Submitted:

03 August 2023

Posted:

07 August 2023

You are already at the latest version

Abstract

Keywords:

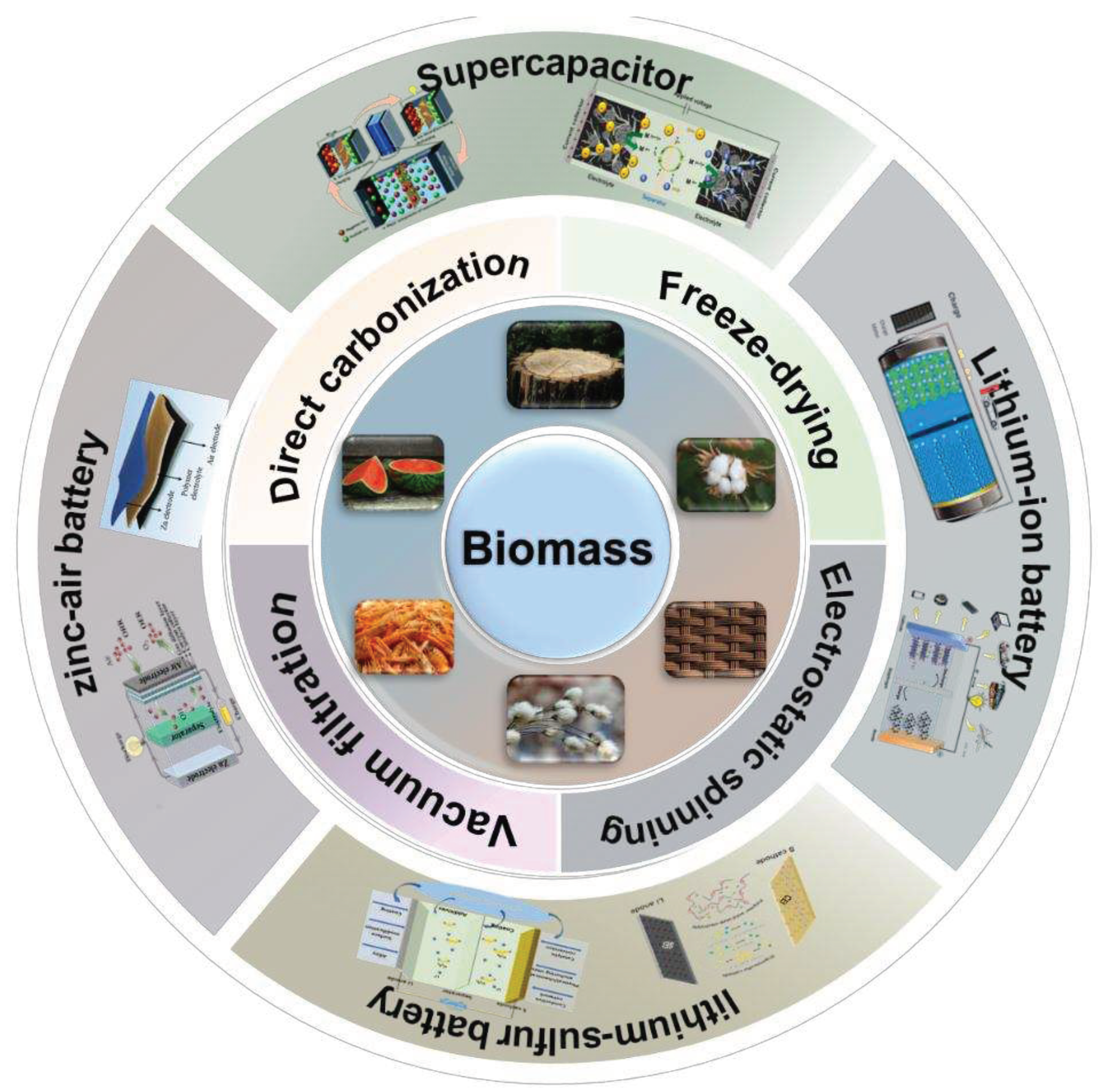

1. Introduction

2. Synthesis

2.1. Resources

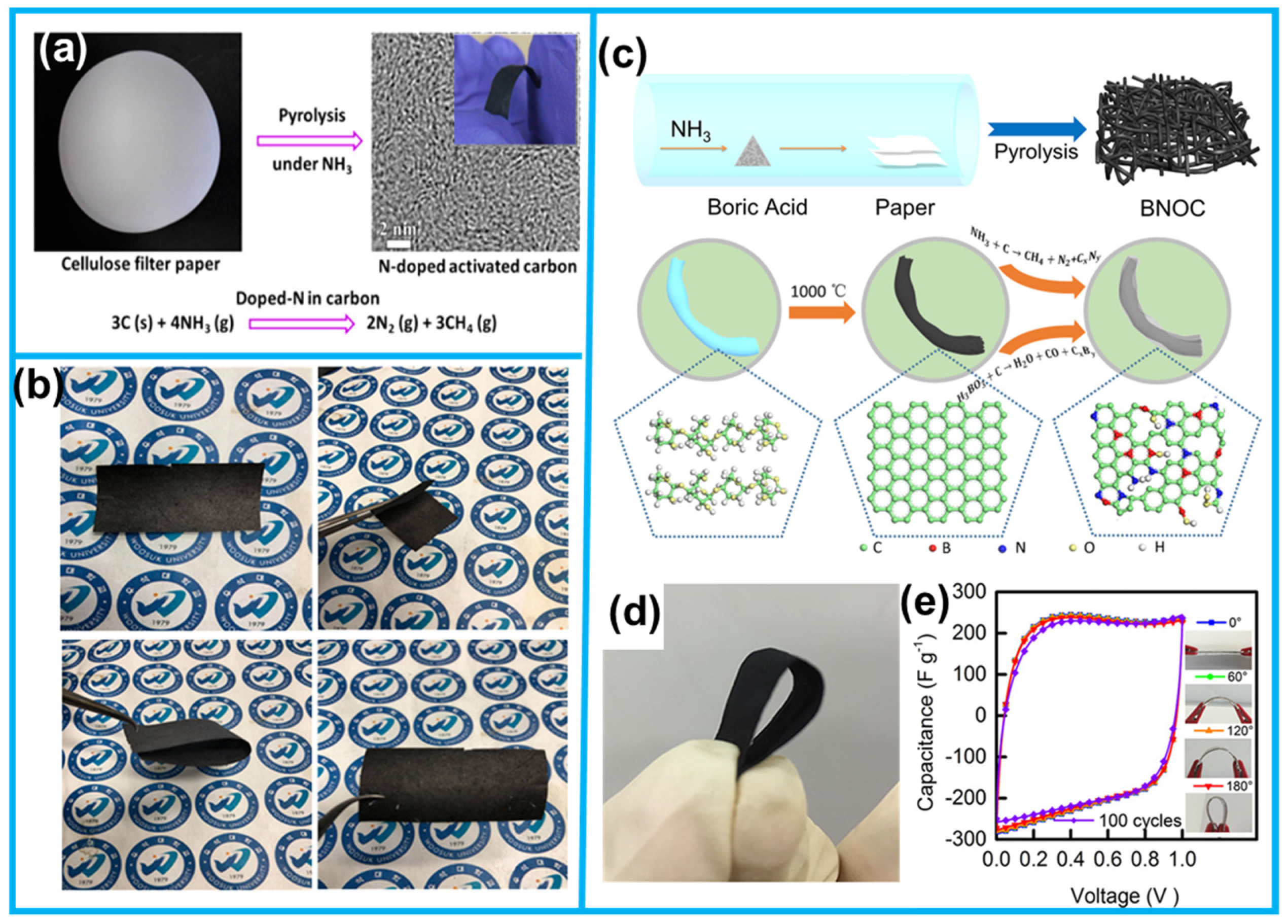

2.1.1. Cellulose

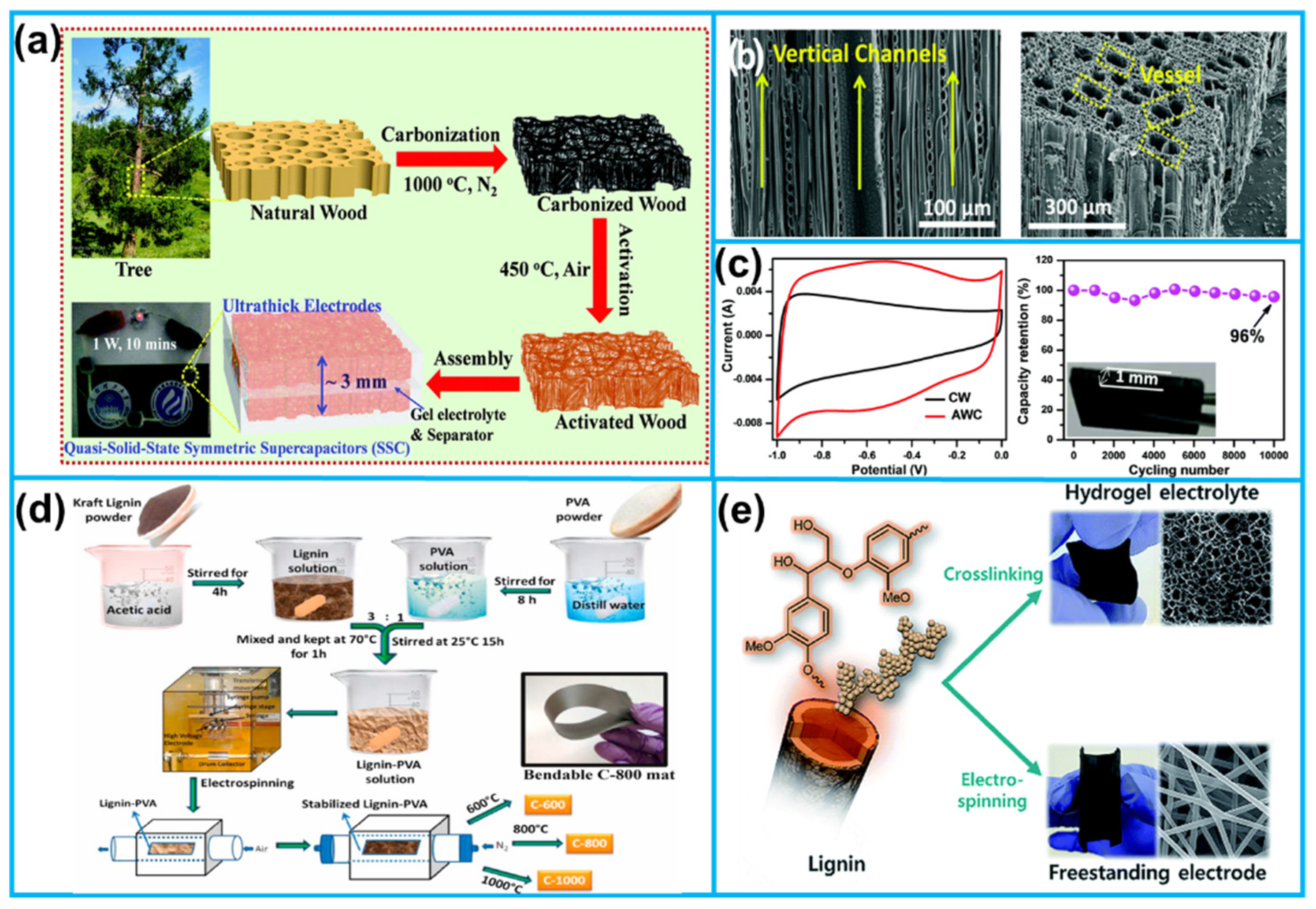

2.1.2. Lignin

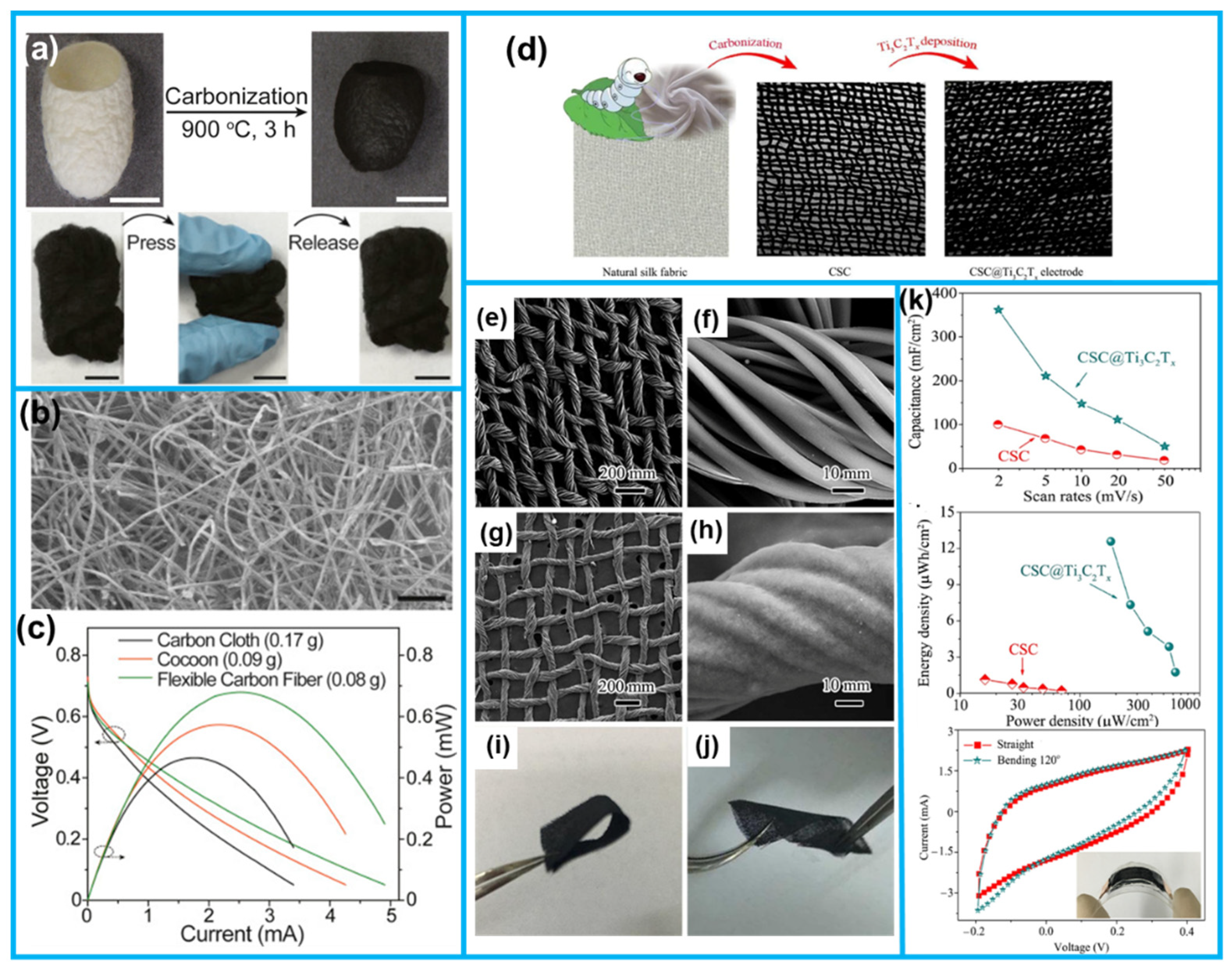

2.1.3. Silk

2.2. Synthesis

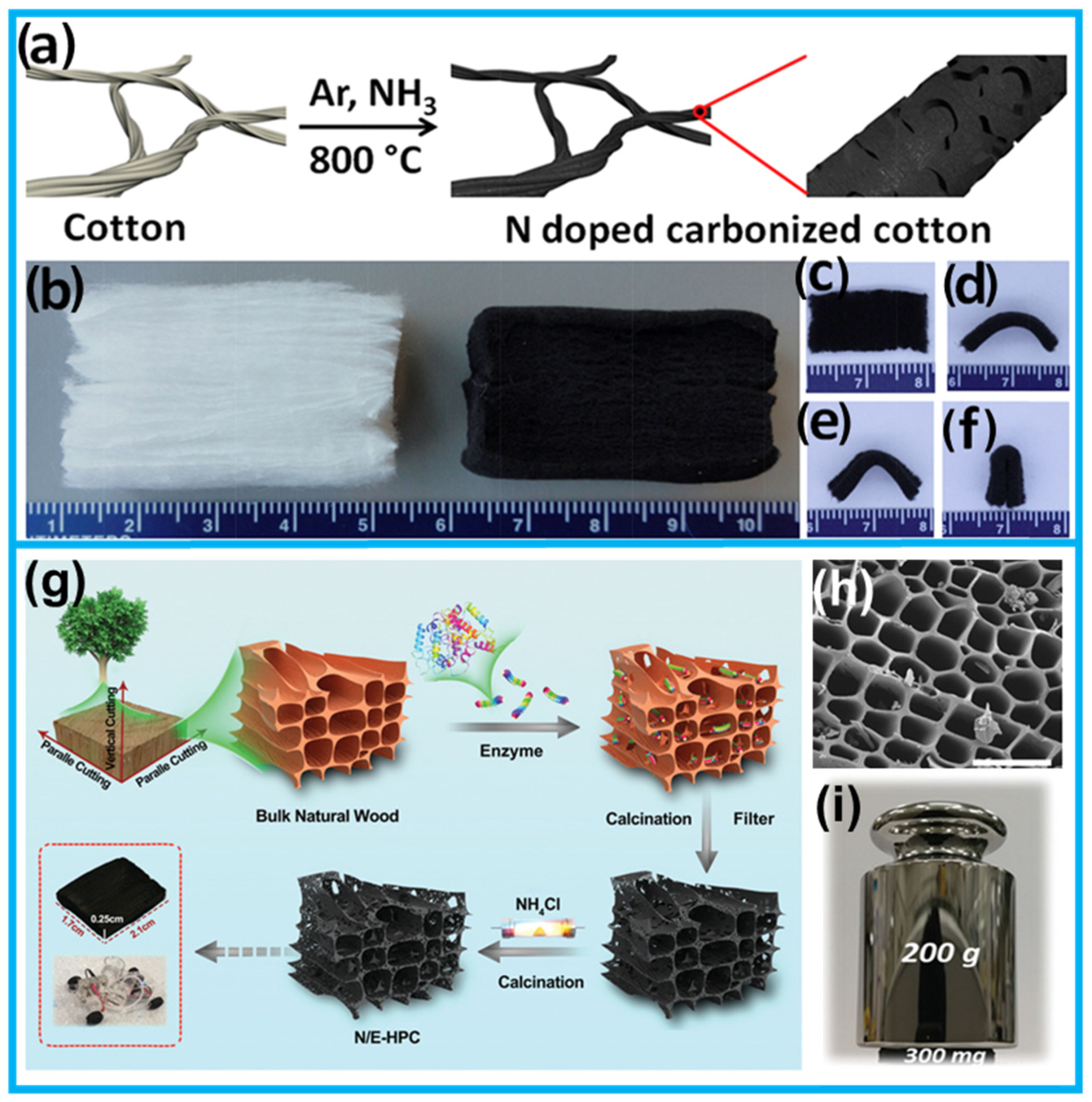

2.2.1. Direct Carbonation

2.2.2. Freeze drying & Carbonation

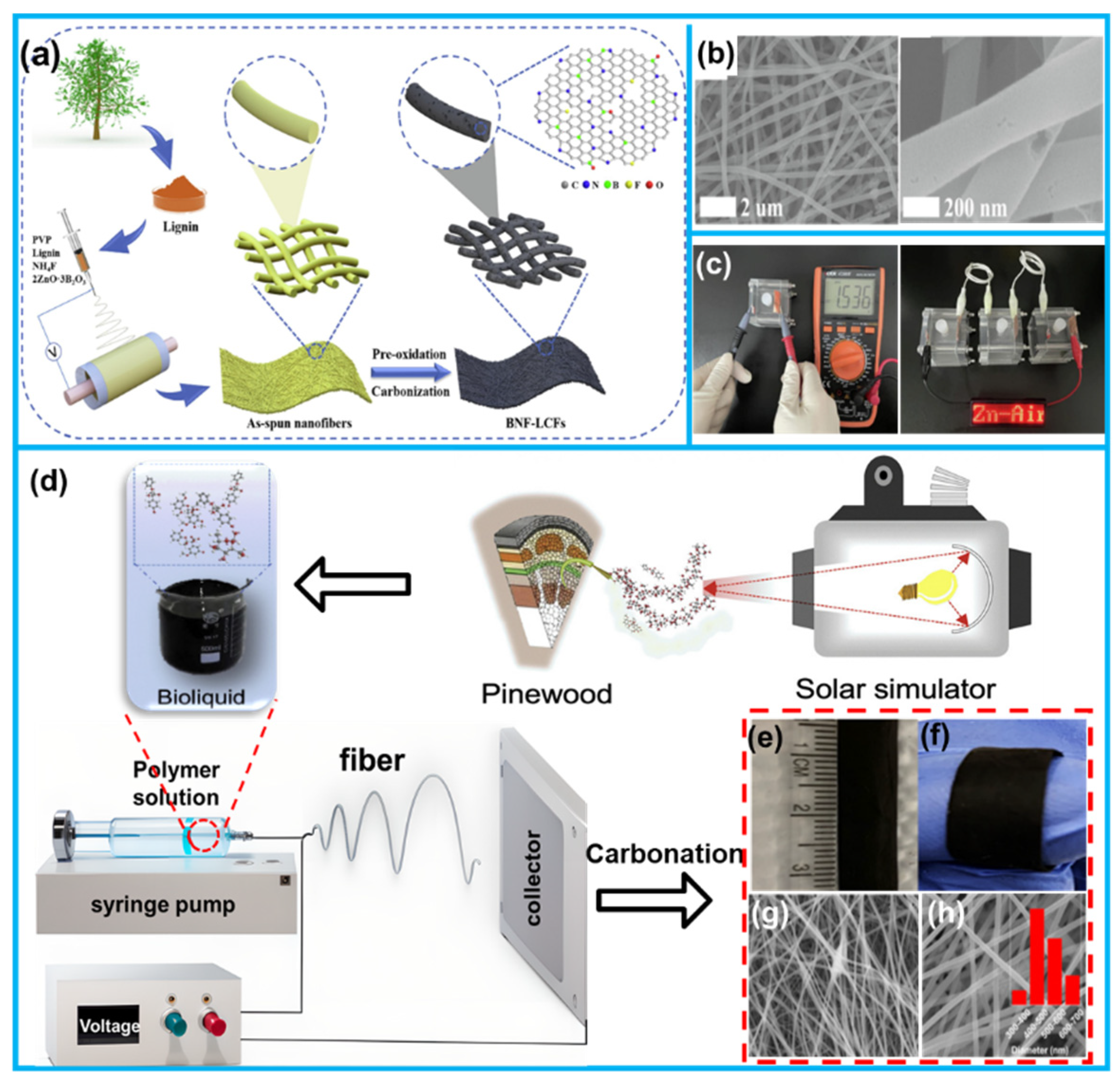

2.2.4. Electrostatic spinning & Carbonation

3. Application of flexible free-standing carbon architectures from biomass

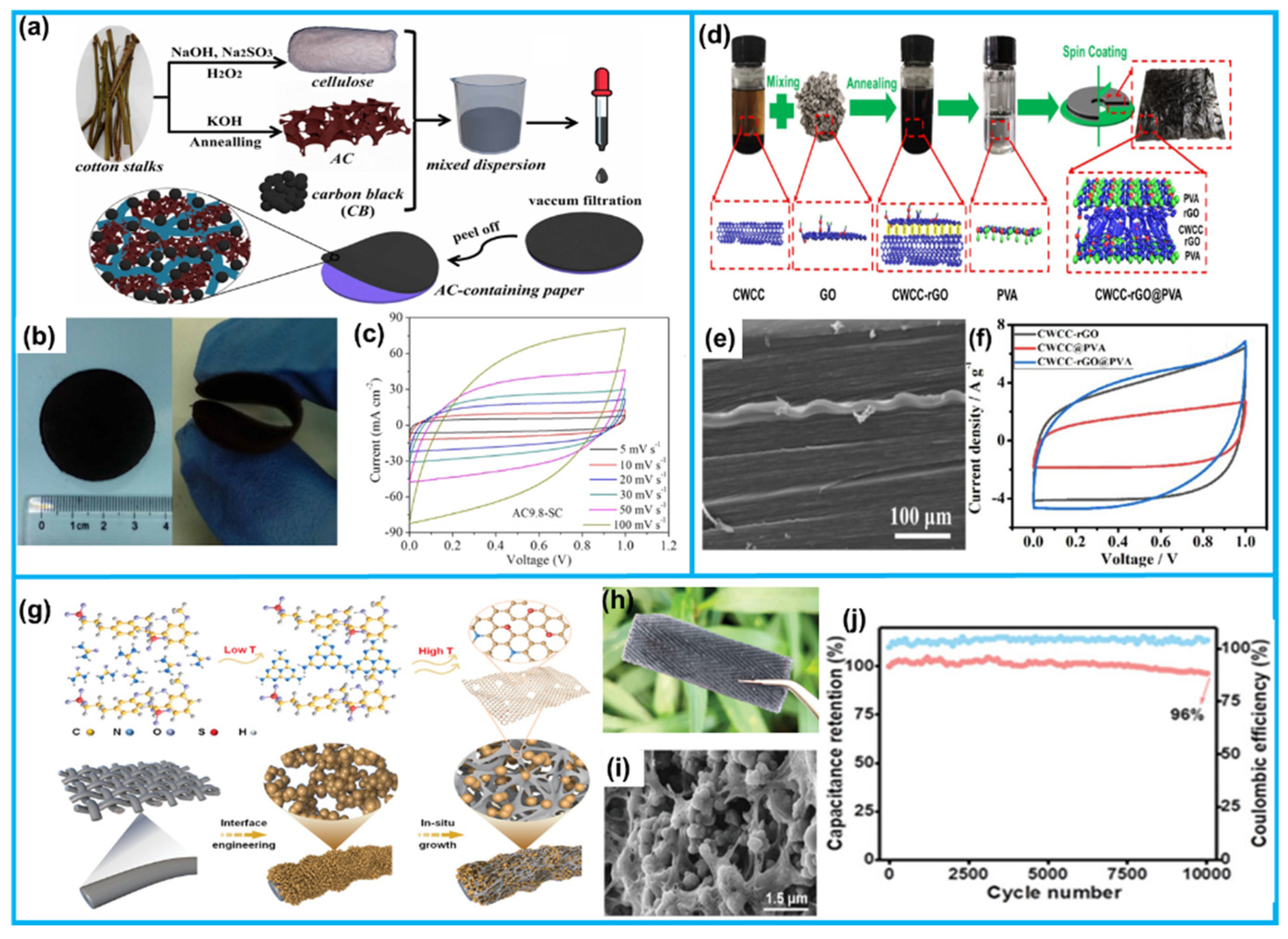

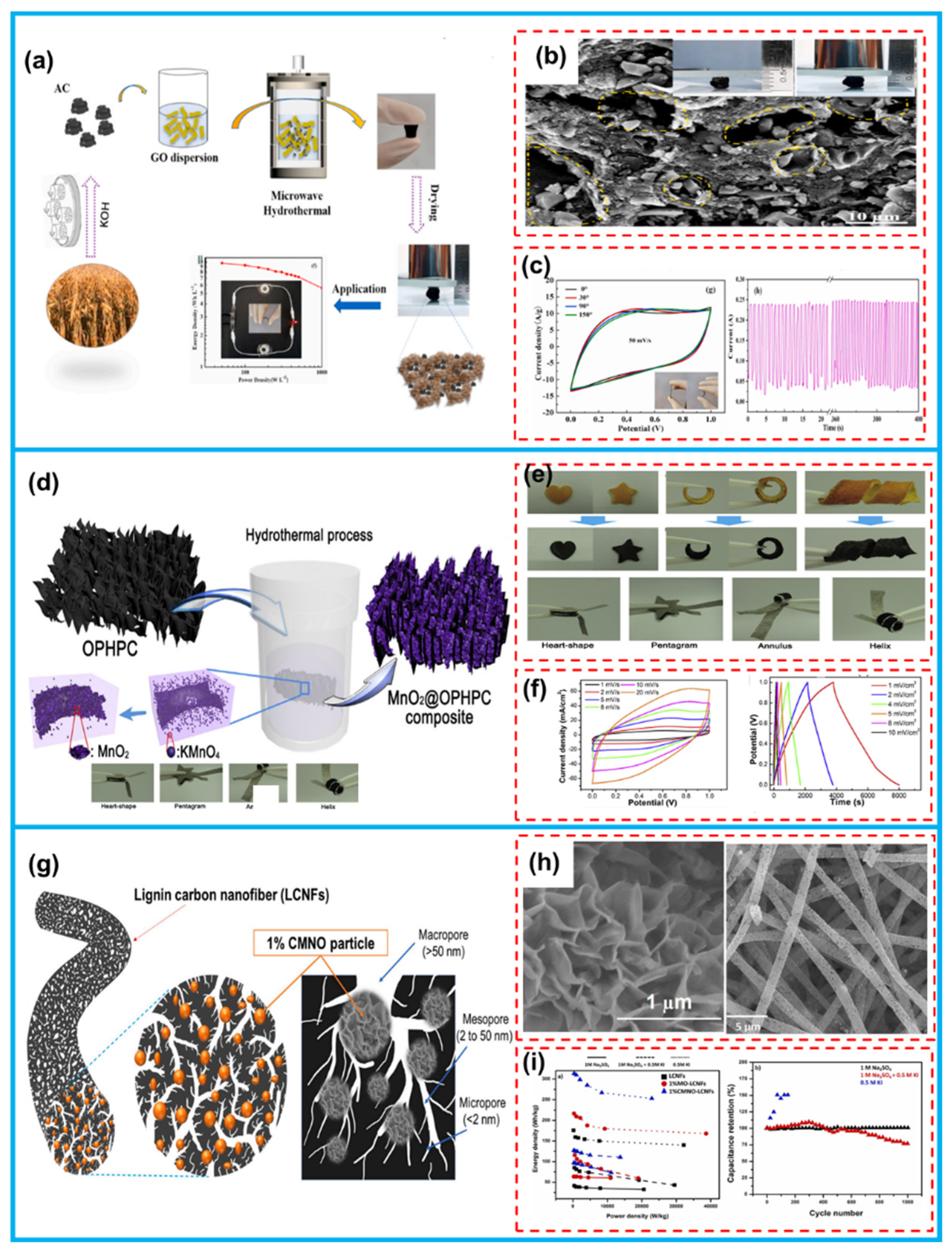

3.1. Supercapacitors

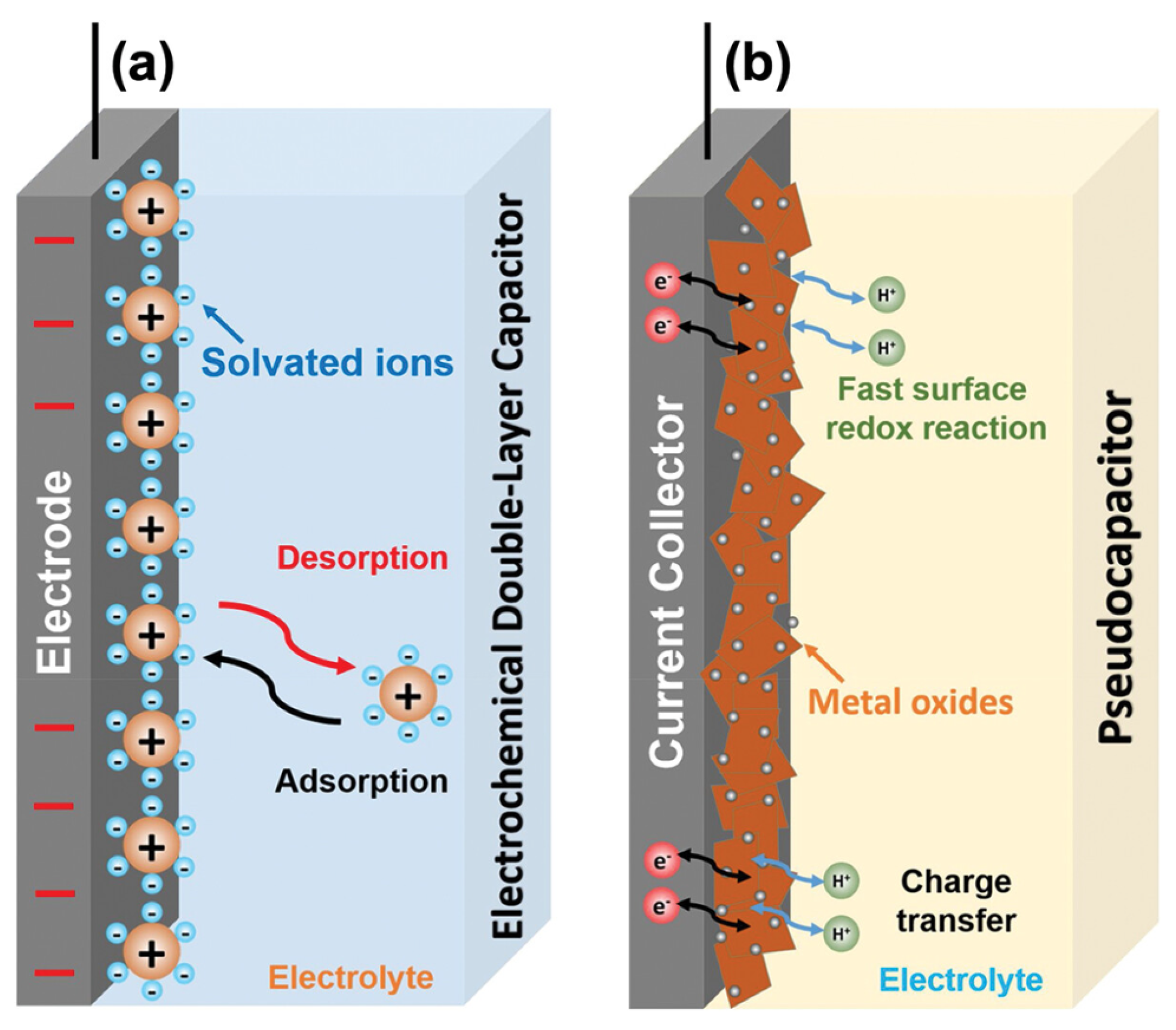

3.1.1. Electric double-layer capacitor (EDLC)

3.1.2. Preudocapacitor (PC)

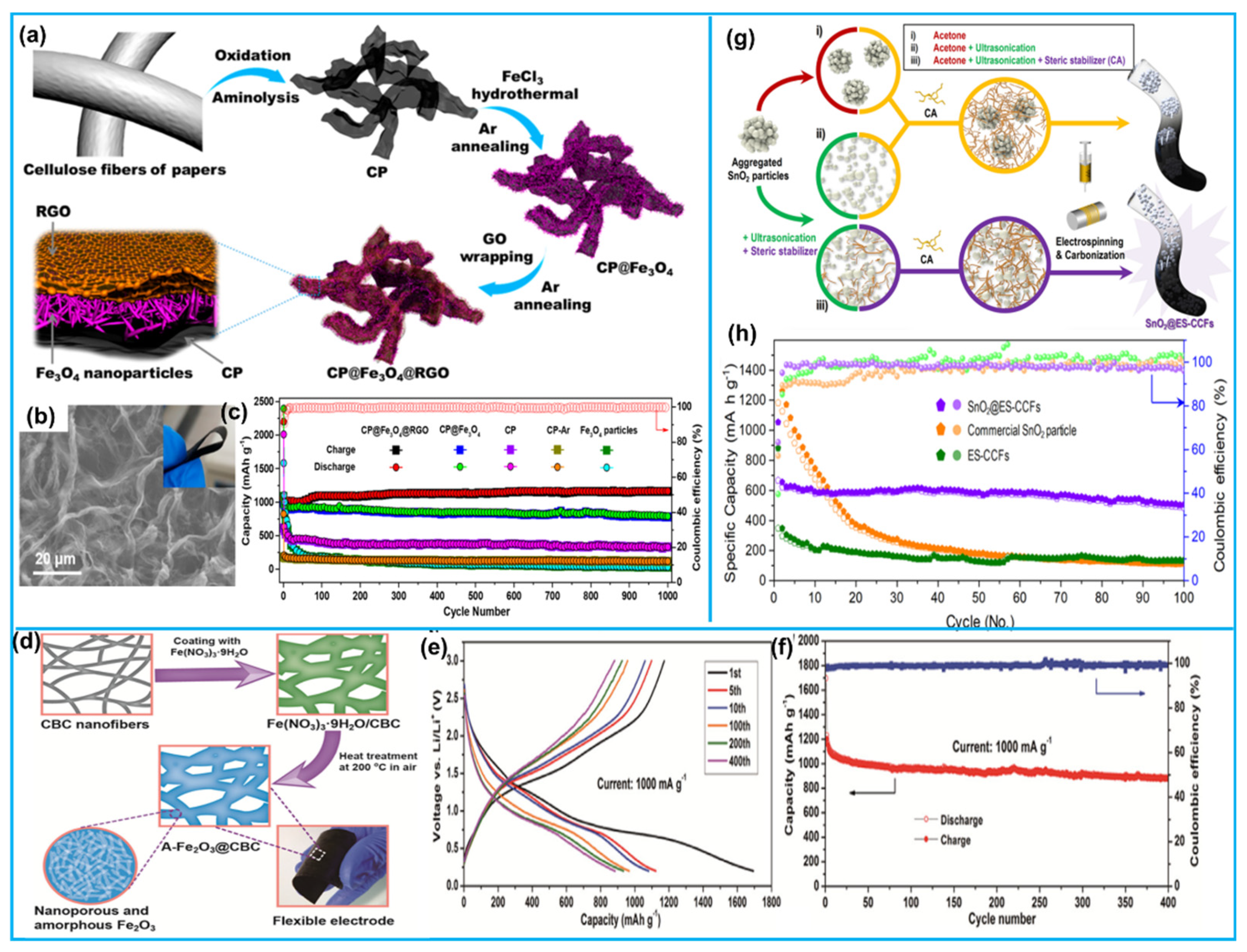

3.2. Lithium batteries

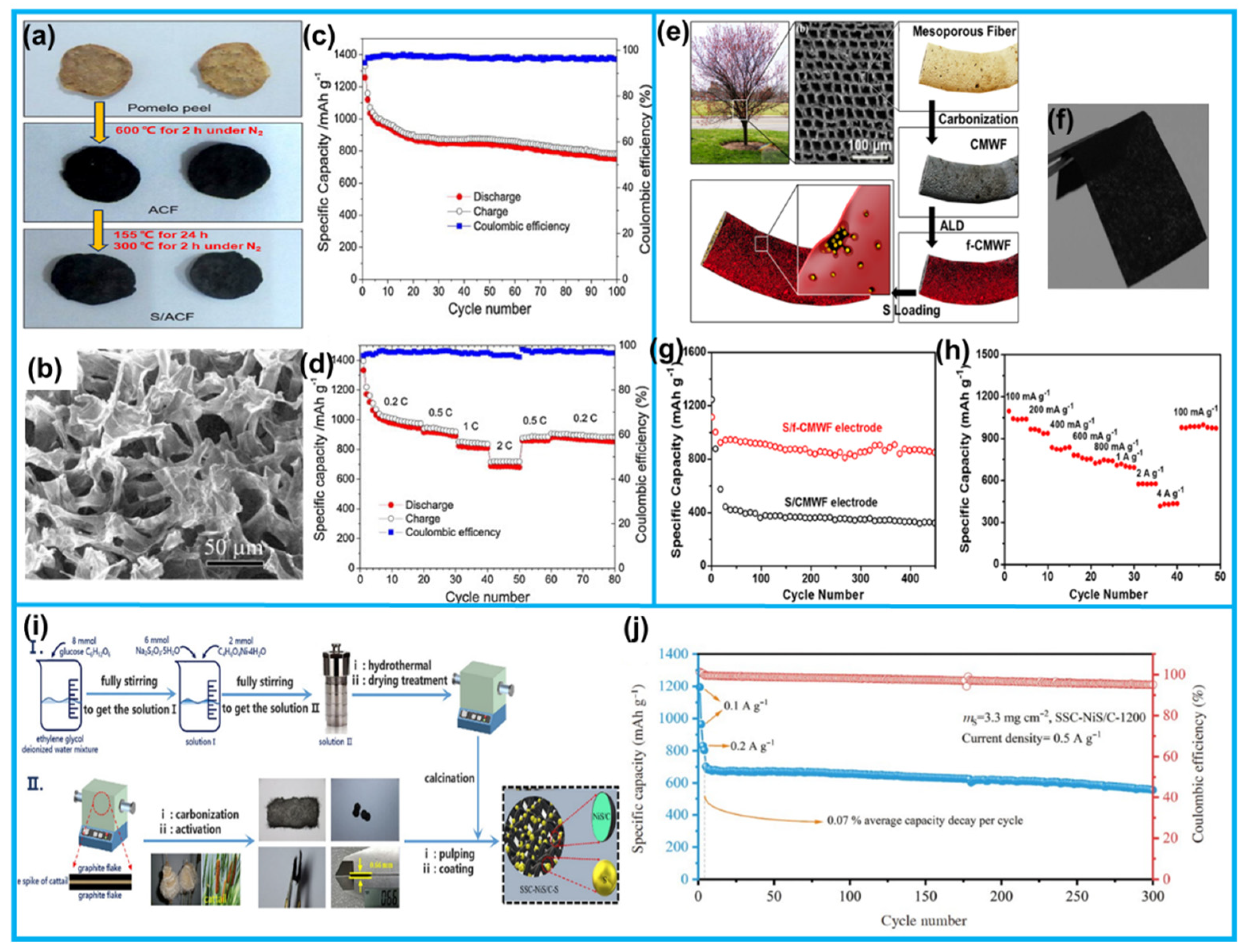

3.2.1. Lithium-ion battery

3.2.2. Lithium-sulfur battery

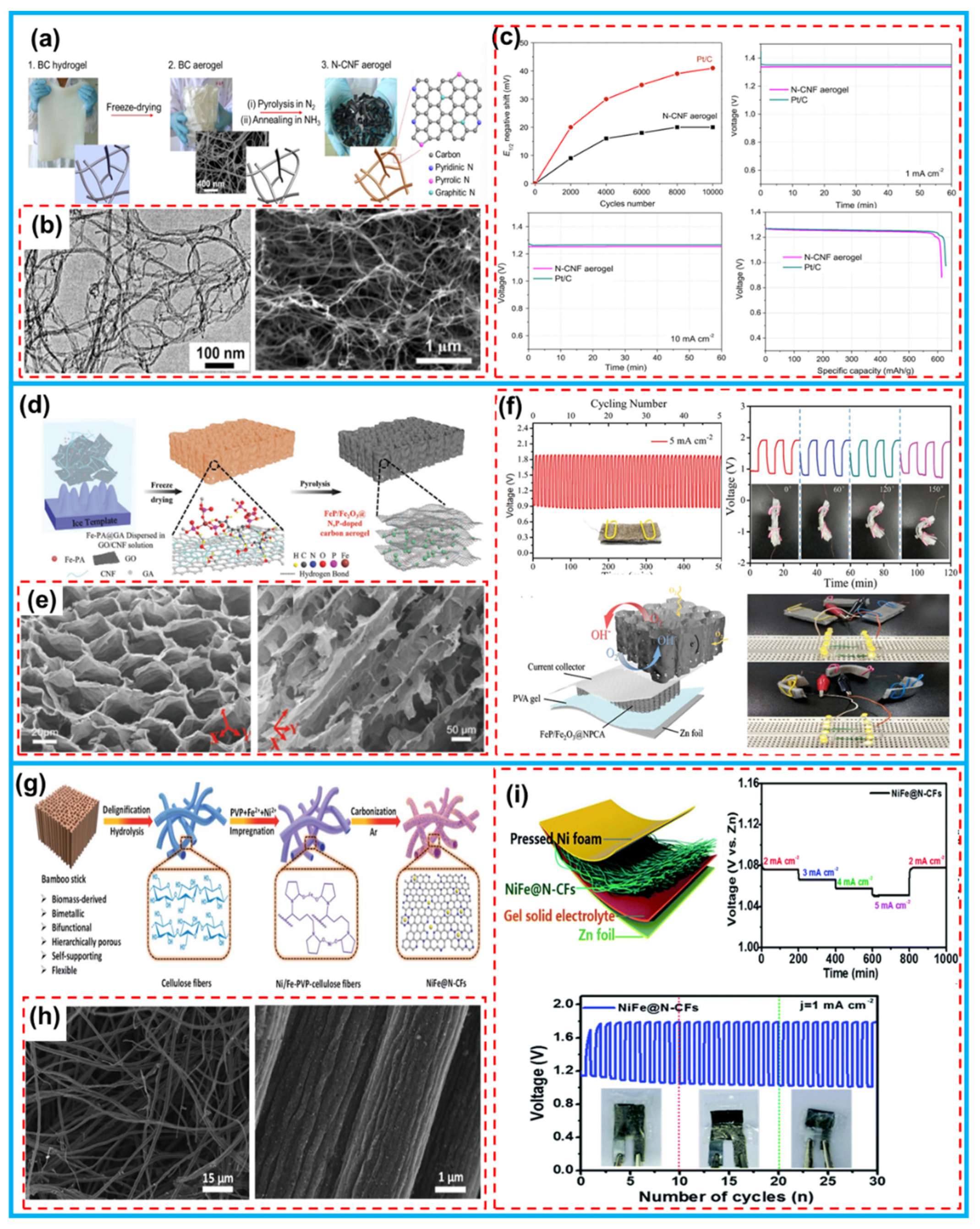

3.3. Zinc-Air Batteries

| Biomass | Electrode Material |

SBET (m2·g-1) | Vt (cm3·g-1) | Application | Electrochemical performance | ref |

|---|---|---|---|---|---|---|

| Raw wood | ZIF-67@wood (N:9.34 at%O:5.82 at%Co:1.87 at%) |

291.37 | 0.195 | Supercapacitors | 101.74 μWh cm−2, 5 mW cm−2, 10k cycles | [54] |

| Co(OH)2/carbonized wood composite (Co(OH)2 : 5.7 mg cm-2) | 568.13 | 0.69 mWh cm−2, 1.126 W cm−2, 10k cycles | [65] | |||

