3.1. Rotation influences on the external flow

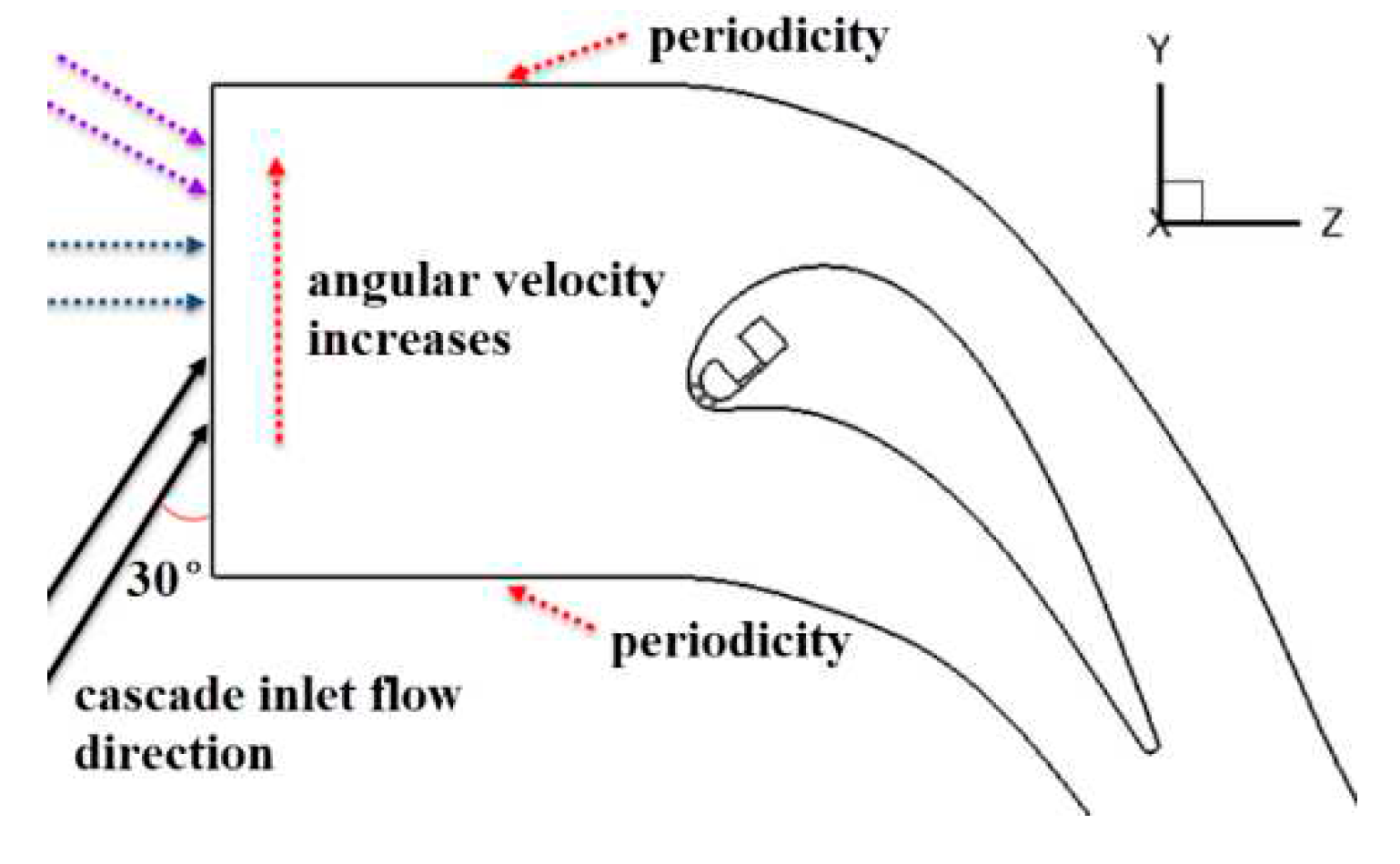

Figure 7 shows the sketmatic figure of the direction of the

MF inlet flow versus the angular velocity. There are three types of velocity vector: the

MF inlet flow absolute velocity

c, the angular velocity

u and the

MF inlet flow velocity relative to the rotation frame w, in which

c=

u +

w. When the angular velocity u is 0rpm, velocity c and velocity

w are identical. The angle between the velocity w and Y- axis is 30°. As the angular velocity

u increases under the fixed velocity

c, the angle between the velocity

w and Y- axis gradually increases. A flow stagnating to the blade will bring about a line-shaped stagnation region on the

BLE surface, whose position is related to the flow direction. Given the blade could be regarded as a rotation frame, it can be concluded in

Figure 7 that the stagnation region will move from the pressure surface side to the suction surface side on the

BLE surface with the increasing angular velocity

u. Such a phenomenon can be seen in

Figure 8. The line-shaped stagnation region is termed “

SL (stagnation line)” in the following text.

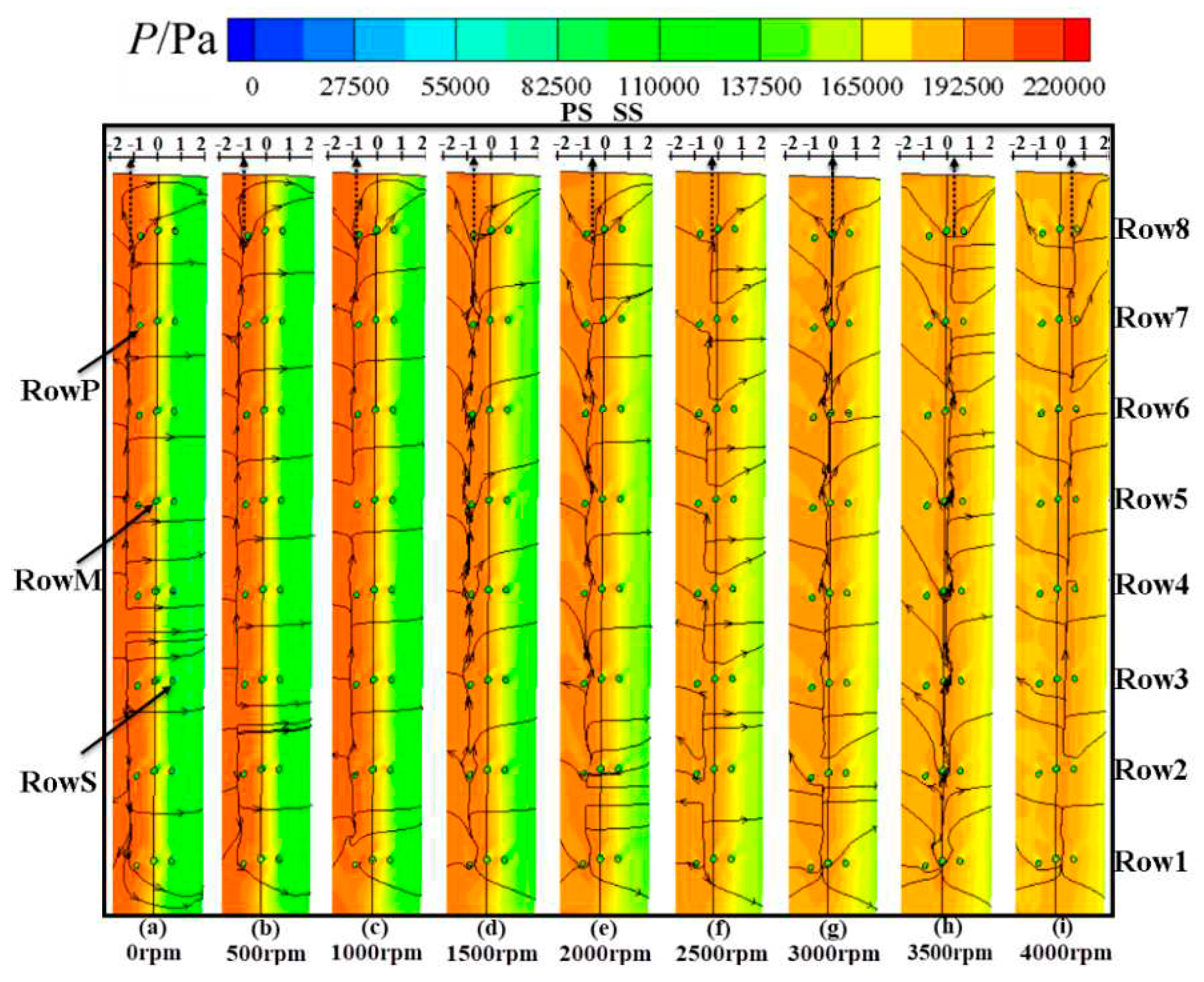

Figure 8 illustrates the pressure contour and surface streamlines on the

BLE. The presence of

SLs could be observed as characterized by the opposite streamline directions on each side of these lines. At 0 rpm, the

SL presents a relatively straight profile from hub to shroud side and is positioned to the left side of RowP. When the rotating speed rises, the

SL shifts towards the suction surface of the blade and eventually settles on the left of film hole RowS. This shift is attributed to the keeping growing norm of the circumferential velocity

u as presented in the velocity triangle, leading to a direction change in the of

w, as explained in

Figure 7. Metaphorically, the upper portion of the

SL moves "faster" towards the blade suction surface compared to the portion near the hub with increasing rotating speed, primarily due to the higher circumferential velocity near the shroud. This difference becomes more distinct at higher rotating speeds. Additionally, the surface streamlines gradually curve towards the side of the shroud given the effects of the growing centrifugal force associated with the growing rotational speed. It is worth noting that the position of the

SL aligns with RowP and RowM positions at 1500 rpm, 3000 rpm and 3500 rpm, respectively. The position of the

SL will affect the heat and mass transfer between the coolant film flow and the

MF.

