Submitted:

06 August 2023

Posted:

08 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

2.1. Research Problem

- Building Orientation: BIM can help optimize the building’s orientation to maximize natural lighting, minimize heat gain or loss, and enhance energy efficiency.

- Building Massing: BIM enables the exploration and optimization of building massing strategies to improve energy performance, ventilation, and occupant comfort.

- Daylight Analysis: BIM tools can simulate and analyze the availability and distribution of natural daylight within the building, allowing designers to optimize window placements and shading devices for energy savings and occupant well-being.

- Water Harvesting: BIM can assist in the design and implementation of water harvesting systems, such as rainwater collection and graywater recycling, to reduce reliance on external water sources and promote sustainable water management.

- Energy Modeling: BIM facilitates energy modeling and simulation, enabling designers to assess the energy performance of the building and identify opportunities for energy efficiency improvements through equipment selection, insulation, and HVAC system optimization.

- Materials: BIM can incorporate databases of sustainable materials, allowing designers to evaluate and select environmentally friendly materials based on their life cycle analysis, embodied carbon, and other sustainability criteria [24].

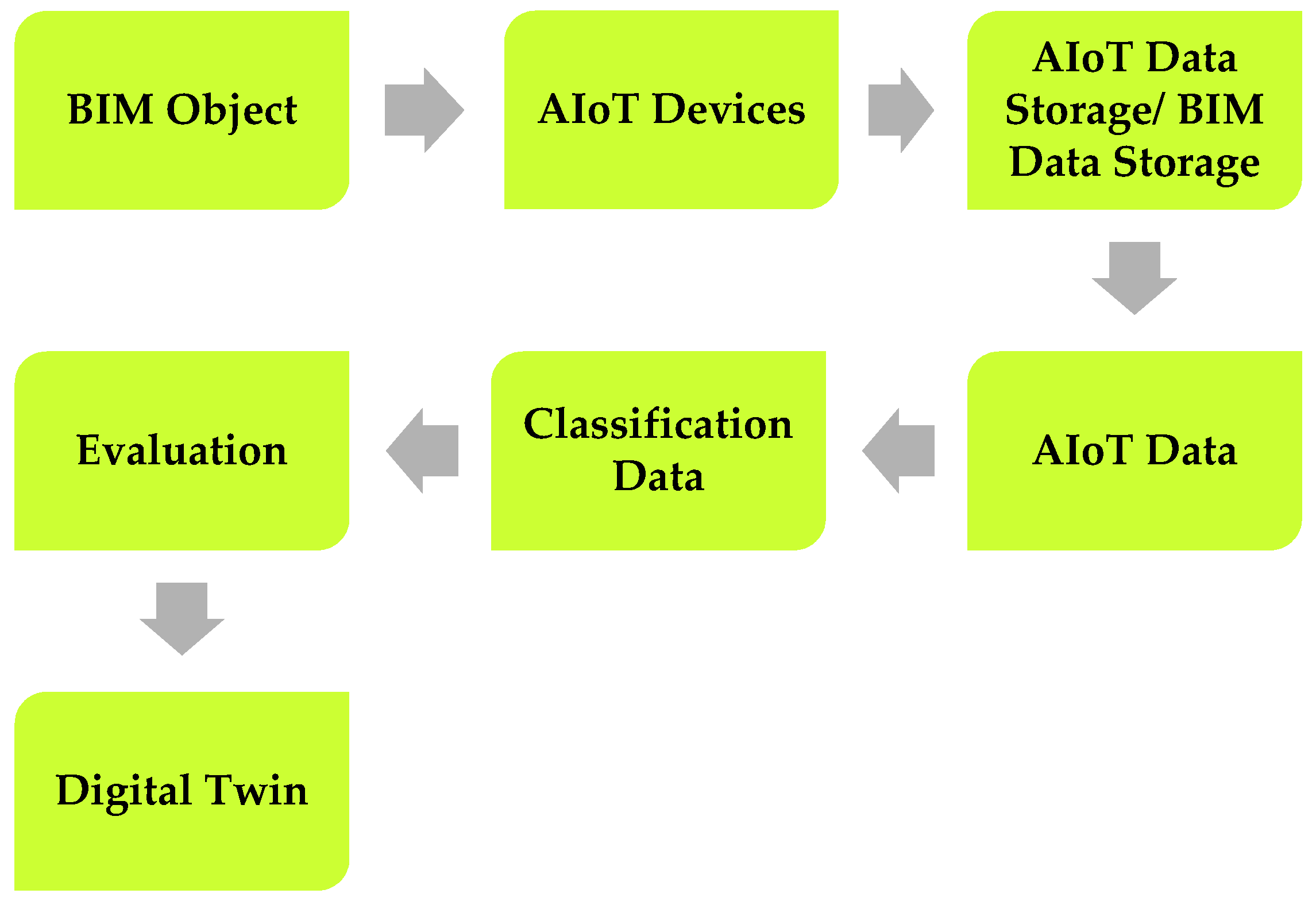

2.2. Strategies to Integration of BIM and AIoT

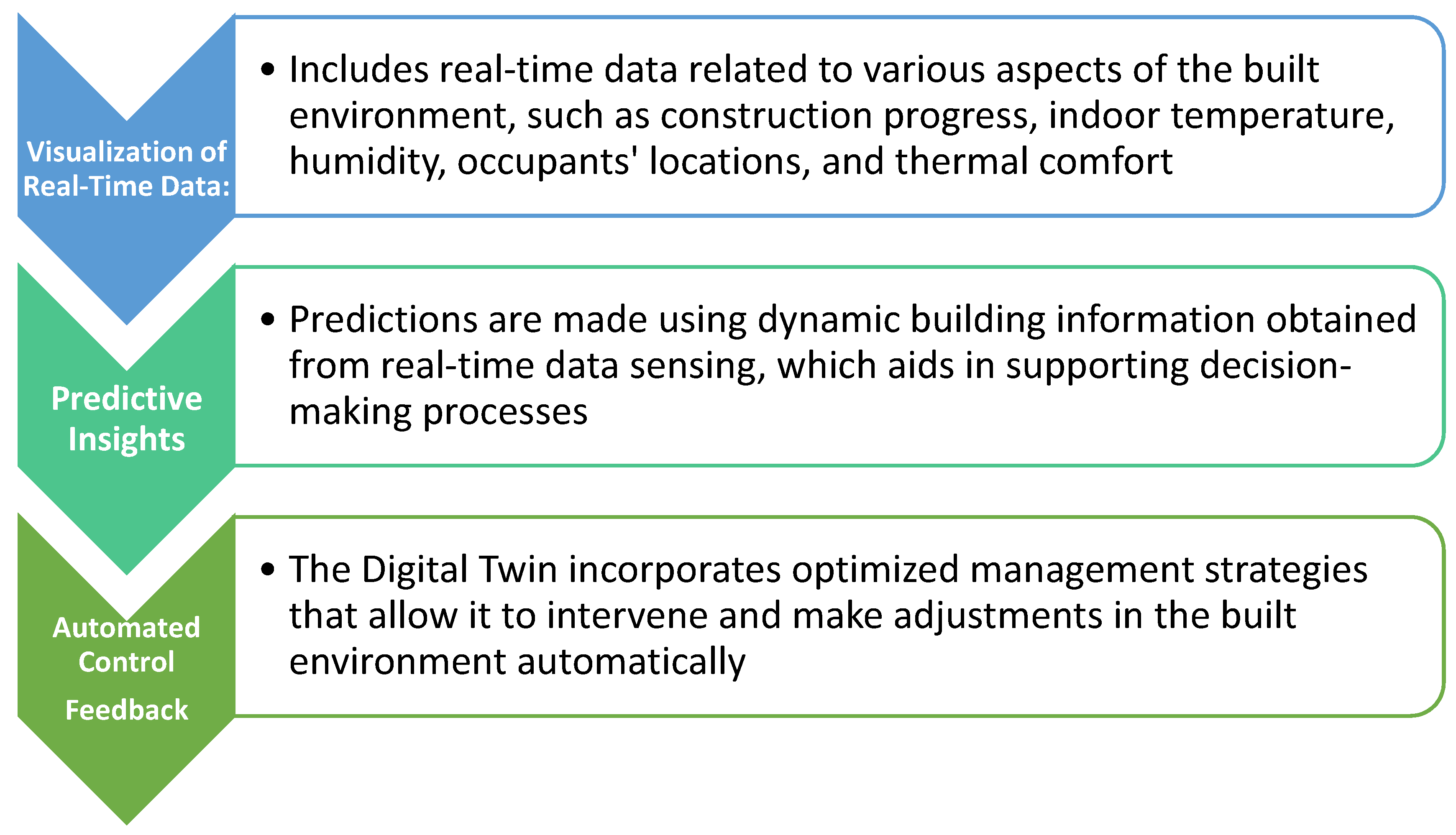

2.3. Digital Twin Model

3. Results

