Submitted:

28 July 2023

Posted:

31 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

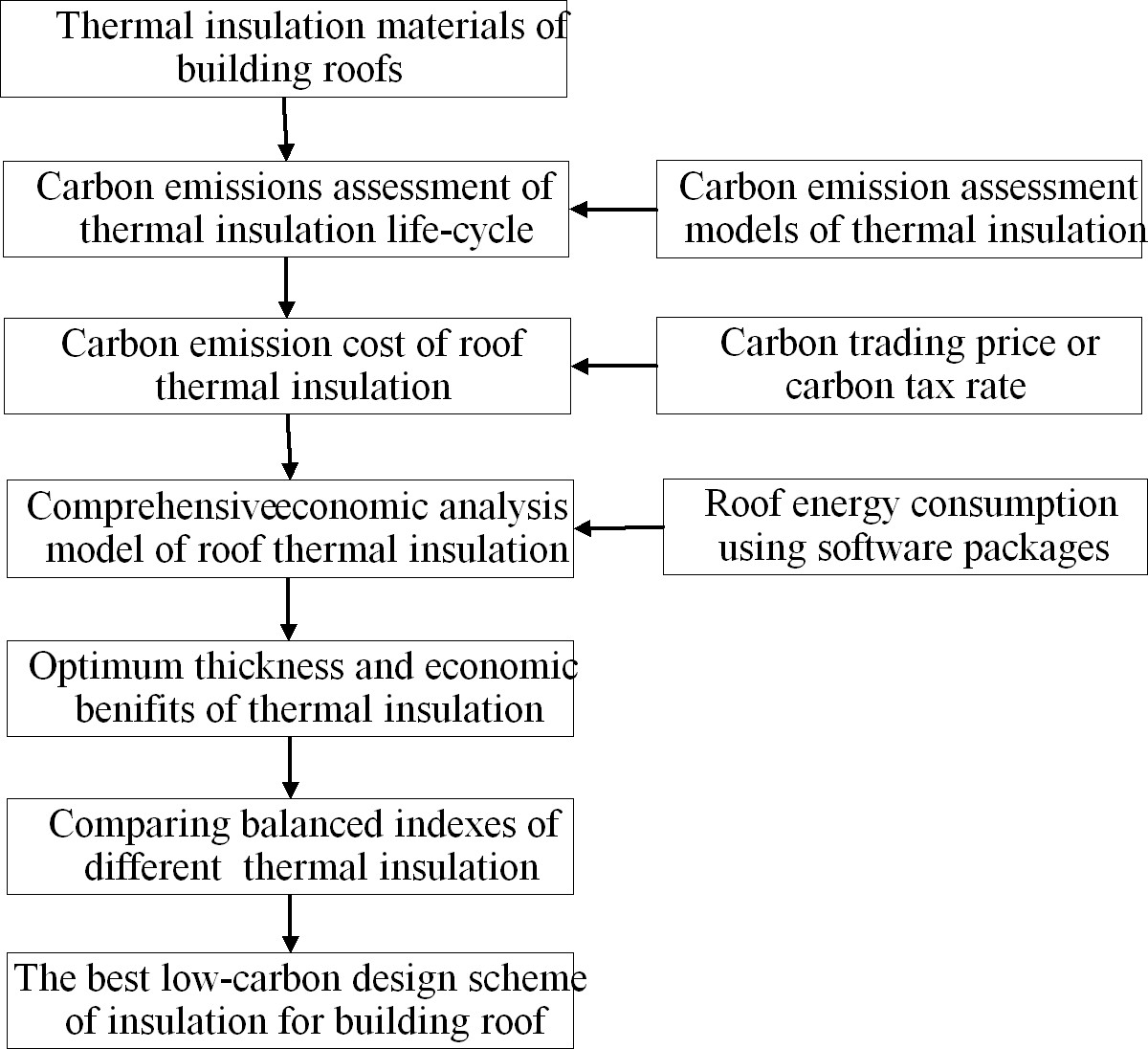

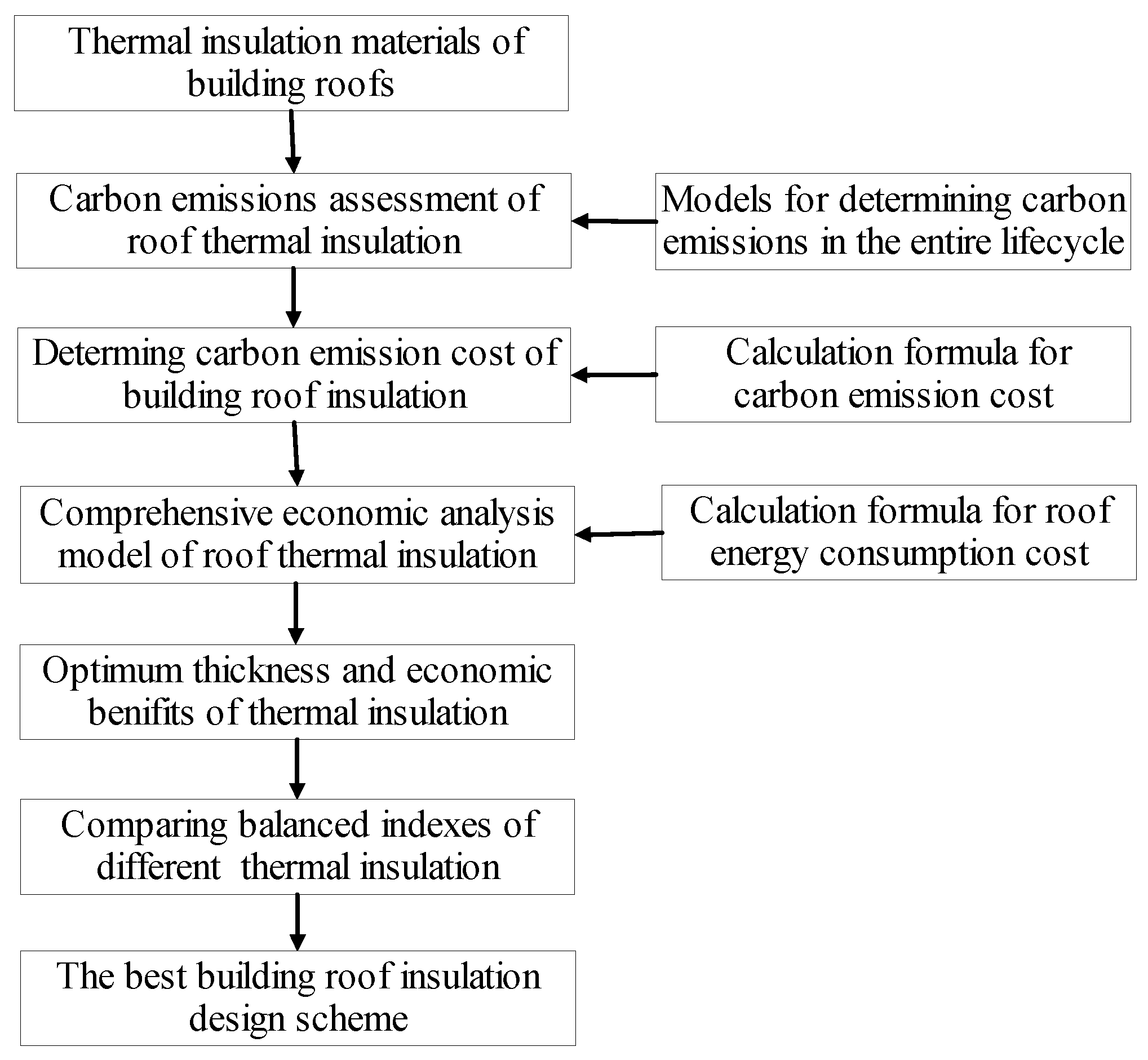

2.1. Accounting for building roof insulation optimization design method

2.2. Carbon emission of low-temperature granary roof insulation

2.2.1. Basic concepts and carbon exchange ways

2.2.2. Determination method of carbon missions for roof insulation

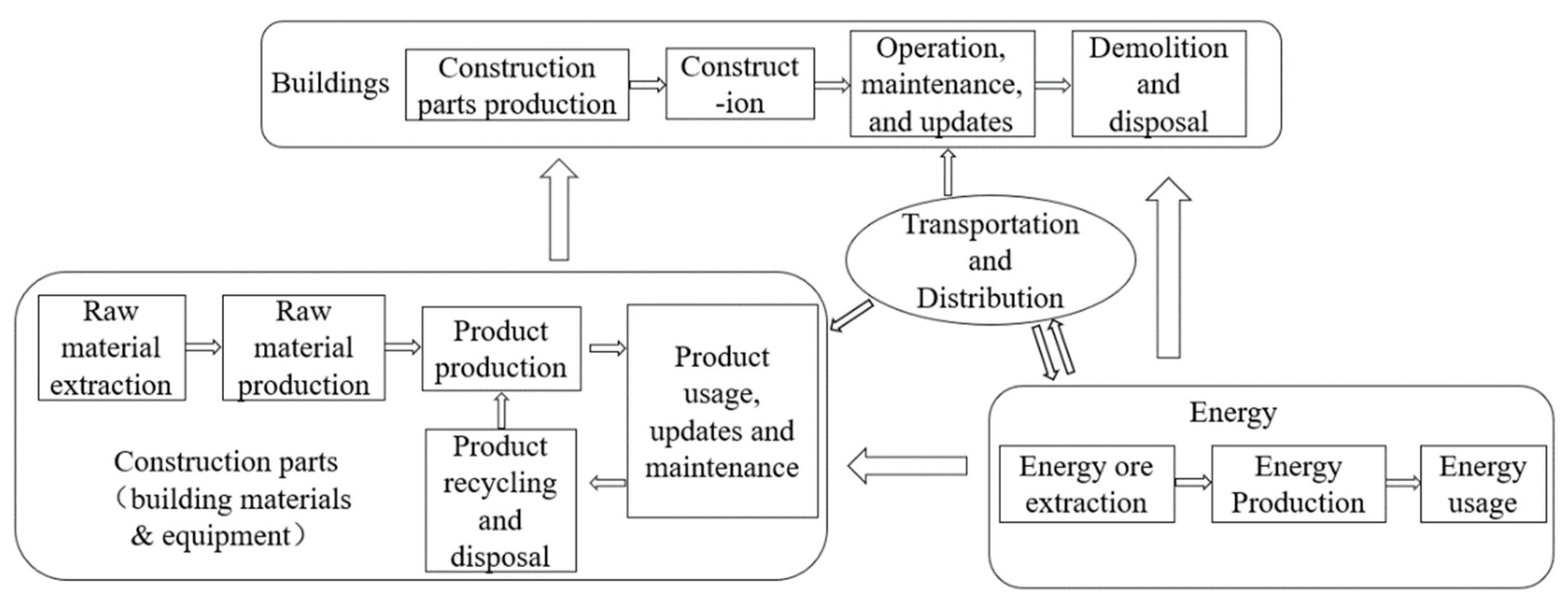

2.2.3. Building life cycle assessment

2.2.4. Life cycle carbon emission evaluation model

2.3. Comprehensive economic analysis model for roof insulation

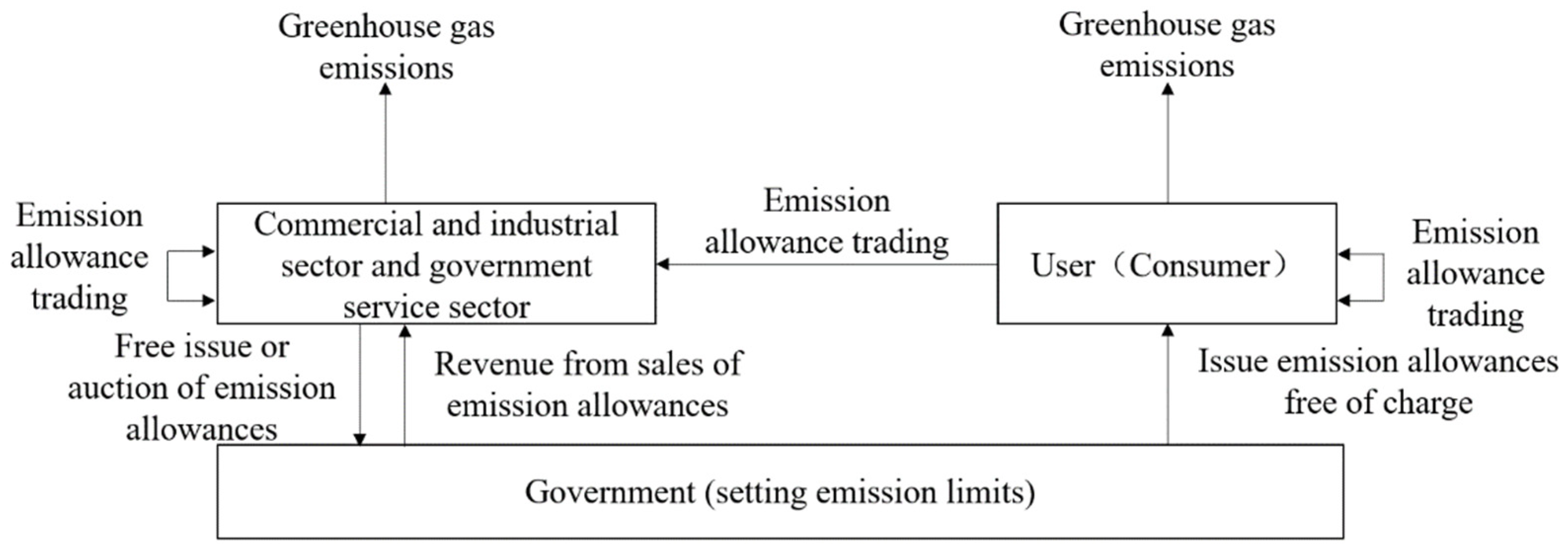

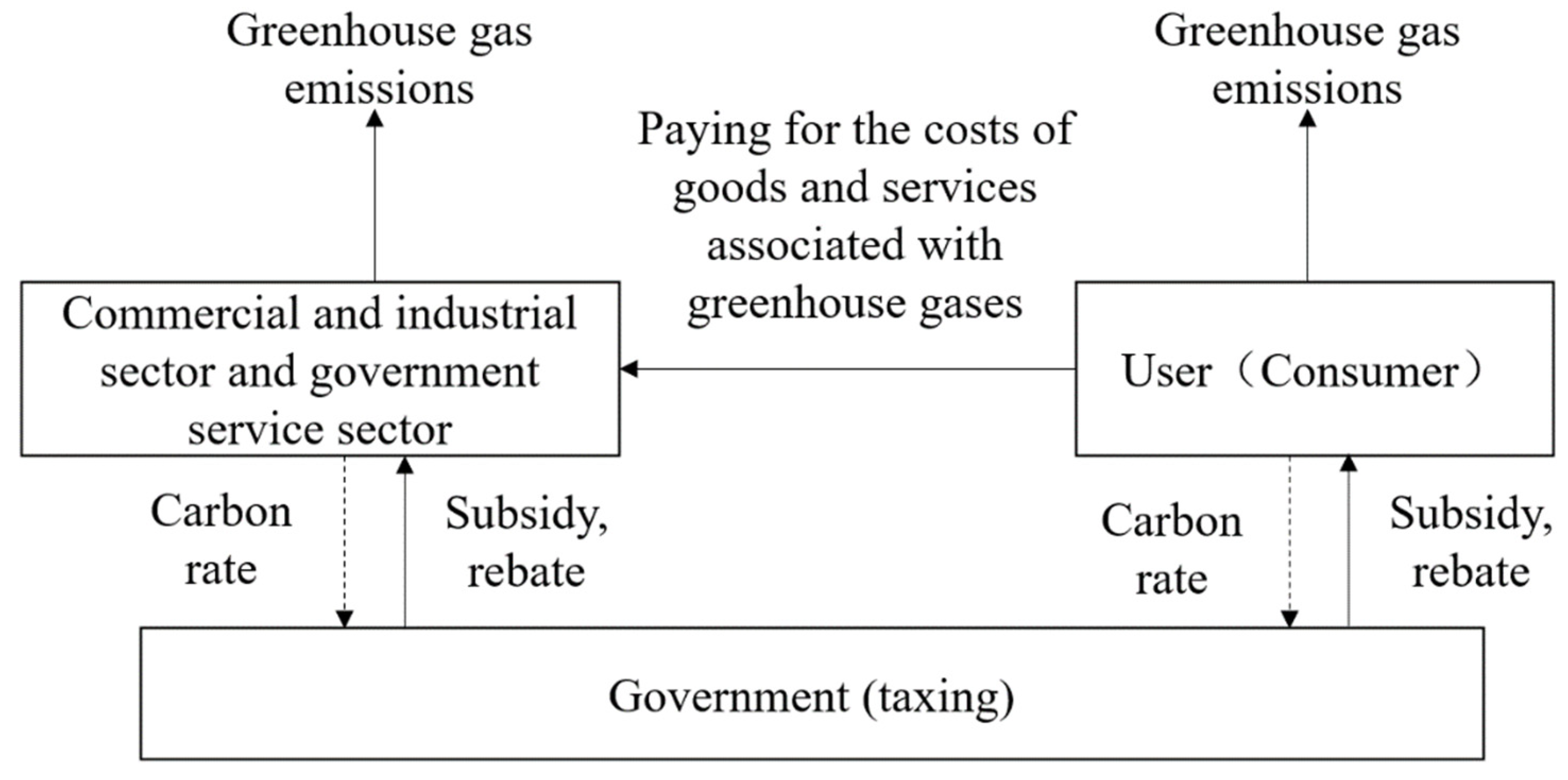

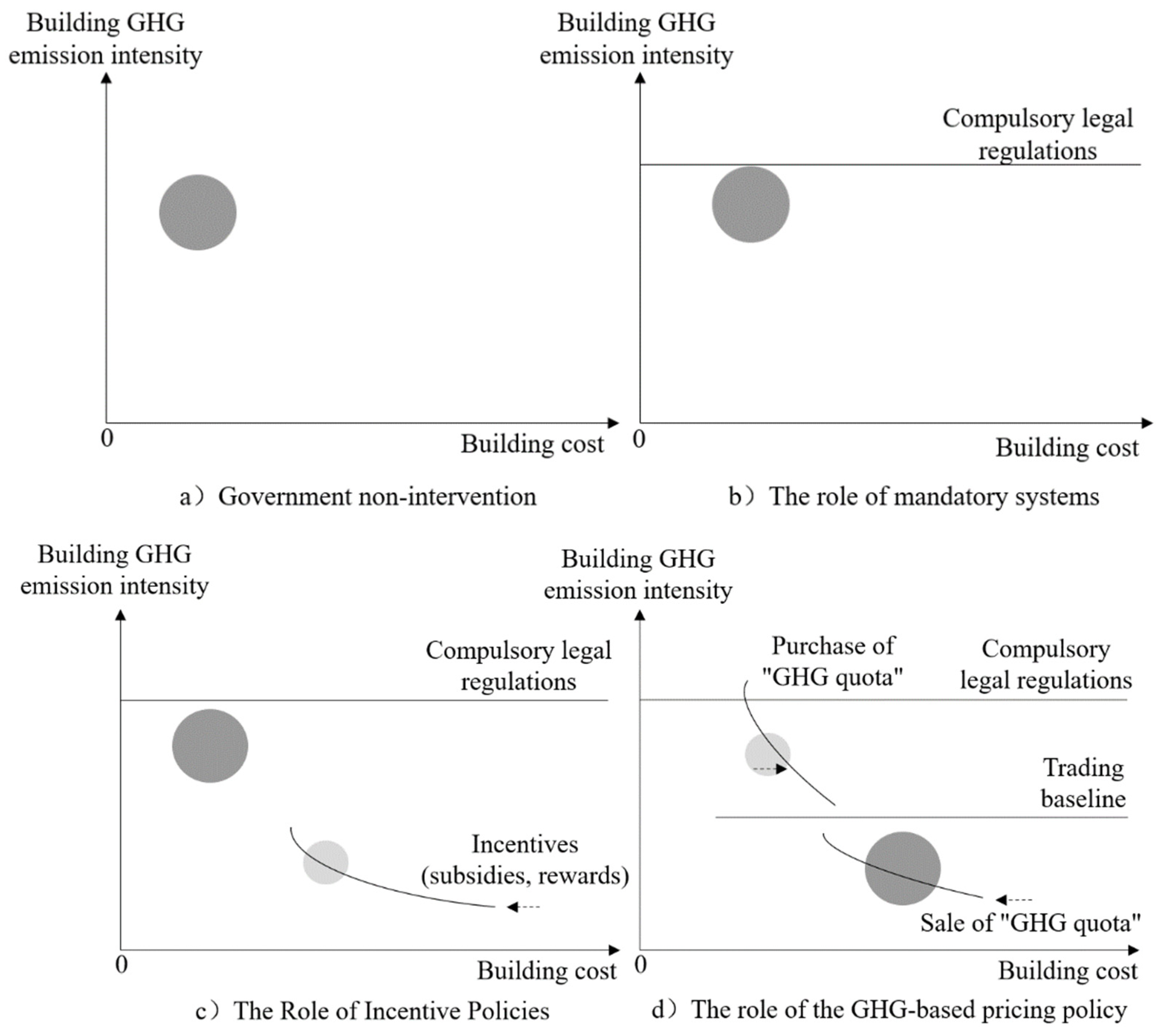

2.3.1. Carbon reduction policies and life-cycle carbon costs

2.3.2. Carbon emission costs roof thermal insulation

2.3.3. Comprehensive economic analysis model for roof insulation

2.4. Balanced index of carbon reduction effect

