1. Introduction

Rice is a principal food crop for the people of the world. Globally, rice production occupies an area of nearly 165 million hectares, producing 787 million tonnes of paddy rice in 2021, representing an average productivity of 4.67 t ha

-1 [

1]. In India, the total area under rice cultivation is 43.8 m ha, with a total production of 118.4 million tonnes of milled rice and a productivity of 2.70 t ha

-1.

Nearly 90% of the world’s rice is produced in Asia, with India as a significant contributor. It is India’s number one staple food crop and contributes significantly to the livelihood of most people. In recent years, the area under rice cropping has been decreasing, however, due to urbanization, migration of labor from agriculture to non-agricultural sectors, increasing input and labor costs, and growing water shortages; all seriously threaten the continuing cultivation of rice [

2].

Among cereals, irrigated lowland rice with continuous flooding consumes the most water of any crop, with considerable wastage of water. The challenge is to develop technologies that maintain or increase rice production with reduced water consumption. Unfortunately, the world’s rice production is in crisis, and India is not an exception with its declining cultivated area, erratic production, stagnant yields, and escalating input costs. Hence, growing more rice but with fewer input requirements is needed, particularly with less water requirement [

3].

In recent years, the System of Rice Intensification (SRI) method has been gaining wider acceptance worldwide due to its greater yield and lower costs as well as more efficient utilization of water. It has demonstrated positive results in China and India and more than 60 other countries in Asia, Africa, and Latin America [

4].

As transplanting rice seedlings requires nearly 25% of the labor for irrigated rice production [

5], finding ways to reduce this requirement, e.g., through mechanization, is very desirable. The labor requirements for SRI methods vary considerably, affected by skill, experience, and other factors. While SRI transplanting involves only 10-20% as many seedlings, these need to be planted with much greater care, so greater labor requirements, at least initially, impede the adoption of SRI. The rice sector will benefit from having labor-saving crop cultivation methods that also reduce farmers’ costs of production if this does not lower their grain output.

The operations of transplanting, weeding, and harvesting require about 60-80% of the labor needed for rice production [

6]. Harvesting, both the cutting and threshing of grain, is already mechanized or can be. The mechanization of transplanting and weeding for SRI is less advanced, unfortunately. In particular, mechanical transplanting could reduce the time needed for crop establishment, thereby and thus enhance the profitability of rice production [

7]. Thus, this partial mechanization of SRI (MSRI) deserves thorough evaluation in comparison with manual transplanting.

Another option for crop establishment is the direct seeding of rice (DSR), which is becoming more popular among farmers in India as it requires less labor than transplanting and is less costly. Yields with DSR can be comparable with those of transplanted rice if there is good seed germination. Thus, this option also warrants evaluation. Accordingly, field experiments were conducted in both wet and dry seasons to assess these different rice production methods regarding grain yield, energy efficiency, water productivity, and economic profitability.

Switching from NTP to SRI methods or to DSR would certainly change the soil food web in rice ecosystems, favoring species that prefer a more aerobic soil environment. This could have either beneficial or negative impacts on crop performance. For example, SRI water management could lead to increased populations of pathogenic plant-parasitic nematodes such as root-knot and lesion nematodes which need aerobic conditions [

8].

At the same time, applying more organic matter and fewer chemical inputs to the soil, as with SRI, can support the expansion of populations of beneficial soil microbes, higher levels of soil enzyme activity, more nutrient availability, and an enhanced nutrient pool for both plants and roots [

9]. The balance between the positive and negative effects of SRI management thus should be evaluated.

To assess the impacts of agricultural management on the soil biota, practices should be tracked over several years to understand their longer-term effects on the soil food web. Some studies have previously indicated that SRI practices compared to NTP foster more favorable soil-microbe-plant relationships [

10]. In particular, we decided to track changes in the populations of soil nematodes under both the SRI and NTP management since these common organisms are so destructive for rice plants.

The aerobic soil conditions maintained under SRI management encourage improved root health and function, leading to greater root growth and favoring the development and activity of a larger and more diverse soil microbiota [

11]. Indicators such as the populations of bacteria, fungus, actinomycetes and the levels of soil enzyme activity were monitored in this six-year study to comprehend what alterations in soil microbiology might result over time from SRI vs. usual rice cultivation.

