2. LITERATURE REVIEW

2.1. Occupational safety and health practices (OSHP)

Occupational Safety and Health Practices (OSHP) are the strategies, policies, actions, and procedures that an organization might use to ensure the safety of its workers. Many safety related components are included in OSHP. They are: management commitment, safety training, workers' involvement, safety rules and procedures, and safety promotion policies. [11] Also said that occupational safety and health practices include elements such as safety culture, employee attitude, employer involvement, leadership style, and safety and health training. Nowadays, safety and health practices become more important to all industry especially in manufacturing industry [11]. Study show that Director of Reflection India stated that the application of OSHP in the factory can help to improve the morale of the staff and reduce the absenteeism. Indirectly it maximizes performance and productivity of the company because the rate of accidents also reduces when safety program and practices are applied. In addition, when the rates of accidents reduce the cost of running a business such as health care and insurance cost also decrease, the company does not need to spend huge sum of money on compensations for workers. It increases the performance of the organization.

2.2. Types of Hazard in the Manufacturing Industry

The nature of worker exposure to workplace dangers is determined by the type of employment The increased number of physical, chemical, biological, and psychological stressors linked with working activities in Ghana can be blamed for the high rate of injury [12]. Says that various occupational health and safety hazards which give rise to occupational injuries, diseases, disabilities or death through work. This occupational health and safety hazards are classified in to six:

Physical hazards, which can adversely affect health, include noise, vibration, ionizing and non-ionizing radiation, heat and other unhealthy microclimatic conditions. Between 10 and 30% of the workforce in industrialized countries and up to 80% in developing and newly industrialized countries are exposed to a variety of these potential hazards.

- (2)

Mechanical Hazards

Mechanical factors include unshielded machinery, unsafe structures at the workplace and dangerous unprotected tools are among the most prevalent hazards in both industrialized and developing countries. They affect the health of a high proportion of the workforce.

- (3)

Chemical Hazards

These arises from excessive air borne concentrations of Chemical dust, Mists, Fumes, Liquids, Vapors ,Gases , dust

- (4)

Biological Hazards

Many biological agents such as viruses, bacteria, parasites, fungi, mold and organic dusts have been found to occur in occupational exposures. In the industrialized countries around 15 % of workers may be at risk of viral or bacterial infection, allergies and respiratory diseases. In many developing countries the number one exposure is biological agents.

- (5)

Ergonomic Hazards

Examples include excessively poorly designed tools, work environments, or work routines. Accidents or illnesses in the workplace can be caused by improper lifting or reaching, poor vision, or repeated motions in an awkward position. Heavy physical workloads or un ergonomic working situations, such as lifting and moving heavy things or repetitive manual tasks, may be experienced by 10% to 30% of the workforce in developed countries and 50% to 70% of the workforce in underdeveloped countries. In general, ergonomics concerns the interaction of humans with extra environmental factors such as heat, light, sound, airborne pollutants, and all work-related instruments and equipment.

- (6)

Psychosocial hazards

Up to 50% of all workers in industrial countries judge their work to be “mentally heavy”. Psychological stress caused by time pressure, hectic work, and risk of unemployment has become more prevalent during the past decade. Other factors that may have adverse psychological effects include jobs with heavy responsibility for human or economic concerns, monotonous work or work that requires constant concentration.

2.3. Relationship between OSH and employee productivity

According to [14], the health and safety of all employees is intimately linked to the company's productivity in all workplaces. Reduced absenteeism is the key productivity benefit of occupational health and safety. Employee performance is influenced by job happiness. Employees' mental and physical health can be maintained through occupational health with a good psychosocial state. Productivity improvement is a major concern in today's businesses. In the literature of organizational behavior and human resource development, productivity via work performance is a well-explored [15]. The employees' perspective is crucial when it comes to safety issues. They added that due to disruptions in production processes, damage to manufacturing equipment, and a bad influence on the company's reputation, industrial accidents not only harm human capital but also cause financial losses. If a safety performance measurement system is developed to comprehend the cost of illness and injury, organizations can employ a cost-benefit ratio as a fundamental tool of economic assessment. Businesses must also analyze non-economic factors like cultural traits and any current management structures when considering workplace safety [16].

2.4. Factors that affect Occupational Safety and Health Practices

Numerous factors have an impact on workplace safety and health practices. The lack of management commitment, safety performance, safety climate, hazard management, safety culture and safety and health training are all contributing factors to the ineffective application of safety standards and procedures. Occupation Safety Management Systems(safety planning, safety policy, safety promotion, safety communication and awareness, safety training and safety control, monitoring and review) are built in tools used by businesses to manage hazards that could endanger the health and safety of their employees while also making sure that they can easily comply with all applicable legal requirements [17].