| N-doped porous carbon monoliths (N: 3.2wt%) | 708.2 | 0.38 | 9.3 Wh m−2, 248.3 W m−2, 5k cycles | [66] | ||

| N-doped carbon aerogels | 2183 | 1.83 | 5.5 W h kg–1, 3.7 kW kg–1, 10k cycles | [68] | ||

| Fabric | N-doped activated carbon cloth |

2116 | 1.458 | 215.9 F g−1 (1 A g−1), 98%, 20k cycles | [75] | |

| N-doped carbon interface | 3625 mF cm−2, 1.06 mWh cm−2, 10k cycles | [82] | ||||

| Silk | Carbonized silk fabric-MnO2 | 25.85 | 14.58 W h kg−1, 0.25 kW kg−1, 10k cycles | [89] | ||

| Paper | B, N, and O heteroatom-doped 3D interconnected carbon microfiber networks | 1382.5 | 0.973 | 12.4 W h kg–1, 300.6 kW kg–1, 242.4 F g–1, 100 cycles | [23] | |

| Cellulose-based activated carbon fiber papers | 808 | 0.52 | 48.8 F cm-3, 134.1 F g-1, 10k cycles | [92] | ||

| Activated carbon fibers | 762.65 | 0.356 | 56.25 mWh cm-2, 997 mW cm-2, 5k cycles | [34] | ||

| Cotton stalks | Integrated paper electrodes | 1972 | 0.369 | 331 μW h cm−2, 0.3 mW h cm−3, 10k cycles | [116] | |

| Cellulose | Cellulose–polypyrrole@reduced graphene oxide composite electrodes |

24.8 | 489 mF cm−2 (0.5 mA cm−2), 1k cycles | [25] | ||

| Carboxymethylcellulose | MXene/cellulose/carbon nanotubes composite electrodes | 95.2 | Supercapacitors | 258.8 μWh cm−2, 750 μW cm−2, 15k cycles | [118] | |

| Bamboo pulp | Super-flexible porous carbon fibrous film | 309 | 0.178 | 10.3 W h kg−1, 250 W kg−1, 8k cycles | [121] | |

| Bacterial -cellulose | Carbon aerogels | 893 | 0.30 | 297 F g–1 (1 A g–1), 14.83 Wh kg−1 (0.60 kW kg−1), 65k cycles | [38] | |

| Raw cotton | Porous carbon fibers |

