1. Introduction

Rapeseed is an ancient cultivated crop, planted all over the world, with the planting area and yield second only to soybean in oil crops. China is one of the countries with the longest history of rapeseed origin and cultivation, with a perennial planting area of about 100 million acres, and the area and production account for about 20% of the global total[

1,

2,

3,

4]. Rapeseed machine high harvesting loss is prominent, which the loss of rapeseed siliques to pod-shattering caused by the action of reels or plant pulling each other during harvesting accounts for a high percentage. Losses due to silique shattering have been reported in the literature to be 8%-12% of the total seed yield, shattering loss can increase to 20% if harvesting time is delayed[

5,

6,

7,

8]. Therefore, analyzing pod-shattering characteristics of rapeseed during the harvesting time when the siliques are subjected to external forces is of great value in selecting and breeding machine harvestable rapeseed varieties, optimising the design of the reel branch mechanism and movement parameters, and reducing shattering of rapeseed to reduce the harvesting losses[

9,

10,

11,

12].

The screening of crack-resistant varieties can reduce the process of machine harvesting of silique shattering loss, in order to screen crack-resistant rapeseed varieties, domestic and foreign scholars have proposed a variety of shatter resistant test methods[

13,

14], such as Kadkol et al.[

15] assessed shatter resistance of rapeseed silique by experimentally determining the force or energy required to bend the siliques, Pu Hui-Ming et al. [

16] put forward the tensile method of cracking with a pulling meter to test shatter resistance of rapeseed silique, Qiao Jin-Ping et al. [

17] use random collision method to test shatter resistance of rapeseed silique, Li Yaoming et al. [

18,

19] proposed impending fracturing method to evaluate shatter resistance of rape silique. However, the existing rapeseed shatter resistance evaluation methods do not evaluate the shatter resistance performance from the actual stress process and state of the silique during rapeseed harvesting, which is easy to cause that the screening of some varieties are still easy to shattering harvested by machine when the external force is applied. Reducing the external force on the siliques during harvesting can also reduce shattering, some scholars have optimised the design of large-diameter non-uniform velocity rolling over reels, changed the rotational speed of the reels, the installation position and the angle of the reel teeth to reduce the collision force of the reel teeth on the rapeseed silique in the process of harvesting, and designed the bidirectional electric driven side vertical cutter etc., so as to reduce perturbation of cutting and branching, reduce vibration of rapeseed silique and decrease shattering loss caused by the cutting and vibration of the branching[

20,

21,

22,

23,

24,

25,

26,

27]. However, due to the lack of research on the relationship between silique stress and shattering, there is a lack of basis for optimization of the reel or branching mechanism.

In this paper, based on the actual force process of rapeseed silique during harvesting, the pendulum method is used to simulate the collision and impact process of external force on the silique, and the impending fracturing method is used to test the different support and force surfaces of the silique, to study the factors affecting shattering of rapeseed silique during harvesting, so as to provide the theoretical basis for the screening of machine-harvesting varieties of shatter resistant rapeseed, rapeseed cutting table reel branch design and parameter optimization.

2. Materials and Methods

2.1. Sample Material

The rapeseed samples used in the experiment were collected from the rapeseed fields planted by Hejiaqiao Agricultural Machinery Professional Cooperative in Daitou Town, Liyang City, Jiangsu Province, during 1 to 5 June 2022, and the rapeseed varieties were Zhenyou 8, Ningza 1818, and Fengyou 306 respectively. Five plants with uniform growth, the same colour and lustre, and free from pests and diseases were randomly selected from the field of each rapeseed variety. Cut the siliques from the main branches of rapeseed and the apical, middle and bottom ends of the branches, without separating the petals and retaining the stalks, and store them in zip-lock bags by variety and category to reduce water loss, and mark them with marking pens.

In order to compare the differences in shattering performance between different rapeseed varieties, all three rapeseed varieties were selected for testing at the harvesting stage of the rapeseed combine, and the water content of the seeds and siliques were chosen to be close to each other. The moisture content of the samples measured before the test were as follows: moisture content of Ningza 1818 siliques was 16.31%, moisture content of seeds was 18.85%, moisture content of FengYou 306 siliques was 17.15%, moisture content of seeds was 19.72%, moisture content of ZhenYou 8 siliques was 17.52%, moisture content of seeds was 19.43%.

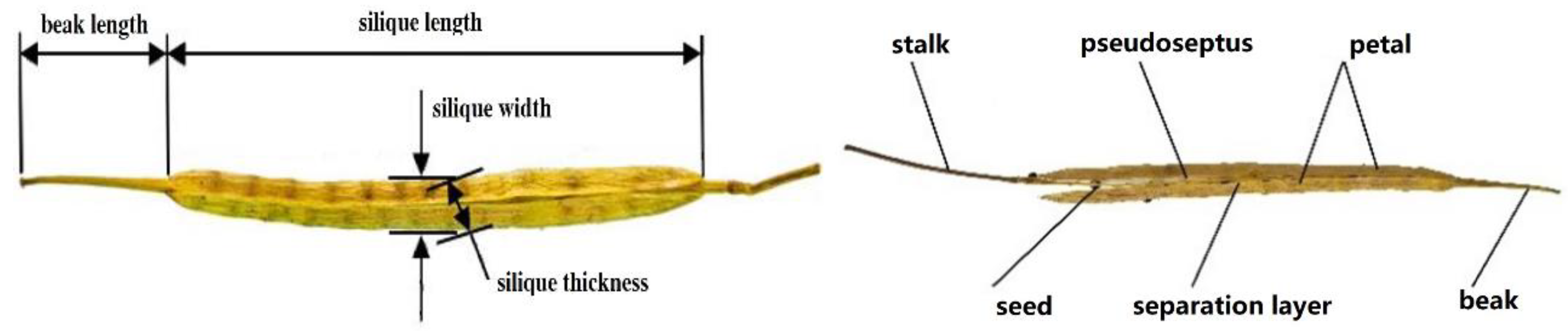

The morphological and geometrical characteristics of rapeseed silique are shown in

Figure 1. Vernier caliper (precision 0.02mm) was used to measure the length, beak length, silique width, silique thickness and pericarp thickness of rapeseed siliques, and 20 siliques were measured to take the maximum value, minimum value and average value. The width of the silique is the distance between the two sides of the middle of the pericarp of the silique, and the thickness of the silique is the distance between the two flaps of the plane where the pseudoseptum of the silique is located.

The geometrical parameters of the three rapeseed varieties are shown in

Table 1. The geometrical dimensions discrepancy of different rapeseed varieties are varied considerably, with the length of the silique of Ningza 1818 being the longest, with a mean value of 68.6 mm, the width of the silique of Zhenyou 8 being the largest, with a mean value of 5.23 mm, and the thickness of the silique of Ningza 1818 being the largest, with a mean value of 3.37 mm.

2.2. Test equipment and methods

2.2.1. Swing impact test

The swing impact method was adopted to simulate the collision impact of reel operation process on the siliques during rapeseed harvesting, and the collision impact test was carried out on the single-constrained and supported-constrained siliques to analyse the effects of the different collision speeds, collision positions and other parameters on the pod-shattering of rapeseed siliques in the harvesting time. Due to the silique stalk and support friction are small, by external load force is easy to slide down, with medical tape wrapped 3 to 4 laps of the silique stalk is clamped part of the enhancement of the friction between the silique stalk and the fixture, as well as to prevent the fixture clamping and fixing the process of the silique stalk caused by the damage.

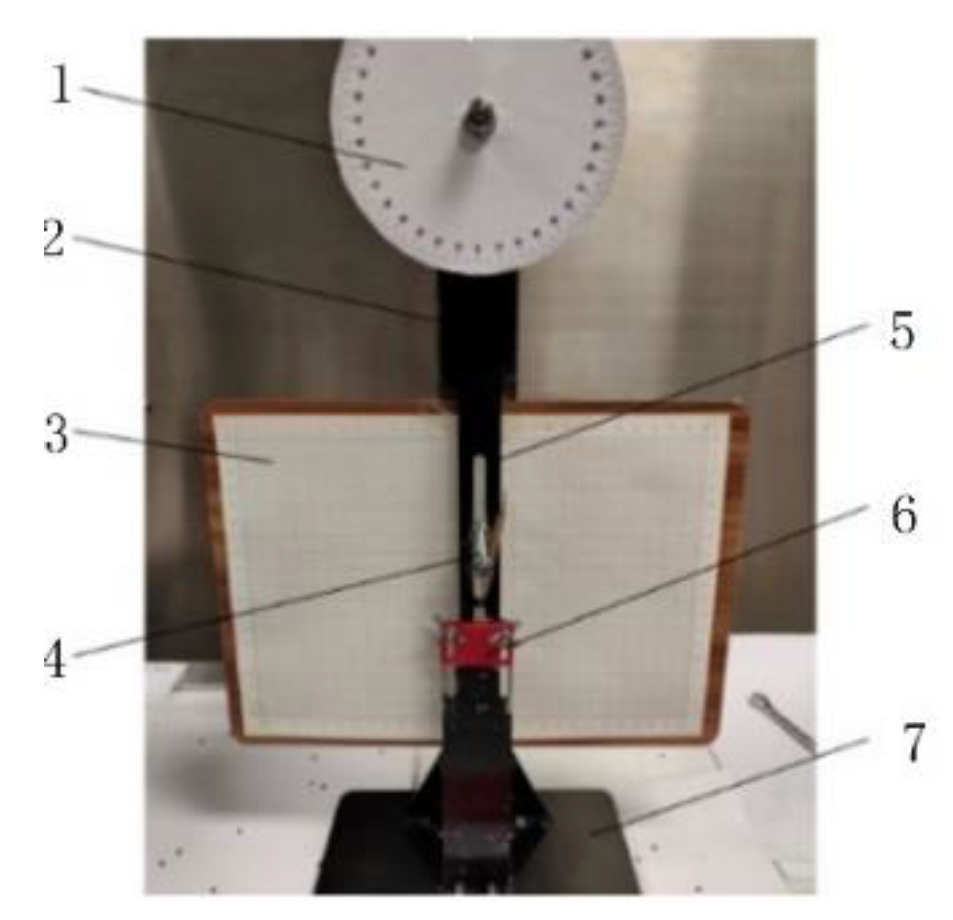

Based on the self-designed swing silique collision impact test device, as shown in

Figure 2. The stalk of the rapeseed silique was fixed with a fixture, and by releasing the impact parts and counterweights of different heights, different collision impact speeds were realised to hit the silique, and the number of siliques shattered was recorded in the test, and twenty rapeseed siliques were used in each group of tests.