4. Data Analysis

4.1. Factors that affect Occupational Safety and Health Practices

Safety leadership: More than 65% of workers disagree with the safety leadership's response, 10% are neutral, and the remaining 25% are in agreement. Since the answers to all of the aforementioned questions indicate that the organization has a significant talent gap in the position of safety leadership, the company must be bridging this gap. According to a response from Safety Performance, 20% of employees are neutral, 10% are in agreement, and more than 70% disagree. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company. More than 50% of workers disagree with Safety Climate's response, 15% are indifferent, and 35% are in agreement. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company .The Hazard Management reaction is opposed by more than 71% of the workforce; 10% are indifferent, and 19% are in agreement. The must be filling this talent gap since the responses to all of the aforementioned questions show that there is a substantial shortage of qualified candidates for the position of safety leadership. According to Safety Planning's response, more than 50% of employees disapprove, 30% are ambivalent, and 20% are in agreement. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company. When the Safety Policy reacts, more than 50% of the workforce disagrees, 30% are neutral, and 20% are in agreement. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company. A majority of workers—more than 52%—disagree with the safety promotion response, while 18% are neutral and 30% concur. The business must be filling this talent gap since the responses to all of the aforementioned questions show that there is a substantial shortage of qualified candidates for the position of safety leadership. In response to Safety Training, more than 68% of workers disapprove, 14% are neutral, and the remaining 18% agree. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company. In response to Internal Communication and Awareness, more than 50% of employees disapprove, 24% are neutral, and 26% are in agreement. The business must be filling this talent gap since the responses to all of the aforementioned questions show that there is a substantial shortage of qualified candidates for the position of safety leadership. More than 50% of workers disagree with the safety culture's response, 10% are neutral, and the remaining 40% are in agreement. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company. The firm's productivity reaction is opposed by more than 30% of employees, while 24% are neutral and 46% are in agreement. The business must be filling this talent gap since the responses to all of the aforementioned questions show that there is a substantial shortage of qualified candidates for the position of safety leadership. More than 55% of employees disagree, 10% are neutral, and 35% agree with the Control, monitoring, and Review responses. Since the answers to the aforementioned questions all indicate that there is a significant gap in the company's performance in the area of safety, this gap must be filled by the company.

4.2. Confirmatory Factor Analysis (Measurement model)

Confirmatory factor analysis (CFA) is a tool that determines if the data matches a specific proposed model or not and is used to validate or refute the measurement hypothesis. These techniques were employed in the current study to evaluate concept validity [18]. Confirmatory factor analysis (CFA) frequently uses a measurement model, and researchers must adhere to the rule that the factor loading for an item must be 0.50 or greater [23]. To evaluate the relevance of postulated linkages, a structural model is developed. Convergent and discriminant validity are both necessary to establish construct validity [18].

