1. Introduction

In the past, consuming liquids like milk, juice or water that were a few days old could lead to serious illnesses or death. However, with the advent of pasteurization, a process named after the 19th century French scientist Louis Pasteur, todayʹs beverages have a much longer shelf life and are safe to consume.

Louis Pasteur, a French chemist, in 1864, conducted experiments which proved the effectiveness of heating wine as a way to kill off harmful bacteria. By heating recently made wine to around 60 C (140 F) for a short duration, he was able to eliminate pathogens that could have been present in the wine. He also inactivated enzymes that cause the wine to spoil quickly.

Before Pasteur, there were recorded instances of exposing wine to high temperatures to increase its shelf life. Artifacts from 12th-century China and 15th to 17th-century Japan have documented evidence of these methods

Pasteurization is a process that involves heating food products such as juice and dairy to eliminate harmful bacteria, pathogens, and diseases. This makes them safe for consumption. On the other hand, unpasteurized food, like raw milk, may also be safe to consume, but for a shorter period. The implementation of pasteurization has significantly improved food safety in the dairy industry. In 1973, the FDA made it mandatory for all dairy products sold across states to undergo pasteurization. Currently, almost all milk products sold in stores have gone through this process

There are many different levels and methods of pasteurization, which vary based off the temperatures used to heat up a product and the amount of time spent doing so. Deciding on what pasteurization method to use largely depends on the type of product you’re working with. When it comes to pasteurizing dairy products such as milk and cream, two of the most common types are vat pasteurization and HTST pasteurization.

Pasteurization is a heat treatment process named after the French microbiologist Louis Pasteur. The process was invented in the 1860s as a way to preserve food and beverages and prevent spoilage caused by microorganisms such as bacteria, yeast, and molds.

The concept of pasteurization is based on the idea that by heating a product to a high enough temperature for a sufficient amount of time, harmful microorganisms can be eliminated, thus extending the shelf life of the product. At the time of its invention, pasteurization was a major breakthrough in the food industry and greatly reduced the spread of food-borne illnesses.

Pasteur initially developed the process while studying the spoilage of wine and beer. He discovered that heating the liquids to a temperature of around 63-65°C for a few minutes could kill the spoilage microorganisms and prevent further fermentation. This process, known as "Pasteurization," quickly became popular in the dairy industry for preserving milk and other dairy products.

Today, pasteurization is used in a wide range of food and beverage products, including milk, fruit juices, and canned goods. There are different methods of pasteurization, including high- temperature short-time (HTST) pasteurization, where the product is heated to a high temperature for a brief time, and ultra-pasteurization (UP), where the product is heated to a higher temperature for a shorter period of time.

In conclusion, pasteurization is a critical process in the food industry that has helped prevent food spoilage and the spread of food-borne illnesses for over a century. The process is named after Louis Pasteur, who invented it while studying the spoilage of wine and beer, and it has since been adopted and adapted for use in a wide range of food and beverage products.

2. Literature Review

Irene R. Grant, Edward I. Hitchings, Alan McCartney, Fiona Ferguson and Michael T. Rowe, “Effect of Commercial-Scale High-Temperature, Short-Time Pasteurization on the Viability of Mycobacterium paratuberculosis in Naturally Infected Cows’ Milk”26th November 2001.This works proposes Raw cowsʹ milk infected with Mycobacterium paratuberculosis was pasteurized using a commercial scale pasteurizer. Milk was subjected to 4 different pasteurization treatments and tested for M. paratuberculosis after decontamination. Results showed that M. paratuberculosis bacteria were capable of surviving pasteurization if present in large numbers. Homogenization increased lethality to some extent but the extended 25-s holding time was not more effective than the 15-s holding time.

I.R. Grant, H.J. Ball and M.T. Rowe, “Effect of higher pasteurization temperatures, and longer holding times at 72°C, on the inactivation of in milk January 1999. works Milk spiked with was treated at various temperatures (72 to 90°C) and holding times (15s to 25s) using lab pasteurizing units. 3 strains of the bacterium were studied (NCTC 8578, B2, and DVL 943) and subjected to all treatments 3 times. Results showed that while substantial reductions were achieved, a portion of the bacteria survived up to 90°C for 15s. A longer holding time of 25s at 72°C was found to be more effective. Only one of the three strains survived after 20s at 72°C but was inactivated after 25s. The conclusion is that a longer holding time is more effective in inactivating . in milk.