The studies reported here were undertaken to assess what would be the best rice crop management methodology for India, comparing SRI, modified (partially mechanized) SRI, direct-seeded rice, and the manual transplanting of seedlings with continuous flooding of fields, this latter being currently prevailing practice in India.

2. Materials and Methods

Field experiments were conducted for six years, 2012-2013 to 2017-2018, during the wet seasons, June–November, and dry seasons, December to April, at the ICAR-Indian Institute of Rice Research (IIRR), Rajendranagar, Hyderabad, Telangana state. The soils at the IIRR research farm (17°33’N latitude, 78°38’E longitude) are of medium fertility, with slightly acidic clay loam soil (pH 5.6), low nitrogen (245.9 kg ha-1), medium phosphorous (33.9 kg ha-1), and medium potassium (184.5 kg ha-1).

Initially, SRI was compared with MSRI and conventional rice-growing practices, i.e., normal transplanting, to consider the effects of mechanical transplanting (Experiments 1 and 2). Since the results from SRI and MSRI were quite similar, in subsequent experiments, MSRI was compared with DSR and NTP (Experiments 3 and 4).

Thus, the SRI methodology for rice cropping according to its original recommended practices was assessed in comparison to three other methods of crop management: (a) mechanically-transplanted SRI (MSRI); (b) direct-seeding of rice (DSR) using a drum seeder under wet puddled conditions; and (c) conventional normal transplanting practices (NTP) with manual transplanting and flood irrigation. Trials were replicated three times to minimize the effects of any soil differences and measurement errors. The differences in practices are shown in

Table 1.

The rice varieties used for the comparisons were RP Bio-226 in 2013 and Varadhan in 2013 and 2014, and then RNR-15048 (also known as Telangana Sona) was planted in the trials during the 2015-18 seasons. These are all high-yielding varieties with a duration of 120-130 days.

For the mechanical transplanting (MSRI), a VST Shakti Yanji paddy transplanter (Chinese) powered by a diesel engine was used to transplant 16-18 days-old seedlings from a mat-type nursery. It was able to plant eight rows in a single pass, with a spacing of 24 cm between rows and 10-12 cm between the plants depending on the speed of the machine. For DSR methods, an eight-row drum seeder operated by manual labor modified in the Institute workshop was used to sow germinated seeds in rows spaced 20 cm apart, with 6 cm spacing between plants in each row. Differences among the various methods of crop establishment are best represented by the plant densities that were compared in this study, shown in

Table 1.

Weather data including mean minimum and maximum temperatures and precipitation were recorded for wet and dry seasons from 2012-13 to 2017-18 (

Table 2). Average

temperatures during the wet seasons of 2012-2017 ranged from 25.1-26.8°C. The lowest wet season rainfall (373 mm) was recorded in 2015. Dry season rainfall ranged widely, from an average of 159 mm in 2015 to just 7 mm the following year.

Grain yield: The rice plants in each trial plot (7×6 m) were harvested and threshed. Grains from each plot were kept separate and dried under the sun (to 14% moisture), with grain yield from each plot then calculated and recorded in tonnes ha-1.

Water productivity: The amount of water applied to each plot was measured using digital water meters, and the total amount supplied to each plot throughout the cropping season was calculated. To maintain the water regime assigned to each plot, elevated bunds were constructed to separate all plots, and fiber sheets were buried one meter deep around each plot to impede lateral flow.

Water productivity (amount of rice per unit of water) was calculated and expressed in kg ha-1 mm-1. The frequency of AWD applications for each non-NTP crop establishment method was adjusted according to rainy events throughout the season. To manage the water supply, the depth of the perched water table in the soil was monitored using a PVC pipe, known as a field water tube, and in India as a 'pani pipe.' The pipe ( inner diameter 15 cm; length 40 cm) was placed into the ground to a depth of 15 cm, and the soil was removed from inside the tube. Water could enter the pipe through perforations in the15-cm section below the soil's surface. The farmer could know the amount of water in the soil either by observing the water table directly or by measuring the water depth in the pipe.

For NTP plots, the depth of water in the field was kept at 5 cm up to the rice crop’s dough stage, and any extra water was drained from the plot. In all the treatments for the first ten days following transplanting, the field’s water level was maintained at 2.5 cm depth. After that, the water level in each plot was adjusted according to the treatment prescribed until ten days before harvest. At that time, water was removed from the plots to facilitate harvesting. Water productivity was calculated as the grain yield (kg ha-1) divided by the sum of irrigation applications + effective rainfall (in mm).

