Introduction

The mining industry's productivity has been steadily falling over the last few decades (Anna & Brian, 2016; Chen et al., 2004; Lala et al., 2016). These fluctuations in commodity efficiency and productivity have presented challenges to global demand and supply balances. Mining exporting countries, in particular, are vulnerable to delayed growth due to low productivity (Duan, 2022; Weldegiorgis et al., 2023; Yasmin et al., 2022). The significant growth in resource demand caused by global industrialisation and urbanisation has put great pressure on mining companies to boost productivity. Industry leaders have primarily focused on partial measures of productivity (e.g., labour productivity) as performance indicators, which do not fully reflect the factors underpinning total factor productivity (Fernandez, 2021; Garcia et al., 2001). Unlocking productivity potentials and researching alternatives for reversing falling trends are critical for a country's economic success. The recent reduction in mining production has piqued the interest of policymakers and corporate executives.

Innovation in mining has been a key agenda for both mining businesses and policy makers. In recent years, the mining industry has focused on innovation to increase productivity through a number of productivity-enhancing initiatives and technologies, such as mine automation (Anna & Brian, 2016; Gruenhagen & Parker, 2020; Humphreys, 2020). While automated mining operations are characterised by increased safety, operating cost reduction, and environmental consequences, these systems also come at a high cost. The mining industry is attempting to increase productivity by implementing a number of technologies. The development of cutting-edge procedures and technologies to increase output necessitates a substantial financial expenditure (C. Lovell & J. Lovell, 2013). The advancements in technology (through the automation of processes) is increasing the productivity either maintaining a same workforce, or directly reducing the number of employees required (Sánchez & Hartlieb, 2020). Conversely, the fall in ore quality across commodities as a result of the exploitation of high-quality resources is negating productivity increases and increasing the cost of extraction and capital investment. Furthermore, the utilisation of input mixtures and expansion in production scale have an impact on productivity patterns. The extent to which these diverse elements influence production is still unknown. It is critical to determine how all of these different elements explain the mining sector's productivity.

Understanding the causes of productivity decline is difficult. Several factors influence mining industry productivity and efficiency, including management approaches, effective resource allocation, scale economies, and, most importantly, technical innovation (Ahmad, 2020). Embracing new technologies and optimal management practices also influence the efficiency and productivity of the mining industry significantly (Ahmad et al., 2023). Automation and robotics advancements in technology, for instance, contribute to decreased carbon emissions and increased mining industry productivity (Humphreys, 2020). The development of technologies and their use in the mining industry have enhanced mineral recovery while lowering production costs and energy use (Sánchez & Hartlieb, 2020).

his study examines total factor productivity in the mining sector and its many factors using a large mine-level panel data set comprising copper, gold, and platinum. We study numerous factors that explain the differences in efficiency and productivity between mines and areas. The breakdown of TFP into its constituent parts provides useful policy insights into how to improve mining sector performance.

The following is how the paper is structured: Section 2 presents a review of the literature on TFP measurement and the components of its change. There is also a brief assessment of existing studies on mining sector productivity and their limitations. Section 3 goes into detail on the TFP measuring methods and data that were used in the analysis. Section 4 discusses the results and discussion of TFP and its associated measures of efficiency change. Finally, Section 5 concludes with closing remarks and potential policy initiatives to increase mineral productivity.

Literature review

The idea of productivity and its decomposition into its components such as technical efficiency and allocative efficiency was first introduced by Farrell (1957) in his seminal work. Farrell pointed out that a producer is always concerned to expand the output level of the firm without using more resources. Excessive use of inputs for a given level of output or the production of less output from a given level of inputs results in technical inefficiency while inappropriate use of the mix of inputs leads to allocative inefficiency. After Farrell’s work, other measures were developed including scale efficiency (Färe et al., 1994; Nishimizu & Page, 1982). Technical efficiency is usually measured using either an input or an output-oriented approach. Input-oriented technical efficiency is defined as the ability of a firm to minimize its input use to produce a given level of output (or holding output mixes fixed in case of multiple-outputs) while output-oriented technical efficiency is defined as maximization of output with a given level of inputs (or holding input mixes fixed in case of multiple-inputs).

Researchers have attempted to understand the causes of declining productivity trends and have examined the various variables that account for variations in mining performance. However, most of the existing literature has focused on partial productivity (such as labour) or aggregate level productivity using residual approach (C. A. K. Lovell & J. E. Lovell, 2013; Mahadevan & Asafu-Adjaye, 2005; Parida & Madheswaran, 2021; Syed et al., 2015). However, most of these studies either use partial productivity or aggregate or residual approaches to derive the TFP estimates for the mining sector. Partial productivity (e.g., labour) measures provide the useful insights about the firms performance, however, they can be limited in scope to provide an overall picture of the firm. On the other hand, the total factor productivity and its associated measures of efficiency change can provide a comprehensive picture and identify the area of improvement

A vast literature covers the use of this approach by researchers to analyse components of TFP change in almost every field of economics and business. Researchers have made extensive use of DEA methods to compute the components of technical change and technical, allocative and scale efficiency. Both input and output-oriented approaches have been adopted to measure technical and allocative inefficiencies (Charnes et al., 1978; Schmidt & Knox Lovell, 1979). Applications range from agriculture (Ahmad et al., 2021; BRAVO-URETA & PINHEIRO, 1997; Kalirajan, 1990) to manufacturing (Ahmad & Burki, 2016; Chen et al., 2004) to the services sector (Burki & Ahmad, 2010; Drake et al., 2006; Fukuyama & Weber, 2002). However, there are other important drivers of TFP including scale and scope economies, and technical change, which needs to investigated to draw comprehensive policy insights (Ahmad, 2020). For instance, it would be interesting to know whether the uptake of technology is driving the productivity or scale and scope economies (as a result of appropriate output and input mixes) are important levers of TFP in the mining sector.

Over the past few decades, policy discussions have centered on the efficiency and productivity of the mining industry. Many studies (Humphreys, 2020; Isaiah et al., 2021; Shao et al., 2016) concentrate on the theoretical and empirical foundations of efficiency and productivity and relate it to various factors including innovation and technical change, adoption of technologies, scale and scope economies, investment lags, capacity utilisation, and input quality. However, most studies (have examined the total productivity of the mining sector using aggregate data (Grifell-Tatjé & Lovell, 2014; Mahadevan & Asafu-Adjaye, 2005; Syed et al., 2015; Topp, 2008). For instance, Topp et al.(2008) use data from the Australian mining industry to estimate productivity and find a downward trend in mining total factor productivity (TFP) between 2001-2002 and 2006-2007, concluding that the depletion of resources and capital adjustment have contributed to the drop in TFP. The analytical approach proposed by Grifell-Tatje and Lovell (2014), on the other hand, divides changes in productivity into variations in capacity utilisation and price recovery. They point out that an analysis of Chile's mining industry productivity by (Ilboudo, 2014) using the Solow residual approach suggests that R&D spending and technology appear to be important productivity drivers.

Other studies used either mine level or aggregate data to investigate the efficiency and productivity of specific commodities (Ahmad et al., 2023; de Solminihac et al., 2018; Isaiah et al., 2021). de Solminihac et al. (2018), use the Solow residual approach to compute the total factor productivity (TFP) of the Chilean copper sector and conclude the rising input costs and declining ore quality reduce the worker productivity. Oliveira et al. (2017) a limited data of 25 gold mining companies and note a marginal improvement in environmental efficiency. Hernán et al. (2018) use traditional Solow method to explain copper productivity in Chilean mining sector and note that a 42% decline in labour productivity during 1999 to 2010. Ahmad et al., (2023) use global gold mine level data for the year 2019 to estimate carbon adjusted efficiency and technology gap among different production environments and technologies such as open pit and underground. They note significant disparities in efficiency (ranging from 18 % to 100%) across mines attributed to technology gap.

