1. Introduction

The used of bamboo culms in the construction industry presents an environmental advantage because of the reduction in carbon dioxide generation compared to conventional structural materials [

1]. Bamboo possesses numerous notable physical properties that contribute to its wide range of applications.

These properties encompass size, color, dimension, texture and grain, density, moisture content, thermal conductivity, and absorption. The dimensions and length of bamboo can vary depending on the species and the maturity of the plant [

2]. Bamboo exhibits numerous notable physical properties that play a vital role in its diverse applications. These properties encompass size, color, dimension, texture, grain, density, moisture content, thermal conductivity, and absorption. The dimensions and length of bamboo can differ based on the species and the maturity of the plant [

2], in comparison to timber, bamboo achieves maturity at a faster rate, typically taking only three to four years to reach maturity [

3] while age more than 6 years slowly lacks its strength – up to 12 years old [

4]. Physical properties can vary considerably among different species due to their distinct cellular structures and varying fiber proportions, which in turn can influence their density. Some bamboo species may have a higher density, while others may have a lower density [

5,

6,

7,

8]. Remarkable mechanical properties characterize bamboo, rendering it a versatile and sustainable material. With an impressive strength-to-weight ratio, bamboo showcases excellent tensile [

5,

9,

10,

11,

12], compressive [

10,

13,

14,

15,

16,

17], and flexural strength [

1,

5,

18,

19], allowing it to bear substantial loads and stresses. Its good elasticity enables efficient absorption and distribution of impact energy. Bamboo’s mechanical properties vary based on factors like species, age, and culm regions [

20]. It is highly regarded for its strength, flexibility, and resilience, making it suitable for various applications, including construction, furniture, and engineered products. Bamboo composite or engineered bamboo is widely explored to optimize the utilization of bamboo. The mechanical properties of engineered bamboo products can be influenced by processing methods [

21].

Despite of the excellent potentials of bamboo, its durability and resistance to weathering actions might compromise because it decays compared to the conventionally manufactured materials. That is why treatment is basically considered. Treating bamboo is widely studied nowadays and still continuous to develop an effective and optimal treatment. Bamboo can be treated by natural methods such as drying, heating (boil, fired, oven), steaming, soaking, smoked, oil application, and impregnation of natural resin (e.g., rosin). Nowadays, chemical treatment is used by various researchers since it can be done in less time compared to the natural method. However, some of chemicals are unsafe and environmental threat. Some chemicals used in treating bamboo are Boric acid, Copper Naphthenate (CuN), Polycarboxylic acids (CA), Butanetetracarboxylic acid (BTCA), Disodium octaborate tetrahydrate (DOT) aqueous, Boron – based preservatives, epoxy resin, Deltamethrin, and alkali with sodium hydroxide. These components were used by the literature in this paper. For some studies, they combined natural and chemical treatment [

21,

22,

23,

24]. Bamboo is a sustainable material that is used in construction; however, it has limited application [

25] and global adoption. The existing codes and standards may not be sufficient to optimize the usage since there are various variations with regards to bamboo species, age, locations, methods of preparation and testing, and others. It could be potential interest to assess the variations of the result from the available standard methods from international and other national standards.

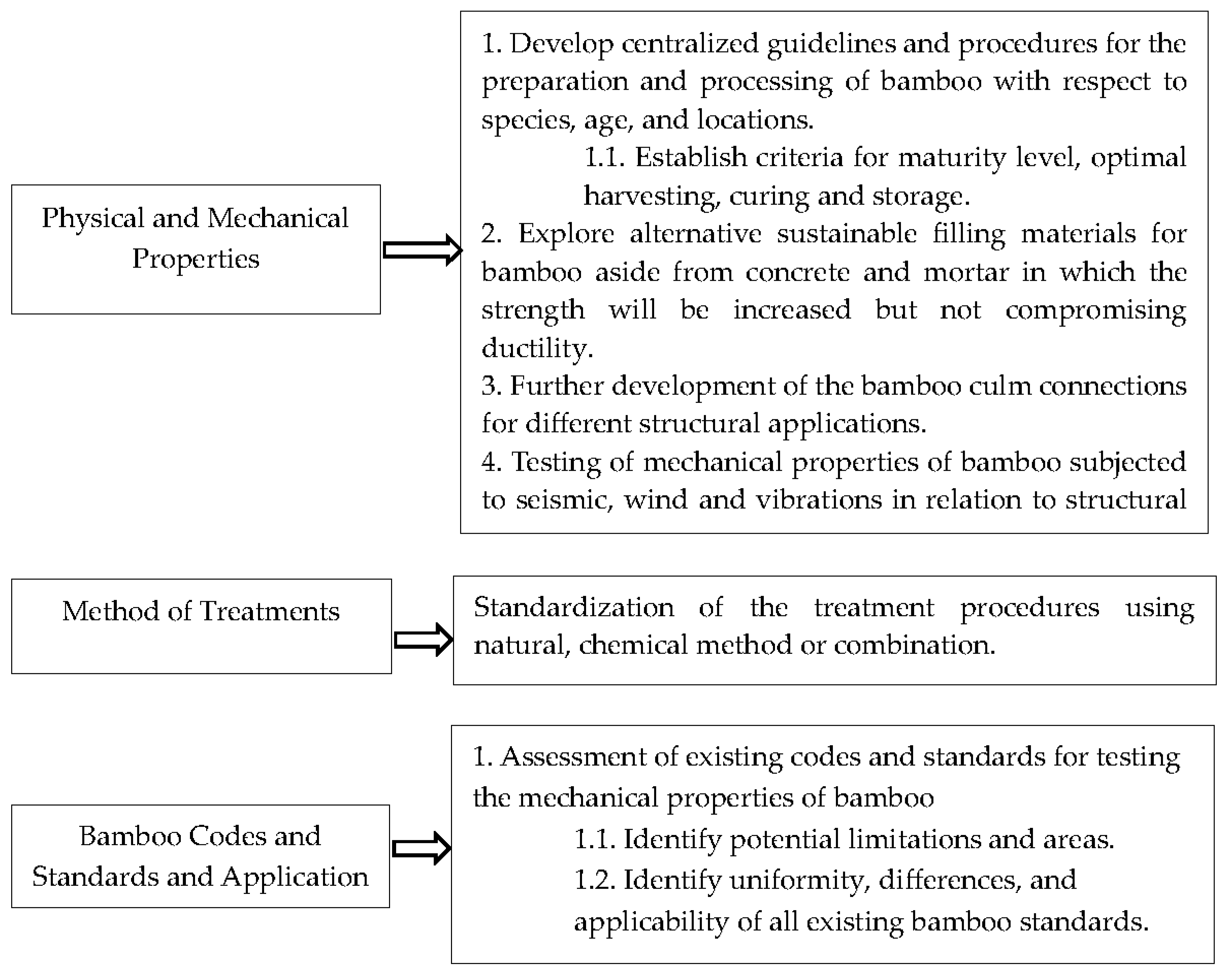

This paper provides a review on the use of bamboo culms as building materials in construction as to the species, physical and mechanical properties, treatment, and codes and standards tackled by the gathered literature; and determine the research gaps which could be addressed for future work. The paper highlights several research gaps in bamboo’s physical and mechanical properties. These include the need for centralized guidelines in preparation and processing, exploring sustainable filling materials, advancing culm connections, testing under different loads, standardizing treatment methods, and assessing existing codes and standards for bamboo. Addressing these gaps will optimize bamboo’s potential as a sustainable construction material.

2. Methodology

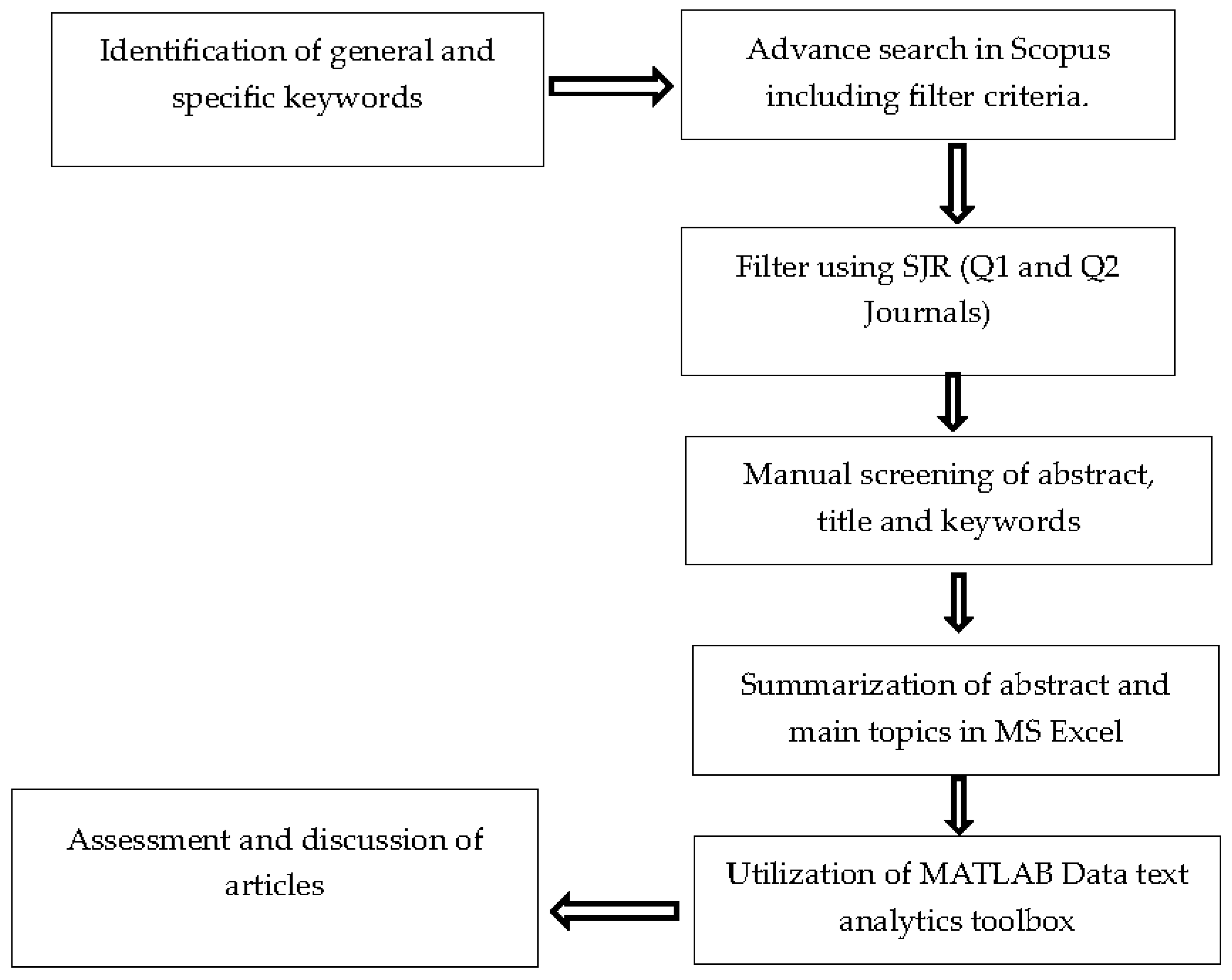

The collection of relevant literature or articles is a crucial step in conducting a comprehensive review paper. A summary of the research methodology is shown in

Figure 1. In this paper, the Scopus database was utilized as a primary resource for gathering scholarly articles. Scopus is widely recognized as a comprehensive abstract and citation database, encompassing a vast range of disciplines [

26]. Furthermore, Scopus offers advanced search functionalities, citation analysis, and author metrics, enabling the researcher to conduct thorough and efficient literature searches, evaluate the impact of previous studies, and identify influential authors.

The general topic for the review had already recognized as “Use of bamboo culms as building materials in construction”. Presently, the Scopus provides 14,456 articles for “bamboo”, 1,753 articles for “bamboo culms”, “86,867 for “building materials”, and 437,526 for “construction. These keywords were combined and used the advance search and Boolean operators. The search was filtered to articles only and limit to subject areas such as Engineering, Material Science, Environmental Engineering, Chemical Engineering, Agricultural and Biological Sciences. Publication year was limit from 2003 to 2023 to have a latest and wider range of studies to be reviewed. A total of 793 document were found. The articles were filtered based on high-ranking journals from SCImago Journal Ranking (SJR) selecting only those Q1 and Q2 journals such as Construction and Building Materials, Buildings, Journal of Materials in Civil Engineering, Materials, and Royal Society Open science. The SCImago journal rank indicator is novel instrument for the evaluation of the scientific journals that may challenge the established premiership of the Impact Factor (IF) in ranking scientific journals, and its primary strength of SCImago is that it uses Scopus as the data source for the development of the SJR indicator [

27]. Choosing only the highly ranked journals, the articles were narrowed to 138.