Fertilization: Recommended doses of NPK (N, P2O5, and K2O at 120, 60 and 40 kg ha-1, respectively) were applied to all plots as the effects of fertilization was not a factor evaluated in this study. Nutrient applications were the same for all the trials. Nitrogen was supplied 50% from inorganic and 50% from organic sources, the latter being farmyard manure (FYM). The urea was provided in 3 splits (1/2 as basal application + then ¼ at 30 DAT and at 50 DAT); single super-phosphate was applied basally at planting; and muriate of potash was given in 2 splits (a basal application and 50 DAS). In principle, the fertilization of the SRI plots should have been entirely organic, but we did not make the source of externally-supplied nutrients a variable in these trials.

Energy use efficiency: Energy indices derived from various published studies were used to calculate the energy equivalence of inputs and outputs for the respective crop establishment methods. Inputs included human labor, machinery, farmyard manure (FYM), chemical fertilizers, plant protection chemicals, herbicides, and electricity. The tasks of weeding, watering, and application of FYM, fertilizer, and pesticides were carried out by human labor, while harvesting and the preparation of land were done with machines.

Paddy grain and paddy straw were the products considered as outputs. Calculations were made to determine the energy represented by these outputs to compare them with the energy embodied in the respective inputs per hectare. To estimate energy efficiency, the input and output values were the corresponding energy-equivalence coefficients shown in

Table 3 [

12,

13,

14,

15,

16].

The total energy needed for labor, farm equipment, seed, fertilizer, and irrigation consumption in each system was added up, and the associated output was also summarized in terms of energy in GJ ha-1. The energy output represented by the main product (grain) and by-product (straw) could be summarized by multiplying the production by their respective energy equivalents. Energy use efficiency (EUE) was computed as the gross energy output (in GJ ha-1) x 100, divided by total energy input (in GJ ha-1).