The number of pod-shattering siliques was counted using the criterion that the petals were cracked more than 2 mm from the stalk, or that the petals were separated from the pseudoseptum on at least one side, or that the rapeseed could be seen to fly away and fall off as the criterion for determining shattering siliques. The silique shattering rate was calculated as follows:

where:

- silique shattering rate,

- number of siliques ruptured in the experiment,

- total number of rapeseed siliques used in the experiment.

2.2.2. Impending fracturing test

The universal material testing machine was used to carry out the mechanical properties of rapeseed silique bending test, to study the silique in the plant in different growth position, silique force position, support mode, loading speed, etc. and silique mechanical properties of the direct relationship between the silique. The rapeseed silique impending fracturing test was carried out in the panicle crop harvesting laboratory of Nanjing Agricultural Mechanisation Research Institute (NIAM), and the test equipment used was the WDW-10 microcomputer-controlled electronic universal testing machine, which has a test range of 0 to 1kN, a maximum travelling stroke of 700 mm, and a displacement sensor and force sensor accuracy of %.

During the test, first set the downward loading speed of the universal test tensile apparatus 15 mm·min-1 in the computer software, and then place the silique samples on the support of the three-point bending test fixture in accordance with the test requirements to ensure that the probe of the testing machine is located at the midpoint of the silique. Adjust the position of the tensile tester with the sensor so that it is at the critical point of contact with the silique, start the preload <0.5 N, the span L of the support is adjusted according to the test factors. Before the start of each group of tests, you need to zero the displacement and load parameters to avoid human error. Manually click the run button, and the universal test tensile tester began to run slowly downward, and the software appears in the bending deformation and load force change curve and slowly increase. At the end of the test, the change curve data in the software is exported, and the change curve of the compression load with bending deformation of rapeseed silique is plotted by MATLAB software.

The rapeseed variety, the silique stress surface, the load loading speed, and the silique support position was selected as the test factors, and the silique cracking force and the bending strength were used as the test evaluation indexes. Silique cracking force refers to the load force corresponding to the highest point at the straight line segment presenting linear elastic deformation with the increase of bending deformation, which is also the peak force of the sudden drop fluctuation of the pressure load when the first crack or petal crack appears in the silique.

The bending strength of the silique was calculated as follows:

The cross-section of the rapeseed silique is approximately elliptical circular shape, the direction of the silique width is defined as the

-axis, and its moment of inertia to the

-axis is,

where:

- large cross-section long semi-axis length, that is, half of the width of the silique, mm;

- large cross-section short semi-axis length, that is, half of the thickness of the silique, mm;

- small cross-section long semi-axis length of the small section, that is, half of the width of the silique minus the thickness of the petal, mm;

- length of the short semi-axis of the small section, that is, half of the thickness of the silique minus the thickness of the petal, mm.

Silique width direction bending test process of the maximum bending moment is,

where:

- maximum bending force, N;

- distance between two supports, mm.

Bending section modulus in the direction of the width of the silique:

Bending strength in the direction of the width of the silique:

Similarly, the silique thickness direction is defined as the

-axis and its moment of inertia to the

-axis is,

The maximum bending moment during the bending test in the silique thickness direction was,

where:

- maximum bending force, N;

- distance between the two supports, mm.

The bending section modulus in the direction of the thickness of the silique was,

The flexural strength of the silique was,

3. Results and Analysis

3.1. Swing impact test results and analysis

The growth state of rapeseed silique on the plant can be regarded as a cantilever beam structure, which deforms and shakes freely under the action of the collision impact force, and the length of its stalk directly affects the state of the silique rupturing and shattering. It was found in the previous preliminary test that the position of the stalk was 2 mm from the connection point, and there was a significant difference between the silique shattering with different collision impact speeds. In order to differentiate the effects of different factors on the silique shattering, the position of the stalk was selected to be 2 mm from the connection point as a prerequisite for the test of the swing impact test.

3.1.1. Influence of material type on silique shattering

SUS 304 and REEK nylon materials were selected respectively, and the collision impact test was carried out with a collision impact speed of 3.5 m·s

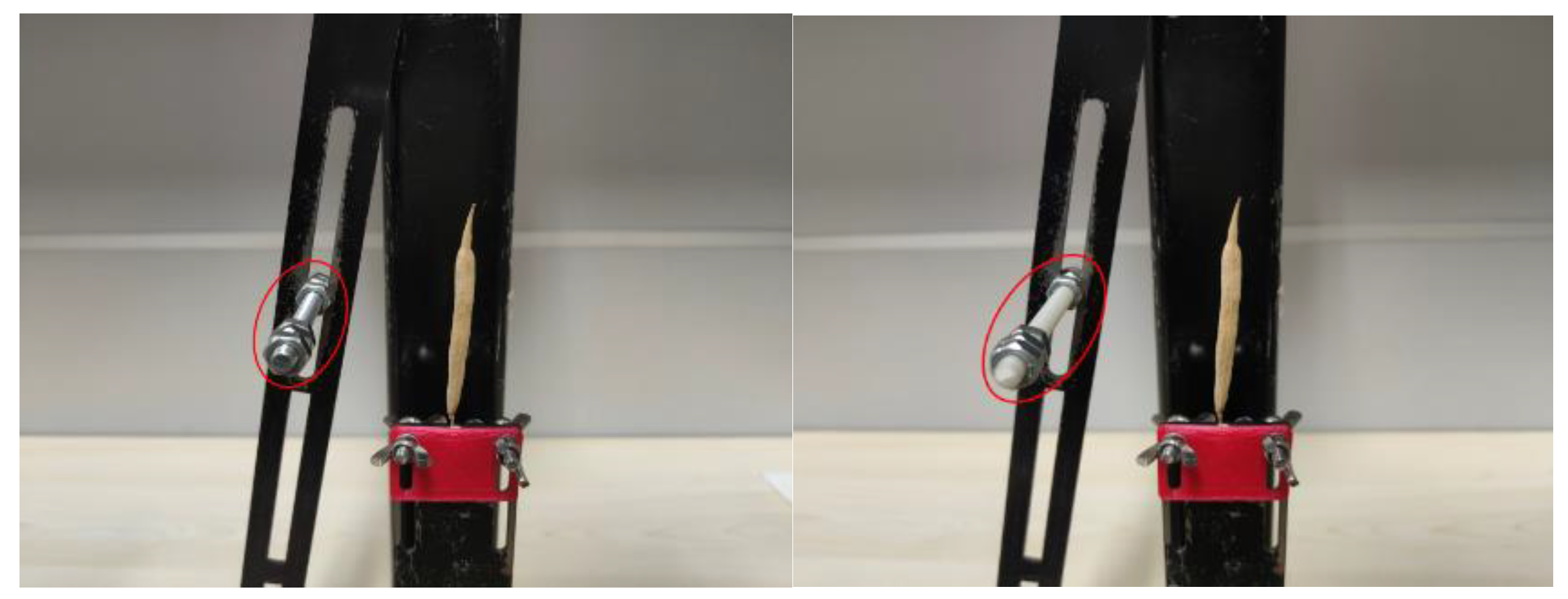

-1 on the combined surface of the silique flaps at the middle of the main branch of Zhenyou 8 and Fengyou306 rapeseed, colliding with the middle part of the silique, as shown in

Figure 3.

In swing impact tests with SUS304 material, the shattering rate was 40% for Zhenyou 8 and 45% for Fengyou 306. With REEK nylon material, the shattering rate of Zhenou 8 is 30%, and the shattering rate of FengYou 306 is 40%. Different types of collision materials, the shattering rate of Fengyou 306 was higher than that of Zhenyou 8. The differences in shattering caused by different material types were also significant, and the shattering rates of the same rapeseed varieties with REEK nylon materials were smaller than those of SUS304 materials, indicating that both rapeseed varieties and collision material types had a significant effect on shattering of rapeseed silique.