A. , L. , S. Chen, K. and J. Odumeru, “Effect of Pasteurization on Survival of in Milk”29-July 2002. work proposes () is responsible for Johneʹs disease in cattle, goats, and sheep and may be linked to Crohnʹs disease in humans. 18 pasteurization experiments were conducted with raw or ultra-high temperature milk spiked with at different levels. Results showed that may survive high temperature short time (HTST) pasteurization when present at ≥105 /ml, but no survivors were isolated from 710 retail milk samples tested by nested IS900 PCR.

IRENE R. GRANT, HYWEL J. BALL, SYDNEY D. NEILL AND MICHAEL T. ROWE, "Inactivation of in Cows’ Milk at Pasteurization Temperatures" 13-Nov 1995, This work proposes the inactivation of 11 strains of M. at pasteurization temperatures was studied using cowʹs milk inoculated with the bacterium at two levels. The pasteurization was done in a laboratory using two methods: the standard holder method (63.5&C for 30 min) and the high-temperature, short- time (HTST) method (71.7&C for 15 s). The thermal death curve for M. was found to be concave, showing rapid initial death followed by significant "tailing." The results suggest that large numbers of M. in milk may not be fully inactivated by the two pasteurization methods under laboratory conditions.

Micaela Belen Calahorrano-Moreno, Jonathan Jerry Ordoñez-Bailon, Ricardo José Baquerizo- Crespo, Alex Alberto Dueñas-Rivadeneira, Maria B S M MontenegroJoan Manuel Rodríguez-Díaz, “Contaminants in the cowʹs milk we consume & Pasteurization and other technologies in the elimination of contaminants”.25-January 2022 Cowʹs milk is a widely consumed product globally but can contain chemical and microbiological contaminants. This review examines the major contaminants in cowʹs milk, their sources, and impact on human health. The ineffectiveness of pasteurization in eliminating contaminants and the need for alternative treatment methods are highlighted. New technologies are being explored as alternatives to pasteurization, but they are not entirely effective and require further research to improve food safety.

V.H. K.T. & J.R. “Milk pasteurization and safety: a brief history and update”.1997-A summary of the history of milk pasteurization is provided and updated. The current pasteurization standardsʹ ability to protect against milk-borne pathogens such as , Listeria , and Escherichia 0157:H7 is discussed and found to be inadequate. The standards are considered adequate for public health assurance if good manufacturing practices are followed, except for the of Bacillus .

3. Methods

- 1.

Milk chilling:

Milk chilling is a crucial step in handling large volumes of milk, although it is not a pasteurization process. Milk leaves the cowʹs udder at elevated temperatures, promoting rapid bacterial growth and speeding spoilage. But, reducing the temperature to 2°C to 5°C slows bacterial growth and metabolism, preserving the quality of the milk before pasteurization.

- 2.

Pre-heating and standardization stage:

In the (regeneration) and Standardization Stage, chilled milk is heated to 40°C after bulking to simplify butterfat separation during standardization. The process utilizes regenerative heating, using the heat from the pasteurized milk to warm the incoming chilled milk in a counter-current flow that cools the pasteurized milk. The goal of standardization is to achieve a uniform butterfat content in the product.

- 3.

Clarification stage:

Clarification is crucial for removing any foreign matter from the product. Large solid particles are filtered out by straining the milk through tubular metal filters. A different type of centrifugal is used to eliminate soil and sediments from the milk. The filters, typically in twin sets, enable continuous processing as one can be cleaned while the other is in use. Clean the filters regularly, every 2 to 10 hours depending on dirt levels, to prevent bacterial growth.

- 4.

Standardization stage:

Standardizing milk fat is important to ensure consistent quality in the market and cater to different consumer preferences. Some customers prefer skim milk, others low-fat, standardized, or high-fat milk. Standardization meets the demands of all customers and allows for separation of the butterfat used to make cream, butter, ghee, and other fat-based products.

- 5.

Homeogenizationstage :

Homogenization is a physical process that reduces milk fat globules into small droplets to prevent cream separation. The small droplets, now denser, do not rise in a milk column. A milk , operating at 100 to 170 bars, splits the fat globules into very small droplets, increasing fat integration in the milk. As a result, the milk fat stays uniformly dispersed in the milk.

- 6.

Heating section :

Uses steam heat to raise milk temperature from 60°C to the required 72°C to kill botulinum spores. Heat is exchanged between steam and milk through PHE plates in a counter-current flow. A temperature sensor at the end controls a flow diversion valve, redirecting any milk that doesnʹt reach the required temp back to the heating section until it does.

- 7.

Holding section :

After being heated, milk enters tubes calibrated to hold it for at least 16 secs at the pasteurization temp. If temp falls below requirement, a sensor redirects milk back to the heating section. After meeting temp requirement, milk returns to the regeneration section to heat incoming chilled milk and cool itself to around 30°C

- 8.

