1. Introduction

Quinoa and sorghum have gained increased interests from the food industry, specifically the baking industry. One reason for this growing interest is that both grains are very low demanding in terms of cultivation and can be grown in various environments, even in hot and dry areas, where true cereals are less successful [

1]. For this reason, they are generally acknowledged as food security plants of the future, particularly in the view of the ongoing climate change. Another reason is that these two grains are gluten-free, thus suitable for the production of gluten-free products for people with intolerances to gluten containing cereals like wheat, rye and barley. This attribute has been one of the most important drivers for the rising cultivation and use of quinoa world-wide [

2].

Bread and bakery products are one of the most common staple foods world-wide. Most of these bakery products are based on wheat, but due to the ongoing climate change and the already noticeable effects on wheat cultivation (yield and quality of harvested grains) an increase in biodiversity is needed. Hence, an integration of a wider range of grains might be necessary to maintain the supply of these products in the future. With respect to quinoa and sorghum, they both lack network forming proteins and are therefore not able to develop cohesive and elastic dough properties when used alone [

3,

4,

5]. Their use in baking is either done by blending them with wheat, or by adopting gluten-free recipes. Gluten-free breads in the market are often produced from refined flours (like rice) or pure starches (like maize, wheat or potato starch) and they still often lack protein and dietary fibre. The use of wholegrain flours from gluten-free sources like sorghum or quinoa would be a beneficial option, as they provide valuable nutrients [

6,

7].

There is a bulk of research studies available on the use of quinoa in (gluten-free) baking [

8], but in the market such bakery products containing quinoa are still a niche product. Reasons for this might be that the addition of quinoa to bakery products is noticeable altering the final product quality, particularly in terms of texture and taste [

9]. Additionally, the higher price of quinoa makes it more difficult for its integration into daily staple foods. Sorghum might be another interesting grain that could offer the potential to provide affordable and palatable bakery products. Sorghum has been a major staple food in Africa and India, where local food processing of sorghum often includes microbial fermentation with the aim to improve the nutritional and sensory properties of the final products. Outside of Africa and India, sorghum is mainly used as animal feed or bioethanol production and only rarely as food [

10]. Hence, the use of sorghum in Western style bakery products is still under-researched. The yield of sorghum is comparable or even higher than wheat, which might allow to commercialise it at similar costs.

Up to now, both sorghum and quinoa are mainly used as wholegrain flours. As their grain size, depending on their genotypes, and also its kernel morphology, differs greatly from cereals like wheat, production of milling fractions at a large scale has not yet been established. However, the production and use of chemically defined and distinct fractions might enhance the future use of these two kernels for a wider range of products. Compared to wholemeal flour, an increased level of starch or protein or chemical components might be of help. For milling and fractionation of these two grains, protocols from cereal milling require specific adaption on the one hand, on the other hand thorough knowledge of the composition of such produced flour fractions is necessary in order to select the desired fraction with a targeted composition or properties [

11].

In order to support the future exploitation of sorghum and quinoa, this study aimed to investigate if milling fractionation and sourdough technology might be feasible tools to enhance their potential for a broader food use. In detail, the research tasks of this study were 1) to investigate the production of chemically distinct milling fractions by roller milling and 2) to explore the baking properties and shelf-life of gluten-free bread produced from 100% quinoa or 100% sorghum by sourdough fermentation. The use of the same methods for all trials allowed to compare the behaviour and performance of sorghum and quinoa for the investigated processes.

2. Materials and Methods

2.1. Raw material

Quinoa was obtained from Naturmühle Caj. Strobl (Linz-Ebelsberg, Austria) with the origin of the grains coming from Bolivia. Three sorghum species (Albita, Alfödi, GK Emese) grown in Hungary were provided by the Research Group of Cereal Science and Food Quality, Department of Applied Biotechnology and Food Science, Budapest University of Technology and Economics, Hungary. All seeds were stored in sealed plastic bags at 4°C.

2.2. Chemical analyses

Chemical analyses were performed using ICC standard methods. Dry matter was determined according to ICC Standard 110/1, the ash content according to ICC Standard 104/1, starch according to ICC Standard 168, protein according to ICC Standard 105/2, and dietary fibre according to ICC Standard 156. All chemical analyses were done in triplicate.

2.3. Pasting properties

Pasting properties were evaluated according to the ICC standard method No. 162 using a rapid viscoanalyzer (RVA) 4500 (PerkinElmer Inc., Waltham, MA, United States). The samples were prepared by dispersing 3.5 g of flour (14% (w/w)) in 25 ml of distilled water. Determinations were replicated at least three times and the results were shown as mean values.

2.4. Dry fractionation by roller milling

For fractionation of the samples a laboratory scale roller mill (E8, Haubelt Laborgeräte GmbH, Istanbul, Turkey) was used. The mill consists of a precrash system where the seed kernels are broken, two plain drums, where the gap (distance of drums) is variable (0 for the widest possible gap and 10 for the closest gap, which is less than 1 mm). After milling, the flour was sieved through two vibrating sieves, which separated the flour into three different milling fractions: (1) course fraction, (2) middle fraction, and (3) fine fraction.

In pre-trials several gap settings were investigated with the aim to obtain distinct milling fractions, which were evaluated by determination of the ash content. Also yield of the fractions was considered. For quinoa fractionation gap settings investigated were 0, 5, 8 and 10, for sorghum (only variety Albita) the gap settings were 3, 5, 7. The setting of the pre-crasher was kept constant at 6, as well as the time for sieving at 2 min. Mesh size of the sieves used were 475 µm (top) and 212 µm (bottom). Pre-trials were run once, but ash content of all obtained fractions was measured in triplicate. According to the results of the pre-trials the main trails were run at a reduced number of gaps, which was 5 and 8 for quinoa, and 5 for the three sorghum varieties. All main milling trials were performed in triplicate. No conditioning of the kernels was done prior to milling.

2.5. Gluten-free bread baking

Gluten-free bread baking was performed using the sourdough technology as suggested by Ramos et al., 2021. Additionally, water addition was varied at 70-80-90%, as gluten-free batters are known to require a higher level of water. In the first step, the sourdough was pre-fermented for 16 h. For the preparation of sourdough, flour (quinoa or sorghum flour) and water was mixed in a ratio of 1:1 with 10% sourdough starter (Reinzucht-Sauerteig Reis glutenfrei, Ernst Böcker GmbH & Co. K.G., Minden, Germany), which was then fermented at 27°C, 80% RH for 16 h. The sourdough was immediately used for bread baking. Bread dough was prepared by mixing 100% sourdough with 75% flour (mixture of quinoa or sorghum with gluten -free wheat starch in a ratio of 1:1), 3% albumin (Enthoven-Bouwhuis Eiprodukten B.V., Raalte, NL), 1.5% fat powder (REVEL®, Loders Croklaan B.V., Wormerveer, NL), 1.8% salt, 1.5% instant dry yeast (Lesaffre, Marq-en-Bareoul, France) and 1% sugar (percentage was based on flour weight). Water was added to produce a batter with 70, 80 and 90% moisture content (w.b.). The batter was mixed in a laboratory dough mixer (Teddy Varimixer, Varimixer A/S, Brondby, Denmark) at speed 1 for 2 min followed by speed 4 for 4 min, then divided into two portions of 300 g, which were placed in baking tins with dimensions of 13 × 9 × 7 cm (top dimension) and 15 × 11 × 7 cm (L × W × H; bottom dimension). Proofing was performed in a fermentation chamber (Model 60/rW, MANZ Backtechnik GmbH, Creglingen, Germany) at 30 °C and 85% RH (relative humidity) for 50 min. Baking was conducted in a deck oven (Model 60/rW, MANZ Backtechnik GmbH, Creglingen, Germany) at 180 °C (top and bottom heat) for 40 min. After baking, the bread was cooled and stored in a climate chamber (Climacell® EVO, MMM Gmbh, München, Germany) at 20 °C and 50% RH for 18 h before analysis. Baking was conducted in triplicate, resulting in six bread loaves per recipe.

2.6. Storage tests of gluten-free bread

Five bread loaves of one quinoa and one sorghum recipe, both at 90% batter moisture, were baked as described above and stored at 20°C, 50% RH. After 1, 3, 5, 7 and 9 days the crumb firmness was determined. The obtained Fmax-values were used to describe bread staling (caused by starch retrogradation) using the equation of Avrami (equ 1).

Ɵ = Starch ratio, which has not re-crystallised; T

0 = initial F

max at day 0; T

inf = final F

max at day 9; T

t = F

max at time “t“; k = rate constant; n = Avrami-exponent

2.7. Evaluation of physical bread properties

The baking loss was calculated as (Wbb-Wab)/Wbbx100, where Wbb refers to the mass of the batter and Wab refers to the mass of the bread after baking and cooling.

