Submitted:

10 August 2023

Posted:

10 August 2023

You are already at the latest version

Abstract

Keywords:

1. An Introduction to Thematic Area Interaction: The AEC Framework in the Context of Industry 6.0

2. Review of Industry 6.0 Perspectives and Their Implementation in AEC Sector

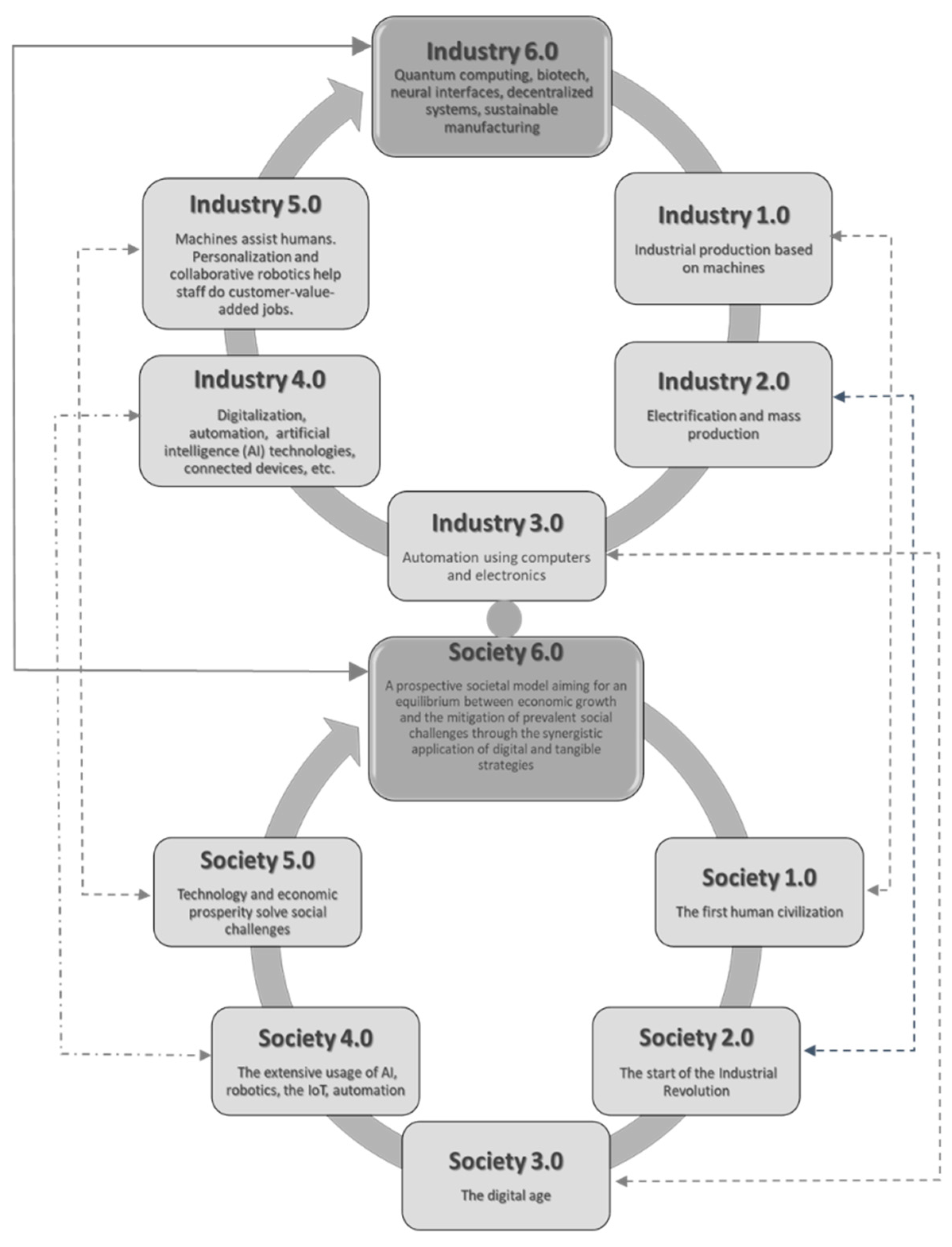

2.1. Industry and society 1.0-6.0 in the context of development

- Society 1.0 – 6.0 Evolutions

- Industry 1.0–6.0 of the Industrial Revolution