Cooling section:

The pasteurized milk undergoes regenerative cooling and is then transferred to the cooling section of the plate heat exchanger (PHE). Here, the temperature of the milk is reduced to 4°C through the use of chilled water or PHE coolant. The cooled milk is then transported to the packaging machines for sterile packaging and storage in the refrigeration room.

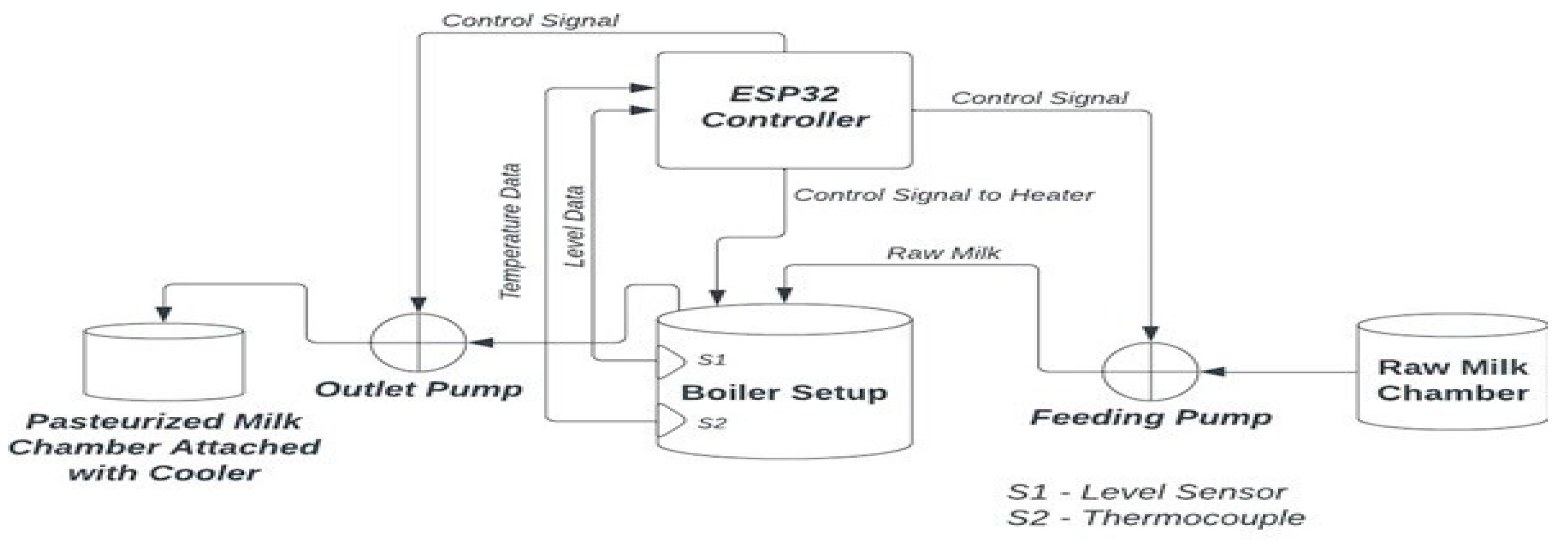

4. System Architecture

Initially, raw milk is held in a raw milk chamber. When the pump is turned on, it will suck the raw milk from the raw milk chamber and transfer it to the boiler setup. The milk level in boiler setup will be continuously monitored by an ultrasonic level sensor. When the level of milk reaches a distance of 3 cm or less, which is the distance between the sensor and the raw milk, the motor will be turned off using a relay switch. This ensures that there is no further flow of milk from raw milk chamber to boiler setup.

Once the milk has reached a certain level in the boiler setup, the heater needs to be turned on. A relay switch will be used to turn on the heater. The temperature of the milk will be continuously detected by a thermocouple k type sensor that is in contact with the milk.

According to the HTST (High-Temperature Short-Time) pasteurization method, the milk needs to be heated to 72 degrees Celsius and held at that temperature for 15 seconds. The heater will remain active until it reaches 72 degrees Celsius. Once the milk has reached this temperature and has been held there for 15 seconds, the heater will be turned off using the relay switch.

At the same time, the exit motor pump will be turned on. The heated milk will be sucked and transferred to the cooler section, where it will be cooled down to 20 degrees Celsius. This cooling process is essential to prevent further growth of any remaining bacteria.