3.1.2. Impact Velocity and Stress Surface Effects on Silique Shattering

Rapeseed harvesting operations, reel teeth contact silique instantly produce collision impact force, due to rapeseed silique shell consists of 2 shell-like petals and 2 linear petals, in order to analyse the rapeseed varieties and silique of different stress surface by the collision of external forces on the impact of the silique shattering respectively, with a different collision impact speed on the Ningza 1818 and Zhenyou 8 two rapeseed varieties, from the right ahead and the bonding face of the silique petals processed impact test, the point of impact are the central part of the rapeseed silique, the test measured the silique shattering rate shown in

Table 2.

Table 2 test data can be seen, in the other factors are the same, Ningza 1818 and Zhenyou 8 have shown that when subjected to the same collision impact, collision with the bonding surface of the petal compared to the right ahead of the petal is more likely to lead to silique shattering, and with the increasing speed of the collision impact, the silique shattering rate with the increase in the speed of the collision impact are increased.

Table 2 can also be found, the increase in impact velocity will cause the silique shattering rate increase, but the increase is not a linear proportional relationship, in the collision impact velocity is small, collide different stress surface of silique, silique shattering rate difference is small, when the impact velocity increases, collide different stress surface of silique, silique shattering rate difference is obvious. Between different varieties in the collision impact speed greater than 2.5 m·s

-1, the silique shattering rate difference is also obvious, in the collision impact speed is lower, the silique shattering rate difference is not obvious.

3.1.3. Effect of moisture content on shattering in siliques

In order to analyse the effect of moisture content on silique shattering, with Ningza 1818 as the research object, in the rapeseed maturity period, the silique at the middle of the main branch is cut. Select the moisture content of the three levels. The bonding surface of rapeseed silique petal is used as the collision force surface. The collision impact speed is 3.5m·s

-1. The collision impact material is SUS304. Collide the silique at the middle part, the measured experimental data of rapeseed silique shattering rate is shown in

Table 3.

From the data in

Table 3, it can be seen that shattering rate of rapeseed siliques with different moisture content is also different, and shattering rate of siliques decreases gradually with the increase of moisture content, and shattering rate of siliques with 20.61% moisture content is 50% lower than shattering rate with 9.24% moisture content. Shattering rate of rapeseed siliques is not easy to be shattered under the condition of high moisture content.

3.1.4. Influence of silique growth position on silique shattering

In order to analyse the shattering influence of different growth positions of rapeseed silique on the plant, with Ningza 1818 rapeseed varieties as the research object, with rapeseed silique petal bonding surface as the collision force surface, the collision impact speed is 3.5m·s

-1, the collision impact test of the middle of the silique was carried out at the top, middle and bottom of the main rapeseed branch respectively. The test results are shown in

Table 4.

The shattering rates of siliques at the top, middle and bottom of main rapeseed branches were 50%, 40% and 25% respectively. The shattering rates of siliques at the top and middle of the branch were close to each other, but differed significantly from those at the bottom of the branch. Under the same external force, the shattering rate of the silique from the top to the bottom of the main rapeseed branch gradually decreased. The reason is that during the rapeseed maturity period, the maturity degree of the silique at the top, middle and bottom of the same plant is not consistent, the silique with low maturity has strong toughness and is not easy to shatter, while the moisture content of rapeseed silique with relatively high maturity is on the low side, and the brittleness is more obvious when subjected to the same collision impact force, which is easy to plastic deformation leading to the siliques shattering.

3.1.5. The effect of supporting role on silique shattering

Rapeseed has many branches and intertwined with each other, and each silique layer also overlaps, in the process of rapeseed harvesting reeling and branching operations, when reeling rapeseed plants, due to cross pulling and other reasons, it is very easy to appear that the siliques are blocked by other plants to support the role of the siliques, so the study of the siliques by the external supporting role of the impact on the silique shattering to reduce the siliques shattering in reeling and branching has a reference value.

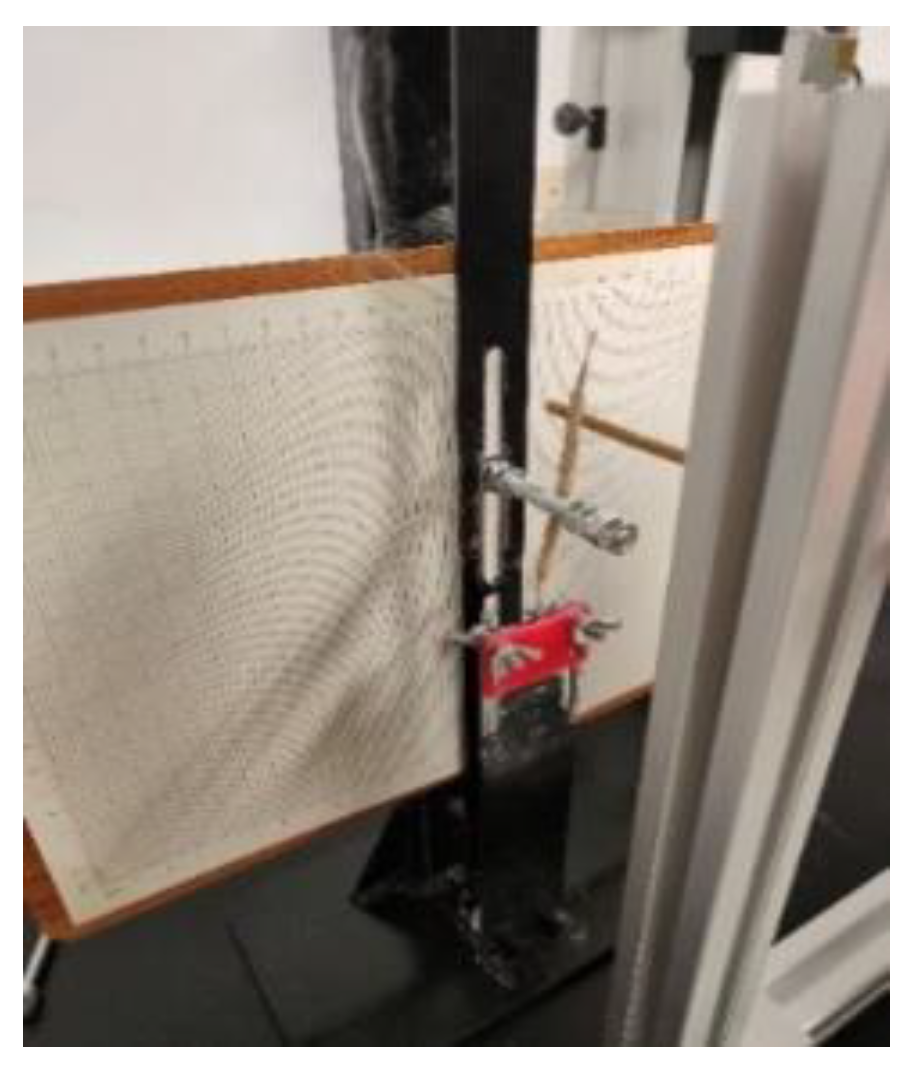

Zhenyou 8 rapeseed was selected as the research object, the silique at the middle position of the rapeseed plant was selected, the clamping position was 2 mm away from the carpopodium, the collision impact material was SUS304, the collision impact speed was 3.5 m·s

-1, the silique force position was the middle part of the fruit flap bonding surface, in order to simulate the different blocking positions, three distances (0mm, 5mm, 10mm) were set at the horizontal position of the silique, and

3.86 mm rapeseed branch was used as blocking material, the test is shown in

Figure 4.

Experimental data of the silique shattering rate are shown in

Table 5.

From the data in

Table 5, it can be seen that when the moisture content of rapeseed silique was 16.32%, the silique shattering rate was 40% under the unsupported effect. When there was support, the shattering rate was 75%~100%, and the shattering rate was significantly higher than the shattering rate under unsupported conditions, and the effect of support distance on shattering was also extremely significant, with the shattering rate being 100% when the support point was 0mm away from the horizontal distance of the top of the silique. When there is support, the reason for the high shattering rate is mainly due to the upper end of the silique is blocked by another object, at this time, the state of the silique can be regarded as a simply-supported beam, and the attachment state of the silique itself on the plant can be regarded as a cantilever beam structure. Under the action of the same external force, the centre of the simply supported beam is more likely to be bent and broken. Under the action of two-end support, it is more likely to lead to silique shattering when the rapeseed silique is subjected to external force.