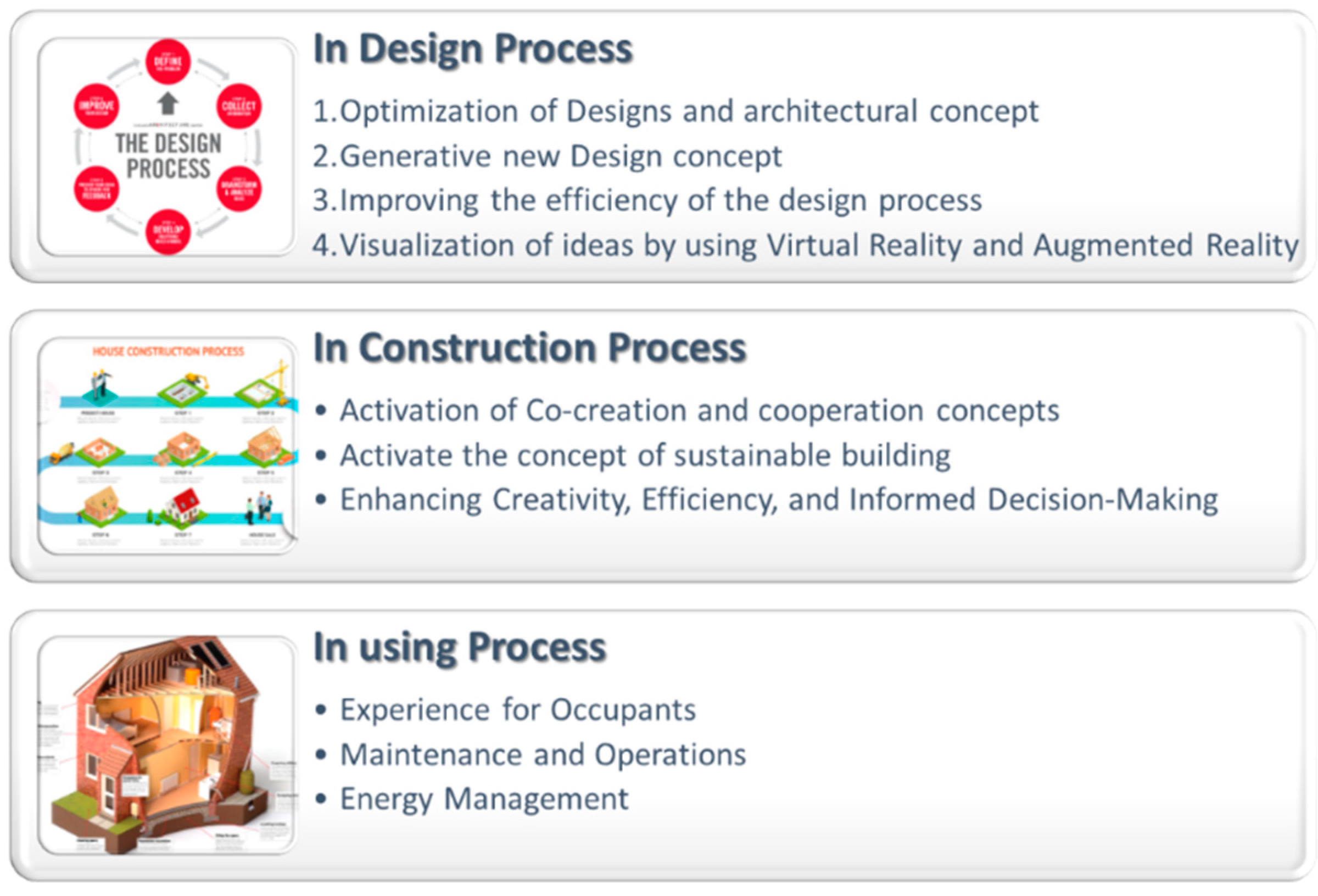

2.2. Benefits of AEC Industry 6.0 in Architecture and Construction

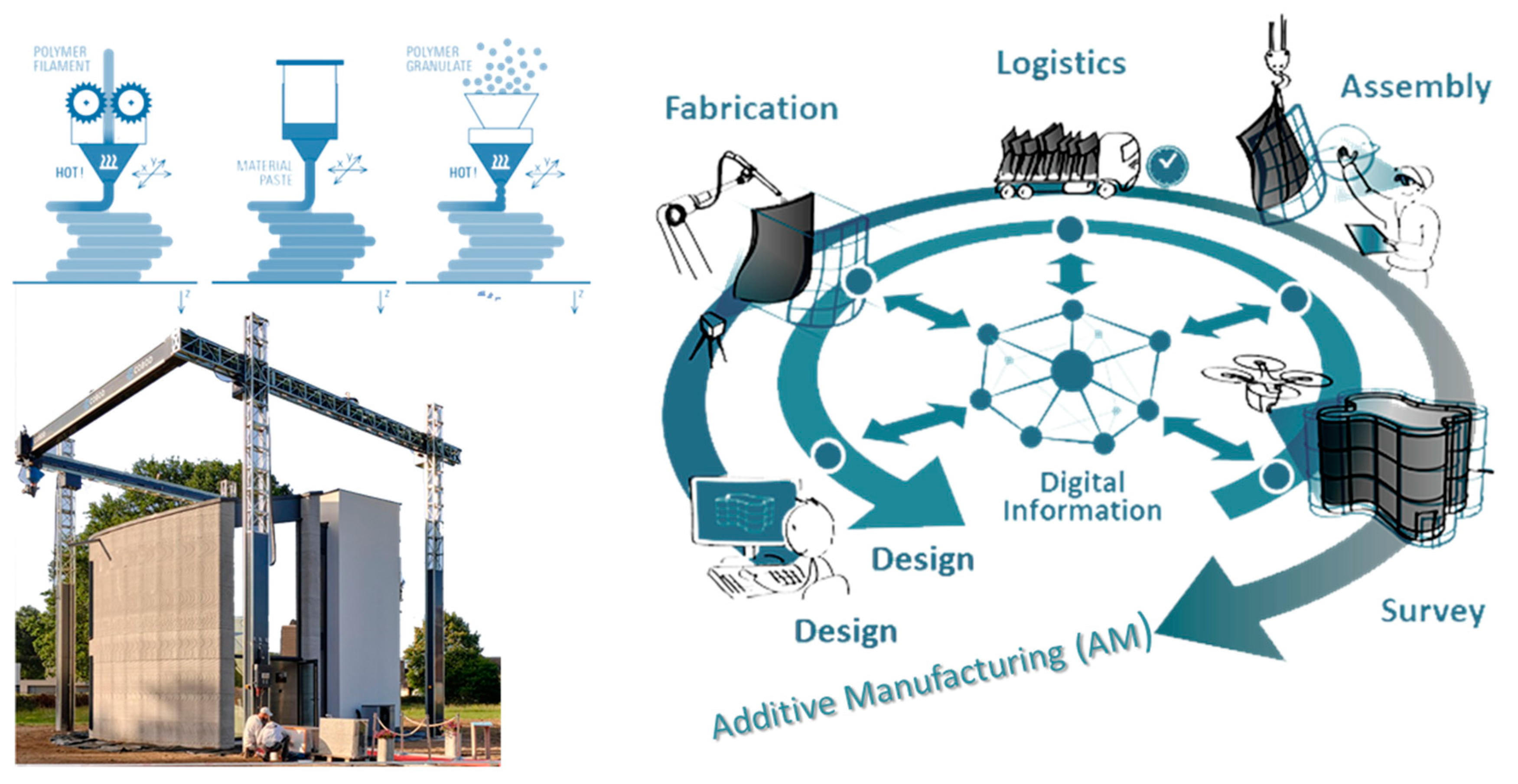

2.3. Additive manufacturing (3D printing)

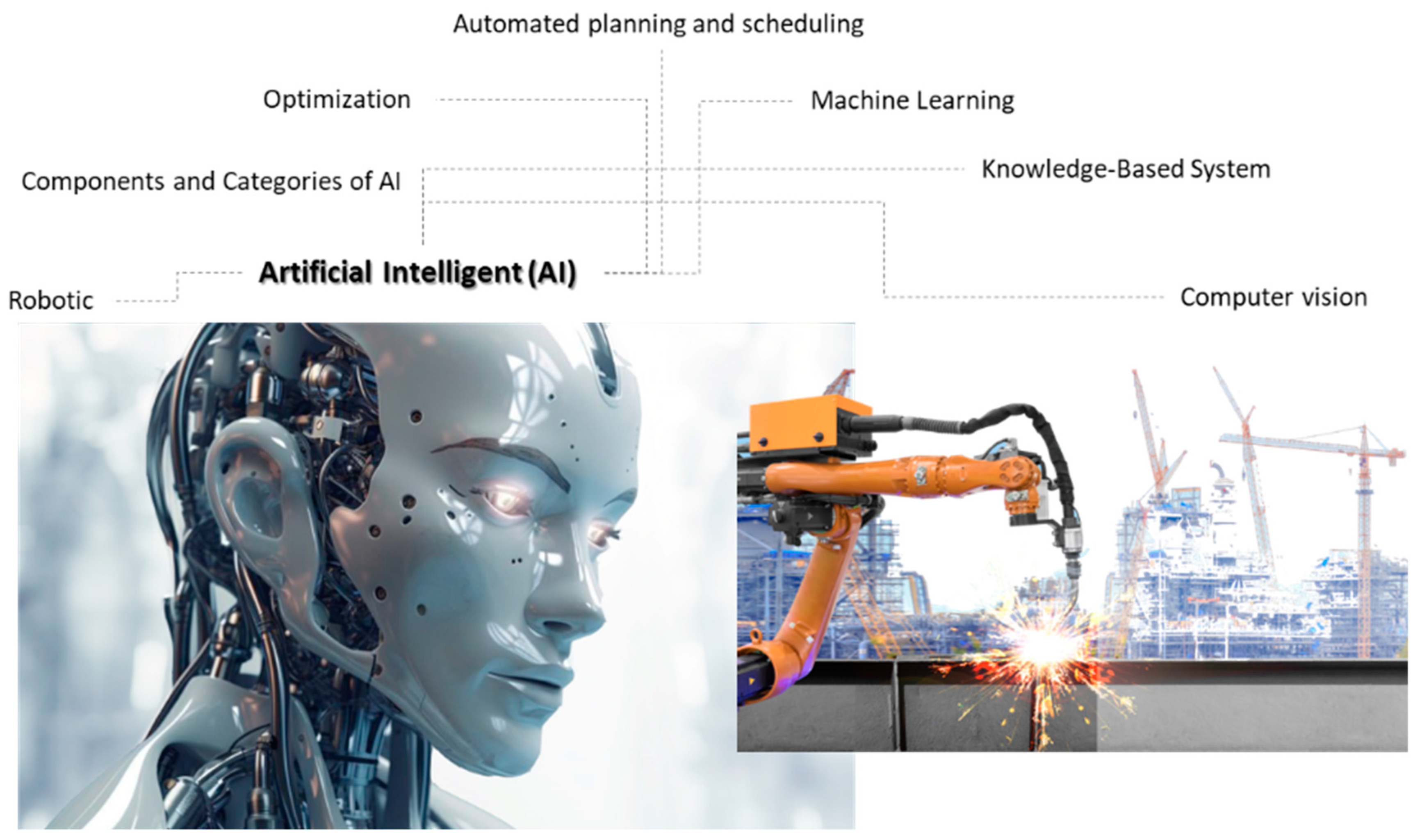

2.4. Artificial intelligence and autonomous robots

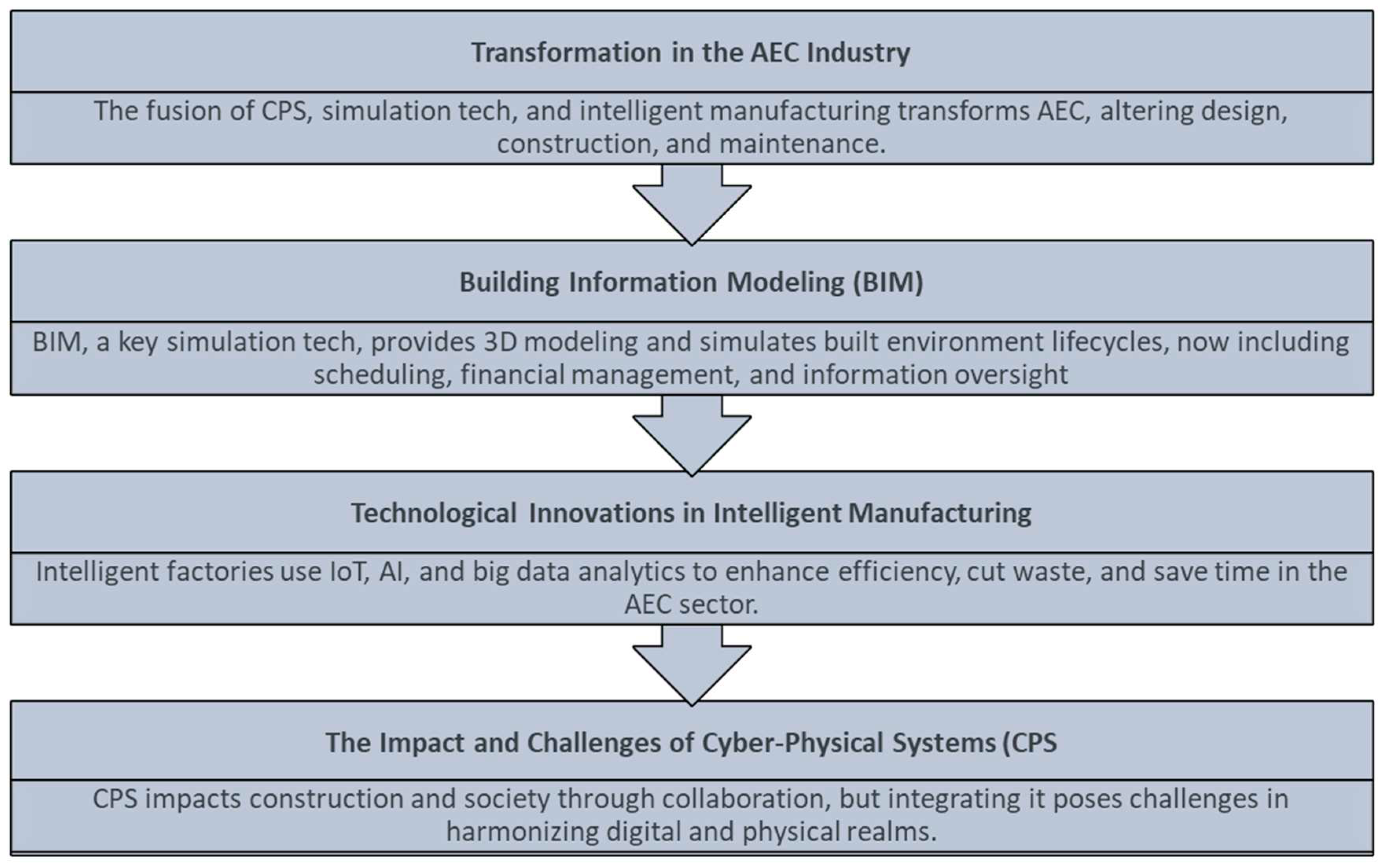

2.5. Optimizing AEC Industry with Cyber-Physical Systems and Smart Factory Simulations