2124.9 | 1.01 | Lithium batteries | 778 mA h g−1 (0.2 C), 450 mA h g-1 (0.5 C), 300 cycles | [73] |

| Silk | Carbonized Silk @Si@graphene | 1070 mAh g−1 (200 mA g−1), 300 cycles | [87] | |||

| N/O-codoped carbonized fibroin (N: 3.4 at% O: 7.9%) | 20.8 | 5.6 mAh cm−2, 457.2 Wh L−1, 300 cycles | [85] | |||

| Bacterial -cellulose | BC aerogels | 375 | 1134 mA h-1, 700 mA h-1 (400 mA g−1), 400 cycles | [102] | ||

| Ov-ZnO@CBC aerogels | 143 | 710 mAh g−1 (1 A g−1), 1k cycles | [103] | |||

| Cellulose nanofibril | FeP/Fe2O3@N,P-doped carbon aerogel (N:3.45at%, P:8.12at% Fe:0.84at%) |

503.43 | Zn–air batteries | 676 mAh g−1, 517 Wh kg−1 (5 mA cm−2), 800 min | [113] | |

| Raw wood | N-doped hierarchical porous carbon (N: 3.7 at%) | 1039 | 801 mA h g−1, 955 W h kg−1, 110 h | [64] | ||

| Dried miscanthus stems | Inner@Co@CNTs | 175.5 mW cm−2, 0.27 V (5 mA cm−2) | [165] | |||

| Raw wood | FeCo@NS-CA aerogels | 140 mW cm–2, 760 mA h g–1, 400 h | [166] | |||

| Co/CoO@NWC | 800 mAh g−1, 0.84 V, 270 h | [167] | ||||

| Lignin | BNF-LCFs | 791.5 mAh g−1, 1.536 V, 200 h | [124] |

4. Conclusions and Perspectives

- (1)

- The conductivity of biomass-derived carbon architectures still exhibits certain differences compared to commercially available carbon papers or carbon cloths. Commercially available carbon papers and carbon cloths typically undergo high-temperature graphitization treatment, resulting in elevated purity and crystallinity that promote the formation of well-carbonized structures and efficient conducting networks. In contrast, the preparation process of biomass-derived carbon architectures may be comparatively simpler, and their conductivity is influenced by the original raw materials, potentially leading to the presence of impurities or defects, resulting in a slight disparity in conductivity compared to commercial carbon papers and carbon cloths. Therefore, novel measures, including interface engineering, nanoscale structure design, and chemical modifications, need to be developed to further enhance their conductivity and unlock their full potential for applications in electrochemical energy storage and related domains.

- (2)

- Further enhancement of the mechanical strength of flexible carbon architectures is necessary. In practical applications, flexible electrodes are subjected to external mechanical forces such as pressure, tension, or bending. Therefore, they must exhibit excellent mechanical strength to ensure stable morphology and structure during usage, thereby enhancing the durability and stability of the electrode. Currently, certain biomass-derived carbon electrodes fall short of meeting the requirement to maintain their original electrochemical performance even after extensive folding, necessitating the development of novel approaches to further enhance their mechanical properties. Moreover, future studies should comprehensively analyze the mechanical properties of flexible electrode materials, including tensile strength, foldability, and other relevant aspects, to meet the demands of future flexible devices.