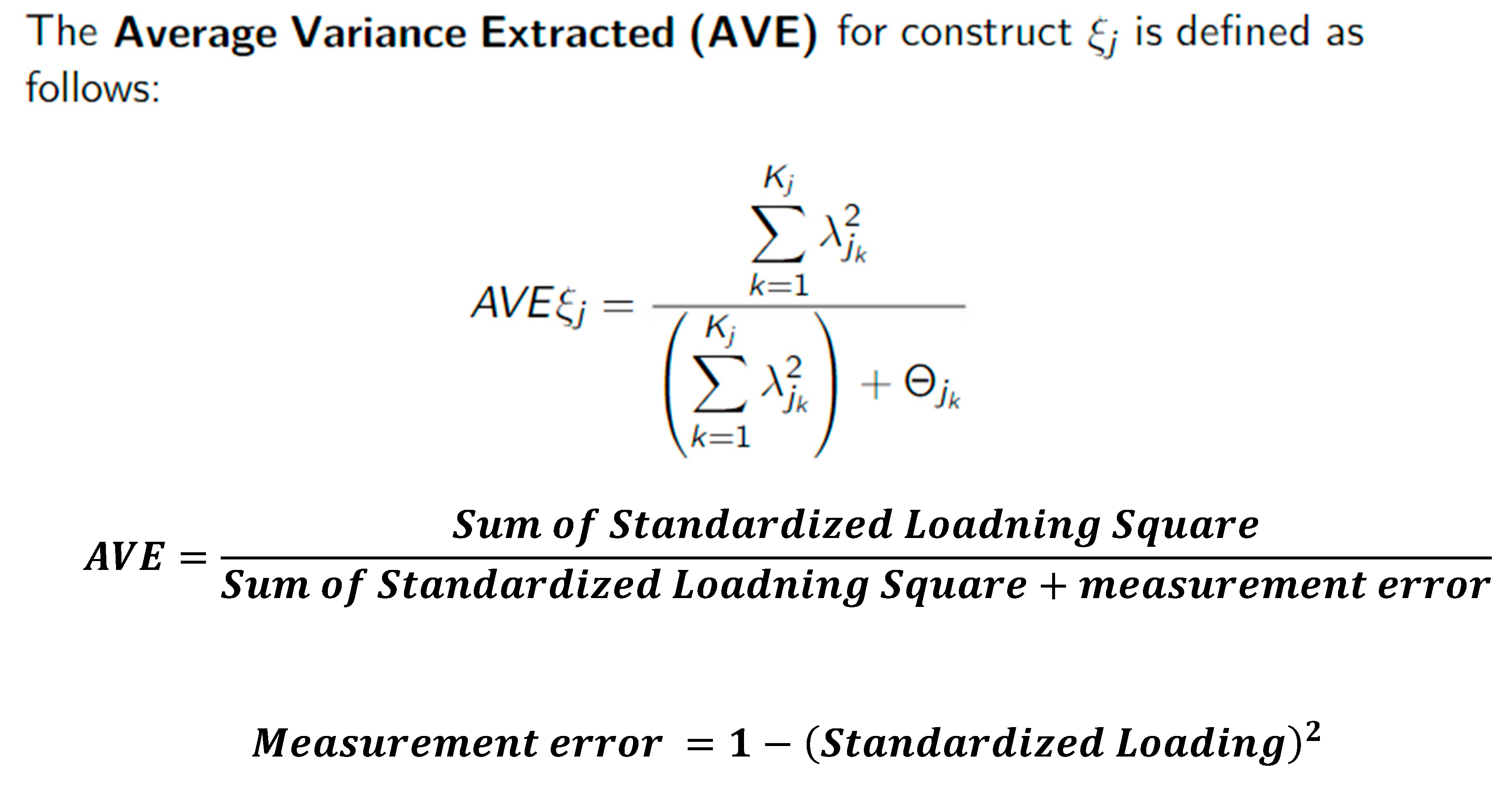

4.3. Convergent validity (average variation extracted)

The difference between the degree of variation collected by a construct and the level caused by measurement error is known as the average variation extracted (AVE). Values above 0.7 are regarded as being extremely good, while a level of.50 is deemed adequate [18].

The calculation result of Average Variance Extracted (AVE) for the different constructs in the study exceeded the required criteria of 0.5.

Figure 3.

Average Variance Extracted (AVE).

Figure 3.

Average Variance Extracted (AVE).

4.4. Composite Reliability

The results of the confirmatory factor analysis (CFA) of the improved structural model are used to compute composite reliability. The following formula is used to determine composite reliability (Omar, 2013).

Figure 4.

Discriminant Validity.

Figure 4.

Discriminant Validity.

For composite reliability, a statistic of 0.70 is the lowest acceptable value. Study demonstrates that the composite reliability for the various constructs in the investigation was higher than the necessary threshold of 0.7.

4.5. Discriminant validity

The degree to which the constructs in the study differ from one another is referred to as discriminant validity (Straub et al., 2004). The degree to which latent variable a discriminates against other latent variables (such as B, C, and D) is known as discriminant validity [18]. Two metrics have been used to assess discriminant validity: the square root of AVE and the correlation of latent constructs. To ensure that a measurement model is valid, its correlation values for each construct must be lower than the square root of AVE [23].

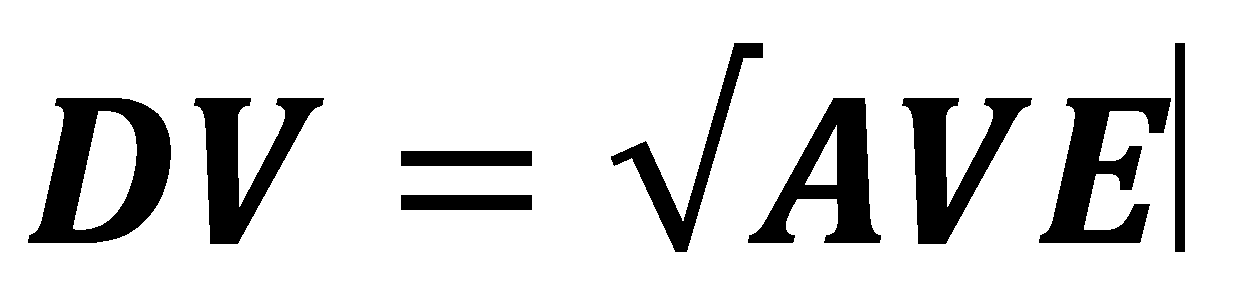

4.6. Structural model and result

Based on the

Table 3 the fit indices are summarized below, while the structural model is depicted in

Figure 3. Overall, the model showed an acceptable level of fit: (ChiSq or CMIN/DF = 4.132, RMR=0.019, GFI=0.971, TLI=0.906, CFI = 0.986, RMSEA = 0.121 and PCLOSE=0.001).

In SEM, the hypothesized links between the various constructs in the research study are evaluated by designing and testing the structural model. The statistical analysis and results from the previous section showed that the research model had proven sufficient reliability and validity, and the model had been judged to have an acceptable fit in the chapter's previous section

4.7. Hypotheses Testing

Diverse statistics were examined in order to evaluate the structural model. These included examining model fit indices to determine whether the data matched the model and reviewing p values to determine which proposed relationships were validated. The unstandardized path coefficients were to be significant at the p 0.05 level in order to evaluate the postulated associations. The findings from the proposed hypothesized relationships are summarized in the section that follows.

According to the findings in

Table 4, six out of eleven hypotheses were statistically supported. Results from each of the hypotheses are described below

- ✓

H1: Safety leadership has direct impact on Safety performance

Hypotheses (H1) seek to assess if Safety leadership has direct impact on Safety performance. The findings reveal that Safety leadership factor has direct impact on Safety performance (p = .001), thus supporting H1.

- ✓

H2: Safety climate has direct impact on Firm Productivity

Hypotheses (H2) seek to assess if Safety climate has direct impact on Firm Productivity. The findings reveal that Safety climate factor has direct impact on Firm Productivity (p = 0.001), thus supporting H2.