3.1. Importance of a Digital Platform in Project Evaluation

- Managing Information: The platform should enable easy access and efficient handling of project data, as well as real estate market information.

- Dealing with Infrastructure Challenges: It should provide access to various digital resources required for smooth infrastructure management.

- Handling Technological Requirements: The platform should offer specialized tools and technologies essential for construction processes.

- Streamlining Corporate Processes: It should optimize control procedures to enhance the overall efficiency of the construction project.

3.2. The Stages of Digital Twin Model Development

- Preparation Stage: This initial phase involves design and decision-making processes. It encompasses planning, conceptualization, and the formulation of crucial decisions that will shape the project’s direction.

- Construction Stage: During this phase, the actual construction of the project takes place. It involves the implementation of the plans and designs prepared in the previous stage.

- Usage Stage: Once the construction is complete, the facility enters the usage stage, where it is put into operation. This stage includes ongoing maintenance, regular operations, and any refurbishment or renovation necessary to ensure smooth functionality.

- End Stage: As the facility nears the end of its useful life or when it becomes obsolete, the deconstruction process begins. This stage involves dismantling or demolishing the structure in a safe and environmentally responsible manner.

- Complete Life Cycle: The complete life cycle encompasses all the stages mentioned above, from the initial preparation to the final deconstruction. It represents the entirety of the project’s existence, from inception to closure.

3.3. Implementation and Further Development of Digital Twin Model

- Development of a cloud platform: This platform serves as a hosting and sharing hub for scan-to-BIM projects. It effectively manages large volumes of data, including point clouds from laser scanning and digital photogrammetry (primary data sources), as well as reports, digital drawings, and multimedia (secondary data sources).

- Enhanced workflow efficiency: The integration of the platform improves workflow, coordination, and collaboration among stakeholders. It provides a user-friendly 3D visualization interface, streamlining processes.

- Improved accessibility of Virtual Reality (VR) projects: The platform facilitates sharing of VR projects by allowing the distribution of executable files that can be installed on dedicated applications.

- Augmented Reality (AR) object implementation and sharing: The platform supports the integration and sharing of AR objects, enhancing the overall user experience.

- Enhanced interoperability of digital models: The platform promotes interoperability by utilizing specific proprietary and open-source exchange formats, enabling seamless data exchange between different software and systems.

- Diversification of digital uses: The platform enables various digital uses, including smart glasses, VR headsets, PCs, mobile phones, and tablets, catering to different user preferences and device capabilities.