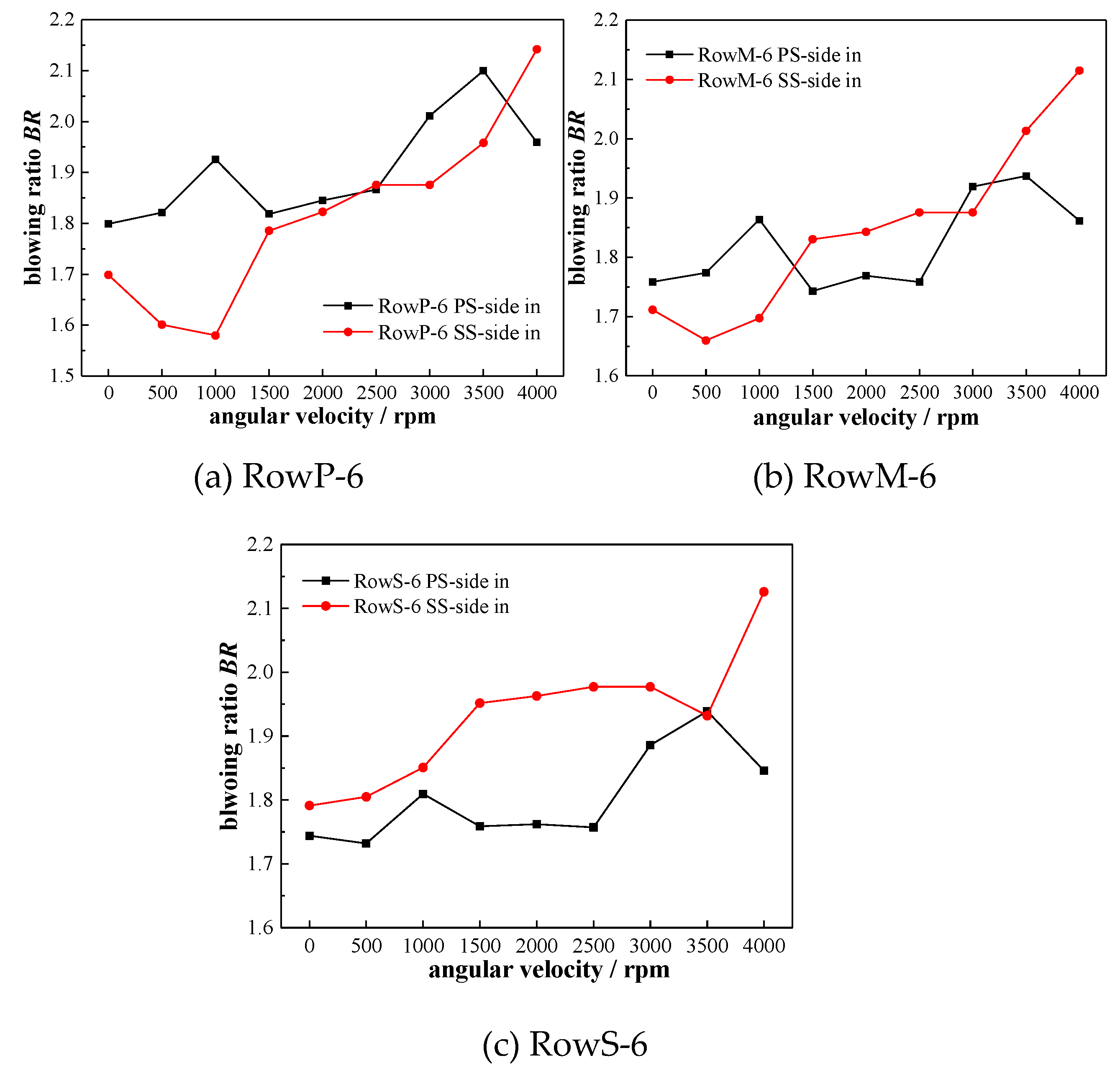

Figure 9 presents the blowing ratio variation versus the rotating speed in PS-side-in and SS-side-in. Referring to

Figure 2, RowP-6, RowM-6 and RowS-6 represents the sixth-row of film hole locates at the pressure surface, the suction surface, and the position between the suction surface and pressure surface, respectively. In general, the blowing ratios of those three film holes fluctuant increase with the growing rotational speed. Such a phenomenon is brought about by the enlarging centrifugal force caused by the increasing rotating speed, which as a result, forces the coolant to move along the blade height direction. It is noteworthy that, the blowing ratios of RowP-6 and RowM-6 at 0-1000rpm are lower in PS-side-in than that in SS-side-in. The reasons are explained as following. On the one hand, the coolant injecting nozzles stay closer to RowP in PS-side-in than SS-side-in as can be seen in

Figure 2. Hence, more coolant will flow to the

MF through RowP in PS-side-in than the SS-side-in. On the other hand, the

SL appears near RowP and RowM at 0-1000rpm as indicated in

Figure 8, which brings about higher

MF pressure near RowP and RowM but lower

MF pressure near RowS. In that case, in SS-side-in, higher proportion of the coolant directly flows into the

MF through RowS rather than RowP or RowM. This causes a lower blowing ratio of RowP and RowM as well as a higher blowing ratio of RowS in SS-side-in compared to PS-side-in at 0-1000rpm. Such phenomena will bring about the difference for the performance of the

VFCC in the following discussion.