- ✓

H3: Safety Hazard management has direct impact on Firm Productivity

Hypotheses (H3) seek to assess if Safety Hazard management has direct impact on Firm Productivity. The findings reveal that Safety Hazard management factor does not have direct impact on Firm Productivity (p = 0.121), thus rejecting H3.

- ✓

H4: Safety Planning has direct impact on Firm Productivity

Hypotheses (H4) seek to assess if Safety Planning has direct impact on Firm Productivity. The findings reveal that Safety Planning does not have direct impact on Firm Productivity (p = 0.885), thus rejecting H4.

- ✓

H5: Safety policy has direct impact on Firm Productivity

Hypotheses (H4) seek to assess if Safety policy has direct impact on Firm Productivity. The findings reveal that Safety policy factor has direct impact on Firm Productivity (p = 0.003), thus supporting H5.

- ✓

H6: Safety promotion has direct impact on Safety performance

Hypotheses (H6) seek to assess if Safety promotion has direct impact on Firm Productivity. The findings reveal that Safety promotion have direct impact on Safety performance (p = 0.0.23), thus supporting H6.

- ✓

H7: Safety training has direct impact on Firm Productivity

Hypotheses (H7) seek to assess if Safety training has direct impact on Firm Productivity. The findings reveal that Safety training factor does not have direct impact on Firm Productivity (p = 0.825), thus rejecting H7.

- ✓

H8: Safety communication and awareness has direct impact on Safety performance

Hypotheses (H8) seek to assess if Safety communication and awareness has direct impact on Safety performance. The findings reveal that Safety communication and awareness does not have direct impact on Firm Productivity (p = 0.110), thus rejecting H8.

- ✓

H9: Safety control, monitoring and review has direct impact on Firm Productivity

Hypotheses (H9) seek to assess if Safety control, monitoring and review has direct impact on Firm Productivity. The findings reveal that Safety control, monitoring and review does not have direct impact on Firm Productivity (p = 0.206), thus rejecting H9.

- ✓

H10: Safety culture has direct impact on Firm Productivity

Hypotheses (H10) seek to assess if Safety culture has direct impact on Firm Productivity. The findings reveal that Safety culture factor has direct impact on Firm Productivity (p = 0.001), thus supporting H10.

- ✓

H11: Safety performance has direct impact on Firm Productivity

Hypotheses (H11) seek to assess if Safety performance has a significant impact on Firm Productivity. The findings reveal that Safety performance has direct impact on Firm Productivity (p = 0.011), thus supporting H11.

Figure 5.

The Structural Model Result.

Figure 5.

The Structural Model Result.

