Submitted:

01 August 2023

Posted:

02 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Material and Methods

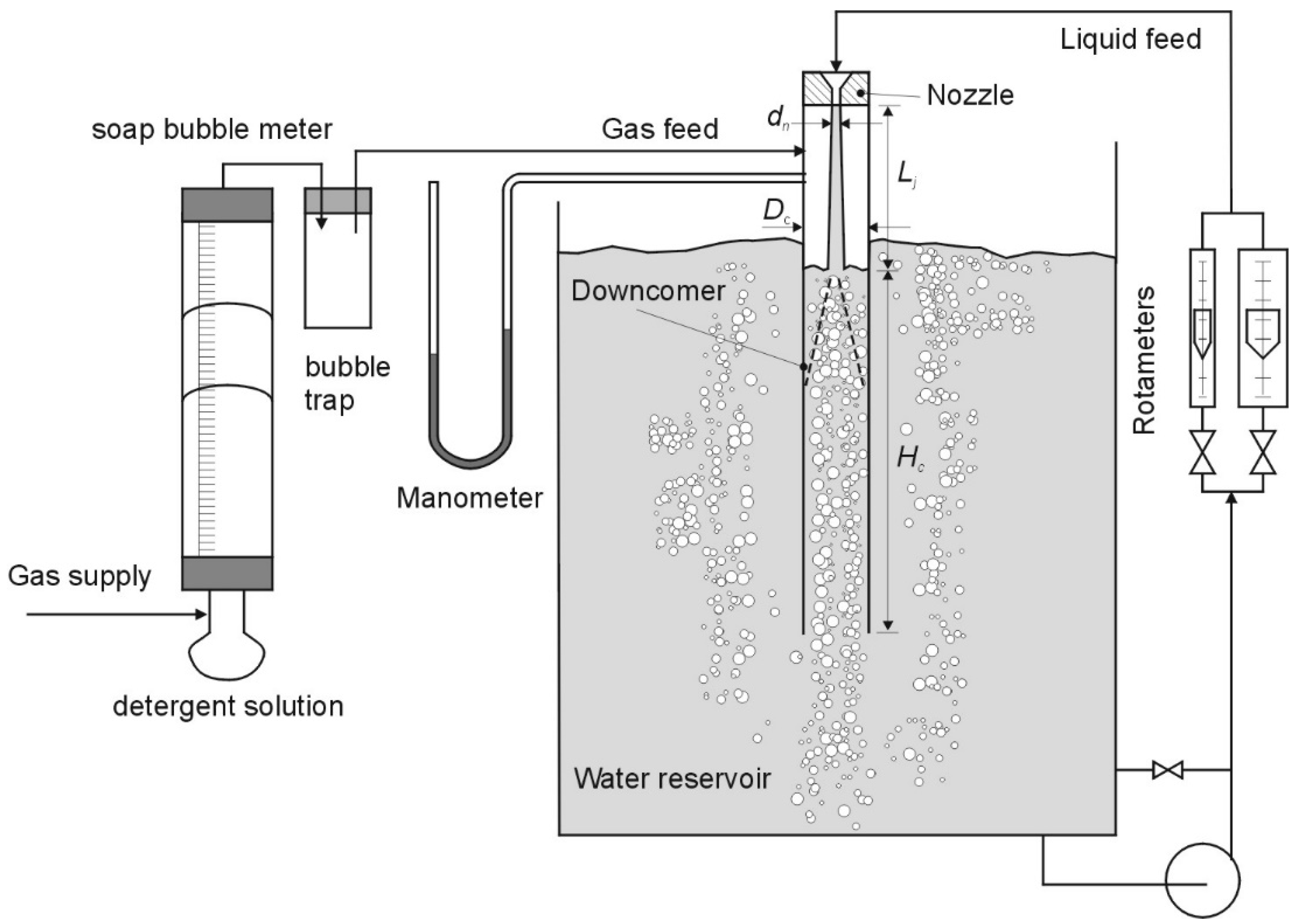

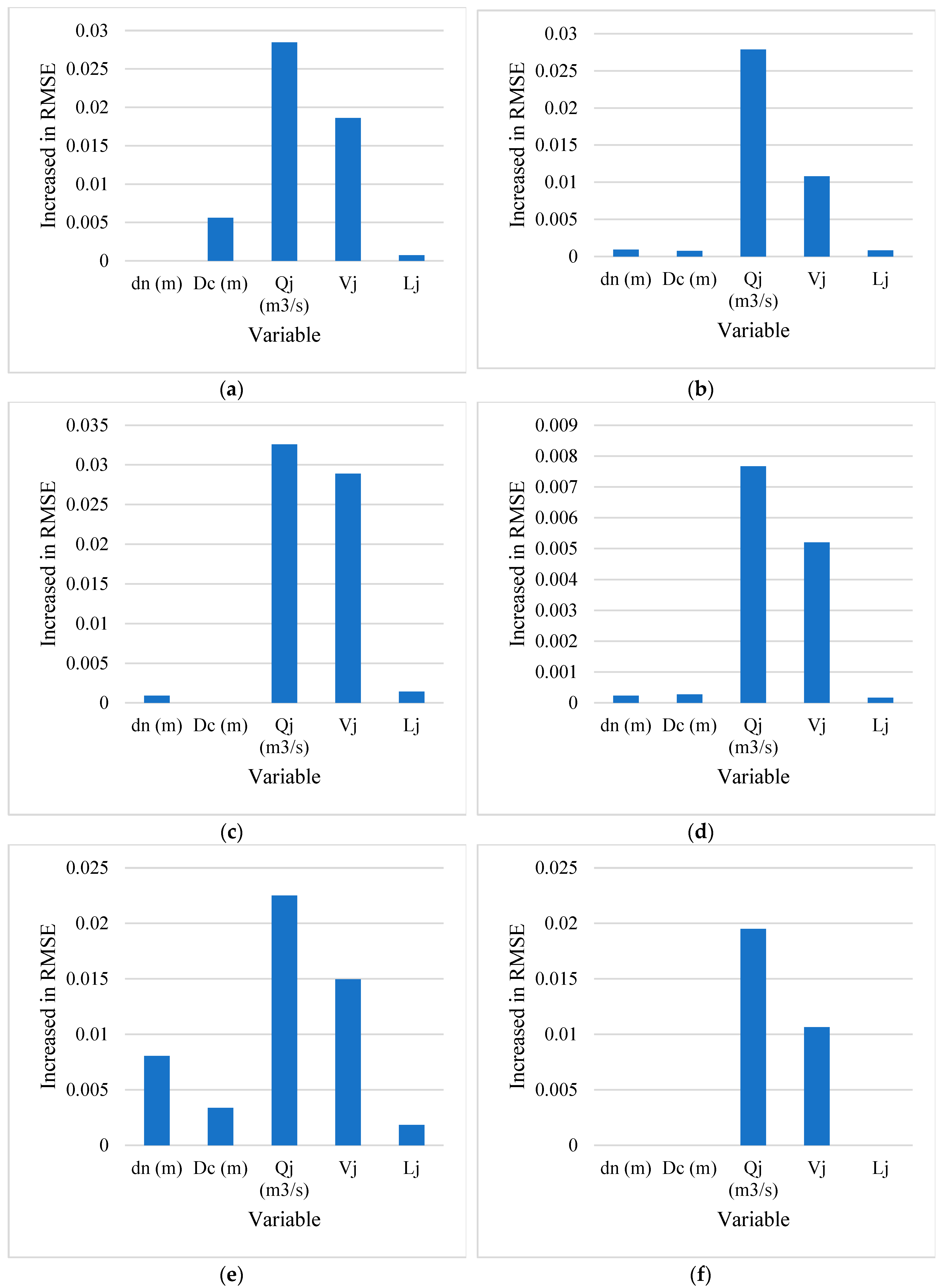

2.1. Experimental Work and Data Collection

2.2. Dataset

2.3. Modelling

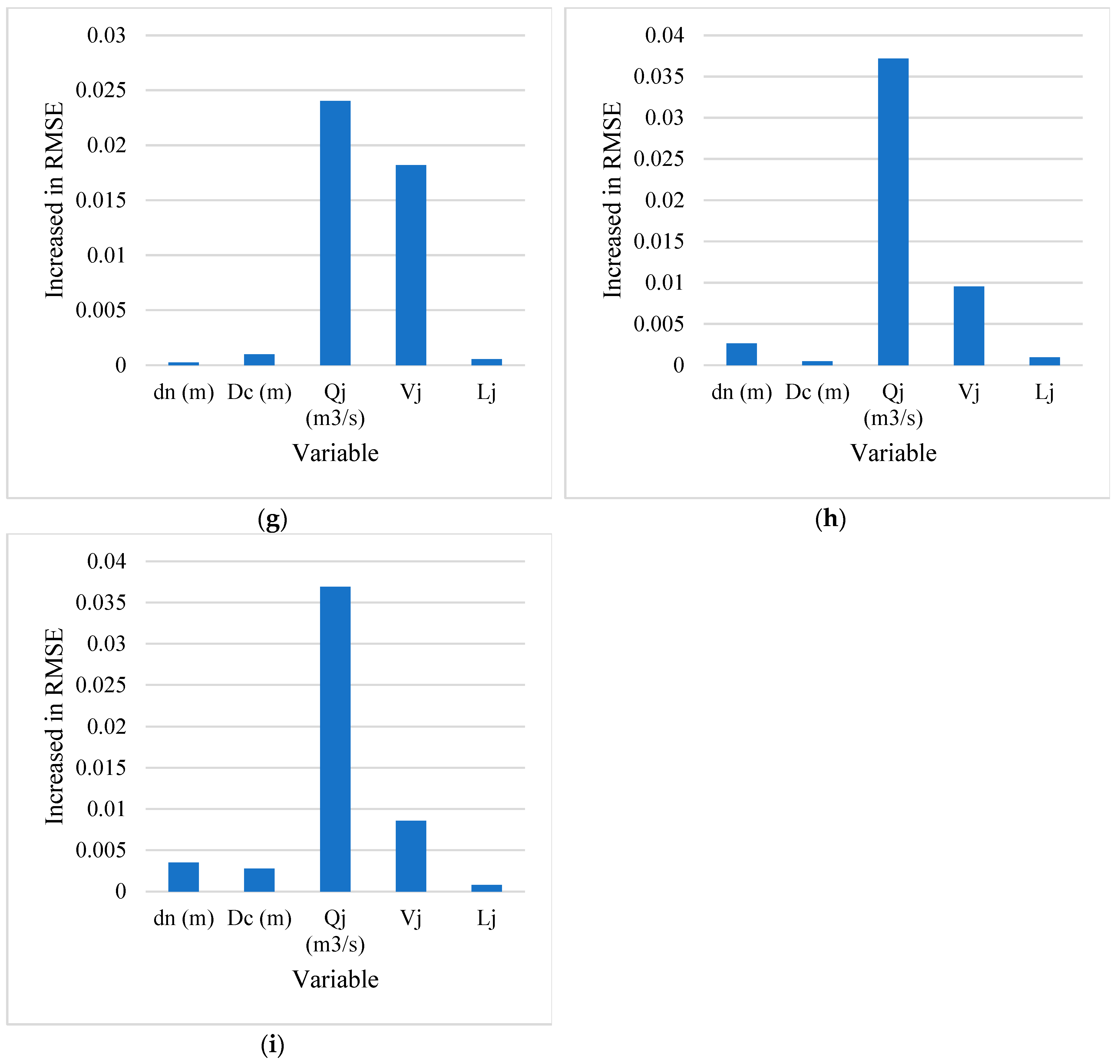

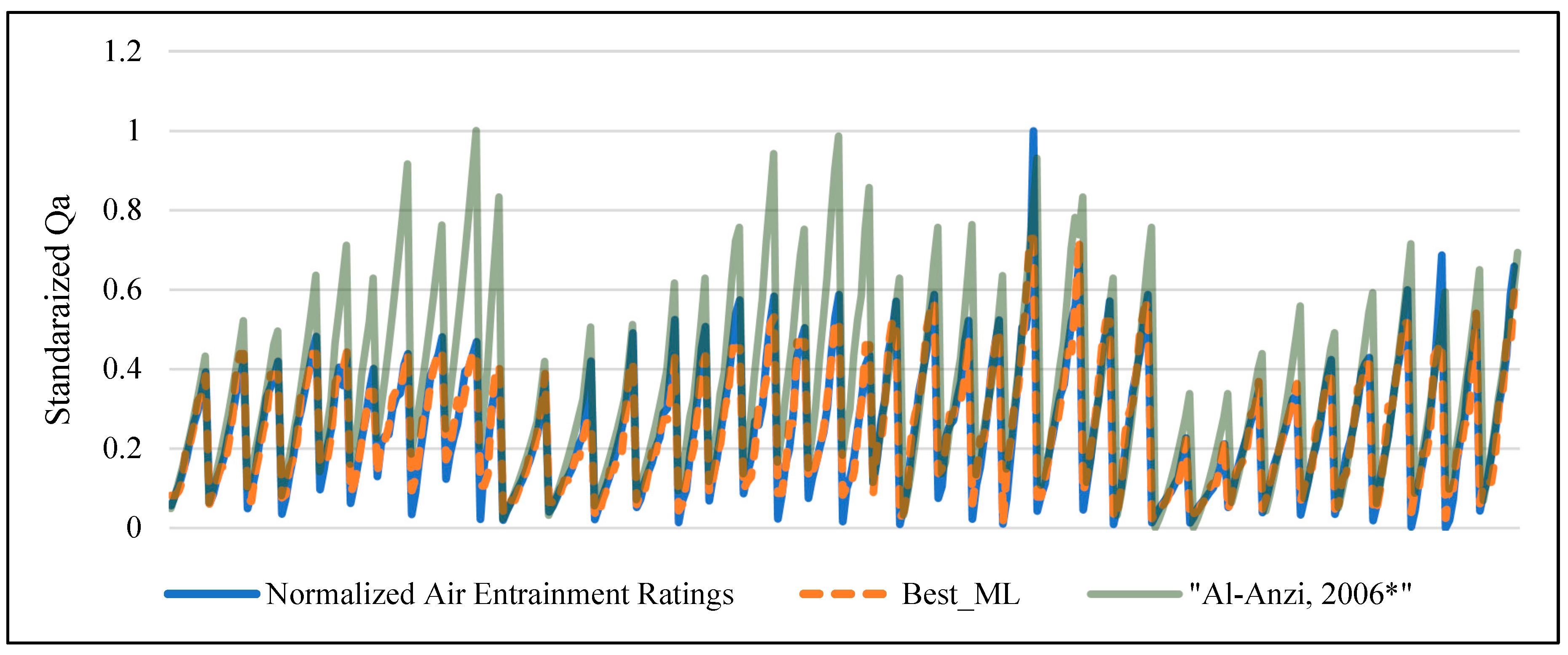

2.4. Results

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akhoundi, A., & Nazif, S. (2018). Sustainability assessment of wastewater reuse alternatives using the evidential reasoning approach. Journal of Cleaner Production, 195, 1350–1376. [CrossRef]

- Al-Anzi, B. S., Cumming, I. W., & Rielly, C. D. (2006). A IR ENTRAINMENT RATES IN A CONFINED PLUNGING LIQUID JET REACTOR. The 10th International Conference on Multiphase Flow in Industrial Plants, 1, 71–82.