3. Application of optimization design method in low-temperature granary roof

3.1. Typical cities in China and concerned building

3.2. Life-cycle carbon emissions of roof thermal insulation

4. Results and discussions

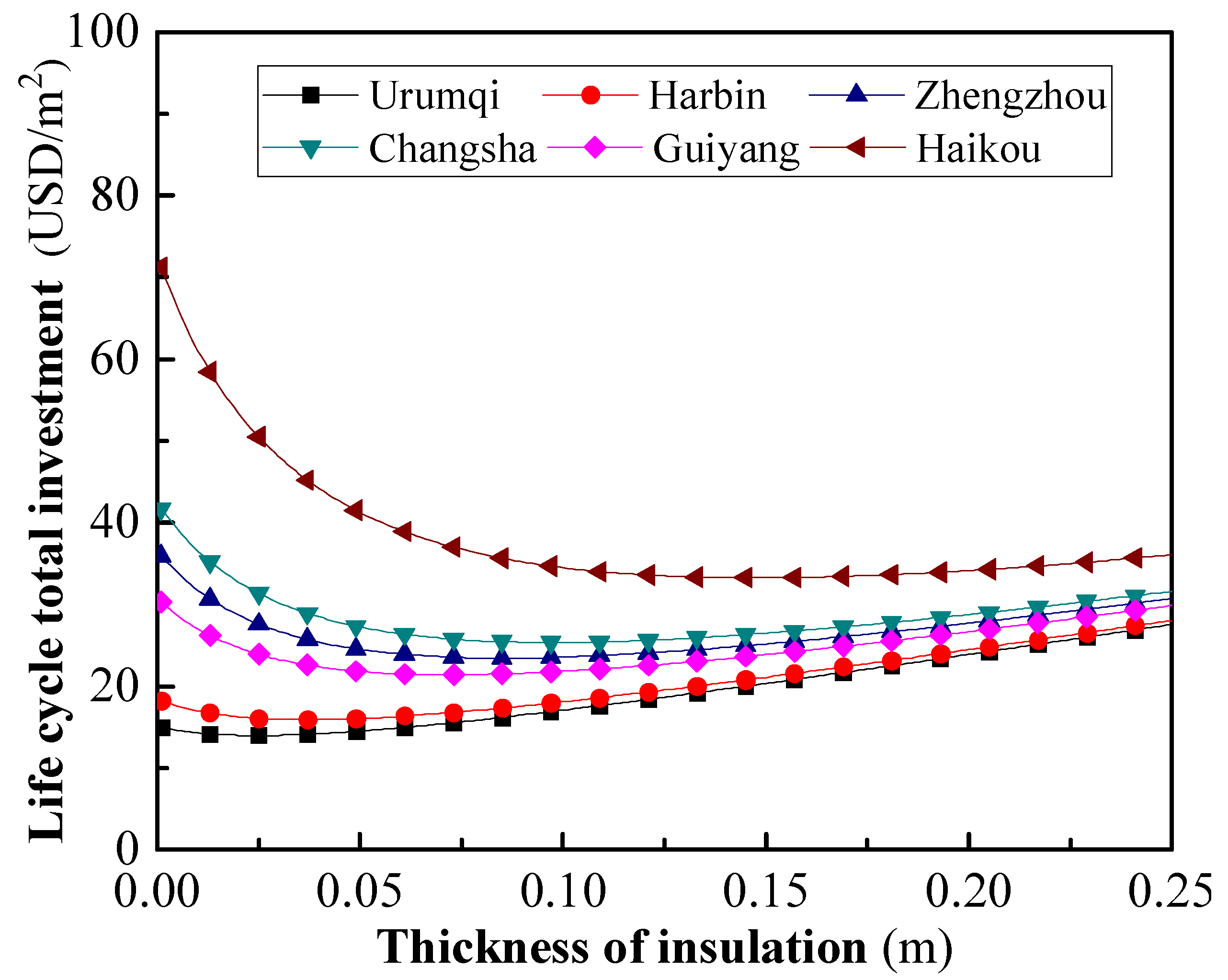

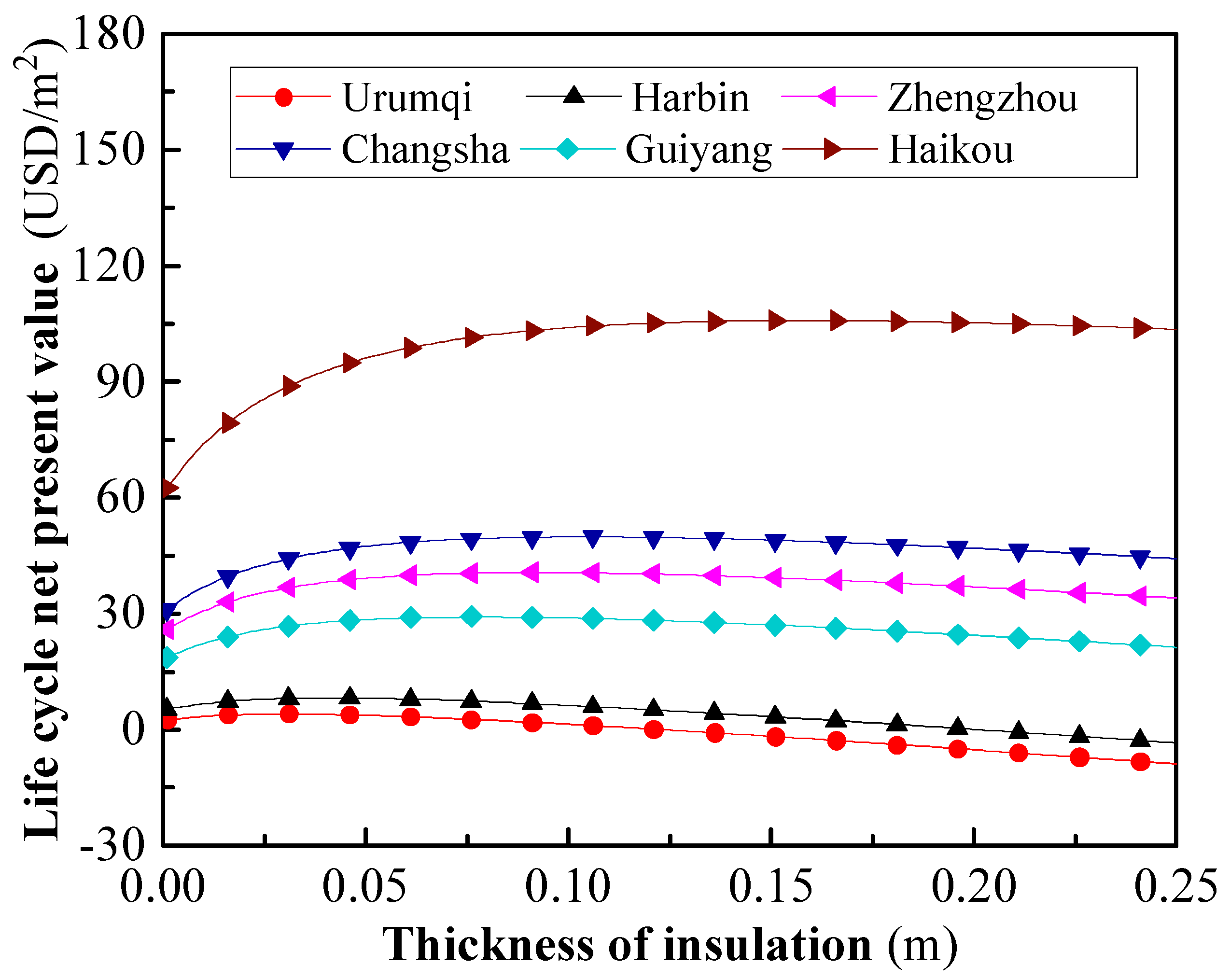

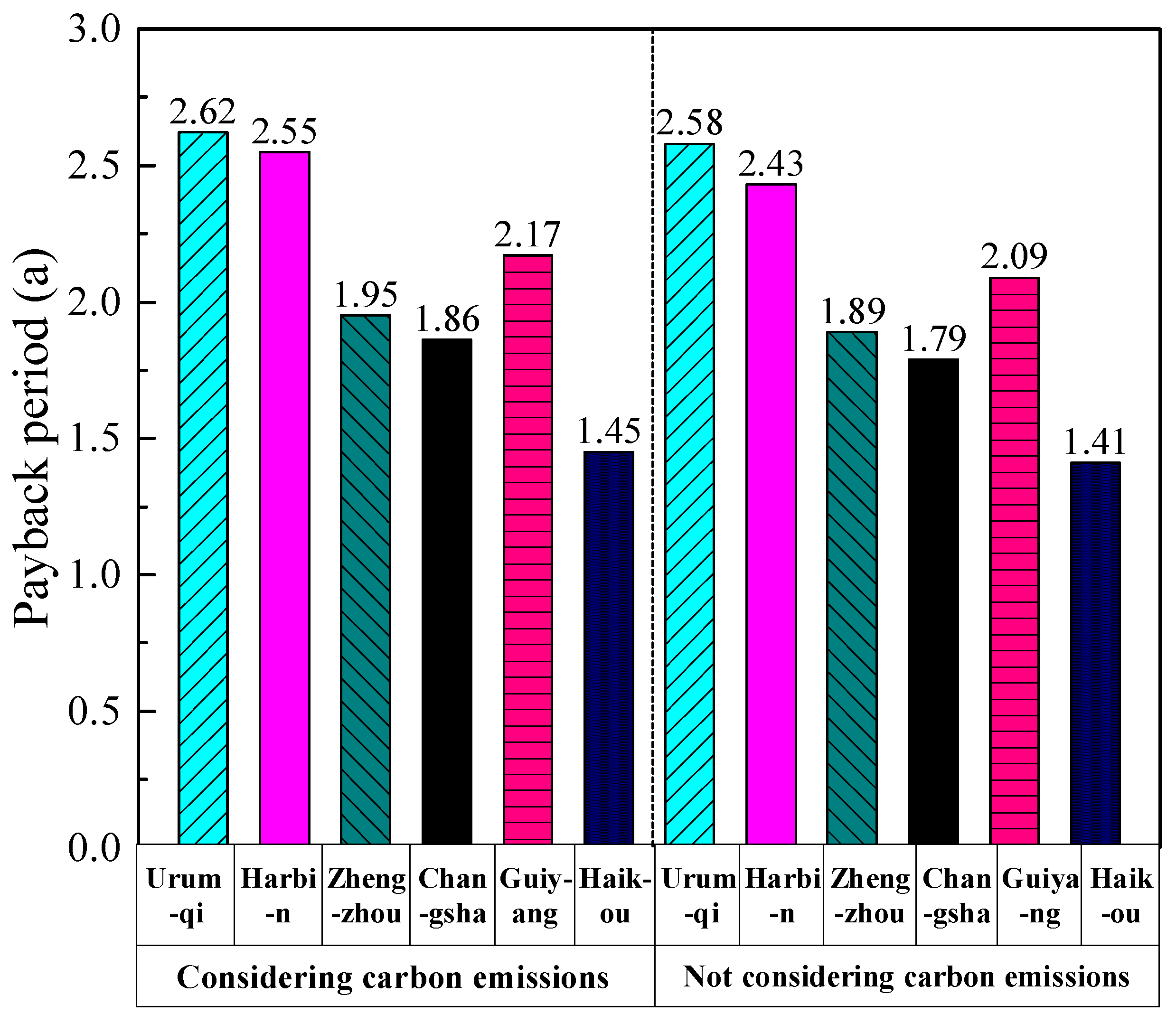

4.1. Economic performance analysis of granary roof insulation

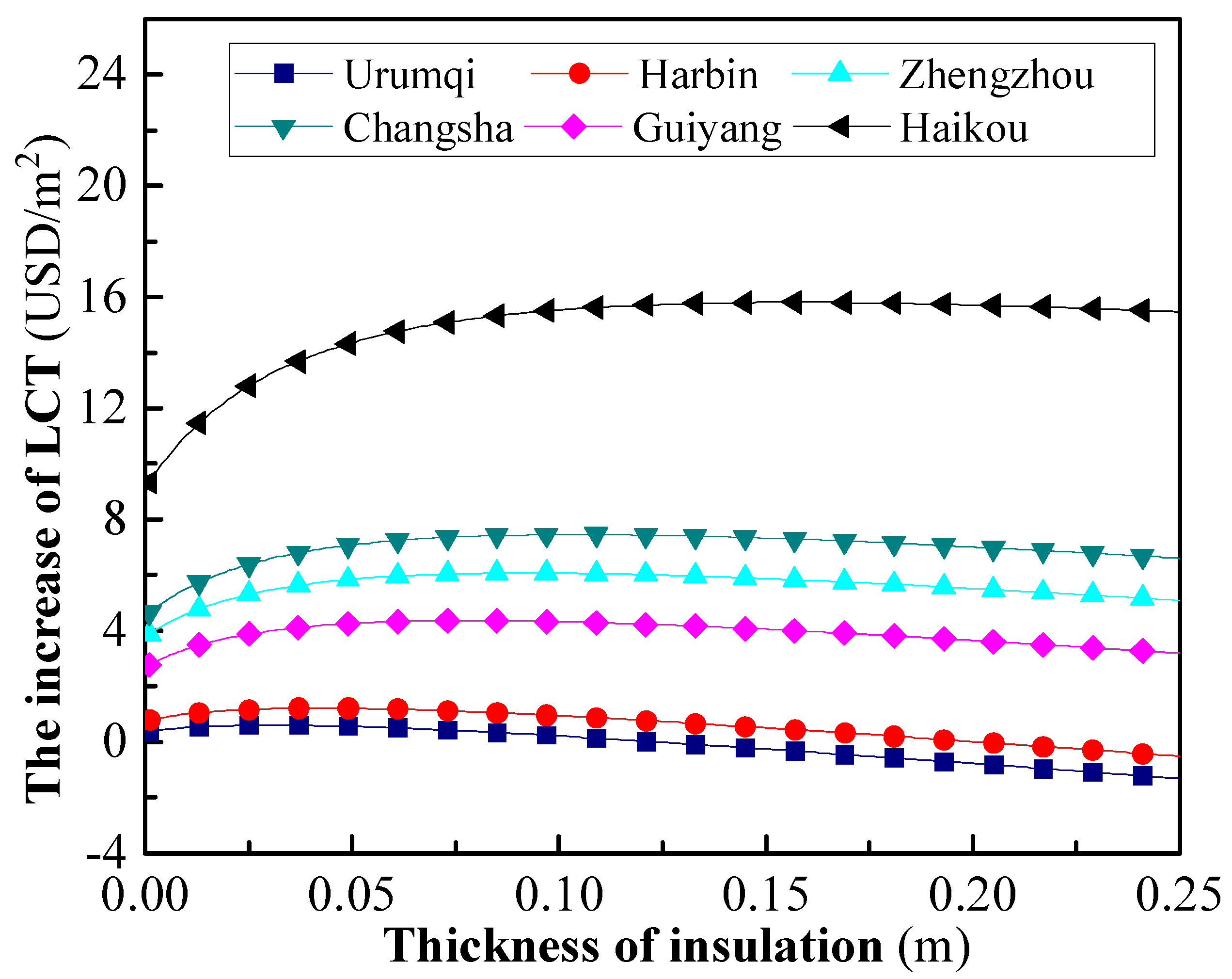

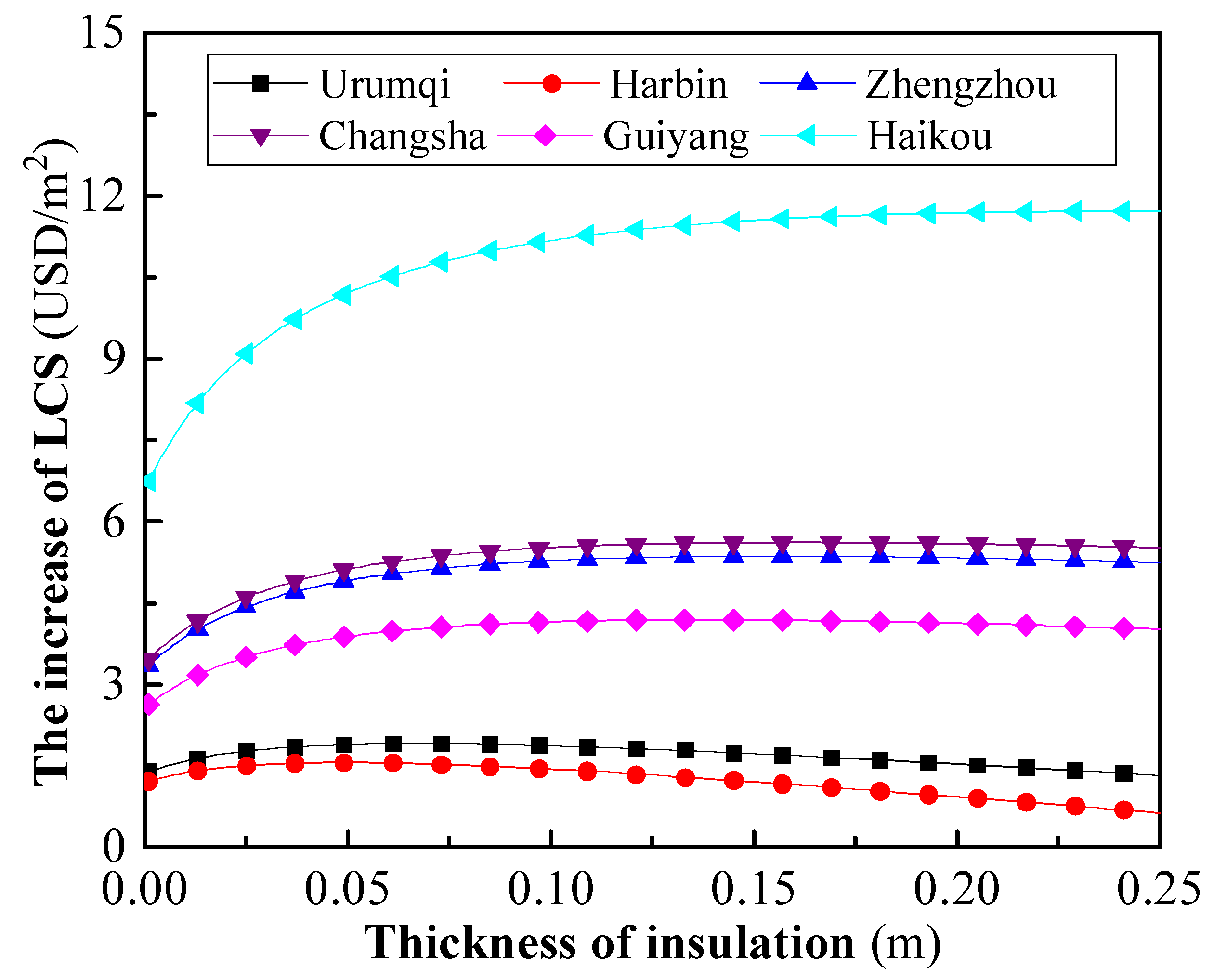

4.2. Roof insulation optimal insulation layer thicknesses

4.3. Effect of carbon emission cost on economic performance of roof insulation

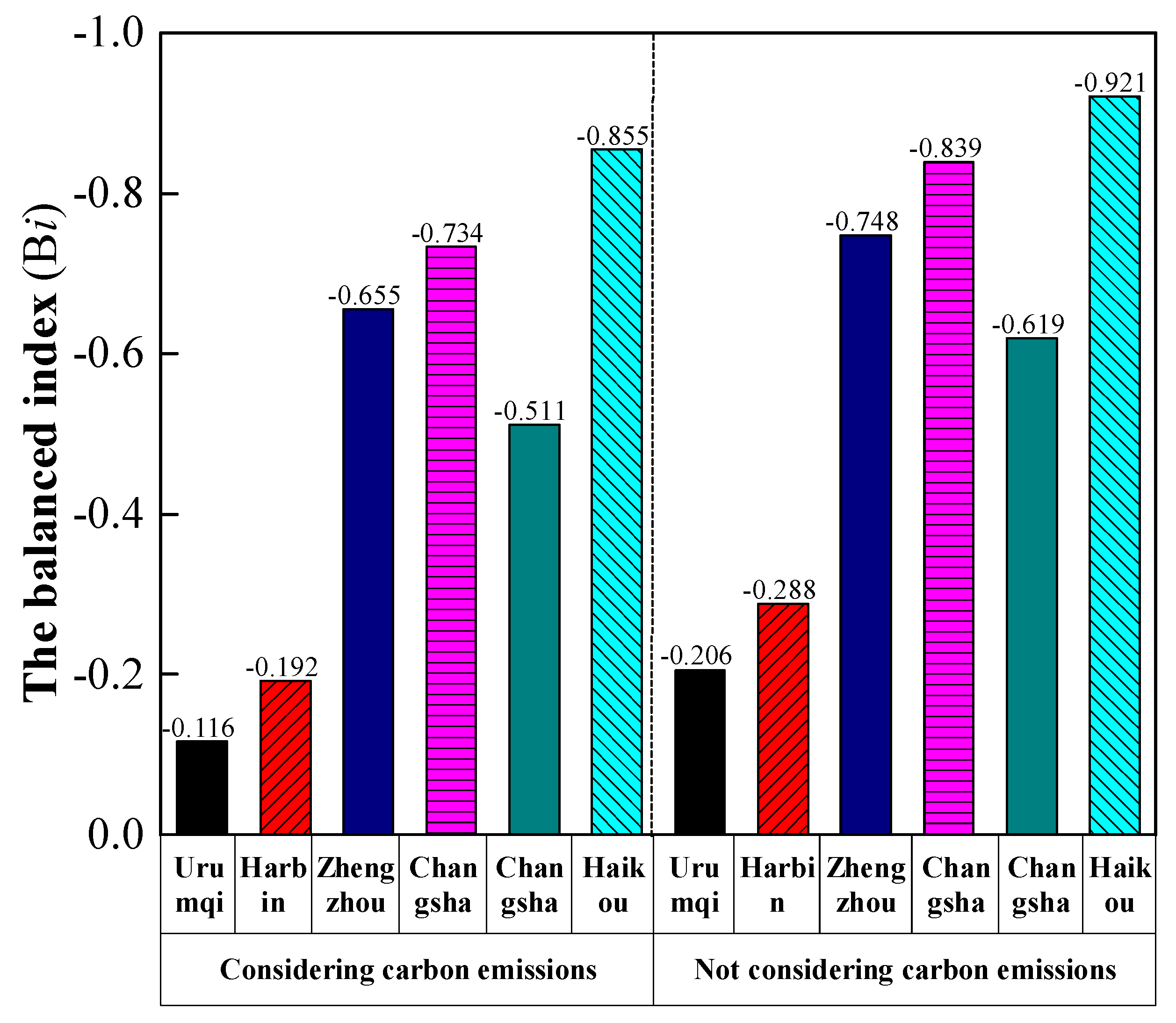

4.4. Calculated balanced indexes for different ecological grain storage zones

5. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Song, J.; Wang, W. Study on the behavior strategy of the subject of low-carbon retrofit of residential buildings based on tripartite evolutionary game. Sustainability 2023, 15, 7629. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Song, J.; Wang, Z.; Wang, W. Multi-objective optimization of ultra-low energy consumption buildings in severely cold regions considering life cycle performance. Sustainability 2022, 14, 16440. [Google Scholar] [CrossRef]

- Carcassi, O.B.; Minotti, P.; Habert, G.; Paoletti, I.; Claude, S.; Pittau, F. Carbon footprint assessment of a novel bio-based composite for building insulation. Sustainability 2022, 14, 1384. [Google Scholar] [CrossRef]

- Luo, T.; Tan, Y.T.; Langston, C.; Xue, X.L. Mapping the knowledge roadmap of low carbon building: Ascientometric analysis. Energy Build. 2019, 194, 163–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Qin, M.; Lv, M.; Li, Y. Data-based analysis of environmental attractiveness towards low-carbon development in seaside cities. Buildings 2022, 12, 2197. [Google Scholar] [CrossRef]

- Andrade, I.; Land, J.; Gallardo, P.; Krumdieck, S. Application of the InTIME methodology for the transition of office buildings to low carbon—a case study. Sustainability 2022, 14, 12053. [Google Scholar] [CrossRef]

- Yang, X.; Sima, Y.; Lv, Y.; Li, M. Research on influencing factors of residential building carbon emissions and carbon peak: a case of Henan province in China. Sustainability 2023, 15, 10243. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Zhang, Z.; Lin, K.; Zheng, M. Current Development Status, Policy Support and Promotion Path of China’s Green Hydrogen Industries under the Target of Carbon Emission Peaking and Carbon Neutrality. Sustainability 2023, 15, 10118. [Google Scholar] [CrossRef]

- Liu, C.; Sharples, S.; Mohammadpourkarbasi, H. A review of building energy retrofit measures, passive design strategies and building regulation for the low carbon development of existing dwellings in the hot summer–cold winter region of China. Energies 2023, 16, 4115. [Google Scholar] [CrossRef]