Measurement of bread volume was performed by applying the BVM 6600 volume analyser (PerkinElmer Inc., Waltham, MA, US). Specific bread volume was calculated as the ratio between volume (cm3) and the bread (g) mass. Four measurements were performed for each formulation.

Determination of crumb firmness and relative elasticity was conducted based on the AACC Method 74–09.01 with some adaptions: A Texture Analyser (Model TA-XT+ Stable Micro systemsTM Co., Godalming, UK) equipped with a 5 kg load cell and a SMS compression probe of 100 mm diameter (SMS P/100) was used to analyse two bread slices of 3 cm thickness per loaf for crumb texture with a uniaxial compression test of 20% strain. The test speed was set at 0.5 mm s−1 with a relaxation time of 120 s and trigger force of 10 g. Pre- and post-test speeds were set at 1 and 10 mm s−1, respectively. The maximum compression force (N) was indicated as crumb firmness Fmax and relative elasticity (%) was determined by dividing the end force by the maximum force. Six values were derived for each recipe.

Crumb and crust colour were measured by applying a Digi-Eye® system (Verivide, Leicester, UK) with a D-90 Nikon digital camera (Tokyo, Japan), resulting in L*, a* and b* – values. Four values for each formulation were determined.

A digital image analysis system was applied to measure crumb porosity by using the software ImageJ (1.47v, National Institute of Health, Bethesda, USA). The analysis was performed on an image of a 2 × 2 cm crumb square, captured with the digital camera features of D-90 Nikon (Tokyo, Japan) from the Digi-Eye® System (Verivide, Leicester, UK). The analysed parameters included number of pores (n=4), average pore size (n=8), percentage of total pore area to total bread area (n=8) and pore uniformity (calculated from the standard deviations of the average pore size per bread, n=4).

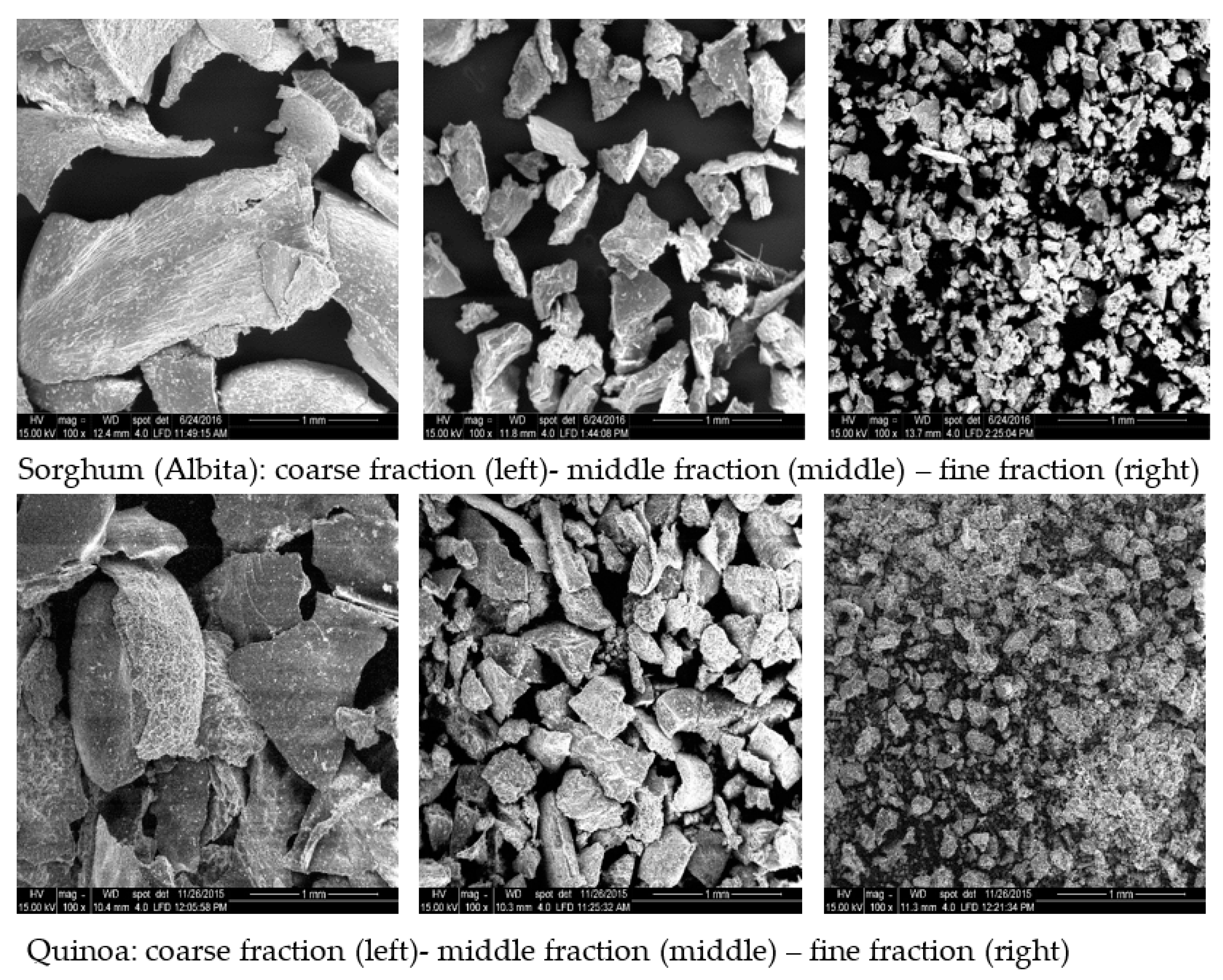

2.8. Scanning electron micrographs

To determine the particle details after fractionation, a scanning electron microscope FEI Inspect S50 (FEI Company Japan Ltd., Japan) at 50x magnification was used.

2.9. Statistical analysis

Statistical analyses were conducted using the software Statgraphics Version XIX (StatPoint Technologies, Inc., Warrenton, VA, USA). To express significant differences between formulations, a one-way ANOVA and Fisher’s least significant difference test at a 5% probability level (p-value <0.05) were applied.

3. Results

3.1. Milling performance - yield of obtained fractions

As described in section Material and Methods, a series of pre-trials was conducted where several roller gaps were investigated for their applicability to produce distinct milling fractions. For a rough estimation of successful separation, the ash content was determined for the obtained fractions (see

Table 1). The ash content is an appropriate predictor to evaluate the separation of outer layers (bran, aleurone, embryo) from the inner kernel (starch endosperm) [