- Al-Anzi, Bader S. (2020). Effect of Primary Variables on A Confined Plunging liquid jet reactor. Water, 12, 1–13. [CrossRef]

- Al-Anzi, Bader S., & Fernandes, J. (2023). Measurement of Total Air Entrainment, Disentrainment and Net Entrainment Flow Rates Utilizing Novel Downcomer Incorporating Al-Anzi’s Disentrainment Ring (ADR) in a Confined Plunging Jet Reactor. Water (Switzerland), 15(5). [CrossRef]

- Al Aani, S., Bonny, T., Hasan, S. W., & Hilal, N. (2019). Can machine language and artificial intelligence revolutionize process automation for water treatment and desalination? Desalination, 458, 84–96. [CrossRef]

- Bagatur, T., Baylar, A., & Sekerdag, N. (2002). The effect of nozzle type on air entrainment by plunging water jets. Water Quality Research Journal, 37(3), 599–612. [CrossRef]

- Bagatur, T., & Onen, F. (2014). A predictive model on air entrainment by plunging water jets using GEP and ANN. KSCE Journal of Civil Engineering, 18(1), 304–314. 1. [CrossRef]

- Bagheri, M., Mirbagheri, S. A., Ehteshami, M., & Bagheri, Z. (2015). Modeling of a sequencing batch reactor treating municipal wastewater using multi-layer perceptron and radial basis function artificial neural networks. Process Safety and Environmental Protection, 93, 111–123. [CrossRef]

- Baylar, A., & Emiroglu, M. E. (2003). Air entrainment and oxygen transfer in a venturi. Proceedings of the Institution of Civil Engineers-Water and Maritime Engineering, 156(3), 249–255.

- Bozkurt, H., van Loosdrecht, M. C. M., Gernaey, K. V, & Sin, G. (2016). Optimal WWTP process selection for treatment of domestic wastewater–A realistic full-scale retrofitting study. Chemical Engineering Journal, 286, 447–458. [CrossRef]

- Buaisha, M., Balku, S., & Özalp-Yaman, S. (2020). Heavy metal removal investigation in conventional activated sludge systems. Civil Engineering Journal, 6(3), 470–477. 3. [CrossRef]

- Cao, W., & Yang, Q. (2020). Online sequential extreme learning machine based adaptive control for wastewater treatment plant. Neurocomputing, 408, 169–175. [CrossRef]