- (3)

- The diverse origins of biomass may lead to variations in the structure, composition, and performance of carbon materials, which can in turn influence the electrochemical performance of electrodes. Therefore, it is essential to conduct a comparative analysis of biomass-derived materials from different regions to assess their respective strengths and weaknesses comprehensively. This approach will provide deeper insights into the characteristics of these materials and identify potential areas for improvement, thereby facilitating the optimization and innovation of carbon electrode material

- (4)

- Enhancing surface modulation of biomass-derived carbon architectures for improved electrochemical performance. Due to the abundant natural functional groups present in biomass, which serve as effective carriers for anchoring metal compounds, there has been significant attention towards utilizing them as favorable platforms. However, the aspect of surface modulation in biomass-derived carbon architectures has received comparatively less focus, the roles played by various functional groups in this context are not yet clearly understood. Consequently, it becomes crucial for future advancements in biomass-derived carbon materials to emphasize surface modulation to further enhance their electrochemical performance and gain a deeper understanding of the underlying mechanisms.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wan, X.; Mu, T.; Yin, G., Intrinsic self-healing chemistry for next-generation flexible energy storage devices. Nano-Micro Letters 2023, 15, (1), 99. [CrossRef]

- Zhang, H.; Zhu, X.; Tai, Y.; Zhou, J.; Li, H.; Li, Z.; Wang, R.; Zhang, J.; Zhang, Y.; Ge, W.; Zhang, F.; Sun, L.; Zhang, G.; Lan, H., Recent advances in nanofiber-based flexible transparent electrodes. Int. J. Extreme Manuf. 2023, 5, (3), 032005. [CrossRef]

- Lei, W.; Jin, D.; Liu, H.; Tong, Z.; Zhang, H., An overview of bacterial cellulose in flexible electrochemical energy storage. ChemSusChem 2020, 13, (15), 3731-3753. [CrossRef]

- Hui, Z.; Zhang, L.; Ren, G.; Sun, G.; Yu, H.-D.; Huang, W., Green flexible electronics: Natural materials, fabrication, and applications. Adv. Mater. 2023, 35, (28), 2211202. [CrossRef]

- Zhu, P.; Gastol, D.; Marshall, J.; Sommerville, R.; Goodship, V.; Kendrick, E., A review of current collectors for lithium-ion batteries. J. Power Sources 2021, 485, 229321. [CrossRef]

- Fang, Z.; Zhao, M.; Peng, Y.; Guan, S., Poly (vinylidene fluoride) binder reinforced poly (propylene carbonate)/3D garnet nanofiber composite polymer electrolyte toward dendrite-free lithium metal batteries. Materials Today Energy 2022, 24, 100952. [CrossRef]

- Wang, H.; Fu, J.; Wang, C.; Zhang, R.; Yang, Y.; Li, Y.; Li, C.; Sun, Q.; Li, H.; Zhai, T., A universal aqueous conductive binder for flexible electrodes. Adv. Funct. Mater. 2021, 31, (34), 2102284. [CrossRef]

- Xue, J.; Zhao, Y.; Cheng, H.; Hu, C.; Hu, Y.; Meng, Y.; Shao, H.; Zhang, Z.; Qu, L., An all-cotton-derived, arbitrarily foldable, high-rate, electrochemical supercapacitor. Phys. Chem. Chem. Phys. 2013, 15, (21), 8042-8045. [CrossRef]

- Shi, C.; Hu, F.; Wu, R.; Xu, Z.; Shao, G.; Yu, R.; Liu, X. Y., New silk road: From mesoscopic reconstruction/functionalization to flexible meso-electronics/photonics based on cocoon silk materials. Adv. Mater. 2021, 33, (50), 2005910. [CrossRef]

- Chen, C.; Zhang, Y.; Li, Y.; Dai, J.; Song, J.; Yao, Y.; Gong, Y.; Kierzewski, I.; Xie, J.; Hu, L., All-wood, low tortuosity, aqueous, biodegradable supercapacitors with ultra-high capacitance. Energy Environ. Sci. 2017, 10, (2), 538-545. [CrossRef]

- Chen, W.; Yu, H.; Lee, S.-Y.; Wei, T.; Li, J.; Fan, Z., Nanocellulose: A promising nanomaterial for advanced electrochemical energy storage. Chem. Soc. Rev 2018, 47, (8), 2837-2872. [CrossRef]

- Li, S.; Ren, G.; Hoque, M. N. F.; Dong, Z.; Warzywoda, J.; Fan, Z., Carbonized cellulose paper as an effective interlayer in lithium-sulfur batteries. Appl. Surf. Sci 2017, 396, 637-643. [CrossRef]

- Ilango, P. R.; Savariraj, A. D.; Huang, H.; Li, L.; Hu, G.; Wang, H.; Hou, X.; Kim, B. C.; Ramakrishna, S.; Peng, S., Electrospun flexible nanofibres for batteries: Design and application. Electrochem. Energy Rev. 2023, 6, (1), 12. [CrossRef]

- Xiao, Z.; Dai, X.; Jiang, D.; Xie, H.; Liu, X.; Wu, M.; Liu, D.; Li, Y.; Qian, Z.; Wang, R., 3D Nanocellulose matrix enhancing the lithiation dynamics of FePS3 anode. Adv. Funct. Mater. 2023, n/a, (n/a), 2304766. [CrossRef]

- Zhao, Y.; Guo, J., Development of flexible Li-ion batteries for flexible electronics. InfoMat 2020, 2, (5), 866-878. [CrossRef]

- Wei, S.; Wan, C.; Wu, Y., Recent advances in wood-based electrode materials for supercapacitors. Green Chem. 2023, 25, (9), 3322-3353. [CrossRef]

- Xiao, X.; Zheng, Z.; Zhong, X.; Gao, R.; Piao, Z.; Jiao, M.; Zhou, G., Rational design of flexible Zn-based batteries for wearable electronic devices. ACS Nano 2023, 17, (3), 1764-1802. [CrossRef]

- Xu, T.; Du, H.; Liu, H.; Liu, W.; Zhang, X.; Si, C.; Liu, P.; Zhang, K., Advanced nanocellulose-based composites for flexible functional energy storage devices. Adv. Mater. 2021, 33, (48), 2101368. [CrossRef]

- Kasprzak, D.; Mayorga-Martinez, C. C.; Pumera, M., Sustainable and flexible energy storage devices: A review. Energy Fuels 2023, 37, (1), 74-97. [CrossRef]

- Rana, M.; Asim, S.; Hao, B.; Yang, S.; Ma, P.-C., Carbon nanotubes on highly interconnected carbonized cotton for flexible and light-weight energy storage. Adv. Sustain. Syst. 2017, 1, (5), 1700022. [CrossRef]

- Manjakkal, L.; Jain, A.; Nandy, S.; Goswami, S.; Tiago Carvalho, J.; Pereira, L.; See, C. H.; Pillai, S. C.; Hogg, R. A., Sustainable electrochemical energy storage devices using natural bast fibres. Chem. Eng. J. 2023, 465, 142845. [CrossRef]

- Ling, Z.; Wang, Z.; Zhang, M.; Yu, C.; Wang, G.; Dong, Y.; Liu, S.; Wang, Y.; Qiu, J., Sustainable synthesis and assembly of biomass-derived B/N Co-doped carbon nanosheets with ultrahigh aspect ratio for high-performance supercapacitors. Adv. Funct. Mater. 2016, 26, (1), 111-119. [CrossRef]

- Dai, P.; Xue, Y.; Zhang, S.; Cao, L.; Tang, D.; Gu, X.; Li, L.; Wang, X.; Jiang, X.; Liu, D.; Kong, L.; Bando, Y.; Golberg, D.; Zhao, X., Paper-derived flexible 3D interconnected carbon microfiber networks with controllable pore sizes for supercapacitors. ACS Appl. Mater. Interfaces 2018, 10, (43), 37046-37056. [CrossRef]

- Gao, T.; Xu, C.; Li, R.; Zhang, R.; Wang, B.; Jiang, X.; Hu, M.; Bando, Y.; Kong, D.; Dai, P.; Wang, X.-B., Biomass-derived carbon paper to sandwich magnetite anode for long-life Li-Ion battery. ACS Nano 2019, 13, (10), 11901-11911. [CrossRef]

- Xu, H.; Li, Y.; Jia, M.; Cui, L.; Chen, C.; Yang, Y.; Jin, X., Design and synthesis of a 3D flexible film electrode based on a sodium carboxymethyl cellulose–polypyrrole@reduced graphene oxide composite for supercapacitors. New J. Chem. 2021, 45, (15), 6630-6639. [CrossRef]

- Zhang, S.; Huang, Y.; Ruan, Y.; Wang, J.; Han, X.; Sun, X., Electrostatic self-assembly of citrus based carbon nanosheets and MXene: Flexible film electrodes and patterned interdigital electrodes for all-solid supercapacitors. J Energy Storage 2023, 58, 106392. [CrossRef]

- Liu, L.; Xia, G.; Wang, D.; Huang, J.; Duan, J.; Zhang, Y.; Dong, P.; Zhang, Y., Biomass-derived self-supporting sulfur host with NiS/C composite for high-loading Li-S battery cathode. Sci. China Technol. Sci. 2023, 66, (1), 181-192. [CrossRef]

- Zhang, Y.; Wang, Z., Review on cellulose paper-based electrodes for sustainable batteries with high energy densities. Front Chem Sci Eng 2023. [CrossRef]

- Shao, W.; Yan, R.; Zhou, M.; Ma, L.; Roth, C.; Ma, T.; Cao, S.; Cheng, C.; Yin, B.; Li, S., Carbon-based electrodes for advanced zinc-air batteries: Oxygen-catalytic site regulation and nanostructure Design. Electrochem. Energy Rev. 2023, 6, (1), 11. [CrossRef]

- Javed, M. S.; Najam, T.; Hussain, I.; Idrees, M.; Ahmad, A.; Imran, M.; Shah, S. S. A.; Luque, R.; Han, W., Fundamentals and scientific challenges in structural design of cathode materials for zinc-ion hybrid supercapacitors. Adv. Energy Mater. 2023, 13, (3), 2202303. [CrossRef]

- Yao, B.; Zhang, J.; Kou, T.; Song, Y.; Liu, T.; Li, Y., Paper-based electrodes for flexible energy storage devices. Adv. Sci. 2017, 4, (7), 1700107. [CrossRef]

- Liang, J.; Jiang, C.; Wu, W., Toward fiber-, paper-, and foam-based flexible solid-state supercapacitors: Electrode materials and device designs. Nanoscale 2019, 11, (15), 7041-7061. [CrossRef]

- Luo, W.; Wang, B.; Heron, C. G.; Allen, M. J.; Morre, J.; Maier, C. S.; Stickle, W. F.; Ji, X., Pyrolysis of cellulose under ammonia leads to nitrogen-doped nanoporous carbon generated through methane formation. Nano Lett. 2014, 14, (4), 2225-2229. [CrossRef]

- Pant, B.; Ojha, G. P.; Acharya, J.; Pant, H. R.; Park, M., Lokta paper-derived free-standing carbon as a binder-free electrode material for high-performance supercapacitors. SM&T 2022, 33, e00450. [CrossRef]

- Huang, J.; Zhao, M.; Hao, Y.; Wei, Q., Recent advances in functional bacterial cellulose for wearable physical sensing applications. Adv. Mater. Technologies 2022, 7, (1), 2100617. [CrossRef]

- Li, X.; Yuan, L.; Liu, R.; He, H.; Hao, J.; Lu, Y.; Wang, Y.; Liang, G.; Yuan, G.; Guo, Z., Engineering textile electrode and bacterial cellulose nanofiber reinforced hydrogel electrolyte to enable high-performance flexible all-solid-state supercapacitors. Adv. Energy Mater. 2021, 11, (12), 2003010. [CrossRef]

- Chen, L.-F.; Huang, Z.-H.; Liang, H.-W.; Yao, W.-T.; Yu, Z.-Y.; Yu, S.-H., Flexible all-solid-state high-power supercapacitor fabricated with nitrogen-doped carbon nanofiber electrode material derived from bacterial cellulose. Energy Environ. Sci. 2013, 6, (11), 3331-3338. [CrossRef]

- Ma, Y.; Chen, D.; Fang, Z.; Zheng, Y.; Li, W.; Xu, S.; Lu, X.; Shao, G.; Liu, Q.; Yang, W., High energy density and extremely stable supercapacitors based on carbon aerogels with 100% capacitance retention up to 65,000 cycles. Proc. Natl. Acad. Sci. U.S.A 2021, 118, (21), e2105610118. [CrossRef]

- Jiajia, W.; Zhanwen, D.; Ping, X.; Zhijiang, C., Fabrication of flexible polyindole/carbon nanotube/bacterial cellulose nanofiber nonwoven electrode doped by D-tartaric acid with high electrochemical performance. Cellulose 2020, 27, (11), 6353-6366. [CrossRef]

- Wang, W.; Yang, Y.; Chen, Z.; Deng, Z.; Fan, L.; Guo, W.; Xu, J.; Meng, Z., High-performance yarn supercapacitor based on directly twisted carbon nanotube@bacterial cellulose membrane. Cellulose 2020, 27, (13), 7649-7661. [CrossRef]