GHG estimation: The closed-chamber method was used to assess plant-mediated CH

4 and N

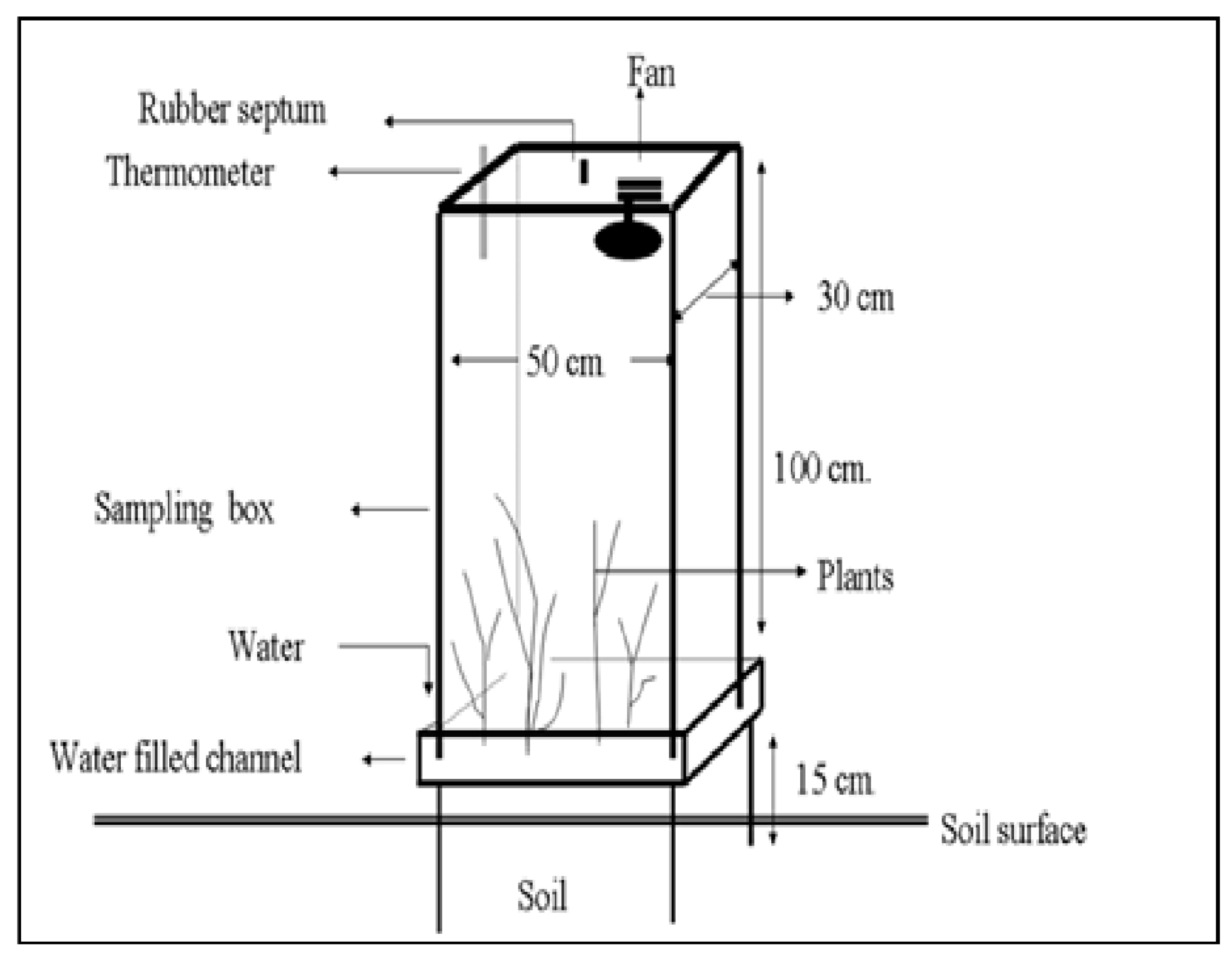

2O emissions from the experimental plots at weekly intervals during the entire season. Samples were taken using chambers (50 cm x 30 cm x 100 cm) built of 6 mm acrylic sheets kept over aluminum stands (

Figure 1) inserted in the soil. To make the system airtight, channels at the base of the aluminum stands were filled with water.

Samples were taken into 20 ml polypropylene syringes with a three-way stopper using a hypodermic needle (24 gauge) through a rubber septum at the top of the chamber. A thermometer was placed into the chamber through a different septum to measure the temperature during the sampling time. A small DC-driven fan powered by a 9-volt battery was used to homogenize the air inside the chamber.

Data on air temperature and precipitation were gathered from the farm’s weather station. Gas samples of approximately 20 ml each were collected on the day of sampling at 0, half, and one hour. The same sampling schedule was followed in all the seasons studied. A gas chromatograph (Model 450-GC, Varian Inc., Walnut Creek, CA) equipped with an electron capture detector, a flame ionization detector, and a thermal conductivity detector were used to evaluate the gas samples obtained for their N2O and CH4 immediately.

Global warming potential (GWP) is an index that summarizes the effects of the respective GHGs that trap heat in the atmosphere, thereby contributing to global warming. Their relative and total contributions to global warming potential (GWP) are evaluated in relation to a single gas, by convention, to CO

2. The GWP for CH

4 (based on a 100-year time horizon) is 25, and for N

2O, it is 298, when the GWP for CO

2 is considered to have the value of 1. In this study, CO

2 emissions were not considered because they are not much affected by management methods. GWP was calculated using the equation: GWP = [kg CH

4 x 25] + [kg N

2O x 298] [

17].

Greenhouse gas intensity: The index of greenhouse gas intensity (GHGI) summarizes the level of emissions per unit of grain yield produced, indicating the amount of emissions released per unit production of biomass. It was calculated by dividing global warming potential (GWP) by grain yield [

18].

Soil microbial population and enzyme activities: In this study, the pre-treatment microbiological parameters were considered to be in a steady state, with subsequent differences measured in soil microbial populations and enzyme activities regarded as the result of respective management practices. Soils from the rhizosphere of rice plants grown under the respective crop establishment methods were sampled to determine their microbial populations and enzyme activities.

The serial dilution and agar plating method was used for the enumeration of populations of bacteria, fungi, and actinomycetes. Nutrient agar medium [

19] was used for the enumeration of total heterotrophic bacteria. The fungi populations were estimated on Martin’s rose bengal agar medium, containing 1.25 g of streptomycin and 0.033 g of rose bengal in 1 litre of the medium [

20]. The actinomycetes population was enumerated using Kuster’s agar medium [

21]. Fluorescein diacetate (FDA) hydrolytic activity in the soils was estimated using fluorescein diacetate as the hydrolysis substrate [

22]. Key soil enzymes, i.e., dehydrogenase, β glucosidase, alkaline phosphatase, and arylsulfatase, were determined by using standard methods [

23].

