Submitted:

31 July 2023

Posted:

02 August 2023

You are already at the latest version

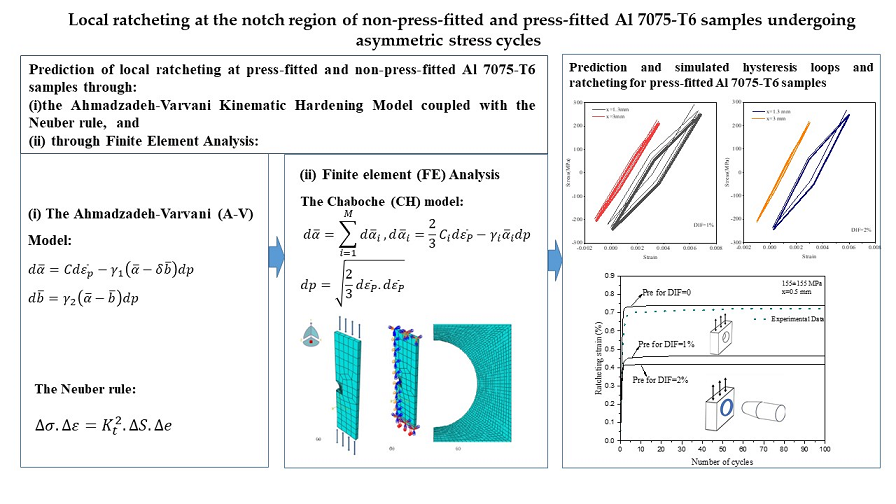

Abstract

Keywords:

1. Introduction

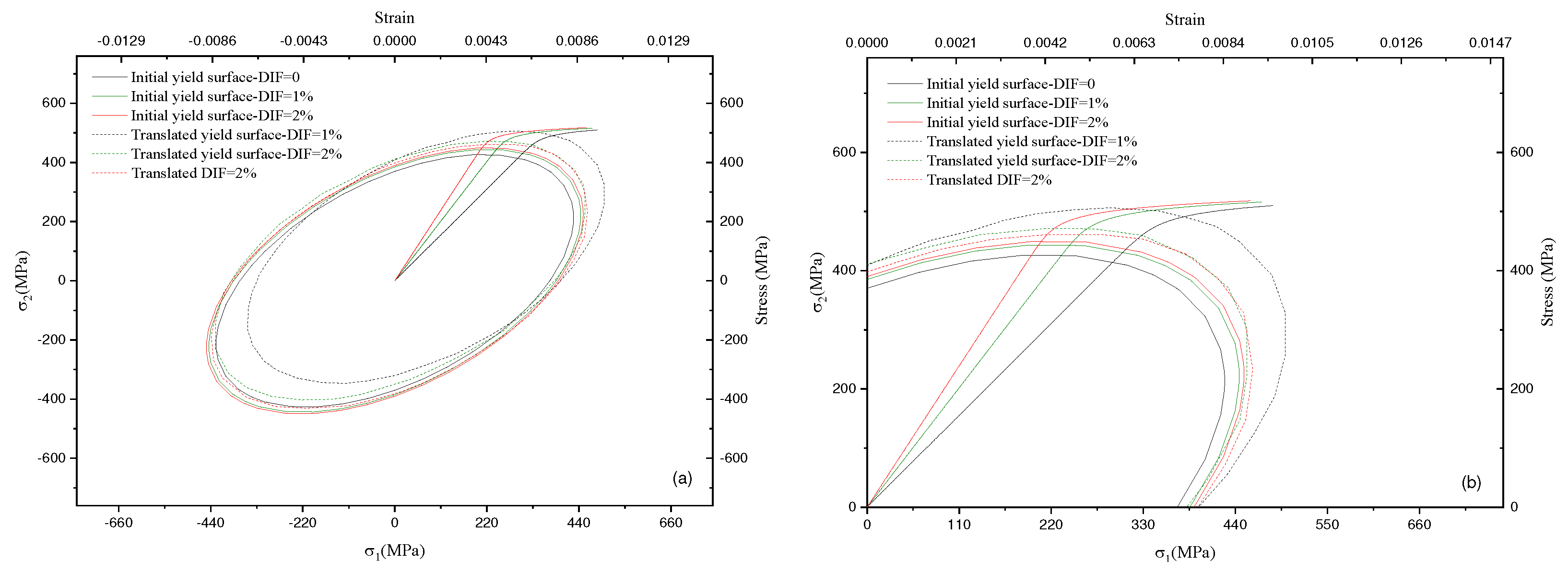

2. Kinematic hardening rules and formulation

2.1. The Ahmadzadeh-Varvani (A-V) kinematic hardening rule

2.2. Neuber’s rule: Relating nominal stress/strain to Local components of stress and strain at notch root

2.3. The Chaboche kinematic hardening rule

3. Results and Discussion

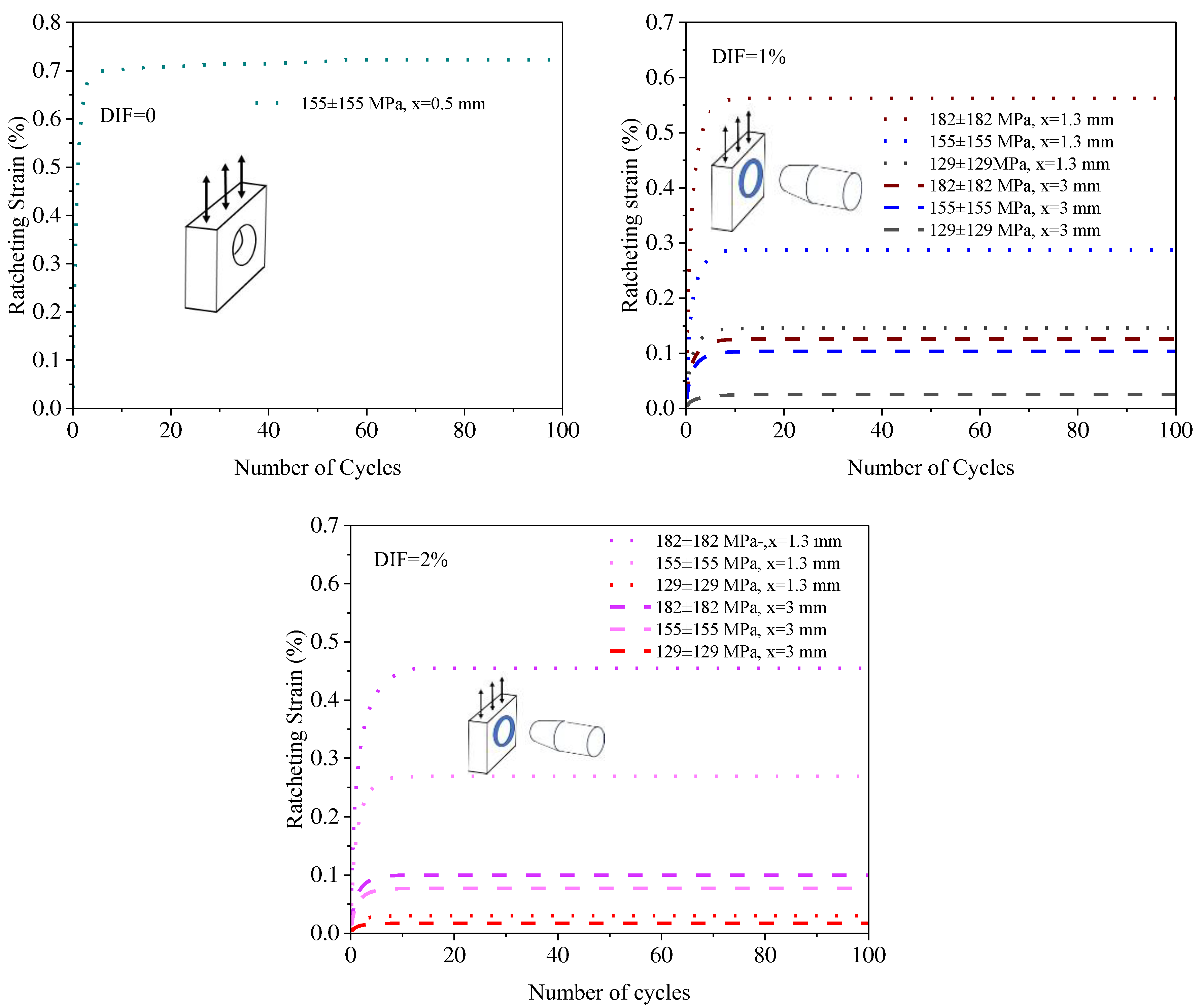

3.1. Ratcheting Data

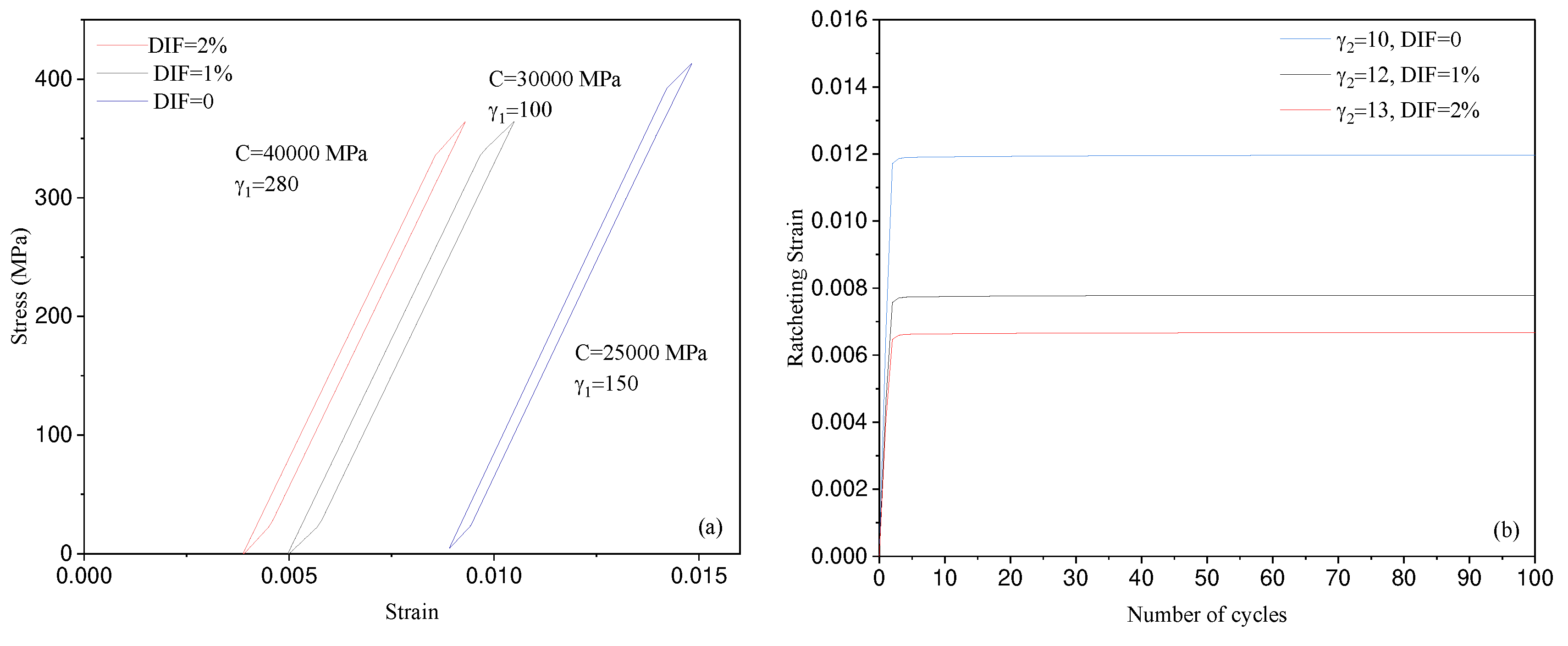

3.2. Kinematic Hardening Rule Coefficients:

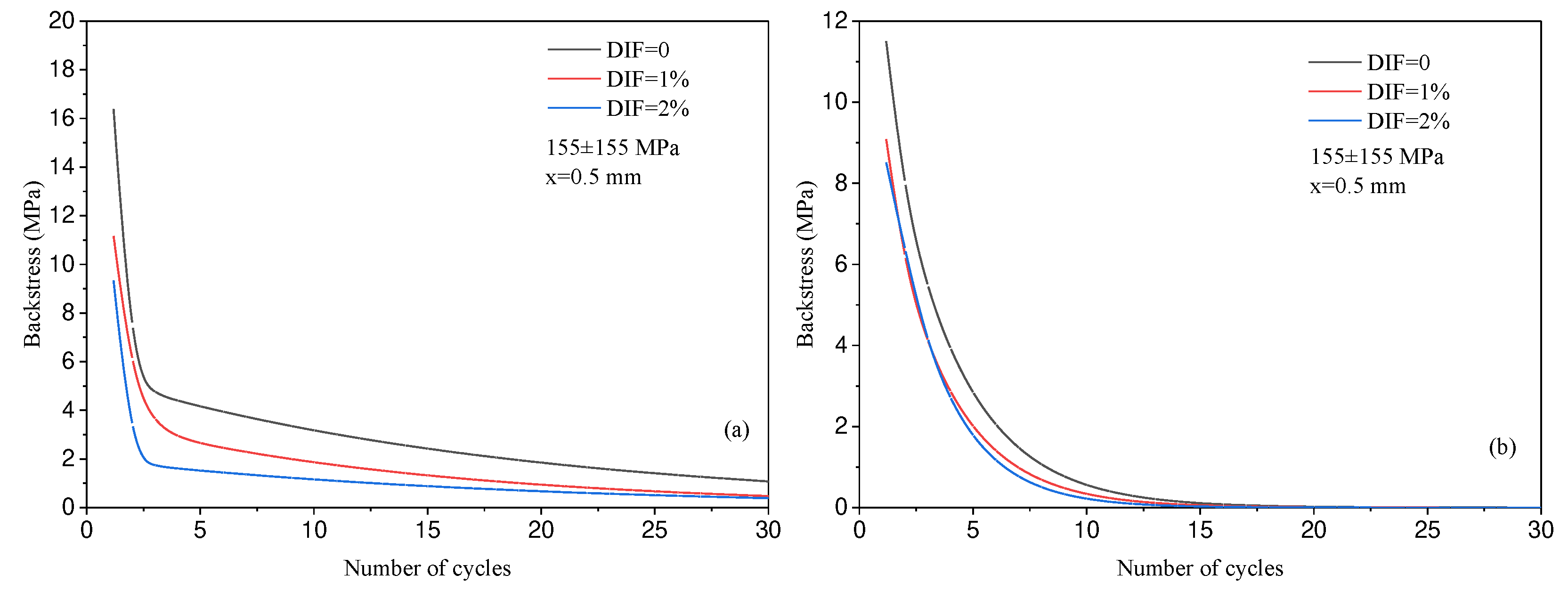

3.4. Backstress evolution with Loading