4. Discussion

5. Conclusions

References

- Webb AL. Energy retrofits in historic and traditional buildings: A review of problems and methods. Renewable and Sustainable Energy Reviews. 2017 Sep;77:748–59. [CrossRef]

- Durante A, Lucchi E, Maturi L. Building integrated photovoltaic in heritage contexts award: An overview of best practices in Italy and Switzerland. IOP Conf Ser: Earth Environ Sci. 2021 Oct 1;863(1):012018. [CrossRef]

- Khurudzhi Ye. V., Chashyn D. Yu., Dikarev K. B., Kutsenko-Skokova A. O., Implementing Building Information Modeling in retrofitting of building projects and energy efficient construction 2023 http://srd.pgasa.dp.ua:8080/bitstream/123456789/10743/1/KHURUDZHI.pdf. [CrossRef]

- Petro Sankov, Yuriy Zakharov, Nataliia Tkach, Dmytro Chashyn & Oleg Yurin, Innovative Program of Quality Assessment of Cities for the Compliance with «Smart City» Category 2023 https://link.springer.com/chapter/10.1007/978-3-031-17385-1_41. [CrossRef]

- Christine Ezzat Danial, Ayman Hassaan Ahmed Mahmoud, Manal Yehia Tawfik., (2023) Methodology for retrofitting energy in existing office buildings using building information modelling programs, p. 2-4. [CrossRef]

- S. Stellaccia,⁎, V. Ratoa, E. Polettib, G. Vasconcelosb, G. Borsoic Multi-criteria analysis of rehabilitation techniques for traditional timber frame walls in Pombalino buildings (Lisbon) 2018.

- Viktória Sándor, Mathias Bank, Kristina Schinegger, and Stefan Rutzinger Collapsing Complexities: Encoding Multidimensional Architecture Models into Images (2023), p. 2-3.

- Hirschberg U, Hovestadt L, Fritz O (eds) (2020) Atlas of digital architecture: Terminology, concepts, methods, tools, examples, phenomena. Birkhauser, Boston.