Most of the available research on the mining industry's productivity and efficiency is either constrained to TFP aggregate level analyses or uses sparse firm/mine level data. To pinpoint numerous performance-enhancing factors, a thorough investigation of the mining sector's productivity is required. It would be crucial to determine whether more resources should be devoted to R&D to increase productivity or innovation and technology adoption. This report attempts to offer a thorough understanding of TFP and its significant drivers in the mining industry.

Methods and data

Productivity is often implicitly measured as the ratio of an aggregate output to an aggregate input (Jorgenson & Griliches, 1967). Aggregation of inputs and outputs must be performed using aggregators (Ahmad, 2020; O'Donnell, 2012). Identification of appropriate aggregator functions is important for the construction of various indexes. Both linear and non-linear aggregators can be used to construct TFP indexes. Linear aggregators have been widely used in cost minimization or revenue maximization estimations. The optimization measures used in the economic literature typically focus on linear aggregators to estimate the components of TFP, for example to minimize costs or to maximize revenues/profits. However, the use of non-linear aggregators is uncommon in the productivity literature.

Decomposition of total factor productivity (TFP) into its different components allows policy makers and researchers to identify the sources of growth of firms or industry. Identification of TFP change as a measure of technical change originates in Robert Solow’s seminal paper 1957, where he estimated aggregate production function to relate output indexes with input indexes and interpreted growth in in outputs associated other than inputs as a result of technical change. Solow (1957) argued that technical change and the capital-to-labour ratio were the only sources of growth in output per head. His measure of technical change is now known as the Solow residual and is used as a measure of TFP growth. However, this interpretation has several limitations as pointed out by Carlaw and Lipsey (2003). They classify different TFP interpretations associating to mainly three components i) technical change, ii) the TFP viewed as free lunches based on Jorgensen and Griliches (1967), and iii) TFP as a measure of ignorance.

Productivity is defined as the ratio of an aggregate output to an aggregate input as

where

is an aggregate output and

is an aggregate input.

TFP of a firm between periods t and s can be defined as

where

and

These indexes satisfy the axioms and tests including monotonicity, linear homogeneity, proportionality, commensurability, and identity.

3.1. Measures of Efficiency

According to O'Donnell (2008, p.12, 13), input and output oriented technical efficiency can be expressed in terms of aggregate inputs and aggregate outputs.

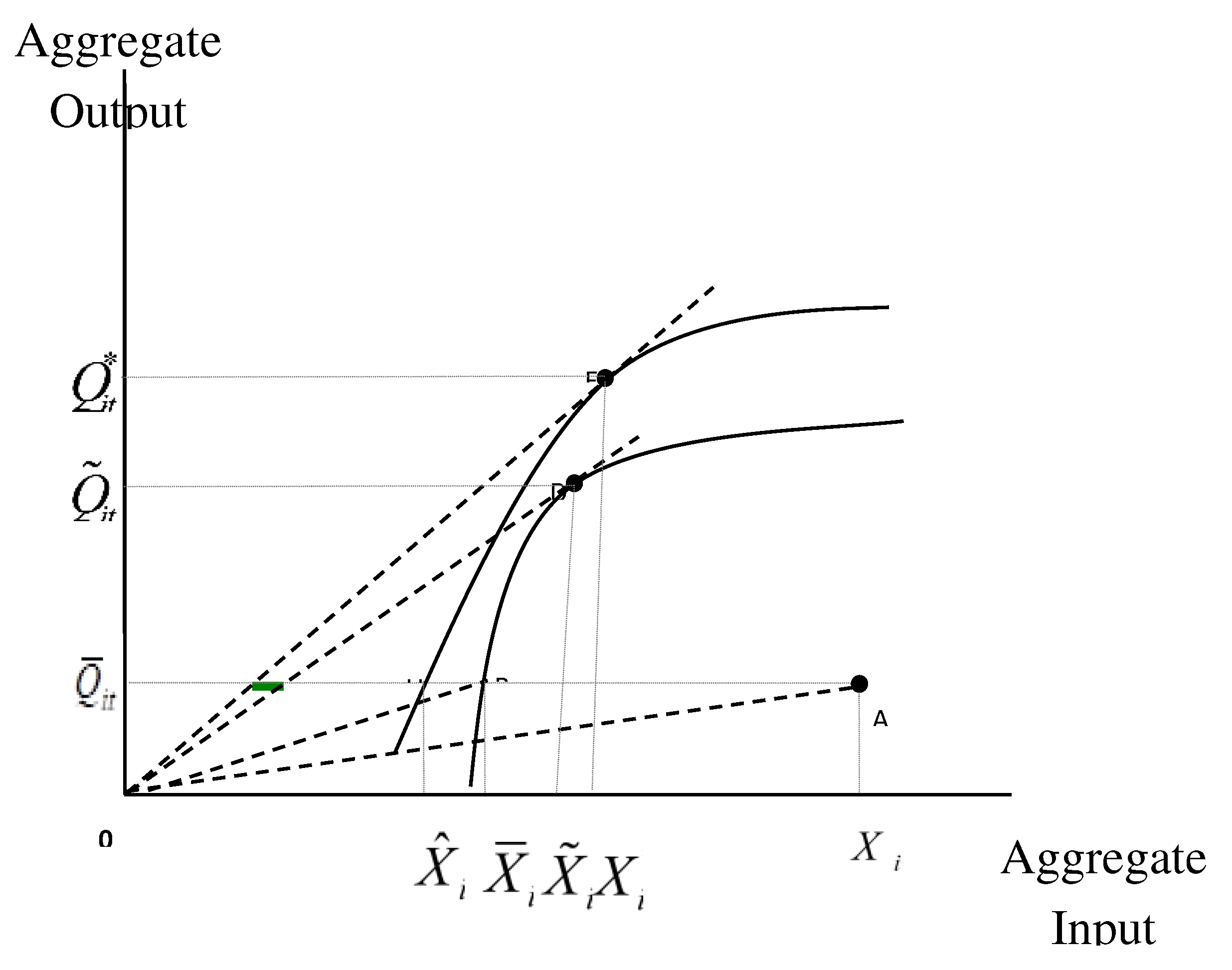

Figure 1 explains the TFP, and efficiency principles employed in this paper using an aggregate quantity framework. It shows a two-dimensional aggregate quantity space to map the district's output and input aggregates across time. According to Eq. (1)'s definition, the TFP of a district operating at point A corresponds to the slope of the ray OA, and the TFP of a district operating at the frontier point E corresponds to the ray OE. Components of the TFP change are identified by ratios of the slopes of several points. The ratios of slopes at these places, which represent these measures, are used to write paths.

First, the input-oriented technical efficiency (ITE), which is based on the slope (OA/OB) of the equation 3, measures the least amount of aggregate input that may be used to create a certain level of aggregate output. An increase in ITE entails closing the productivity gap by approaching the production frontier.

Second, the input-oriented scale efficiency (ISE) is another commonly used measure (Eq. 4) calculating efficiency related to economies/diseconomies of scale, identified by slope (OB/OD).

Third, the input-oriented mix efficiency (IME) is another component of efficiency (Eq. 5) measuring expected change in productivity when there are no restrictions on input and output mix, also termed as economies/diseconomies of scope, given by slope (OB/OU).