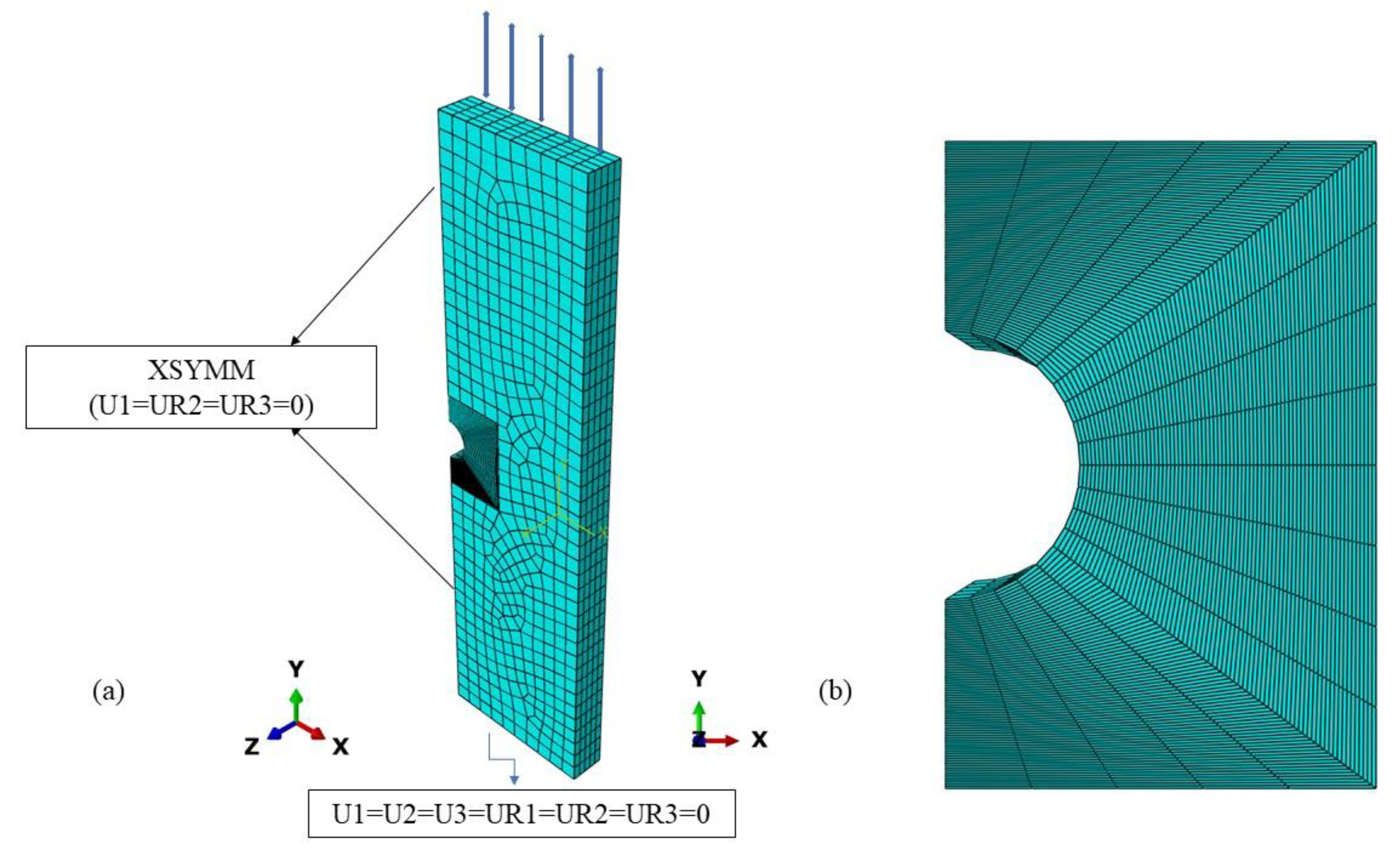

3.5. Finite Element Analysis and stress distribution

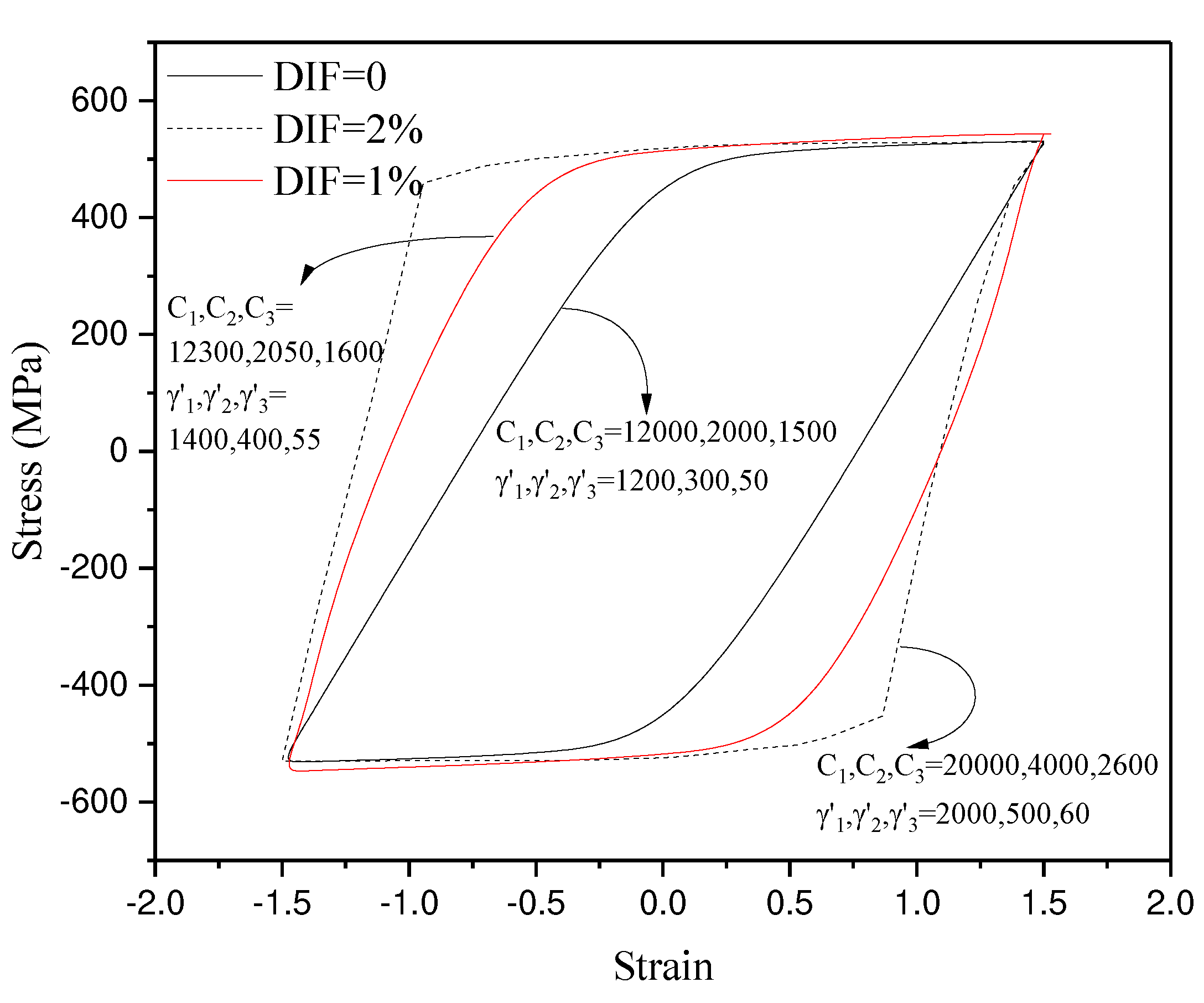

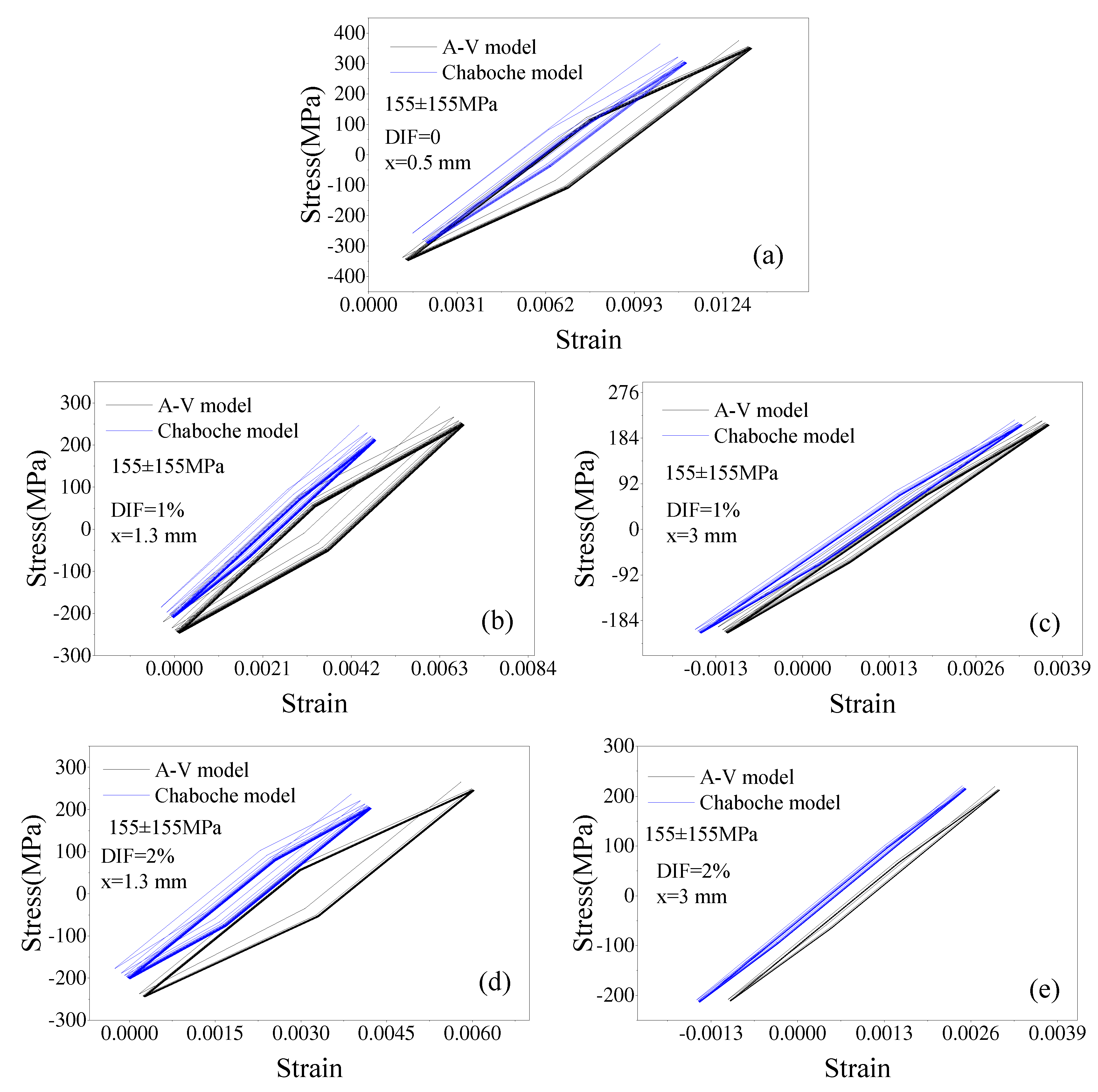

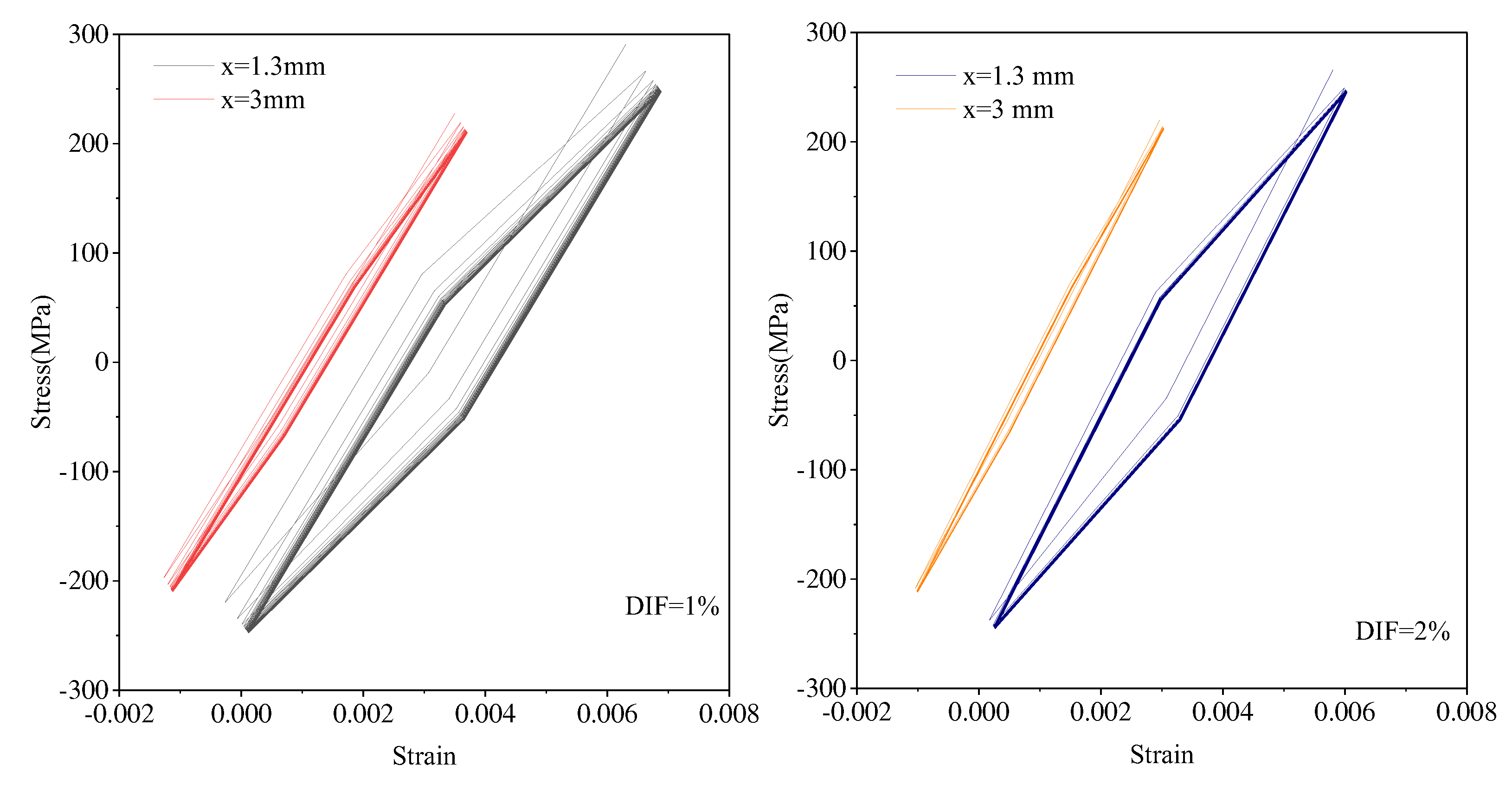

3.6. Predicted Hysteresis Loops

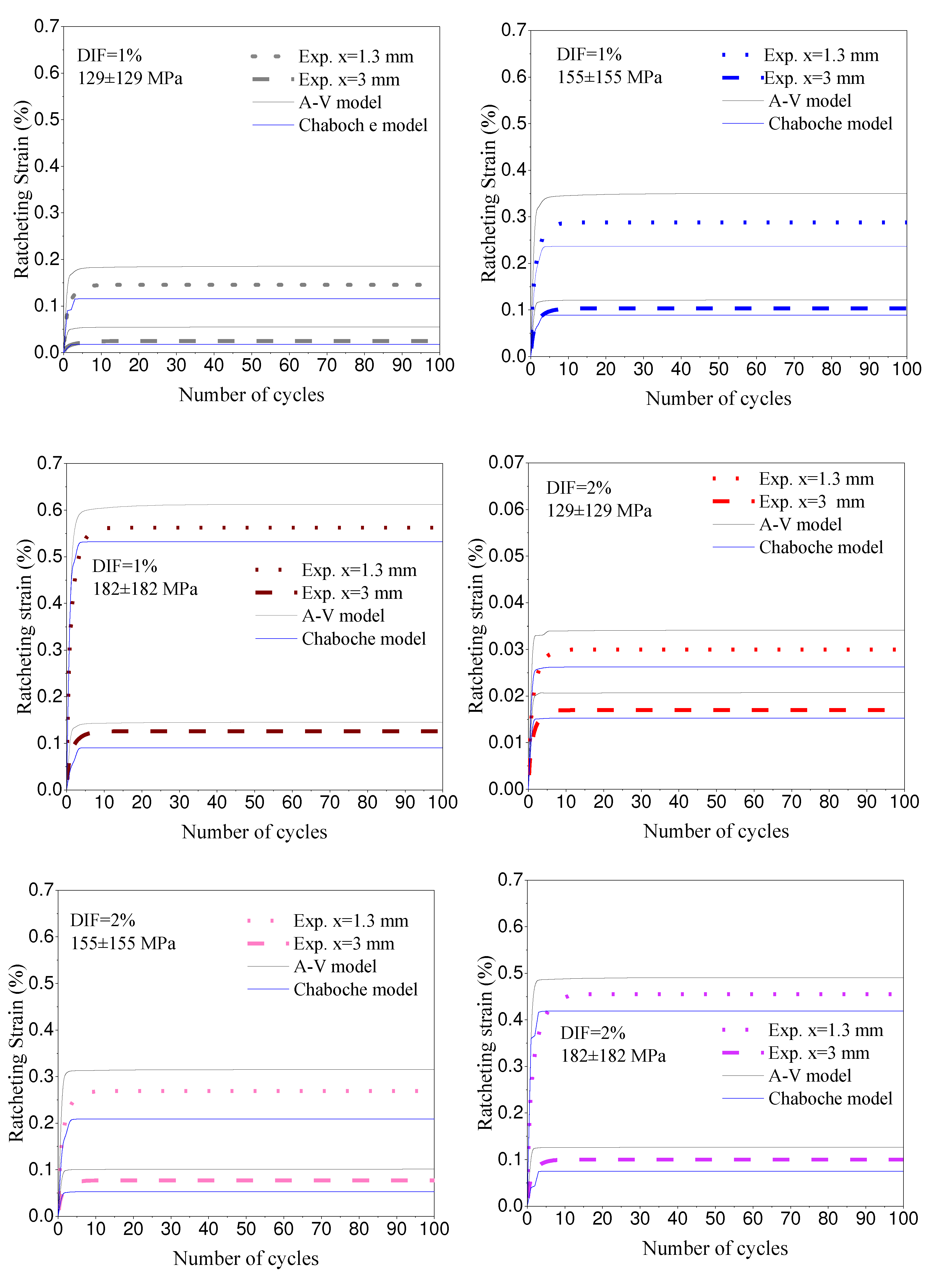

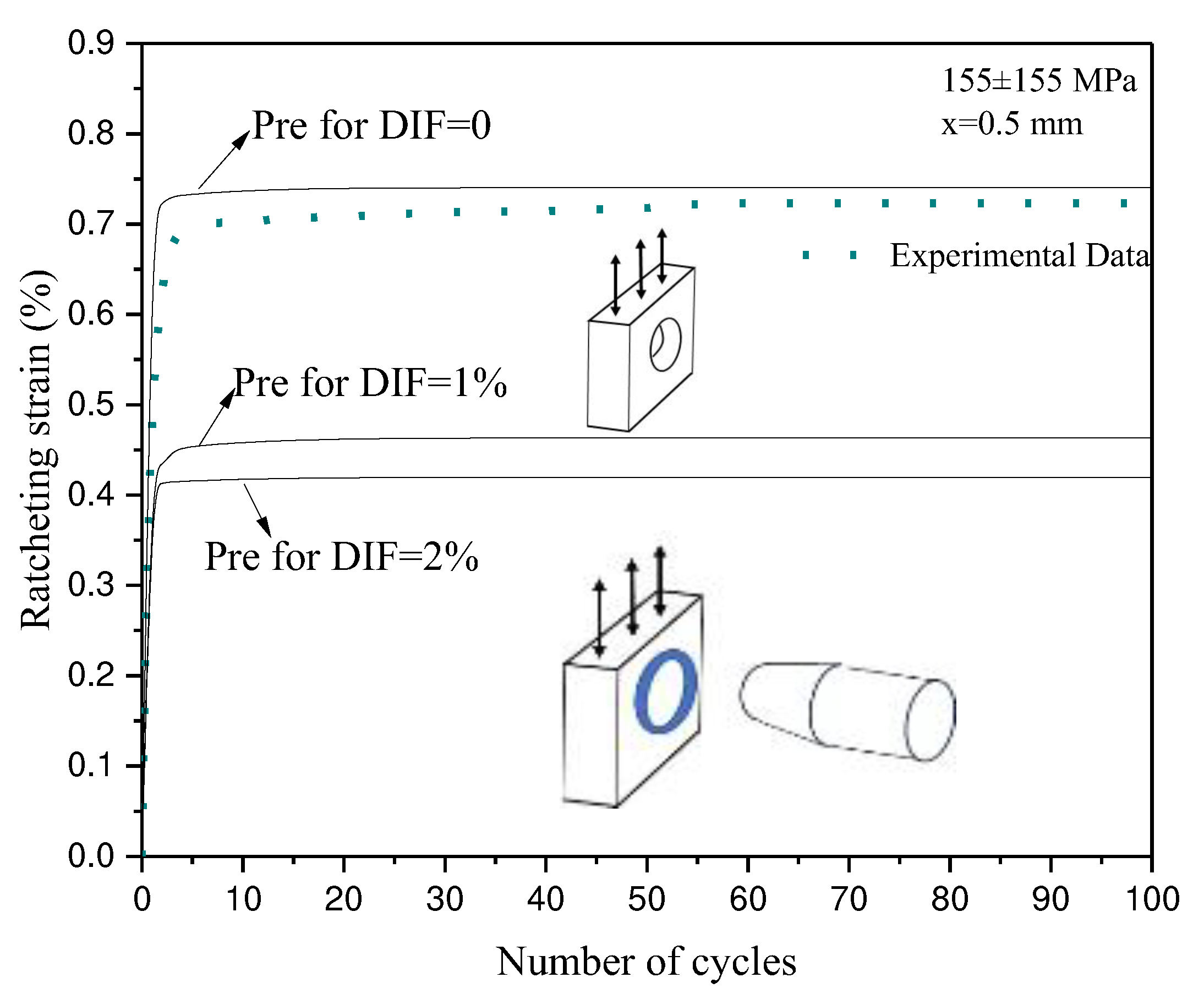

3.7. Local ratcheting strain prediction

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Total strain increment tensor | |

| Elastic strain increment tensor | |

| Plastic strain increment tensor | |

| E | Modulus of elasticity |