- Chakraborty, T., Chakraborty, A. K., & Chattopadhyay, S. (2019). A novel distribution-free hybrid regression model for manufacturing process efficiency improvement. Journal of Computational and Applied Mathematics, 362, 130–142. [CrossRef]

- Chanapathi, T., & Thatikonda, S. (2019). Fuzzy-based regional water quality index for surface water quality assessment. Journal of Hazardous, Toxic, and Radioactive Waste, 23(4), 4019010. [CrossRef]

- Chen, J.-C., Chang, N. B., & Shieh, W. K. (2003). Assessing wastewater reclamation potential by neural network model. Engineering Applications of Artificial Intelligence, 16(2), 149–157. [CrossRef]

- Deswal, S. (2011a). Modeling oxygen-transfer by multiple plunging jets using support vector machines and Gaussian process regression techniques. International Journal of Civil and Environmental Engineering, 5(1), 1–6.

- Deswal, S. (2011b). Modeling oxygen-transfer by multiple plunging jets using support vector machines and Gaussian process regression techniques. World Academy of Science, Engineering and Technology, 73.

- Emiroglu, M. E., & Baylar, A. (2003). Role of nozzles with air holes in air entrainment by a water jet. Water Quality Research Journal, 38(4), 785–795. [CrossRef]

- Erdirencelebi, D., & Yalpir, S. (2011). Adaptive network fuzzy inference system modeling for the input selection and prediction of anaerobic digestion effluent quality. Applied Mathematical Modelling, 35(8), 3821–3832. [CrossRef]

- Fenu, A., Guglielmi, G., Jimenez, J., Sperandio, M., Saroj, D., Lesjean, B., Brepols, C., Thoeye, C., & Nopens, I. (2010). Activated sludge model (ASM) based modelling of membrane bioreactor (MBR) processes: A critical review with special regard to MBR specificities. Water Research, 44(15), 4272–4294. [CrossRef]

- Graham, S. E., Chariton, A. A., & Landis, W. G. (2019). Using Bayesian networks to predict risk to estuary water quality and patterns of benthic environmental DNA in Queensland. Integrated Environmental Assessment and Management, 15(1), 93–111. 1. [CrossRef]

- Granata, F., & de Marinis, G. (2017). Machine learning methods for wastewater hydraulics. Flow Measurement and Instrumentation, 57, 1–9.

- Harby, K., Chiva, S., & Muñoz-Cobo, J.-L. (2014). An experimental study on bubble entrainment and flow characteristics of vertical plunging water jets. Experimental Thermal and Fluid Science, 57, 207–220. [CrossRef]

- Jia, X., Li, Z., Tan, R. R., Foo, D. C. Y., Majozi, T., & Wang, F. (2019). Interdisciplinary contributions to sustainable water management for industrial parks. In Resources, Conservation and Recycling (Vol. 149, pp. 646–648). Elsevier. [CrossRef]

- Li, D., Yang, H. Z., & Liang, X. F. (2013). Prediction analysis of a wastewater treatment system using a Bayesian network. Environmental Modelling & Software, 40, 140–150.

- Liu, H., Zhang, Y., & Zhang, H. (2020). Prediction of effluent quality in papermaking wastewater treatment processes using dynamic kernel-based extreme learning machine. Process Biochemistry, 97, 72–79. [CrossRef]

- Long, S., Zhao, L., Liu, H., Li, J., Zhou, X., Liu, Y., Qiao, Z., Zhao, Y., & Yang, Y. (2019). A Monte Carlo-based integrated model to optimize the cost and pollution reduction in wastewater treatment processes in a typical comprehensive industrial park in China. Science of the Total Environment, 647, 1–10. [CrossRef]

- López-Morales, C. A., & Rodríguez-Tapia, L. (2019). On the economic analysis of wastewater treatment and reuse for designing strategies for water sustainability: Lessons from the Mexico Valley Basin. Resources, Conservation and Recycling, 140, 1–12. [CrossRef]

- López, M. E., Rene, E. R., Boger, Z., Veiga, M. C., & Kennes, C. (2017). Modelling the removal of volatile pollutants under transient conditions in a two-stage bioreactor using artificial neural networks. Journal of Hazardous Materials, 324, 100–109. [CrossRef]

- Lu, H., Li, H., Liu, T., Fan, Y., Yuan, Y., Xie, M., & Qian, X. (2019). Simulating heavy metal concentrations in an aquatic environment using artificial intelligence models and physicochemical indexes. Science of the Total Environment, 694, 133591. [CrossRef]

- Man, Y., Hu, Y., & Ren, J. (2019). Forecasting COD load in municipal sewage based on ARMA and VAR algorithms. Resources, Conservation and Recycling, 144, 56–64. [CrossRef]

- Metcalf, E., Tchobanoglous, G., Stensel, H. D., Tsuchihashi, R., & Burton, F. (2013). Wastewater Engineering: Treatment and Resource Recovery McGraw-Hill. New York, NY, USA.