Soil nematode communities: To provide a baseline understanding of the soil nematode community, soil samples were collected at a depth of 20 cm with a shovel from both the SRI and NTP trial plots before the trials were started. Eighteen replicate plots (5 m2) were maintained for each system. The initial soil samples taken from both the SRI and NTP experimental plots showed no significant differences in the composition of the soil nematode communities.

The rice root nematode (Hirschmanniella spp.) comprised more than 60% of all the plant-parasitic nematodes identified and dominated the communities of plant-parasitic nematodes in both the SRI and NTP plots. Other minor ectoparasitic nematodes included Helictylenchus spp. and Psilenchus spp. More harmful species like Meloidogyne graminicola, which causes root-knot disease, and Pratylenchus species, which causes root lesions, were absent in the samples.

Long-term changes in the composition of soil nematode communities were assessed by analyzing the soil samples collected from the field plots after five years, i.e., after the completion of ten crop cycles: five wet and five dry seasons. Nematode extraction was done using modified Cobb’s sieving and decanting technique with 100 g sub-samples taken from each composite soil sample. Nematode enumeration and identification of nematode trophic groups were done using diagnostic keys [

24]. The total number of plant-parasitic and free-living microbial-feeding nematodes in each sample was counted by observing nematode suspension under an inverted microscope at 40x magnification.

Economic analysis: The costs of cultivation were recorded for inputs such as seed, manures, fertilizers, irrigation, and plant protection chemicals listed using current market prices and then summed up. Similarly, the expenditures incurred for the operations involved in cultivation, such as tillage/land preparation, nursery-raising, transplanting, harvesting and threshing, were added up, and the costs of hiring tractor-driven machinery and the wages of human laborers (based on eight hours of work per day) were included in the cost of cultivation. The Government of India’s minimum support price (MSP) for rice was utilized to calculate the value of production [

25,

26] and was used to calculate the gross return. The net return was determined according to the equation:

A summary analysis was done of the economic returns from each crop establishment method as this is what farmers and policy-makers are most concerned about. A benefit-cost ratio (BCR) is the ratio between the economic returns from production and the costs of that production, both summarized and expressed in terms of Rs. ha-1.

Statistical analysis: Before performing the analysis of variance, descriptive statistics were calculated for the study variables across the different crop establishment methods. In the following section, the data analysis was carried out with a two-factorial randomized block design, considering the method of crop establishment as one factor and crop season as another factor, using SAS version 9.3 [

27,

28], available at the ICAR-Indian Institute of Rice Research in Hyderabad.

3. Results

Grain yield: The basic System of Rice Intensification (SRI) methods resulted in significantly higher grain yields (6.23-6.47 t ha

-1), about 18% more than partially mechanized SRI (4.75–5.72 t ha

-1) (

Table 4, Exp. 1 and 2). In turn, the MSRI method was found to give higher yields (6.27-6.41 t ha

-1) than both DSR (6.02 -6.09 t ha

-1) and normal transplanting (5.36-5.59 t ha

-1) (

Table 4, Exp. 3). The mean yields from SRI, DSR and MSRI were significantly higher than NTP in all experiments as shown in

Table 4.

Water productivity: This was calculated in kg of paddy rice harvested per hectare-millimeter of water (or per 10,000 liters). As shown in

Table 5A, this productivity for SRI was 5.32-6.85 kg ha- mm

-1, and for MSRI 4.14-5.72 kg ha-mm

-1, followed by DSR (5.06-5.11 kg ha-mm

-1), compared 3.52-4.56 kg ha-mm

-1 for NTP. All three methods (SRI, MSRI and DSR) were significantly superior to NTP in terms of water productivity irrespective of the season.

Economic productivity: The evaluation of economic productivity as indicated by benefit:cost ratios showed SRI methods (2.93-3.12) to be about 50% more profitable than NTP (2.14-2.21). Compared with other establishment methods, MSRI showed more favorable B: C ratios (1.48-1.52) compared to DSR (1.21-1.33) and NTP (1.15-1.16). A superior ratio of benefits-to-cost reflects some combination of higher yield and reduced costs of cultivation. [

Table 5B].