These articles underwent a rigorous manual screening wherein they were assessed based on specific author and index keywords. Only those articles that contained relevant terms such as “bamboo,” “bamboo culms,” “bamboo poles,” “bamboo species,” “bamboo properties,” “bamboo construction,” “building materials,” or a combination of these were considered for inclusion. Subsequently, the abstracts of the identified articles were scrutinized to evaluate their relevance to the study. Only those abstracts that provided a clear and concise discussion of essential aspects on bamboo properties, species, testing, treatments, and a key summary of findings in relation to bamboo performance and properties were selected. As a result of this thorough approach, a total of 57 articles were meticulously reviewed and systematically assessed to gather comprehensive insights on the subject matter. These articles were imported into MATLAB software for Text Analytics. The MATLAB Text Data Analytics provides overview of the topic by word clouds, topic mixtures, journal distribution, and publication year. The text analytics with MATLAB can be useful in automating the process of extracting information from text, significantly reducing the time required for manual processing [

28]. This method is similar with the studies of Ongpeng et al [

29,

30,

31,

32] where MATLAB Text Data Analytics was utilized for generating the topics.

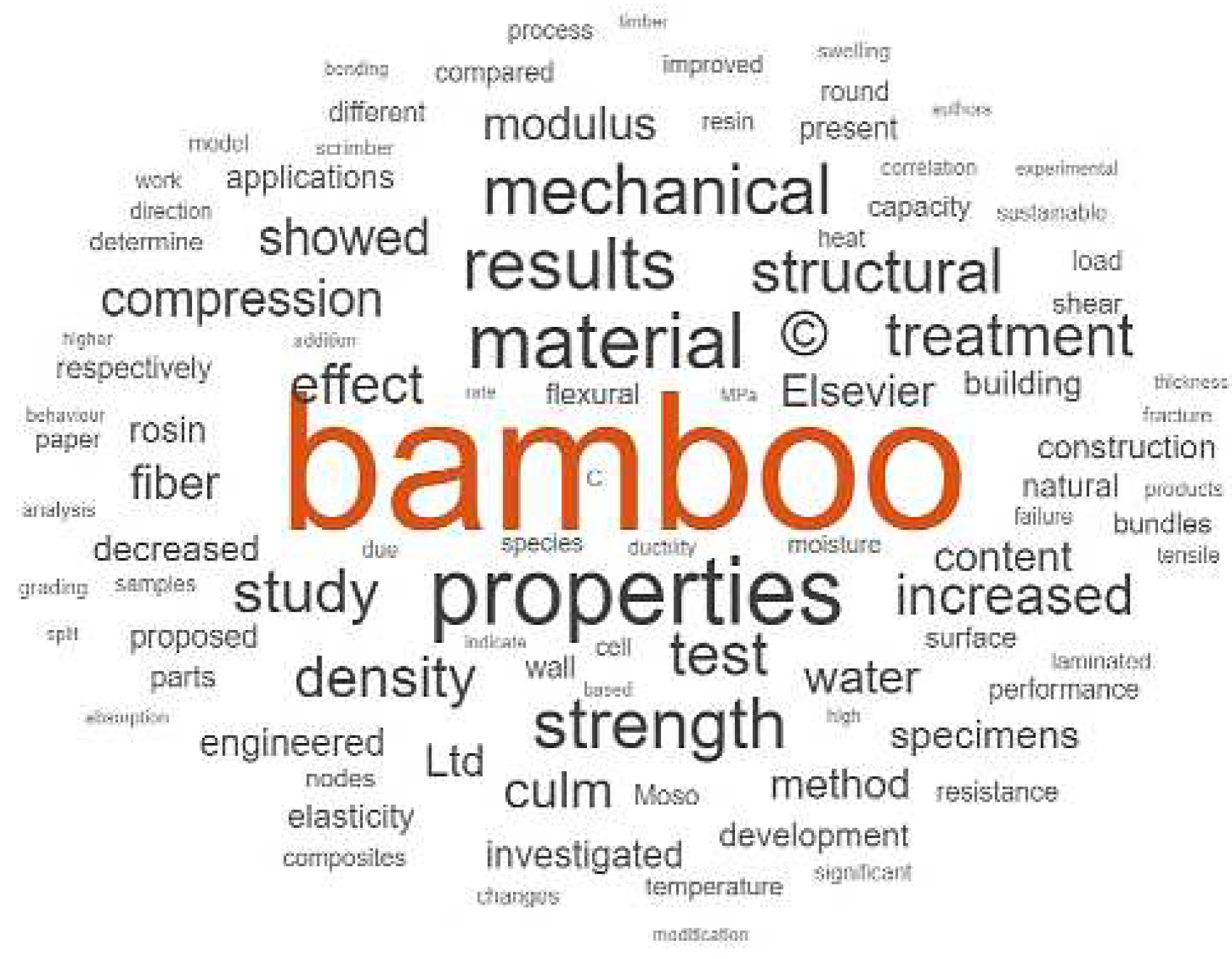

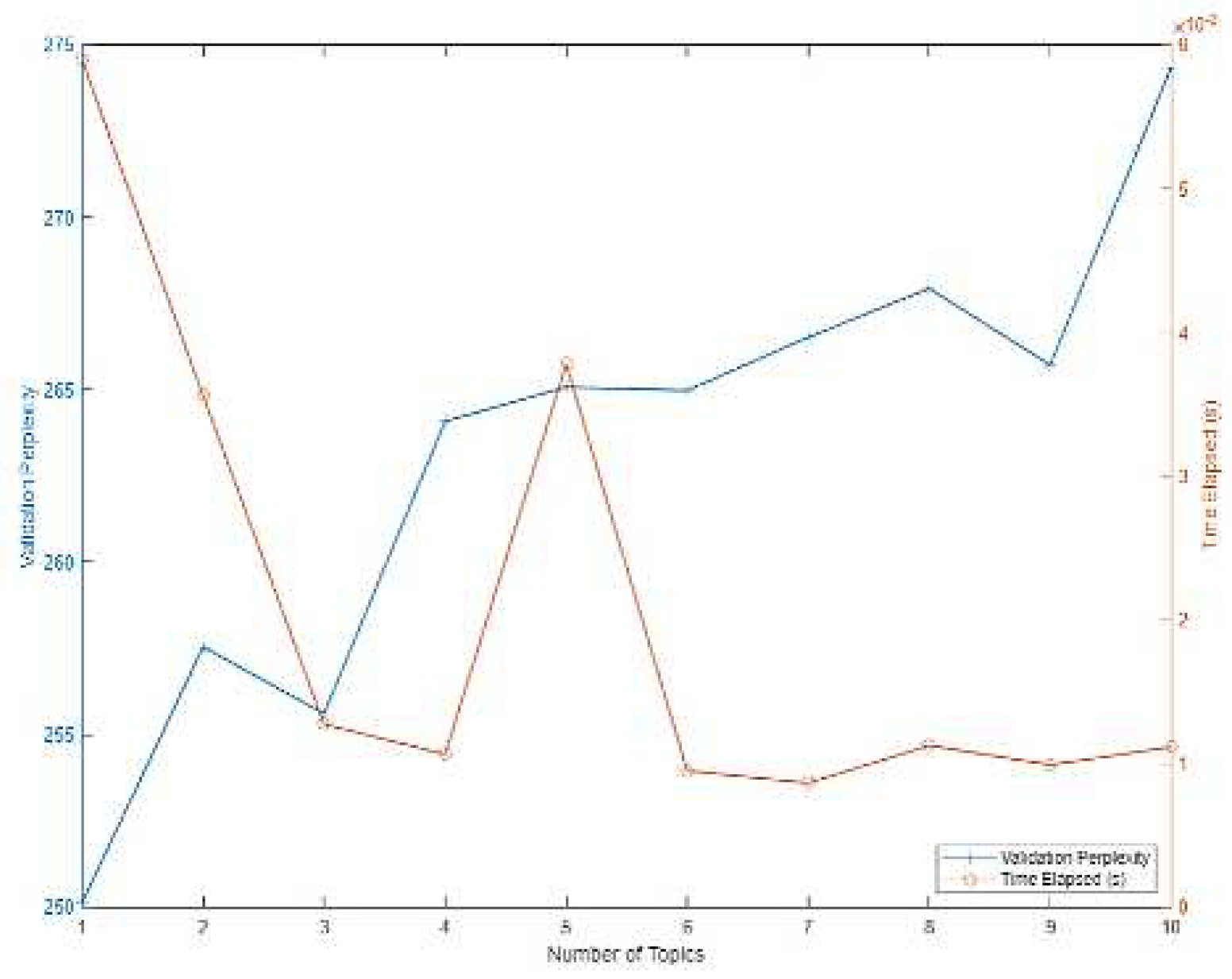

Figure 2 shows the word cloud generated in which it contains regularly occurring word from the documents extracted. It can be seen that the distinct word is “bamboo” which basically the general keyword of the study. The validation perplexity is shown in

Figure 3, from 1 to 10 number of topics, the result showed that on the 3 number of topics, the validation perplexity has the lowest value. For this graph, the lowest perplexity validation is the most suggested number of topics to be used [

28].