2.6. Big Data Applications in the AEC Industry 6.0 Future

3. Method and materials

4. Transforming Construction through Industry 6.0: Technology Integration, Sustainability, and Collaborative Innovation

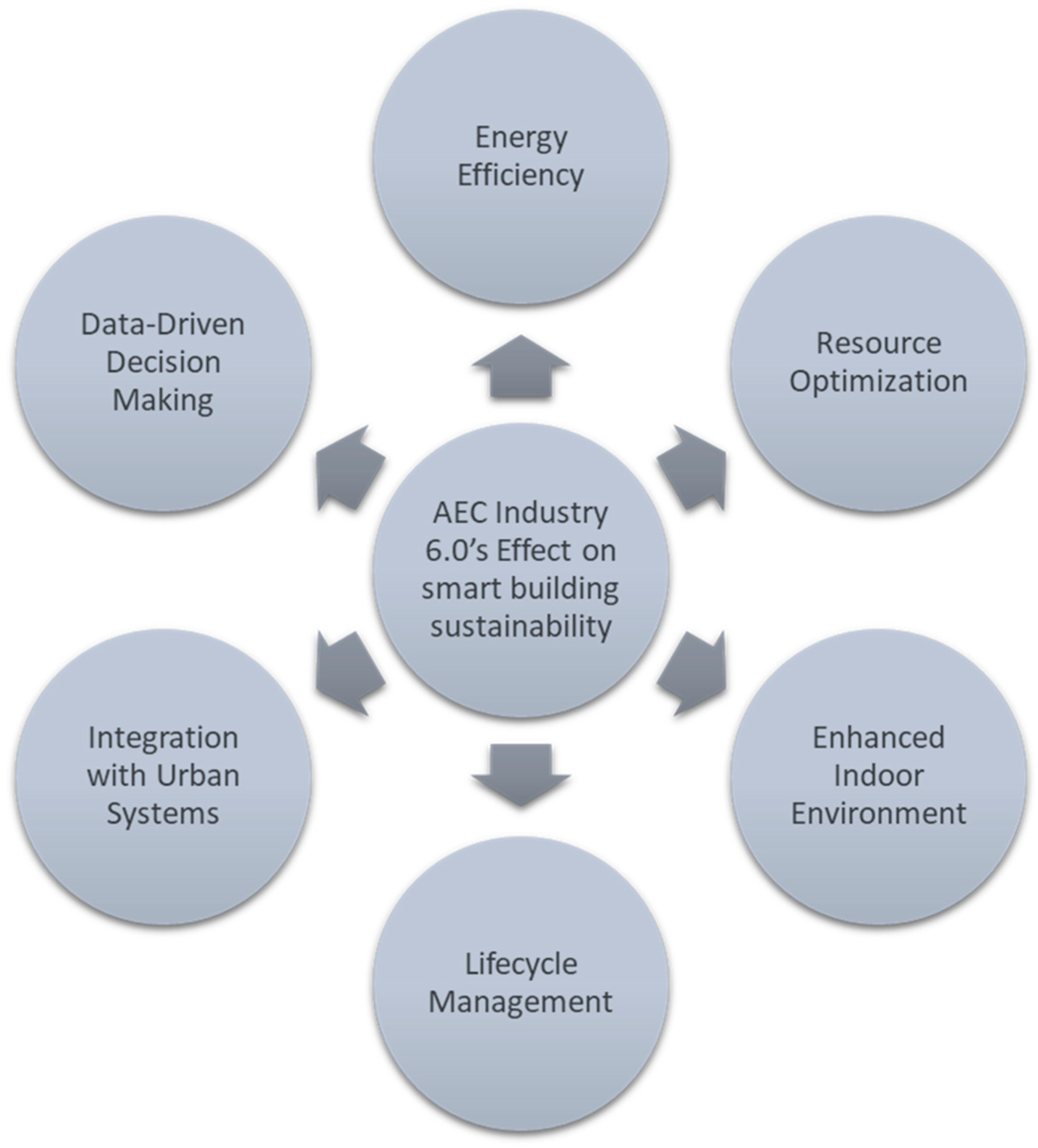

4.1. Development of a Sustainable smart building Using AEC Industry 6.0 Principles

4.2. Revolutionizing the Construction Sector: The Integration of Industry 6.0 and Sustainable Practices

4.3. Smart building within AEC industry 6.0

- I.