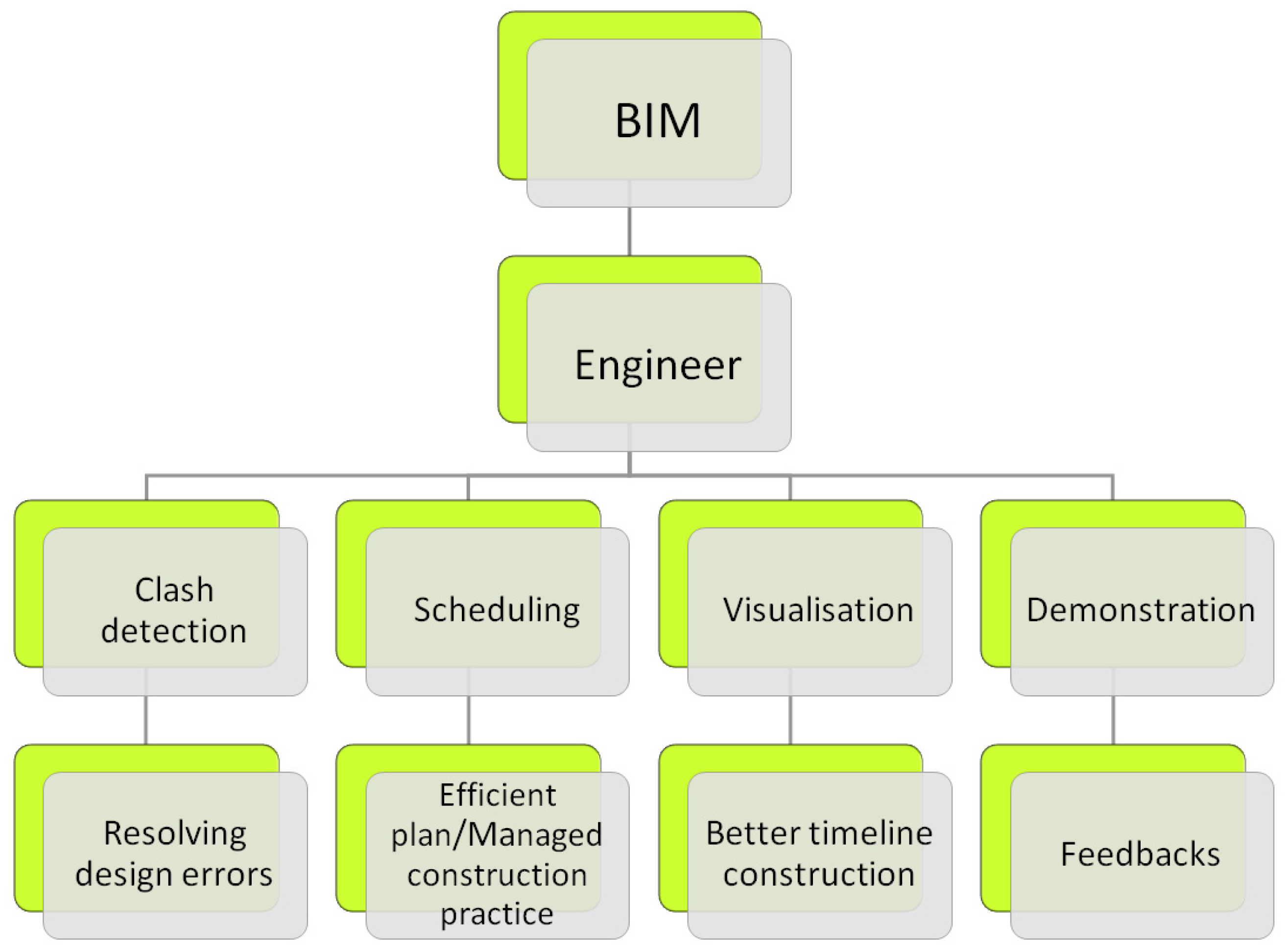

- Alexa Mitchell, BIM Uses and Model-Based Reviews, Transportation research circular E-C282 Building Information Modeling for Bridges and Structures (2022) 43, p. 30-36.

- Jingming Li. Using Text Understanding to Create Formatted Semantic Web from BIM, Hybrid Intelligence, Proceedings of the 4th International Conference on Computational Design and Robotic Fabrication (2022) 548, p. 212-214. [CrossRef]

- Shao, C.; Sun, G. Principles of the Internet of Things and Industry Applications; Tsinghua University Press: Beijing, China, 2013; pp. 320–323.

- Štefaniˇc, M.; Stankovski, V. A Review of Technologies and Applications for Smart Construction. Proc. Inst. Civ. Eng.-Civ. Eng. (2019) 172, p. 83–87. [CrossRef]

- Integration for Smart and Sustainable Environments: A Review. J. Clean. Prod. 2021, 312, 127716.

- S. Tang, D. R. Shelden, C. M. Eastman, P. Pishdad-Bozorgi, and X. Gao, “A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends,” Automation in Construction vol 101, (2019), pp. 127-139. [CrossRef]

- E. Corry, J. O’Donnell, E. Curry, D. Coakley, P. Pauwels, M. Keane, Using semantic web technologies to access soft AEC data, Adv. Eng. Inform. (2014), p. 370–380. [CrossRef]

- Denys Chernysheva, Serhii Dolhopolova, Tetyana Honcharenkoa, Viktor Sapaieva and Maksym Delembovskyi. Digital Object Detection of Construction Site Based on Building Information Modeling and Artificial Intelligence Systems, (2022), p. 3-5.

- T. Honcharenko, V. Mihaylenko, Y. Borodavka, E. Dolya, and V. Savenko, “Information tools for project management of the building territory at the stage of urban planning,” CEUR Workshop Proceedings, 2851, (2021), p. 22-33.