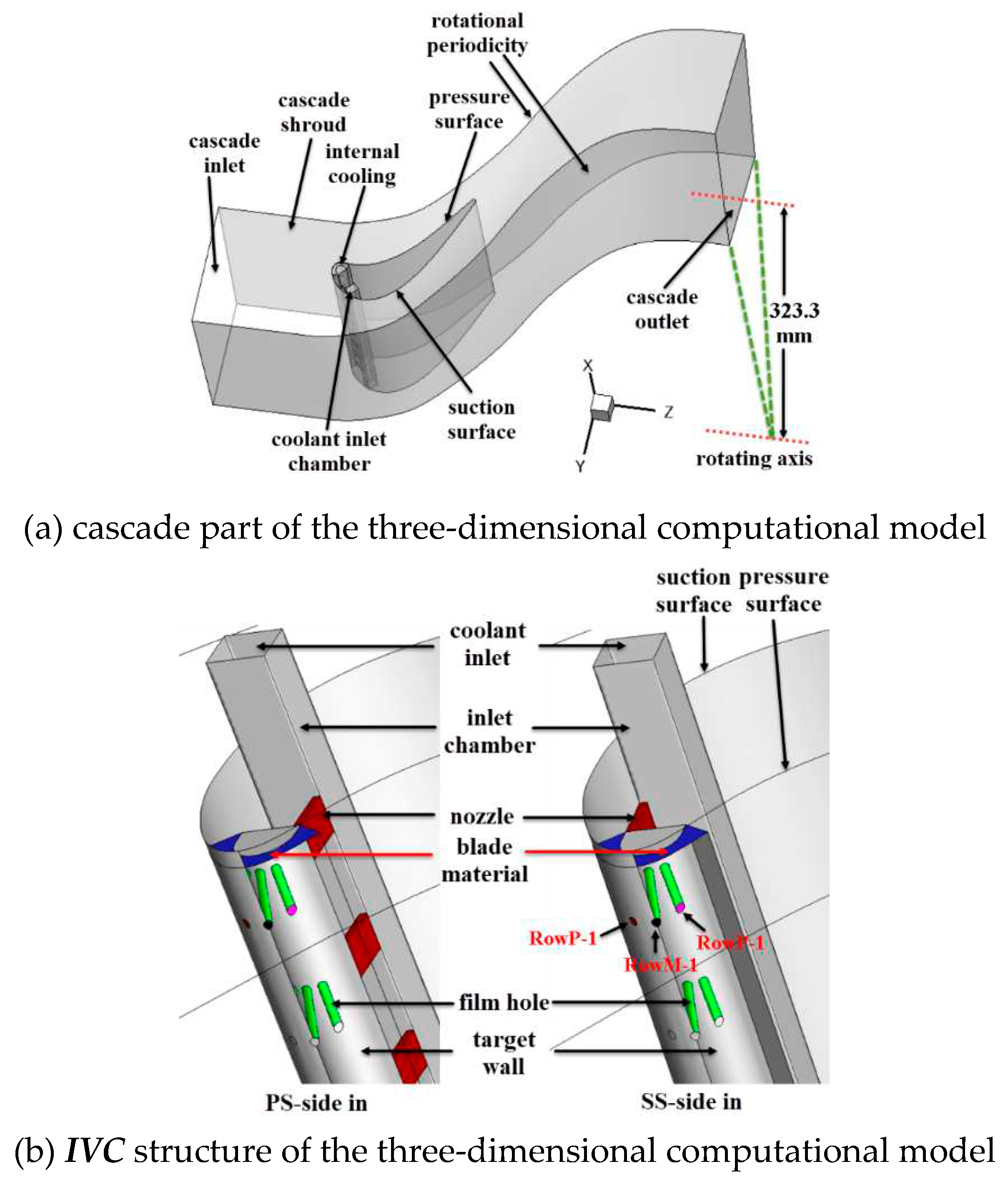

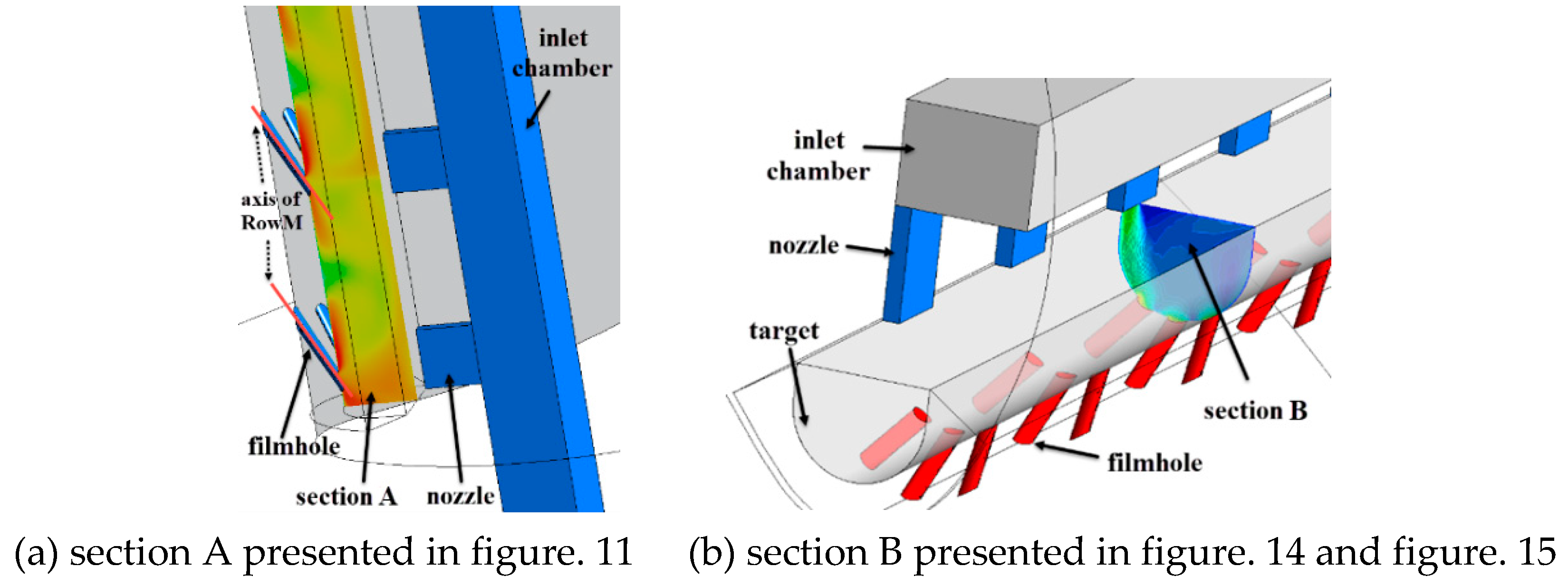

Figure 10 depicts different types of cross-sections for analysis in

Figure 11, Figure 14 and Figure 15. Section A presented in

Figure 10 (a) locates on the axis of RowM and is parallel to the blade height. There are three types of section A. They locates on the axis of RowP, RowM and RowS, respectively. Section A is created to ‘capture’ the external near wall flow field of the

EFC as presented in

Figure 11. Section B shown in

Figure 10 (b) locates on the blade height of Row6 and is vertical to the blade height to ‘capture’ the flow field of the

IVC in Figure 14 and Figure 15.

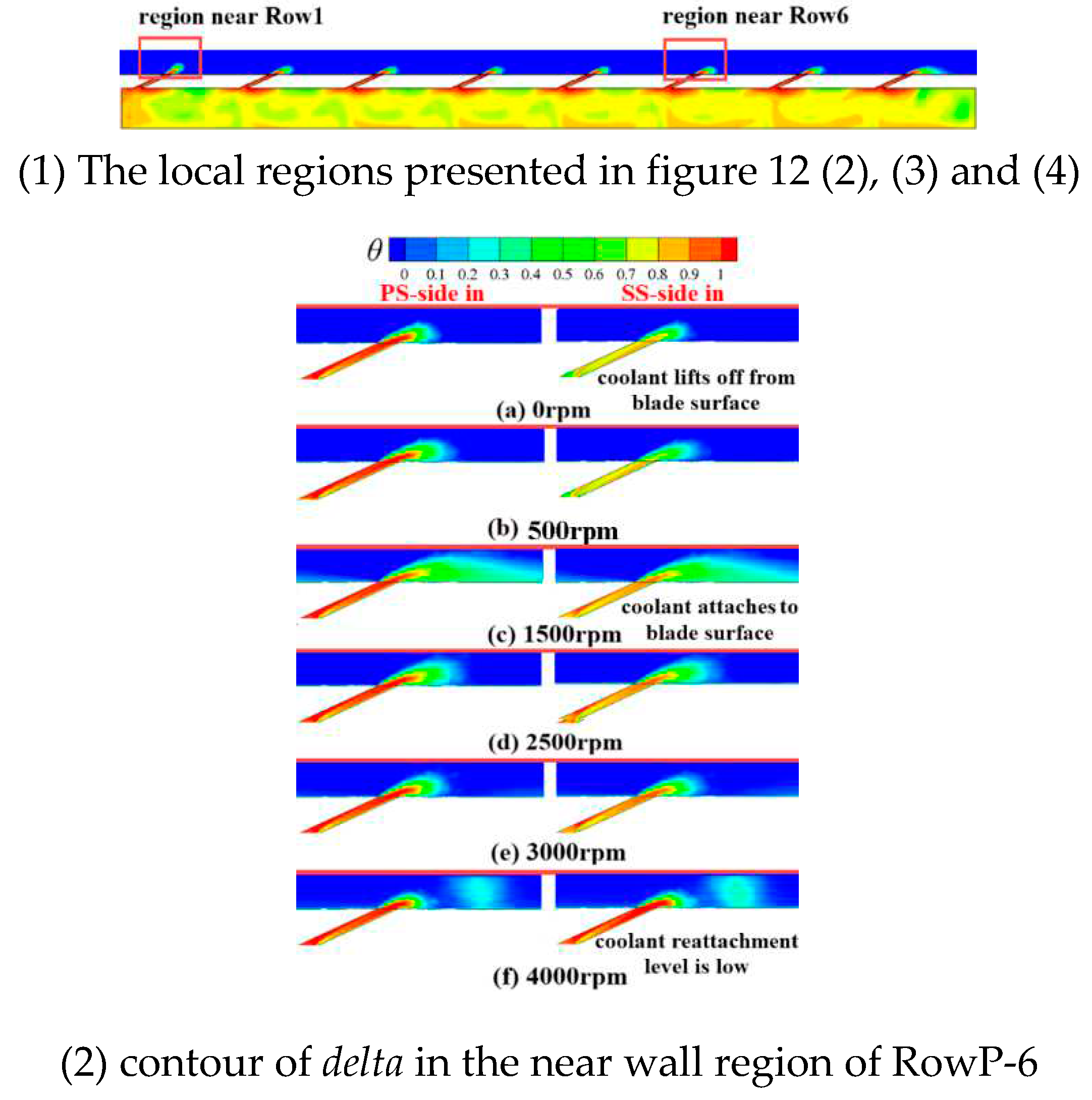

Figure 11 presents the

θ contour on section A as presented in

Figure 10 (b) to exhibit the spreading level of the coolant film on the blade surface.

Figure 11 (1), (2) and (3) illustrate the local-region

θ contour near RowP-6, RowM-6 and RowS6 in PS-side-in and SS-side-in, respectively. In general, there are mainly three types of

EFC flow regimes under all of the rotating speed scenarios. First, the coolant jet lifts away from the surface of the blade and penetrates into the

MF, such as the phenomena revealed in

Figure 11(2)(a), 11(3)(d) and 11(4)(f). The coolant jet lifting off is caused by the low

MF pressure at the outer side region of the film hole and the higher blowing ratio of the film hole. In that case, the coolant film thus fails to protect the blade surface from the

MF hot gas sufficiently. Second, the coolant jet is suppressed by the

MF to the surface of the blade and spreads on the blade surface. This phenomenon appears when the position of the

SL aligns with the film hole position as presented in

Figure 8. At 1500rpm, the

SL stays at the position of RowP. Given the pressure and temperature of the

MF near the

SL position is the highest within the whole fluid domain, the coolant jet from RowP is suppressed onto the blade surface, leading to a large coolant film coverage area on the blade surface as seen in

Figure 11(2)(c). Similarly, the coolant film from RowM attaches to the surface of the blade well at 3000rpm as reveled in

Figure 11(3)(e). Third, the coolant jet lifts off initially and then reattachment to the surface of the blade as shown in

Figure 11(2)(f), 11(3)(a) and 11(4). The reattachment level is affected by both the stagnation position and rotating speed. The increasing centrifugal force as a result of the increasing rotating speed makes the coolant film flow towards the side of the shroud, therefore increasing the reattachment distance as seen in

Figure 11(4). Furthermore, the

SL gets closer to film hole RowS with an increasing rotating speed. The high-pressure hot gas of the

MF flow around the

SL then pushes the coolant jet away and increases the reattachment zone.

The coolant film flow distribution in PS-side-in is rather similar to that in SS-side-in, especially at the rotating speed higher or equal to 1000rpm. At 0rpm or 500rpm, the coolant film from RowM shows higher attachment level in PS-side-in compared to SS-side-in. Because the value of blowing ratio of RowM in PS-side-in is higher than that in SS-side-in as presented in

Figure 9(b). Higher blowing ratio of RowM indicates that larger amount of coolant reattaches to the surface of the blade. In general, the coolant film attachment levels in PS-side-in and SS-side-in under the identical rotating speed are almost the same. This suggests that there’s little difference of the

EFC effectiveness between PS-side-in and SS-side-in.