12]. In

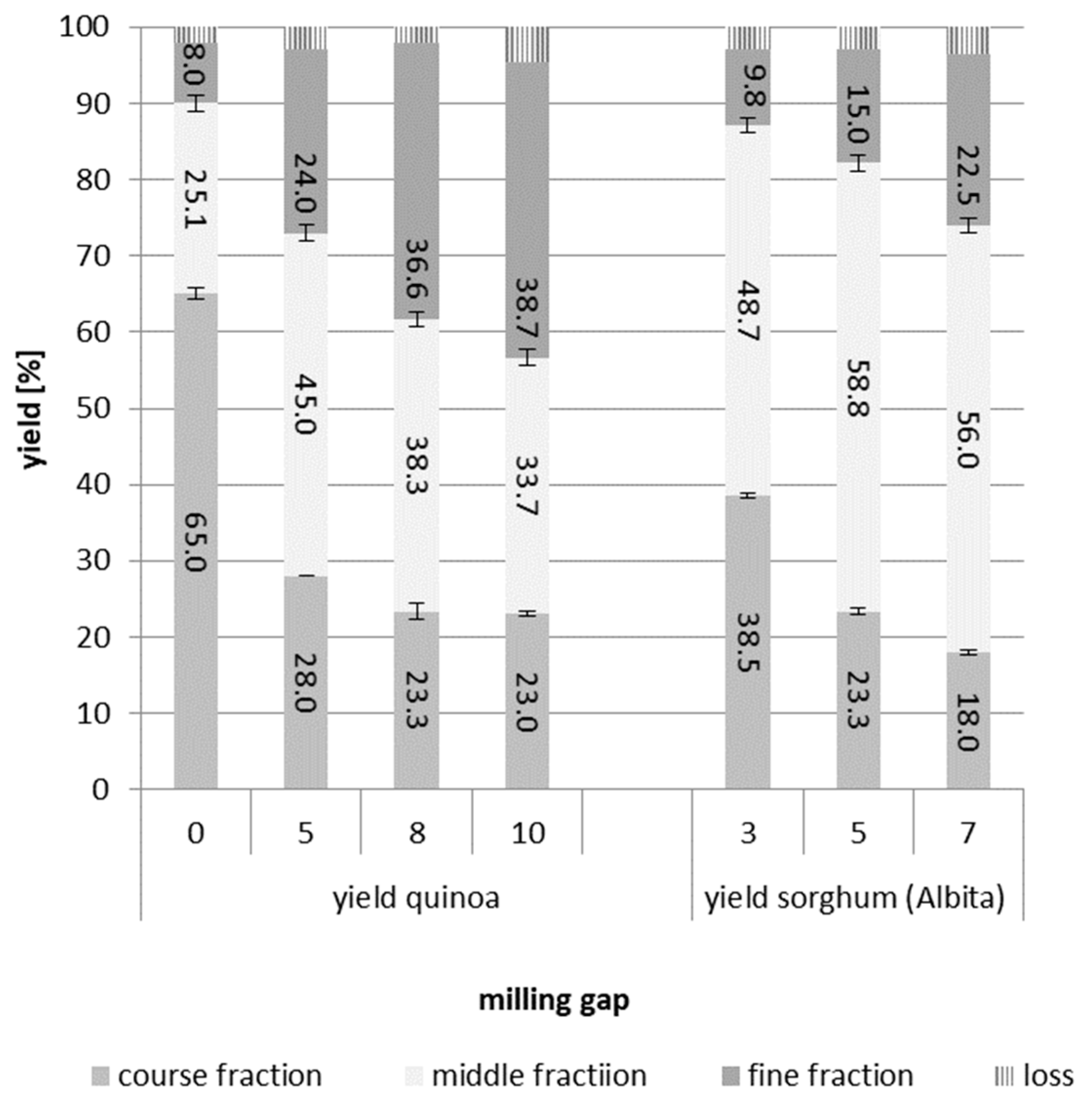

Figure 1 the yield of fractions gained at selected milling gaps is summarized.

For all samples, a too wide and too closed gap between the rollers was not suitable. At gap 0 (widest gap of rollers) quinoa fractions were not clearly separated, the amount of coarse fraction was too high, so containing large amounts of endosperm, which was also shown by its rather low ash content. Decreasing the distance of the rollers improved the fractionation process, but when it was too small (gap 10), separation of the samples worsened again. The ash content in the coarse fraction was decreased compared to setting 5 and 8. For quinoa these pre-trials suggested that gap 5 or 8 seemed most suitable. As differences between these two gaps were low and at this stage not completely clear, it was decided to run the main trials for quinoa at gap 5 and 8. For sorghum fractionation, the results were clearer compared to quinoa: only gap 5 delivered fractions with distinctly different ash content. At gap 7 (closer), the ash content of the fine fraction was higher and of the coarse fraction lower than at gap 5. However, at gap 3 (wider), too much coarse fraction was accumulated, containing obviously too much endosperm. Thus, the main trials for the sorghum varieties were run at gap 5.

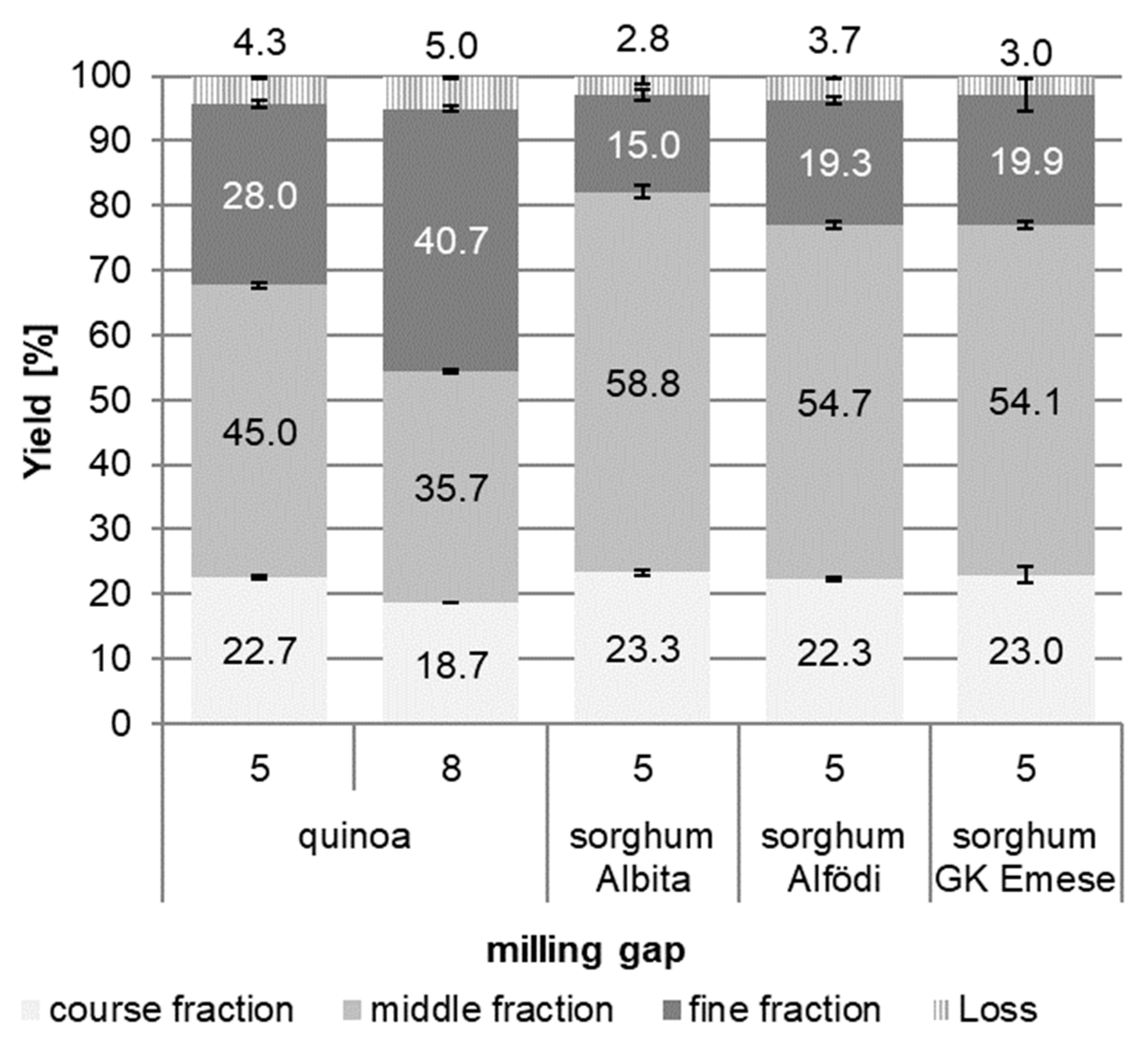

The fraction yields of the main trials can be derived from

Figure 2. Scanning electron microscopy (SEM) pictures of these fractions are shown in

Figure 3. Results demonstrate that all milling trials were very reproducible, standard deviation for all samples were rather low, also results between the two set of trials (pre- and main trials) were comparable.

For quinoa, the separation into distinct milling fractions was not as differentiated as is usually achieved for cereals like wheat. The fine fraction reached only values of up to about 41% (gap 8), and at both gaps, high amounts of course (bran) fraction were gained (up to almost 23% with gap 5). The middle fraction was obtained in similar amounts to the fine fraction (gap 8), with gap 5 yielding an even higher amount than for the fine fraction. This different fraction performance of quinoa compared to cereals (wheat) is most likely a result of the different botanical morphology of the seed. In quinoa, a relatively large embryo surrounds the kernel in the form of a ring and makes up about 25% of the seed weight [

13]. Most of this embryo was found in the bran fraction (as desired), but some broken fragments of it passed through the first sieve to the middle fraction as was visible in the SEM photos (

Figure 3). The low amount of the fine fraction arises from the fact that the seed’s proportion of the starchy perisperm is smaller compared to the proportion of the endosperm in cereals.

In the sorghum roller milling trials, high amounts of course fractions were found as well (around 23% for all varieties), but in contrast to quinoa even lower amounts of the fine fractions were obtained, as the middle fractions comprised the highest amounts (54-59%). Although sorghum is botanically a true cereal, the small kernel size, and the rather large embryo (though within the kernel in contrast to quinoa), it seems rather challenging to separate the milling fractions and to obtain sufficient amounts of fine fractions. For industrial milling, additional milling passages of the middle fraction would be necessary to increase the amount of fine endosperm flour.