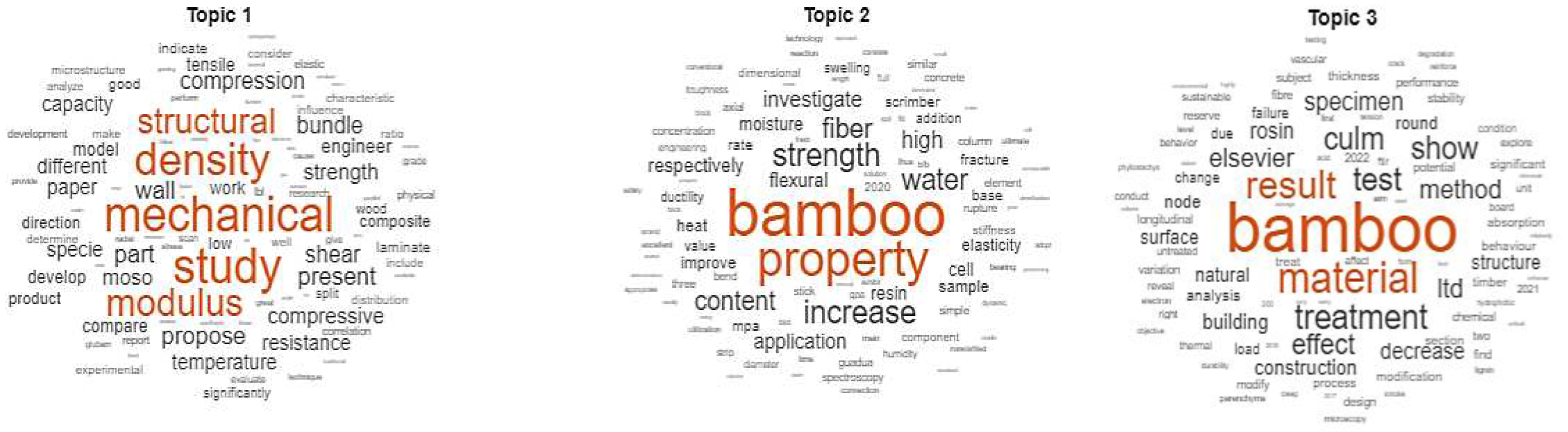

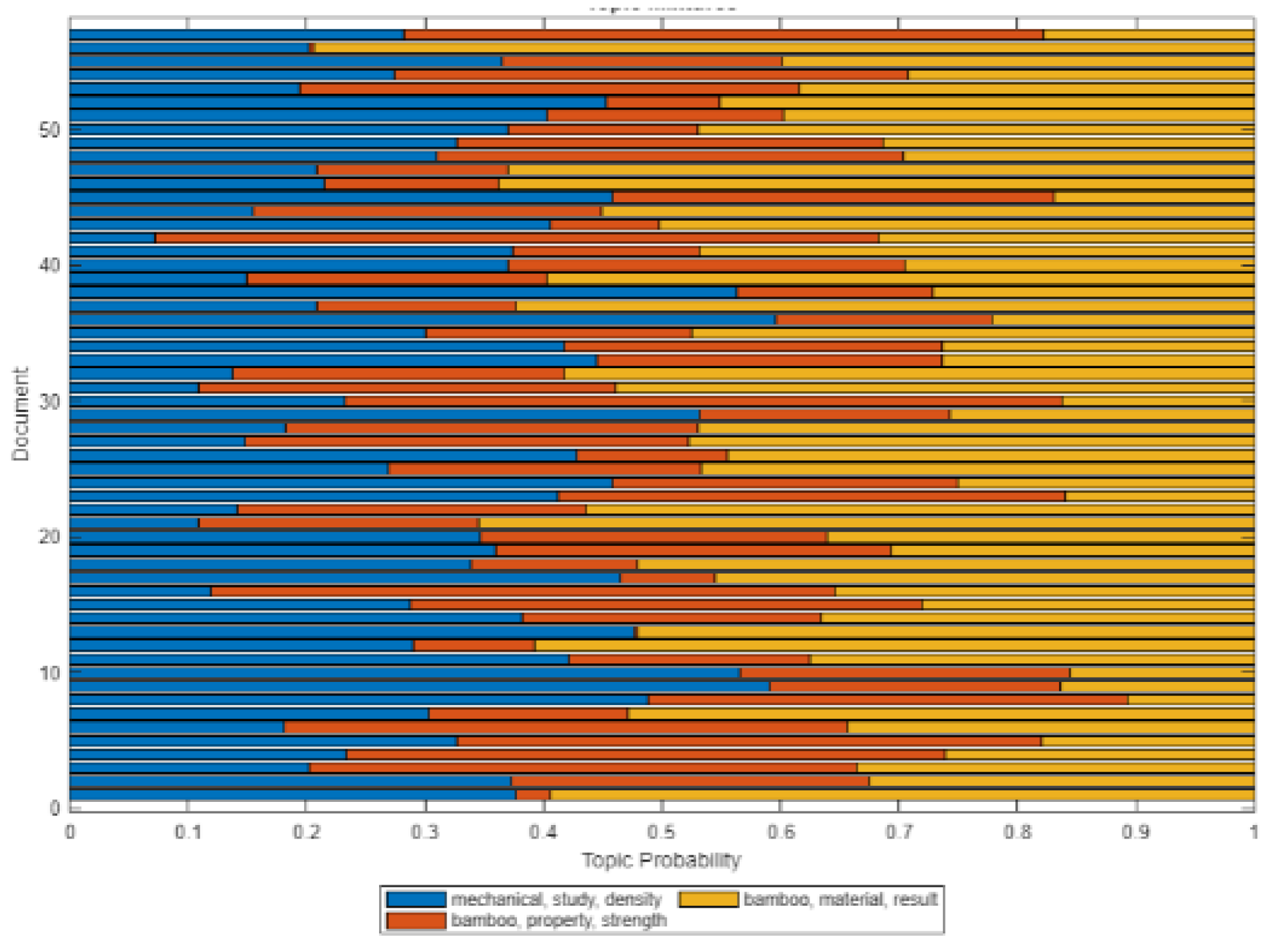

Figure 4 displays the word cloud of the 3 topics and the topic mixtures is presented in

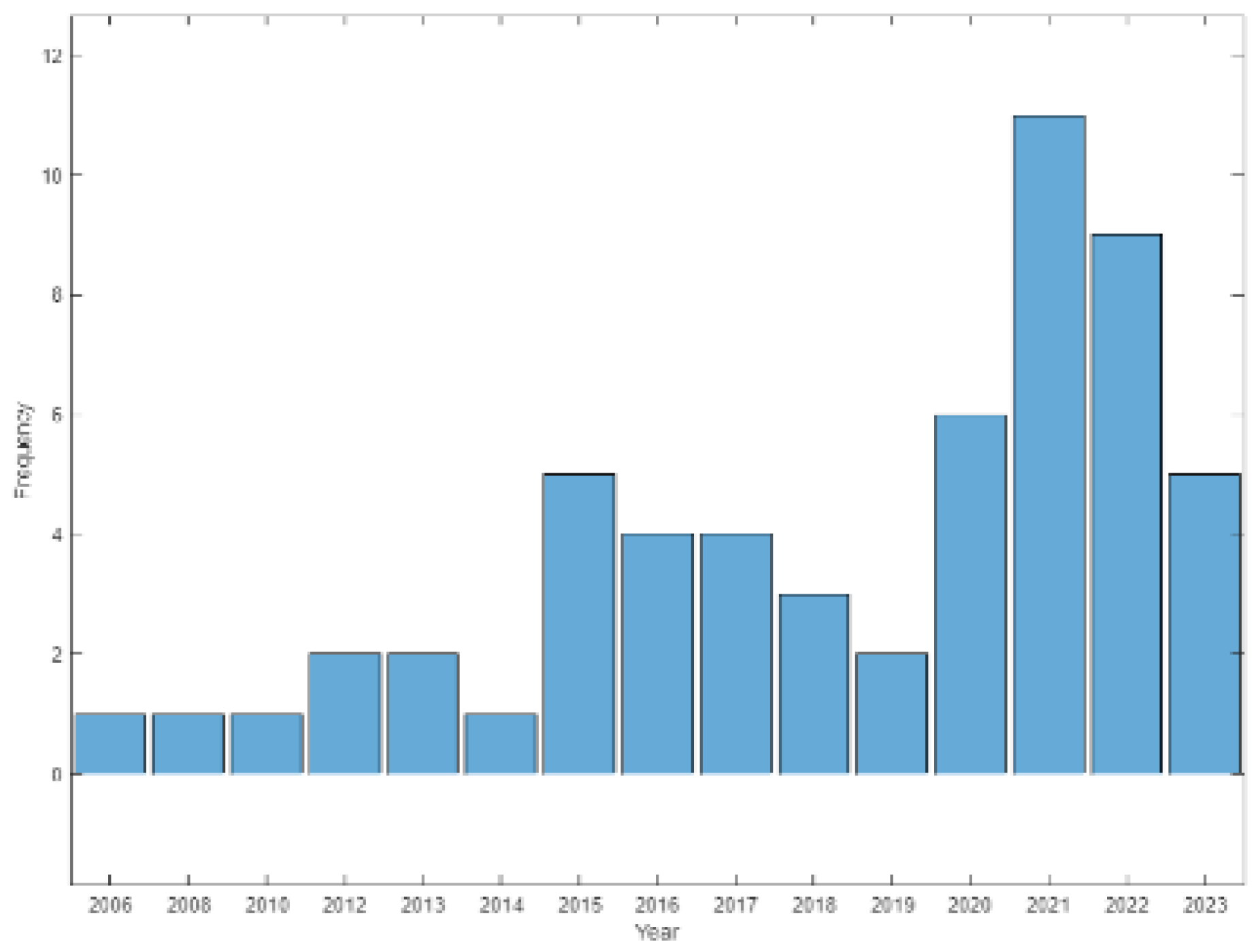

Figure 5. These word highlights for each word cloud were interpreted and developed a specific topic for this study. For topic 1 in which the featured are mechanical, structural, density, study and modulus, the corresponding interpretation is the “Physical and mechanical properties of different bamboo species”. The major featured words in topic 2 are bamboo and property, with the inclusion of words such as application, strength, fiber, water and increase, it was interpreted as “Bamboo standards and applications”. Lastly, the featured words for topic 3 are bamboo, material, result and accompanied with treatment, effect, method, specimen and construction, the corresponding topic 3 is “Bamboo culm treatment methods”. These three topics were discussed qualitatively in this paper. The publication year distribution of the collected articles is presented in

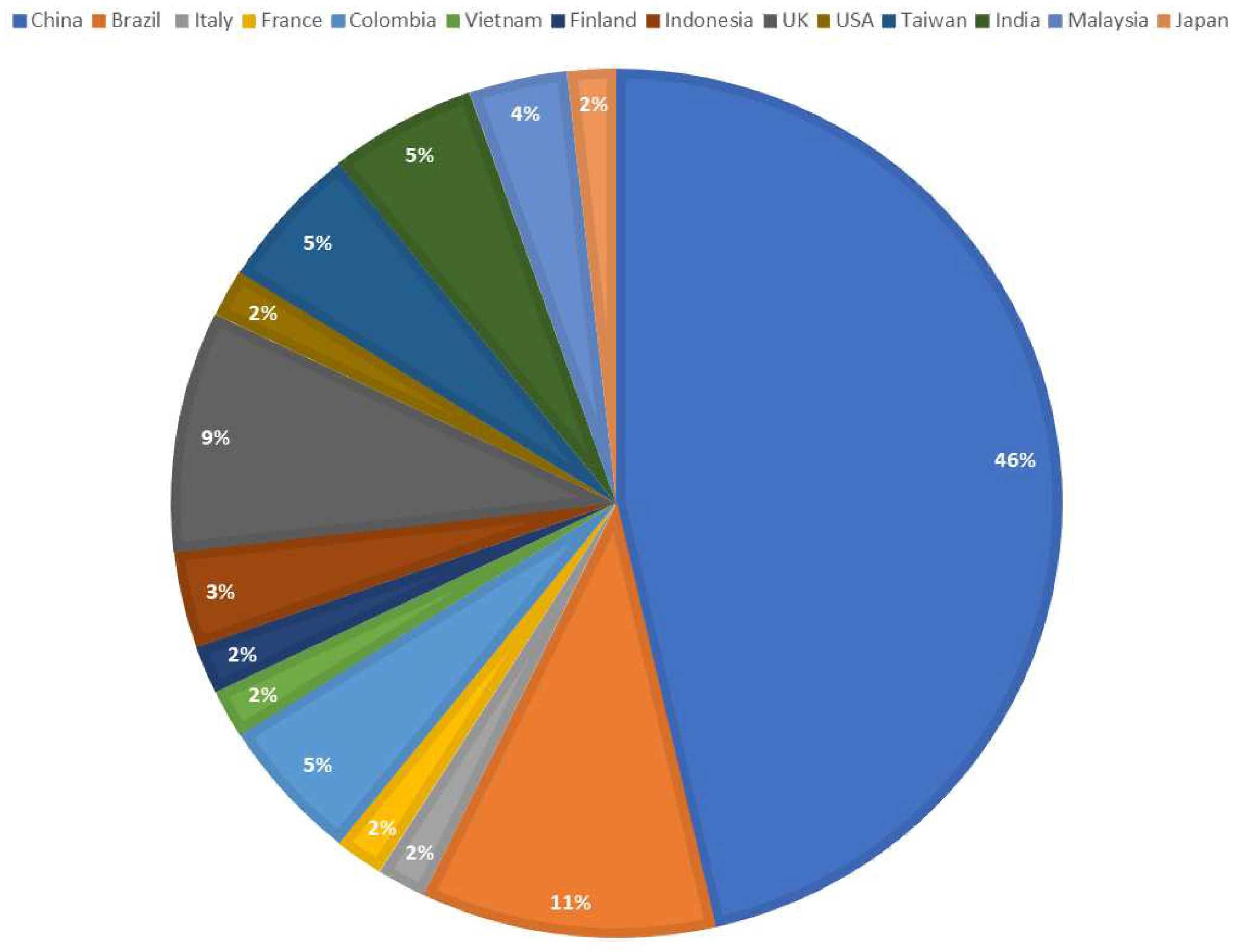

Figure 6. The publication behavior is increasing and decreasing pattern. Few articles were published in 2006 to 2010 and 2014. The number of highest publications was in 2021 but decreased in 2022 and the present year. However, this is justifiable since it still in middle time of the year 2023. Worldwide, China has the highest number of papers who studied bamboo with a total of 6,624 using “bamboo” keyword search [

33].

Figure 7. shows the countries involved in the articles gathered in this paper in which 46% belongs to China.

3. Discussion

The objective of this paper is to provide a review on the use of bamboo culms as building materials and identify the research gap which could be addressed. This section provides an assessment of the different bamboo species used in construction, physical and mechanical properties of bamboo, treatment methods used and how it affects the properties of bamboo, and the standards and applications of bamboo culms and bamboo composites.

3.1. Physical and Mechanical Properties of Different Bamboo Species

There are various bamboo species of bamboo used in gathered literature with different locations. Since most of the studies oriented from China, majority of the bamboo samples were situated from this country. Moso bamboo is the most widely used specie for construction because of excellent mechanical properties [

34]. Physical properties vary in different species [

2] as well as its mechanical properties [

13,

15,

20].

3.1.1. Bamboo species

The globalization of bamboo potential as a construction material is enormous due to its lightweight nature, abundant renewability, and rapid growth [

35]. With its wide advantageous properties, bamboo presents an environmentally friendly and sustainable alternative for various construction applications across the world. Bamboo, belonging to the P

oaceae family of grasses, exhibits remarkable lightweight characteristics and stands as one of the most rapidly growing plants found on our planet [

36]. A total of 1662 bamboo species are known to exist, distributed across 121 genera, among these, 232 species have been introduced to areas beyond their native ranges and have become invasive [

37]. In Asia, China boasts the greatest diversity of bamboo, housing 500 native species. Japan follows with 139 species, while India, Indonesia, and Myanmar have 119, 118, and 97 species, respectively [

38].