- Fabrizio Banfi, Raffaella Brumana, Graziano Salvalai and Mattia Previtali, Digital Twin and Cloud BIM-XR Platform Development: From Scan-to-BIM-to-DT Process to a 4D Multi-User Live App to Improve Building Comfort, Efficiency and Costs, (2022), 26, p. 3-6. [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and Trends in Internet of Things (IoT) Research: Future Applications in the Construction Industry. ECAM (2020), 28, p. 457–481. [CrossRef]

- Yali Chen, Xiaozi Wang, Zhen Liu, Jia Cui, Mohamed Osmani and Peter Demian, Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building (2023), 25, p. 3-5. [CrossRef]

- Horn, R.a., 2020. The BIM2LCA approach: An industry foundation classes (IFC)-based interface to integrate life cycle assessment in integral planning. Sustainability 12, 6558. [CrossRef]

- Timothy O. Olawumi, Daniel W.M. Chan, Identifying and prioritizing the benefits of integrating BIM and sustainability practices in construction projects: A Delphi survey of international experts, Sustainable Cities and Society, Volume 40, 2018, Pages 16-27, ISSN 2210-6707. [CrossRef]

- Yasmin Elkwisni, Ahmed E. ElMaidawy, Historical building information modelling (HBIM) integration with environmental analysis for green rating systems, Mansoura Engineering Journal, 48 (2023), p. 11-15. [CrossRef]

- M. Deng, C. Menassa, and V. Kamat, “From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry,” Journal of Information Technology in Construction, vol. 26, pp. 58-83, March 2021. [CrossRef]

- T. Honcharenko, K. Kyivska, O. Serpinska, V. Savenko, D. Kysliuk, and Y. Orlyk, “Digital transformation of the construction design based on the Building Information Modeling andInternet of Things,” CEUR Workshop Proceedings, ITTAP, vol. 3039, pp. 267–279, November 2021. URL: https://cutt.ly/UCA8A7Z.

- Hafez Salleh, Yap Jia Jee, Zulkiflee Abdul-Samad, Mahanim Hanidv & Nor Azlinda Mohamed Sabli, Implementation of Heritage Building Information Modelling (HBIM) for construction and demolition waste management, Journal of the Malaysian Institute of Planners, vol. 20, issue 5(2022), pp. 302–315. [CrossRef]

| Strategy for inventing | Solutions | Advantages | Limitations |

|---|---|---|---|

|

a) Removing additional (newly added) storeys through demolition. b) Eliminating incompatible elements or unsuitable structures. c) Eliminating (newly created) openings and making alterations to the interior layout. |

Preserving the original layout and safeguarding the architectural value of the building. | Possible inconveniences to users, reduction in floor area, reliance on skilled craftsmanship, and potential decrease in financial value. |

| |||

|

a) Enhancing the rigidity of walls and floors. b) Constructing new walls or structures. |

Potential inconveniences to users, the need for skilled craftsmanship, and a decrease in floor area. | |

|

a) Enhancing the strength by incorporating composite materials without altering the geometry of the walls or increasing their weight. b) Partially filling with reinforced concrete through grouting. c) Local strengthening of specific areas, such as reinforcing connections between timber elements and masonry walls. d) Sealing openings using precast cement elements. |

Practical feasibility | Modifications to the original configuration resulting in an increase in mass. Inconvenience to residents, reduction in floor area, and a decrease in the financial value. |

|

a) Removing extra storeys through demolition or eliminating non-traditional partitions. b) Removing heavy furnishings. |

| Integration approach | Applications |

Current Developments and Difficulties |

|---|---|---|

| Application programming of BIM tools Utilization of a relational database Implementation of a new data schema Adoption of a new query language Incorporation of semantic web technology Utilization of a hybrid approach |

Construction operations and monitoring Construction logistics and facility management Health and safety management Facility management |

Cloud computing Service-oriented architecture and web services for BIM Requirement for integration and information standards Challenges in managing the interaction between BIM and AIoT |

| Data Capturing | Data Processing | Modelling |

|---|---|---|

| Laser Scanning Photogrammetry Image-based and Range-based Combination |

Data Cleaning and Resampling Data Registration Surface Meshing Texturing Creation of Orthographic Image |

Manual Parametric Modelling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).