3.2. Chemical composition of the milling fractions

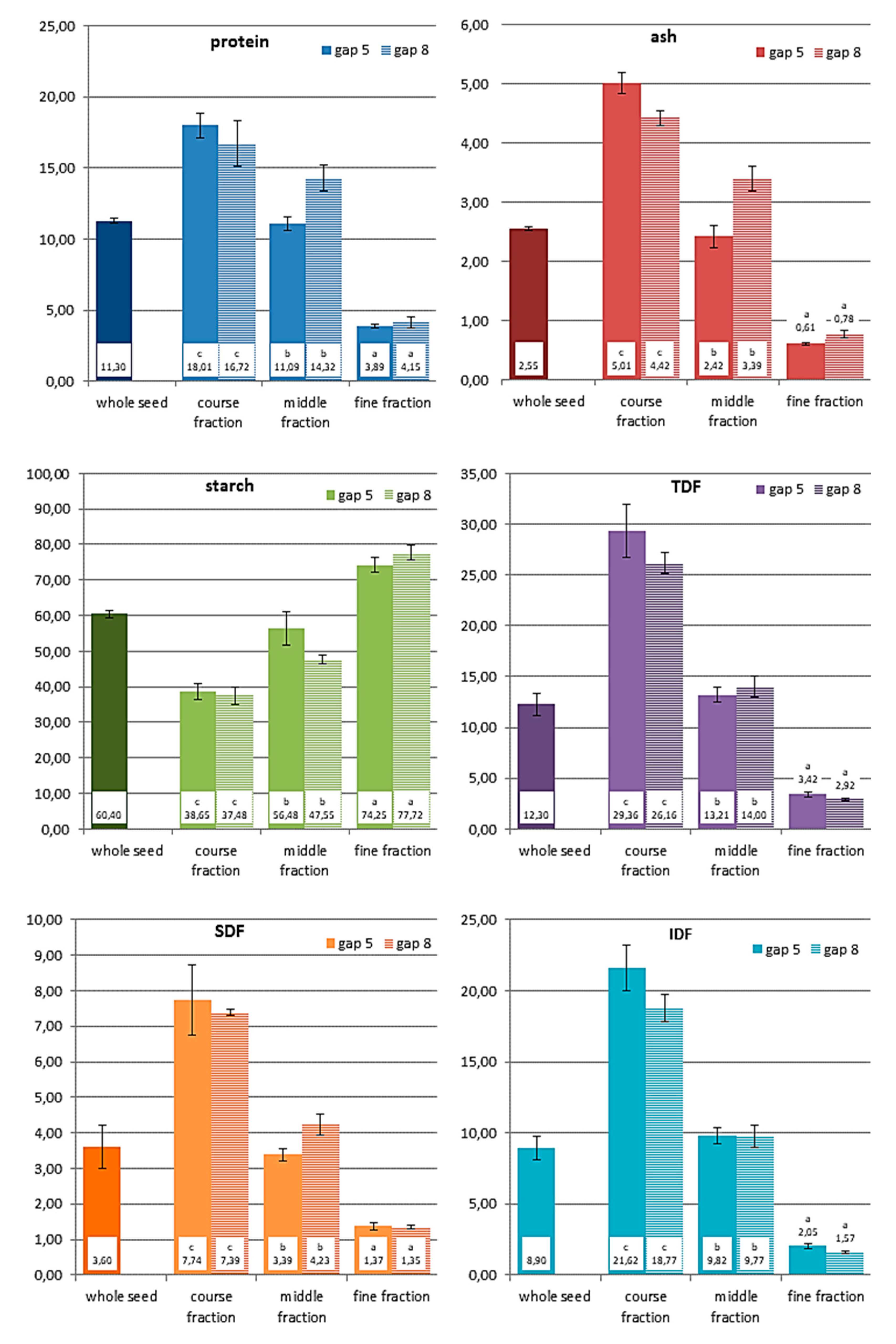

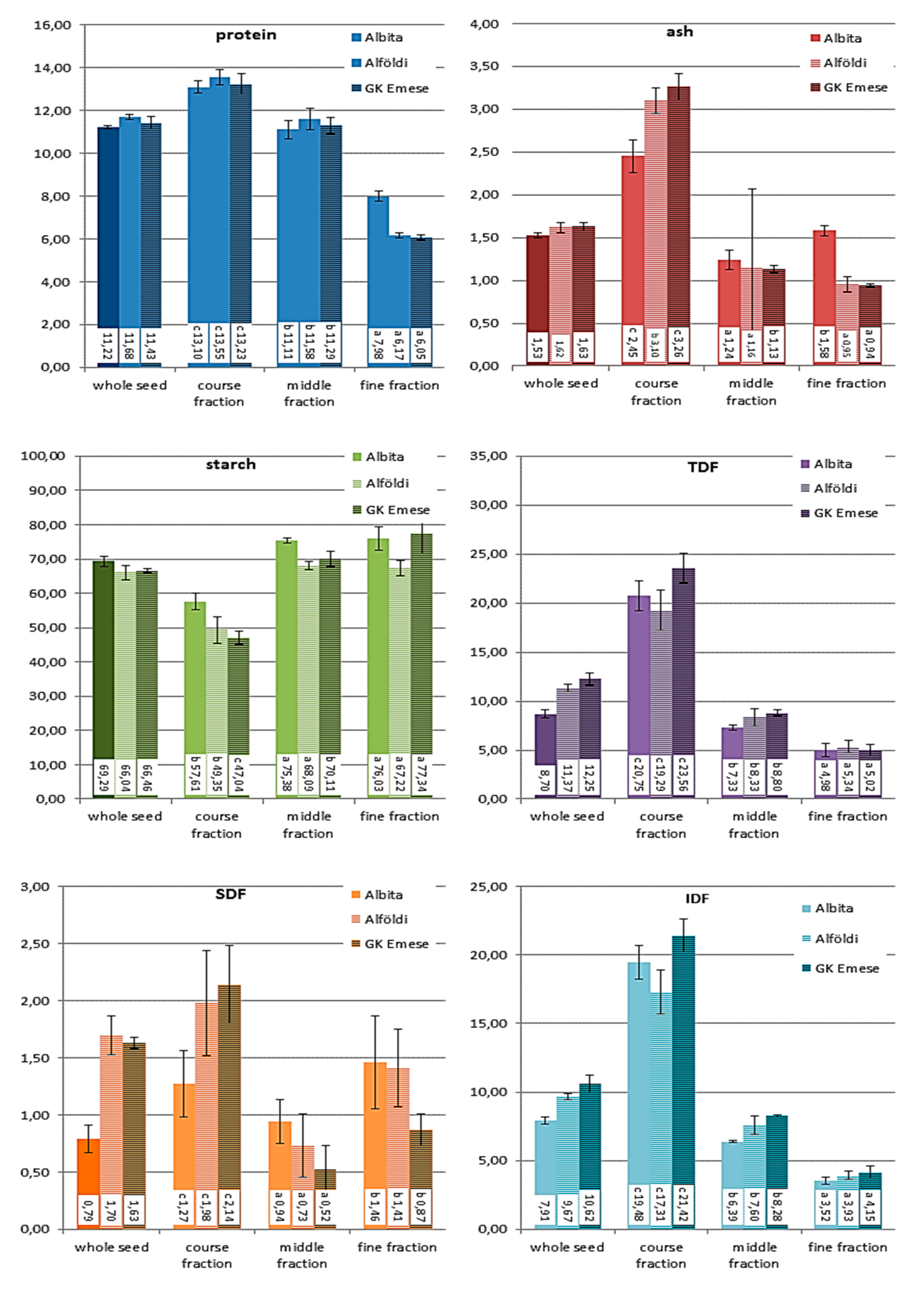

All obtained roller milling fractions were analysed for their content of protein, starch, ash and dietary fibre (total, insoluble and soluble fibre) in order to evaluate, if the milling fractions can be classified into chemical distinct flours. The results are presented in

Figure 4 and

Figure 5.

As already described above and also by other researchers [

4], quinoa fractionation is challenging. Still, the analytical results for the milling fractions obtained with the two different milling gaps demonstrated that they were chemically differing from each other. The course fraction contained the highest amounts of protein, ash and dietary fibre, while starch was abundant in the fine fraction. The middle fraction showed more or less values in-between these two fractions, which was more obvious for fractions milled at gap 5 than at gap 8. All chemical components, starch, protein, dietary fibre and ash, were found in similar amounts in the middle fraction as in the whole seed. The fine fraction had the lowest amounts of ash and dietary fibre.

Compared to wheat milling, the quinoa fractions were still not clearly separated, but they can still be considered to be distinct fractions. When comparing the coarse and the fine fraction, the course fraction in quinoa contained 4-4.6 times more protein, 5.7-8 times more ash, 8.6-9 times more TDF and only half the amount of starch. The middle fraction, which was chemically not really different from wholemeal flour still contains too much outer layers and embryo particles. Additional milling and sieving/sifting passages would allow a further extraction of the starch endosperm from the kernel.