- Fang, D.; Zhou, J.; Sheng, L.; Tang, W.; Tang, J., Juglone bonded carbon nanotubes interweaving cellulose nanofibers as self-standing membrane electrodes for flexible high energy supercapacitors. Chem. Eng. J. 2020, 396, 125325. [CrossRef]

- Tan, H.; Xiao, D.; Navik, R.; Zhao, Y., Facile fabrication of polyaniline/pristine graphene–bacterial cellulose composites as high-performance electrodes for constructing flexible all-solid-state supercapacitors. ACS Omega 2021, 6, (17), 11427-11435. [CrossRef]

- Weng, M.; Zhou, J.; Ye, Y.; Qiu, H.; Zhou, P.; Luo, Z.; Guo, Q., Self-chargeable supercapacitor made with MXene-bacterial cellulose nanofiber composite for wearable devices. J. Colloid Interface Sci. 2023, 647, 277-286. [CrossRef]

- Fan, L.; Zheng, W.; Yang, Y.; Sun, Y.; Peng, S.; Xu, J.; Yin, G., Bacterial cellulose composites (MXene@TOBC@PPy) for flexible supercapacitors with improved electrochemical performance. Cellulose 2023, 30, (10), 6507-6521. [CrossRef]

- Wannasen, L.; Swatsitang, E.; Pinitsoontorn, S., Flexible supercapacitors based on mesoporous nanocrystalline cobalt ammonium phosphates and bacterial cellulose composite electrode. Int. J. Energy Res. 2021, 45, (2), 3075-3088. [CrossRef]

- Sun, Y.; Yang, Y.; Fan, L.; Zheng, W.; Ye, D.; Xu, J., Polypyrrole/SnCl2 modified bacterial cellulose electrodes with high areal capacitance for flexible supercapacitors. Carbohydr. Polym. 2022, 292, 119679. [CrossRef]

- Li, Q.; Tang, R.; Zhou, H.; Hu, X.; Zhang, S., A high-performance and flexible electrode film based on bacterial cellulose/polypyrrole/nitrogen-doped graphene for supercapacitors. Carbohydr. Polym. 2023, 311, 120754. [CrossRef]

- Chen, S.; Chen, Y.; Li, D.; Xu, Y.; Xu, F., Flexible and Sensitivity-Adjustable Pressure Sensors Based on Carbonized Bacterial Nanocellulose/Wood-Derived Cellulose Nanofibril Composite Aerogels. ACS Appl. Mater. Interfaces 2021, 13, (7), 8754-8763. [CrossRef]

- Yang, H.; Xu, R.; Yu, Y., A facile strategy toward sodium-ion batteries with ultra-long cycle life and high initial Coulombic Efficiency: Free-standing porous carbon nanofiber film derived from bacterial cellulose. Energy Stor. Mater. 2019, 22, 105-112. [CrossRef]

- Liu, L.; Ji, Z.; Zhao, S.; Niu, Q.; Hu, S., Wood-based self-supporting flexible electrode materials for energy storage applications. J. Mater. Chem. A 2021, 9, (10), 6172-6179. [CrossRef]

- Zhou, W.; Wu, T.; Chen, M.; Tian, Q.; Han, X.; Xu, X.; Chen, J., Wood-based electrodes enabling stable, anti-freezing, and flexible aqueous zinc-ion batteries. Energy Stor. Mater. 2022, 51, 286-293. [CrossRef]

- Jiao, Y.; Wan, C.; Li, J., Scalable synthesis and characterization of free-standing supercapacitor electrode using natural wood as a green substrate to support rod-shaped polyaniline. J. Mater. Sci. Mater. Electron. 2017, 28, (3), 2634-2641. [CrossRef]

- Shan, X.; Wu, J.; Zhang, X.; Wang, L.; Yang, J.; Chen, Z.; Yu, J.; Wang, X., Review wood for application in electrochemical energy storage devices. Cell Rep. Phys. Sci. 2021, 2, (12), 100654. [CrossRef]

- Zhang, Z.; Deng, S.; Wang, D.; Qing, Y.; Yan, G.; Li, L.; Wu, Y., Low-tortuosity carbon electrode derived from Wood@ZIF-67 for supercapacitor applications. Chem. Eng. J. 2023, 454, 140410. [CrossRef]

- Zhang, W.; Liu, T.; Mou, J.; Huang, J.; Liu, M., Ultra-thick electrodes based on activated wood-carbon towards high-performance quasi-solid-state supercapacitors. Phys. Chem. Chem. Phys. 2020, 22, (4), 2073-2080. [CrossRef]

- Singh, M.; Gupta, A.; Sundriyal, S.; Jain, K.; Dhakate, S. R., Kraft lignin-derived free-standing carbon nanofibers mat for high-performance all-solid-state supercapacitor. Mater. Chem. Phys. 2021, 264, 124454. [CrossRef]

- Park, J. H.; Rana, H. H.; Lee, J. Y.; Park, H. S., Renewable flexible supercapacitors based on all-lignin-based hydrogel electrolytes and nanofiber electrodes. J. Mater. Chem. A 2019, 7, (28), 16962-16968. [CrossRef]

- Ma, X.; Smirnova, A. L.; Fong, H., Flexible lignin-derived carbon nanofiber substrates functionalized with iron (III) oxide nanoparticles as lithium-ion battery anodes. Mater. Sci. Eng. B 2019, 241, 100-104. [CrossRef]

- Karaaslan, M. A.; Lin, L.-T.; Ko, F.; Renneckar, S., Carbon aerogels from softwood kraft lignin for high performance supercapacitor electrodes. Front. Mater. 2022, 9. [CrossRef]

- Lu, M.; Qian, Y.; Yang, C.; Huang, X.; Li, H.; Xie, X.; Huang, L.; Huang, W., Nitrogen-enriched pseudographitic anode derived from silk cocoon with tunable flexibility for microbial fuel cells. Nano Energy 2017, 32, 382-388. [CrossRef]

- Dong, Y.; Xu, D.; Yu, H.-Y.; Mi, Q.; Zou, F.; Yao, X., Highly sensitive, scrub-resistant, robust breathable wearable silk yarn sensors via interfacial multiple covalent reactions for health management. Nano Energy 2023, 108723. [CrossRef]

- Hu, M.; Hu, T.; Cheng, R.; Yang, J.; Cui, C.; Zhang, C.; Wang, X., MXene-coated silk-derived carbon cloth toward flexible electrode for supercapacitor application. J. Energy Chem. 2018, 27, (1), 161-166. [CrossRef]

- Zhang, S.; Tan, R.; Xu, X.; Iqbal, S.; Hu, J., Fibers/textiles-based flexible sweat sensors: A review. ACS Mater. Lett 2023, 5, (5), 1420-1440. [CrossRef]

- Peng, X.; Zhang, L.; Chen, Z.; Zhong, L.; Zhao, D.; Chi, X.; Zhao, X.; Li, L.; Lu, X.; Leng, K.; Liu, C.; Liu, W.; Tang, W.; Loh, K. P., Hierarchically porous carbon plates derived from wood as bifunctional ORR/OER Electrodes. Adv. Mater. 2019, 31, (16), 1900341. [CrossRef]

- Wang, Y.; Lin, X.; Liu, T.; Chen, H.; Chen, S.; Jiang, Z.; Liu, J.; Huang, J.; Liu, M., Wood-derived hierarchically porous electrodes for high-performance all-solid-state supercapacitors. Adv. Funct. Mater. 2018, 28, (52), 1806207. [CrossRef]

- Song, P.; Chen, C.; Shen, X.; Zeng, S.; Premlatha, S.; Ji, Z.; Zhai, L.; Yuan, A.; Liu, Q., Metal-organic frameworks-derived carbon modified wood carbon monoliths as three-dimensional self-supported electrodes with boosted electrochemical energy storage performance. J. Colloid Interface Sci. 2022, 620, 376-387. [CrossRef]

- Li, L.; Zhong, Q.; Kim, N. D.; Ruan, G.; Yang, Y.; Gao, C.; Fei, H.; Li, Y.; Ji, Y.; Tour, J. M., Nitrogen-doped carbonized cotton for highly flexible supercapacitors. Carbon 2016, 105, 260-267. [CrossRef]

- Du, J.; Liu, L.; Hu, Z.; Yu, Y.; Zhang, Y.; Hou, S.; Chen, A., Raw-cotton-derived N-doped carbon fiber aerogel as an efficient electrode for electrochemical capacitors. ACS Sustain. Chem. Eng. 2018, 6, (3), 4008-4015. [CrossRef]

- Liu, X.; Ji, H.; Peng, B.; Cui, Z.; Liu, Q.; Zhao, Q.; Yang, L.; Wang, D., Cotton textile inspires MoS2@reduced graphene oxide anodes towards high-rate capability or long-cycle stability sodium/lithium-ion batteries. Inorg. Chem. Front. 2023, 10, (1), 267-279. [CrossRef]

- Zhao, G.; Xu, X.; Zhu, G.; Shi, J.; Li, Y.; Zhang, S.; Hossain, M. S. A.; Wu, K. C. W.; Tang, J.; Yamauchi, Y., Flexible nitrogen-doped carbon heteroarchitecture derived from ZIF-8/ZIF-67 hybrid coating on cotton biomass waste with high supercapacitive properties. Microporous Mesoporous Mater. 2020, 303, 110257. [CrossRef]

- Fan, Y.-M.; Song, W.-L.; Li, X.; Fan, L.-Z., Assembly of graphene aerogels into the 3D biomass-derived carbon frameworks on conductive substrates for flexible supercapacitors. Carbon 2017, 111, 658-666. [CrossRef]

- Cheng, P.; Li, T.; Yu, H.; Zhi, L.; Liu, Z.; Lei, Z., Biomass-derived carbon fiber aerogel as a binder-free electrode for high-rate supercapacitors. J. Phys. Chem. C 2016, 120, (4), 2079-2086. [CrossRef]

- Li, Y.; Lei, D.; Yang, S.; Chen, J.; Zhao, Z.; Guo, J.; Xiang, M.; Liu, X.; Bai, W., Facile preparation of flexible porous carbon fibers as self-supporting sulfur cathode hosts for high-performance Li–S batteries. Dalton Trans. 2022, 51, (42), 16206-16214. [CrossRef]

- Xiao, P.-W.; Meng, Q.; Zhao, L.; Li, J.-J.; Wei, Z.; Han, B.-H., Biomass-derived flexible porous carbon materials and their applications in supercapacitor and gas adsorption. Mater. Des. 2017, 129, 164-172. [CrossRef]

- Dai, P.; Zhang, S.; Liu, H.; Yan, L.; Gu, X.; Li, L.; Liu, D.; Zhao, X., Cotton fabrics-derived flexible nitrogen-doped activated carbon cloth for high-performance supercapacitors in organic electrolyte. Electrochim. Acta 2020, 354, 136717. [CrossRef]

- He, D.; Wu, L.; Yao, Y.; Zhang, J.; Huang, Z.-H.; Wang, M.-X., A facile route to high nitrogen-containing porous carbon fiber sheets from biomass-flax for high-performance flexible supercapacitors. Appl. Surf. Sci 2020, 507, 145108. [CrossRef]

- Zhang, Y.; Mao, T.; Cheng, L.; Wu, H.; Wu, R.; Zheng, L., Tunable morphology and property of a MnO2/carbonized cotton textile hybrid electrode for electrochemical capacitors. J. Alloys Compd. 2017, 729, 655-662. [CrossRef]

- Ullah, S.; Yu, J.; Liu, H.; Iqbal, W.; Yang, B.; Li, C.; Zhu, C.; Xu, J., Fabrication of MnO2-carbonized cotton yarn derived hierarchical porous active carbon flexible supercapacitor electrodes for potential applications in cable-type devices. Appl. Surf. Sci 2019, 487, 180-188. [CrossRef]

- Ramandi, S.; Entezari, M. H., Self-supporting electrode for flexible supercapacitors: NiCo-layered double hydroxide derived from metal organic frameworks wrapped on graphene/polyaniline nanotubes@cotton cloth. J Energy Storage 2022, 56, 106106. [CrossRef]

- Chang, H.-S.; Lee, B.-M.; Hwang, A.; Yun, J. M.; Choi, J.-H., Preparation and characterization of free-standing electrode materials from waste cotton fabrics for electric double-layer capacitors. Fibers Polym. 2022, 23, (8), 2188-2195. [CrossRef]

- Wang, Y.; Lu, J.; Lin, X.; Zhang, J.; Li, X.; Fu, Q.; Li, J.; Lu, Y.; Ying, Z., Synthesis of a cotton-derived flexible porous carbon fabric electrode using nickel-salt pore forming for supercapacitors. J. Electron. Mater. 2021, 50, (10), 5557-5566. [CrossRef]

- Chen, R.; Tang, H.; He, P.; Zhang, W.; Dai, Y.; Zong, W.; Guo, F.; He, G.; Wang, X., Interface engineering of biomass-derived carbon used as ultrahigh-energy-density and practical mass-loading supercapacitor electrodes. Adv. Funct. Mater. 2023, 33, (8), 2212078. [CrossRef]