In this process, ice cubes are used as a cooling agent to lower the temperature of the heated milk. As the milk passes through the cooling section, the ice cubes absorb the heat, resulting in a temperature drop to around 10-20 degrees Celsius. The milk is effectively cooled down by transferring heat to the ice cubes.. The milk is initially heated in a boiler setup, and then is moved through the system using an exit motor pump. The pump creates a pressure difference that allows the milk to flow from the boiler setup to the coolant section.

Once the heated milk reaches the coolant section, it is surrounded by ice cubes, which act as the cooling agent. The heat of the milk is absorbed by the surrounding ice cubes, causing the temperature of the milk to drop to 4 deg Celsius. This cooling process occurs through a transfer of heat from the milk to the ice cubes. The cooled milk is then available for use in further processes or for consumption.

Overall, this process is an effective way to rapidly cool heated milk, and the use of an ice box as a coolant is a simple and reliable method for achieving this cooling effect

After the pasteurization process, the milk is ready to be supplied on the market, free from any harmful bacteria that may have been present in the raw milk.

5. Results

Figure 2 depicts a setup involving a sensor and a boiler. In this setup, the distance between the sensor and the boiler is set to 12cm. When a motor is turned on, it causes water from a chamber to be sucked into the boiler setup.

As the water level in the boiler increases, the distance between the sensor and the water level gradually decreases from 12cm to a lower value. The sensor continuously monitors this distance.

Once the water level in the boiler reaches 3.5cm or less, the water pumping motor will be automatically turned off. At this point, the sensor will no longer provide any data, as the water level has reached the minimum threshold.

The graph provided in the content likely depicts the relationship between the distance between the sensor and the water level over time. This graph would likely show the distance decreasing until it reaches the minimum threshold, at which point it would remain constant (since the sensor is no longer providing data).

Overall, this setup appears to be some type of automated water level control system for the boiler. By monitoring the distance between the sensor and the water level, the system is able to automatically turn off the water pumping motor when the water level reaches a certain threshold.

the milk is heated using a heater that is triggered as soon as the water level reaches the set threshold. At the start of the heating process, the water used for heating is at room temperature, which is typically around 30 degrees Celsius as shown in the

Figure 3.

Once the heater is turned on, the temperature of the milk will gradually increase over time. The heating process is carefully monitored to ensure that the milk is heated to the desired temperature for pasteurization.

According to the HTST (High Temperature Short Time) pasteurization method, the milk needs to be heated up to 72 degrees Celsius and held at that temperature for 15 seconds to effectively kill harmful bacteria. To achieve this, we have set the threshold temperature for the heating process to begin at 38 degrees Celsius.

Once the milk reaches the threshold temperature of 38 degrees Celsius, it will be held at that temperature for 15 seconds to ensure that it is effectively pasteurized. The temperature during this period will be closely monitored using a thermocouple K sensor to ensure that the milk remains at the desired temperature of 72 degrees Celsius for the entire 15-second duration.

Overall, the proposed system is designed to ensure that the milk is heated and pasteurized effectively using the HTST method. By carefully monitoring the temperature during the heating and holding process, we can ensure that harmful bacteria are effectively eliminated from the milk, making it safe for consumption.

6. Conclusion and Future Work

Currently, level data and temperature data were collected locally using the serial monitor. However, there are limitations to this approach as it requires physical presence to activate or deactivate the system and monitor the process. To overcome these limitations, cloud storage to enable remote access and monitoring of the data, regardless of the userʹs location may be implemented.

By utilizing cloud storage with popular cloud service providers such as Amazon AWS or Google Cloud, the details about store, manage, and access the collected data from anywhere with an internet connection is possible. This eliminates the need for physical presence to interact with the system and provides the flexibility to monitor and manage the data remotely.

With cloud storage, the data collected from the system can be securely stored in the cloud, ensuring data integrity and availability. Authorized users can access the data through web-based dashboards, mobile apps, or other interfaces provided by the cloud service providers. This enables real-time monitoring of the system process and allows for quick response to any issues or anomalies. Moreover, cloud storage also offers scalability, allowing for easy expansion of storage capacity as data volume increases over time. This eliminates the need for local storage upgrades and maintenance efforts, saving time and resources.

Additionally, cloud storage provides the benefit of data backup and disaster recovery. Data stored in the cloud is replicated across multiple data centers, ensuring data redundancy and reducing the risk of data loss due to hardware failures or disasters. This adds an extra layer of reliability to the system and ensures data durability.