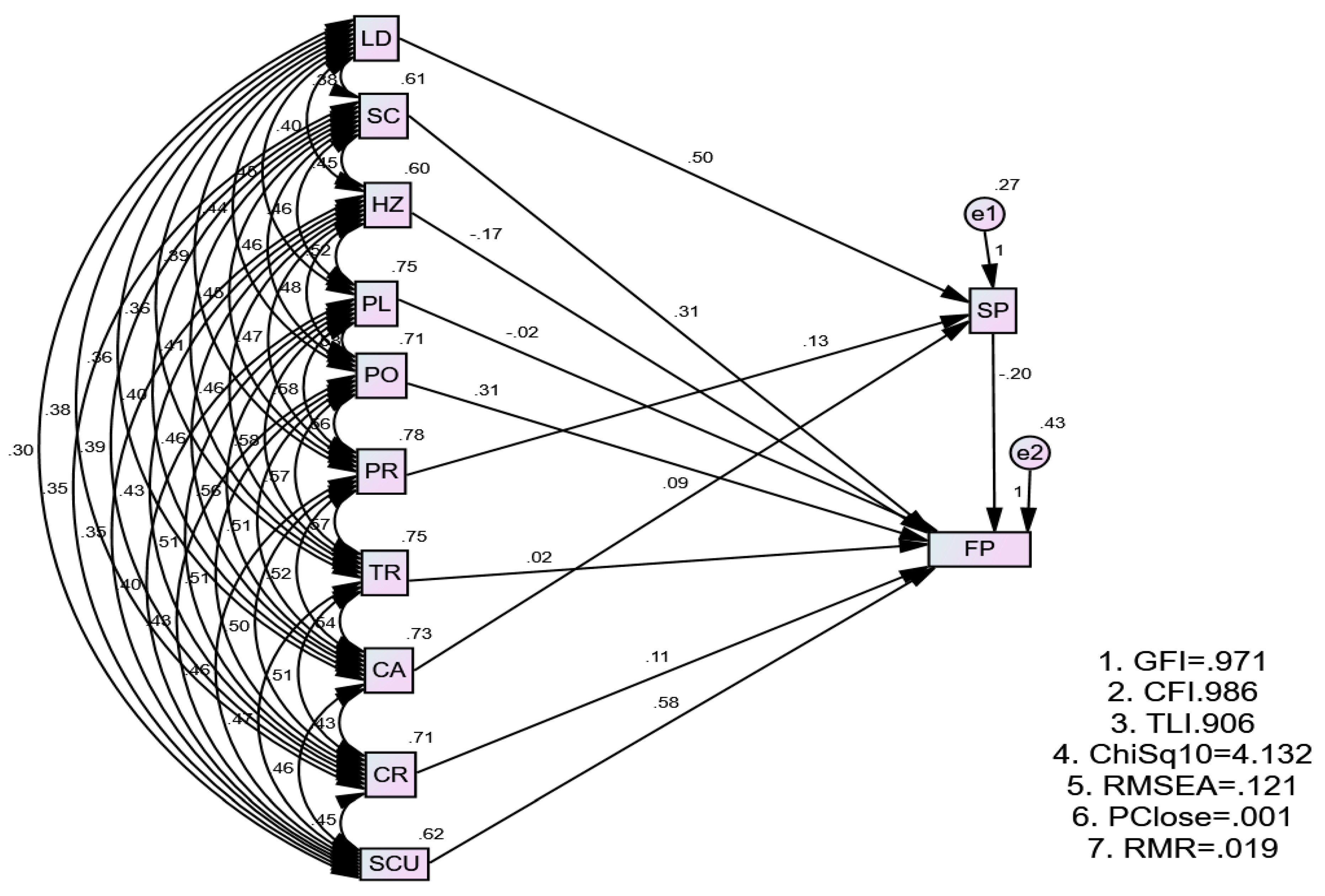

Figure 6.

The Final Structural Model Result.

Figure 6.

The Final Structural Model Result.