- Automated systems: Intelligent systems and sensors optimize energy consumption in smart buildings. Real-time data, occupancy patterns, and ambient conditions optimize lighting, HVAC, and other energy-intensive equipment [81].

- II.

- Dynamic controls: Smart buildings adapt to occupant preferences and time of day. This personalized strategy saves money by turning off lights and thermostats in empty rooms [82].

- III.

- Data analytics and machine learning algorithms optimize power usage. These findings help facility managers manage energy and cost savings [83].

4.4. Comfort in intelligent living spaces

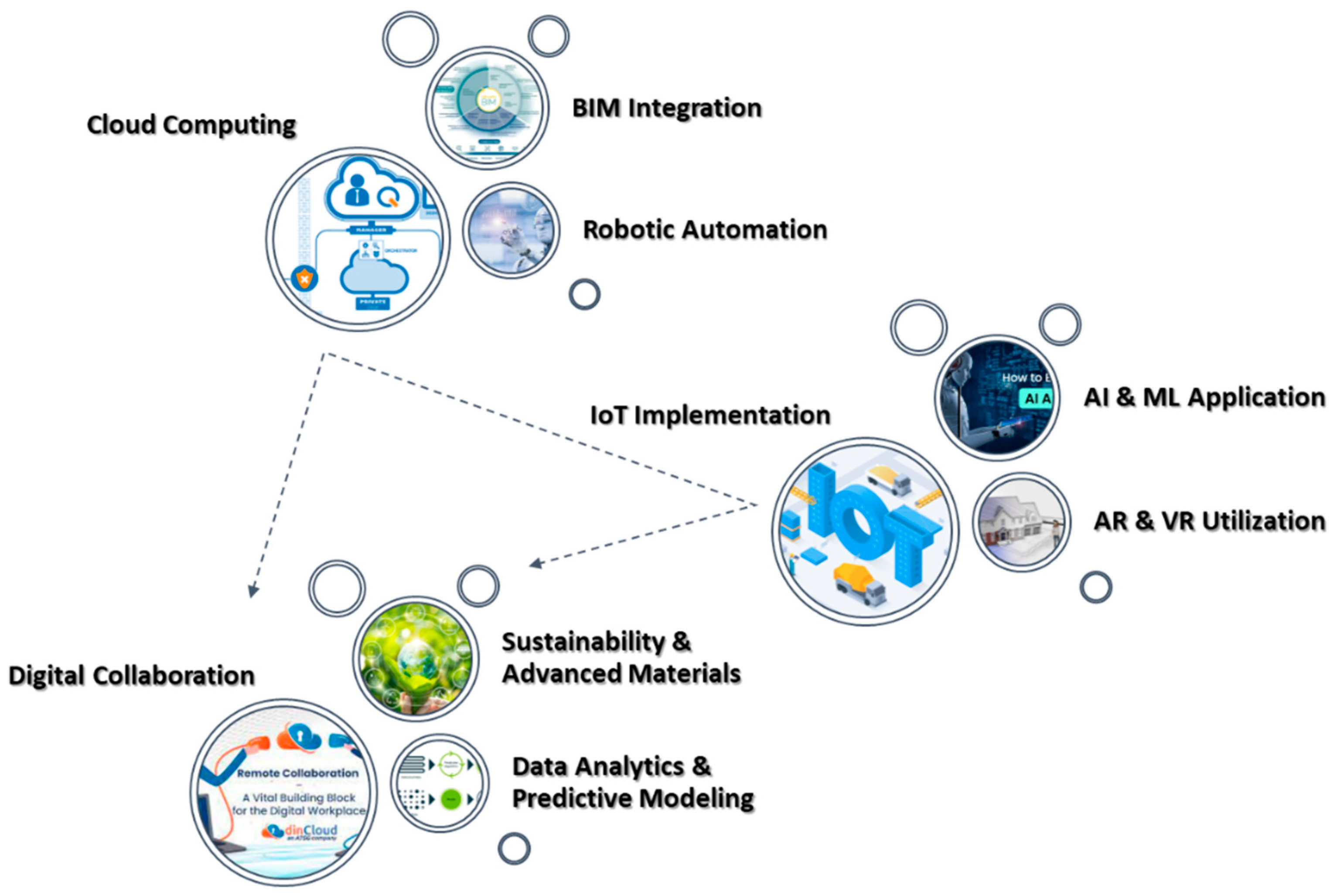

- Production Systems: 3D printing, prefabrication, and offsite manufacturing.

- Cyber-Physical Tools: IoT, robotics, and actuators.

- Computing Technologies: BIM, AI, ML, cloud computing, data analytics, Blockchain, AR, and digital twins.