Looking at the results of the sorghum fractions, it has to be stated, that the application of this roller milling system was even more challenging to produce distinct milling fractions than it was for quinoa, but still some interesting outcomes were achieved. As data for yield have shown, only small amounts of fine fractions were obtained, which were hardly differing from the middle fraction or wholemeal flour in terms of ash content, although ash was accumulated to some extent in the course fraction, where the amount was about twice as much compared to the other flour fractions. Starch was the chemical component, which was least separated into the collected sorghum milling fractions. Obviously too much of the inner (endosperm) part of the kernel remained in the course fraction (starch still made around 50g/100 g dm), which is also reflected by the high yield of this fraction. The amount of protein was descending from the coarse fraction to the fine fraction. Interesting results were found for dietary fibre, the majority of the TDF was found in the course fraction, both, the middle and fine fractions contained rather low amounts. But in contrast to quinoa, it was mainly the insoluble dietary fibre fraction (IDF) that was concentrated in the coarse fraction, a large proportion of the soluble dietary fibre (SDF) was enriched in the fine fraction, significantly higher than in the middle fraction. As soluble fibres are known to have beneficial health effects, sorghum endosperm flour with such high SDF amounts might have future potential for food applications. Yet, in order to improve the yield of the fine fraction and improve the separation of starch (endosperm parts) from the course fractions, sorghum milling requires further milling and sieving/sifting passages. Kebakile et al. (2007) assessed different sorghum milling technologies for product development [

14]. Also, Mezgebe et al., (2020), coupled roller milling with hammer milling for making fermented flat bread of sorghum genotypes [

15]. Furthermore, such roller milling trials with several passages have been performed by Rumler et al. (2021) with sorghum on pilot scale [

11]. Similarly, they obtained fractions with increased bran material that contained higher amounts of ash, protein, fat, total dietary fiber, and total phenolic content but less starch. The additional determined physical quality parameters revealed, that these fractions with higher amounts of brans showed enhanced water absorption and water solubility indices. But also, in their study, the fine and middle fractions were not always chemically distinct. For further industrial milling, conditioning of the kernels (i.e. moistening of the kernels overnight), prior to milling might improve the separation process of the bran from the kernel.

3.3. Pasting properties of the milling fractions (RVA)

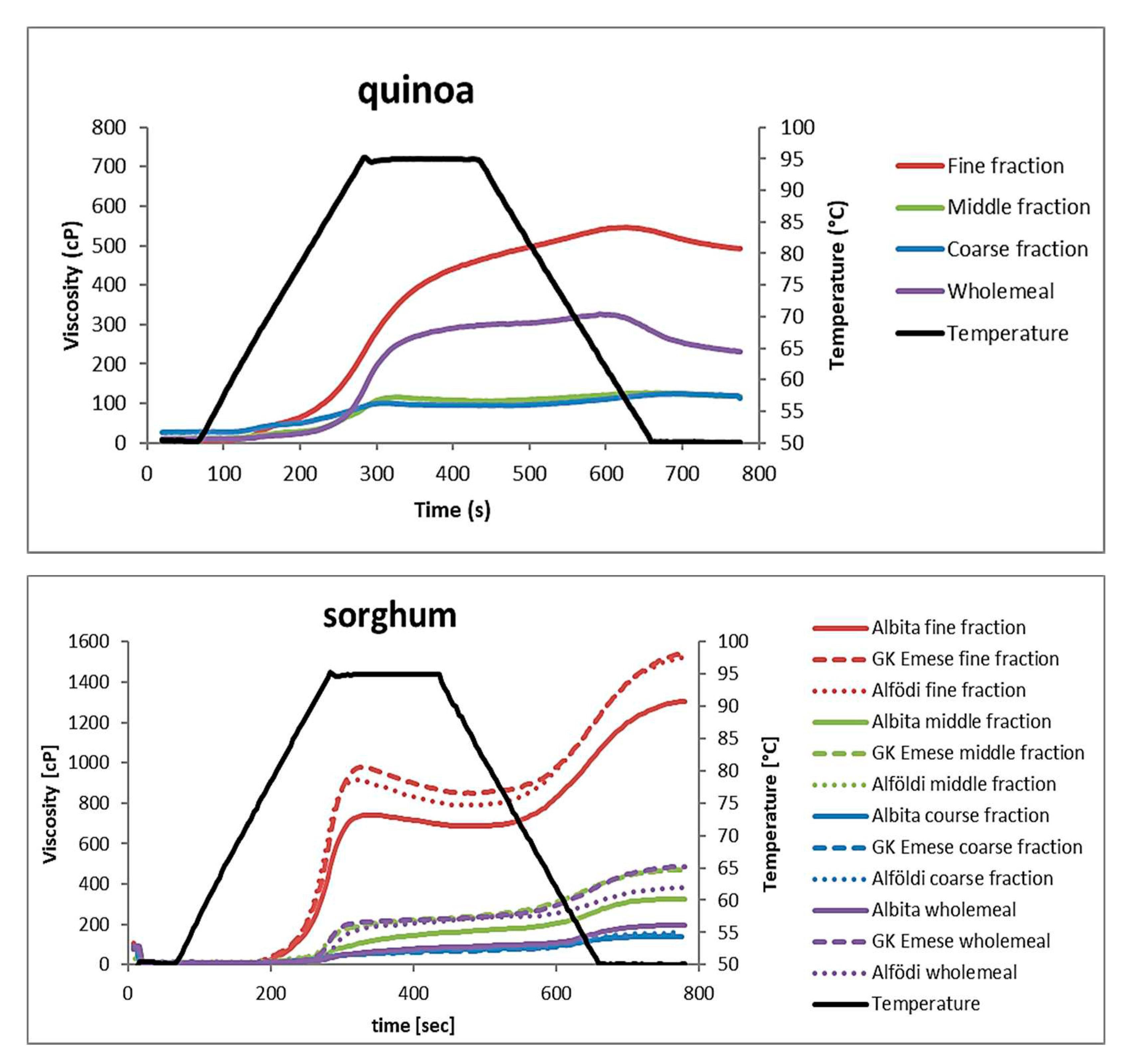

Figure 6 shows the viscosity measurements of all fractions compared to wholemeal flour. All curves are average values of triplicate determinations.

In general, all quinoa fractions showed lower viscosity values than the sorghum fractions. Within the quinoa fractions, the finest fraction showed the highest viscosity values, while the curves for the middle and coarse fraction were almost identical and lower than the wholemeal flour. In quinoa, no breakdown in viscosity (decrease during the holding period) was observed, which indicates their high hot paste stability. Final viscosity (viscosity at the end of the cooling period) decreased for all fractions; they were all showing low setback.

Pasting properties help to indicate baking quality, since there is a tight relationship between rheological and mixing properties of flour/water mixtures, e.g., dough strength/torque, water absorption, shear and temperature stability, crumb firming and storage behaviour [

16,

17]. Peak viscosity is associated with final product quality; high peak viscosity during pasting and low viscosities after the holding period at 95°C are considered predictors of bread firming behaviour during storage, and low setback viscosities indicate low rates of starch retrogradation in bread baking [

17]. Looking at the pasting properties of quinoa, they offer a good potential for improving shelf-life of baked products.

Within the sorghum fractions, only the fine fractions were distinct from the other fractions (higher). Wholemeal flour and middle fraction were more or less very similar and not clearly different from each other, coarse flour fractions showed the lowest viscosities, except for Albita, here wholegrain and coarse flour fraction were alike. Between the three species no relevant differences were observed, viscosity of the Albita fractions was always slightly lower than of the two other species. In contrast to quinoa, all sorghum species showed a small breakdown of the hot paste viscosity, especially the fine fractions, and all flours developed an increase in final viscosity.

Considering the chemical composition of the flour fractions, the starch content alone was not really determinant for RVA viscosity in quinoa. From this point of view, one would expect rather similar curves for wholemeal flour and the middle fraction, which often showed similar composition. In quinoa, the fine fraction contained the highest amount of starch, least protein, TDF, SDF and IDF, thus its higher viscosity is expected. But looking at the middle and coarse fraction, which showed similar RVA curves, the chemical composition gives no clear explanation as these two fractions were not chemically similar. A suggestion could be that although the starch content in the course fraction is lower compared to the middle fraction, the course fraction contains a much higher amount of TDF, which obviously contributes to its viscosity development, in particular SDF. In sorghum fractions, the starch content in the fine fraction was rather similar to wholemeal flour or to the middle fraction (only higher compared to the course fraction), but they showed significantly higher viscosity. The fine fraction contained less protein, less TDF, less IDF, but more SDF than the middle fraction or wholemeal flour, so it is the sum of all these differences which determined the RVA pasting viscosity and thus its food uses.