3.2. Impending fracturing test results and analyses

3.2.1. Effect of support position on mechanical properties of silique

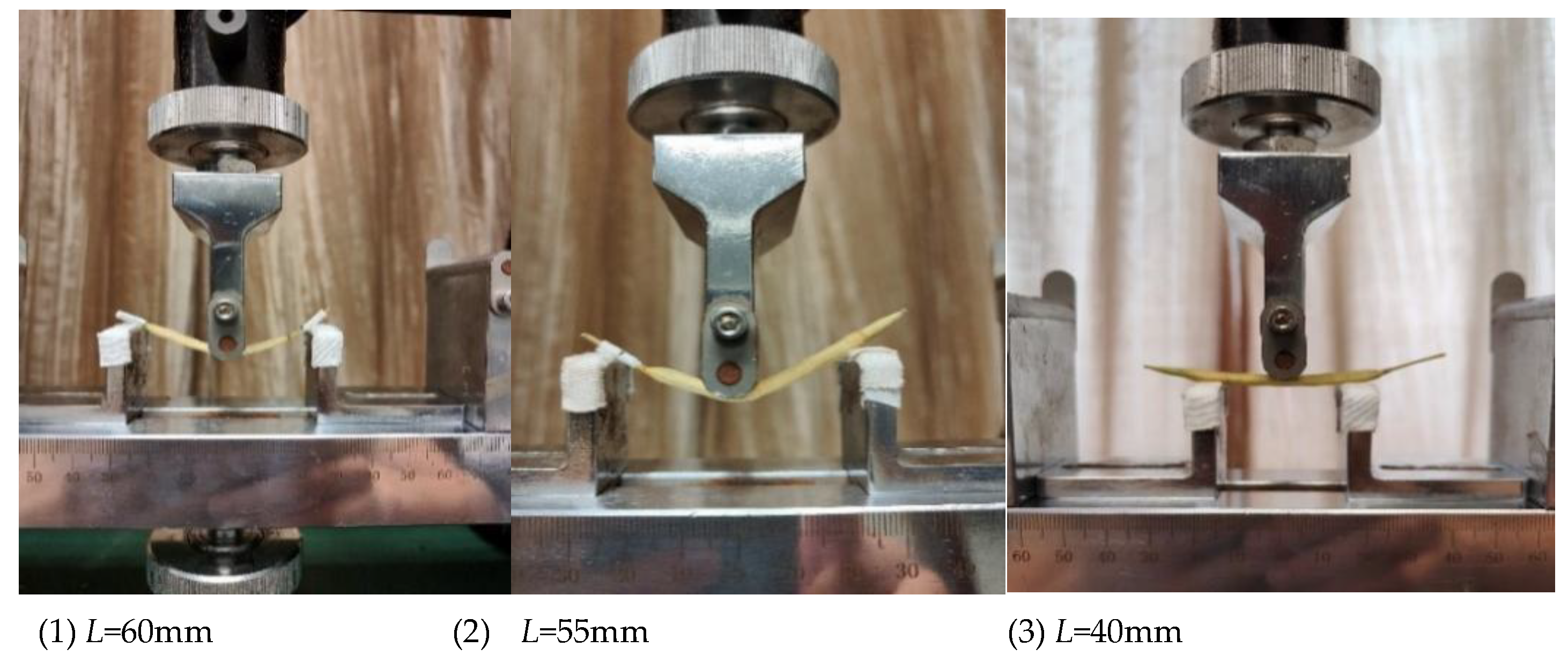

Taking Zhenyou 8 silique as the research object, the siliques at the middle of the main rapeseed branch were selected, and the loading speed was 15mm·min

-1. Rapeseed silique support position was divided into the following three ways: ① carpopodium and horn beak placed at both ends of the support, rapeseed silique petals are completely in the state of stagnation; ② from the horn beak closest to the end of the petals placed at one end of the support, rapeseed carpopodium is at the other end of the support; ③ rapeseed silique body is placed at both ends of the support. The corresponding spans

L of the two supports were 60 mm, 55 mm and 40 mm, respectively, with the loading position at the centre of the support and the stress position at the front of the silique petals, as shown in

Figure 5.

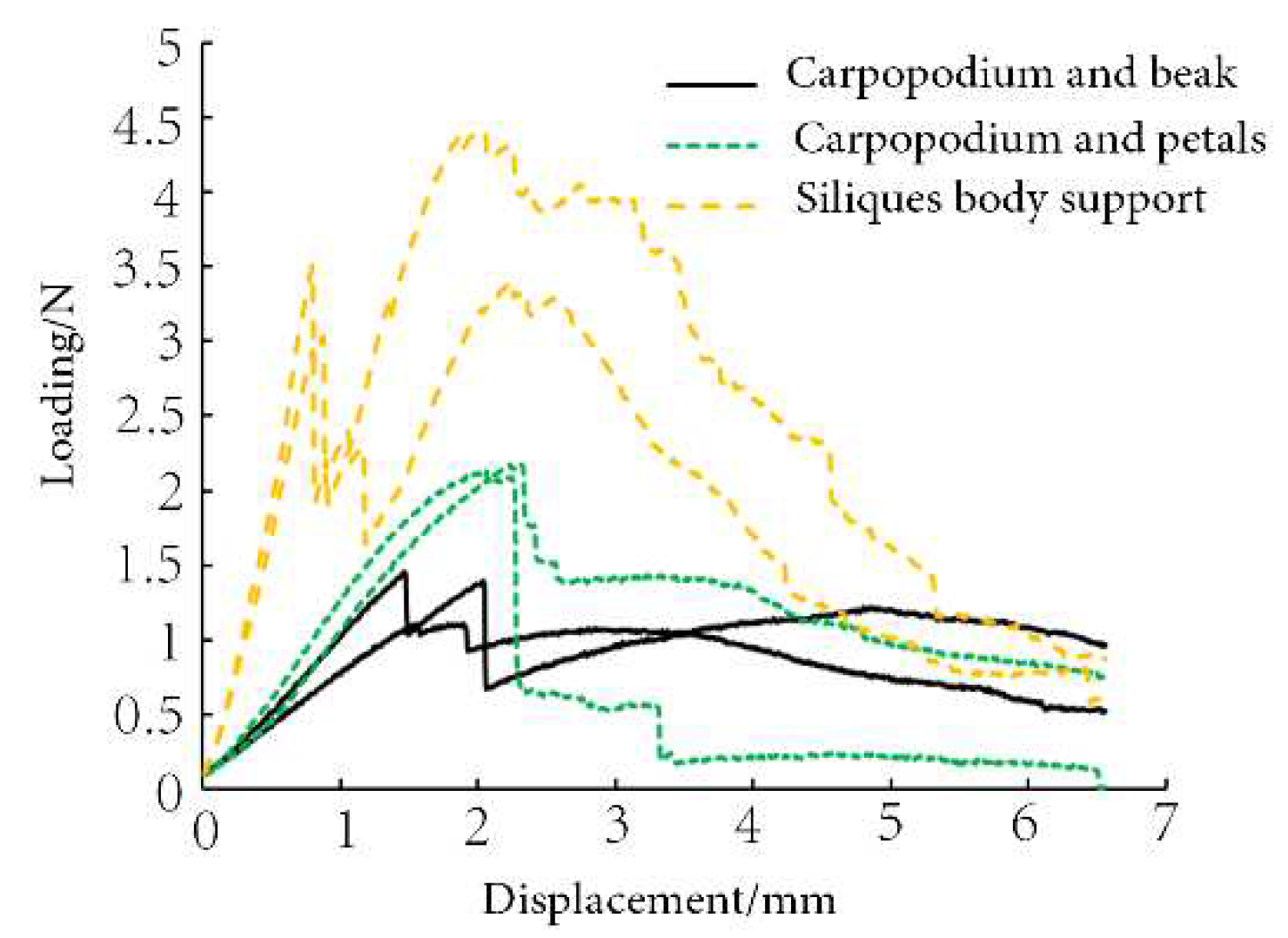

The moisture content of rapeseed silique was measured to be 14.8% and that of seed was 16.31% at the time of test. The variation curves of the load applied to the siliques at different support positions with bending deformation are shown in

Figure 6.

In the initial stage, the load increases with the increase of the bending deformation of the silique, which was approximately linear, and when the peak value appears for the first time, the silique begins to yield, and the bonding of the petal and the pseudoseptum begins to crack. At this time, it is the maximum yield load of the silique, and it is also the maximum cracking force of the silique. With the increase of the displacement, the load was basically stable, and the silique cracks were expanding, and the two petals of the silique begin to slowly undergo the bending deformation. Finally as the displacement continues to increase, the load gradually decreases and fluctuates around a certain value, and the petals separate and the seeds fall off in this process. When the body of rapeseed silique was supported, the load curve appeared two peaks, and the load of the second peak was much higher than the first one, which was because the yield critical value of the silique petals and false septum was reached at the second peak. The experimental data on the maximum cracking force and flexural strength of silique by the support position of rapeseed silique are shown in

Table 6.

The mean value of the maximum cracking force of the silique when it was at the position of support at the carpopodium and beak was 1.46N, the standard deviation was 0.23, and the coefficient of variation was 15.76%, and the mean value of the flexural strength of the silique was 6.09MPa, the standard deviation was 0.95, and the coefficient of variation was 15.61%. The mean value of the maximum cracking force of the silique when it was at the position of the support of the carpopodium and the petals was 2.13 N, the standard deviation was 0.18, and the coefficient of variation was 8.44%, and the mean value of the bending strength of the silique was 8.15MPa, the standard deviation was 0.7, and the coefficient of variation was 8.56%. The mean value of the maximum cracking force of the silique at the position of silique body support was 3.44N, the standard deviation was 0.44, and the coefficient of variation was 12.86%, and the mean value of the flexural strength of the silique was 9.51MPa, the standard deviation was 1.24, and the coefficient of variation was 13.03%.

Silique support position had a significant effect on both the maximum cracking force and bending strength, when supported at the carpopodium and beak, the load was very easy to bend and deform, so the measured maximum cracking force and bending strength is small, which the range of the maximum cracking force were 1.11N to 1.73N, and the bending strength range were 4.62MPa to 7.21 MPa. When the silique body was supported at both ends of the support point was closer, the bending capacity and bending strength of the silique became larger, and the maximum cracking force required to shatter was the largest, which the range of the maximum cracking force were 3.05N to 4.16N, and the bending strength range were 8.48MPa to 11.57 MPa.