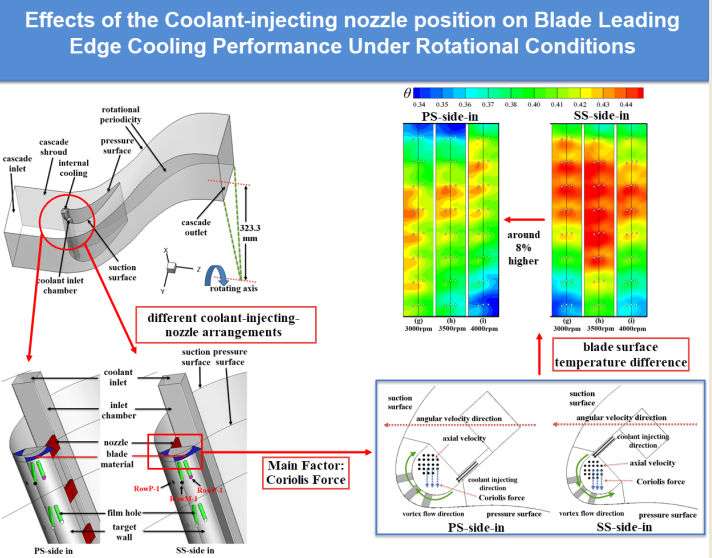

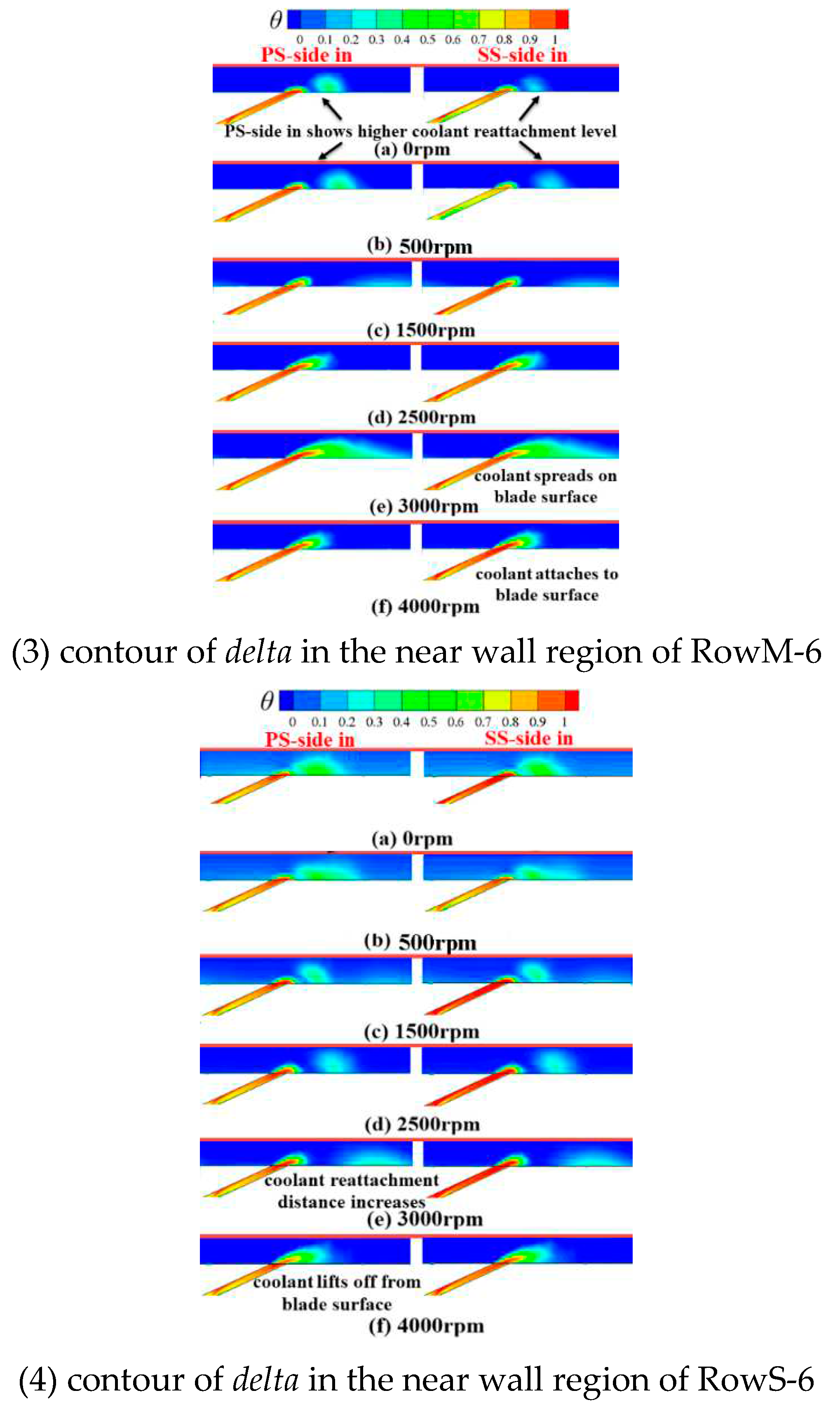

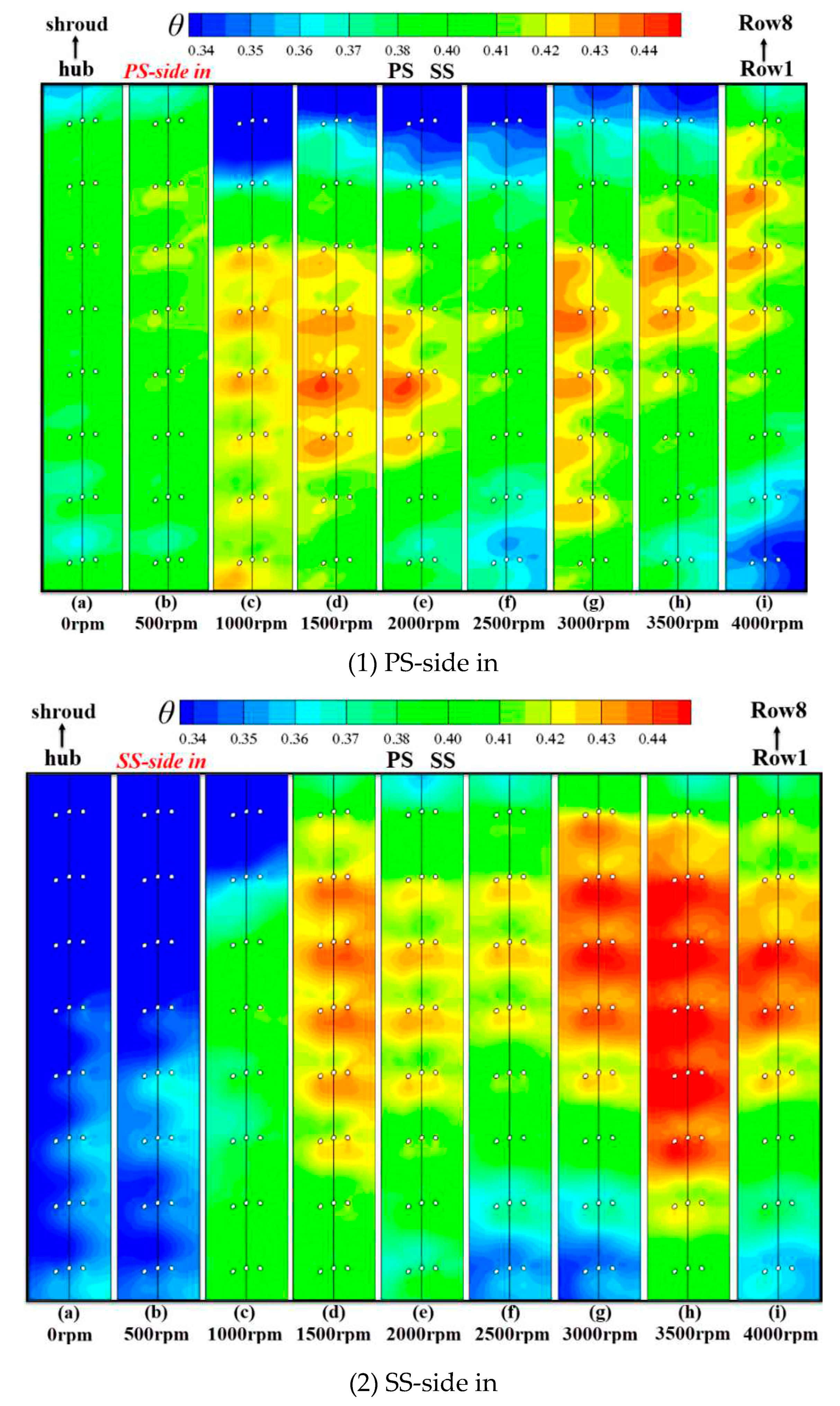

Figure 12 presents

delta (defined in eq(2)) contour on the

BLE surface of the PS-side-in and SS-side-in under all rotating speed range. In general, there are distinct differences on the temperature distributions on the

BLE between the PS-side-in and the SS-side-in. Whereas the coolant film coverage situations on those two cases are quite similar as plotted in

Figure 11. This concludes that the dominating factor that brings about such temperature distribution differences is related to the

IVC rather than the

EFC.

As for the similarities, large-area of the low-temperature regions could be captured at 1500rpm, 3000rpm and 3500rpm, in which the position of the SL aligns with the film hole position. Large-area of coolant film coverage brings about large-area of low temperature regions. When the SL exists at other positions, the coolant film is pushed away by the high-pressure MF near the SL, leading to a higher area-averaged temperature on the BLE surface.