Bamboo exhibits a wide array of applications, encompassing construction, furniture, food, biofuel, textiles, paper, charcoal production, ornamental gardening, and environmental benefits like carbon sequestration and phytoremediation capabilities that enhance soil quality and mitigate erosion [

39]. The most used species for structural construction is given in

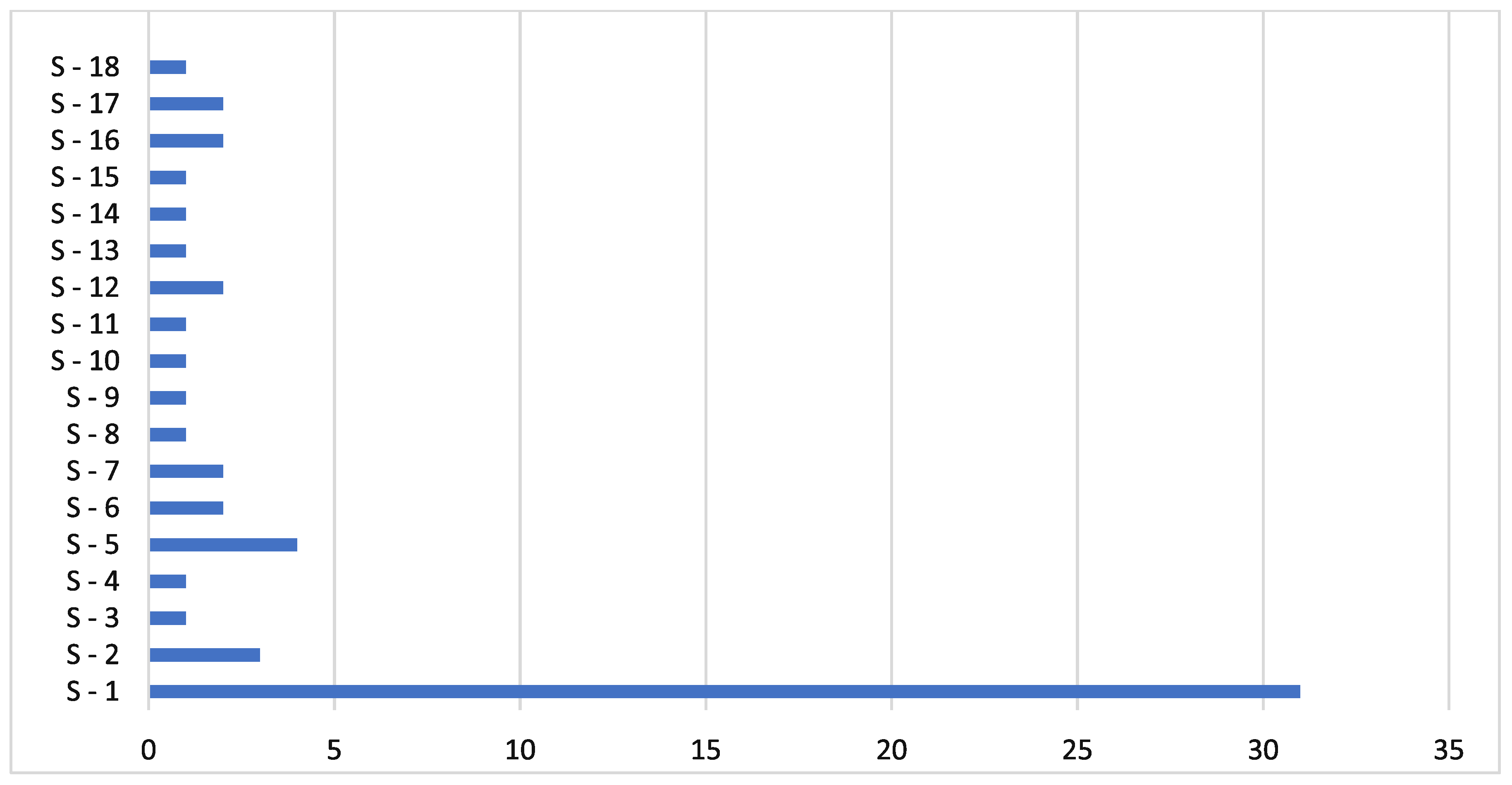

Table 1. Most of these species are found in Asia.

Figure 8 shows 18 different species that were used by the researchers in this study such as (1)Moso (Phyllostachys pubescens/Phyllostachys edulis), (2) Hong (Phyllostachys iridencens), (3)Phyllostachys viridiglaucecsens, (4)Phyllostachys family, (5)Guadua angustifolia kunth a.k., (6)Bambusa vulgaris, (7)Tregai (Bambusa stenostachya), (8)Dendrocalamus strictus, (9)Ater (G.atter), (10)Makino (Phyllostachys makinoi), (11)Pseudosasa amabilis, (12)Bambusa Balcoa, (13)Madake (Phyllostachys bambusoides), (14) P.aurea, (15)Dendrocalamus giganteus, (16) Dendrocalamus asper, (17) Schizostachyum Grande, and (18) Gigantochloa Scortechinii. It can be seen that most of the researchers used Moso bamboo in their study. This paper will use “S” stands for species and numbers “1 – 18” for the specific type as discussed (e.g., S–1,

Moso (Phyllostachys pubescens/Phyllostachys edulis). Moso bamboo stands out as the globally predominant bamboo species in terms of widespread harvesting [

19], temperate bamboo species which basically grows in China [

41] and performed better compared to other species both environmentally and mechanically [

34].

3.1.2. Physical Properties

Bamboo possesses several noteworthy physical properties that contribute to its wide range of applications. These properties include size, color, dimension, texture and grain, density, moisture content, thermal conductivity, and absorption. The dimensions and length of bamboo can differ based on the species and the maturity of the plant [

2], in comparison to timber, bamboo achieves maturity at a faster rate, typically taking only three to four years to reach maturity [

3], while age more than 6 years slowly lacks its strength – up to 12 years old [

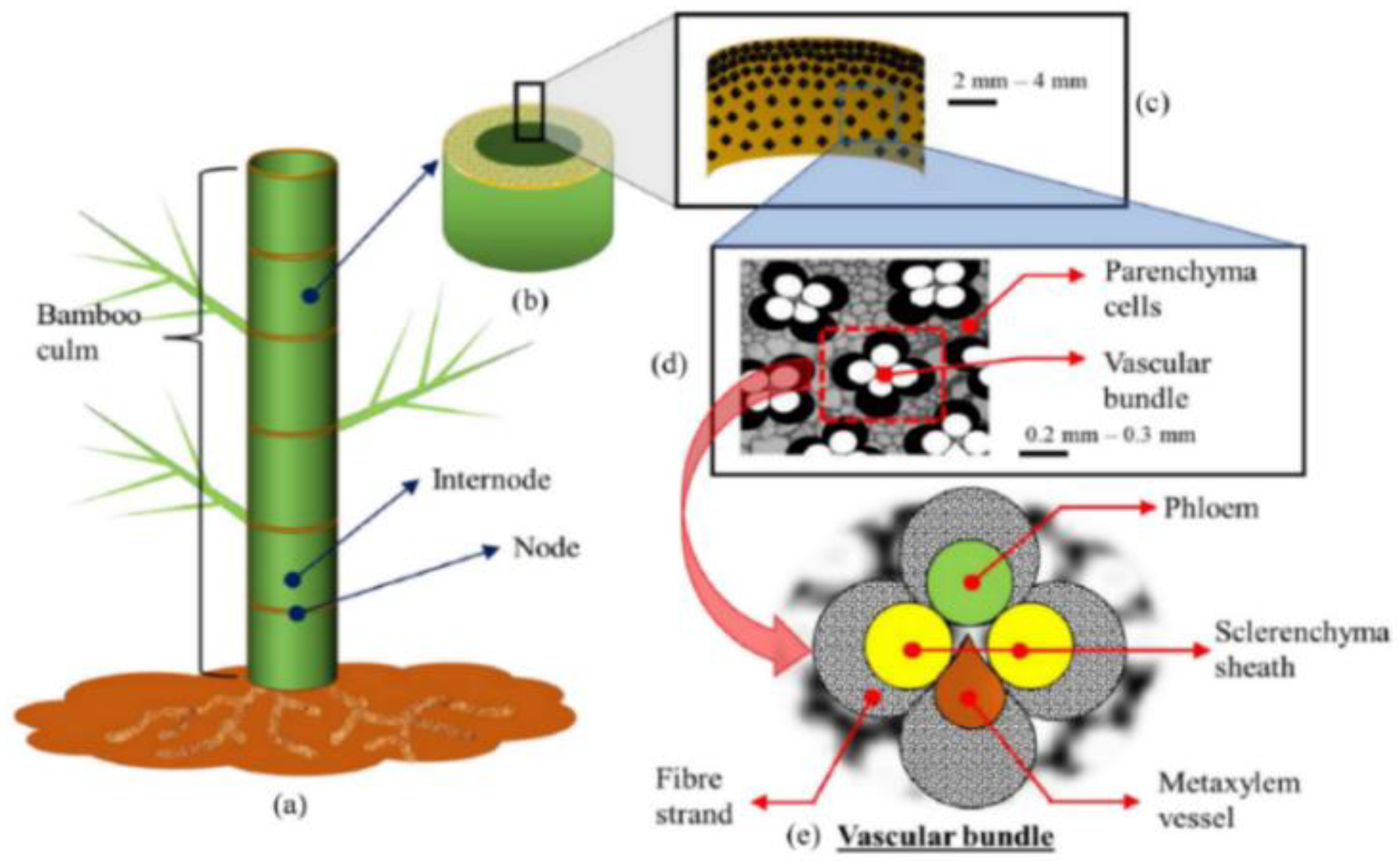

4]. The bamboo culm is composed of vascular bundles and parenchymal base tissue. Within the vascular bundles, fiber caps or sheaths enclose conducting elements such as vessels, sieve tubes, and companion cells, all of which collectively influence bamboo’s characteristics [

2,

36]. It has been observed that vascular bundles are distributed unevenly throughout the culm, ranging from the outer to the inner layer [

42,

43]. Additionally, the shape and size of vascular bundles within the culm exhibit variability.

In

Figure 9, Lee et al [

3] provides a detailed look at the anatomy of a typical bamboo. (a) shows a mature bamboo culm ready for harvesting, with internodes and nodes. The nodes have internal diaphragms and an external ridge. (b) displays a cross-section of the bamboo culm. (c) presents an enlarged cross-section (2 mm to 4 mm scale) highlighting the distribution of vascular bundles, which are more concentrated towards the outer diameter. In (d), a microscopic view (0.2 mm to 0.3 mm scale) reveals the bamboo culm wall in detail, with its main components being the parenchyma cells and vascular bundles. The vascular bundles, with their four-winged structure, consist of fiber strands that determine the mechanical properties of the bamboo.

The culm internode length has increasing pattern from the bottom to the mid-section and then decreasing towards the top, while the culm’s conical shape is decreasing outer diameter from bottom to top; furthermore, the inner diameter of the mid-section is decreasing both towards the bottom and the top, which result in the reduction of culm thickness [

43]. Properties of bamboo can vary significantly among different species. Different bamboo species have distinct cellular structures and varying proportions of fibers, which can impact their density. Some bamboo species may have a higher density, while others may have a lower density. P. edulis has density of 796 kg/m

3 [

5] and Bambusa balcoa has density of 685 kg/m

3 [

6] tend to have higher densities compared to species like Phyllostachys pubescens that has 601-640 kg/m

3 [

7], but these densities can be modified through treatment and mechanical processes. Other species like Bambusa vulgaris, the density is ranging from 630 kg/m

3 to 680 kg/m

3 and does not vary significantly with location [

8].

Table 2 shows the articles that highlighted the physical properties with different species. It can be seen that most of the studies highlighted the density and moisture content of bamboo. The average age is between 3 to 4 years which 6 years is the oldest and 2 years is the youngest sample used.