3.4. Bread baking quality

Gluten-free baking trials were performed from either 100% quinoa or 100% sorghum, both of them by sourdough fermentation. Sorghum food use is improved by microbial fermentation, and previous research suggests that this technology has advantages for gluten-free bread baking in general [

18]. The results of the physical bread quality obtained from these baking trials are summarized in

Table 2, results for shelf-life in

Table 3 and

Figure 7, and bread slices are visualized in

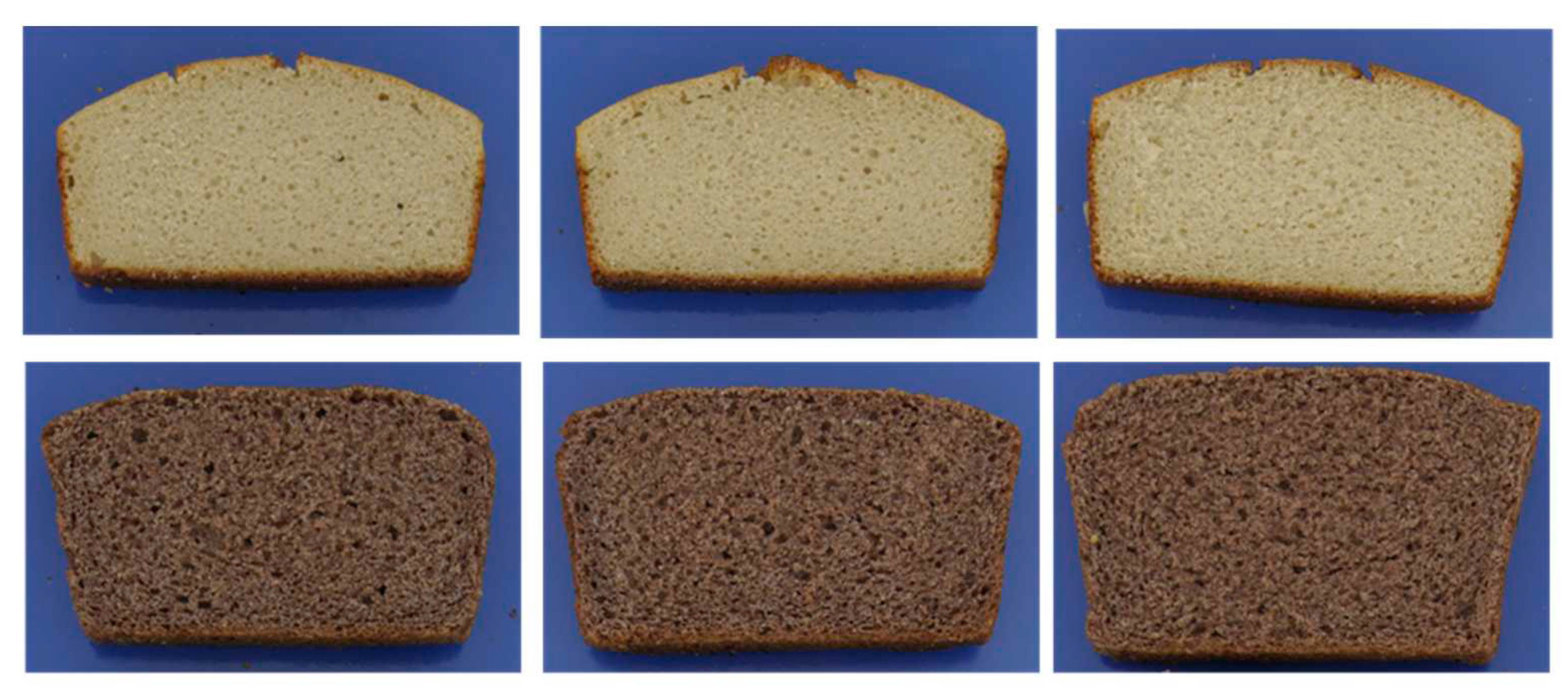

Figure 8.

As could be observed in this study, increasing dough moisture from 70 to 90% resulted in gluten-free breads with improved bread quality parameters, which was even more pronounced for sorghum breads than the quinoa breads. Baking loss showed significant differences between the different levels of water addition. In both breads, from quinoa and sorghum, higher water addition resulted in higher baking losses. Thus, after baking all breads contain about similar dough moisture (data not shown), as higher water addition to the dough was balanced out by higher baking losses. Specific volume was higher in the sorghum breads than the quinoa breads and increased with higher water addition in both of them. Despite the difference in specific volume, crumb firmness was similar between the quinoa and sorghum breads. Higher water addition decreased firmness, which in the quinoa breads also increased relative elasticity. Similar results were found by Hera et al. (2014) [

19] for gluten-free rice breads, also in their study, baking loss and specific volume increased and crumb firmness decreased when dough moisture was increased from 70% to even 110%. The determined pore properties reflect the difference between the quinoa and sorghum breads. Total pore area was higher in sorghum than in quinoa bread (see

Table 2). Quinoa breads showed a rather dense crumb structure, and were characterized by a high number of uniform pores of smaller average size, while sorghum breads had a much lower number of large average sized pores, but pore size was very irregular. Dough moisture hardly influenced the pore average size and the number of pores, but pore uniformity was more irregular at higher moisture, which was also seen in gluten-free breads from amaranth [

20].

Bread crumb colour is mainly influenced by the intrinsic colour of the ingredients, while the crust is caused by the extent of Maillard reaction during baking. Higher baking temperatures and longer baking times accelerate this reaction, while higher dough moisture reduces this browning reaction. This was also observed in this study, higher moisture produced a slightly paler crust. Quinoa breads were generally much lighter, but had higher yellow colour values in crust and crumb, and higher red values in the crust but lower in the crumb than the sorghum breads. Fig. 8 illustrates that sorghum breads were much darker than the quinoa breads. This might influence consumer acceptance, but in countries where higher rye bread consumption is more common this darker colour could as well be an advantage.

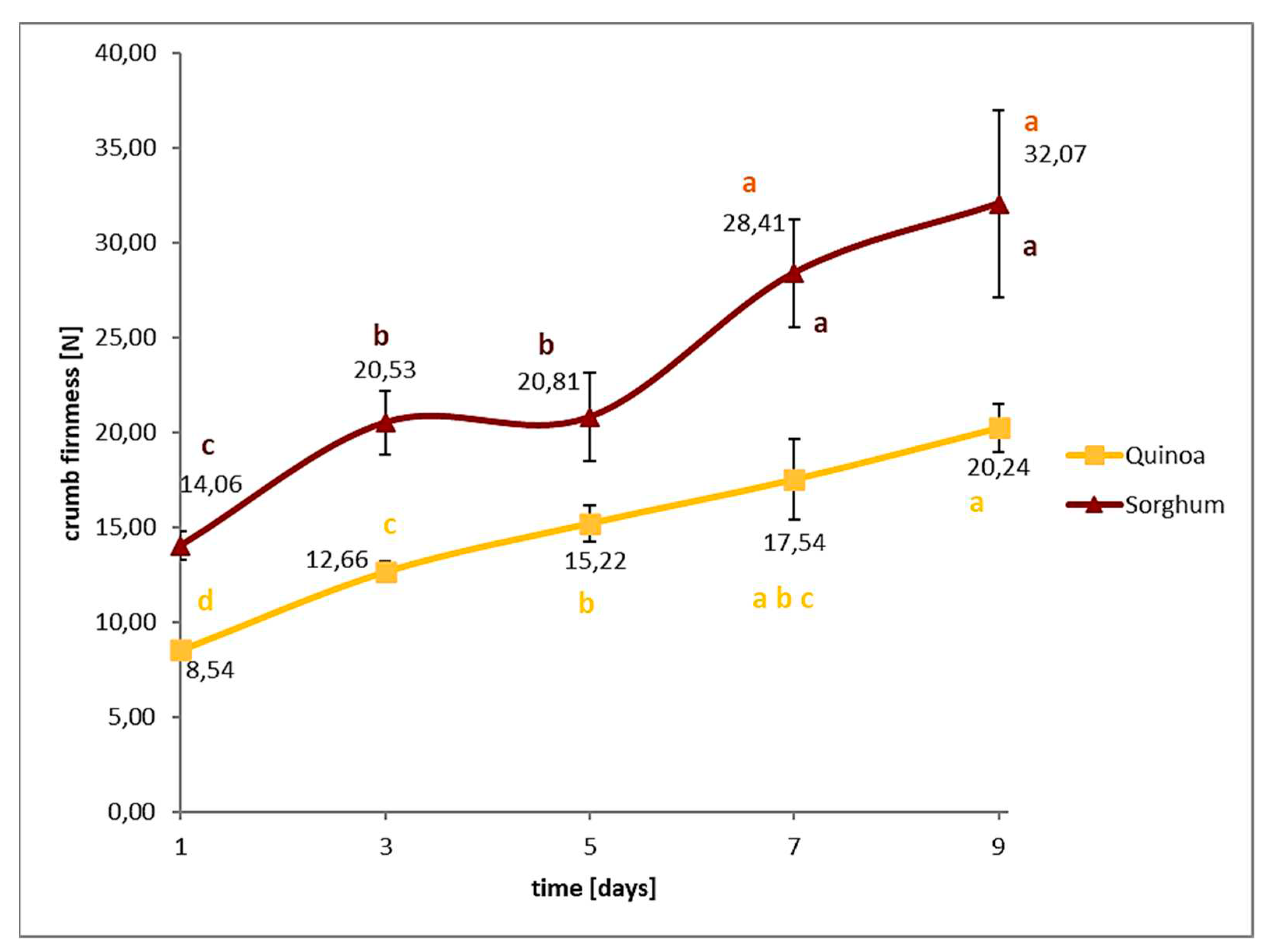

One parameter that often diminishes the quality of (commercially available) gluten-free bread compared to gluten containing ones is, that they tend to stale much faster, thus have a reduced shelf -life. Among others, this is a result of the higher starch and lower protein and dietary fibre content in gluten-free breads, which are often baked from pure starches or polished rice flour. Quinoa and sorghum were used as wholegrain flours in this study, additionally sourdough fermentation was applied, which is known to prolong crumb softness in rye or wheat breads. In order to determine their shelf-life, storage tests of quinoa and sorghum breads produced with 90% dough moisture were undertaken. The obtained crumb firmness values are presented in

