimens are presented in blue while those corresponding to HF10 specimens are shown in red.

While expressions

8 and

9 provide good approximation for

and

, expression

7 seems to be less accurate. As mentioned before, available experimental results are limited and additional experimental results would help defining a reliable function for

. In any case, the initial peak load is not so dependent on the fibre reinforcement, since the material behaviour up to that point depends almost completely on the concrete matrix, not on the fibres. In fact, the effect of fibre reinforcement is particularly relevant after the peak load and the subsequent behaviour is mainly dependent on

and

, and these values can be reliably obtained with the proposed expressions. As can be observed, these proposed functions are defined as bilinear since, as mentioned before, the callibrated values of

and

dramatically decreased at a certain temperature (150°C in the former case and 185°C in the latter).

5. Conclusions

This work has studied how high temperature exposure affects the parameters of a trilinear softening diagram that allows numerically reproducing the behaviour of PFRC specimens through a cohesive model. To do this, the experimental result of [

22] have been used as reference and an embedded cohesive crack fracture model employed, with the softening behaviour defined by a trilinear diagram. The main conclusions of this work can be summarised as follows:

A trilinear diagram calibrated with specimens not exposed to high temperature can be adapted for high temperature exposure by modifying the ordinates of points t, k and r of the trilinear diagram (, and values), which decrease as temperature exposure increases.

The load drop after the initial peak becomes higher as temperature increases. This drop is relevant beginning from a temperature exposure of 150°C. A function for defining , which is the most relevant parameter to correctly model this load drop, is proposed. This function is bilinear and the decrease of is higher for temperature values over 150°C, as observed in the calibrated results of this parameter.

The load drop of the remnant peak load that takes place after the initial peak load can be only observed for temperatures over 175°C. A function for , the most relevant parameter for correctly capturing this remnant peak load, is proposed. This function is also bilinear and the decrease of becomes higher at temperature values over 175°C, in agreement with the calibrated results.

Author Contributions

Conceptualization, M.G.A., J.C.G and A.E.; methodology, M.G.A., J.C.G. and A.E.; numerical analysis, F.S.; investigation, M.G.A., J.C.G., A.E. and F.S.; resources, J.C.G.; writing—original draft preparation, F.S.; writing—review and editing, J.C.G., M.G.A. and A.E.; supervision, J.C.G.; project administration, J.C.G. and M.G.A.; funding acquisition, J.C.G. and A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Innovation of Spain through the Research Fund Project PID2019-108978RB-C31.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors gratefully acknowledge the financial support provided by the Ministry of Science and Innovation of Spain through the Research Fund Project PID2019-108978RB-C31.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Achilleos, C.; Hadjimitsis, D.; Neocleous, K.; Pilakoutas, K.; Neophytou, P.O.; Kallis, S. Proportioning of steel fibre reinforced concrete mixes for pavement construction and their impact on environment and cost. Sustainability 2011, 3, 965–983. [Google Scholar] [CrossRef]

- Buratti, N.; Ferracuti, B.; Savoia, M. Concrete crack reduction in tunnel linings by steel fibre-reinforced concretes. Construction and Building Materials 2013, 44, 249–259. [Google Scholar] [CrossRef]

- Germano, F.; Tiberti, G.; Plizzari, G. Post-peak fatigue performance of steel fiber reinforced concrete under flexure. Materials and Structures 2016, 49, 4229–4245. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical and structural behaviors of ultra-high-performance fiber-reinforced concrete subjected to impact and blast. Construction and building materials 2017, 149, 416–431. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Fischer, G.; Edvardsen, C.; Skovhus, T.L.; Michel, A. Durability of Steel Fibre Reinforced Concrete (SFRC) exposed to acid attack–A literature review. Construction and Building Materials 2019, 200, 490–501. [Google Scholar] [CrossRef]

- China CECS38:2004. Technical Specification for Fiber Reinforced Concrete Structures provides Guidelines for Various Applications. Dalian University of Technology: Dalian, China 2004.

- fib Model Code 2010. Fédération Internationale du Béton fib/International Federation for Structural Concrete: Paris, France 2013.

- Sweden Standard SS812310: 2014. Svenska Institutet för Standarder (SIS)—Bygg och anläggning: Stockholm, Sweden 2014.

- Código estructural: Anejos 1-18. Ministerio de Transportes, Movilidad y Agenda Urbana, Madrid, España 2021.

- Enfedaque, A.; Suárez, F.; Alberti, M.G.; Gálvez, J.C. Suitability of Constitutive Models of the Structural Concrete Codes When Applied to Polyolefin Fibre Reinforced Concrete. Materials 2022, 15, 2323. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Kaplan, M.F. Concrete at high temperatures: material properties and mathematical models 1996.