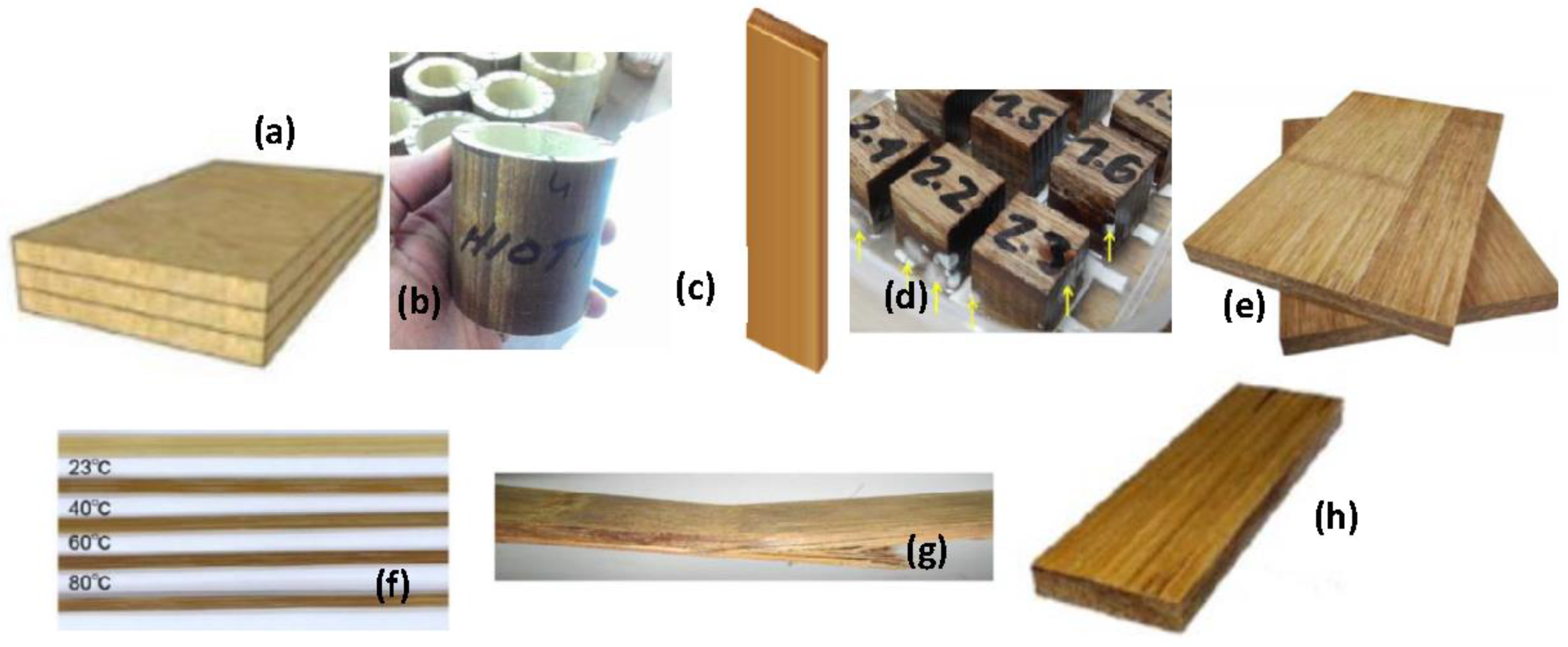

Various types of samples have been used for density testing as shown in

Figure 10. These Bamboo strand composite lumber (BSCL), bamboo culm, Modified bamboo splits, Bamboo scrimber, Outdoor bamboo – fiber reinforced composite (OBFRC), bamboo slivers, Laminated bamboo timber (LBT), and Unidirectional round bamboo stick boards (UBSBs). UBSBs undergo processes such as splitting, peeling, converting it to round bamboo stick, drying and heating treatment, immersion in PF resin, then flattening process to form a UBSBs [

44]. Bamboo culm samples is just a cut from the whole culm which basically the length is twice the diameter [

14]. MBS is a product of flattening and densification of natural bamboo splits. Bamboo scrimber undergo processes such as splitting, flattening, crushing, steam carbonizing at 170°C for 100 minutes then it impregnates with PF resin (15-17%), then it undergoes cold molding and finally a bamboo scrimber is formed after activation of resin for 12 hours at 80-120° [

20]. OBFRC processes includes mechanical fluffing (splitting, peeling or skin removal) to produce bamboo fiber mats, these mats will be impregnated by PF resin then will be assembled for hot pressing to finally form a OBFRC slabs [

45]. The LBT processes includes splitting, treating with borax, air-drying then split into strips, strips were then glued and pressed horizontally at temperature of 140°C and a pressure of 1.47 MPa for 30 minutes [

46]. The BSCL processes involves splitting of bamboo culm, peeling of outer skin, cutting into parts, dripping and drying, after drying it will then be assemble and hot pressed to form a BSCL [

47].

Density

One of the most important physical properties of bamboo is its density, some studies noted the density of the bamboo as shown in

Table 3. It is important to determine the density of bamboo culm that will be used because it is one of the key parameters that influence the performance of material [

2,

36]. The dry density of bamboo commonly used in structure is ranging from 500 kg/m

3 to 800 kg/m

3 [

40]. Various studies confirmed that the density of bamboo has significant influence on the mechanical properties [

19,

20,

47,

50,

62], water absorption [

20,

63], and the higher the density means more compacted are the bamboo fibers together [

20]. Density is the most relevant parameter to mechanical properties of original bamboo parallel to the grain [

50]. Sun et al. [

47] observed in Moso bamboo that higher density of 900 kg/m

3 has a significant influence on shear strength and modulus of rupture under natural drying treatment, soaking time affects density and higher density swells after boiling.

In a study conducted by Dixon et al [

41], a comparison was made of the structure and flexural properties of Moso, Guadua, and Tre Gai bamboo. The results revealed that, at a given density, Guadua exhibited a higher axial modulus of elasticity compared to Moso and Tre Gai, which showed similar properties. Additionally, the ultrastructural analysis indicated that Guadua has a higher stiffness in its solid cell wall. The density of Moso bamboo decreases from the external surface to the internal surface of the culm wall in the radial direction, both in the internodes and nodes parts [

7]. The internode has uniform density, and it fluctuates at the nodal parts [

7,

46]. The weakness in node is influence of low density and the irregular vascular bundle arrangements [

46]. Luan et al [

48] observed that for bamboo split, the density of the inner part was tremendously increased to over 1.0 g/cm

3 and is consistent with that of the outer part under steamed treatment. The density of specimens containing nodes is consistently higher than that of specimens without nodes [

14]. This observation is considered trivial because diaphragms contribute to the overall mass but are not taken into account in the measurement of volume or length. Kadivar et al [

56] observed that density increase on bamboo after DOT treatment. An increase in density also of bamboo splits was observed by Luan et al [

48] after-steam after steam treatment. Wu et al [

11] tested the bamboo slivers and confirmed that density increased after treatment by 45.6%-88.3% treated at 40°C.

Moisture Content

Table 4 shows few of the literature in this paper that noted the moisture content (MC) of bamboo. Bamboo is considered suitable for use when its moisture content is around 8% to 12% [

46,

54,

59,

61]. The mechanical properties and durability of bamboo depends on the moisture content that is why it needs to be maintained the moisture content below 20% [

64]. This range is often preferred for construction purposes, furniture making, and other applications where dimensional stability and resistance to warping or cracking are important.

Most of the studies stored their bamboo culm specimens and allowed to reach the equilibrium MC before it will be tested [

49,

51,

61]. It is known that bamboo culm shrinks when dry and swell when wet [

14]. That is why it is important to attain the equal moisture content of bamboo before undergo testing and processing. Some of the studies took care the moisture content of the bamboo by undergoing treatments and process modifications. Su et al [

49] used the rosin treatment in Hong bamboo and found out that equilibrium moisture content decreased across relative humidity values. The test found that the film formed on the surface of the bamboo culms might greatly weaken the surface wettability and moisture absorption of bamboo culms. The study of Bahtiar et al [

14] on the structural grading of Guadua angustifolia demonstrated that the correlation between moisture content and mechanical properties of bamboo bears a striking resemblance to that of wood, with compression resistance of short members as the grading foundation. The moisture content of Guadua angustifolia kunth species typically falls within the range of 9% to 10% [

38] similar range with that of [

14] having higher MC at nodal section but considered insignificant. Sa Riberio et al [

8] studied the MC of untreated Bambusa vulgaris and found that average MC is 12.95%, higher than that obtained by Dixon et al after borax treatment for 3 species Moso , Guadua, and Tregai which 4%, 6%, and 6%, respectively.

Porosity and Absorption

Bamboo is considerably porous, which refers to the presence of small open spaces or pores within its structure. Bamboo has a certain capacity to absorb and retain moisture. The absorption characteristics of bamboo are influenced by its porosity, as well as the structure and composition of its cell walls, which consist of cellulose, hemicellulose, and lignin. When bamboo is exposed to moisture, it can absorb water into its cell walls, causing it to swell and increase in dimensions. The absorption rate and capacity of bamboo depend on factors such as the specific bamboo species, the density of the material, and the environmental conditions.

The porosity of bamboo culm may be improved by treatment and processing procedures. Su et al [

49] conducted a study on Hong bamboo, employing rosin resin impregnation treatment, to investigate its effects on hygroscopicity, dimensional stability, and pore structure of the round bamboo culm. The results showed that introducing rosin into the bamboo culm reduced its porosity by 14.43% and total pore volume by 23.81%. Moreover, after 144 hours at 65% relative humidity, the moisture absorption decreased by 39.27%, while the rosin treatment led to a reduction in the swelling of wall thickness and diameter of the bamboo culm from oven-dry to water saturation by 42.20% and 25.40%, respectively. Another study was conducted by Su et al [

49] again with the same species using rosin treatment focused on the penetration and distribution of rosin along the longitudinal axis of a round bamboo culm in which same impregnation method but differs in processing time. The results showed that rosin could penetrate into the middle part from both ends of the 150-mm-long culm under the ssame condition of 1.00 MPa impregnation pressure. The water permeability test showed that all culms along the longitudinal axis had lower water absorption and absorption rate within 24 h than the control group and both ends of the culm had a better hydrophobicity than the rest parts. The rosin impregnation showed a positive effect on hydrophobic protection of bamboo culm. Huang et al [

53] addressed that the Hygrothermal properties show stronger correlation with open porosity than with bulk density.

Microstructure

Bamboo microstructure was widely studied by the different researchers. Bamboo is a radially graded, transversely isotropic composite material [

7]. The microstructure of bamboo can vary among different bamboo species and culm regions. The arrangement and characteristics of the vascular bundles, parenchyma cells, and fiber strands impact the overall mechanical behavior and physical properties of bamboo. Dixon et al [

41] investigated three different bamboo species: Moso, Guadua, and Tregai. They observed that Moso and Tre Gai exhibited similar volume fractions of fibers and similar variations across the culm wall, whereas Guadua generally had a higher fiber volume fraction but a similar distribution. The average fiber volume fractions obtained for each species were 0.20 for Moso, 0.33 for Guadua, and 0.16 for Tre Gai. The variation in density of Moso bamboo can be attributed to the distinct proportions and growth patterns of its vascular bundle tissues and parenchyma ground tissues [

7]. The volume of lumen in parenchyma tissue was significantly reduced, resulting in a nearly uniform distribution instead of gradually changing along the thickness direction [

48]. Lee et al [

51] examined the structure of Moso bamboo subjected to heating treatment and found that bamboo treated at higher temperatures experienced significant damage to its tissue structures, especially the parenchyma cells. Through FTIR spectroscopy, they observed that as the treatment temperatures increased, the intensity of characteristic absorption peaks of polysaccharides decreased, while the intensity of lignin peaks increased. Yang et al [

23] performed an alkali pre – treatment method of 6% Sodium hydroxide (NaOH) at Moso bamboo which aimed to remove the hydrophobic layer from bamboo surface and improve the permeability for the main treatment which is the impregnation of two types of rosin such as epoxy – modified and natural rosin. The study found that by modifying rosin with epoxy, it was possible to fill the cell lumens of bamboo, including the small nanopores in cell walls and spaces between cells. This filling of the bamboo’s structure resulted in improved dimensional stability, with a decrease in swelling by 33.74%. The modified rosin also enhanced the hydrophobicity of the bamboo, as indicated by an increased contact angle and a reduction in water absorption by 24.73%. The modified rosin physically filled the vessels, parenchyma cells, and other structures of the bamboo after impregnation. Ramful et al [

54] studied Madake bamboo and conducted smoke treatment to the culms and found that bamboo showed an increase in lignin content at a specific peak of 1114 cm

-1. This increase was due to the thermal effect of temperatures above 100 C, resulting in poly-condensation reactions. It is believed that this higher lignin content contributed to a significant improvement in the hardness of smoked bamboo, which was found to be twice as hard as untreated bamboo, thus, subjecting bamboo to high temperatures increased the lignin content, making the smoked bamboo much harder compared to untreated bamboo.

3.1.3. Mechanical Properties

Bamboo exhibits remarkable mechanical properties that make it a versatile and sustainable material. With its high strength-to-weight ratio, bamboo possesses excellent tensile, compressive, and flexural strength, allowing it to withstand substantial loads and stresses. It also demonstrates good elasticity, which enables it to absorb and distribute impact energy effectively. Additionally, bamboo exhibits a high degree of toughness and durability, making it resistant to cracking and deformation. Bamboo exhibits varying mechanical properties depending on factors like species, age, and culm regions. It is highly esteemed for its strength, flexibility, and resilience, making it well-suited for diverse applications such as construction, furniture, and engineered products. Bamboo composite or engineered bamboo is widely explored to optimize the utilization of bamboo. The mechanical properties of engineered bamboo products can be influenced by processing methods [

21].

Table 5 shows the summary of the studies highlighted the mechanical properties of bamboo. Compressive strength (CS), tensile strength (TS), flexural strength (FS), shear strength (SS), modulus of rupture (MOR), and modulus of elasticity (MOE), hardness, ultimate bearing capacity and includes durability.