4.5. Sustainable Development in the AEC Industry Area

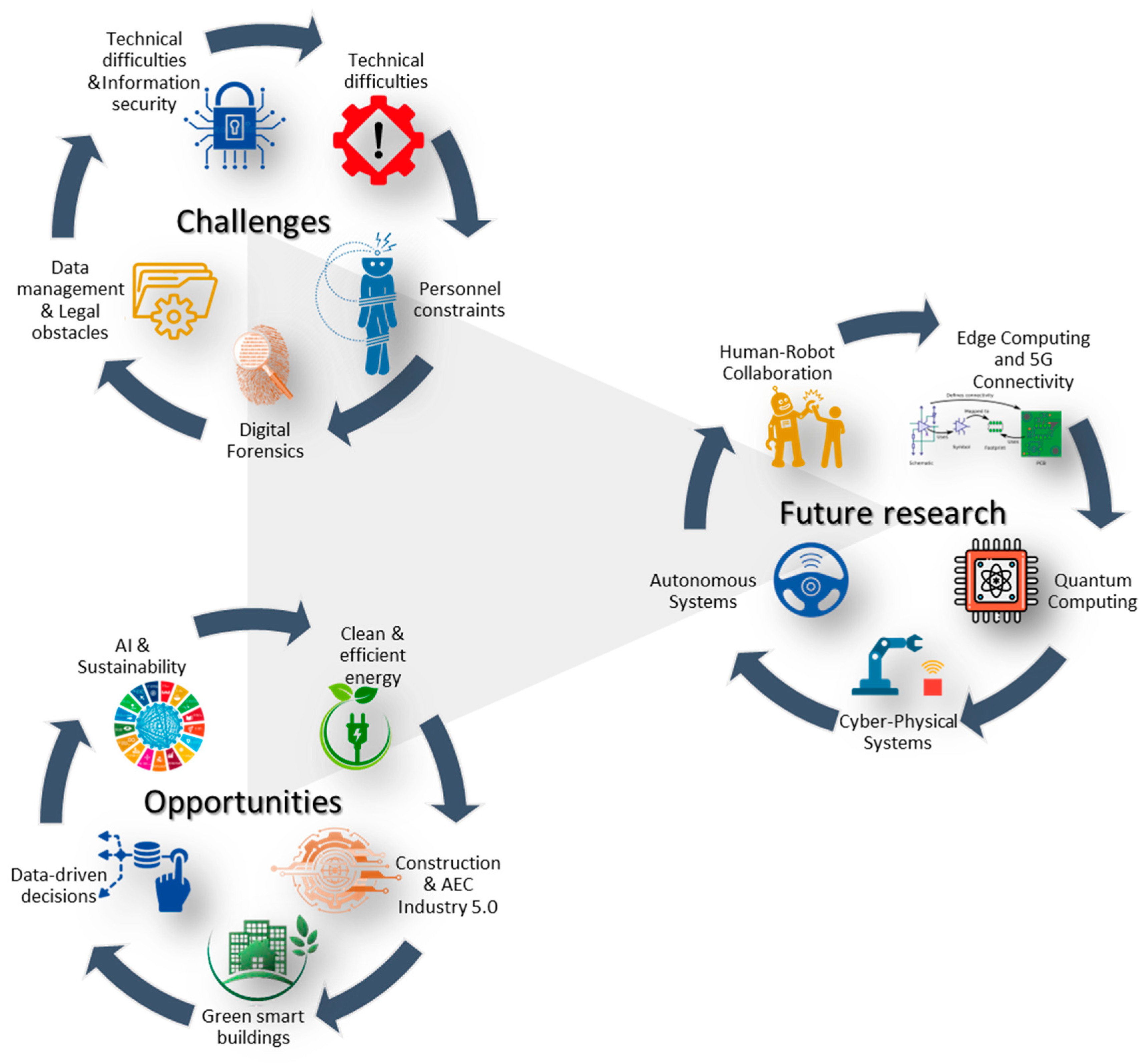

5. Results and future AEC Industry 6.0 Research

5.1. The Future of Industrial Automation: AEC 5.0 to 6.0 and Beyond

5.2. The Human at the Center of AEC Industry 5.0: An Approach to Society

| Analyzing area | Subjects and Keywords | References |

|---|---|---|

| AEC (Architecture, Engineering, Construction) Industry 1-6, Smart design, and sustainability | Architectural, Engineering, Construction, Industry, foundational concepts. AI, productivity, design alternatives, Interdisciplinary collaboration, intelligent building design, AI Sustainable design, environmental data, renewable energy. Holistic methodologies, construction. Visualization enhancement, sustainability. Contemporary age, Industry 1, Industry 2, industrialization, Industry 3, Industry 4 Digital age, Industry 5 social challenges Industry 6.0, design and construction industry, connected environment, dynamic industry networks. |

[1], [7], [9], [10], [11], [12], [17], [18], [28], [29], [31], [32], [33], [34], [35], [36], [38], [39] [40], [[41], [48], [51], [54], [59], [60], [65], [70], [72],[73], [79], [84], [88], [93], [94], [95], [99], [102], [108], [109], [110], [112], [113], [114], [115], [116], [117], [118], [120], [125] |

| Additive Manufacturing | Adaptable value networks, The importance of adopting a critical perspective |

[39], [61], [84] |

| The Role of 3D Printing in Building and Urban Planning | The transformative power of additive manufacturing, especially 3D printing, on the production processes in the AEC industry. The benefits of 3D printing in enhancing the design and aesthetic aspects of buildings and infrastructures |

[43], [44], [45], [46], [47], |

| Artificial Intelligence and Autonomous Robots, Digital Twin technology, Supply Chain | Artificial intelligence (AI), robotic technologies, supply chain 5.0., operational bottlenecks, process optimization, AI algorithms. Interconnected devices, sensors, and autonomous functionalities. Blockchain. Flexible supply chains. Simplifies the industrial supply chain. Robots, collaborative robots (cobots), digital strategy. System operations, resource maximization. Algorithmic Decision Systems, personal data, correlations |

[2], [3], [5], [7], [8], [10], [23], [39], [40], [44], [45], [62], [64], [74], [78], [89], [92] |

| Machine & Deep Learning and Advanced Robotics, metaverse | Artificial intelligence, human intelligence, and augmented intelligence (AuI). Robotics Deep learning, precision, and detection. Data analysis, advanced robots, productivity, safety. Decision-making, life cycle. Machine Learning, Augmented Reality, Virtual Reality, small-scale projects. Virtual environment, metaverse, augmented reality, avatars, and holograms. |

[8],[9], [10], [13], [20],[21], [49], [53], [63], [66], [69], [71], [83], [90], [91], [99], [102], [103], [105], [106], [122] |

| Cyber-Physical Systems | cyber-physical systems, connectivity, and communication. Cyber-physical procedures, Industry 5.0, Zeb, Shah, automation, |

[36], [55], [66], [67], [92], [94], [100] |

| Building Information Modeling (BIM) as a Simulation Technology, digital twin | Smart sensors, construction sites, real-time monitoring. Real-time visualization and design iterations. Technological components, core principles. Data interchange, Building Information modeling (BIM), Facility Management (FM), physical and virtual buildings, infrastructures, and integrated project delivery. Simulators. |

[4], [16], [19], [26], [27], [44], [53], [55], [62], [63], [67], [68], [89], [92], [98] |

| Digital Transformation | Immersive digital representations, stakeholders. Digital technologies, Industry | [16], [33], [43], [121] |

| Big Data AI and IoT | Amalgamation, Lot, IoT, AI, Analytical capacities, Big Data, construction patterns, building practices, project irregularities. | [10], [23], [34], [54], [56], [63], [65], [75], [87], [90], [91], [103], [104] |

| Client-Centric Approach | Technology, long-standing customs. Client-oriented approach, real-time feedback, human expertise | [30], [57] |

| Eco-friendly Construction and Sustainability | Sustainable operations The importance of robots working alongside humans, aiming to create a more eco-friendly and personalized construction environment. Construction sector equality, eco-friendly construction |

[22], [50], [58], [111] |

| Human-centric Design and Resilience | human-centricity, sustainable design. The emphasis of Industry 5.0 is on the collaboration between humans and machines. Merging human capabilities with advanced technologies for better building outcomes. Human-Centric Innovation. |

[10], [22], [24], [37], [42], [58], [62], [119], [120] |

| Challenges and Prospects | Project challenges, milestones, temporal, financial. The challenges the building sector faces in merging digital and physical realms The challenges faced by contemporary manufacturers and the importance of maintaining equipment. |

[6], [52], [72], [101] |

| Energy Efficiency, Disassembly, circular economy, recycling. HAVC, Comfort, | Energy efficiency. Lighting, sound, airflow, and simulation. Sustainable energy HVAC, safety, indoor air quality, energy consumption |

[11], [12], [14], [25], [62], [73], [75], [76], [77], [80], [81], [82], [83], [85], [86], [87], [88], [93], [96], [97], [107], [108], [109], [111], [112], [113], [123] |

6. Discussion

7. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leng, Jiewu, et al. “Industry 5.0: Prospect and retrospect.” Journal of Manufacturing Systems 65 (2022): 279-295. https://doi.org/10.1016/j.jmsy.2022.09.017. [CrossRef]

- Frederico, G.F. From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions. Logistics 2021, 5, 49. https://doi.org/10.3390/logistics5030049. [CrossRef]

- Maddikunta, Praveen Kumar Reddy, et al. Industry 5.0: A survey on enabling technologies and potential applications. Journal of Industrial Information Integration, 2022, 26: 100257. [CrossRef]

- Adio-moses,David; ASAOLU, Olumuyiwa Sunday. Artificial intelligence for sustainable development of intelligent buildings. In: Proceedings of the 9th CIDB Postgraduate Conference, University of Cape Town, South Africa. 2016.

- Chethana, C.; Shaik, Meeravali; PAREEK, Piyush. Artificial Intelligence Applications for Process Optimization in Small Software Firms. Available at SSRN 4466032, 2023.

- Abdulkadir, Mohammud. Project Management Schedule Planning for a Short-distance Factory Relocation: A case study. 2023.

- RAJA SANTHI, Abirami; MUTHUSWAMY, Padmakumar. Industry 5.0 or Industry 4.0 S? Introduction to Industry 4.0 and a peek into the prospective Industry 5.0 technologies. International Journal on Interactive Design and Manufacturing (IJIDeM), 2023, 17.2: 947-979. [CrossRef]

- NGUYEN, Huu Du; TRAN, Kim Phuc. Artificial Intelligence for Smart Manufacturing in Industry 5.0: Methods, Applications, and Challenges. Artificial Intelligence for Smart Manufacturing: Methods, Applications, and Challenges, 2023, 5-33. [CrossRef]

- GOMATHI, L.; MISHRA, Anand Kumar; TYAGI, Amit Kumar. Industry 5.0 for Healthcare 5.0: Opportunities, Challenges and Future Research Possibilities. In: 2023 7th International Conference on Trends in Electronics and Informatics (ICOEI). IEEE, 2023. P. 204-213.