- Varona, F.; Baeza, F.J.; Bru, D.; Ivorra, S. Evolution of the bond strength between reinforcing steel and fibre reinforced concrete after high temperature exposure. Construction and Building Materials 2018, 176, 359–370. [Google Scholar] [CrossRef]

- Liu, X.; Ye, G.; De Schutter, G.; Yuan, Y.; Taerwe, L. On the mechanism of polypropylene fibres in preventing fire spalling in self-compacting and high-performance cement paste. Cement and concrete research 2008, 38, 487–499. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Z.; Tu, W.; Yan, X.; Zhang, M. Behaviour of recycled tyre polymer fibre reinforced concrete at elevated temperatures. Cement and Concrete Composites 2021, 124, 104257. [Google Scholar] [CrossRef]

- Lopez, J.A.; Serna, P.; Camacho, E.; Coll, H.; Navarro-Gregori, J. First ultra-high-performance fibre-reinforced concrete footbridge in Spain: Design and construction. Structural Engineering International 2014, 24, 101–104. [Google Scholar] [CrossRef]

- Varona, F.B.; Baeza, F.J.; Bru, D.; Ivorra, S. Influence of high temperature on the mechanical properties of hybrid fibre reinforced normal and high strength concrete. Construction and Building Materials 2018, 159, 73–82. [Google Scholar] [CrossRef]

- Yermak, N.; Pliya, P.; Beaucour, A.L.; Simon, A.; Noumowé, A. Influence of steel and/or polypropylene fibres on the behaviour of concrete at high temperature: Spalling, transfer and mechanical properties. Construction and Building Materials 2017, 132, 240–250. [Google Scholar] [CrossRef]

- Alberti, M.; Enfedaque, A.; Gálvez, J. Comparison between polyolefin fibre reinforced vibrated conventional concrete and self-compacting concrete. Construction and Building Materials 2015, 85, 182–194. [Google Scholar] [CrossRef]

- Alberti, M.; Enfedaque, A.; Gálvez, J.; Agrawal, V. Fibre distribution and orientation of macro-synthetic polyolefin fibre reinforced concrete elements. Construction and Building Materials 2016, 122, 505–517. [Google Scholar] [CrossRef]

- Alberti, M.; Enfedaque, A.; Gálvez, J. Fracture mechanics of polyolefin fibre reinforced concrete: Study of the influence of the concrete properties, casting procedures, the fibre length and specimen size. Engineering Fracture Mechanics 2016, 154, 225–244. [Google Scholar] [CrossRef]

- Picazo, A.; Gálvez, J.; Alberti, M.; Enfedaque, A. Assessment of the shear behaviour of polyolefin fibre reinforced concrete and verification by means of digital image correlation. Construction and Building Materials 2018, 181, 565–578. [Google Scholar] [CrossRef]

- Alberti, M.G.; Gálvez, J.C.; Enfedaque, A.; Castellanos, R. Influence of high temperature on the fracture properties of polyolefin fibre reinforced concrete. Materials 2021, 14, 601. [Google Scholar] [CrossRef] [PubMed]

- Gálvez, J.; Planas, J.; Sancho, J.; Reyes, E.; Cendón, D.; Casati, M. An embedded cohesive crack model for finite element analysis of quasi-brittle materials. Eng Fract Mech 2013, 109, 369–386. [Google Scholar] [CrossRef]

- Reyes, E.; Gálvez, J.; Casati, M.; Cendón, D.; Sancho, J.; Planas, J. An embedded cohesive crack model for finite element analysis of brickwork masonry fracture. Engineering Fracture Mechanics 2009, 76, 1930–1944. [Google Scholar] [CrossRef]

- Jirásek, M., Damage and Smeared Crack Models. In Numerical Modeling of Concrete Cracking; Hofstetter, G.; Meschke, G., Eds.; Springer Vienna: Vienna, 2011; pp. 1–49.

- Alberti, M.; Enfedaque, A.; Gálvez, J.; Reyes, E. Numerical modelling of the fracture of polyolefin fibre reinforced concrete by using a cohesive fracture approach. Composites Part B: Engineering 2017, 111, 200–210. [Google Scholar] [CrossRef]

- Suárez, F.; Gálvez, J.; Enfedaque, A.; Alberti, M. Modelling fracture on polyolefin fibre reinforced concrete specimens subjected to mixed-mode loading. Engineering Fracture Mechanics 2019, 211, 244–253. [Google Scholar] [CrossRef]

- Suárez, F.; Gálvez, J.C.; Alberti, M.G.; Enfedaque, A. Fracture and Size Effect of PFRC Specimens Simulated by Using a Trilinear Softening Diagram: A Predictive Approach. Materials 2021, 14. [Google Scholar] [CrossRef] [PubMed]

- Planas, J.; Guinea, G.; Gálvez, J.; Sanz, B.; Fathy, A. Indirect Test for Stress-Crack Opening Curve, from Experimental Determination of the Stress-Crack Opening Curve for Concrete in Tension—Final Report of RILEM Technical Committee TC 187-SOC 2007.

- Sancho, J.; Planas, J.; Cendón, D.; Reyes, E.; Gálvez, J. An embedded crack model for finite element analysis of concrete fracture. Engineering Fracture Mechanics 2007, 74, 75–86, Fracture of Concrete Materials and Structures. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem Concr Res 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Enfedaque, A.; Alberti, M.; Gálvez, J.; Domingo, J. Numerical simulation of the fracture behaviour of glass fibre reinforced cement. Construction and Building Materials 2017, 136, 108–117. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).