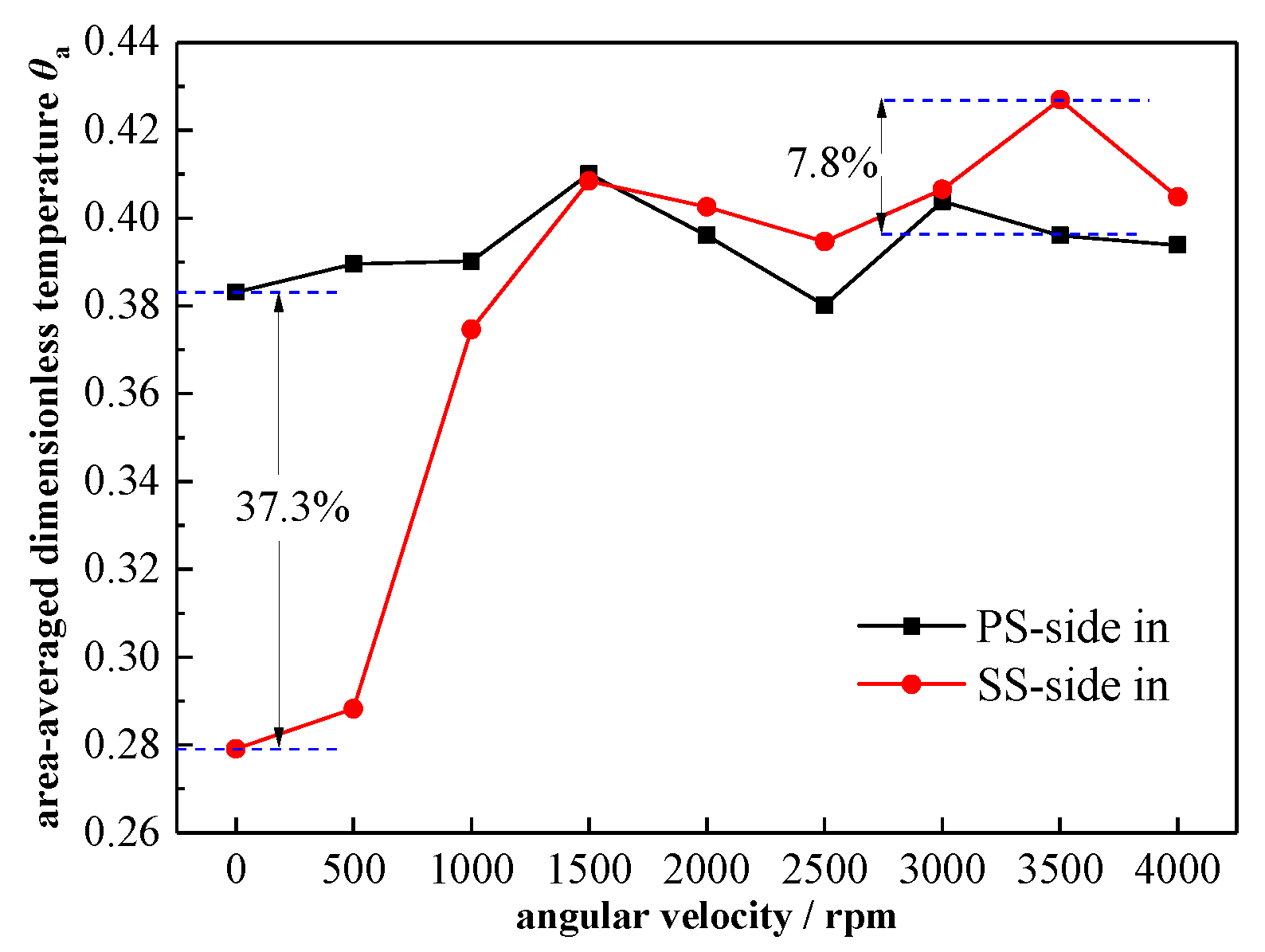

As for the differences, there are mainly three aspects of dissimilarities between the PS-side-in and the SS-side-in. First, the blade surface temperature is much higher in SS-side-in than that of the PS-side-in when the rotating speed is lower or equal to 1000rpm. Second, the blade surface temperature in SS-side-in becomes higher than that in the PS-side-in when the rotating speed is higher than 1500rpm. Such a variation becomes larger with the increasing rotating speed. Those phenomena could also be captured in

Figure 13, which shows the area-averaged

delta (

θa) on the

BLE surface under all rotating speeds. The highest differences appear at 0rpm and 3500rpm, where

θa in PS-side-in is 37.3% higher than the SS-sid-in and

θa in SS-side-in is 7.8% higher than that in PS-side-in, respectively. Third, there are large-area of high-temperature regions appear near the shroud in the PS-side-in at 1000-3500rpm. Nevertheless, those high-temperature regions disappear in the SS-side-in.

In summary, the arrangement of the internal coolant injecting nozzles confirms little influence on the flow field of the EFC. However, the nozzle arrangement presents significant influences on the temperature of the BLE. This indicates that the nozzle configurations will change the IVC performance, and then affects the VFCC performance. The discussion on the IVC is presented next.