Figure 7, the results of the Avrami parameters are summarized in

Table 3. From the results, it can be seen clearly that the staling rate of both breads was slow, also demonstrated by their low Avrami-exponent (n) or rate constant (k) value. High values of n or k indicate a faster staling rate, although high n and k values do usually not occur combined [

21]. Sorghum breads showed higher initial crumb firmness than the quinoa breads, but both breads doubled this value only after 7 days. The previous described pasting properties (low setback and peak viscosity) already suggested, that both grains, in particular quinoa, possess slow starch retrogradation rates, thus can retard bread firming during storage.

5. Conclusions

The study showed that sorghum and quinoa flour and milling fractions have interesting properties for food application. The trials performed on lab-scale provided some preliminary insights into the production of flours with targeted properties, e.g. enrichment of certain nutrients, or adaptation of physical properties; for future upscaling further research is needed. Determination of pasting properties revealed that both grains, quinoa more than sorghum, possess slow starch retrogradation tendencies, which is an advantageous feature for bakery products.

With respect to baking standards, sorghum breads with acceptable volume and crumb structure were obtained. In quinoa bread, the crumb was slightly denser, addition of higher amounts of protein or emulsifiers might enhance quinoa bread texture. Both grains, and probably also the application of sourdough fermentation, produced breads with a prolonged shelf-life of up to one week, which is a clear benefit for consumers.

Author Contributions

Conceptualization, R.S., D.B., S.D., and R.Y.; methodology, R.S., S.D., M.K. and R.S.; software, R.S. and S.D.; validation, R.S., D.B., S.D., K.M., S.T. and R.Y.; formal analysis, R.S., D.B., D.S, K.M., S.T. and R.Y.; investigation, R.S., D.B., S.D. K.M., and S.T; resources, R.S. and R.Y.; data curation, R.S., D.B., S.D. K.M., and S.T; writing—original draft preparation, R.S., D.B. and R.Y. writing—review and editing, R.S., D.B. and R.Y.; visualization, R.S., D.B. and R.Y.; supervision, R.S., K.M., S.T.; project administration, R.S., K.M., S.T.; funding acquisition, R.S., K.M. and R.Y. All authors have read and agreed to the published version of the manuscript.”.

Funding

This research was financially supported by Prince of Songkla University and Ministry of Higher Education, Science, Research and Innovation under the Reinventing University Project (Grant Number REV65014) and by the Ernst Mach Grant from the OeAD – Austria´s Agency for Education and Internationalization (Reference number MPC-2022-03967).

Data Availability Statement

All obtained data is included within this paper.

Acknowledgments

Alexandra Zimmermann, Claudia Lechner and Eva-Maria Grünling are acknowledged for their great support in the practical performance of these research trials.

Conflicts of Interests

The authors declare no conflict of interest.

Ethics declarations

Not applicable.

References

- Taylor, J.; Duodu, K. Sorghum and Millets Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Woodhead Publishing: Duxford, UK, 2018; pp. 10–52. ISBN 9780128115275. [Google Scholar]

- FAO. Available online: https://www.fao.org/quinoa (accessed on 5 February 2023).

- Akin, P.A.; Demirkesen, I.; Bean, S.R.; Aramouni, F.; Boyaci, I.H. Sorghum Flour Application in Bread: Technological Challenges and Opportunities. Foods 2022, 11, 2466. [Google Scholar] [CrossRef] [PubMed]

- Coţovanu, I.; Ungureanu-Iuga, M.; Mironeasa, S. Investigation of quinoa seeds fractions and their application in wheat bread production. Plants 2021, 10, 2150. [Google Scholar] [CrossRef] [PubMed]

- Kurek, M.A.; Sokolova, N. Optimization of bread quality with quinoa flour of different particle size and degree of wheat flour replacement. Food Sci. Technol. 2020, 40, 307–314. [Google Scholar] [CrossRef]

- Serna-Saldivar, S.O.; Espinosa-Ramírez, J. Grain Structure and Grain Chemical Composition. In Sorghum and Millets: Chemistry, Technology, and Nutritional Attributes, 2nd ed.; Taylor, J.R.N., Duodu, K.G., Eds.; Woodhead Publishing: Duxford, UK, 2019; pp. 85–129. [Google Scholar]

- Pereira, E.; Encina-Zelada, C.; Barros, L.; Gonzales-Barron, U.; Cadavez, V.; Isabel, C.F.R.; Ferreira, I. Chemical and nutritional characterization of Chenopodium quinoa Willd (quinoa) grains: A good alternative to nutritious food. Food Chem. 2019, 280, 110–114. [Google Scholar] [CrossRef] [PubMed]

- Bender, D.; Schoenlechner, R. Recent developments and knowledge in pseudocereals including technological aspects. Acta Aliment. 2021, 50, 583–609. [Google Scholar] [CrossRef]

- Bender, D.; Schoenlechner, R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Rumler, R.; Bender, D.; Schoenlechner, R. Sorghum and its potential for the Western diet. J. Cereal Sci. 2022, 1014, 103425. [Google Scholar] [CrossRef]

- Rumler, R.; Bender, D.; Speranza, S.; Frauenlob, J.; Gamper, L.; Hoek, J.; Jager, H.; Schoenlechner, R. Chemical and physical characterization of sorghum milling fractions and sorghum whole meal flours obtained via stone or roller milling. Foods 2021, 10, 870. [Google Scholar] [CrossRef] [PubMed]

- Kulp, K.; Ponte, J.G. Handbook of Cereal Science and Technology, 2nd ed.; CRC Press: New York, USA, 2000; pp. 5–29. ISBN 0-8247-8294-1. [Google Scholar]

- Prego, I.; Maldonado, S.; Otegui, M. Seed structure and localization of reserves in Chenopodium quinoa. Ann. Bot. 1998, 82, 481–488. [Google Scholar] [CrossRef]

- Kebakile, M.M.; Rooney, L.W.; Taylor, J.R.N. Effects of hand pounding, abrasive decortication, roller milling and sorghum type on sorghum meal extraction and quality. Cereal Foods World 2007, 52, 129–137. [Google Scholar] [CrossRef]

- Mezgebe, A. G.; Taylor, J. R. N.; de Kock, H. L. Influence of waxy (high amylopectin) and high protein digestibility traits in sorghum on injera sourdough-type flatbread sensory characteristics. Foods 2020, 9, 1749. [Google Scholar] [CrossRef] [PubMed]

- Bourne, M.C. Viscosity Measurement. In Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Bourne, M.C., Ed.; Academic Press: New York, USA, 2002; pp. 249–250. [Google Scholar]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a tool for measuring starch-related physiochemical properties in cereals: a review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

- Ramos, L.; Alonso-Hernando, A.; Martínez-Castro, M.; Morán-Pérez, J.A.; Cabrero-Lobato, P.; Pascual-Maté, A.; Téllez-Jiménez, E.; Mujico, J.R. Sourdough biotechnology applied to gluten-free baked goods: rescuing the tradition. Foods 2021, 10, 1498. [Google Scholar] [CrossRef] [PubMed]

- De La Hera, E.; Rosell, C.M.; Gomez, M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014, 151, 526–531. [Google Scholar] [CrossRef] [PubMed]

- Schoenlechner, R.; Mandala, I.; Kiskini, A.; Kostaropoulos, A.; Berghofer, E. Effect of water, albumen and fat on the quality of gluten-free bread containing amaranth. Int. J. Food Sci. Technol. 2010, 45, 661–669. [Google Scholar] [CrossRef]

- Armero, E.; Collar, C. Crumb firming kinetics of wheat breads with anti-staling additives. J. Cereal Sci. 1998, 28, 165–174. [Google Scholar] [CrossRef]

Figure 1.