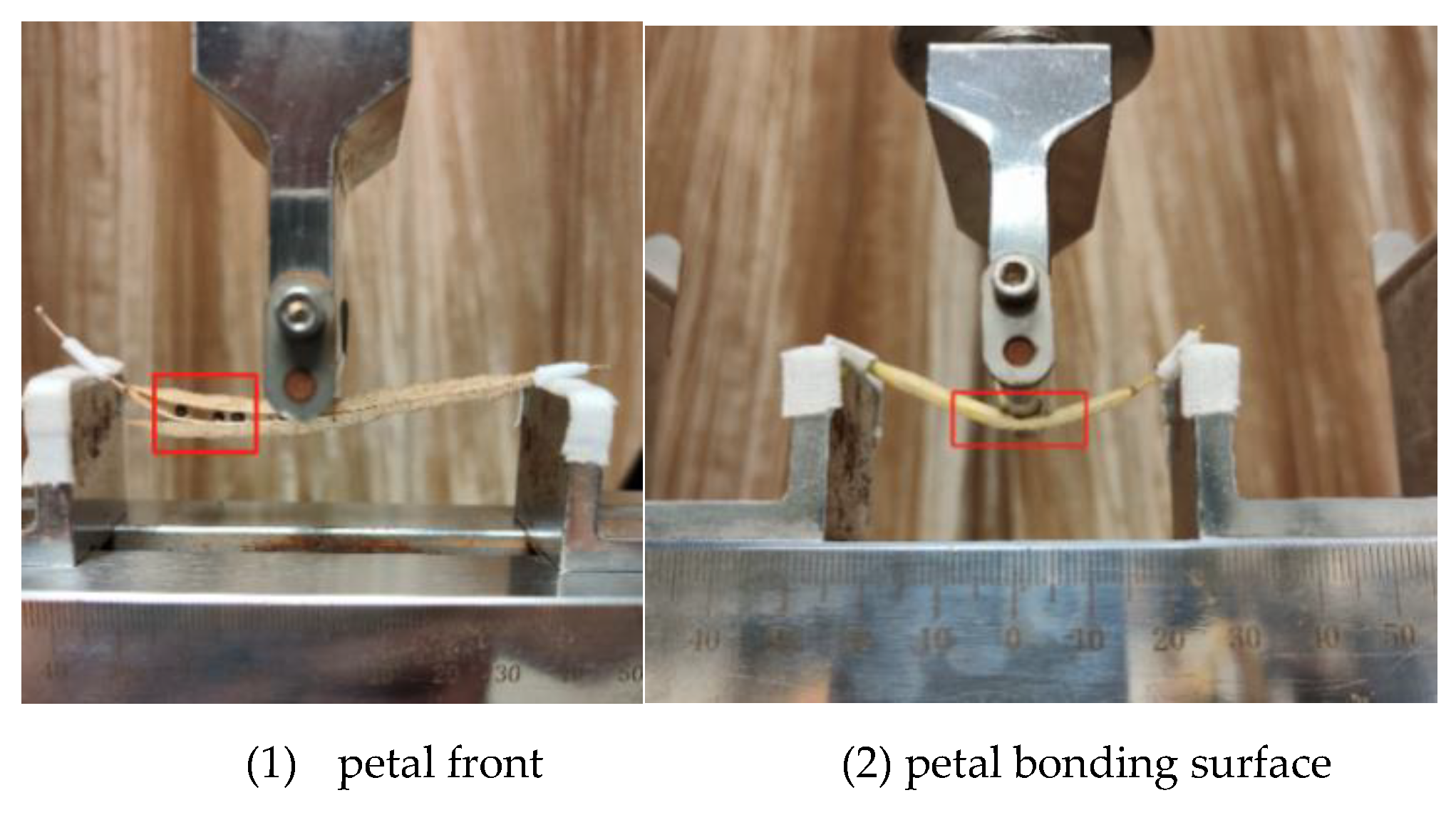

3.2.2. Effect of stress on the mechanical properties of siliques

In order to analyse the mechanical properties of different stress surfaces of rapeseed siliques under pressure conditions, three rapeseed varieties, Zhenyou8, Ningza1818 and Fengyou306, were loaded uniformly from the front side of the petals and the bonding surface at a rate of 5mm·min

-1. Due to the length of different rapeseed siliques and the influence of the different support positions on the mechanical properties of the siliques, in order to test the results were comparable, silique carpopodium and beak ends were placed on the support for the test conditions, according to the length of rapeseed silique, were adjusted to support the span of the seat. Zhenyou8 corresponding span was 40mm, Ningza1818 corresponding span was 53mm, Fengyou306 corresponding span was 50mm. The test was shown in

Figure 7, the measured maximum cracking force and flexural strength of different stress surfaces of silique were shown in

Table 7.

From the experimental data in

Table 7, it can be seen that for different rapeseed varieties, the maximum cracking force and flexural strength of silique were different. The homogeneity test of variance was carried out on the data in

Table 7, the maximum cracking force of silique was p=0.082>0.05, and the flexural strength was p=0.412>0.05, and the data showed a normal distribution, which meets the requirement of analysis of variance. The analysis of variance of maximum cracking force of silique under rapeseed varieties and different stress surfaces impending fracturing test was shown in

Table 8.

As shown in

Table 8, the effects of rapeseed varieties (p<0.001) and different stress surfaces of silique (p<0.001) on the maximum cracking force of silique were highly significant. Using the SNK method for multiple comparisons of rapeseed varieties[

28], the maximum cracking force of Zhenyou 8 was significantly different from the two varieties of Ningza 1818 and Fengyou 306, and the difference between the maximum cracking force of Fengyou 306 and Ningza 1818 was non-significant. For the same rapeseed variety, the maximum cracking force of the petal bonding surface was less than that of the petal front surface, and the difference was significant.

The analysis of variance of the flexural strength of silique under rapeseed varieties and different stress surfaces were shown in

Table 9.

The influence of rapeseed varieties with different stress surfaces on the flexural strength of the silique were all highly significant. Using the SNK method for multiple comparisons of rapeseed varieties, the flexural strength of Ningza 1818 was significantly different from the two varieties of Ningza 1818 and Fengyou 306, the difference between the flexural strength of Fengyou 306 and Zhenyou 8 was non-significant, and the flexural strength of the petals bonding surface was less than that of the front side of the petals, and the difference was significant.

3.2.3. Effect of loading speed and silique growth position on mechanical properties of siliques

Zhenyou 8 was used as the research object, and 12 siliques each were selected from the top, middle and bottom of the main rapeseed branch. Through the previous analysis, the stability of the silique carpopodium and beak support was poor, and the silique was easier to rupture and shattering when the bonding surface of the petals was subjected to force, and the silique body was selected as the support position and the direction of the front of the silique petals to be loaded at the loading speeds of 5 mm·min

-1, 15 mm·min

-1, and 25 mm·min

-1, respectively. Before the start of the test, the water content of the silique was measured to be 14.8%, and the seed was 16.31%, and the test data were shown in

Table 10.

From the data in

Table 10, it can be seen that the maximum cracking force and flexural strength required to silique shattering at the middle of the rapeseed plant were the greatest, and the maximum cracking force and flexural strength of the silique at the middle of the rapeseed plant were also greater than those of the bottom and top siliques at the same loading speed. The average values of maximum cracking force and flexural strength of siliques were maximum at a loading speed of 15 mm·min

-1.

The homogeneity test of variance for maximum cracking force (p=0.304 >0.05) and flexural strength (p=0.282>0.05) were performed on the test results under the distribution position of silique and different loading speed treatments respectively, and the data showed normal distribution, which satisfied the requirement of analysis of variance. The analysis of variance of the maximum cracking force of siliques under different loading speeds and silique growth positions were shown in

Table 11.

The p-values for both locations of silique growth and loading speed were less than 0.01, indicating that the effect of the two factors on the maximum cracking force of rapeseed siliques were extremely significant within 99% of the confidence interval. Multiple comparisons of the maximum cracking force of siliques under different distribution positions of siliques were carried out using the SNK method. The maximum cracking force of siliques at the middle of main rapeseed branch was significantly different from that of siliques in other positions, and the difference in the maximum peak force of shattering between siliques at the bottom and top of main rapeseed branch was not significant. Multiple comparisons of load loading speeds showed that all three levels of loading speeds had significant differences on the maximum cracking force, and the effects on the maximum cracking force of silique shattering were ranked as follows: medium speed (15 mm·min-1) > high speed (25 mm·min-1) > low speed (5 mm·min-1).

The analysis of variance of the flexural strength of siliques under different loading speeds and silique growth positions were shown in

Table 12.

The model significance (p<0.001) of the flexural strength of siliques indicated that silique distribution location (p=0.008<0.01) and the load loading speed (p<0.001) had a highly significant effect on the flexural strength. Multiple comparisons of the flexural strength of siliques under different distribution positions of siliques were carried out using the SNK method. The flexural strength of siliques at the middle of the main rapeseed branch was significantly different from that of siliques in other positions, and the difference in flexural strength between siliques at the bottom and at the top of the main rapeseed branch was not significant. Multiple comparisons of load loading speeds were made, and it was seen that there was a significant difference between the three loading speeds on the flexural strength of the silique, with the effects on the flexural strength of the silique ranked as follows: medium speed (15 mm·min-1) > high speed (25 mm·min-1) > low speed (5 mm·min-1).