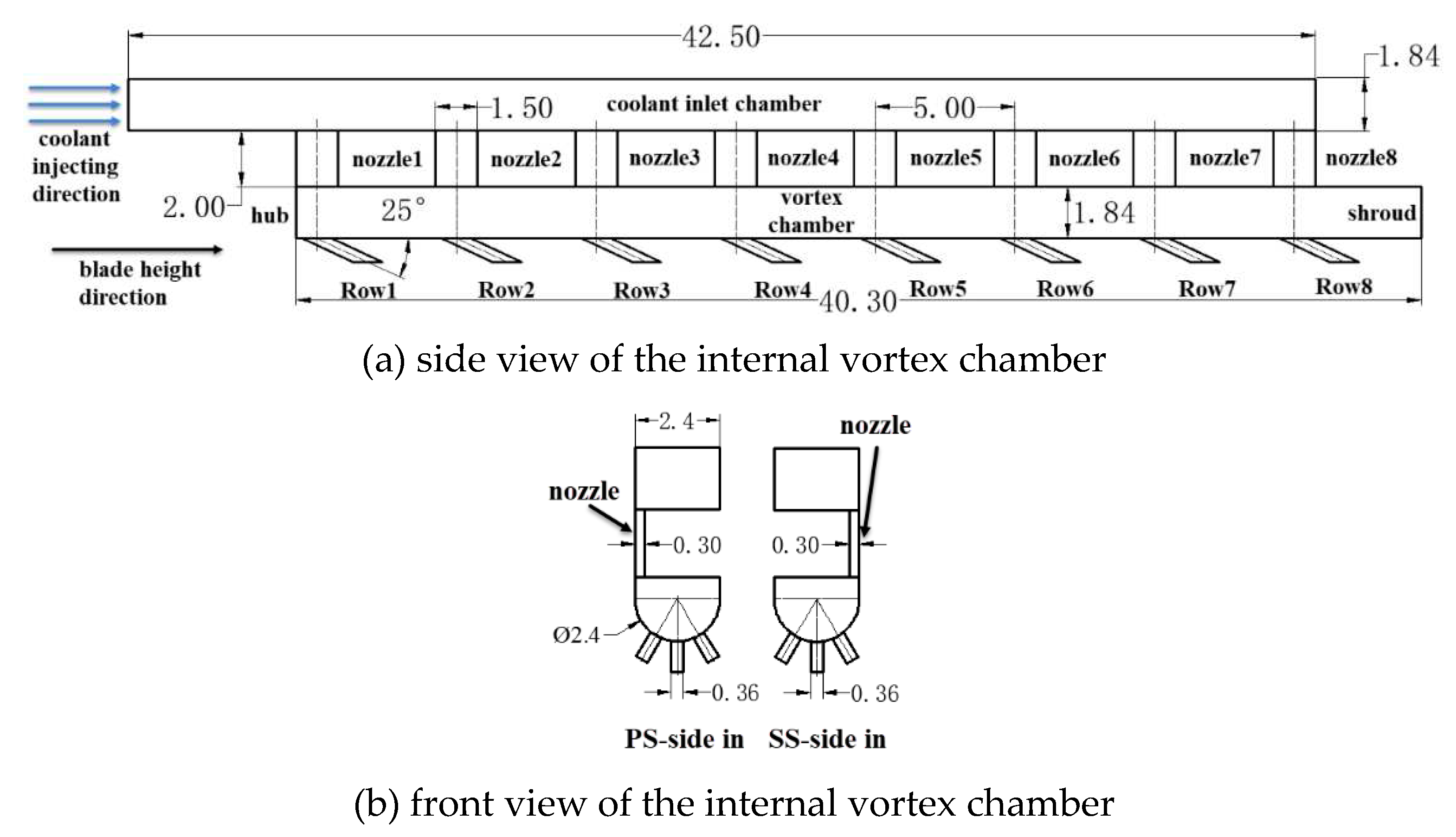

3.2. Rotation influences the on IVC flow

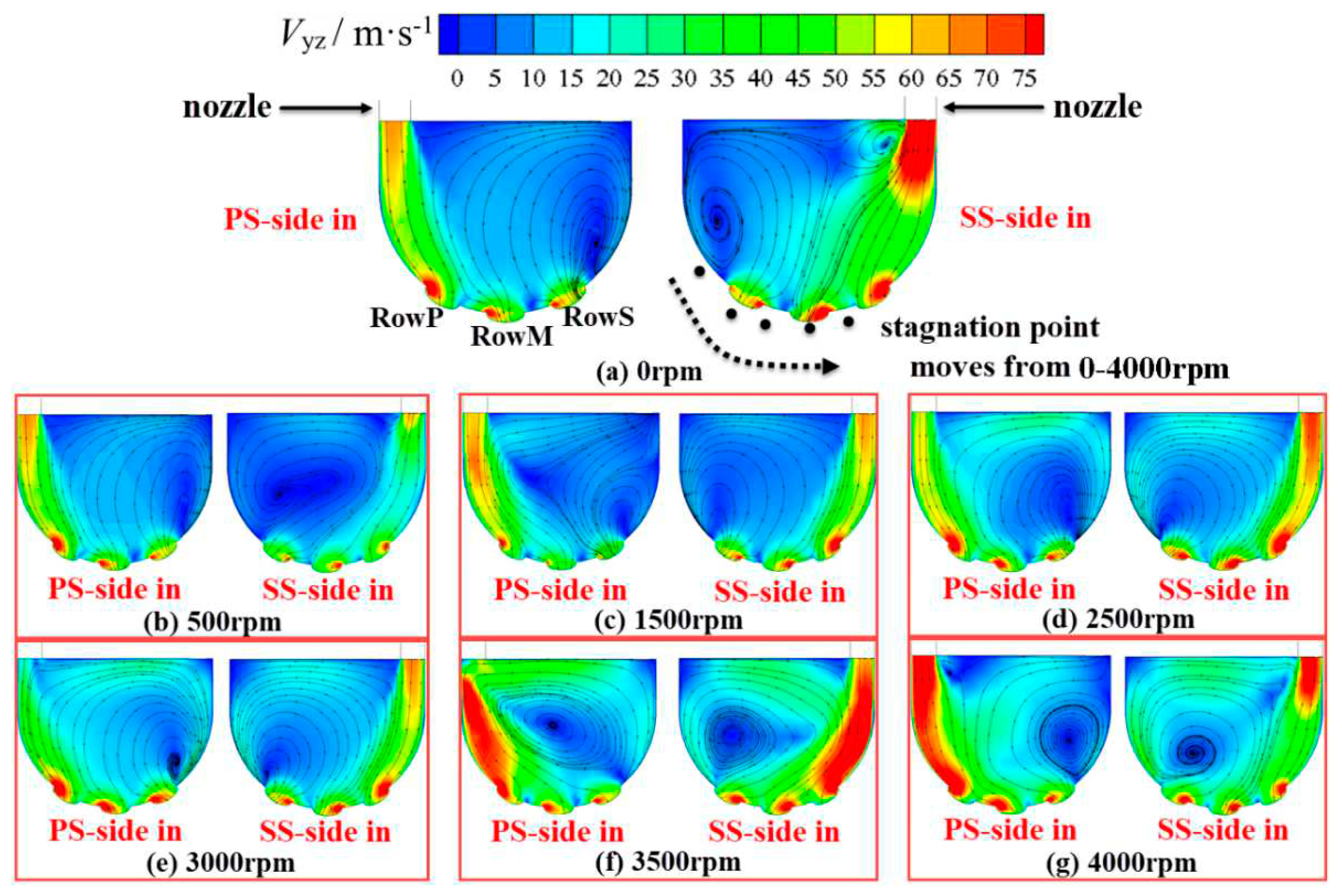

The rotation influences on the flow field of the

IVC are discussed in Figure 14 and Figure 15. Figure 14 shows contour of velocity

Vyz as well as the streamline on the Y-Z section as presented in

Figure 8 (c).

Vyz is defined as:

where

Vy stands for the Y- component of the coolant velocity in the rotational frame

Vz stands for the Z- component of the coolant velocity in the rotational frame

As can be seen in

Figure 14, the coolant blows into the vortex chamber tangentially and scours the target surface. The coolant flow ‘crashes’ the target surface and forms large-scale vortices, leading to intense convective heat transfer on the target wall. A high-velocity region near the target wall and a low-velocity region in the core region of the vortex chamber are formed. Position of the target wall is indicated in

Figure 2. Then the coolant flows towards the

MF through the showerhead film holes drove by the relatively larger pressure difference between the vortex chamber and the cascade, which is pointed out as the ‘suction effect’ by Fan

et al.[

12]. Such a ‘suction effect’ changes the position and the intensity of the vorticity of the large-scale vortex in the vortex chamber. In addition, the coolant flow will be accelerated by the ‘suction effect’, which will augment the heat transfer intensity around the region near the film holes. As the intensity of the ‘suction effect’ is dominated by the position of the stagnation point as presented in

Figure 14.

When the rotating speed is relatively low, particularly at 0-500rpm, the stagnation point stays near RowP, bringing about higher-pressure and lower-pressure at the outer region of RowP and RowS. Therefore, high proportion of the coolant from the nozzle directly flows into the

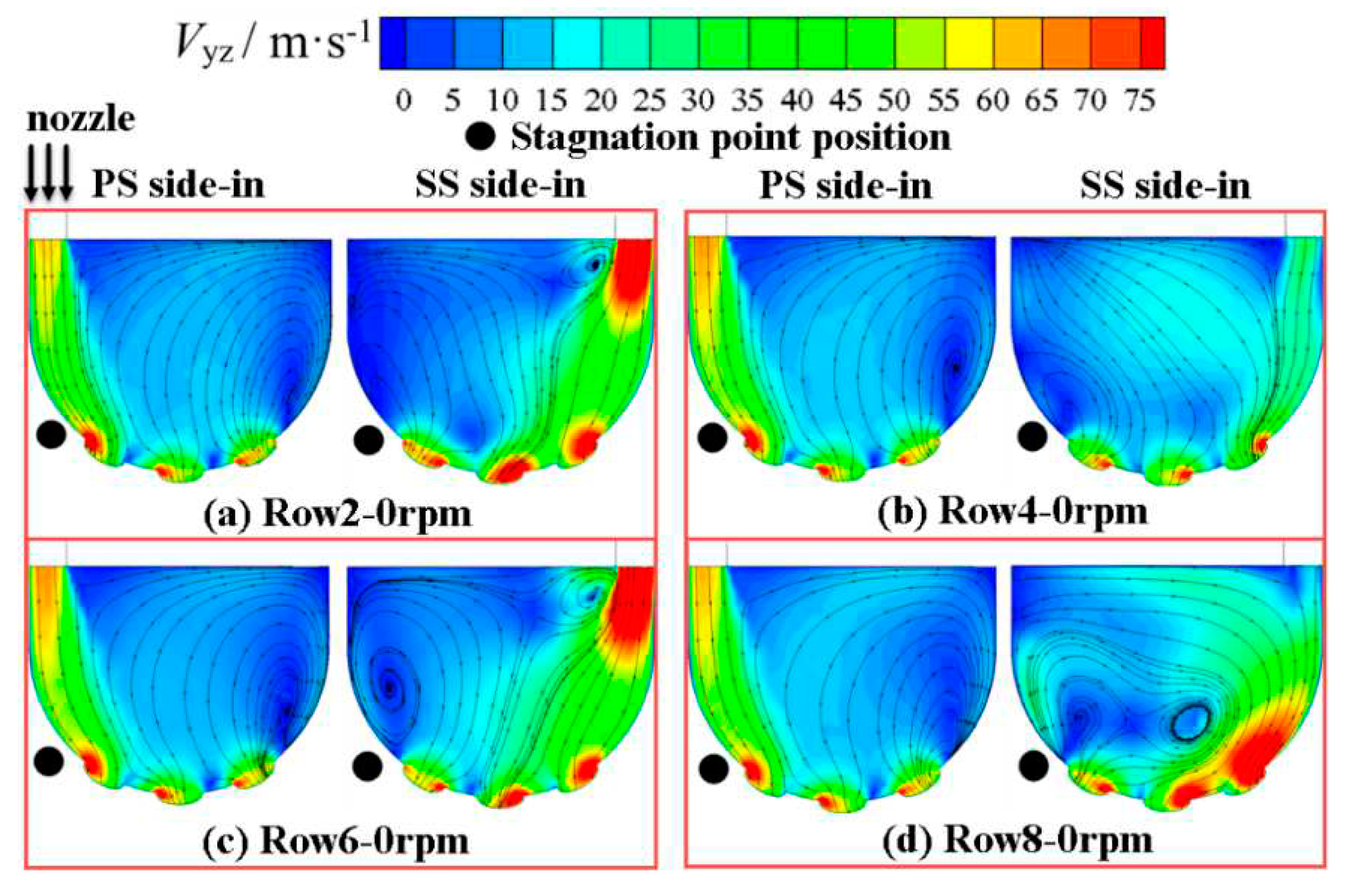

MF through RowS in SS-side-in rather than flows along the target wall. As for PS-side-in, relatively low proportion of the coolant from the nozzle flows into RowP. Some coolant is forced by the suction effect of RowS and flows downstream along the target wall. Such a phenomenon is more distinct as revealed in

Figure 15, that presents the velocity contour and streamline on the cross-sections at various blade height at 0rpm. It can be concluded that, the much more intense “suction effect” of RowS in SS-side-in makes the large-scale vortex losing its original shape. The flow field in the vortex chamber in SS-side-in is more chaotic than that in PS-side-in. Therefore, the intensity of the internal heat transfer in SS-side-in will be much lower than that in PS-side-in. This conclusion could be captured in Figure 17, which shows the area-averaged

Nusselt

Number

Nua on the target surface. The value of

Nua in PS-side-in is 52.6% higher than the SS-side-in. The low the intensity of the internal heat transfer explains well the reason why the blade surface temperature in SS-side-in is much higher at 0-500rpm than that in PS-side in as seen in

Figure 12(a) and (b).