5. DISCUSSION, CONCLUSIONS AND RECOMMENDATIONS

- ❖

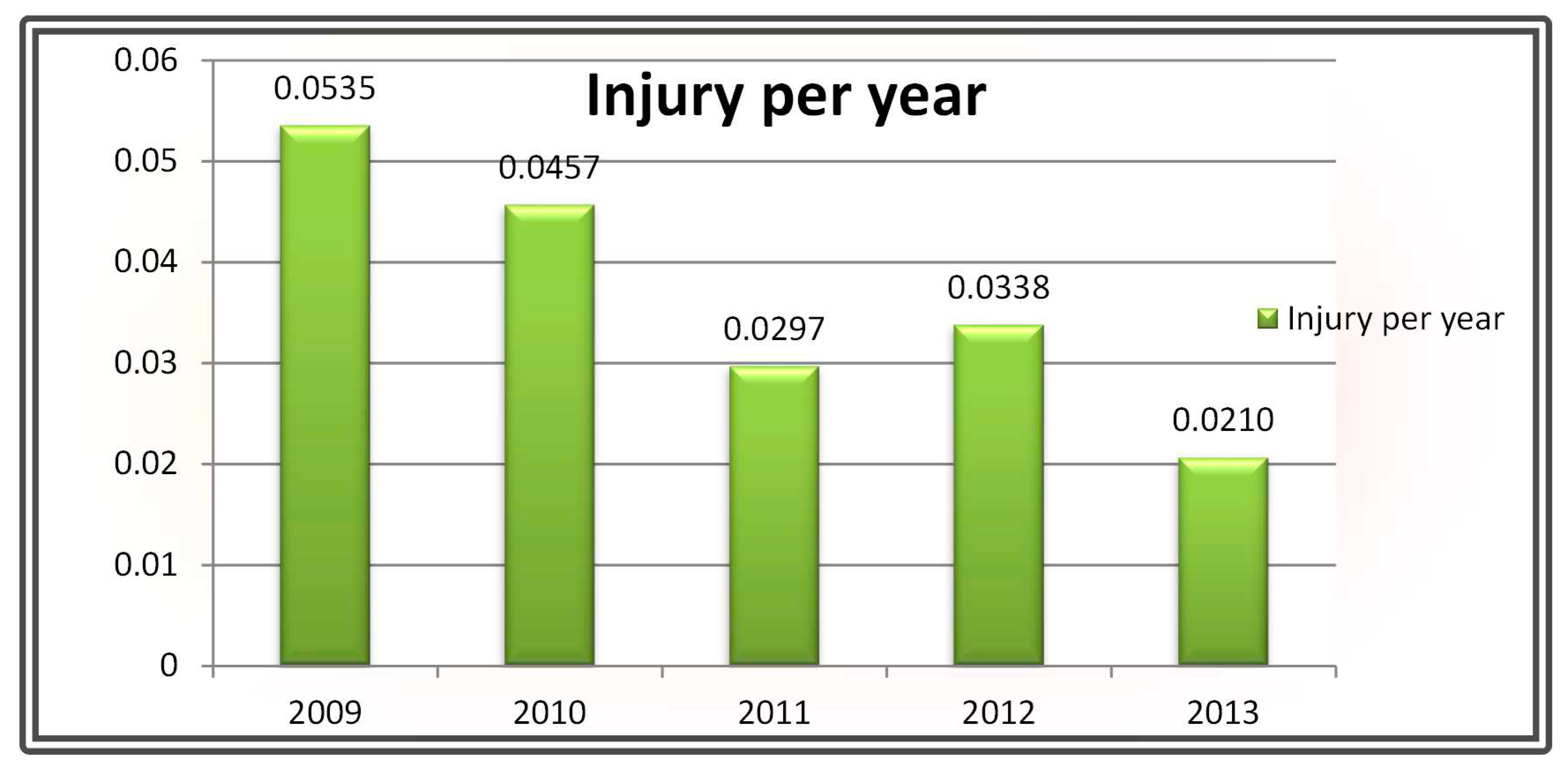

Research question one

The first research question was, "What are the different kinds of risks, accidents, and injuries occurring in the metal industry?" In order to answer the first research question, secondary data were surveyed. The metal manufacturing business experienced greater issues than other types of industries, according to Shikdar & Sawaqed (2003). A significant public health concern is the high prevalence of occupational injuries in the metal fabrication industry. Eyes, fingers, ankles, and feet were mentioned, in addition to compression and crush occurrences (Gulhan et al., 2012). According to a study by Miwano et al., (2018) the category of chemical and biological risks has the highest exposure rate, followed by the category of physical hazards. The study's findings showed that psychosocial and ergonomic dangers had lower percentages .In the section on literature reviews, this subject is more succinctly covered and answered

- ❖

Research question two

Research Question Two asked, “What are the factors that affect Occupational Safety and Health Practices at Akaki basic metal industry?”

Factors that affect Occupational Safety and Health Practices at Akaki basic metal industry are as follow.

This study discovered a strong positive relationship between safety leadership and safety performance. According to Kheni's (2008) research, when management places a high priority on workplace health and safety, employees understand that the employer values their lives. As a result, people work more safely and strive to act more safely at work. The study also demonstrates that employees are more willing to contribute to workplace health and safety when they feel free to discuss issues or suggestions for improvements in workplace safety with management or supervisors. Additionally, staff members are more likely to act safely when asked about safety at sessions about workplace safety and health. To ensure the efficient and successful administration of workplace health and safety, good leadership is required. These leaders' traits include tenacity, a desire to see health and safety improve, a willingness to collaborate with others to promote health and safety, and an understanding that good health and safety result from others' cooperation and efforts. This indicates that effective leadership enhances workplace performance in terms of occupational safety and health. Previous studies have noted the significance of safety leadership on employee safety performance