1 Fourth, residual input-oriented scale efficiency (RISE) in Eq. (6) measuring the slope (OU/OE) takes the ratio at technically efficient and mix-efficient points with maximum TFP and thus is a scale effect. It is termed as residual because on the restricted frontier, all points are mix efficient, but they have different input and output mixes. In other words, this is essentially a measure of scale efficiency, which may contain a residual mix effect – or potential TFP change by relaxing restrictions on input-output mix.

3.2. TFP and its decomposition

TFP efficiency (TFPE) is a useful overall measure of district performance in Eq. (7). It is measured by the ratio of observed TFP to the maximum feasible TFP (TFP*) given the existing technology, equal to slope (OA/OE). The TFP efficiency is

These definitions provide for the following meaningful decomposition.

When a mine transitions from a technically efficient point on the mix-restricted frontier to a point of maximum production on the unconstrained frontier, ISME measures the increase in TFP (O'Donnell, 2012a). Simply expressed, ISME, also known as scale-mix efficiency, quantifies the productivity gap caused by scale-mix inefficiencies.

3.3. Data and variables

We use mine level data for each mineral that has been obtained from S&P Global Market Intelligence’s reports on cost database. These data are standardised based on calendar year-end. All production units are converted into a common scale extracted from financial and technical reports of each company. The missing values where information is unavailable are extrapolated using industry benchmarks and average values (such as productivity and energy consumption rates). All data was in US dollars denomination and derived in terms of unit costs. For further details refer to S&P Market Intelligence Metals & Mining Database.

Table 1 presents the descriptive statistics of output and input variables for all three commodities used in the TFP analysis.

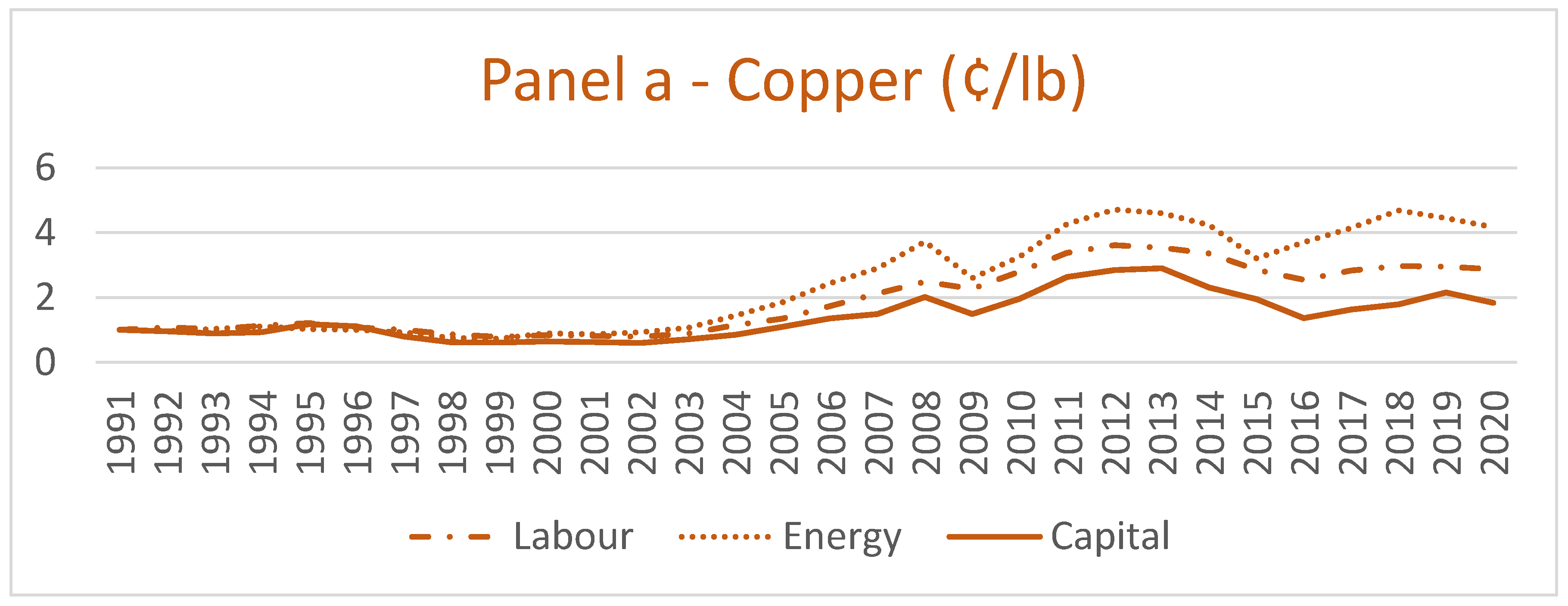

Figure 2 panel (a-c) show the input cost trends from 1991 to 2020. As can be noted there has been an upward trend in labour, energy, and capital costs since Year 2002. Copper mining is a capital-intensive sector, and because of many causes, including diminishing ore grades and investments in technology, the capital costs have risen over time. Similarly, rising energy costs are affecting the sector’s efficiency and productivity. Panel a of

Figure 2 shows that in the year 2020 the energy cost of copper production was recorded above 4 cents per pound. Similar trend can be observed in gold and platinum sectors (as depicted in Panel b & c).

Empirical results and discussion

The data envelopment analysis (DEA) programme was used with DPIN3.0 software to compute the TFP and its associated components as indicated in Equation (2-8) and the graph. By addressing the linear programming issue outlined in O'Donnell (2012), DEA computes the efficiency and other components of TFP. We use the variables return to scale to calculate the input-oriented technical efficiency of each mine i in period t. To compute the efficiency estimates, we employ the primal input-oriented technique.