Compressive strength

The literature stated that compressive strength of bamboo differs with each other with respect to species, size, locations, treatment methods and processing [

20]. Among all the species studied in this article, Drury et al [

15] reported that Moso bamboo from China has the highest compressive strength of 69.9 MPa tested with nodes in their study comparing four bamboo species such as Moso, Guadua, Madake and Tali which obtained from three different countries. Awalludin et al [

13] observed in their comparative study of the mechanical properties of the different species that Bambusa Vulgaris, D. Asper, and Gigantochloa Scortechii have the excellent mechanical properties in compression as well as tensile strength.

Bamboo culms

Generally, the compressive strength is correlated with the density [

1,

9,

50],. Bahtiar et al [

14] studied the structural grading of the the Guadua angustifolia on short members to determine the compression resistance and developed a prediction model. The grading capacity could be predicted through the linear mass, and the density is the indicating predictor for the compressive strength. Here, the compressive strength of samples that has node is higher compared to non – node samples although the difference is not significant (82.2 MPa and and 75 MPa). Still, the result is different to some of the studies that observed nodal samples has lower strength compared to those without nodes [

42,

72]. According to Nie et al [

72], the influence of bamboo nodes on the compressive behavior increases with an increasing nominal diameter. Specifically, specimens with relatively larger diameters and without nodes can experience an increase of up to 18.2% in ultimate stress compared to bamboo tubes with nodes. The influence of bamboo nodes on the compressive behavior of bamboo tubes should be considered during the design of practical structures, especially for bamboo columns with relatively larger diameters. But with respect to ultimate bearing capacity, nodal samples are better. In addition, Drury et al [

15] observed that the compressive strength of culm is not affected by the nodes because in his study of the comparison of strength of different species, the highest compressive strength was obtained by the sample that has node in both Moso and Madake species. However, in the result of Guadua, Tali and Black Java specimens, the highest compressive strength were obtained from the internodal specimens. Gauss et al [

16] identified that nodes have significant local effect on behaviour on the tensile, but it can be disregarded in compression and shear. Failure mode is also a general concern in bamboo specimen tested in axial loading. Zhou et al [

50] observed a ductile failure characteristic in Phyllostachys edulis bamboo tested in parallel to grain similar to the observation of Cui et al [

10] on bamboo fiber bundles. Basically, the common mode of failure of bamboo culms tested in parallel to grain are splitting and end bearing [

13,

42,

72,

75]. The end bearing failure mostly influenced by high moisture content [

75]. In the study conducted by Nie et al in 2022 [

72], it was observed that in full-culm bamboo tubes with bamboo nodes, longitudinal cracks appeared first on the bamboo nodes, followed by the tearing of the inner diaphragm into multiple sections.

Various research findings have led different researchers to conflicting conclusions regarding the variation of bamboo strength along its culm length. Mukhopadhyay et al [

70] confirms higher compressive and cleavage strengths in the relatively upper parts of culms, which aligns with the findings of Jusoh et al [

76]. But Chung et al [

75] observed that both physical and mechanical properties of is constant along bamboo culm length. Compressive strength of bamboo can be improved with treatments. The bamboo treated with polycarboxylic acid increased compressive strength up to 17 – 20% [

52]. Bui et al [

66] tested the bamboo culm treated with different types of oil with varying temperature and different cooling method. A uniaxial compressive strength test was performed. It was observed that the best compressive strength was obtained by the samples treated with heat only of 180°C and a duration of 1-2 hours without oil, sunflower oil is only applied on cooling process. The result states that oil is needed only for cooling.

Concrete – filled bamboo culms

Aside from treatment, the strength of bamboo culm can be further improved, and failure will be delayed by filling materials inside it. The compressive strength of bamboo filled with concrete and mortar was investigated by Li et al [

42]. Culm specimens are comprised of nodes and without nodes, with and without stiffener, with and without reinforcement, and the combinations of these parameters. It was observed that both concrete and mortar – filled culm has higher axial load bearing capacity and initial stiffness. But concrete fill is more efficient than mortar. This coincides with the study of Nie et al [

72] which also utilized concrete filler to bamboo culm which proved that by adopting the method of internal concrete filling, the ultimate bearing capacity of full-culm bamboo tubes can be significantly enhanced. Also, Li et al [

42] observed that the concrete filled specimen’s failure occurred in splitting mode. The splitting failure can be delayed by the nodes and stiffener. The horizontal stiffener on the bamboo that passing through the bamboo internodes has good effect on the ultimate bearing capacity (UBC) and axial strains of both concrete and mortar filler but for the stiffener that passes through the node is not advisable since in decrease bearing capacity. The average UBC of concrete filled culm was increased to a maximum of 65.3% compared with no fill bamboo culms. But this UBC of the bamboo was further improved by [

72] by using bamboo sheet-strengthened concrete-filled full-culm bamboo tubes (BSCBs) in which the bamboo sheets are wrapped to bamboo tubes with epoxy resin adhesive. This method improves the ultimate bearing capacity more than 2.5 times higher than the concrete filled bamboo alone. However, [

72] did not include in their study the effect of node on both concrete filled and sheet – strengthened - concrete filled bamboo culm. For these studies, different filling materials could have different effect also such as geopolymer concrete, recycled concrete with ash or a combination which is a possible future interest.

Bamboo Composite

Baboo culm is also utilized to produce composite materials or used as reinforcement in which the application could be optimized. Sayed et al [

77] studied the bamboo stick and used it as reinforcement to concrete. Fabricated a concrete tube having bamboo sticks. The bamboo stick as reinforcement improves the compressive strength of concrete. The test result shows that with the addition of 0.6 % of sticks, the BSRC compressive strength rose by 3.24 and 17.33 % for length-to-diameter ratios 20 and 30, respectively. The compressive strength of specimens was enhanced by adding 1.2 % and 2.4 % bamboo sticks with a length-to-diameter ratio of 10 by 21.38 and 20.94 %, respectively. For a laminated bamboo lumber made from Moso bamboo, the bamboo nodes have a beneficial effect when tested in perpendicular and parallel to grain because it increased the compressive strength by 11.25% and 27%, respectively [

68]. A semi – caramelised laminated bamboo demonstrated a slight high capacity in compression for both perpendicular and parallel to grain [

21]. Rao et al [

45] studied a composite bamboo material which is the Outdoor bamboo – fiber reinforced composite (OBFRC) to be used in flooring. This study utilized resin and observed the 20% content is effective. The compressive strength of the specimen decreases gradually as the resin content increases. Yang et al [

19] fabricated a Unidirectional round bamboo stick boards (USBS) from bamboo culm and recognized the improvement of compressive strength under heat treatment of 155°C, and not advised to increase the temperature more. An engineered bamboo scrimber was fabricated and tested by Kumar et al [

20] from Moso species and observed that the compressive strength of bamboo is comparable to that of the commonly used grade of concrete in residential buildings and can be further improved by treatment because treated bamboo performed better. In laminated bamboo lumber, nodes have beneficial effect in compression tested in parallel to grain which seemed increased the compressive strength by 11.25% and 27% for perpendicular to grain.

Hardness

The hardness of bamboo is not mainly concerned by most of the studies in this article. The study of Dong et al [

52] on bamboo scrimber treated with three methods such as heating, polycarboxylic acid (Citric Acid), and Butanetetracarboxylic acid (BTCA) observed the hardness of bamboo after heat treatment was dramatically reduced. But in other treatments such as CA and BTCA have no significant impact and noted that the hemicelluloses degradation of bamboo caused by heating could be the main factor on the decrease of the surface hardness. Another study which also differentiates the hardness with respect to different treatments was conducted [

54]. In their study, the methods were smoke, dried, and dyed treatment. The hardness of the specimen was measured from the radial - longitudinal section and observed that smoked treatment resulted to great hardness ranging from 75 MPa to 250 MPa. This obtained value is two – fold higher compared to the untreated samples. Furthermore, Cui et al [

10] attributed the increase in hardness of Moso bamboo fiber bundles to a change in chemical structure resulting from treatment modification, and their observations revealed a positive correlation between temperature and the hardness of the fiber cell walls, with an increase from 0.36 to 0.47 GPa.

Tensile Strength

Culms

Like compressive strength, tensile strength of bamboo can vary depending on several factors, including the species, age, growing conditions, processing methods and treatment. The comparative study of Awalludin et al [

13]observed that Bambusa Vulgaris, D. Asper, and Gigantochloa Scortechii have excellent tensile strength. Zhou et al [

50]observed that the tensile strength of bamboo culm is correlated with the density, as the density increased the tensile strength also increases. This is similar with the findings of [

20]on density and strength with a typical brittle failure. Gauss et al [

16] identified that nodes have significant local effect on behaviour on the tensile properties. On the other hand, the tensile behaviour of the bamboo culm is dictated by the fibers volume fractions [

9]. The integrated process of flattening and densification on the gradient structure of bamboo improves the tensile properties across the gradient was observed by [

48]. Also, the tensile properties of full-thickness bamboo splits were improved, and the change in stress distribution led to a stable structure. Cui et al [

10] examined Moso bamboo fiber bundles (BFB) obtained manually from Moso bamboo culms. The fiber bundles underwent heat treatment at temperatures ranging from160°C to 220°C. The initial average tensile strength of the unheated specimens was measured at 423.29 MPa. As the temperature increased, the tensile strength gradually decreased, reaching 191.61 MPa at 220°C. In parallel study of Wang et al [

55], the mean tensile strength of bamboo fiber bundles (BFB) ranged from 653.3 MPa to 766.2 MPa. Like the previous study, it utilized heating treatment and same species but this one is saturated heating treatment while that of previous is dry heating. The average tensile strength obtained in this study is higher compared to previous.

Composite

Sun et al [

47] determined the tensile strength of bamboo strand – based structural composite lumber undergone with rosin treatment, study confirmed that there was a decreased in the tensile strength of the high – density board with the content of rosin. The thickness of the strand has no impact on the mechanical property of composite material with different densities. The mechanical properties of laminated bamboo lumber (LBL) from Moso species under drying treatment were determined by [

68] in both perpendicular and parallel to grain. The presence of nodes had a negative impact on the tensile resistance of the bamboo, indicating that the strength against pulling forces was reduced. A similar study on laminated bamboo lumber (LBL) and tested also in both perpendicular and parallel to grain but with different treatment was conducted by [

21]. The material subjected to bleaching exhibited a slightly higher tensile strength compared to the caramelised and semi – caramelised treated bamboo. However, the tensile strength of non – treated sample is still higher. The effect of node in the result of the test was not indicated in this study.

The tensile and bending performance of the bamboo sliver were tested by Wu et al [

11]. After treating the specimens with alkali, the outer bamboo slivers showed the highest tensile strength at 60 °C, while the inner bamboo slivers achieved their highest tensile strength at 40 °C, with both values being 86.6% and 132.0% higher, respectively, than the tensile strength of the untreated ones.

Concrete - filled

Tensile test was primarily conducted by Li et al [

42] in their study on the bamboo culm filled with concrete and cement mortar as one of the baselines for the evaluation of the ultimate bearing capacity. The average

longitudinal tensile strength, longitudinal tensile modulus and longitudinal ultimate tensile stain of bamboo obtained from these coupon tests were 147.06 MPa, 13.70 GPa and 1.07%, respectively. The samples tested in transverse obtained average values of 8.36 MPa for circumferential tensile strength, 2.11 GPa for circumferential tensile modulus, and 0.40% for circumferential ultimate tensile strain. It was observed that the ultimate bearing capacity of bamboo filled with concrete and mortar increased by 226% and 86%, respectively compared to hollow specimen. Another bamboo filled with concrete study of Nie et al [

72] performed a tensile test for the evaluation of the ultimate bearing capacity of the bamboo culms filled with concrete. The average tensile strength, tensile modulus and ultimate tensile strain were 184.28 MPa, 14.74 GPa and 1.26%, respectively were obtained from testing parallel to the grain. For the test in perpendicular to the grain, only the average hoop tensile strength of bamboo is indicated which is 9.38 MPa. Both studies used Moso bamboo species. It can be observed that between these two studies, the bamboo culm what was used by the previous study has higher tensile properties compared to the later. But it would have been better if the later study also indicated the sets of tensile properties obtained in testing perpendicular to the grain.