- Yitmen, I.; Almusaed, A.; Alizadehsalehi, S. Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience. Sustainability 2023, 15, 9105. https://doi.org/10.3390/su15119105. [CrossRef]

- RAY, Partha Pratim. ChatGPT: A comprehensive review of the background, applications, key challenges, bias, ethics, limitations, and future scope. Internet of Things and Cyber-Physical Systems, 2023.

- 12. AL-DHAIMESH, Sadeer Hel; TAIB, Nooriati. A Review: Investigation of Augmented Reality–BIM Benefits in Design Process in Aec Industry. Informatica, 2023, 47.5. [CrossRef]

- LAMPE, Brooke; MENG, Weizhi. A survey of deep learning-based intrusion detection in automotive applications. Expert Systems with Applications, 2023, 119771. [CrossRef]

- AHMED, Naveed, et al. Optimal design, operational controls, and data-driven machine learning in sustainable borehole heat exchanger coupled heat pumps: Key implementation challenges and advancement opportunities. Energy for Sustainable Development, 2023, 74: 231-257. [CrossRef]

- 15. Grech, A.; Mehnen, J.; Wodehouse, A. An Extended AI-Experience: Industry 5.0 in Creative Product Innovation. Sensors 2023, 23, 3009. https://doi.org/10.3390/s23063009. [CrossRef]

- Singh, Khushboo. “Evaluation Planning for Artificial Intelligence-based Industry 6.0 Metaverse Integration.” Intelligent Human Systems Integration (IHSI 2023): Integrating People and Intelligent Systems 69.69 (2023).

- GHANSAH, Frank Ato; LU, Weisheng. A scientometric and content analysis are significant opportunities for digital twins for smart buildings. Smart and Sustainable Built Environment, 2023, ahead-of-print.

- Pang, T.Y.; Lee, T.-K.; Murshed, M. Towards a New Paradigm for Digital Health Training and Education in Australia: Exploring the Implication of the Fifth Industrial Revolution. Appl. Sci. 2023, 13, 6854. https://doi.org/10.3390/app13116854. [CrossRef]

- GHOBAKHLOO, Morteza, et al. Behind the definition of Industry 5.0: a systematic review of technologies, principles, components, and values. Journal of Industrial and Production Engineering, 2023, 1-16. [CrossRef]

- Sleem, Ahmed, and Ibrahim Elhenawy. “Survey of Artificial Intelligence of Things for Smart Buildings: A closer outlook." Journal of Intelligent Systems & Internet of Things 8.2 (2023). [CrossRef]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental Profile on Building Material Passports for Hot Climates. Sustainability 2020, 12, 3720. https://doi.org/10.3390/su12093720. [CrossRef]

- Alves et al. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. https://doi.org/10.3390/pr11010193. [CrossRef]

- Singh, Mahipal, Rekha Goyat, and Renu Panwar. “Fundamental pillars for industry 4.0 development: implementation framework and challenges in the manufacturing environment.” The TQM Journal (2023. [CrossRef]

- Gangwar, Veer P., and Deepika Reddy. “Hospitality Industry 5.0: Emerging Trends in Guest Perception and Experiences.” Opportunities and Challenges of Business 5.0 in Emerging Markets (2023): 185-211.

- Kim, D.; Yoon, Y.; Lee, J.; Mago, P.J.; Lee, K.; Cho, H. Design and Implementation of Smart Buildings: A Review of Current Research” Trend. Energies 2022, 15, 4278. https://doi.org/10.3390/en15124278. [CrossRef]

- Almusaed, A.; Yitmen, I. Architectural Reply for Smart Building Design Concepts Based on Artificial Intelligence Simulation Models and Digital Twins. Sustainability 2023, 15, 4955. https://doi.org/10.3390/su15064955. [CrossRef]

- Hosamo, H. H., Imran, A., Cardenas-Cartagena, J., Svennevig, P. R., Svidt, K., & Nielsen, H. K., A review of the digital twin technology in the AEC-FM industry. Advances in Civil Engineering, 2022.

- Ikudayisi, Ayodele Emmanuel, et al. “Integrated practices in the Architecture, Engineering, and Construction industry: Current Scope and Pathway towards Industry 5.0.” Journal of Building Engineering (2023): 106788. [CrossRef]

- Manzoor, B.; Othman, I.; Pomares, J.C. Digital Technologies in the Architecture, Engineering, and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities. Int. J. Environ. Res. Public Health 2021, 18, 6135. https://doi.org/10.3390/ijerph18116135. [CrossRef]

- Tavares, M.C.; Azevedo, G.; Marques, R.P. The Challenges and Opportunities of Era 5.0 for a More Humanistic and Sustainable Society—A Literature Review. Societies 2022, 12, 149. https://doi.org/10.3390/soc12060149. [CrossRef]

- HAYAT, Ahatsham, et al. Introduction to Industry 4.0. In: Blockchain and its Applications in Industry 4.0. Singapore: Springer Nature Singapore, 2023. P. 29-59.

- OMRANE, Amina; AKBARI, Mohsen; PATRA, Gouranga. How to Digitize Human Resource Management in the Era of Industry 4.0? In: Digital Technologies for Smart Business, Economics, and Education: Towards a Promising Future. Cham: Springer International Publishing, 2023. P. 1-18. [CrossRef]

- BARAGDE, Dileep Baburao. Information Technology for Enhancing Public Sector Sustainability. In: Leadership and Governance for Sustainability. IGI Global, 2023. P. 204-221. [CrossRef]

- Žižek, S.Š.; Mulej, M.; Potočnik, A. The Sustainable Socially Responsible Society: Well-Being Society 6.0. Sustainability 2021, 13, 9186. https://doi.org/10.3390/su13169186. [CrossRef]

- Dixit, Uday Shanker. “Evolution of Manufacturing: Growing on a Circular Track.” Additive and Subtractive Manufacturing Processes (2023): 1-30.

- 36. ATIEH, Anas Mahmoud; COOKE, Kavian Omar; OSIYEVSKYY, Oleksiy. The role of intelligent manufacturing systems in implementing Industry 4.0 by small and medium enterprises in developing countries. Engineering Reports, 2023, 5.3: e12578. [CrossRef]

- Pizoń, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203. https://doi.org/10.3390/machines11020203. [CrossRef]

- Singh, Khushboo. “Evaluation Planning for Artificial Intelligence-based Industry 6.0 Metaverse Integration.” Intelligent Human Systems Integration (IHSI 2023): Integrating People and Intelligent Systems 69.69 (2023).

- Chourasia, Shubhangi, et al. “Sustainability of Industry 6.0 in global perspective: benefits and challenges.” Mapan 37.2 (2022): 443-452. [CrossRef]

- Li, Fangyu, et al. “Towards big data-driven construction industry.” Journal of Industrial Information Integration (2023): 100483. https://doi.org/10.1016/j.jii.2023.100483. [CrossRef]

- Duggal, Angel Swastik, et al. “A sequential roadmap to Industry 6.0: Exploring future manufacturing trends.” It Communications 16.5 (2022): 521-531. [CrossRef]

- Nasir, Osama, and Mohammad Arif Kamal. “Exploring the role of parametric architecture in building design: An inclusive approach.” Facta Universitatis, Series: Architecture and Civil Engineering (2023): 095-114. https://doi.org/10.2298/FUACE230114007N. [CrossRef]

- Matthias Leschok et al. 3D printing facades: Design, fabrication, and assessment methods. Automation in Construction, Volume 152, August 2023, 104918. https://doi.org/10.1016/j.autcon.2023.104918. [CrossRef]

- S. Salinas Monroy, P. Li, Y. Fang, and K. A. Loparo, “Blockchain-empowered Distributed Additive Manufacturing-as-a-Service: An Architectural Perspective,” in IEEE Network, https://doi.org/10.1109/MNET.129.2200459. [CrossRef]

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429. https://doi.org/10.3390/buildings13020429. [CrossRef]

- Matthias Leschok et al. 3D printing facades: Design, fabrication, and assessment methods, Automation in Construction, Volume 152, August 2023, 104918, https://doi.org/10.1016/j.autcon.2023.104918. [CrossRef]

- Bereitschaft, Bradley. “The changing ethnic-racial profile of ‘very walkable urban neighborhoods in the US (2010–2020): Are minorities under-represented?” Urban Studies 60.4 (2023): 638-654. [CrossRef]

- Ha, Hoang Thi, and Daljit Singh, eds. “Southeast Asian Affairs 2023.” (2023).