- ❖

Research Question three

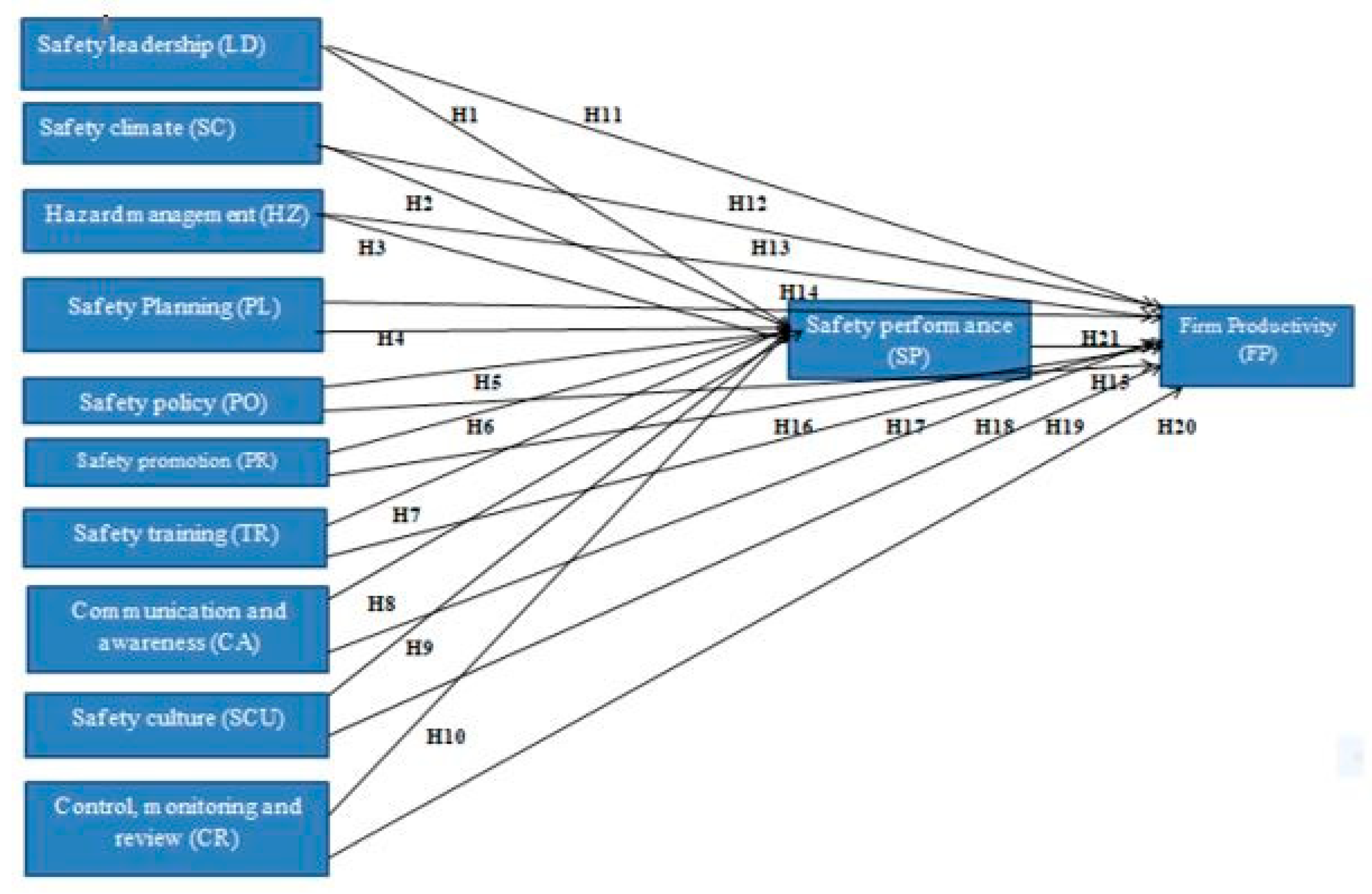

Research Question four asked, “What Industrial Occupational Safety and Health Model is Appropriate for Akaki Basic Metal Industry?” The Akaki Basic Metal Industry's occupational safety and health model was created based on the principles of the preceding chapter, as evidenced by the structural model output. Based on the data gathered from the earlier analysis carried out in this research, this part has developed an OSH improvement model. The section has also sought to evaluate the relevance of each OSH element and the suggested model to the study's overall aims. Safety culture was the first component of the model element, which was intended to increase firm productivity. The adoption of a safety policy was the second measure taken to increase firm productivity. The safety climate, which aims to increase firm productivity, made up the third component of the model element. The final two components, safety promotion and safety leadership, were linked to safety performance in order to improve success factors, and firm productivity was linked to safety performance. Jilcha, (2020) discovered in earlier studies that the model for improving industrial workplace safety and health has good effects in the direction of sustainable development. The outcomes represent achievements in lowering work-related accidents, diseases, and costs as well as in creating long-lasting workplace safety and health management systems. Making the development of the OSH strategic plan, the team of steering committees, the allocation of funding and enforcement, the development of policy, and the establishment of management standards as the most important aspects for OSH improvements a priority

- ❖

Research question four

Research Question three asked, “To what extents do factors that affect firm productivity at the work place?” The investigation also revealed the magnitude of the factors influencing corporate productivity. The results reveal that there has been a significant impact, but that the beneficial influence on safety culture, safety laws, and the climate has outweighed the negative impact on firm productivity and safety performance. The magnitudes of the factor loading coefficients for the health and safety variables in the multiple regression models showed that this was the case. The results of the study showed that safety culture, safety police, and safety atmosphere all had levels of factors that affected company production that ranged from greater to lower factor loading coefficients. Safety performance increases by 0.519 for every increase in safety leadership and by 0.185 for every increase in safety promotion. According to this, safety promotion and leadership had a favorable impact on safety performance, but when safety performance increased, firm productivity decreased by 0.186, making safety performance a negative determinant of firm productivity. When safety culture increases by 1, firm productivity increases by 0.612, by 0.3 when safety police increases by 1, and by 0.246 when safety climate increases by 1, indicating that safety culture, safety police, and safety climate were, respectively, the degree of factor loading coefficients for firm productivity. Employee productivity is impacted by the aforementioned variables. According to a prior study by [

22], analyzing employee performance is crucial to understanding organizational performance. The ability of employees to work productively and boost the company's competitive edge is significantly influenced by organizational performance.

5.1. Qualitative Result

The following findings were presented in light of employee interviews, workplace observations, and an open-ended study question: Due to a lack of safety guards, industrial workers were exposed to heat and flying materials. Lack of personal protective equipment (PPE) and improper ventilation in the forging and surface treatment rooms Workers in the furnace area of the Founder work shop were exposed to smoke, and the majority of them didn't wear chemical masks or gauze to guard against dust and fire. Additionally, when workers were observed in several working areas, they were found operating without PPE and only wearing overcoats. The safety signs that were posted were insufficient, and some of them were worn and hard to read. For the employment of ray welding and cutting machines, there is no personal protective equipment (PPE) to shield the radiation from harming the fertility of both male and female workers in the fabrication work shop. Workers also complained that the company lacks an occupational safety and health department as a result; there is no responsible department to gather and record employee injury data from the company clinic; there is no department for safety planning; to offer training; to promote communication; to control; to monitor; to review; and to manage safety hazards in the workplace. The other employees complained that they were paid very little or had poor earnings from the company. Employees who are paid poor wages are not happy with their jobs. there was an elevated risk of occupational injury in Ethiopia due to a lack of personal protective equipment, supervision, and training in occupational health and safety. According to the earlier study [

2], it is impossible to expect a society to achieve its development goals without healthy workers, safe workplaces, and contented citizens. To put it another way, un well workers cannot perform at the levels of productivity and efficiency that are expected of them. According to the aforementioned respondents, there is a knowledge gap among firm employees regarding their level of comprehension of the components of the worker safety and health management system and their participation in it. Because of this, the model analysis's surprising conclusion was to exclude these factors. Therefore, it is suggested that the corporation and the local government officials who are responsible for the issue take corrective action.