4.1. Technical Efficiency

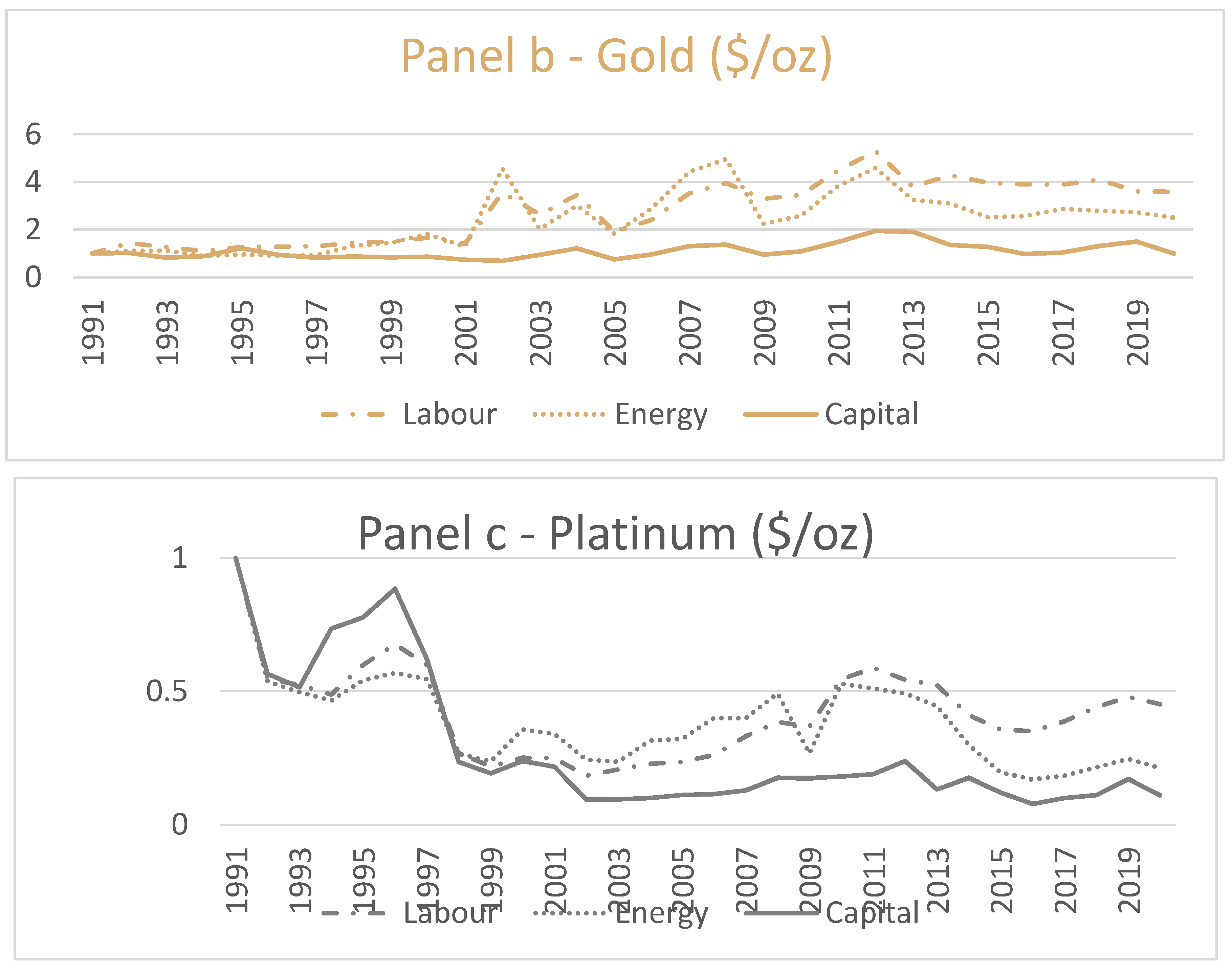

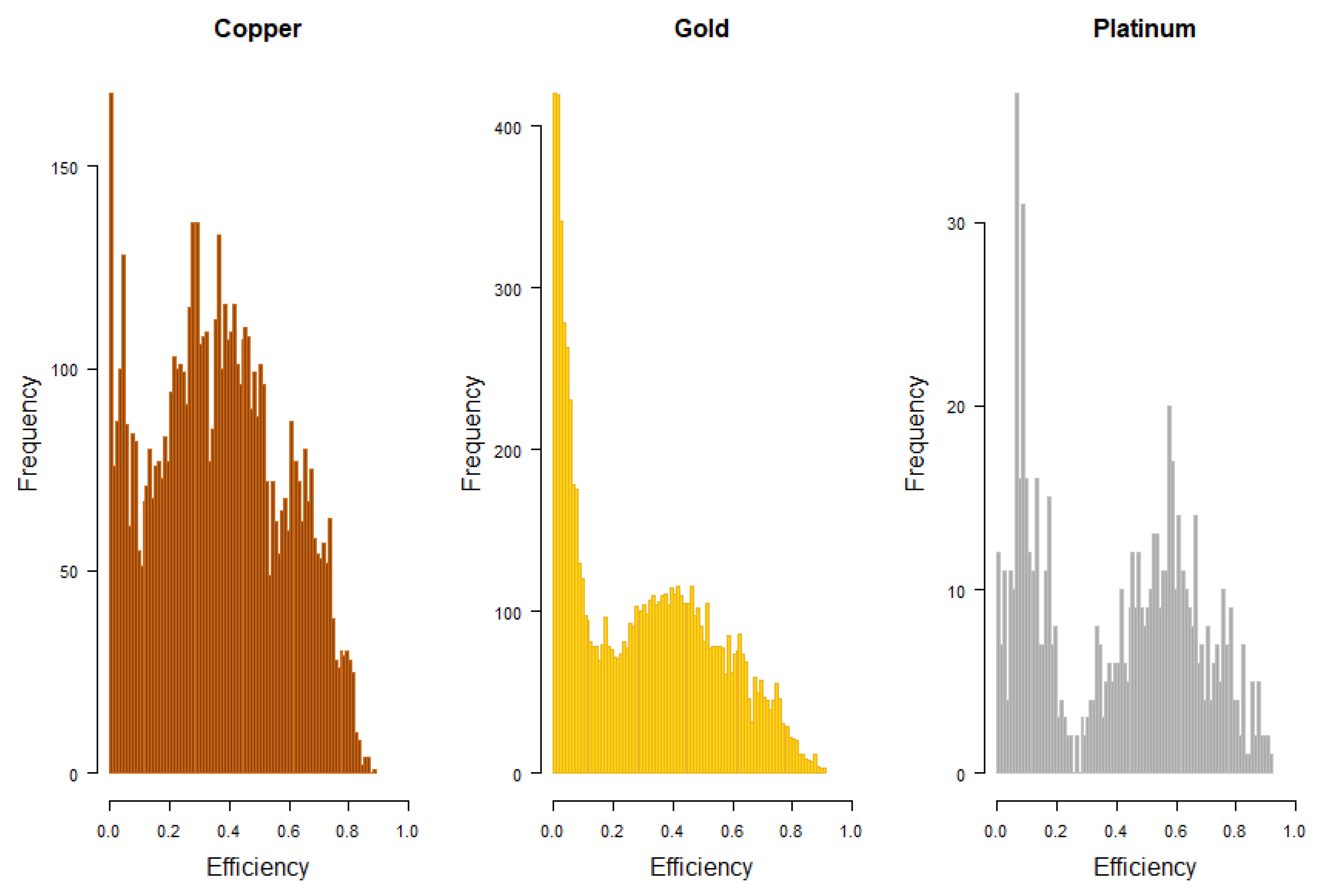

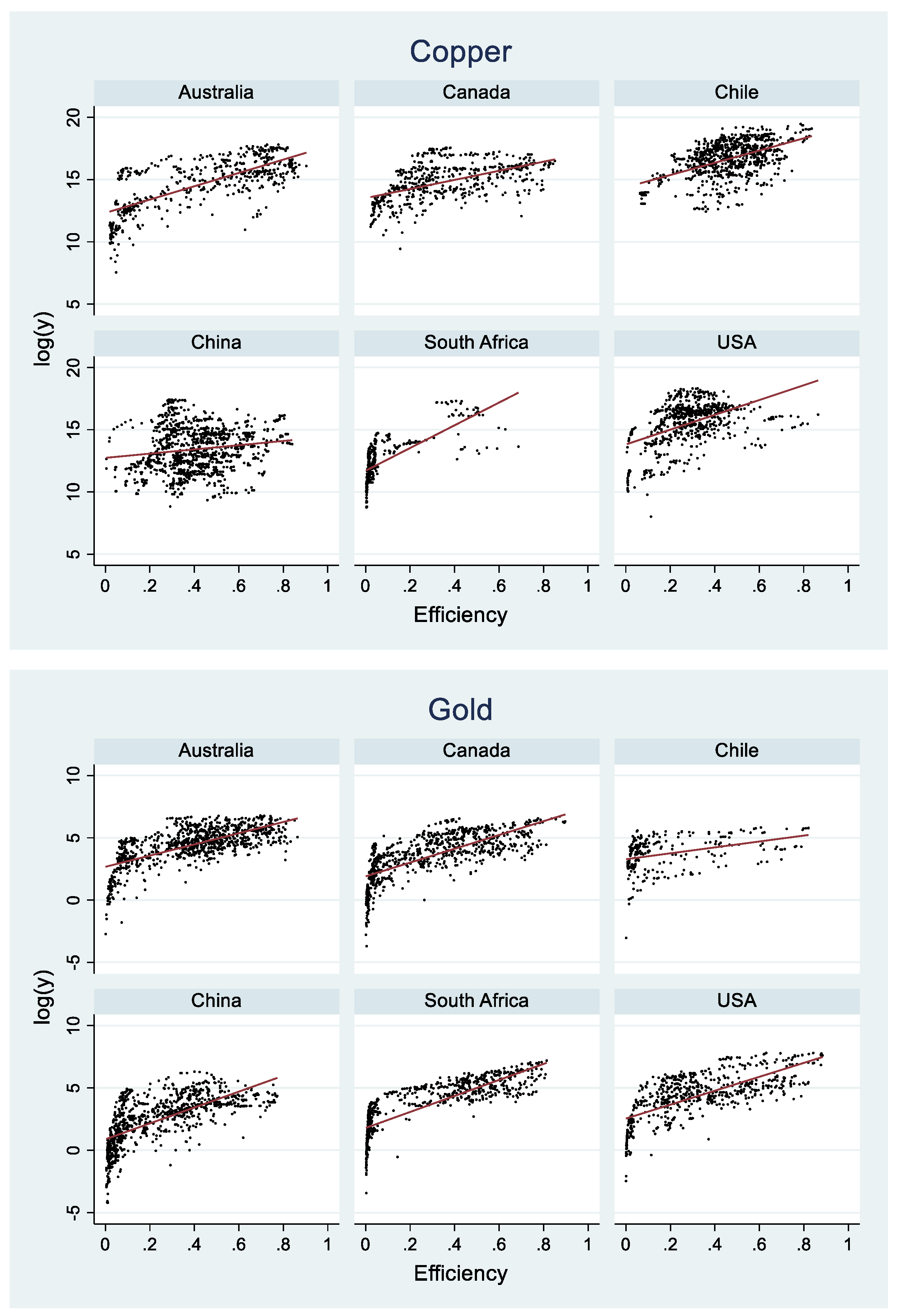

Figure 3 depicts the technological efficiency distribution for copper, gold, and platinum. There are significant differences in efficiency across mines and areas for all three commodities. Estimates of copper mine-level technical efficiency reveal that mines are 40 percent efficient in transforming inputs into outputs on average. In other words, enterprises may create the same amount of output while using only half of their inputs. The considerable variance in technical efficiency across copper mines can be attributable to a number of factors, including ore quality, technologies, and mining practices. A further examination of mine level efficiency reveals that mines in Portugal and Saudi Arabia have the highest technical efficiency on average, whereas considerable mine-level dispersion is observed in Australia, Canada, and Laos. Again, these disparities could be attributed to ore quality and technology differences adopted by different firms.

Estimates of gold efficiency are provided in

Figure 3 subgraph 2. Again, the distribution of efficiency appears to be more negatively skewed, since a huge number of mines demonstrate a low level of technical efficiency. A thorough examination of mine and country level data on technological efficiency finds significant variation at both the mine and regional levels. It has been observed that more efficient mines are located in African regions, which may be due to ore quality. However, a wide range of efficiency was discovered in Ecuadorean, Bolivian, and Canadian mines. These findings are analogous to those of Ahmad et al. (2023), who discovered significant technological gaps between mines and locations. Mines in the United States, Russia, and other locations, for example, have lower technical efficiency, which could be attributed to lower ore grade as well as differing operating environments and technologies.

Platinum efficiency estimates show a similar scenario, albeit with a somewhat higher average technical efficiency. Platinum's average efficiency remains at 0.50, ranging from very low to high efficient mines. For example, the most efficient platinum mining are located in the United States (0.91), followed by South Africa (0.87). Australian mines are likewise less technologically efficient. Similarly, Canadian mines stay clear from the border. Global data also shows that the most prolific mines are located in South Africa, which may be due to the ore quality, which makes those mines more efficient and productive. Because of price instability, the aluminium industry has been under tremendous pressure to pursue cost-cutting and productivity-boosting strategies. This can be accomplished by increasing output or reducing the quantity of resources consumed in order to boost productivity.