In summary, leveraging cloud storage with popular cloud service providers offers several advantages in monitoring and accessing data remotely, overcoming the limitations of offline presence, and enabling efficient management of data collected from the system. Cloud storage provides scalability, data redundancy, and disaster recovery, making it a reliable solution for monitoring and managing data in the future.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Adarsa Narayanan Mallick,Mohit Kumar & Kamaldeep Arora,”Automatic pasteurized formula milk preparation machine with automatic sterilized containers”,2022 44th Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC),pp.5-8,2022. [CrossRef]

- O. Amole ,O.E.Olabode and S.G.Akinjobi,“Optimal Temperature Control Scheme for Milk pasteurization process using different turning techniques for a proportional integral derivative controller”,Iranian Journal of Electrical and Electronic Engineering 03 (2022) 2170,pp.5-9,2022.

- Soheil SOBHANARDAKANI,”Human Health Risk Assessment of Cd, Cu, Pb and Zn through Consumption of Raw and Pasteurized Cow’s Milk”,Iran J Public Health,Vol.47,pp.1172–1180,2018.

- 4.M. VAHEDI,M. NASROLAHI,M. SHARIF, A.M. MIRABI,”Bacteriological study of raw and unexpired pasteurized cowʹs milk collected at the dairy farms and super markets in Sari city in 2011”,PubMed Central,Vol.54,pp.103-109,2013.

- I.R. Grant, E.I. Hitchings, A. McCartney, F. Ferguson, M.T. Rowe.,,“Effect of commercial-scale high- temperature, short-time pasteurization on the viability of Mycobacterium paratuberculosis in naturally infected cow‘s milk”,Applied and Environmental Microbiology,Vol.68,pp.148-153,2002. [CrossRef]

- Grant I.R.H.J .Ball and M.T.Rowe,”Effect of higher pasteurization temperatures and longer holding times at 72oC on the,inactivation of mycobacterium paratuberculosis in milk.Lett.Appl.Microbiolʹʹ,Letters in Applied Microbiology,Vol.28,pp.461-465,1999. [CrossRef]

- N.Sung,M.T.Collins.,“Thermal tolerance of Mycobacterium paratuberculosis”,Applied and Environmental Microbiology,Vol.64,pp.96-102,1998. 42. [CrossRef]

- J.R. Stabel, E.M. Steadham, C.A. Bolin,“Isolation of Mycobacterium paratuberculosis from colostrum and milk of subclinically infected cows”,American Journal of Veterinary Research,pp.3-7,1997.

- Millar, D., J. Ford, J. Sanderson, S. Withey, M. Tizard, T. Doran, and J. Hermon-Taylor,”IS 900 PCR to detect Mycobacterium paratuberculosis in retail supplies of whole pasteurized cows”,Applied and Environmental Microbiology,Vol.62,pp.143-146,1996. [CrossRef]

- A.F. Hope, P.A. Tulk, R.J. Condron., “Investigation of the thermal death of Mycobacterium paratuberculosis in whole milk”,International Dairy Federation,pp.452-457,1996.

- I.R. Grant, H.J. Ball, S.D. Neill, M.T. Rowe., “Inactivation of Mycobacterium paratuberculosis in cow‘s milk at pasteurization temperatures”,Applied and Environmental Microbiology,Vol.62,pp.153-156,1996. [CrossRef]

- Grant I R, Ball H J and Rowe M T,”Thermal inactivation of several Mycobacterium spp. in milk by pasteurization”,Letters in Applied Microbiology,Vol.22,pp.253-256,1996. [CrossRef]

- Chiodini, R. J., and J. Hermon-Taylor,”The thermal resistance of Mycobacterium paratuberculosis in raw milk under conditions simulating pasteurization”,J Vet Diagn Inves,pp.629-631,1993. [CrossRef]

- Knabel S J, Walker H W, Hartman P A and Mendonca A F,”Effects of growth temperature and strictly anaerobic recovery on the survival of Listeria monocytogenes during pasteurization”. Applied and Environmental Microbiology ,Vol.No.56,pp.108-112,1990. [CrossRef]

- Franklin,J.G,”A comparison of the bactericidal efficiencies of laboratory holder and HTST methods of milk pasteurization and the keeping qualities of the processed milks”. International Journal of Dairy Technology.,Vol.No.18.,pp.115-118,1965. 43. [CrossRef]

- Y.A.Alekseeva,D.Ts.Garmaev,T.A.Khoroshailo,”Automated systems application for the advanced cow milking technologies development”,AIP Conference Proceedings,Vol.2402,pp.556-562,1961. [CrossRef]

- PHOLISA DUMALISILE, R CORLI WITTHUHN and TREVOR J BRITZ,”impact of different pasteurization temperatures on the survival of microbial contaminants isolated from pasteurized milk”,International journal of Dairy technology,Vol.58,pp.74-82,1961. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).