Energy use efficiency: SRI methods recorded 11.8% higher energy use efficiency, followed by MSRI (9.7%). SRI’s higher grain yield led to more gross energy output and greater net output than from the MSRI crop establishment with mechanized transplanting. However, in turn, the DSR method showed slightly higher mean energy efficiency over MSRI (10.1% vs 9.7%), while all three methods (SRI, MSRI, and DSR) were significantly superior to NTP (8.3%) (

Table 6).

Greenhouse gas (GHG) emissions: Crop establishment methods significantly affected methane and nitrous oxide emissions. The highest seasonal integrated CH

4 emission of methane was observed with the conventional NTP methods (26.9 to 36.6 kg ha

-1 season

-1 in Experiments 1 and 3), while the lowest was with SRI methods (18.9-21.6 kg ha

-1), one-third less. CH

4 emissions were even lower for MSRI (11.6 to 20.6 kg ha

-1 season

-1 (Experiments 3) in comparison to NTP (27.8 to 36.6 kg ha

-1 season

-1). CH

4 emissions from different methods followed the order of NTP > DSR > MSRI > SRI, indicating the superiority of the SRI method in this regard (

Table 7). It was seen that CH

4 emissions with SRI and MSRI methods in the wet season were relatively less compared to the other rice-establishment methods.

The nitrous oxide fluxes were relatively lower from NTP (6.5 to 10.1 kg ha-1 season-1 (in Experiments 1 and 3) than from MSRI and SRI (7.3 to 10.7, and 10.1 to 10.3 kg ha-1 season-1, respectively). The difference is due to more hypoxic (flooded) soils and aerobic soil conditions.

The global warming potentials from the various systems were assessed based on the field measurements recorded. The differences in GWP among the four systems (SRI, MSRI, DSR and NTP) during the dry season (3552 to 3742 kg CO

2-eq ha

-1 ) were not significant (

Table 7). Even though NO

2 is more potent gas than CH

4 in terms of GWP, the on-par results of the different crop establishment methods were mainly due to considerable methane reduction because of AWD adoption other than the NTP method. As a whole, GHG emission intensity varied from 0.56 to 0.65 kg CO

2 eq. kg

−1 grain yield in SRI, MSRI and DSR was lower as compared to normal transplanting (0.73 to 0.75 kg CO

2 eq. kg

−1 grain yield). Relative to the normal transplanting method, the SRI reduced the GHGI by 21% and DSR reduced the GHGI by 23% and MSRI by 13% indicating the positive effects of the alternate and improved methods over normal transplanting.

Microbial populations and enzyme activities: SRI methods supported significantly higher bacterial, fungal, and actinomycetes populations (respectively, 7.2, 5.2, and 4.6 log CFU g-1soil) as compared to normal transplantation (6.7, 4.7 and 3.9 log CFU g-1 soil respectively). The bacterial population was observed to increase by 8%, the fungal population by 12%, and the actinomycetes by 20% under SRI methods of cultivation over NTP.

With SRI, significantly higher soil dehydrogenase and FDA activities were observed than with NTP.by 8.5% and 15.8%, respectively. A significant increase in glucosidase activity (91.24 µg p-nitrophenol released g

−1 soil h

−1) in SRI soil was also observed compared to NTP (51.18 g

−1 soil h

−1). SRI plots recorded numerically but not significantly higher activities of other enzymes like alkaline phosphatase and arylsulfatase over NTP plots (

Table 8).