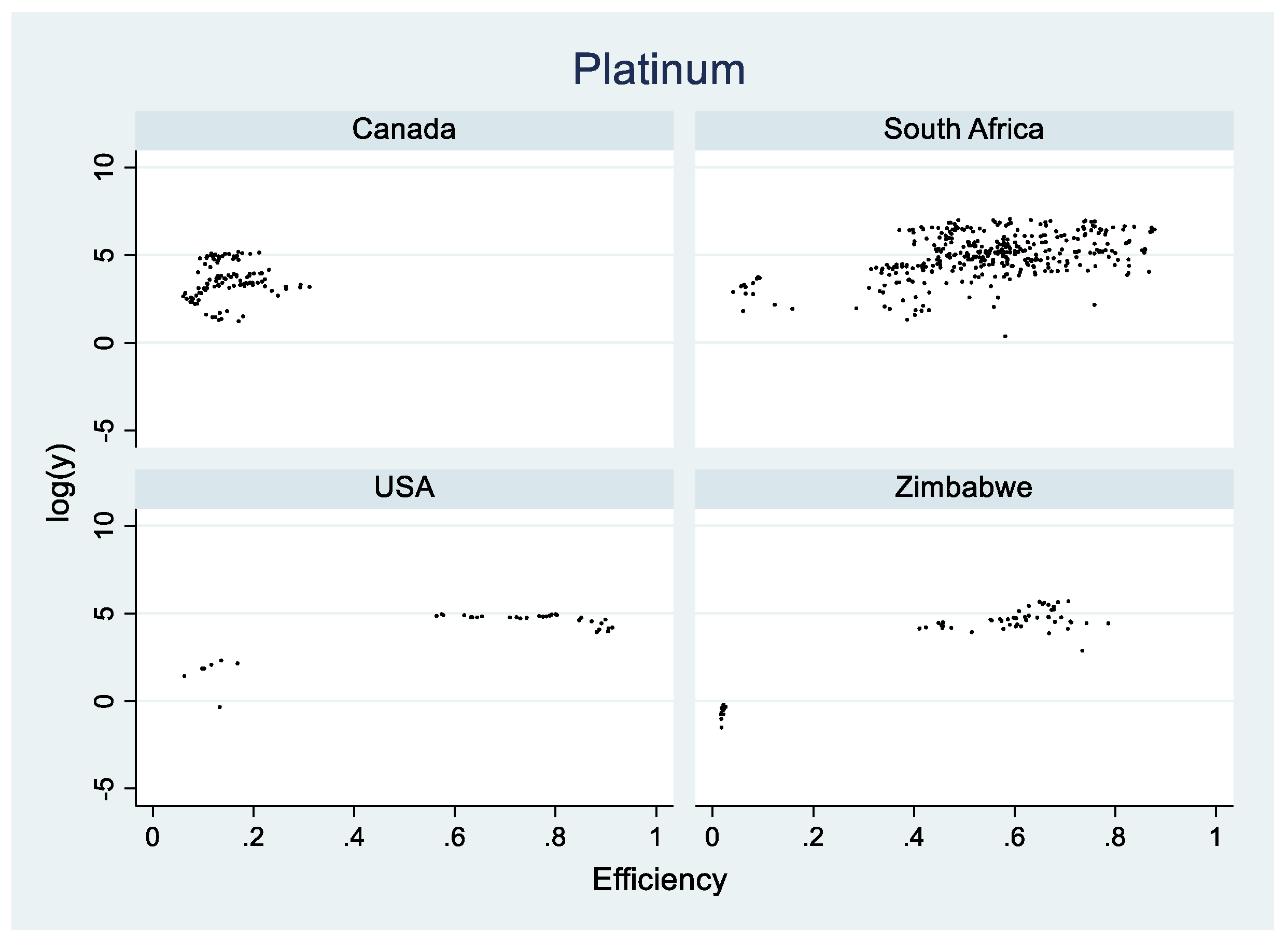

Figure 4 (a-c) depicts a correlation analysis between productive capacity and technical efficiency to further explain the probable efficiency differentials among different platinum mines located in different localities. At the national level, there is a substantial link between production scale and efficiency. For example, copper mines in Australia exhibit a significant association with scale operations, and technical efficiency means that greater mine operations may be the result of creative technology adoption. Analysing mines in Canada, Chile, and South Africa yields similar results. On the other hand, it appears that these ties are weak in Chinese and US mining operations. The relationship between copper mine size and cost has been examined by many researchers (Crowson, 2003; Bozorgebrahimi et al. 2005; Christensen and Green; Yatchew 1997). However, there are mixed findings whether there exist strong scale economies or not.

The link between gold efficiency and production scales is depicted in

Figure 4, panel b. Gold mining, like copper mining, has a positive relationship between productive capacity and efficiency. In Australia, Canada, and Chile, there is a definite correlation between efficiency and mining operation scale. This link is less pronounced in China, South Africa, and the United States. There could be a variety of causes for this pattern, such as diseconomies of scale, which demands more investigation into other productivity drivers. Mining operations' efficiency can also be influenced by the different operating environments, such as open pit and underground operations (Kulshreshtha & Parikh, 2002). For instance, Ahmad et al. (2023) find that open pit mines appear to be more efficient perhaps due to operations scales that help increase the mine level productivity.

Panel c of

Figure 4 depicts the link between platinum mine output and efficiency. The findings show that the scale of production is positively connected to efficiency. Mining efficiency appears to have no favorable link with scale operations. As the graph shows, the majority of Canadian mines are somewhat inefficient. Similarly, small mines in Zimbabwe have lower technical efficiency, correlating with scale effects. In South Africa, there is a definite positive relationship between mine production scale and efficiency. South Africa produces about 80% of the world's platinum, hence the country's economy has a considerable impact on supply.

4.2. Changes in Productivity and its drivers

TFP has been further analysed using global mine-level panel data from three commodities: copper, gold, and aluminium. The emphasis is on illustrating measures of efficiency change that explain the primary drivers of p TFP.

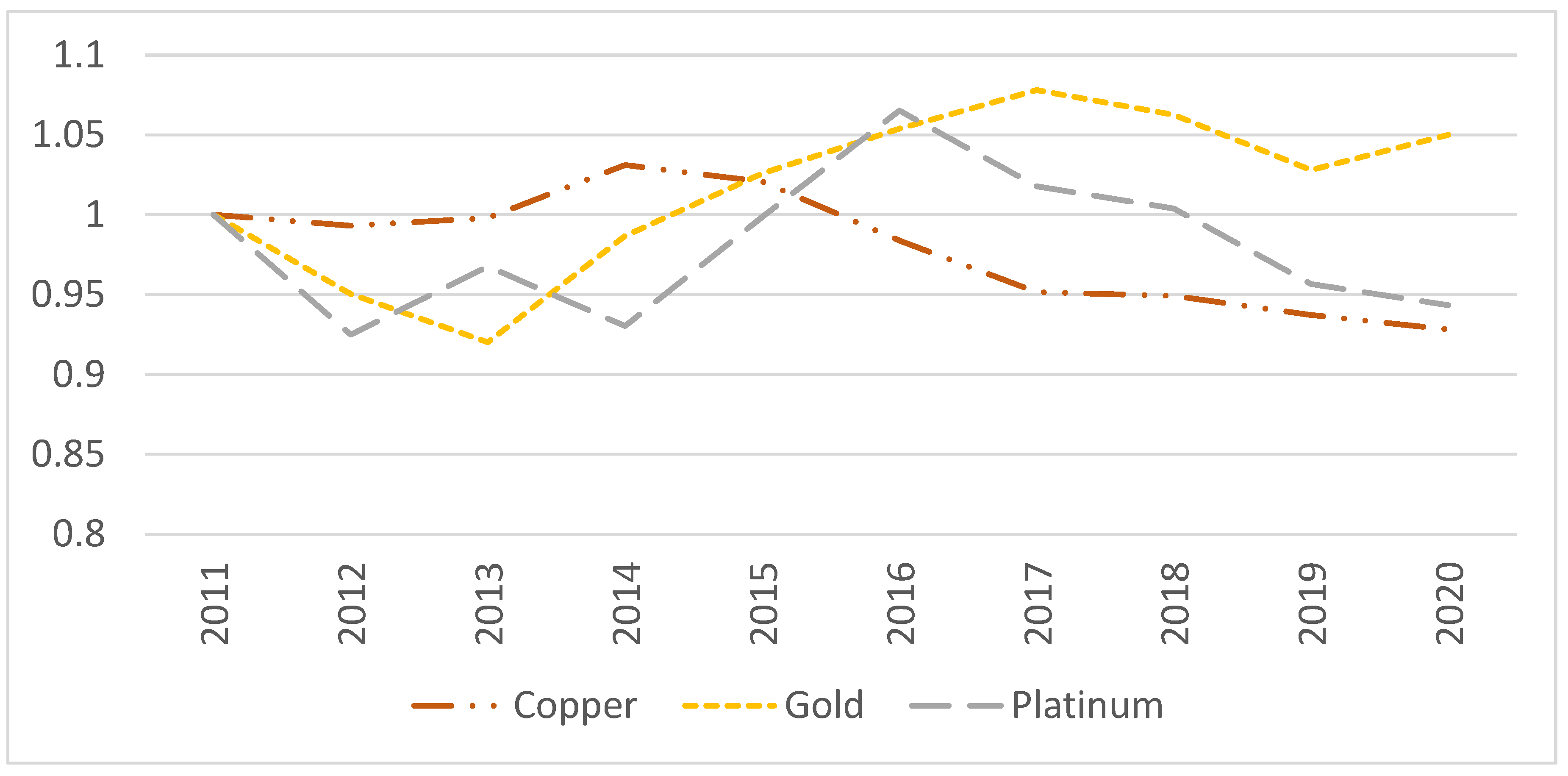

Figure 5 depicts the trend in TFP change for a selection of commodities.

TFP trends show ups and downs across the timeframe, according to the results. For example, since 2013, there has been an upward trend in gold TFP change. Copper productivity, on the other hand, has been falling since 2014. Copper mining productivity may be declining indefinitely due to rising production costs. Platinum TFP, on the other hand, shows mixed patterns. Productivity increased until 2016, after which it continuously dropped.