- Mohandes, M., Rehman, S., & Rahman, S. M. (2011). Estimation of wind speed profile using adaptive neuro-fuzzy inference system (ANFIS). Applied Energy, 88(11), 4024–4032. 4032. [CrossRef]

- Müller, A. C., & Guido, S. (2016). Introduction to machine learning with Python: a guide for data scientists. “ O’Reilly Media, Inc.”.

- Nadiri, A. A., Shokri, S., Tsai, F. T.-C., & Asghari Moghaddam, A. (2018). Prediction of effluent quality parameters of a wastewater treatment plant using a supervised committee fuzzy logic model. Journal of Cleaner Production, 180, 539–549. [CrossRef]

- Nopens, I., Batstone, D. J., Copp, J. B., Jeppsson, U., Volcke, E., Alex, J., & Vanrolleghem, P. A. (2009). An ASM/ADM model interface for dynamic plant-wide simulation. Water Research, 43(7), 1913–1923. [CrossRef]

- Ohkawa, A., Kusabiraki, D., Shiokawa, Y., Sakai, N., & Fujii, M. (1986). Flow and oxygen transfer in a plunging water jet system using inclined short nozzles and performance characteristics of its system in aerobic treatment of wastewater. Biotechnology and Bioengineering, 28(12), 1845–1856. 12. [CrossRef]

- Onen, F. (2014). Prediction of penetration depth in a plunging water jet using soft computing approaches. Neural Computing and Applications, 25(1), 217–227. [CrossRef]

- Qiao, Y., Zhang, S., Wu, N., Wang, X., Li, Z., Zhou, M., & Qu, T. (2019). Data-driven approach to optimal control of ACC systems and layout design in large rooms with thermal comfort consideration by using PSO. Journal of Cleaner Production, 236, 117578. [CrossRef]

- Qu, X. L., Khezzar, L., Danciu, D., Labois, M., & Lakehal, D. (2011). Characterization of plunging liquid jets: A combined experimental and numerical investigation. International Journal of Multiphase Flow, 37(7), 722–731. [CrossRef]

- Ranjan, S. (2008). Hydraulics of jet aerators. Journal of the Institution of Engineers (India): Environmental Engineering Division, 88, 29–32.

- Ranjan, Subodh. (2007). Hydraulics of hollow jet aerators. Journal of Indian Water Resources Society, 27(1–2), 27–31.

- Rout, P. R., Zhang, T. C., Bhunia, P., & Surampalli, R. Y. (2021). Treatment technologies for emerging contaminants in wastewater treatment plants: A review. Science of the Total Environment, 753, 141990. [CrossRef]

- Sattar, A. A., Elhakeem, M., Rezaie-Balf, M., Gharabaghi, B., & Bonakdari, H. (2019). Artificial intelligence models for prediction of the aeration efficiency of the stepped weir. Flow Measurement and Instrumentation, 65, 78–89. [CrossRef]

- Shi, S., & Xu, G. (2018). Novel performance prediction model of a biofilm system treating domestic wastewater based on stacked denoising auto-encoders deep learning network. Chemical Engineering Journal, 347, 280–290. [CrossRef]

- Sousa, V., Matos, J. P., & Matias, N. (2014). Evaluation of artificial intelligence tool performance and uncertainty for predicting sewer structural condition. Automation in Construction, 44, 84–91. [CrossRef]

- Tojo, K., & Miyanami, K. (1982). Oxygen transfer in jet mixers. The Chemical Engineering Journal, 24(1), 89–97. 1.

- Van de Sande, E., & Smith, J. M. (1975). Mass transfer from plunging water jets. The Chemical Engineering Journal, 10(3), 225–233. 3.

- Vučić, V., Süring, C., Harms, H., Müller, S., & Günther, S. (2021). A framework for P-cycle assessment in wastewater treatment plants. Science of The Total Environment, 760, 143392. [CrossRef]

- Wagner, W. P. (2017). Trends in expert system development: A longitudinal content analysis of over thirty years of expert system case studies. Expert Systems with Applications, 76, 85–96.