3.3. Influence of morphological characteristics of rapeseed silique on silique shattering

3.3.1. Correlation analysis between silique morphological characters with silique shattering

Taking Ningza 1818 rapeseed silique as the research object, the vernier caliper (precision 0.02mm) was used to measure 7 silique traits such as silique length, beak length, silique middle width, silique middle thickness, pericarp thickness, diameter of carpopodium, angle between carpopodium and silique, etc., and the statistical data of silique traits of Ningza 1818 rapeseed silique were measured and shown in

Table 13.

Using the swing impact test method, the dynamic impact test was carried out at the middle position of the frontal part of the petal silique, with a collision impact speed of 3.5 m·s

-1, and the collision impact material was SUS304, and the silique shattering corresponding to each morphological feature of the silique was recorded. Pearson's correlation analysis was used to study the correlation between 90 rapeseed siliques shattering and silique morphological characteristics. Silique shattering situation was divided into two cases, 0 represents no silique shattering and 1 represents silique shattering, which was a dichotomous variable and was analysed by point two series correlation analysis. The results of correlation analyses between silique shattering and morphological characters were shown in

Table 14.

As shown in

Table 14, there were different degrees of correlation between the silique shattering situation and the morphological characteristics of the silique itself. There was a highly significant positive correlation between silique length, beak length and silique width, a highly significant positive correlation between silique thickness and petal thickness and silique width, a significant positive correlation between silique thickness and beak length and silique width and pericarp thickness, and a highly significant positive correlation between stalk diameter and silique width, silique thickness and petal thickness, and a significant positive correlation between petiole diameter and silique length. The Pearson's correlation coefficients between the various morphological characters of silique revealed that longer siliques had a greater chance of having a longer beak, a greater width and a thicker stalk diameter, while thicker siliques had a greater chance of having a wider width, a longer beak, a thicker flap and a thicker stalk diameter.

A point-two series correlation analysis between silique shattering and morphological characteristics of silique as measured by the swing impact test showed that there was a significant positive correlation between shattering and beak length (point-two series correlation coefficient of 0.226) and a highly significant positive correlation with stalk diameter (point-two series correlation coefficient of 0.594, which was moderately correlated), provided that all other influencing factors were constant.

3.3.2. Grey correlation analysis between silique shattering with siliques morphological characters

In order to further investigate the correlation between the silique morphological characteristics and whether or not the siliques were shattered, grey correlation analysis was carried out using SPSS software for seven morphological parameters of the silique (length of the silique/mm, length of the beak/mm, width of the middle part of the silique/mm, thickness of the middle part of the silique/mm, thickness of the pericarp/mm, diameter of the silique stalk/mm, and the angle of the silique stalk to the silique/°), as well as for the data of 90 experiments. The correlation between the seven morphological parameters and shattering were also investigated by using whether the siliques were shattered or not as the "reference value" (parent series). When using grey correlation analysis, the resolution coefficient was taken as 0.5, and the value of correlation coefficient was calculated by combining with the formula of correlation coefficient, and finally the value of correlation was calculated, and the results of the analysis were shown in

Table 15.

Using grey correlation analysis, it was concluded that the influence of silique morphological characteristics on silique shattering situation was in the following order: the angle of the silique stalk to the silique > carpopodium diameter > pericarp thickness > beak length > silique thickness > silique broad surface > silique length. The morphological characteristics of rapeseed silique can be used as the appearance index for screening shatter resistance rapeseed, and provide certain reference for selecting and breeding rapeseed varieties with strong shatter resistance to machine harvesting.

4. Discussion

Rapeseed silique were easy to pod-shattering was extremely unfavorable to mechanized harvesting, limiting the further improvement of production efficiency, so based on the actual force state of rapeseed siliques during machine harvesting, to carry out the analysis of different varieties of rapeseed siliques to resist shattering, on the selection of good suitable for machine harvesting rapeseed varieties[

29], as well as to optimize the structure of the reel and separate mechanism and working parameters, to reduce the loss of rapeseed mechanical harvesting had very important theoretical significance and practical significance.

In this paper, we chose the main promoted rapeseed variety in Chinese Yangtze River, China, Zhenyou 8, Ningza 1818, and Fengyou 306, and used the swinging impact method and the impending fracturing method to carry out the rapeseed pod-shattering and fracturing test, respectively. For the same variety of rapeseed siliques, the top, middle and bottom of rapeseed silique of the main branch were subdivided. In the swing impact and impending fracturing test, respectively, according to the biological characteristics of rapeseed siliques, the stress surface was divided into the front surface and the bonding surface of rapeseed siliques.

Under the same stress conditions, the pod-shattering rate of REEK nylon material was reduced by 5 % to 10 %. REEK nylon material can be used to reduce the pod-shattering in the process of reeling and separating in rapeseed harvesting. The impact resistance of the front side of rapeseed was 2 to 4 times that of the bonding surface of rapeseed petals, the maximum cracking force of the bonding surface of the rapeseed petals was smaller than that of the front side of the rapeseed petals in impending fracturing, and the difference was significant, the maximum cracking force was small, which also indicated that the bonding surface of the rapeseed petals was easy to crack and shatter, and the two tests verified each other that the bonding surface of the rapeseed petals was more likely to shatter when impacted.

Under the same stress conditions, in the swing impact test, the shattering rate of the top rapeseed silique was twice that of the bottom siliques, and the silique at the bottom of the main branch was not easy to shatter, followed by the middle siliques, and at the top siliques were most easy to shatter. The impending fracturing test also showed that the maximum cracking force and the bending strength of rapeseed siliques in different parts of the main branch differed significantly, but the impending fracturing test indicated that the maximum cracking force and bending strength of rapeseed siliques in the middle part of the main branch were not enough to shatter, siliques in the middle of the main branch were the highest, and the results differed from those of the swing impact test method, which might be due to the influence of the loading speed and the support position on the results of the test, and the next step could be to continue to carry out the correlation analysis and analyze to find out the reasons for the difference between the two methods.

5. Conclusions

(1) Based on the swing silique impact test method, according to the silique force state in the process of rapeseed harvesting and reeling, carried out the silique crash impact test of Ningza 1810, Zhenyou 8 and Fengyou 306 oilseed rape. Rapeseed varieties, moisture content of silique, silique growth position, collision materials, impact speed, force position and other factors had a significant effect on the silique shattering. Collision impact speed was lower than 1.5m·s-1, the effect of various factors on the silique shattering was not significant. Rapeseed silique with a higher moisture content was not easy to shatter, the front side of the silique petal was more resistant to external impacts than the bonding surface of the petals. The impact resistance of the front side of rapeseed was 2 to 4 times that of the bonding surface of rapeseed petals. Rapeseed siliques growing in the bottom of the plant were superior to those at the top and centre of the plant in terms of resistance to external impacts, the shattering rate of the top rapeseed silique was twice that of the bottom siliques, and when siliques were supported, they were more likely to shatter under external forces compared to unsupported ones.

(2) Based on the universal material testing machine, an experimental study on the mechanical properties of rapeseed silique was carried out using the impending fracturing method, and the silique support position, force position, loading speed, and silique growth position had significant effects on the mechanical properties of silique. The maximum cracking force and flexural strength were higher, when the fruit body of the silique was supported, the range of the maximum cracking force were 3.05N to 4.16N, and the bending strength range were 8.48 MPa to 11.57 MPa. The maximum cracking force and flexural strength of silique frontal surfaces were stronger than those of the bonding surfaces, and the rapeseed silique at the middle of the branch was stronger than that at the top and bottom of the branch in terms of the maximum cracking force and flexural strength.

(3) The correlation between the morphological characteristics of silique and the characteristics of silique shattering was tested by using the swing impact test method, based on Pearson correlation analysis and grey correlation analysis, the order of magnitude of the effect of morphological characteristics of rapeseed silique on silique shattering performance was as follows: angle of the silique stalk to the silique, diameter of stalk, thickness of pericarp, length of beak, thickness of silique, broad surface of silique, and length of silique.

Author Contributions

Conceptualization, methodology, data curation, formal analysis, writing—original draft, writing—review and editing, M.Z. and G.L.; investigation, Y.Y.; data curation, M.J. and Y. Y.; funding acquisition, M.Z.; validation, G.L.; supervision, G.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by Jiangsu Agricultural Science and Technology Innovation Fund(SCX(22)2103),The Foundation Research Project of Jiangsu Province the Natural Science Fund (BK20211022) , Funds for Modern Agricultural Industry Technology System Construction of China (CARS-12) and Key Research Program & Technology Innovation Program of Chinese Academy of Agricultural Sciences(CAAS-ZDRW202204)

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the authors.

Data Availability Statement

All data are presented in this article in the form of figures and tables.