- Mohsen Soori, Behrooz Arezoo, Roza Dastres, Artificial intelligence, machine learning and deep learning in advanced robotics, a review, Cognitive Robotics, Volume 3, 2023, Pages 54-70, https://doi.org/10.1016/j.cogr.2023.04.001. [CrossRef]

- Safdari, Aboutaleb. “From Basic Empathy to Basic Trust in Human-Robot Relation: A Phenomenological Proposal.” ALIFE 2023: Ghost in the Machine: Proceedings of the 2023 Artificial Life Conference. MIT Press, 2023.

- uz Zaman, Uzair Khaleeq, et al., eds. Handbook of Manufacturing Systems and Design: An Industry 4.0 Perspective. CRC Press, 2023.

- Nguyen, T.D.; Adhikari, S. The Role of BIM in Integrating Digital Twin in Building Construction: A Literature Review. Sustainability 2023, 15, 10462. https://doi.org/10.3390/su151310462. [CrossRef]

- Doukari, Omar, Mohamad Kassem, and David Greenwood. “Building Information Modelling.” Disrupting Buildings: Digitalisation and the Transformation of Deep Renovation. Cham: Springer International Publishing, 2023. 39-51.

- Soori, Mohsen, Behrooz Arezoo, and Roza Dastres. “Internet of things for smart factories in industry 4.0, a review.” Internet of Things and Cyber-Physical Systems (2023) https://doi.org/10.1016/j.iotcps.2023.04.006. [CrossRef]

- Hamzah, M et al. Distributed Control of Cyber-Physical Systems on Various Domains: A Critical Review. Systems 2023, 11, 208. https://doi.org/10.3390/systems11040208. [CrossRef]

- Ayodele E. I., Albert P.C. Chan, Amos Darko, Yomi M.D., Integrated practices in the Architecture, Engineering, and Construction industry: Current scope and pathway towards Industry 5.0. Journal of Building Engineering, Volume 73, 15 August 2023, 106788, https://doi.org/10.1016/j.jobe.2023.106788. [CrossRef]

- Yadav, Ruchika, Shakti Arora, and Sunil Dhull. “A Pathway to Industrial Revolution 6.0.” Int. J. Mech. Eng 7 (2022): 1452-1459.

- Hickey, Paul Joseph. A Study of Gender Diversity in US Architecture, Engineering, and Construction (AEC) Industry Leadership. Diss. University of Maryland, College Park, 2023.

- RAO, Purnima, et al. A systematic literature review on SME financing: Trends and future directions. Journal of Small Business Management, 2023, 61.3: 1247-1277. [CrossRef]

- CRONIN, Matthew A.; GEORGE, Elizabeth. The why and how of the integrative review. Organizational Research Methods, 2023, 26.1: 168-192. [CrossRef]

- AL-ALAMI, Suhair. Literature from a Critical Perspective: Food for Thought. Utopian Thought and Latin American Practice: An International Journal of Iberian and Latin American Philosophy and Social Theory 1 (2021): 334-342.

- Almusaed, A.; Almssad, A.; Alasadi, A.; Yitmen, I.; Al-Samaraee, S. Assessing the Role and Efficiency of Thermal Insulation by the “BIO-GREEN PANEL” in Enhancing Sustainability in a Built Environment. Sustainability 2023, 15, 10418. https://doi.org/10.3390/su151310418. [CrossRef]

- Almusaed, A.; Yitmen, I.; Almssad, A. Enhancing Smart Home Design with AI Models: A Case Study of Living Spaces Implementation Review. Energies 2023, 16, 2636. https://doi.org/10.3390/en16062636. [CrossRef]

- Alojaiman, B. Technological Modernizations in the Industry 5.0 Era: A Descriptive Analysis and Future Research Directions. Processes 2023, 11, 1318. https://doi.org/10.3390/pr11051318. [CrossRef]

- Melnyk, Leonid Hryhorovych, et al. “Instruments for ensuring the phase transition of economic systems to management based on industries 3.0, 4.0, 5.0.”,2023.

- Păvăloaia, V.-D.; Necula, S.-C. Artificial Intelligence as a Disruptive Technology—A Systematic Literature Review. Electronics 2023, 12, 1102. https://doi.org/10.3390/electronics12051102. [CrossRef]

- Ehab, A.; Burnett, G.; Heath, T. Enhancing Public Engagement in Architectural Design: A Comparative Analysis of Advanced Virtual Reality Approaches in Building Information Modeling and Gamification Techniques. Buildings 2023, 13, 1262. https://doi.org/10.3390/buildings13051262. [CrossRef]

- Lai H. et al., BIM-Based Platform for Collaborative Building Design and Project Management, May 2019Journal of Computing in Civil Engineering 33(3), https://doi.org/10.1061/(ASCE)CP.1943-5487.0000830. [CrossRef]

- Waqar, A.; Skrzypkowski, K.; Almujibah, H.; Zagórski, K.; Khan, M.B.; Zagórska, A.; Benjeddou, O. Success of Implementing Cloud Computing for Smart Development in Small Construction Projects. Appl. Sci. 2023, 13, 5713. https://doi.org/10.3390/app13095713. [CrossRef]

- Latif, Sehrish. “The role of industry 4.0-enabled data-driven shared platform as an enabler of the product-service system in the context of circular economy: a systematic literature review and future research directions.” Business Strategy & Development (2023).

- Dwivedi, Yogesh K., et al. “So what if ChatGPT wrote it?” Multidisciplinary perspectives on opportunities, challenges and implications of generative conversational AI for research, practice, and policy.” International Journal of Information Management 71 (2023): 102642.

- Zairul, M.; Zaremohzzabieh, Z. Thematic Trends in Industry 4.0 Revolution Potential towards Sustainability in the Construction Industry. Sustainability 2023, 15, 7720. https://doi.org/10.3390/su15097720. [CrossRef]

- Aliero, M.S.; Asif, M.; Ghani, I.; Pasha, M.F.; Jeong, S.R. Systematic Review Analysis on Smart Building: Challenges and Opportunities. Sustainability 2022, 14, 3009. https://doi.org/10.3390/su14053009. [CrossRef]

- Salem, T.; Dragomir, M. Digital Twins for Construction Projects—Developing a Risk Systematization Approach to Facilitate Anomaly Detection in Smart Buildings. Telecom 2023, 4, 135-145. https://doi.org/10.3390/telecom4010009. [CrossRef]

- Krishnan, P.; Prabu, A.V.; Loganathan, S.; Routray, S.; Ghosh, U.; AL-Numay, M. Analyzing and Managing Various Energy-Related Environmental Factors for Providing Personalized IoT Services for Smart Buildings in Smart Environment. Sustainability 2023, 15, 6548. https://doi.org/10.3390/su15086548. [CrossRef]

- Velykorusova, A.; Zavadskas, E.K.; Tupenaite, L.; Kanapeckiene, L.; Migilinskas, D.; Kutut, V.; Ubarte, I.; Abaravicius, Z.; Kaklauskas, A. Intelligent Multi-Criteria Decision Support for Renovation Solutions for a Building Based on Emotion Recognition by Applying the COPRAS Method and BIM Integration. Appl. Sci. 2023, 13, 5453. https://doi.org/10.3390/app13095453. [CrossRef]

- BIONDO, Elias Junior. Real-time indoor air quality (IAQ) monitoring system for smart buildings. 2023. Ph.D. Thesis.