When the rotating speed is higher than 1500rpm, there’s an opposite result in internal heat transfer intensity. The intensity of the internal heat transfer in SS-side-in becomes higher than the PS-side-in. Such a phenomenon could be observed in

Figure 14. In

Figure 14 (d)~(f), the high-velocity near wall region originating from the nozzle covers a larger area in SS-side-in than that in PS-side-in. There are mainly two reasons. Firstly, as the rotational speed gradually grows to 3500rpm, the stagnation point gradually moves towards the position near RowS, leading to a relatively higher-pressure and lower-pressure at the outer side of RowS and RowP. As for the PS-side-in, high proportion of coolant from the nozzle directly flows into RowP rather than flows downstream along the target wall. For the SS-side-in, relatively low proportion of coolant from the nozzle flows into RowS, and some coolant flows downstream along the target wall. Hence, the high-velocity near wall region in SS-side-in covers a relatively larger proportion of the target wall than that in PS-side-in, allowing a larger intensity of the heat transfer of the

IVC in SS-side-in compared to PS-side-in.

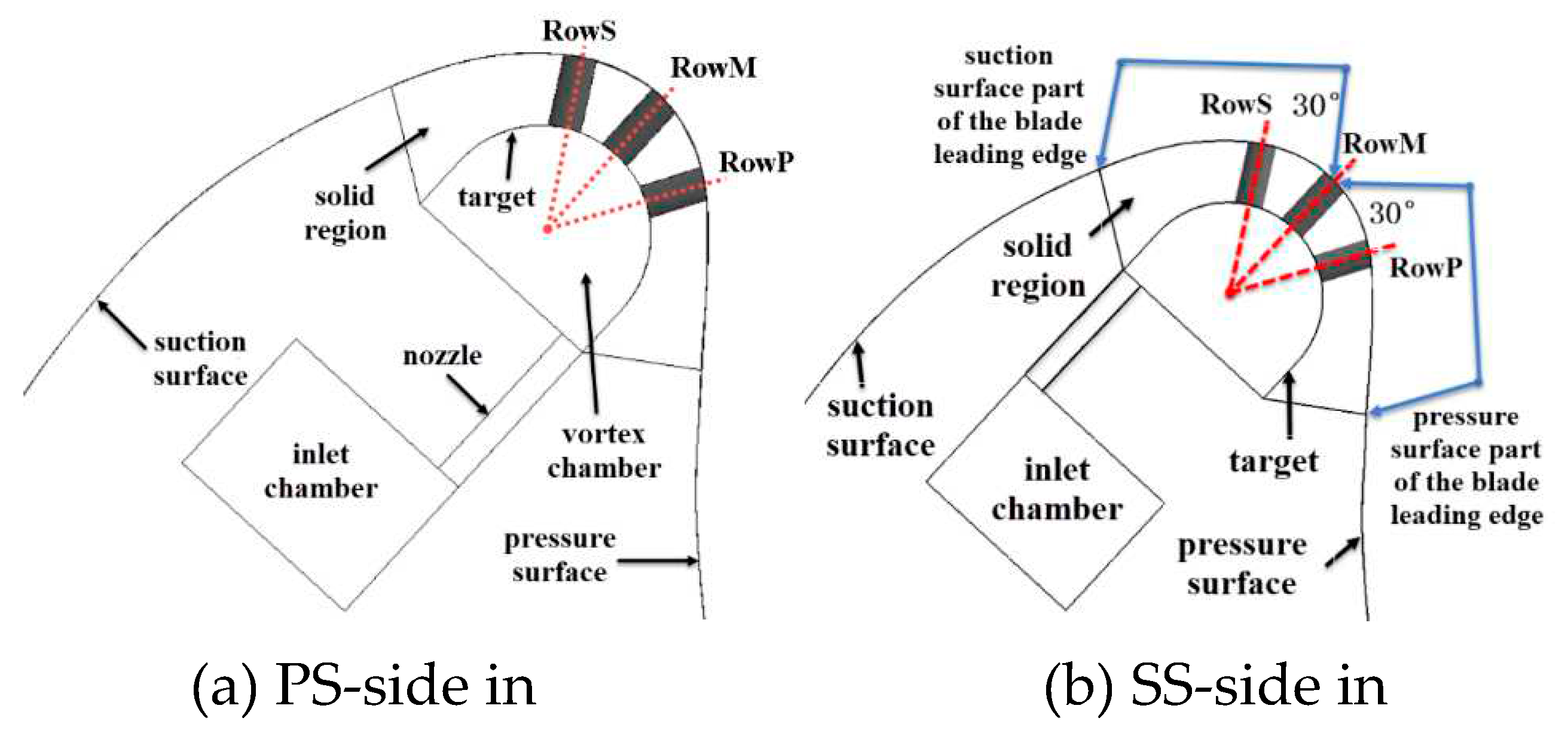

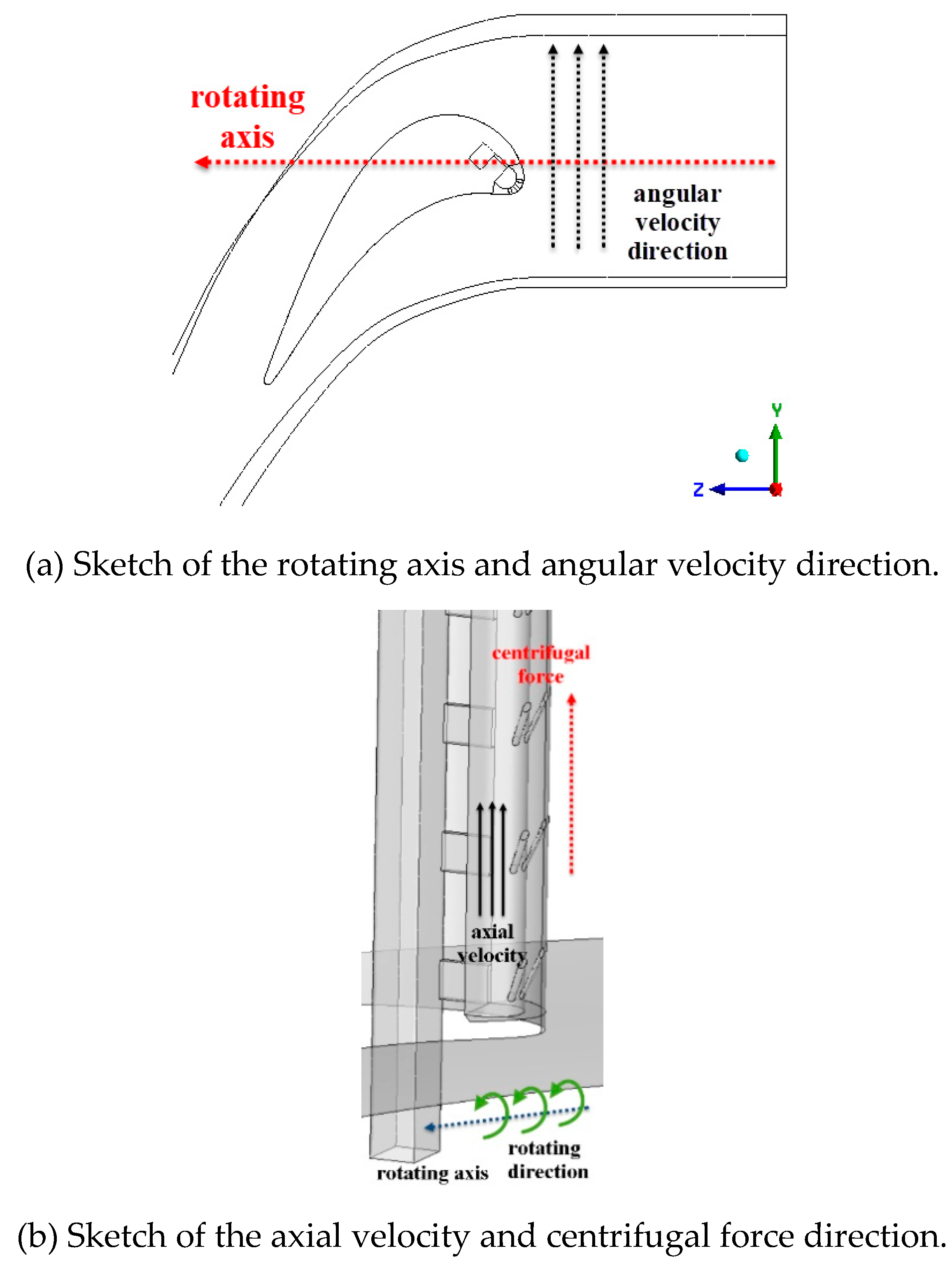

Secondly, the differences of the internal vortex flow field between the PS-side-in and the SS-side-in are related to the centrifugal force and the Coriolis force brought about by the rotation.

Figure 16 exhibits the sketch of the Coriolis force effect on the internal vortex flow.

Figure 16(b) shows the direction of the centrifugal force and the axial velocity. The rotation brings about the centrifugal force towards the blade height direction, which forces the coolant flows towards shroud and forms the axial velocity

Vr. The higher rotating speed leads to the higher axial velocity

Vr. As seen in

Figure 16(a) and (c), the red dotted line represents the direction of the angular velocity

ω. Therefore, based on the equation

Fc=-2

ω×

Vr, the Coriolis force Fc could be represented by the blue dotted line. The higher rotating speed leads to the

ω and

Vr, which permits higher Coriolis force Fc. In terms of the PS-side-in, the direction of the Coriolis force

Fc is nearly opposite to the near wall vortex flow direction, that prevents the high-velocity coolant near the target wall developing downstream. In terms of the SS-side-in, the direction of the Coriolis force

Fc is like the near wall vortex flow direction, which promotes the high-velocity coolant near the target wall developing downstream. Therefore, the Coriolis force will provide a more intense of heat transfer of the

IVC in SS-side-in than that in PS-side-in, and this effect will be more intensify under higher rotating speed.