Shear Strength

Bamboo possesses a unique fibrous structure with interconnected fibers that contribute to its mechanical properties [

3,

42,

43], including shear resistance. The shear stress behavior of bamboo is a critical aspect in understanding its mechanical properties and suitability for various applications. Bamboo, known for its remarkable strength and flexibility, exhibits distinct shear characteristics due to its unique fibrous structure [

42]. Regarding the shear property of a composite bamboo material, the existence of a node in the test specimen leads to a localized stiffening effect. Additionally, the type of adhesive used, and its spread rate were found to have a significant impact on the compression and shear bond strengths of LBL [

46]. Similar to the study of Zhang et al [

68] in Moso bamboo which undergo drying treatment, the presence of nodes did not affect the shear strength of LBL units but had an obvious negative impact on the shear modulus causing an average reduction of 34.62%. In the study of Kumar et al [

20] which determined the effect of density on the mechanical properties of bamboo scrimber, the shear strength of bamboo was found to range from 4.09 to 5.86 N/mm2, which is comparable to concrete. However, this strength can be further enhanced by transforming bamboo into a composite material or applying appropriate treatment methods. Bamboo’s eco-friendly nature is evident as it decomposes faster than other construction materials and does not generate harmful waste that could harm ecosystems.

However, the shear strength of bamboo culms and or bamboo composites may be influenced by different treatment methods. Steamed treatment with distinct degree of temperature may enhance the shear strength of bamboo, an existing proof is the study of Sharma et al [

21] which found that the semi-caramelized bamboo exhibited a slightly higher average shear strength (17 MPa) compared to the untreated samples. The hornification treatment highlights the significant impact of shear deformation on overall deflection, necessitating the use of appropriate strain measurement techniques for more accurate modulus determination [

22]. Another treatment involves using oil, which was found to have no significant impact on the ultimate strain of bamboo materials thermally treated with oil below 140°C. However, the ultimate strain noticeably decreased at heating temperatures above 180°C, mainly due to the degradation of hemicellulose, resulting in a reduction in the viscoelasticity of the cell wall [

61]. For a composite bamboo material such as outdoor-bamboo-fiber-reinforced composite (OBFRC), resin content significantly affected the OBFRC shear strength. With the increase in rosin from 10 to 20%, the shear strength gradually increased to 19.21 MPa.The effective mechanical bonding does not increase when the resin content exceeds 20% [

45].

Flexural and Bending

The flexural strength of bamboo is on par with other timber and compared to wood, the strength in flexure of bamboo is better [

18] which may be further influenced by different treatment methods. Similar with other mechanical properties of bamboo, the flexural strength of bamboo has positive relationship with the density [

44]. On the other hand, Chen et al [

5] confirmed that the flexural strength of bamboo exhibited a direct correlation with the vascular bundle content, while the flexural ductility showed a direct correlation with the parenchyma composition. However, there was a contradictory association between the flexural strength and ductility in bamboo. Also, bamboo outperforms the wood with respect to flexural ductility.

Composite

Greco et al [

65] investigated the impact of Ultraviolet (UV) irradiation on the mechanical properties of bamboo culm in both dried and untreated samples. The research revealed that UV exposure for up to 360 hours resulted in a decrease in the lignin content and surface changes, but it did not compromise the longitudinal fiber structure. Therefore, the study confirms that UV exposure lasting 360 hours has no significant effect on the bending properties of bamboo. Cid et al [

22] determined the effect of hornification treatment on the flexural behavior of bamboo. Distinct mechanisms were observed for each orientation examined: a brittle response was observed when the inner face was subjected to tension, while a ductile response was observed when the outer face was under tension. The treatment, in general, resulted in decreased ultimate deflection and increased stiffness and strength. However, the effect on strength was not significant when the inner wall was subjected to tension. Lorenzo et al [

12] used prestressed stainless-steel bands to reinforce the bamboo pole when tested in bending stress. But the result showed that the reinforcement has no significant effect in counteracting the development of significant circumferential tensile stresses in the pole. This was extensively tested through simulation, but the result remains the same. A laminated veneer lumber (LVL) was tested by Wang et al [

55] and observed that the bending strength and modulus were significantly increased with addition of bamboo fiber bundles (BFB). Another composite is the laminated bamboo lumber (LBL), which was fabricated from a bamboo culm that with and without nodes to determine the effect of node to the mechanical properties of composite material. Increasing the intervals between nodes in LBL resulted in improved flexural performance. The study findings also indicated that most bending failures occurred at the nodes. This can be attributed to the nodes having lower strength due to their low density and irregular arrangement of vascular bundles [

46].

Modulus of Rupture

The modulus of rupture is a mechanical property of bamboo that measures its resistance to breaking or fracturing under bending stress. It is also referred to as the bending strength or flexural strength of bamboo. The modulus of rupture represents the maximum stress that bamboo can withstand before it fails or fractures when subjected to a bending load. The modulus of rupture of Moso, Tregai and Guadua bamboo species are similar at a given density [

41]. Sa Ribeiro et al [

8] determined the MOR of culm of Bambusa vulgaris which ranging from 48 MPa to 132 MPa. For the bamboo composite such as Bamboo strand composite lumber (BSCL), the MOR is high as 300 MPa. The MOR of a single glue line (SGL) bamboo composite has higher value than the DGL or the double glue line, MOR values also has wider brushed surface for a given assembly time limit [

59]. For the bamboo that is treated, the MOR properties could be affected. When the sample was treated at 140 °C, the MOR increased compared to the control, but under severe treatment at 180 °C for 30 minutes, the mechanical properties of bamboo were negatively impacted, resulting in a 47% decrease in the MOR compared to the control [

55].

Modulus of Elasticity

The modulus of elasticity also known as Young’s modulus, is a mechanical property of bamboo that measures its stiffness or rigidity. It represents the ability of material to resist deformation under an applied load and return to its original shape when the load eliminated. In simpler terms, it quantifies how much bamboo will stretch or compress when subjected to a given amount of stress. The MOE of bamboo is higher than that of wood of about 0.84 times [

5]. Guadua exhibits a higher axial modulus of elasticity compared to Moso or Tre Gai, with the latter two showing similar values. Additionally, ultrastructural results indicate that Guadua has a higher solid cell wall stiffness. At a given density, their moduli of rupture are also similar [

41].

The modulus of elasticity of bamboo improves when undergo treatment methods [

10,

21,

41,

52]. Cid et al [

22] confirmed that after treatment (hornification with cold impregnation of epoxy resin), there was a decrease in the water retention capacity and deflection at failure of bamboo, along with an increase in the modulus of elasticity, reaching up to 70%. The elastic modulus and hardness of the fiber cell walls exhibited a positive correlation with temperature, with the modulus of elasticity increasing from 15.96 to 18.70 GPa and the hardness increasing from 0.36 to 0.47 GPa, respectively [

10]. Gottron et al [

58] the orientation of the specimen significantly influenced both the creep behavior and residual strength of creep-conditioned specimens; specimens loaded with the outer culm-wall in tension exhibited a larger modulus of elasticity. After treatment at 80°C (alkali treatment with different temperatures), the modulus of elasticity of outer bamboo slivers increased by 75.1%, while that of inner bamboo slivers increased by 41.1%, compared to the untreated ones [

11].

Composite

Sa Ribeiro et al [

8] investigated the modulus of elasticity of Bambusa vulgaris culm, which ranged from 6.1 GPa to 14.2 GPa. The analysis of the results revealed that bamboo culm density and dynamic modulus of elasticity are useful indicators for determining its strength and stiffness. Thin-walled bamboo laminated bamboo esterilla sheets (LBES) showed higher MOE which is superior for flexural member [

59]. For the bamboo composite such as Bamboo strand composite lumber, the MOE is high as 30000 MPa [

47]. BSCLs have potential to be considered as a high-performance alternative to wood-based Structural Composite Lumber. For the composite bamboo undergo treatment, it also has significant effect on the MOE. Samples treated with Phenol formaldehyde demonstrated superior performance compared to polyvinyl acetate in the LBT bonding, showing higher values for both MOE and MOR [

46]. Heat treatment with saturated steam was observed by Wang et al [

55] have a more pronounced effect on the modulus of elasticity of bamboo compared to the modulus of rupture. When the sample was treated at 140 °C, both MOR and MOE increased in comparison to the control. However, extensive treatment had a detrimental impact on the mechanical properties of bamboo. The Moso LBL units exhibited superior mechanical properties compared to certain engineered wood products like glulam and reinforced glulam. However, they were not as strong as wood scrimber. In contrast to engineering bamboo, the LBL units showed inferior performance to bamboo scrimber in all aspects but demonstrated better performance than laminated bamboo and glued laminated bamboo [

68].

Table 6 provides a comprehensive summary of the mechanical properties of bamboo, includes compressive strength, tensile strength, flexural strength, shear strength, corresponding modulus of elasticity and modulus of rupture, hardness, and ultimate bearing capacity. While some studies presented their findings in terms of percentage increase and overall improvement without specific numerical values, those results were not incorporated into the summary.

3.2. Bamboo Culm Treatment Methods

Bamboo is a natural material with rapid growth and impressive mechanical strengths; however, its long-term performance as a construction material is often questioned due to sensitivity to moisture and durability concerns, requiring further research for sustainable treatment solutions ([

49,

57,

66]. Hence, most of the studies on mechanical properties of bamboo emphasized the treatments and methods used. This paper discusses the treatments used by the collected literatures. Bamboo culms could be naturally or chemically treated, or a combination.

Table 7 and

Table 8 and show the summary of the treatments used by different articles collected in the respective bamboo species used. Natural treatments used in these papers are heating or thermal treatment with different methods (air and sun drying, boiling, oven), smoked, rosin impregnation, fire or flame, soaking or saturation (salt, seawater), oil treatment, and hornification. The chemical treatment includes the use of Borax, Alkali, Epoxy resin, Boron – based preservatives, Polycarboxylic acids (citric acid and butanetetracarboxylic acid), Disodium octaborate tetrahydrate (DOT) aqueous, rosin impregnation, Copper naphthenate (CuN) impregnation, and or a combination.

3.2.1. Natural Treatment Methods

The use of natural treatments on bamboo is more environmentally advantageous, making it a preferred choice for enhancing its properties and durability. Another thing, natural treatments are more economical. There are 20 studies used natural treatment on bamboo and most of them found that treatments have a beneficial impact on the improvement on the properties on bamboo. Some of the studies did not emphasize the impact of treatment on the physical and mechanical properties of bamboo, only few have discussed. Number of studies used heat treatment and discovered that it has a positive impact on the properties of bamboo [

3,

10,

18,

44,

54,

55]. But the performance is affected by temperature in which higher temperature will obtain a decrease on the properties [

18,

23,

61,

66]. The heat treatment had a notable impact on the surface color of the bamboo. Higher treatment temperatures resulted in darker surface colors and larger contact angles, leading to improved hydrophobicity of the bamboo [

3].

Cui et al [

10] used heat treatment and observed that heat treatment of 180°C, the fracture surfaces of both bamboo bundles and single fibers exhibited a smoother appearance which is a favourable outcome because smoother fracture surfaces observed after heat treatment on bamboo bundles and single fibers are indicative of positive effects, suggesting an enhancement in the mechanical properties and structural performance of the bamboo material. Similar method was used by Wang et al [

55] except that they performed mechanical modification, the thermal-mechanical method effectively extract the fiber bundles from bamboo culms with little damage on the microstructure of bamboo fibers. This method did the isolation of the fiber bundles while preserving the integrity of the bamboo fibers’ microstructure.

For a composite bamboo, the compressive strength, shear strength, and modulus of rupture values of Unidirectional bamboo stick boards (UBSBs) significantly improved when using bamboo sticks heat-treated at 155°C, but higher heat treatment temperatures above 155°C resulted in a decrease in the mechanical properties of UBSBs [

44]. Temperature has a significant impact for all treatments that utilized temperatures in which there is a ceiling value of temperature. For the study of Mena et al [

18] which used drying treatment found that the flexural strength decreases if the temperature increased more than 15°C. Heating with sunflower and vegetable oil treatment was performed by Bui et al [

66] and noticed that the maximum temperature of positive impact on compressive strength is up to 180°C only, higher than it will decrease the compressive strength. Also, the oil is best if apply after heating which they refer as “cooling” stage only. Tang et al [

61] applied Tung oil treatment to bamboo at temperatures ranging from 100°C to 200°C. Their findings indicated that the mechanical properties of bamboo, such as ultimate stress, modulus of elasticity , and modulus of rupture, remained unaffected when heat-treated below 200°C, in comparison to untreated bamboo. The ceiling temperature in their study will not determine because 200°C is the highest temperature that they used. Maybe the result will be different with the temperature higher than 200°C, this could be a call for a future study.

The density of bamboo culm improved after the steamed treatment [

48]. Wang et al [

55] verified the difference of steamed and heat treatment and observed that the equilibrium moisture content (EMC) of bamboo culms was effectively reduced through high-temperature saturated steam treatment. The smoke treatment has good performance according to Ramful et al [

54] because smoke treatment on bamboo resulted in a hydrophobic surface with improved water-repelling ability. The treatment led to reduced hygroscopicity and increased lignin content due to thermal effects and poly-condensation reactions. Another advantage of smoke treatment is it improves the hardness ranging from 75 MPa to 250 MPa which is 2 folds higher than untreated. Another treatment which is rare in most countries is the rosin treatment. Here the rosin is impregnated to the bamboo culm or bamboo composite. The effect of rosin on the porosity of bamboo is significant in which it decreased up to 14.43% as verified by [

49] using Hong bamboo species. The moisture absorption of the rosin – treated culms is significantly lower compared to the untreated.