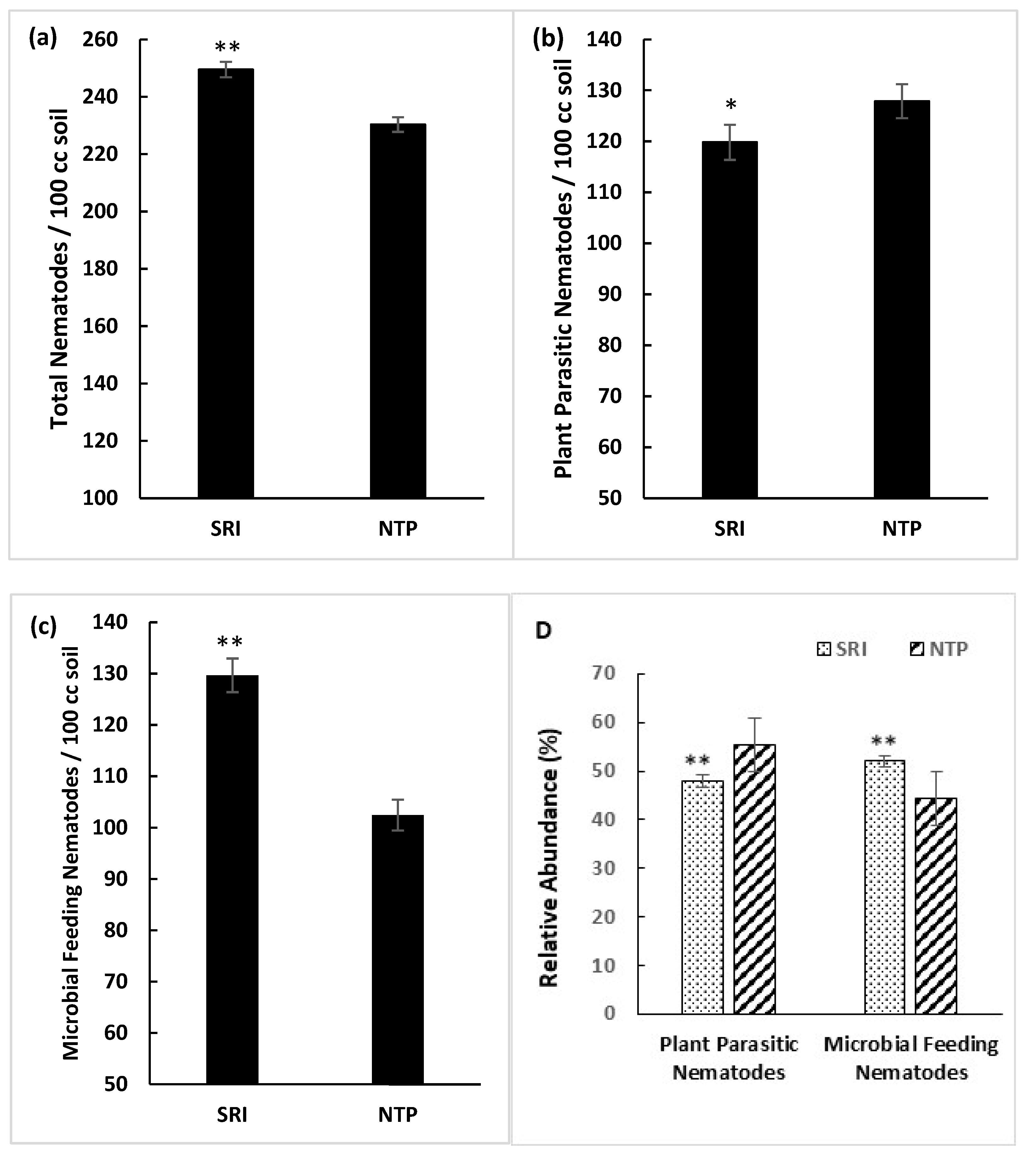

Effects on soil nematode community: Nematode analyses after five years, i.e., after ten crop seasons, showed the SRI system having significantly more impact on nematode abundance than did the NTP system (

Figure 2). There were more nematodes in total associated with the SRI system, however, the numbers of plant-parasitic nematodes (PPN) were much less than with NTP, and the SRI plots had a substantially greater abundance of microbial-feeding nematodes than in NTP soil. The relative abundance of nematodes that feed on microorganisms, which is benign and even beneficial for plants, was 52% under SRI (52%) compared with 44.5% for NTP. Conversely, the relative abundance of nematodes that parasitize plants was lower with SRI (48%) as compared to NTP (55.5 %). This could be one effect that is contributing to SRI’s higher yield.

4. Discussion

In this study, use of the originally-recommended SRI methods with manual transplanting yielded the highest economic returns compared to the other three methods evaluated. Crop yield can be maximized when all the plants achieve their highest productivity using available water, nutrients, and sunlight resources. Further, the best results from rice crops that start from transplanting can be achieved when seedlings are transplanted before their 4

th phyllochron of growth, with optimum square spacing, usually 16 hills m

-2 [

29]. In our trials, because of machine design constraints, the version of MSRI that was evaluated did not have any reduction in plant density, so some of the benefits of this proposed practice were probably forgone. If a more appropriate mechanical transplanter can be designed and used, it is anticipated that MSRI may become more economically advantageous, with higher yield while labor requirements are reduced.