| Plastic modulus | |

| Backstress tensor | |

| Stress tensor | |

| 𝐼̅ | Unit tensor |

| Poisson’s ratio | |

| G | Shear modulus |

| Deviatoric stress tensor | |

| Yield strength | |

| D | Circular notch diameter |

| Coefficients of the A-V model | |

| , | Chaboche materials coefficients |

| Stress concentration factor | |

| Internal variable of the A-V model tensor | |

| Ramberg-Osgood coefficients | |

| S,e | Nominal stress and strain |

| R | Stress ratio |

| , | Stress and strain concentration factors |

| Uniaxial local stress and strain at the notch root | |

| Strain energy per unit volume at the notch root | |

| Elastic strain energy per unit volume due to the nominal remote stress |

References

- Chakherlou, T. N.; Oskouei, R. H. and Vogwell, J. Experimental and numerical investigation of the effect of clamping force on the fatigue behaviour of bolted plates. Eng. Fail Anal. 2008, 15, 563–574. [Google Scholar] [CrossRef]

- Chakherlou, T. N.; Abazadeh, B. and Vogwell, J. The effect of bolt clamping force on the fracture strength and the stress intensity factor of a plate containing a fastener hole with edge cracks. Eng. Fail. Anal. 2009, 16, 242–253. [Google Scholar] [CrossRef]

- Chakherlou, T. N.; Vogwell, J. A novel method of cold expansion which creates near-uniform compressive tangential residual stress around a fastener hole. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 343–351. [Google Scholar] [CrossRef]

- Chakherlou, T. N.; Aghdam, A. B. An experimental investigation on the effect of short time exposure to elevated temperature on fatigue life of cold expanded fastener holes. Mater. Design 2008, 29, 1504–1511. [Google Scholar] [CrossRef]

- Callinan, R. J.; Wang, C. H. On the fatigue enhancement of interference fitted stop drilled holes. Int. J. Fatigue 1999, 21, 865–72. [Google Scholar] [CrossRef]

- Chakherlou, T. N.; Mirzajanzadeh, M. and Saeedi, K. H. Fatigue crack growth and life prediction of a single interference fitted holed plate. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 633–644. [Google Scholar]

- Iyer, K.; Rubin, C.A.; Hahn, G.T. Influence of interference and clamping on fretting fatigue in single rivet-row lap joints. J. Tribol ASME 2001, 123, 686–698. [Google Scholar] [CrossRef]