- Wang, J., & Deng, Z. (2016). Modeling and prediction of oyster norovirus outbreaks along Gulf of Mexico coast. Environmental Health Perspectives, 124(5), 627–633. 124, 5, 627–633. [CrossRef]

- Wu, X., Yang, Y., Wu, G., Mao, J., & Zhou, T. (2016). Simulation and optimization of a coking wastewater biological treatment process by activated sludge models (ASM). Journal of Environmental Management, 165, 235–242. [CrossRef]

- (a)Yang, Z., Liu, Y., & Li, C. (2011). Interpolation of missing wind data based on ANFIS. Renewable Energy, 36(3), 993–998.

- Zhang, Y., Gao, X., Smith, K., Inial, G., Liu, S., Conil, L. B., & Pan, B. (2019). Integrating water quality and operation into prediction of water production in drinking water treatment plants by genetic algorithm enhanced artificial neural network. Water Research, 164, 114888. [CrossRef]

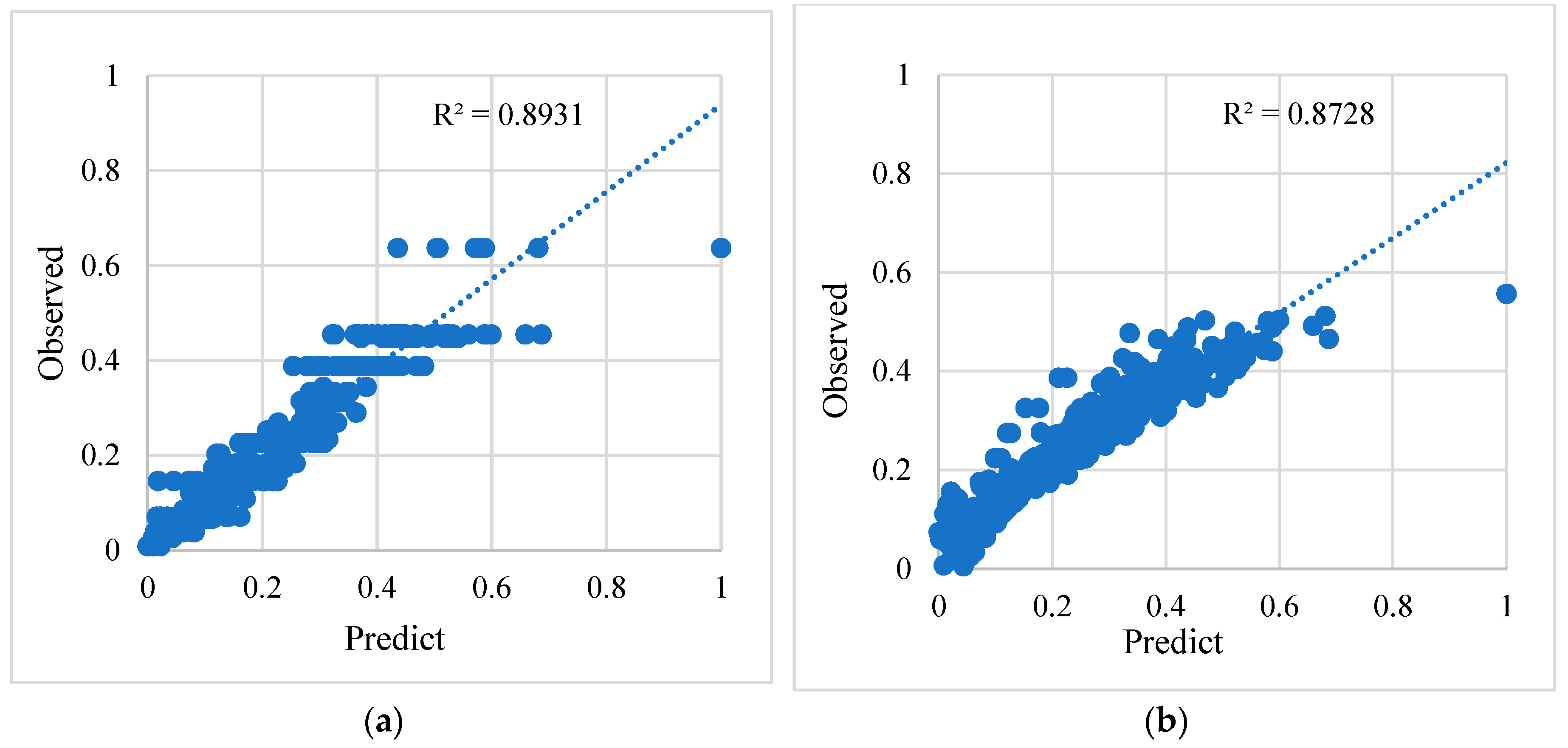

| Regressor | MAE | RMSE | R2 |

|---|---|---|---|

| Decision Tree | 0.0387 | 0.0539 | 0.8931 |

| Elastic Net | 0.0442 | 0.0618 | 0.8728 |

| Extra Tree | 0.0430 | 0.0598 | 0.8685 |

| Gradient Boosting | 0.1014 | 0.1255 | 0.9027 |

| K-Neighbours | 0.0271 | 0.0403 | 0.9423 |

| Lasso | 0.0656 | 0.0854 | 0.8279 |

| Random Forest | 0.0371 | 0.0552 | 0.8873 |

| Ridge | 0.0408 | 0.0581 | 0.8753 |

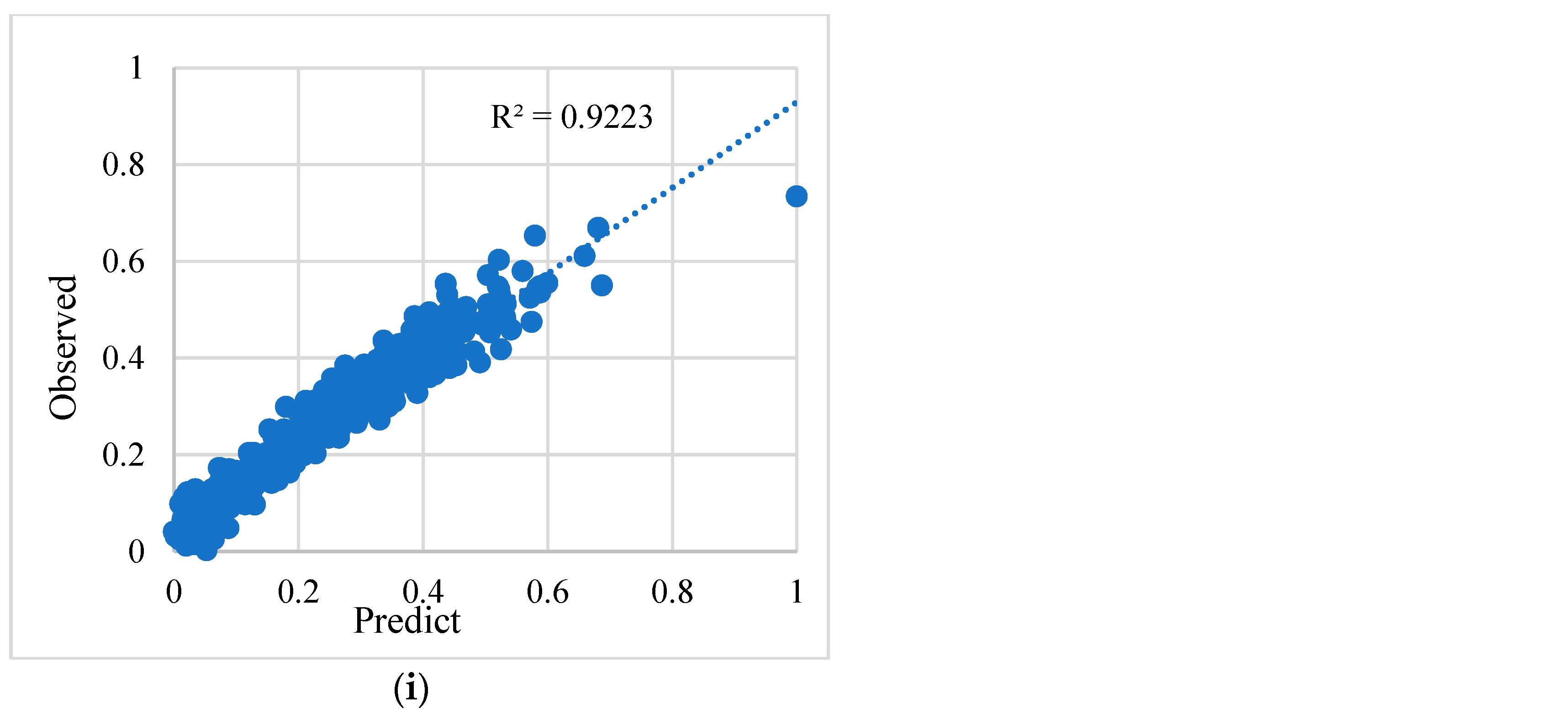

| Support Vector Machine | 0.0381 | 0.0484 | 0.9223 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).