Milling pre trials for quinoa and sorghum at different milling gaps (= distance of rollers): yields (%) obtained for fine (<212 µm), middle (212-475 µm) and course (>475 µm) fractions.

Figure 1.

Milling pre trials for quinoa and sorghum at different milling gaps (= distance of rollers): yields (%) obtained for fine (<212 µm), middle (212-475 µm) and course (>475 µm) fractions.

Figure 2.

Milling main trials for quinoa and sorghum: yields (%) obtained for fine (<212 µm), middle (212-475 µm) and course (>475 µm) fractions. Quinoa was milled at two different milling gaps (5 and 8), sorghum at gap 5.

Figure 2.

Milling main trials for quinoa and sorghum: yields (%) obtained for fine (<212 µm), middle (212-475 µm) and course (>475 µm) fractions. Quinoa was milled at two different milling gaps (5 and 8), sorghum at gap 5.

Figure 3.

Scanning electron microscopy pictures of the obtained milling fractions, gap 5 (sorghum top, quinoa bottom).

Figure 3.

Scanning electron microscopy pictures of the obtained milling fractions, gap 5 (sorghum top, quinoa bottom).

Figure 4.

Chemical composition of quinoa fractions milled at two different gap settings (gap 5 – wider gap, gap 8 – closer gap); results are presented as average values and standard deviation of triplicate measurements (% dm). Different lowercase letters before the values indicate significant differences between the milling fractions (within same gap setting).

Figure 4.

Chemical composition of quinoa fractions milled at two different gap settings (gap 5 – wider gap, gap 8 – closer gap); results are presented as average values and standard deviation of triplicate measurements (% dm). Different lowercase letters before the values indicate significant differences between the milling fractions (within same gap setting).

Figure 5.

Chemical composition of sorghum fractions milled at gap 5; results are presented as average values and standard deviation of triplicate measurements (% dm). Different lowercase letters before the values indicate significant differences between the milling fractions (within same sorghum species).

Figure 5.

Chemical composition of sorghum fractions milled at gap 5; results are presented as average values and standard deviation of triplicate measurements (% dm). Different lowercase letters before the values indicate significant differences between the milling fractions (within same sorghum species).

Figure 6.

Pasting properties (determined by RVA) of the quinoa and sorghum milling fractions.

Figure 6.

Pasting properties (determined by RVA) of the quinoa and sorghum milling fractions.

Figure 7.

Storage tests for quinoa and sorghum sourdough breads.

Figure 7.

Storage tests for quinoa and sorghum sourdough breads.

Figure 8.

Gluten-free breads from quinoa (top) and sorghum (bottom), with 70-80-90 % dough moisture from left to right.

Figure 8.

Gluten-free breads from quinoa (top) and sorghum (bottom), with 70-80-90 % dough moisture from left to right.

Table 1.

Ash content of the quinoa and sorghum fractions obtained in the pre-trials (mg/100g dm, n=3), different superscript letters indicate significant differences between the milling fractions (within same gap setting).

Table 1.

Ash content of the quinoa and sorghum fractions obtained in the pre-trials (mg/100g dm, n=3), different superscript letters indicate significant differences between the milling fractions (within same gap setting).

| Gap |

Course Fraction

(>475 µm) |

Middle Fraction

(212-475 µm) |

Fine Fraction

(<212 µm) |

| Quinoa |

| 0 |

3.1±0.07c

|

1.6±0.01b

|

0.8±0.04a

|

| 5 |

4.6±0.55c

|

2.2±0.15b

|

0.8±0.04a

|

| 8 |

4.5±0.27c

|

2.9±0.00b

|

0.9±0.06a

|

| 10 |

3.6±0.26c

|

3.1±0.03bc

|

1.4±0.0a

|

| Sorghum (Albita) |

| 3 |

2.46±0.206b

|

1.07±0.085a

|

1.38±0.048a

|

| 5 |

2.45±0.189c

|

1.23±0.107a

|

1.58±0.065b

|

| 7 |

1.99±0.038a

|

1.27±0.014b

|

1.89±0.12a

|

Table 2.

Physical properties of quinoa and sorghum breads. Results are average values of at least triplicate values ± standard deviation, superscript lowercase letters indicate significant differences between the different dough moistures.

Table 2.

Physical properties of quinoa and sorghum breads. Results are average values of at least triplicate values ± standard deviation, superscript lowercase letters indicate significant differences between the different dough moistures.

| |

|

Water addition |

Quinoa |

Sorghum |

| Baking loss [%, n=4] |

70

80

90 |

12.57± 0.81a

13.19 ± 0.37ab

14.20 ± 0.39b

|

13.76 ± 0.97a

14.86 ±0.29ab

15.40 ± 0.29b

|

| Specific Volume [cm³/g, n=4] |

70

80

90 |

1.78 ± 0.03a

1.78 ± 0.06a

1.86 ± 0.03b

|

2.20 ± 0.05a

2.23 ± 0.02a

2.46 ± 0.02b

|

| Texture |

Crumb firmness Fmax [N, n=6] |

70

80

90 |

17.16 ± 0.77c

13.08 ± 0.22b

10.20 ± 0.03a

|

17.04 ± 1.32b

15.39 ± 1.07b

10.23 ± 0.02a

|

| Relative Elasticity [%, n=6] |

70

80

90 |

59.88 ± 0.54a

62.29 ± 0.38b

64.99 ± 0.48c

|

51.27 ± 1.53a

47.58 ± 2.00a

53.99 ± 0.22b

|

| Colour crust |

L* [n=4] |

70

80

90 |

47.82 ± 1.52a

42.84 ± 3.81ab

39.28 ± 1.61b

|

37.59 ± 1.10a

35.85 ± 0.96a

39.47 ± 1.44b

|

| a* [n=4] |

70

80

90 |

18.39 ± 0.49a

19.44 ± 0.59a

19.38 ± 0.77a

|

13.53 ± 3.41ab

13.11 ± 0.16ab

14.11 ± 1.70b

|

| b* [n=4] |

70

80

90 |

35.98 ± 0.32b

31.39 ± 2.50ab

27.64 ± 1.02a

|

16.12 ± 0.85a

15.89 ± 0.15a

18.04 ± 1.96b

|

| Pore properties |

Average pore size [mm², n=8] |

70

80

90 |

3.48 ± 0.03a

2.76 ± 0.06a

3.37 ± 0.39a

|

11.55 ± 0.63a

9.81 ± 1.06a

10.94 ± 1.17a

|

| Pore area [%, n=8] |

70

80

90 |

38.92 ± 2.67a

37.50 ± 2.63a

37.57 ± 1.61a

|

48.05 ± 0.78b

48.18 ± 0.94b

46.41 ± 1.15a

|

| Number of pores [n=4] |

70

80

90 |

45.17 ± 5.72a

51.13 ± 7.68b

47.88 ± 3.97ab

|

15.5 ± 1.32a

18.38 ± 1.89a

17.38 ± 1.65a

|

| Pore uniformity [n=4] |

70

80

90 |

3.02 ± 0.58ab

2.32 ± 0.22a

3.37 ± 0.18b

|

42.31 ± 3.87ab

18.74 ± 3.52a

27.33 ± 2.34b

|

| Colour crumb |

L* [n=4] |

70

80

90 |

62.14 ± 1.07a

64.35 ± 0.68b

64.25 ± 1.62b

|

35.96 ± 0.62b

34.47 ± 1.28a

37.57 ± 0.76c

|

| a* [n=4] |

70

80

90 |

6.76 ± 0.14a

6.78 ± 0.21a

6.71 ± 0.03a

|

11.06 ± 0.33b

10.17 ± 0.30a

11.99 ± 0.14c

|

| b* [n=4] |

70

80

90 |

24.86 ± 0.48a

25.23 ± 0.44a

25.18 ± 0.57b

|

12.29 ± 0.17a

12.20 ± 0.12a

13.05 ± 0.21b

|

Table 3.

Avrami parameters for storage tests of quinoa and sorghum breads. (Ɵ = starch ratio, which has not re-crystallised, T0 = initial Fmax at day 0, Tinf = final Fmax at day 9, Tt = Fmax at time “t”, k = rate constant, n = Avrami-exponent).

Table 3.

Avrami parameters for storage tests of quinoa and sorghum breads. (Ɵ = starch ratio, which has not re-crystallised, T0 = initial Fmax at day 0, Tinf = final Fmax at day 9, Tt = Fmax at time “t”, k = rate constant, n = Avrami-exponent).

| Paramter |

Quinoa |

Sorghum |

| k |

0.049 |

0.026 |

| n |

1.822 |

2.086 |

| Tinf (N) |

20.24 |

32.07 |

| T0 |

8.54 |

14.06 |

| R² |

0.979 |

0.924 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).