Acknowledgments

The authors thank the editor and anonymous reviewers for providing helpful suggestions for improving the quality of this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, L.; Zhang, J.; Chen, Z. Picuture of rape; Jiangsu Phoenix Science and Technology Press: China, 2020. [Google Scholar]

- Wang, H. New-demand oriented oilseed rape industry developing strategy. Chin. J. Oil Crop Sci. 2018, 40, 613–617. [Google Scholar]

- Wu, C.; Wang, J.; Liao, Q.; Wang, Z.; Wu, W. Current status and problems of rapeseed production. J. Chin. Agric. Mech. 2017, 38, 124–131. [Google Scholar]

- Ma, N.; Zhang, C.; Li, J. , Zhang, M.; Cheng, Y.; Li, G.; Zhang, S. Mechanical harvesting effects on seed yield loss, quality traits and profitability of winter oilseed rape (Brassica napus, L.). J. Integr. Agric. 2012, 11, 1297–1304. [Google Scholar]

- Ostergaard, L.; Kempin, S.; Bies, D.; Klee, H.; Yanofsky, M. Pod shatter-resistant Brassica fruit produced by ectopic expression of the fruitfull gene. Plant Biotechnol. J. 2006, 4, 45–51. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Xu, L.; Zhao, Z. Experiment on strength of rapeseed pod dehiscence based on impending fracturing method. Trans. Chin. Soc. Agric. Eng. 2012, 28, 111–115. [Google Scholar]

- Zhang, M.; Wu, C.; Jin, M.; Mu, S.; Liang, S.; Tang, Q. Effects of harvesting method and date on yield loss and seed quality of rapeseed. Oil Crop Sci. 2019, 4, 166–174. [Google Scholar]

- Jin, C.; Qi, Y.; Liu, G.; Yang, T.; Ni, Y. Mechanism analysis and parameter optimization of soybean combine harvester reel. Trans. Chin. Soc. Agric. Mach. 2023, 54, 104–113. [Google Scholar]

- Price, J.; Hobson, R.; Neals, M.; Bruce, D. Seed losses in commercial harvesting of oilseed rape. J. Agric. Eng. Res. 1996, 65, 183–191. [Google Scholar] [CrossRef]

- Pari, L.; Assirelli, A.; Suardi, A.; Civitarese, V.; Del, A.; Santangelo, E. Seed losses during the harvesting of oilseed rape (Brassica napus L.) at on-farm scale. J. Agric. Eng. 2013, XLIV, e126. [Google Scholar] [CrossRef]

- Bruce,D. ; Farrent, J.; Morgan, C.; Child, R. Determining the oilseed rape pod strength needed to reduce seed loss due to pod shatter. Biosyst. Eng. 2002, 81, 179–184. [Google Scholar]

- Stephenson, P.; Stacey, N.; Brueser, M.; Pullen, N.; Ostergaard, L. The power of model-to-crop translation illustrated by reducing seed loss from pod shatter in oilseed rape. Plant Reprod. 2019, 32, 331–340. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Li, G.; Yang, Y.; Jin, M.; Jiang, T. Design and Parameter Optimization of Variable Speed Reel for Oilseed Rape Combine Harvester. Preprints 2023, 2023061850. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Qing, Y. Insertion trajectory analysis and experiment of rape combine harvester reel. J. Agric. Mech. Res. 2020, 10, 189–194. [Google Scholar]

- Kadkol, G.; Macmillan, R.; Burrow, R.; Halloran, G. Evaluation of Brassica genotypes for resistance to shatter. I: Development of a laboratory test. Euphytica, 1984, 33, 63–73. [Google Scholar] [CrossRef]

- Pu, H.; Long, W.; Gao, J.; Hu, M. Silique shatter resistance and correlation analysis in brassica napus. Chinese Journal of Oil Crop Sciences 2013, 35, 469–475. [Google Scholar]

- Qiao, J.; Li, Y.; Zhao, Z.; Xu, L. Test and analysis on the silique shatter resistance of mature oilseed rape (Brassica napus L.). Journal of Agricultural Mechanization Research 2015, 37, 204–207. [Google Scholar]

- Li, Y. Design and Analysis of Grain Combine Harvester; China Machine Press: Beijing, China, 2014. [Google Scholar]

- Qing, Y.; Li, Y.; Ma, Z.; Xu, L.; Yang, Y. Technology of 2-DOF collision testing for rape pod shatter resistance. Trans. Chin. Soc. Agric. Eng. 2019, 35, 33–40. [Google Scholar]

- Zhang, M.; Jin, M.; Wang, G.; Liang, S.; Wu, C. Design and test of double crank planar five-bar reel in rape windrower. Trans. Chin. Soc. Agric. Mach. 2022, 53, 44–51. [Google Scholar]

- Guan, Z.; Wu, C.; Wang, G.; Li, H.; Mu, S. Design of bidirectional electric driven side vertical cutter for rape combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–8. [Google Scholar]

- Xu, L.; Li, Y. Modeling and experiment to threshing unit of stripper combine. Afr. J. Biotechnol. 2011, 10, 4106–4113. [Google Scholar]

- Li, H.; Wu, C.; Mu, S.; Guan, Z.; Jiang, T. Formation mechanism of laying angle of vertical rape windrower based on ANSYS-ADAMS. Trans. Chin. Soc. Agric. Eng. 2020, 36, 96–105. [Google Scholar]

- Li, P.; Liao, Q.; Li, L.; Han, C.; Huang, P.; Li, H. Design and experiment of the main device of 4SY-1.8 modified rape windrower. Trans. Chin. Soc. Agric. Eng. 2014, 45, 53–58. [Google Scholar]

- Jin, C.; Wu, C.; Jin, M.; Lu, Y.; Yuan, W.; Tang, Z. Design and experiment of 4SY-2 rape windrower. Trans. Chin. Soc. Agric. Mach. 2010, 41, 76–79. [Google Scholar]

- Liao, Q. Mechanization Technology of Rape Production; Science Press: Beijin, China, 2018. [Google Scholar]

- Lu, T.; Li, B.; Zhou, C.; Chen, D. New type of gear-cam modular reel. J. Mech. Transm. 2015, 39, 133–137. [Google Scholar]

- Xu, X.; He, M. Experiment Design and Application of Design-Expert and SPSS; Science Press: Beijing, China, 2010. [Google Scholar]

- Wen, Y.; Fu, Y.; Tu, J.; Ma, C.; Shen, J.; Zhang, S. Research progress of rapeseed resistance angle. Journal of Plant Genetic Resources. 2009, 10, 140–145. [Google Scholar]

Figure 1.

Morphological characteristics of rapeseed silique.

Figure 1.

Morphological characteristics of rapeseed silique.

Figure 2.

Swing silique collision impact test device. (1) Dial, (2) Support bar, (3) Speed calibration plate, (4) Impact member, (5) Oscillating bar,(6) Fixture, (7) Pedestal.

Figure 2.

Swing silique collision impact test device. (1) Dial, (2) Support bar, (3) Speed calibration plate, (4) Impact member, (5) Oscillating bar,(6) Fixture, (7) Pedestal.

Figure 3.

Collision test of different materials with silique.

Figure 3.

Collision test of different materials with silique.

Figure 4.

External support collision test.

Figure 4.

External support collision test.

Figure 5.

Fracture test of silique support stress position.

Figure 5.

Fracture test of silique support stress position.

Figure 6.

Load versus siliques bending deformation curve.

Figure 6.

Load versus siliques bending deformation curve.

Figure 7.

Different stress surfaces of silique.

Figure 7.

Different stress surfaces of silique.

Table 1.

Parameters of geometrical characteristics of rapeseed siliques.

Table 1.

Parameters of geometrical characteristics of rapeseed siliques.

| Morphological Characteristics of Oilseed rape silique |

Zhenyou 8 |

Ningza 1818 |

Fengyou 306 |

| Maximum value |

Minimum value |

Average value |

Maximum value |

Minimum value |

Average value |

Maximum value |

Minimum value |

average value |

| Silique length (mm) |

65.0 |

42.5 |

55.2 |

75.0 |

58.0 |

68.6 |

75.0 |

60.5 |

66.6 |

| Silique width (mm) |

5.76 |

4.60 |

5.23 |

5.86 |

4.14 |

4.83 |

5.52 |

4.48 |

5.01 |

| Silique thickness (mm) |

3.62 |

2.92 |

3.27 |

3.90 |

3.04 |

3.37 |

3.84 |

2.48 |

3.24 |

| Beak length (mm) |

13.0 |

9.0 |

10.9 |

20.0 |

14.0 |

15.9 |

18.0 |

13.0 |

15.9 |

| Pericarp thickness (mm) |

0.34 |

0.16 |

0.28 |

0.36 |

0.24 |

0.30 |

0.34 |

0.22 |

0.28 |

Table 2.

Impact velocity and stress on silique shattering rate test data.

Table 2.

Impact velocity and stress on silique shattering rate test data.

| Impact velocity/m·s-1

|

Ningza1818 |

Zhenyou 8 |

| Right ahead |

Bonding surface |

Right ahead |

Bonding surface |

| 1.5 |

0% |

5% |

0% |

0% |

| 2.5 |

10% |

30% |

5% |

15% |

| 3.5 |

15% |

50% |

5% |

40% |

| 4.5 |

30% |

65% |

15% |

60% |

Table 3.

Silique shattering rate experimental data on moisture content.

Table 3.

Silique shattering rate experimental data on moisture content.

| Moisture content of silique/% |

Moisture content of rapeseed/% |

Silique shattering rate/% |

| 20.61 |

23.85 |

25 |

| 15.83 |

17.29 |

45 |

| 9.24 |

8.06 |

75 |

Table 4.

Experimental data of different growth positions of silique on shattering rate.

Table 4.

Experimental data of different growth positions of silique on shattering rate.

| |

Different distribution locations of silique |

| Top of main branch |

Middle of main branch |

Bottom of main branch |

| Shattering rate/% |

50 |

40 |

25 |

Table 5.