5.2. Conclusions

The following conclusions were made based on the study findings of Occupational Safety and Health Model Development in Manufacturing in the Akaki Basic Metal Industry. To meet the general objective of the study, it has followed a well-structured research design. This study has also hypothesized and cross-validated the complex associations between indicators of twenty-one observed variables and latent factors in a developing region. A developed questionnaire was used to gather information (n = 215) on variables of interest from Akaki Basic Metal Industry. To test and validate the hypothesized model, CFA was conducted on both the calibration and validation using AMOS. The CFA results offered a perfect understanding of the causal relationship among various constructs. As the developed model achieved the desired GOF indices, construct reliability, and convergent and divergent validities. Construct dependability, convergent and divergent validities, and the requisite GOF indices were all obtained by the constructed model.

The metal industry has a variety of accidents and injuries, including those to the eyes, fingers, ankles, and feet, as well as compression and crush. The metal industry is most exposed to physical dangers, followed by chemical and biological threats. According to the findings, safety leadership, climate, policy, promotion, culture, performance, and firm productivity are the elements that have an impact on occupational safety and health practices at Akaki Basic Metal Industry. In the analysis, these variables have a strong association and are significant. The other factors, including safety hazard management, safety communication and awareness, safety control, monitoring and review, safety planning, and safety training, did not significantly affect the results. Those variables do not, according to our findings, influence occupational safety and health practices at Akaka’s basic metal business. According to the qualitative discussion in the previous chapter, the case company did not have an occupational safety and health department, and the majority of respondents gave the answers 1 and 2 (strongly disagree and disagree), which suggests that those variables were not important. However, they are crucial to the practice of occupational safety and health. However, by integrating occupational safety and health in the workplace, the organization enhances these factors. The findings of this study suggest that safety leadership and safety promotion are, respectively, the most critical elements that influence safety performance. In order to decrease workplace accidents and injuries and enhance employee performance and firm productivity, safety culture, safety police, and safety climate evaluation are also significant critical variables that influence firm productivity. The Akaki Basic Metal Industry's best model is identified by a previous finding. The model variables employed to enhance the state of firm productivity were safety culture, safety policy, and safety climate. In order to enhance safety performance, the final two components safety promotion and safety leadership were combined. However, safety performance has a negative correlation with firm production.

The involvement of metal employees in workplace safety and health increases their performance in terms of safety, which is one of this study's significant contributions. Additionally, unless management is strongly committed to workplace safety, safety procedures and rules will not be effective on their own. As a result, how the company facilitates a safety climate and safety culture at work has a big impact on how people behave when it comes to safety. Employees will be more eager to abide by safety rules if they believe that administrative personnel are concerned about their OHS. A program for workplace safety and health has also been established and put into place. However, if employers and employees do not carry out their respective obligations, a successful occupational health and safety program cannot exist.

5.3. RECOMMENDATIONS

Given the results of the study and the conclusions presented above, the following advice is provided

- ✔

Management must implement occupational safety and health in order to enhance the management of occupational safety and health and other elements that lower workplace accidents and injuries.The management of Akaki Basic Metal Industry should organize and hold routine workshops, seminars, and refresher trainings on workplace health and safety, monitor health and safety concerns, release safety-related documents, and take numerous other actions to instill a sense of safety awareness in workers. Certain accidents might have been avoided if workers had been properly supervised while doing their duties at the job. The management must inform other employers about risks and hazards.

- ✔

In order to prevent radiation from harming both male and female employees' fertility, the management supplies personal protective equipment for new employees as well as the use of ray welding and cutting machine processes. A regular monitoring team should be established by management to ensure that workers are donning the provided protective gear before performing their duties, strictly adhering to the safety precautions put in place to prevent accidents, and establishing internal rules and regulations governing working conditions.

- ✔

The safety of the workplace can be substantially improved if employees are aware that management and they are both responsible for safety and health procedures. Facilities and systems for the workplace should be adequate, secure, and free from health risks, and management should provide and maintain them.

- ✔

Additionally, the government needs to put in place monitoring teams that will visit firms on a regular basis to see if they are adhering to the rules outlined in the nation's labor proclamation. Akaki Basic Metal Industry would be more effective in terms of program evaluation and improvement if it conducted a formal annual review of the workers' safety and health management program and modified the program as necessary to address flaws.

5.4. Limitation of the study and directions for future research

This research has certain limitations there are: First, employee behavior, employee satisfaction and employee income are highly influence in employees productivity also affect firm productivity but this study are not include this factors. Secondly, this study only focused on the Akaki Basic Metal Industry, the results may differ from other industries in Ethiopia or other countries. Finally the researcher used open end questionnaire and observation method among many survey data collection techniques. Based on the research question Amos needs more than 200 research questions to analyze data. But this study used only 215 research questions so that, the data that were collected might not large enough.

The researcher proposes further research to be conducted on organizational safety and health of firm productivity of Akaki Basic Metal Industry to come up with additional measured variable like employee behavior, employee income and employee satisfaction ,therefore future researcher could conduct his/her research based on this gap. The study may be future research extend to other metal factories in the other regions of Ethiopia or another country. It is possible that this may mean testing the model using sample populations drawn from beyond the Akaki Basic Metal Industry (>215questions).