- Mao, D.; Yi, S.; He, Z.; Zhu, Q., Non-woven fabrics derived binder-free gas diffusion catalyst cathode for long cycle Li-O2 batteries. J. Electroanal. Chem. 2022, 915, 116356. [CrossRef]

- Madhu, R.; Kusmartsev, F. V.; Kim, K.-h.; Ahn, H.-J., Flexible and free-standing electrode for high-performance vanadium redox flow battery: Bamboo-like carbon fiber skeleton from textile fabric. Electrochim. Acta 2023, 439, 141619. [CrossRef]

- An, Y.; Luo, C.; Yao, D.; Wen, S.; Zheng, P.; Chi, S.; Yang, Y.; Chang, J.; Deng, Y.; Wang, C., Natural cocoons enabling flexible and stable fabric lithium–sulfur full batteries. Nano-Micro Letters 2021, 13, (1), 84. [CrossRef]

- Sahu, V.; Grover, S.; Tulachan, B.; Sharma, M.; Srivastava, G.; Roy, M.; Saxena, M.; Sethy, N.; Bhargava, K.; Philip, D.; Kim, H.; Singh, G.; Singh, S. K.; Das, M.; Sharma, R. K., Heavily nitrogen doped, graphene supercapacitor from silk cocoon. Electrochim. Acta 2015, 160, 244-253. [CrossRef]

- Liang, M.; Wang, W.; Jiang, Y.; Liao, C.; Long, Q.; Lai, X.; Liao, L., Fabrication of C@Si@G for flexible lithium-ion batteries. J. Alloys Compd. 2021, 878, 160357. [CrossRef]

- Pan, P.; Hu, Y.; Wu, K.; Cheng, Z.; Shen, Z.; Jiang, L.; Mao, J.; Ni, C.; Ge, Y.; Wang, Z., Growth of ZnCo2O4 nanocubes on flexible biochar substrate derived from natural silk waste fabric for lithium-ion battery anode. J. Alloys Compd. 2020, 814, 152306. [CrossRef]

- Xia, T.; Wang, Q.; Wu, W.; Ao, C.; Zheng, Z.; Lu, C.; Chen, Z.; Zhang, W., Fabrication and characterization of MnO2-Coated carbon fabrics from silk for shape-editable supercapacitors. J. Alloys Compd. 2021, 854, 157289. [CrossRef]

- Cai, H.; Wang, Y.; Xu, M.; Cheng, L.; Liu, Z.; Li, Z.; Dai, F., Low cost, green and effective preparation of multifunctional flexible silk fabric electrode with ultra-high capacitance retention. Carbon 2022, 188, 197-208. [CrossRef]

- Shi, Y.; Liu, Y.; Zhang, J.; Huang, X.; Qian, X., In-situ etching activation towards flexible carbonized paper-supported electrode with transition-metal oxides embedded into carbonized cellulose fibers. Ind Crops Prod 2023, 201, 116894. [CrossRef]

- Chen, J.; Xie, J.; Jia, C. Q.; Song, C.; Hu, J.; Li, H., Economical preparation of high-performance activated carbon fiber papers as self-supporting supercapacitor electrodes. Chem. Eng. J. 2022, 450, 137938. [CrossRef]

- Ren, G.; Li, S.; Fan, Z.-X.; Hoque, M. N. F.; Fan, Z., Ultrahigh-rate supercapacitors with large capacitance based on edge oriented graphene coated carbonized cellulous paper as flexible freestanding electrodes. J. Power Sources 2016, 325, 152-160. [CrossRef]

- Wang, Y.; Qu, Q.; Gao, S.; Tang, G.; Liu, K.; He, S.; Huang, C., Biomass derived carbon as binder-free electrode materials for supercapacitors. Carbon 2019, 155, 706-726. [CrossRef]

- Zhou, X.-L.; Ji, Z.-Y.; Wang, J.; Zhang, X.; Guo, X.-F.; Liu, J.; Zhang, P.-P.; Bi, J.-T.; Zhao, Y.-Y.; Yuan, J.-S., Highly efficient recovery of bromine from shale gas wastewater by selective electrochemical oxidation. J. Environ. Chem. Eng. 2022, 10, (3), 107946. [CrossRef]

- Zhang, J.; Xiang, J.; Dong, Z.; Liu, Y.; Wu, Y.; Xu, C.; Du, G., Biomass derived activated carbon with 3D connected architecture for rechargeable lithium−sulfur batteries. Electrochim. Acta 2014, 116, 146-151. [CrossRef]

- Chhetri, K.; Subedi, S.; Muthurasu, A.; Ko, T. H.; Dahal, B.; Kim, H. Y., A review on nanofiber reinforced aerogels for energy storage and conversion applications. J Energy Storage 2022, 46, 103927. [CrossRef]

- Lee, J.-H.; Park, S.-J., Recent advances in preparations and applications of carbon aerogels: A review. Carbon 2020, 163, 1-18. [CrossRef]

- Wu, Z.-Y.; Liang, H.-W.; Hu, B.-C.; Yu, S.-H., Emerging carbon-nanofiber aerogels: Chemosynthesis versus biosynthesis. Angew. Chem. Int. Ed. 2018, 57, (48), 15646-15662. [CrossRef]

- Hao, X.; Wang, J.; Ding, B.; Wang, Y.; Chang, Z.; Dou, H.; Zhang, X., Bacterial-cellulose-derived interconnected meso-microporous carbon nanofiber networks as binder-free electrodes for high-performance supercapacitors. J. Power Sources 2017, 352, 34-41. [CrossRef]

- Huang, Y.; Lin, Z.; Zheng, M.; Wang, T.; Yang, J.; Yuan, F.; Lu, X.; Liu, L.; Sun, D., Amorphous Fe2O3 nanoshells coated on carbonized bacterial cellulose nanofibers as a flexible anode for high-performance lithium ion batteries. J. Power Sources 2016, 307, 649-656. [CrossRef]

- Huang, Y.; Zheng, M.; Lin, Z.; Zhao, B.; Zhang, S.; Yang, J.; Zhu, C.; Zhang, H.; Sun, D.; Shi, Y., Flexible cathodes and multifunctional interlayers based on carbonized bacterial cellulose for high-performance lithium–sulfur batteries. J. Mater. Chem. A 2015, 3, (20), 10910-10918. [CrossRef]

- Cao, M.; Feng, Y.; Wang, D.; Xie, Y.; Gu, X.; Yao, J., Construction of oxygen vacancy-rich ZnO@carbon nanofiber aerogels as a free-standing anode for superior lithium storage. J. Colloid Interface Sci. 2023, 644, 177-185. [CrossRef]

- Anjan, A.; Bharti, V. K.; Sharma, C. S.; Khandelwal, M., Carbonized bacterial cellulose-derived binder-free, flexible, and free-standing cathode host for high-performance stable potassium–sulfur batteries. ACS Appl. Energy Mater. 2023, 6, (5), 3042-3051. [CrossRef]

- Li, H.; Yuan, D.; Tang, C.; Wang, S.; Sun, J.; Li, Z.; Tang, T.; Wang, F.; Gong, H.; He, C., Lignin-derived interconnected hierarchical porous carbon monolith with large areal/volumetric capacitances for supercapacitor. Carbon 2016, 100, 151-157. [CrossRef]

- Cai, T.; Kuang, L.; Wang, C.; Jin, C.; Wang, Z.; Sun, Q., Cellulose as an adhesive for the synthesis of carbon aerogel with a 3D hierarchical network structure for capacitive energy storage. ChemElectroChem 2019, 6, (9), 2586-2594. [CrossRef]

- Liu, Q.; Chen, Z.; Jing, S.; Zhuo, H.; Hu, Y.; Liu, J.; Zhong, L.; Peng, X.; Liu, C., A foldable composite electrode with excellent electrochemical performance using microfibrillated cellulose fibers as a framework. J. Mater. Chem. A 2018, 6, (41), 20338-20346. [CrossRef]

- Chen, Y.; Zhang, L.; Yang, Y.; Pang, B.; Xu, W.; Duan, G.; Jiang, S.; Zhang, K., Recent progress on nanocellulose aerogels: Preparation, modification, composite Fabrication, applications. Adv. Mater. 2021, 33, (11), 2005569. [CrossRef]

- Zheng, Q.; Cai, Z.; Ma, Z.; Gong, S., Cellulose nanofibril/reduced graphene oxide/carbon nanotube hybrid aerogels for highly flexible and all-solid-state supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, (5), 3263-3271. [CrossRef]

- Xia, L.; Li, X.; Wu, Y.; Hu, S.; Liao, Y.; Huang, L.; Qing, Y.; Lu, X., Electrodes derived from carbon fiber-reinforced cellulose nanofiber/multiwalled carbon nanotube hybrid aerogels for high-energy flexible asymmetric supercapacitors. Chem. Eng. J. 2020, 379, 122325. [CrossRef]

- Yu, M.; Han, Y.; Li, Y.; Li, J.; Wang, L., Polypyrrole-anchored cattail biomass-derived carbon aerogels for high performance binder-free supercapacitors. Carbohydr. Polym. 2018, 199, 555-562. [CrossRef]

- Zhu, S.; Taberna, P.-L.; Zhao, N.; Simon, P., Salt-template synthesis of mesoporous carbon monolith for ionogel-based supercapacitors. Electrochem commun 2018, 96, 6-10. [CrossRef]

- Wu, K.; Zhang, L.; Yuan, Y.; Zhong, L.; Chen, Z.; Chi, X.; Lu, H.; Chen, Z.; Zou, R.; Li, T.; Jiang, C.; Chen, Y.; Peng, X.; Lu, J., An iron-decorated carbon aerogel for rechargeable flow and flexible zn–air batteries. Adv. Mater. 2020, 32, (32), 2002292. [CrossRef]

- Wang, J.; He, J.; Kan, D.; Chen, K.; Song, M.; Huo, W., MXene film prepared by vacuum-assisted filtration: Properties and applications. In Crystals, 2022; Vol. 12. [CrossRef]

- How, Y. Y.; Numan, A.; Mustafa, M. N.; Walvekar, R.; Khalid, M.; Mubarak, N. M., A review on the binder-free electrode fabrication for electrochemical energy storage devices. J Energy Storage 2022, 51, 104324. [CrossRef]

- Chen, J.; Fang, K.; Chen, Q.; Xu, J.; Wong, C.-P., Integrated paper electrodes derived from cotton stalks for high-performance flexible supercapacitors. Nano Energy 2018, 53, 337-344. [CrossRef]

- Liu, T.; Kavian, R.; Chen, Z.; Cruz, S. S.; Noda, S.; Lee, S. W., Biomass-derived carbonaceous positive electrodes for sustainable lithium-ion storage. Nanoscale 2016, 8, (6), 3671-3677. [CrossRef]

- Xu, H.; Zhu, J.; Xu, M.; Lei, Z.; Hu, Q.; Jin, X., Flexible and alternately layered high electrochemical active electrode based on MXene, carboxymethylcellulose, and carbon nanotube for asymmetric micro-supercapacitors. J. Colloid Interface Sci. 2023, 645, 974-984. [CrossRef]

- Yang, P.; Xi, X.; Huang, T.; Zhong, Q.; Jiang, B.; Liu, R.; Wu, D., An acid-assisted vacuum filtration approach towards flexible PDI/SWCNT cathodes for highly stable organic lithium ion batteries. Electrochim. Acta 2020, 338, 135771. [CrossRef]

- Li, Y.; Du, Y.-F.; Sun, G.-H.; Cheng, J.-Y.; Song, G.; Song, M.-X.; Su, F.-Y.; Yang, F.; Xie, L.-J.; Chen, C.-M., Self-standing hard carbon anode derived from hyper-linked nanocellulose with high cycling stability for lithium-ion batteries. EcoMat 2021, 3, (2), e12091. [CrossRef]

- Zhang, Y.; Hui, S.; Lin, X.; Ying, Z.; Li, Y.; Xie, J., Novel effective strategy for high-performance biomass-based super-flexible hierarchically porous carbon fibrous film electrode for supercapacitors. J. Alloys Compd. 2021, 883, 160713. [CrossRef]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M. E.; Tan, L., A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro-Centrifugal Spinning. Macromol Mater Eng 2023, 308, (3), 2200502. [CrossRef]

- Chen, J.; Yu, Z.; Li, C.; Lv, Y.; Hong, S.; Hu, P.; Liu, Y., Review of the Principles, Devices, Parameters, and Applications for Centrifugal Electrospinning. Macromol Mater Eng 2022, 307, (8), 2200057. [CrossRef]

- Wang, Y.; Gan, R.; Zhao, S.; Ma, W.; Zhang, X.; Song, Y.; Ma, C.; Shi, J., B, N, F tri-doped lignin-derived carbon nanofibers as an efficient metal-free bifunctional electrocatalyst for ORR and OER in rechargeable liquid/solid-state Zn-air batteries. Appl. Surf. Sci 2022, 598, 153891. [CrossRef]

- Tao, L.; Zheng, Y.; Zhang, Y.; Ma, H.; Di, M.; Zheng, Z., Liquefied walnut shell-derived carbon nanofibrous mats as highly efficient anode materials for lithium ion batteries. RSC Advances 2017, 7, (43), 27113-27120. [CrossRef]