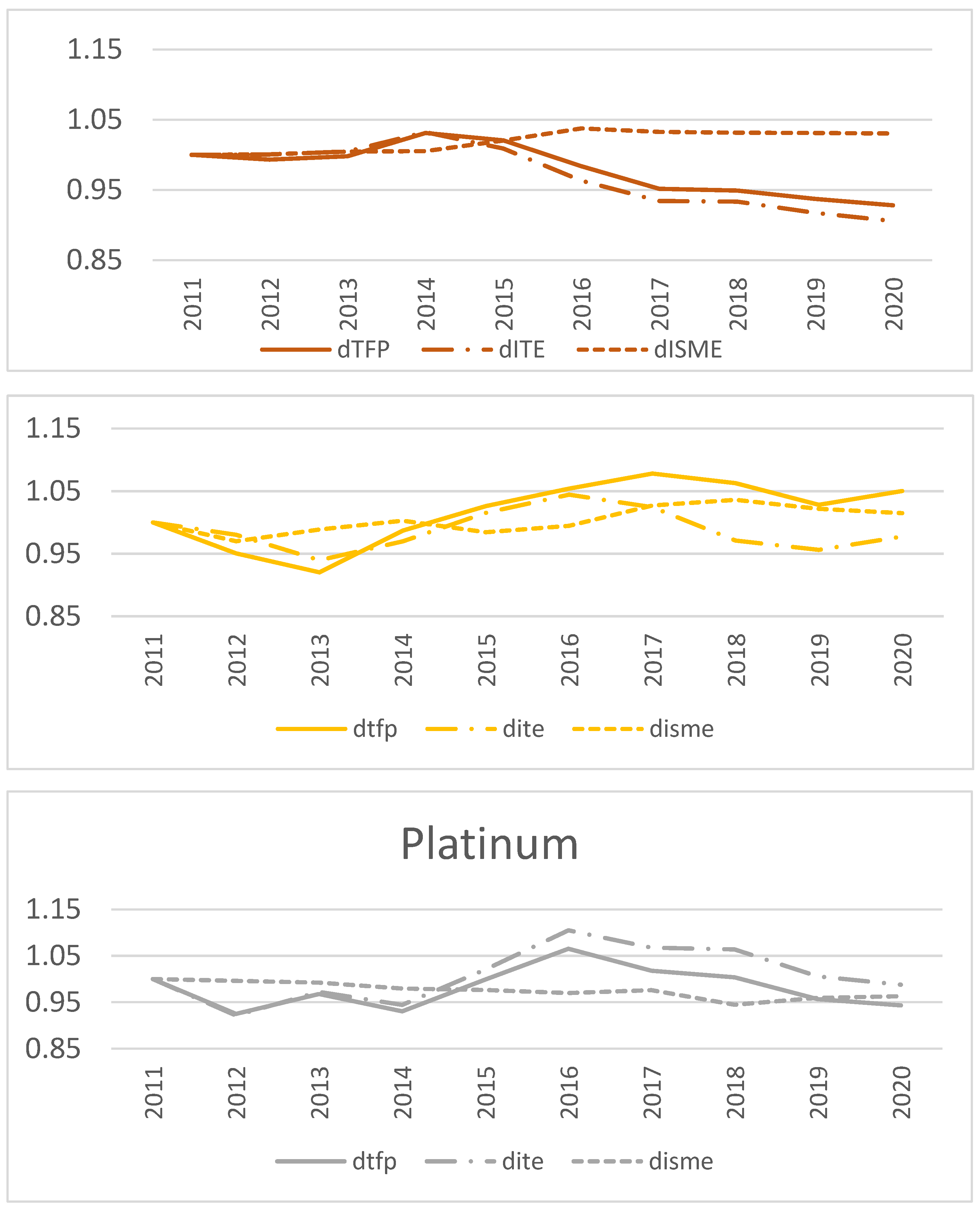

A further decomposition of productivity is depicted in

Figure 6 (a-c). TFP was divided into two parts: technical efficiency changes and scale mix efficiency change. While technical efficiency refers to best practices, scale mix efficiency refers to size and scope economies. In the industry, economies of scale and breadth are critical for determining effective market structures (Triebs et al., 2016). In reaction to pricing changes, businesses frequently alter the scale of their operations and/or the composition of their output and input mixtures. Significant losses in scale-mix efficiency in Australia's mining sector, for example, have been linked to increases in people and capital utilisation over the last ten years. Because of these advances in input utilisation, sectoral trade terms have also improved. The appropriate course of action for the government will be determined by whether rises in company profits are more or less significant than increases in productivity (C. J. O'Donnell, 2012).

Figure 6 (a) describes the changes in copper TFP and associated measures of change including technical efficiency and input scale mix efficiency change. While the change in input scale mix efficiency has been steady after 2016, there has been a continuous decline in TFP, which seems to be largely driven by technical efficiency. Panel b of

Figure 6 depicts the gold TFP and its associated components. It is noted that gold TFP has been on increase since 2013 with a slight dip in 2019. Scale and scope economies seem to contribute to TFP whereas technical efficiency has been on decline. Platinum TFP and its associated components are presented in Panel c of

Figure 6. Results show that a change TFP is mainly explained through changes in technical efficiency whereas scale mix efficiency shows a slight decline over the time.

Figure 2011. to 2020 utilising global mine level panel data of selected commodities (i.e., copper, gold, and platinum). We used rigorous methodologies to evaluate TFP and its associated components for persons, miners, and organisations in various places. TFP and its components, such as technical efficiency and input scale mix efficiency, were computed using a non-parametric approach. We use DPIN3.0 software to calculate exhaustive TFP measurements for commodity level individual miners using the DEA technique. The main advantage of DEA is that it takes no functional form for the unknown technology. Furthermore, under this approach, i) no specific assumptions for the error term are required, ii) multiple input multiple output technologies can be estimated without any statistical issues (such as endogeneity), and iii) its implementation is simple, requiring readily available computer software.

Empirical results show significant disparities in technical efficiency among mines across different commodities and regions. These differentials in efficiency may be the result of variation in technology adoption and ore quality of commodities under the analysis. A further analysis of decomposition of TFP into its different components identify the areas of improvement that could help increase TFP. For instance, copper and platinum sector TFP is mainly driven technical efficiency suggesting that the adoption of innovative practices and investment in technology adoption could improve the overall productivity of these commodities. On the other hand, gold sector TFP is largely explained by input scale mix efficiency indicate that appropriate input mix and optimum scale of production could improve the overall productivity of platinum mining. The findings also suggest that better capacity utilization of mines and production scale could help improve the mining sector productivity of selected commodities.

This is the first study to our knowledge that provides a detailed examination of commodity level productivity and its primary drivers across three commodities. The findings imply that different operating circumstances and technical heterogeneity have an effect on mining productivity. New manufacturing techniques and technological advancements may assist the mining sector to enhance output. Furthermore, differences in regional productivity and its determinants (e.g., South Africa vs. Zimbabwe) provide policymakers with insights on how to support scale and scope economies through optimal input mixes.

The current study did not look into the technological gaps that could be impeding productivity across mines and regions. Future studies could investigate the technology gap within the mining sector and across regions. Furthermore, assessing environmental productivity trajectories could yield substantial policy consequences, particularly after controlling for greenhouse gas emissions, which is still on the study agenda for the future.

References

- Ahmad, S. (2020). Estimating input-mix efficiency in a parametric framework: application to state-level agricultural data for the United States. Applied Economics, 52, 3976–3997. [CrossRef]

- Ahmad, S., & Burki, A. A. (2016). Banking deregulation and allocative efficiency in Pakistan. Applied Economics, 48, 1182–1196. [CrossRef]

- Ahmad, S., Shankar, S., Steen, J., Verreynne, M.-L., & Burki, A. A. (2021). Using measures of efficiency for regionally-targeted smallholder policy intervention: The case of Pakistan’s horticulture sector. Land Use Policy, 101, 105179. [CrossRef]

- Ahmad, S., Steen, J., Ali, S., & Valenta, R. (2023). Carbon-adjusted efficiency and technology gaps in gold mining. Resources Policy, 81, 10332. [CrossRef]

- Anna, L., & Brian, S. (2016). Productivity and Innovation in the Mining Industry. In: Retrieved from Canberra.