- Wei, J.; Shi, W.; Ran, J.; Pu, J.; Li, J.; Wang, K. Exploring the Driving Factors and Their Spatial Effects on Carbon Emissions in the Building Sector. Energies 2023, 16, 3094. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, H.; Li, X.; Jones, P.; Perisoglou, E. Multi - objective optimization of ultra-low energy housing in hot summer cold winter climate zone of China based on a probabilistic behavioral model. Buildings 2023, 13, 1172. [Google Scholar] [CrossRef]

- Wang, Z.L.; Zhang, S.Y.; Qiu, L.M. A new low-carbon design method based on multi-agent interactive reinforcement learning. Proc IMechE Part C: J. Mechanical. Engineering. Science 2019, 233, 539–553. [Google Scholar] [CrossRef]

- Han, Y.M.; Li, J.Z.; Lou, X.Y.; Fan, C.Y.; Geng, Z.Q. Energy saving of buildings for reducing carbon dioxide emissions using novel dendrite net integrated adaptive mean square gradient. Appl. Energy 2021, 309, 118409. [Google Scholar] [CrossRef]

- Ren, S.D.; Gui, F.Z.; Zhao, Y.W.; Zhan, M.; Wang, W.L.; Zhou, J.Q. An Extenics-based scheduled configuration methodology for low-carbon product design in consideration of contradictory problem solving. Sustainability 2021, 13, 5859. [Google Scholar] [CrossRef]

- Su, S.; Wang, Q.; Han, L.X.; Hong, J.Q.; Liu, Z.W. BIM-DLCA: An integrated dynamic environmental impact assessment model for buildings. Build. Environ. 2020, 183, 107218. [Google Scholar] [CrossRef]

- Cang, Y.J.; Luo, Z.X.; Yang, L.; Han, B. A new method for calculating the embodied carbon emissions from buildings in schematic design: Taking “building element” as basic unit. Build. Environ. 2020, 185, 107306. [Google Scholar] [CrossRef]

- Peng, J.; Li, W.Q.; Li, Y.; Xie, Y.M.; Xu, Z.L. Innovative product design method for low-carbon footprint based on multi-layer carbon footprint information. J. Clean. Prod. 2019, 228, 729–745. [Google Scholar] [CrossRef]

- Wang, Z.L.; Zhang, S.Y.; Qiu, L.M. A new low-carbon design method based on multi-agent interactive reinforcement learning. Proc IMechE Part C: J. Mechanical. Engineering. Science 2019, 233, 539–553. [Google Scholar] [CrossRef]

- Ylmen, P.; Mjornell, K.; Berlin, J.; Arfvidsson, J. Approach to manage parameter and choice uncertainty in life cycle optimisation of building design: Case study of optimal insulation thickness. Build. Environ. 2021, 191, 107544. [Google Scholar] [CrossRef]

- Mohsin, M.; Rasheed, A.K.; Sun, H.P. Developing low carbon economies: an aggregated composite index based on carbon emissions. Sustain. Energy Techn. 2019, 35, 365–374. [Google Scholar] [CrossRef]

- Mohsin, M.; Rasheed, A.K.; Sun, H.P. Developing low carbon economies: an aggregated composite index based on carbon emissions. Sustain. Energy Techn. 2019, 35, 365–374. [Google Scholar] [CrossRef]

- Habibi, S.; Valladares, O.P.; Peña, D.M. Sustainability performance by ten representative intelligent Façade technologies: A systematic review. Sustain. Energy Techn. 2022, 52(A), 102001. [Google Scholar] [CrossRef]