- Wang, T.; Rony, A. H.; Sun, K.; Gong, W.; He, X.; Lu, W.; Tang, M.; Ye, R.; Yu, J.; Kang, L.; Luo, H.; Smith, S. J.; Eddings, E. G.; Fan, M., Carbon nanofibers prepared from solar pyrolysis of pinewood as binder-free electrodes for flexible Supercapacitors. Cell Rep. Phys. Sci. 2020, 1, (6), 100079. [CrossRef]

- Oh, S.-I.; Kim, J.-C.; Kim, D.-W., Cellulose-derived tin-oxide-nanoparticle-embedded carbon fibers as binder-free flexible Li-ion battery anodes. Cellulose 2019, 26, (4), 2557-2571. [CrossRef]

- Wu, Y.; Xu, G.; Zhang, W.; Song, C.; Wang, L.; Fang, X.; Xu, L.; Han, S.; Cui, J.; Gan, L., Construction of ZIF@electrospun cellulose nanofiber derived N doped metallic cobalt embedded carbon nanofiber composite as binder-free supercapacitance electrode. Carbohydr. Polym. 2021, 267, 118166. [CrossRef]

- Panith, P.; Butnoi, P.; Intasanta, V., The hybrid structure of nanoflower-like CoxMnyNizO4 nanoparticles embedded biomass-lignin carbon nanofibers as free-standing and binder-free electrodes for high performance supercapacitors. J. Alloys Compd. 2022, 918, 165659. [CrossRef]

- Zhang, R.; Wang, L.; Zhao, J.; Guo, S., Effects of sodium alginate on the composition, morphology, and electrochemical properties of electrospun carbon nanofibers as electrodes for supercapacitors. ACS Sustain. Chem. Eng. 2019, 7, (1), 632-640. [CrossRef]

- Li, Q.; Zhu, Y. Q.; Eichhorn, S. J., Structural supercapacitors using a solid resin electrolyte with carbonized electrospun cellulose/carbon nanotube electrodes. J. Mater. Sci. 2018, 53, (20), 14598-14607. [CrossRef]

- Hu, W.; Xiang, R.; Lin, J.; Cheng, Y.; Lu, C., Lignocellulosic biomass-derived carbon electrodes for flexible supercapacitors: An Overview. In Materials, 2021; Vol. 14. [CrossRef]

- Yang, H., A comparative study of supercapacitor capacitance characterization methods. J Energy Storage 2020, 29, 101316. [CrossRef]

- Wang, Z.; Zhu, M.; Pei, Z.; Xue, Q.; Li, H.; Huang, Y.; Zhi, C., Polymers for supercapacitors: Boosting the development of the flexible and wearable energy storage. Mater. Sci. Eng. R Rep 2020, 139, 100520. [CrossRef]

- Bhat, M. Y.; Hashmi, S. A.; Khan, M.; Choi, D.; Qurashi, A., Frontiers and recent developments on supercapacitor’s materials, design, and applications: Transport and power system applications. J Energy Storage 2023, 58, 106104. [CrossRef]

- Wang, G.; Liang, R.; Liu, L.; Zhong, B., Improving the specific capacitance of carbon nanotubes-based supercapacitors by combining introducing functional groups on carbon nanotubes with using redox-active electrolyte. Electrochim. Acta 2014, 115, 183-188. [CrossRef]

- Bai, X.; Hu, X.; Zhou, S.; Yan, J.; Sun, C.; Chen, P.; Li, L., In situ polymerization and characterization of grafted poly (3,4-ethylenedioxythiophene)/multiwalled carbon nanotubes composite with high electrochemical performances. Electrochim. Acta 2013, 87, 394-400. [CrossRef]

- Madhu, R.; Periasamy, A. P.; Schlee, P.; Hérou, S.; Titirici, M.-M., Lignin: A sustainable precursor for nanostructured carbon materials for supercapacitors. Carbon 2023, 207, 172-197. [CrossRef]

- Xiao, J.; Li, H.; Zhang, H.; He, S.; Zhang, Q.; Liu, K.; Jiang, S.; Duan, G.; Zhang, K., Nanocellulose and its derived composite electrodes toward supercapacitors: Fabrication, properties, and challenges. J.Bioresour.Bioprod. 2022, 7, (4), 245-269. [CrossRef]

- Kang, W.; Zeng, L.; Liu, X.; He, H.; Li, X.; Zhang, W.; Lee, P. S.; Wang, Q.; Zhang, C., Insight into cellulose nanosizing for advanced electrochemical energy storage and conversion: A Review. Electrochem. Energy Rev. 2022, 5, (3), 8. [CrossRef]

- Zhuo, H.; Hu, Y.; Chen, Z.; Zhong, L., Cellulose carbon aerogel/PPy composites for high-performance supercapacitor. Carbohydr. Polym. 2019, 215, 322-329. [CrossRef]

- Xiong, C.; Li, B.; Duan, C.; Dai, L.; Nie, S.; Qin, C.; Xu, Y.; Ni, Y., Carbonized wood cell chamber-reduced graphene oxide@PVA flexible conductive material for supercapacitor, strain sensing and moisture-electric generation applications. Chem. Eng. J. 2021, 418, 129518. [CrossRef]

- Wu, Q.; Gao, M.; Jiang, C.; Gu, X.; Wang, Z.; Huang, L.; Yu, S., Carbon-carbon dense network composite with hierarchical structure for additive-free and high volumetric performance supercapacitor. J. Power Sources 2021, 497, 229878. [CrossRef]

- Wang, C.; Xiong, Y.; Wang, H.; Sun, Q., All-round utilization of biomass derived all-solid-state asymmetric carbon-based supercapacitor. J. Colloid Interface Sci. 2018, 528, 349-359. [CrossRef]

- Francis, M. K.; Bhargav, P. B.; Ramesh, A.; Ahmed, N.; Balaji, C., Electrochemical performance analysis of NiMoO4/α-MoO3 composite as anode material for high capacity lithium-ion batteries. Applied Physics A 2022, 128, (2), 132. [CrossRef]

- Urbonaite, S.; Poux, T.; Novák, P., Progress Towards Commercially Viable Li–S Battery Cells. Adv. Energy Mater. 2015, 5, (16), 1500118. [CrossRef]

- Liang, Y.; Zhao, C. Z.; Yuan, H.; Chen, Y.; Zhang, W.; Huang, J. Q.; Yu, D.; Liu, Y.; Titirici, M. M.; Chueh, Y. L., A review of rechargeable batteries for portable electronic devices. InfoMat 2019, 1, (1), 6-32. [CrossRef]

- Wang, H.; Zhang, W.; Xu, J.; Guo, Z., Advances in polar materials for lithium–sulfur batteries. Adv. Funct. Mater. 2018, 28, (38), 1707520. [CrossRef]

- Gao, Z.; Zhang, Y.; Song, N.; Li, X., Towards flexible lithium-sulfur battery from natural cotton textile. Electrochim. Acta 2017, 246, 507-516. [CrossRef]

- Liu, T.; Sun, X.; Sun, S.; Niu, Q.; Liu, H.; Song, W.; Cao, F.; Li, X.; Ohsaka, T.; Wu, J., A robust and low-cost biomass carbon fiber@SiO2 interlayer for reliable lithium-sulfur batteries. Electrochim. Acta 2019, 295, 684-692. [CrossRef]

- Xi, K.; He, D.; Harris, C.; Wang, Y.; Lai, C.; Li, H.; Coxon, P. R.; Ding, S.; Wang, C.; Kumar, R. V., Enhanced sulfur transformation by multifunctional FeS2/FeS/S composites for high-volumetric capacity cathodes in lithium–sulfur batteries. Adv. Sci. 2019, 6, (6), 1800815. [CrossRef]

- Tu, J.; Li, H.; Lan, T.; Zeng, S.-Z.; Zou, J.; Zhang, Q.; Zeng, X., Facile synthesis of TiN nanocrystals/graphene hybrid to chemically suppress the shuttle effect for lithium-sulfur batteries. J. Alloys Compd. 2020, 822, 153751. [CrossRef]

- Sun, W.; Liu, C.; Li, Y.; Luo, S.; Liu, S.; Hong, X.; Xie, K.; Liu, Y.; Tan, X.; Zheng, C., Rational construction of Fe2N@ C yolk–shell nanoboxes as multifunctional hosts for ultralong lithium–sulfur batteries. ACS nano 2019, 13, (10), 12137-12147. [CrossRef]

- Wang, W.; Xu, H.; Liu, Y., Platform ruralism: Digital platforms and the techno-spatial fix. Geoforum 2022, 131, 12-19. [CrossRef]

- Ding, P.; Yan, T.; Li, K.; Wu, Q.; Zhu, X.; Chen, H.; Ju, A., Freestanding TiO@heteroatom-doped hollow multi-channel carbon fibers for lithium-sulfur batteries. J. Alloys Compd. 2022, 928, 167056. [CrossRef]

- Fang, X.; Zhang, M.; Gao, Y.; Guo, J.; Li, Y., The polyethylene glycol@MoO3/canbon nanotubes/S composite fixing polysulfides for lithium-sulfur batteries. J Solid State Chem 2022, 307, 122749. [CrossRef]

- Luo, C.; Zhu, H.; Luo, W.; Shen, F.; Fan, X.; Dai, J.; Liang, Y.; Wang, C.; Hu, L., Atomic-Layer-Deposition functionalized carbonized mesoporous wood fiber for high sulfur loading lithium sulfur batteries. ACS Appl. Mater. Interfaces 2017, 9, (17), 14801-14807. [CrossRef]

- Wang, Q.; Shang, L.; Shi, R.; Zhang, X.; Zhao, Y.; Waterhouse, G. I. N.; Wu, L.-Z.; Tung, C.-H.; Zhang, T., NiFe layered double hydroxide nanoparticles on Co,N-codoped carbon nanoframes as efficient bifunctional catalysts for rechargeable zinc–air batteries. Adv. Energy Mater. 2017, 7, (21), 1700467. [CrossRef]

- Liu, X.; Wang, L.; Yu, P.; Tian, C.; Sun, F.; Ma, J.; Li, W.; Fu, H., A stable bifunctional catalyst for rechargeable zinc–air batteries: Iron–cobalt nanoparticles embedded in a nitrogen-doped 3D carbon matrix. Angew. Chem. Int. Ed. 2018, 57, (49), 16166-16170. [CrossRef]

- Aasen, D.; Clark, M. P.; Ivey, D. G., (Co,Fe)3O4 decorated nitrogen-doped carbon nanotubes in nano-composite gas diffusion layers as highly stable bifunctional catalysts for rechargeable zinc-air batteries. Batteries Supercaps 2020, 3, (2), 174-184. [CrossRef]

- Li, Y.; Zhong, C.; Liu, J.; Zeng, X.; Qu, S.; Han, X.; Deng, Y.; Hu, W.; Lu, J., Atomically thin mesoporous Co3O4 layers strongly coupled with N-rGO nanosheets as high-performance bifunctional catalysts for 1D knittable zinc–air batteries. Adv. Mater. 2018, 30, (4), 1703657. [CrossRef]

- Liu, Q.; Wang, Y.; Dai, L.; Yao, J., Scalable fabrication of nanoporous carbon fiber films as bifunctional catalytic electrodes for flexible zn-air batteries. Adv. Mater. 2016, 28, (15), 3000-3006. [CrossRef]

- Liang, H.-W.; Wu, Z.-Y.; Chen, L.-F.; Li, C.; Yu, S.-H., Bacterial cellulose derived nitrogen-doped carbon nanofiber aerogel: An efficient metal-free oxygen reduction electrocatalyst for zinc-air battery. Nano Energy 2015, 11, 366-376. [CrossRef]

- Ma, T. Y.; Ran, J.; Dai, S.; Jaroniec, M.; Qiao, S. Z., Phosphorus-doped graphitic carbon nitrides grown in situ on carbon-fiber paper: Flexible and reversible oxygen electrodes. Angewandte Chemie 2015, 127, (15), 4729-4733. [CrossRef]

- Son, H. J.; Cho, Y. R.; Park, Y.-E.; Ahn, S. H., Flexible, compressible, versatile biomass-derived freestanding carbon monoliths as binder- and substrate-free tri-functional electrodes for solid-state zinc-air batteries and overall water splitting. Appl. Catal. B 2022, 304, 120977. [CrossRef]

- Pang, H.; Sun, P.; Gong, H.; Zhang, N.; Cao, J.; Zhang, R.; Luo, M.; Li, Y.; Sun, G.; Li, Y.; Deng, J.; Gao, M.; Wang, M.; Kong, B., Wood-derived bimetallic and heteroatomic hierarchically porous carbon aerogel for rechargeable flow zn–air batteries. ACS Appl. Mater. Interfaces 2021, 13, (33), 39458-39469. [CrossRef]

- Cui, X.; Liu, Y.; Han, G.; Cao, M.; Han, L.; Zhou, B.; Mehdi, S.; Wu, X.; Li, B.; Jiang, J., Wood-derived integral air electrode for enhanced interfacial electrocatalysis in rechargeable zinc–air battery. Small 2021, 17, (38), 2101607. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).