- Chakherlou, T. N.; Alvandi-Tabrizi, Y. and Kiani, A. On the fatigue behavior of cold expanded fastener holes subjected to bolt tightening. Int. J. Fatigue 2011, 33, 800–810. [Google Scholar]

- Kolasangiani, K.; Farhangdoost, K.; Shariati, M.; Varvani-Farahani, A. Ratcheting assessment of notched steel samples subjected to asymmetric loading cycles through coupled kinematic hardening-Neuber rules. Int. J. Mech. Sci. 2018, 144, 24–32. [Google Scholar] [CrossRef]

- Shekarian, A.; Varvani-Farahani, A. Ratcheting prediction at the notch root of steel samples over asymmetric loading cycles, J. Eng. Mater. Technol. Trans. 2020, 142(2), 1–23. [Google Scholar] [CrossRef]

- Shekarian, A.; Varvani-Farahani, A. Concurrent ratcheting and stress relaxation at the notch root of steel samples undergoing asymmetric tensile loading cycles, Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1402–1413. [Google Scholar] [CrossRef]

- Shekarian, A.; Varvani-Farahani, A. Ratcheting behavior of notched stainless-steel samples subjected to asymmetric loading cycles. J. Iron Steel Res. Int. 2021, 28(1), 86–97. [Google Scholar] [CrossRef]

- Shekarian, A.; Varvani-Farahani, A. Ratcheting response of SS316 steel samples with different notch shapes under various loading spectra. J. Mater. Eng. Perform. 2021, 30(5), 3524–3535. [Google Scholar] [CrossRef]

- Neuber, H. Theory of stress concentration for shear-strained prismatical bodies with arbitrary nonlinear stress-strain law. J. Appl. Mech., 1961, 28, 544–550. [Google Scholar] [CrossRef]

- Chaboche, J. On some modifications of kinematic hardening to improve the description of ratcheting effects. Int. J. Plast. 1991, 7, 661–678. [Google Scholar] [CrossRef]

- Ahmadzadeh, G. R.; Varvani-Farahani, A. Ratcheting assessment of materials based on the modified Armstrong–Frederick hardening rule at various uniaxial stress levels, Fatigue Fract. Eng. Mater. Struct. 2013, 36(12), 1232–1245. [Google Scholar] [CrossRef]

- Wang, C.H.; Rose, L.R.F. Transient and steady-state deformation at notch root under cyclic loading, Mech. Mater. 1998, 30(3), 229–241. [Google Scholar]

- Hu, W.; Wang, C.H.; Barter, S. Analysis of cyclic mean stress relaxation and strain ratchetting behavior of aluminum 7050. Aeronautical and Maritime Research Lab Melbourne (Australia), 1999.

- Rahman, S.M.; Hassan, T. Advanced cyclic plasticity models in simulating ratcheting responses of straight and elbow piping components, and notched plates. ASME Pressure Vessels and Piping Conference 2005, 421–427. [Google Scholar]

- Ohno, N.; Wang, J.D. Kinematic hardening rules with critical state of dynamic recovery, part I: formulations and basic features for ratcheting behavior. Int. J. Plasticity 1993, 9, 375–390. [Google Scholar] [CrossRef]

- Ohno, N.; Abdel Karim, M. Uniaxial ratcheting of 316FR steel at room temperature – part II: Constitutive modeling and simulation. ASME J. Appl. Mech. 2000, 122, 35–41. [Google Scholar]

- Firat, M. A notch strain calculation of a notched specimen under axial-torsion loadings. Mater. Des. 2011, 32(7), 3876–3882. [Google Scholar] [CrossRef]

- Barkey, M.E. Calculation of notch strains under multiaxial nominal loading. PhD thesis, Department of Theoretical and Applied Mechanics, University of Illinois at Urbana-Champaign, Illinois, 1993.

- Liu, C.; Shi, S; Cai, Y. ; Chen, X. Ratcheting behavior of pressurized-bending elbow pipe after thermal aging. Int. J. Press. Vessel. Pip. 2019, 169, 160–169. [Google Scholar] [CrossRef]

- Chen, X.; Jiao, R.; Kim, K.S. ; On the Ohno-Wang kinematic hardening rules for multiaxial ratcheting modeling of medium carbon steel. Int. J. Plast. 2005, 21(1), 161–184. [Google Scholar] [CrossRef]

- Hatami, F; Varvani-Farahani, A; Accumulation of plastic strain at notch root of steel specimens undergoing asymmetric fatigue cycles: Analysis and simulation. Materials. 2023, 16(6), 2153. [CrossRef] [PubMed]

- Chakherlou, T. N.; AJRI, M. Strain ratcheting and stress relaxation around interference-fitted single-holed plates under cyclic loading: experimental and numerical investigations. Fatigue Fract Eng Mater Struct 2012, 327–339. [Google Scholar] [CrossRef]

- Varvani-Farahani, A. A comparative study in descriptions of coupled kinematic hardening rules and ratcheting assessment over asymmetric stress cycles. Fatigue Fract. Eng. Mater. Struct. 2017, 40(6), 882–893. [Google Scholar] [CrossRef]

- Ramberg, W.; Osgood, W.R. Description of stress-strain curves by three parameters. NACA Technical Note No. 902 ( 1943.

- Kolasangiani, K. Analysis of Local and Global Ratcheting Behavior of AISI 1045 Steel Specimens with Cutout. PhD thesis, department of Mechanical Engineering, Ferdowsi University of Mashhad, 2018.

- Benedetti, M.; Menapace, C.; Fontanari, V. and Santus, C. On the variability in static and cyclic mechanical properties of extruded 7075-T6 aluminum alloy. Fatigue Fract Eng Mater Struct 2021, 44, 2975–2989. [Google Scholar] [CrossRef]

- ABAQUS User’s manual, Version 6.13. Hibbitt, Karlsson and Sorensen (2016).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).