Experimental data of silique shattering rate under supported conditions.

Table 5.

Experimental data of silique shattering rate under supported conditions.

| Unsupported |

Support position |

| Horizon 0mm |

Horizon 5mm |

Horizon 10mm |

| 40% |

100% |

90% |

75% |

Table 6.

Impending fracturing test values at silique support locations.

Table 6.

Impending fracturing test values at silique support locations.

| Serial number |

Carpopodium and beak |

Carpopodiums and petals |

Siliques body support |

| Maximum cracking force/N |

Flexural strength/MPa |

Maximum cracking force/N |

Flexural strength/MPa |

Maximum cracking force/N |

Flexural strength/MPa |

| 1 |

1.45 |

6.05 |

2.14 |

8.19 |

3.12 |

8.61 |

| 2 |

1.11 |

4.62 |

2.18 |

8.33 |

3.41 |

9.45 |

| 3 |

1.44 |

6.02 |

1.90 |

7.24 |

3.48 |

9.45 |

| 4 |

1.57 |

6.54 |

2.4 |

9.16 |

3.05 |

8.48 |

| 5 |

1.73 |

7.21 |

2.05 |

7.83 |

4.16 |

11.57 |

| Average value |

1.46 |

6.09 |

2.13 |

8.15 |

3.44 |

9.51 |

Table 7.

Impending fracturing test data for different silique stress surfaces.

Table 7.

Impending fracturing test data for different silique stress surfaces.

| |

Zhenyou8 |

Ningza1818 |

Fengyou306 |

| Average value of maximum cracking force /N |

Average value of flexural strength/MPa |

Average value of maximum cracking force/N |

Average value of flexural strength/MPa |

Average value of maximum cracking force/N |

Average value of flexural strength/MPa |

| Petal front |

1.68 |

4.66 |

1.51 |

5.81 |

1.33 |

4.63 |

| Petal bonding surface |

1.03 |

3.82 |

0.72 |

3.44 |

0.76 |

3.54 |

| Average value |

1.35 |

4.24 |

1.12 |

4.62 |

1.04 |

4.09 |

Table 8.

Analysis of variance table of maximum cracking force of silique on rapeseed varieties and stress surfaces.

Table 8.

Analysis of variance table of maximum cracking force of silique on rapeseed varieties and stress surfaces.

| Source of variation |

SS |

f |

MS |

F value |

P value |

| Rapeseed varieties |

1.055 |

2 |

0.528 |

21.668 |

<0.001*** |

| Silique different stress surfaces |

6.687 |

1 |

6.687 |

274.563 |

<0.001*** |

| Rapeseed varieties×different stress surfaces |

0.145 |

2 |

0.072 |

2.969 |

0.06 |

| Error |

1.315 |

4 |

0.024 |

|

|

| Total variation |

9.202 |

9 |

|

|

|

Table 9.

Analysis of variance table for flexural strength of silique on rapeseed varieties and stress surfaces.

Table 9.

Analysis of variance table for flexural strength of silique on rapeseed varieties and stress surfaces.

| Source of variation |

SS |

df |

MS |

F value |

P value |

| Rapeseed varieties |

3.110 |

2 |

1.555 |

4.798 |

0.012 |

| Silique different stress surfaces |

30.774 |

1 |

30.774 |

94.976 |

<0.001 |

| Rapeseed varieties×Different stress surfaces |

6.731 |

2 |

3.366 |

10.387 |

<0.001 |

| Error |

17.497 |

54 |

0.324 |

|

|

| Total variation |

58.111 |

59 |

|

|

|

Table 10.

Impending fracturing test data with different loading rate and silique growth position.

Table 10.

Impending fracturing test data with different loading rate and silique growth position.

| |

Silique at the top of plant |

Silique at the middle of plant |

Silique at the bottom of plant |

| Average value of the maximum cracking force /N |

Average value of flexural strength/MPa |

Average value of maximum cracking force /N |

Average value of flexural strength/MPa |

Average value of maximum cracking force /N |

Average value of flexural strength/MPa |

| Loading speed 5mm·min-1

|

1.85 |

5.15 |

1.91 |

5.32 |

1.86 |

5.16 |

| Loading speed 15 mm·min-1

|

2.21 |

6.14 |

2.32 |

6.45 |

2.18 |

6.06 |

| Loading speed 25 mm·min-1

|

2.07 |

5.75 |

2.15 |

5.98 |

1.96 |

5.46 |

| Average value |

2.02 |

5.63 |

2.11 |

5.86 |

2.00 |

5.57 |

Table 11.

Analysis of variance of silique position and loading speed on the maximum cracking force of siliques.

Table 11.

Analysis of variance of silique position and loading speed on the maximum cracking force of siliques.

| Source of variation |

Type III sum of squares |

Degree of freedom |

Mean square |

F |

Significance |

| Correction model |

0.891 |

8 |

0.111 |

14.001 |

<0.001 |

| Intercept |

135.296 |

1 |

135.296 |

17007.528 |

<0.001 |

| Silique distribution location |

0.095 |

2 |

0.047 |

5.951 |

0.008 |

| Loading speed |

0.776 |

2 |

0.388 |

48.785 |

<0.001 |

| Silique distribution location×Loading speed |

0.019 |

4 |

0.005 |

0.610 |

0.625 |

| Error |

0.191 |

24 |

0.008 |

|

|

| Total |

139.453 |

33 |

|

|

|

| Correction total |

1.082 |

32 |

|

|

|

Table 12.

Analysis of variance of silique position and loading speed on silique flexural strength.

Table 12.

Analysis of variance of silique position and loading speed on silique flexural strength.

| Source of variation |

Type III sum of squares |

Degree of freedom |

Mean square |

F |

Significance |

| Correction model |

6.907 |

8 |

0.863 |

14.050 |

<0.001 |

| Intercept |

1045.86 |

1 |

1045.857 |

17020.024 |

<0.001 |

| Silique distribution location |

0.739 |

2 |

0.370 |

6.017 |

0.008 |

| Loading speed |

6.012 |

2 |

3.006 |

48.922 |

<0.001 |

| Silique distribution location×Loading speed |

0.149 |

4 |

0.037 |

0.608 |

0.661 |

| Error |

1.475 |

24 |

0.061 |

|

|

| Total |

1078.045 |

33 |

|

|

|

| Correction total |

8.382 |

32 |

|

|

|

Table 13.

Morphological parameters of Ningza 1818 rapeseed silique.

Table 13.

Morphological parameters of Ningza 1818 rapeseed silique.

| Silique characters |

Range of variability |

Average value |

Standard deviation |

Coefficient of variation/% |

Skewness coefficient |

Kurtosis coefficient |

| Silique length/mm |

45~76 |

66.122 |

6.3491 |

9.60 |

-0.994 |

1.184 |

| Beak length/mm |

13~20 |

15.522 |

1.4318 |

9.22 |

0.659 |

1.169 |

| Width/mm |

3.94~5.96 |

4.8471 |

0.42494 |

8.77 |

0.333 |

0.657 |

| Thickness/mm |

2.96~4.26 |

3.3467 |

0.29354 |

8.77 |

1.091 |

0.718 |

| Pericarp thickness/mm |

0.22~0.36 |

0.2947 |

0.03507 |

11.90 |

0.048 |

-0.836 |

| Diameter of carpopodium/mm |

0.56~0.88 |

0.6998 |

0.06469 |

9.24 |

0.393 |

0.558 |

| Angle/° |

0~29 |

10.489 |

8.2697 |

78.84 |

0.41 |

-0.833 |

Table 14.

Correlation analysis between shattering with morphological characters.

Table 14.

Correlation analysis between shattering with morphological characters.

| Characteristic |

Length

/mm |

Beak length

/mm |

Width

/mm |

Thickness

/mm |

Pericarp Thickness/mm |

diameter of carpopodium/mm |

Angle |

Shattering |

| Silique length (mm) |

1 |

|

|

|

|

|

|

|

| Beak length (mm) |

0.296** |

1 |

|

|

|

|

|

|

| Silique width (mm) |

0.346** |

-0.135 |

1 |

|

|

|

|

|

| Silique thickness (mm) |

-0.024 |

0.220* |

0.377** |

1 |

|

|

|

|

| Petal thickness (mm) |

-0.071 |

0.186 |

0.244* |

0.784** |

1 |

|

|

|

| Diameter of carpopodium (mm) |

0.232* |

0.135 |

0.576** |

0.587** |

0.456** |

1 |

|

|

| Angle between carpopodium and silique |

0.139 |

0.1 |

0.092 |

-0.038 |

-0.013 |

0.168 |

1 |

|

| Shattering |

0.07 |

0.226* |

0.15 |

0.197 |

0.19 |

0.594** |

-0.068 |

1 |

Table 15.

Grey correlation analysis.

Table 15.

Grey correlation analysis.

| Silique morphological characteristics |

Correlation |

Rank |

| The angle of the silique stalk to the silique (°) |

0.586 |

1 |

| Diameter of the silique stalk (mm) |

0.552 |

2 |

| Thickness of the pericarp (mm) |

0.546 |

3 |

| Length of the beak (mm) |

0.545 |

4 |

| Thickness of the silique (mm) |

0.544 |

5 |

| Width of the silique (mm) |

0.543 |

6 |

| Length of the silique (mm) |

0.542 |

7 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).