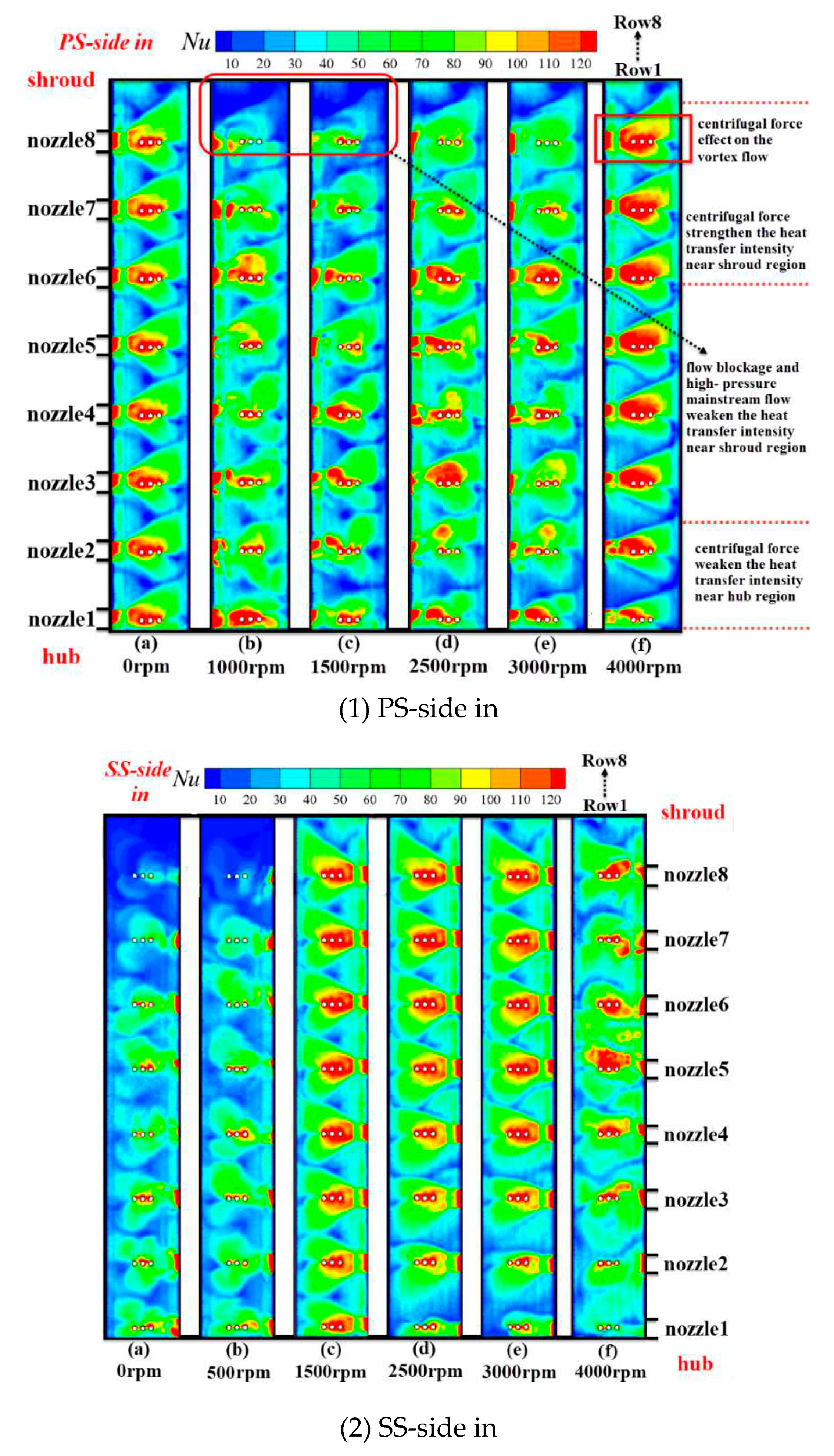

Figure 17 exhibits the Nusselt contour on the target surface in the PS-side-in and SS-side-in. It can be noticed that the high-

Nu region originating from the nozzle develops downstream and covers a relatively larger area in the SS-side-in compared to that in the PS-side-in region at 1500-3000rpm. In addition, the angular velocity ω and the axial velocity

Vr close to the shroud region are higher than the other regions in the vortex chamber. Thus, the Coriolis force effect on the vortex flow will be more intense close to the shroud region, resulting in higher

Nu around the shroud region in the SS-side-in as compared to PS-side-in. Given the coolant flow is unable to flow axially out of the vortex chamber through the shroud wall, there will be flow blockage near the shroud region. Together with the effect of the high-pressure

MF outer flow, the intensity of the vortex flow heat transfer close to the shroud region in PS-side-in will be weakened. This explained the phenomenon shown in

Figure 12 that large-area of high temperature regions appear near the shroud region in PS-side-in rather than that in SS-side-in. Another noteworthy observation is the high-

Nu region close to the film holes. This heat transfer enhancement phenomenon is brought about by the “suction effect” as discussed before.

To sum up, the arrangement of the coolant injecting nozzles makes a difference in the interaction between the Coriolis force and the internal vortex flow. The nozzle position will significantly impact the intensity of the internal heat transfer, and change the overall VFCC performance. The nozzles arranged near the pressure surface side is recommended to the turbines running under relatively low rotating speed range. And the nozzles arranged near the suction surface side is recommend for the relatively high rotating speed conditions. Such conclusion cannot be drawn in the IVC research under the symmetrical MF as in the past work or neglecting the MF effects.

Previous studies, including Li et al. [

21] and Wang et al. [

16], have evaluated the performance of VFCC in BLE by separately analyzing the effectiveness θ of the EFC as well as the heat transfer intensity (Nu) of the IVC. However, these studies were carried out under the adiabatic conditions, so a higher value for both θ and Nu was considered indicative of superior performance of a specified VFCC. In the present research, we found that the BLE surface temperature is affected by the heat conduction between IVC flow and the external film coolant coverage within conjugate approach. The higher intensity of the internal heat transfer results in the lower actual temperature on the BLE surface. However, a lower intensity of the internal heat transfer does not necessarily mean a higher actual temperature on the BLE surface. This is because better coolant film coverage on the BLE surface and lower internal heat transfer intensity can also lead to relatively better cooling performance. Therefore, when heat conduction brought about by the blade material is taken into consideration, the temperature on the BLE surface will be the more reasonable criterion for evaluation as compared to Nu.

To properly evaluate the cooling concept performance, it's important to consider the flow loss and heat transfer situation simultaneously. Shevchuk et al. [

22] have proposed an aerodynamic parameter that takes into account both the heat transfer situation and pressure loss. The defination of this aerodynamic parameter is defined as:

Nua represents the area-averaged Nusselt number on the target wall of the vortex chamber.

Nu0 = 0.023ReD0.8Pr0.4 stands for the Dittus-Boelter correlation of the smooth channel axial flow, in Nu0:

Pout stands for the mean pressure of the film hole channel internal side

Pin stands for the mean pressure of the coolant flow at internal inlet

Vj stands for the velocity of the coolant flow at internal inlet

Dc means the cross-section hydraulic diameter of the vortex chamber

Tw represents the target wall temperature

ρ represents the fluid density

L represents the vortex chamber axial length

The aim of incorporating cooling structures in turbine blades is to lower temperature of the blade and prevent thermal damage while minimizing coolant usage. Thus, in equation (4), we can replace Nusselt number Nu with the delta on the BLE surface. Similarly, friction factor f can be substituted with the mass flow of the coolant at the internal inlet M

c. This approach yields a more appropriate criterion φ for assessing the impact of rotation on the performance of VFCC in engineering application scenarios:

where:

θa means delta on the BLE surface (area-averaged value)

θ0 means delta on the BLE surface (area-averaged value) at stationary case (0 rpm)

Mc means the mass flow of the coolant flow at the internal inlet

Mc0 means the mass flow of the coolant flow at the internal inlet at stationary case (0 rpm)

n is the alterable weighting index whose meaning is provided in the following text

A higher delta on the blade surface (namely a lower blade surface temperature) together with a lower consumption of the coolant air means a higher value of VFCC performance parameter φ. By adjusting the value of n, engineers can modify this criteria used to evaluate cooling performance. When n is relatively higher, the temperature of the blade surface becomes the more important criterion, while when n is relatively lower, the coolant consumption takes on greater significance.

Table 3 and

Table 4 show the value of φ for n = 3 in the case of PS-side-in and SS-side-in, respectively.

It's evident that coolant consumption rises steeply with the growing rotating speed. When the SL is positioned near RowP, coolant consumption is considerably lower at 1500rpm and 3000rpm. The SS-side-in shows superior cooling performance to the PS-side-in under the relatively high rotating speed. These findings hold true for the cooling structure examined in this study.

Our goal is to examine how rotational effects impact the characteristics of the composite conjugate cooling. Given that various sorts of gas turbines have their own designated rotating speeds, it's important to conduct more thorough simulations within specific ranges of rotating speeds while designing the BLE cooling conceptions such as the VFCC structures for various gas turbine applications (air, sea, land).