- Rosti, B.; Omidvar, A.; Monghasemi, N. Optimal insulation thickness of common classic and modern exterior walls in different climate zones of Iran. J. Build. Eng. 2020, 27, 100954. [Google Scholar] [CrossRef]

- Khastar, M.; Aslani, A.; Nejati, M.; Bekhrad, K.; Naaranoja, M. Evaluation of the carbon tax effects on the structure of Finnish industries: A computable general equilibrium analysis. Sustain. Energy Techn. 2020, 37, 100611. [Google Scholar] [CrossRef]

- Timilsina, G.R. Carbon tax under the Clean Development Mechanism: a unique approach for reducing greenhouse gas emissions in developing countries. Climat. Pol. 2009, 9, 139–154. [Google Scholar] [CrossRef]

- Jia, Z.; Lin, B. Rethinking the choice of carbon tax and carbon trading in China. Technolog. Forecast. Soc. 2020, 159, 120187. [Google Scholar] [CrossRef]

- Quan, B.A.I.; Shan, H.U.; Li, J.G. Interpretation of IPCC AR6 on buildings. Adv. Clim. Chang. Res. 2022, 18, 557. Available online: http://www.Climatechange.cn/EN/Y2022/V18/I5/557.

- Garbaccio, R.F.; Ho, M.S.; Jorgenson, D.W. Controlling carbon emissions in China. Environ. Dev. Econ. 1999, 4, 493–518. [Google Scholar] [CrossRef]

- Li, D.Z.; Chen, H.X.; Hui, E.M.; Zhang, J.B.; Li, Q.M. A methodology for estimating the life-cycle carbon efficiency of a residential building. Build Environ. 2013, 59, 448–455. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wang, F.L. Life-cycle assessment and control measures for carbon emissions of typical buildings in China. Build. Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Liu, J.Y.; Zhang, Y.J. Has carbon emissions trading system promoted non-fossil energy development in China. Appl. Energ. 2021, 302, 117613. [Google Scholar] [CrossRef]

- Lou, Y.L.; Yang, Y.Z.; Ye, Y.Y.; He, C.; Zuo, W.D. The economic impacts of carbon emission trading scheme on building retrofits: A case study with U. S. medium office buildings. Build. Environ. 2022, 221, 109311. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar energy thermal processes. Physics Today 1976, 29(4), 62–67. [Google Scholar] [CrossRef]

- FRED economic Data, Interest rates, Discount rate for China. Available online: https:// fred. stlouisfed. org/ series/ INTDSRCNM193N (accessed on 21 July 2020).

- Trading Economics, China inflation rate, 2020. Available online: https://tradingeconomics. com/ china/ inflation - cpi (accessed on 21 July 2020).

- Yu, J.H.; Yang, C.Z.; Tian, L.W.; Liao, D. A study on optimum insulation thicknesses of external walls in hot summer and cold winter zone of China. Appl. Energ. 2009, 86(11), 2520–2529. [Google Scholar] [CrossRef]

- Li, D.Z.; Chen, H.X.; Hui, E.C.M.; Zhang, J.B.; Li, Q.M. A methodology for estimating the life-cycle carbon efficiency of a residential building. Build Environ 2013, 59, 448–455. [Google Scholar] [CrossRef]

- Zhang, X.C.; Wang, F.L. Life-cycle assessment and control measures for carbon emissions of typical buildings in China. Build Environ 2015, 86, 89–97 https://doi org/101016/jbuildenv201501003. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: an overview. Energy Build 2010, 42(10), 1592–1600. [Google Scholar] [CrossRef]

- Zhao, S.; Zhu, Y.; Lou, P.; Hu, Y.; Xu, C.; Chen, Y. Optimization model of substation building envelope–renewable energy utilization based on life-cycle minimum carbon emissions. Buildings 2023, 13, 1602. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, W.; Xu, X.; Deng, R.; Ding, X.; Chen, T. Analysis of carbon emission reduction paths for the production of prefabricated building components based on evolutionary game theory. Buildings 2023, 13, 1557. [Google Scholar] [CrossRef]

- Jia, Z.; Lin, B. Rethinking the choice of carbon tax and carbon trading in China. Technolog. Forecast. Soc. 2020, 159, 120187. [Google Scholar] [CrossRef]

| Layers | Material name | Thermal conductivity (W/m·K) | Density (kg/m3) | Specific heat capacity(J/kg·K) | Thickness (mm) |

|---|---|---|---|---|---|

| 1 | Waterproof layer | 0.23 | 900 | 1620 | 5 |

| 2 | Cement mortar | 0.93 | 1800 | 1050 | 20 |

| 3 | EPS | 0.039 | 25 | 1380 | 30 |

| 4 | Cement mortar | 0.93 | 1800 | 1050 | 20 |

| 5 | Cement slag | 0.26 | 900 | 920 | 100 |

| 6 | Reinforced concrete | 1.74 | 2500 | 920 | 120 |

| 7 | Cement mortar | 0.93 | 1800 | 1050 | 25 |

| Typical city | Number of days for average temperature > 5℃ | Cooling load without insulation (MW/m2) | Cooling load With insulation (MW/m2) |

|---|---|---|---|

| Xining | 0-30 | - | - |

| Urumqi | 112-194 | 211.514328 | 64.965168 |

| Harbin | 55-122 | 186.863112 | 58.068504 |

| Zhengzhou | 143-192 | 496.436294 | 149.47992 |

| Changsha | 121-253 | 518.710788 | 158.03532 |

| Guiyang | 173-224 | 399.005784 | 122.57575 |

| Haikou | 289-352 | 1017.59494 | 312.38114 |

| Insulation type | Insulation stage | Carbon emissions(tCO2e/m3) | Carbon emission cost (USD/m3) |

|---|---|---|---|

| EPS | Production | 4.5E-01 | 3.73E+00 |

| Transportation | 2.1E-05 | 1.73E-04 | |

| Construction | 5.6E-04 | 4.60E-03 | |

| Demolition | 5.0E-04 | 4.11E-03 | |

| Disposal stage | 7.0E-05 | 5.75E-04 | |

| Total | 4.51E-01 | 3.74E+00 | |

| XPS | Production | 6.3E-01 | 5.22E+00 |

| Transportation | 2.9E-05 | 2.39E-04 | |

| Construction | 5.6E-04 | 4.6E-03 | |

| Demolition | 5.0E-04 | 4.11E-03 | |

| Disposal stage | 9.7E-05 | 7.98E-04 | |

| Total | 6.31E-01 | 5.23E+00 | |

| PU | Production | 7.5E-01 | 6.22E+00 |

| Transportation | 2.9E-05 | 2.39E-04 | |

| Construction | 5.6E-04 | 4.6E-03 | |

| Demolition | 5.0E-04 | 4.11E-03 | |

| Disposal stage | 8.3E-05 | 6.83E-04 | |

| Total | 7.51E-01 | 6.23E+00 | |

| RW | Production | 5.5E-01 | 4.56E+00 |

| Transportation | 4.8E-05 | 3.94E-04 | |

| Construction | 4.6E-04 | 3.78E-03 | |

| Demolition | 4.1E-04 | 3.38E-03 | |

| Disposal stage | 1.6E-05 | 1.31E-04 | |

| Total | 5.51E-01 | 4.57E+00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).