- BRAVO-URETA, B. E., & PINHEIRO, A. E. (1997). TECHNICAL, ECONOMIC, AND ALLOCATIVE EFFICIENCY IN PEASANT FARMING: EVIDENCE FROM THE DOMINICAN REPUBLIC. The Developing Economies, 35, 48–67. [CrossRef]

- Burki, A. A.; Ahmad, S. Bank governance changes in Pakistan: Is there a performance effect? Journal of Economics and Business 2010, 62, 129–146. [Google Scholar] [CrossRef]

- Carlaw, K. I., & Lipsey, R. G. (2003). Productivity, Technology and Economic Growth: What is the Relationship? Journal of Economic Surveys 17, 457-495. [CrossRef]

- Charnes, A.; Cooper, W. W.; Rhodes, E. Measuring the efficiency of decision making units. European journal of operational research 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Z.; Xie, H. Y. Measuring intellectual capital: a new model and empirical study. Journal of Intellectual capital 2004, 5, 195–212. [Google Scholar] [CrossRef]

- de Solminihac, H., Gonzales, L. E., & Cerda, R. (2018). Copper mining productivity: Lessons from Chile. Journal of Policy Modeling, 40, 182–193. [CrossRef]

- Drake, J.; Swisdak, M.; Che, H.; Shay, M. Electron acceleration from contracting magnetic islands during reconnection. Nature 2006, 443, 553–556. [Google Scholar] [CrossRef] [PubMed]

- Duan, L. Estimation of export cutoff productivity of Chinese industrial enterprises. Plos one 2022, 17, e0277842. [Google Scholar] [CrossRef] [PubMed]

- Färe, R., Grosskopf, S., Norris, M., & Zhang, Z. (1994). Productivity Growth, Technical Progress, and Efficiency Change in Industrialized Countries. The American Economic Review, 84, 66–83. Available online: http://www.jstor.org/stable/2117971.

- Farrell, M. J. (1957). The Measurement of Productive Efficiency. Journal of the Royal Statistical Society, 120, 253–290. [CrossRef]

- Fernandez, V. (2021). Copper mining in Chile and its regional employment linkages. Resources Policy, 70, 101173. [CrossRef]

- Fukuyama, H.; Weber, W. L. Estimating output allocative efficiency and productivity change: Application to Japanese banks. European journal of operational research 2002, 137, 177–190. [Google Scholar] [CrossRef]

- Garcia, P., Knights, P. F., & Tilton, J. E. (2001). Labor productivity and comparative advantage in mining:: the copper industry in Chile. Resources Policy, 27, 97–105. [CrossRef]

- Grifell-Tatjé, E.; Lovell, C. K. Productivity, price recovery, capacity constraints and their financial consequences. Journal of Productivity Analysis 2014, 41, 3–17. [Google Scholar] [CrossRef]

- Gruenhagen, J. H., & Parker, R. (2020). Factors driving or impeding the diffusion and adoption of innovation in mining: A systematic review of the literature. Resources Policy, 65, 101540. [CrossRef]

- Humphreys, D. Mining productivity and the fourth industrial revolution. Mineral Economics 2020, 33, 115–125. [Google Scholar] [CrossRef]

- Ilboudo, P. S. (2014). Foreign direct investment and total factor productivity in the mining sector: the case of Chile.

- Isaiah, M., Johane, D., Dambala, G., & Fiona, T. (2021). Environmental and Technical Efficiency in Large Gold Mines in Developing Countries.

- Jorgenson, D. W., & Griliches, Z. (1967). The Explanation of Productivity Change. The Review of Economic Studie, 34, 249–283. [CrossRef]

- Kalirajan, K. P. (1990). On measuring economic efficiency [https://doi.org/10.1002/jae.3950050106]. Journal of Applied Econometrics, 5, 75–85.

- Lala, A.; Moyo, M.; Rehbach, S.; Sellschop, R. Productivity in mining operations: Reversing the downward trend. AusIMM Bulletin 2016, 46–49. [Google Scholar]

- Lovell, C.; Lovell, J. Productivity decline in Australian coal mining. Journal of Productivity Analysis 2013, 40, 443–455. [Google Scholar] [CrossRef]

- Lovell, C. A. K., & Lovell, J. E. (2013). Productivity decline in Australian coal mining. Journal of Productivity Analysis, 40, 443–455. [CrossRef]

- Mahadevan, R.; Asafu-Adjaye, J. The productivity–inflation nexus: the case of the Australian mining sector. Energy economics 2005, 27, 209–224. [Google Scholar] [CrossRef]

- Nishimizu, M., & Page, J. M. (1982). Total Factor Productivity Growth, Technological Progress and Technical Efficiency Change: Dimensions of Productivity Change in Yugoslavia, 1965–78. The Economic Journal, 92, 920–936. [CrossRef]

- O'Donnell, C. J. Nonparametric estimates of the components of productivity and profitability change in US agriculture. American Journal of Agricultural Economics 2012, 94, 873–890. [Google Scholar] [CrossRef]

- Oliveira, R., Camanho, A. S., & Zanella, A. (2017). Expanded eco-efficiency assessment of large mining firms. Journal of Cleaner Production, 142, 2364–2373. [CrossRef]

- Parida, M., & Madheswaran, S. (2021). Effect of firm ownership on productivity: empirical evidence from the Indian mining industry. Mineral Economics, 34, 87–103. [CrossRef]

- Sánchez, F., & Hartlieb, P. (2020). Innovation in the Mining Industry: Technological Trends and a Case Study of the Challenges of Disruptive Innovation. Mining, Metallurgy & Exploration, 37, 1385–1399. [CrossRef]

- Schmidt, P., & Knox Lovell, C. A. (1979). Estimating technical and allocative inefficiency relative to stochastic production and cost frontiers. Journal of Econometrics, 9, 343–366. [CrossRef]

- Shao, L.; He, Y.; Feng, C.; Zhang, S. An empirical analysis of total-factor productivity in 30 sub-sub-sectors of China's nonferrous metal industry. Resources Policy 2016, 50, 264–269. [Google Scholar] [CrossRef]

- Solow, R. M. (1957). Technical Change and the Aggregate Production Function. The Review of Economics and Statistics, 39, 312–320. [CrossRef]

- Syed, A.; Grafton, R. Q.; Kalirajan, K.; Parham, D. Multifactor productivity growth and the Australian mining sector. Australian Journal of Agricultural and Resource Economics 2015, 59, 549–570. [Google Scholar] [CrossRef]

- Topp, V. (2008). Productivity in the mining industry: measurement and interpretation.

- Weldegiorgis, F. S., Dietsche, E., & Ahmad, S. (2023). Inter-Sectoral Economic Linkages in the Mining Industries of Botswana and Tanzania: Analysis Using Partial Hypothetical Extraction Method. Resources, 12, 78. Available online: https://www.mdpi.com/2079-9276/12/7/78.

- Yasmin, T.; El Refae, G. A.; Eletter, S.; Kaba, A. Examining the total factor productivity changing patterns in Kazakhstan: An input-output analysis. Journal of Eastern European and Central Asian Research (JEECAR) 2022, 9, 938–950. [Google Scholar] [CrossRef]

| 1 |

Ahmad (2020) have also proposed mix efficiency measurement in a parametric framework. |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).