The greater economic benefit from both MSRI and SRI in these trials was seen from their more favorable B:C ratios. MSRI has a particular attraction because of its labor-saving and lower costs of production. Despite several advantages of manual SRI over MSRI shown in this study, given the labor constraints facing many, even most rice-producing farmers, there is reason to adapt and modify SRI practices in response to local conditions. Suitable implements for mechanized transplanting would justify promoting SRI practices on a larger scale in India, particularly in areas where agricultural labor is scarce [

30].

A further need for SRI expansion is to develop appropriate motorized implements for mechanical weeding of SRI crops. These would cover multiple rows simultaneously and utilize mechanical power instead of human energy to propel the weeder. Development and timely availability of durable, effective, and affordable equipment for weeding will make SRI adoption more attractive to farmers, helping them to capitalize upon biological processes and potentials that SRI methods tap [

31].

The AWD method of irrigation followed in the SRI, MSRI and DSR trials recorded relatively lower emissions of CH4 due in large part to the more aerobic soil conditions resulting from intermittent drying and wetting. Regarding nitrous oxide (N2O), TPR recorded the lowest emissions of N2O-N, not surprisingly. However, the different crop establishment methods were at similar levels in this respect.

The intermittently aerobic and anaerobic soil conditions created by AWD reduce the numbers and activity of methane-producing archaea, which results in less emissions of this deleterious GHG. In the short run, i.e., within a 25-year time horizon, CH4 is 80 times more potent than carbon dioxide (CO2).

The most effective way to reduce greenhouse gas emissions from paddy fields is to reduce CH

4 emissions through water management [

32]. As this study did not evaluate alternative sources of fertilization, it could not assess how much GHG reduction us possible by moving rice production away from its current reliance on inorganic N fertilization and toward organic sources of nutrients for soil organisms and plants.

A study of SRI effects in Andhra Pradesh state [now Telangana] by researchers from Oxford University and India’s National Institute for Rural Development assessed GHG emission and other effects. They found that in addition to an average 60% increase in yield, plus reductions of 60% and 74% in the use of groundwater and fossil energy, smallholders who used SRI methods of production decreased their GHG emissions by 40% ha

-1 and by 60% kg

-1 of rice produced. Their evaluation was more inclusive than we were able to do because it also considered CO

2 emissions throughout the whole process (life-cycle) of rice production [

33,

34].

Our results showed, as anticipated, that SRI practices enhance the structure of the soil food web by providing a more favorable environment for beneficial soil organisms, from microbes to earthworms. This study documented a build-up of beneficial microbivorous nematodes that promote ecosystem processes like decomposition and nutrient mineralization in the rice ecosystem. These effects have positive implications for crop growth and productivity.

The yield gains with SRI management need not be compromised by an increase in the total nematode population under aerobic soil conditions. In our five-year trials, the nematode community under SRI was dominated by less-pathogenic species, i.e., by microbial-feeding nematodes. This may not be the case in fields that have endemic populations of more pathogenic species, like the root-knot nematode

Meloidogyne graminicola. Researchers in Thailand have reported that rice yields with SRI were lower than NTP due to a rapid build-up of rice root-knot nematodes under SRI water management [

35]. Farmers should therefore be cautioned when adopting SRI to monitor for parasitic nematodes. Because these are aerobic organisms, they can be controlled by intermittent flooding rice paddies, which can be integrated into an AWD schedule.

Microbial populations under the SRI method of crop establishment are increased by more root exudation, by having more soil organic matter due to weed incorporation, and by more aerobic soil compared to traditional submerged rice cultivation [

36]. In our study, increases were observed in dehydrogenase enzyme activity (representing microbial oxide reduction processes), in fluorescein diacetate hydrolysis (indicative of the presence of enzymes like lipases, esterases, and proteases), and in glucosidase (which has a critical role in carbon cycling). These effects could all be attributed to the enhanced abundance and activity of soil microbes. These result from having more root exudation from greater root biomass. There would also be greater carbon mineralization from more organic inputs to the soil with SRI methods, but this was not tested and evaluated in our trials.

In this study, enhanced levels of other beneficial enzymes like alkaline phosphatase and arylsulfatase were also observed with SRI methods of cultivation (37). The more aerobic soil conditions with SRI resulting from reduced irrigation and the use of a cono-weeder to control weeds, disturbing the surface soil around the rice plants several times, create a more favorable environment for soil microflora and their activities than with conventional rice cultivation. However, this was not a focus of our research, and it remains an important subject to be studied in depth.