3.2.2. Chemical Treatment Methods

Chemical treatment on bamboo enhanced its physical and mechanical properties [

11,

21,

22,

44,

52,

68]. Compared to the natural treatment methods, using chemical will obtain more faster results. However, some of the drawbacks are its environmental, health and safety factors. There are 19 studies reported in their methodology the use of chemical treatment in bamboo culms and composite for some. The chemical treatment includes the use of Borax, Alkali, Epoxy resin, Boron – based preservatives, Polycarboxylic acids (citric acid and butanetetracarboxylic acid), Disodium octaborate tetrahydrate (DOT) aqueous, rosin impregnation, Copper naphthenate (CuN) impregnation, and or a combination. Some of the studies did not discuss the impact of treatments used to the properties of bamboo.

All studies that used borax treatment did not directly discussed the effect of the treatment to the properties of bamboo. However, all studies observed a significant performance of the specimen on the testing. But again, it cannot claim if it is due to the treatment or to the processing method [

1,

13,

15,

41,

46,

67]. But on the literature available and to other studies like Handana et al [

80], using Borax treatment is an excellent choice. Borax solution, being environmentally friendly and water-soluble, is an ideal choice for preservation in both cold and hot soaking techniques. Its effectiveness in protecting bamboo from insect and fungal attacks has been well-established. Yang et al [

23] used alkali treatment and observe that as the alkali concentration increased, the weight loss rate of the bamboo samples also increased gradually. The contact angle decreased with higher alkali concentration, indicating a more effective removal of wax and silica from the outer and inner layers of bamboo. These changes significantly improved bamboo’s permeability, making it a favourable environment for subsequent modification. As the alkali treatment temperature increased, the parenchyma cells in bamboo experienced greater collapse, leading to a significant reduction in width and thickness, resulting in a denser structure, especially in the inner bamboo slivers. The highest density for both outer and inner slivers was achieved at 40°C, increasing by 45.6% and 88.3% respectively, compared to untreated slivers [

11]. Similar treatment used by Zhang et al [

68] which also observed a similar result on the improvement on the mechanical properties of bamboo using alkali treatment. Sharma et al [

21] differentiate the effect of using bleached to heat treatment. In heat treatment, it is classified into two such as caramelised and semi caramelised.

The mean shear strength of the semi-caramelised bamboo is higher to the bleached bamboo. They found that the specimens undergo bleaching had a slightly higher tensile strength. An improvement of the tensile strength of bamboo is similar with the findings of Cid et al [

22]. except that they used different treatment, here, they used Epoxy resin. Dong et al [

52] conducted a study showing that polycarboxylic acids treatment is an eco-friendly and cost-effective method to enhance bamboo properties. Treated samples exhibited high termite resistance and minimal mass loss. The compression strength of bamboo increased by 17-20% after treatment. However, heat treatment reduced the surface hardness significantly, whereas CA and BTCA treatments had no evident impact. The decrease in surface hardness is likely due to hemicellulose degradation caused by heating. Jiang et al [

81] performed Copper naphthenate (CuN) impregnation and oil on bamboo specimens and observed that the the application of CuN during heat-cold impregnation enhanced the termite resistance of bamboo significantly. Compared to the untreated control, heat oil treatment, and heat-cold impregnation of mineral oil alone, the CuN-treated round bamboo showed notable improvements in decay and mold resistances.

3.3. Bamboo Codes, Standards and Application

Bamboo is a sustainable material that is used in construction; however, its application is still limited [

25]. In the early ages, it is already used as a building material for construction of light houses. This material is use also as bracings and temporary scaffoldings for light construction in Asian countries. But the application of this material cannot be optimized because of some constraints such as preservation and connections. As it is known that the weakness of bamboo is its decay in due time and will be attacked by termites and other insects if not treated [

83]. Bamboo connection is also a concern, especially use of whole culm. Many researchers nowadays still working on the development of bamboo connections to maximize its performance. The codes and standards available regarding the requirements, procedures are also insufficient to fully adapt the use of bamboo as structural material [

25].

3.3.1. Codes and Standards Utilized by References

The significant impact of testing methods on results has prompted most industries to establish standardized testing procedures [

35]. There are available International Standards requirements and testing procedures in bamboo. However, there are variations on the result [

84] maybe because of different variables such as methods, species, origin, type of testing machines and others. Among the various variables, the testing standard emerged as the most influential factor affecting the mechanical property values of bamboo [

35]. Some of the literatures in thus paper did not mention the codes and standard used in their studies.

Table 9 shows the different codes and standards used in this paper.

The International Standards used includes (1) ISO 22157-2019 [

1,

15,

34,

50,

65]: 2004 [

8,

13,

14,

16,

21,

22,

79]: test methods for determination of physical and mechanical properties of bamboo culms; (2) ISO 22156 [

67,

85]: bamboo – structural design which basically concerned with the requirements for the mechanical resistance, service and durability of bamboo structures; (3) ISO 12122-1 [

38]: determination of the characteristic values for a defined population of timber products; (4) ISO 19624 [

14,

38]: basic principles and procedures of the grading of bamboo culms for bamboo structures; (5) ASDTM D143 [

46,

59,

60,

74]: standard test methods for small clear specimens of timber; (6) ASTM D3379-75 [

78]: standard test method for tensile and young’s modulus for high – modulus single filament materials; (7) ISO 9427 [

78]: methods of determining the density of wood – based panels; (8) ISO 16979 [

55]: determination of the moisture content of wood – based panels; (9) ASTM D1037-12 [

44,

78]: standard test methods for evaluating properties of wood – based fiber and particle panel materials; (10) ASTM D3039 [

9]: standard method for tensile testing composites; (11) ASTM 3043-00 [

46]: standard test for structural panels in flexure; (12) ASTM D7078-12 [

46]: standard test method for shear properties of composite materials by V-notched rail shear method; (13) ASTM 5266-99 [

46]standard practice for estimating the percentage of wood failure in adhesive joints; and (14) ASTM D3822-07 [

68]: standard test method for tensile properties of single textile fibers.

China has their own codes in standards of bamboo. The earliest is the (1) GB/T 15780 [

11,

52]: testing methods for physical and mechanical properties of bamboos; (2) JG/T 199:2007 [

1,

12,

50,

68]: testing methods for physical and mechanical properties of bamboo used in building; (3) GB/T 1928-2009 [

49]: general requirements for physical and mechanical tests of wood; (4) GB/T 17657-2013 [

45]: test methods for evaluating the properties of wood – based panels and surface decorated wood – based panels; (5) GB/T 30364-2013 [

45]: guidelines for bamboo scrimber; and (6)GB/T 20241-2006 [

45]: a guidelines of the laminated veneer lumber.

There are studies in the literatures that used European standards such as (1) EN 12512, and (2) BS EN 408.The EN 12512 [

85] governs the requirements and test methods for materials, geometry, strength, stiffness, and durability aspects of dowel fasteners used in load bearing of timber structures. Another is the BS EN 408 [

21] which guides the determination of some physical and mechanical properties of timber structures and glued laminated timber. The Italy has UNI 11842-2021 [

65] which governs the test procedures for the mechanical characterization of bamboo culms. Greco et al [

65] used this in their investigation on the photodegradation of bamboo in UV rays. JIS – A treatment method is Japanese International Standard which used by Bui et al [

66]in their study on the effect of heat and oil treatment on the mechanical properties of bamboo. they observed that the compressive strength of bamboo was improved after heat treatment and oil application (after heating). They noted that the maximum temperature is 180C because larger than it will degrade the strength. Lastly, Mukhopadhay et al [

70] used the National Building Code NBC SP7 – 2005 of India in their investigation of compressive and cleavage strengths of Indian bamboo species. It is observed that most of the studies utilized International Standards. Based on the gathered articles in this paper, there is no study that has common parameters that can be used to differentiate the standards because they differ in methods, preparations, treatment, and species. This could be an avenue for future interest. Putting more interest on the codification and standardization of bamboo usage is needed for the growing interest in this material [

24]. Kumar et al [

20] pointed that there are still no code and standard in characterizing engineered bamboo composites, thus comparing it with the literatures is the best they can do to assess the results, which each of which also utilized different standards. There is available literature outside the articles gathered, which conducted an assessment on the tensile strength of bamboo which assessed the result obtained between ISO 22157 and modified ASTM D143 [

86]. They observed that the result of tensile strength obtained from modified ASTM has obtained a higher value compared to ISO 22157. This could be a leading option for the designer in considering standard test for tensile. The further assessment and comparison of different properties might be a subject for future study. Furthermore, it would be better if there will be a centralized Standard Guidelines for the usage of bamboo considering different variations such as species, locations, treatments, and others. Another thing, there is no existing standard procedure for treating bamboo, maybe it could be another future interest to promote standardization for bamboo optimization.

3.3.2. Bamboo Applications

Bamboo is a sustainable material. In old times, bamboo was considered a material for the poor since it is mostly used by the marginalized people in the remoted areas. But in present time, it is known worldwide due to its good properties as building materials and its aesthetic purpose [

25]. However, the bamboo needs to be treated and properly processed to optimize it and have a long service life. That is why engineered and or bamboo composite arises. In which bamboo is mixed and or combined with other materials to perform better. This section briefly discusses some of the bamboo applications presented and mentioned by the gathered literatures. [

19] used bamboo sticks in reinforced concrete mix for structural columns. The other way around was the study of [

42,

72,

73] in which they used concrete to reinforce the bamboo and determined the ultimate load bearing capacity of bamboo culm which can be used for structural column. Sun et al [

47] studied bamboo strand composite lumber (BSCL) for building material application. A laminated bamboo lumber was the focused of Liliefna et al [

59] and Zhang et al [

69] to be used in flexural members. A bamboo stick boards was introduced by Yang et al [

19] which they recommended for structural construction. Bamboo – based panel were explored by Huang et al [

53] and Wang et al [

78] in which they suggested to be used in structural construction. Xiao et al [

60] and Anokye et al [

46] studied glued laminated bamboo or commonly known as “glubam”. Both studies addressed the glubam can be used un general structure application. Flooring application was the recommendation of Rao et al [

45] in their study on the outdoor bamboo fiber – reinforced composites (OBFRC). They concluded that the OBFRC is good in outdoor purposes not only it has good strength but also aesthetic. To be used as a building material is one of the many applications of bamboo. This material is excellent in many ways. Engineered or bamboo composite is indeed improved and widened the application of bamboo, however it is difficult and expensive. The use of bamboo culms as building materials in construction still an interest of many researchers today. The common weakness of bamboo culms or bamboo poles that needs further study is the preservation and the connection. This is another avenue of future study on promoting the optimization of bamboo culms, which is a sustainable building material.

4. Research Gap

Bamboo culms in construction is extensively studied by various of researchers all over the world especially to physical and mechanical properties. The collected literature also undertaken most the study on the physical and mechanical properties, treatment, and some applications. However, upon general assessment, there are still concerns that needs to address in relation to properties, treatment methods, and codes and standards used.

Figure 11 shows the summarized gaps and concern that might be address for future study.

4.1. Properties of bamboo

Species, age, and location of bamboo influence the differences in its physical and mechanical properties. It is important to note that selection and preparation of bamboo should be highly considered. The selection and preparation of bamboo samples presented in different studies varies with each other as to their location, availability, and others did not discuss. The identification of optimal harvesting, curing and storage practices must be standardized and establish a criteria for selecting species and maturity levels. The selection of nodal and internodal specimen should be indicated also, since there are variations in the performance testing results [

14,

42,

75,

87], the use of both nodal and internodal should always be considered since the nodes cannot be disregarded [

72]. Another thing is the exploration on the improvement on the properties of bamboo which includes modification of treatments, preparation and processing for composite products, and incorporation of other materials particularly sustainable materials. For bamboo culms as structural material, filling it with concrete [

72,

73,

87], and cement mortar [

42] were studied and found that ultimate bearing capacity has increased [

72,

87], however it reduces ductility of the bamboo [

42,

72]. This could be further studied in which the ultimate strength will be improved without compromising the ductility of bamboo material. Furthermore, the continuing trend issue in bamboo as structural material is the development of connections in different application. A single article in this paper discussed the nailed connection using Moso [

85] which was laterally loaded. Basically, this connection is subject to splitting of bamboo. Various researchers involve in modifications of bamboo connection includes plate with bolt [

64] steel cap with lashing [

88], buckle plate connection [

89], modified steel clamps [

90], bolted with sleeves and inserts [

91], and wooden block joint with hose clams [