- UTKU, Durdu Hakan, et al. Digital Twin Applications for Smart and Connected Cities. In: Digital Twin Driven Intelligent Systems and Emerging Metaverse. Singapore: Springer Nature Singapore, 2023. P. 141-154.

- Haidar H. H. et al., Improving building occupant comfort through a digital twin approach: A Bayesian network model and predictive maintenance method., Energy and Buildings, Volume 288, 1 June 2023, 112992. https://doi.org/10.1016/j.enbuild.2023.112992. [CrossRef]

- EJIDIKE, Cyril Chinonso; MEWOMO, Modupe Cecilia. Benefits of adopting smart building technologies in building construction in developing countries: a literature review. SN Applied Sciences, 2023, 5.2: 52. [CrossRef]

- MOHAN KRISHNA, S.; PERUMAL, Thinagaran; SURYA, Sumukh. Interoperability in IoT-driven smart buildings. Internet of Things in Modern Computing: Theory and Applications, 2023.

- HEIDARI, Amirreza; KHOVALYG, Dolaana. DeepValve: Development and experimental testing of a Reinforcement Learning control framework for occupant-centric office heating. Engineering Applications of Artificial Intelligence, 2023, 123: 106310. [CrossRef]

- ZHUANG, Dian, et al. Data-driven predictive control for smart HVAC system in IoT-integrated buildings with time-series forecasting and reinforcement learning. Applied Energy, 2023, 338: 120936.

- Merabet, Ghezlane Halhoul, et al. “Intelligent building control systems for thermal comfort and energy-efficiency: A systematic review of artificial intelligence-assisted techniques.” Renewable and Sustainable Energy Reviews 144 (2021): 110969, https://doi.org/10.1016/j.rser.2021.110969. [CrossRef]

- Majid Al Mughairi, Thomas Beach, Yacine Rezgui, Post-occupancy evaluation for enhancing building performance and automation deployment, Journal of Building Engineering, Volume 77, 15 October 2023, 107388, https://doi.org/10.1016/j.jobe.2023.107388. [CrossRef]

- Bueno, A.M.; de Paula Xavier, A.A.; Broday, E.E. Evaluating the Connection between Thermal Comfort and Productivity in Buildings: A Systematic Literature Review. Buildings 2021, 11, 244. https://doi.org/10.3390/buildings11060244. [CrossRef]

- Kureshi, R.R.; Thakker, D.; Mishra, B.K.; Barnes, J. From Raising Awareness to a Behavioural Change: A Case Study of Indoor Air Quality Improvement Using IoT and COM-B Model. Sensors 2023, 23, 3613. https://doi.org/10.3390/s23073613. [CrossRef]

- Maryam Gholamzadehmir et al., Adaptive-predictive control strategy for HVAC systems in intelligent buildings – A review, Sustainable Cities and Society, Volume 63, December 2020, 102480, https://doi.org/10.1016/j.scs.2020.102480. [CrossRef]

- Lam, K.H.; To, W.M.; Lee, P.K.C. Smart Building Management System (SBMS) for Commercial Buildings—Key Attributes and Usage Intentions from Building Professionals’ Perspective. Sustainability 2023, 15, 80. https://doi.org/10.3390/su15010080. [CrossRef]

- Shah, S.F.A.; Iqbal, M.; Aziz, Z.; Rana, T.A.; Khalid, A.; Cheah, Y.-N.; Arif, M. The Role of Machine Learning and the Internet of Things in Smart Buildings for Energy Efficiency. Appl. Sci. 2022, 12, 7882. https://doi.org/10.3390/app12157882. [CrossRef]

- Almusaed A, Almssad A. Blending Human Ware with Software and Hardware in the Design of Smart Cities [Internet]. Sustainable Smart Cities - A Vision for Tomorrow. IntechOpen; 2023. Available from: http://dx.doi.org/10.5772/intechopen.109053. [CrossRef]

- Baduge, Shanaka Kristombu, et al. “Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications.” Automation in Construction 141 (2022): 104440. https://doi.org/10.1016/j.autcon.2022.104440. [CrossRef]

- Jung, C.; El Samanoudy, G. Mitigating Indoor Air Pollution in University Dormitory: The Need for Better Ventilation and Resident Awareness. Buildings 2023, 13, 1144. https://doi.org/10.3390/buildings13051144. [CrossRef]

- Martínez-Peláez, R.; Ochoa-Brust, A.; Rivera, S.; Félix, V.G.; Ostos, R.; Brito, H.; Félix, R.A.; Mena, L.J. Role of Digital Transformation for Achieving Sustainability: Mediated Role of Stakeholders, Key Capabilities, and Technology. Sustainability 2023, 15, 11221. https://doi.org/10.3390/su151411221. [CrossRef]

- Wang, K.; Guo, F. Towards Sustainable Development through the Perspective of Construction 4.0: Systematic Literature Review and Bibliometric Analysis. Buildings 2022, 12, 1708. https://doi.org/10.3390/buildings12101708. [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. https://doi.org/10.3390/su141711087. [CrossRef]

- Sandanayake, M.S. Environmental Impacts of Construction in Building Industry—A Review of Knowledge Advances, Gaps, and Future Directions. Knowledge 2022, 2, 139-156. https://doi.org/10.3390/knowledge2010008. [CrossRef]

- Christine E. et al., Methodology for retrofitting energy in existing office buildings using building information modeling programs, Ain Shams Engineering Journal, Volume 14, Issue 6, June 2023, 102175, https://doi.org/10.1016/j.asej.2023.102175. [CrossRef]

- Taesi, C.; Aggogeri, F.; Pellegrini, N. COBOT Applications—Recent Advances and Challenges. Robotics 2023, 12, 79. https://doi.org/10.3390/robotics12030079. [CrossRef]

- Zeb, Shah, et al. “Industry 5.0 is coming: A survey on intelligent next wireless networks as technological enablers.” arXiv preprint arXiv:2205.09084 (2022), https://doi.org/10.48550/arXiv.2205.09084. [CrossRef]

- Rojek, I. et al. An Artificial Intelligence Approach for Improving Maintenance to Supervise Machine Failures and Support Their Repair. Appl. Sci. 2023, 13, 4971. https://doi.org/10.3390/app13084971. [CrossRef]

- Taboada, I.; Daneshpajouh, A.; Toledo, N.; de Vass, T. Artificial Intelligence Enabled Project Management: A Systematic Literature Review. Appl. Sci. 2023 , 13 , 5014. https://doi.org/10.3390/app13085014. [CrossRef]

- Liyanage, Madhusanka, et al., “Driving forces for multi-access edge computing (MEC) IoT integration in 5G.” ICT Express 7.2 (2021): 127-137. https://doi.org/10.1016/j.icte.2021.05.007. [CrossRef]

- Hemant Kumar Apat, Rashmi Ranjan Nayak, Bibhudatta Sahoo, A comprehensive review on Internet of Things application placement in Fog computing environment, Internet of Things, Volume 23, October 2023, 100866, https://doi.org/10.1016/j.iot.2023.100866. [CrossRef]

- Alojaiman, B. Technological Modernizations in the Industry 5.0 Era: A Descriptive Analysis and Future Research Directions. Processes 2023, 11, 1318. https://doi.org/10.3390/pr11051318. [CrossRef]

- Bonsón, Enrique, Michaela Bednárová, and David Perea. “Disclosures about algorithmic decision making in the corporate reports of Western European companies.” International Journal of Accounting Information Systems 48 (2023): 100596. https://doi.org/10.1016/j.accinf.2022.100596. [CrossRef]

- Illiashenko, O.et al. Security-Informed Safety Analysis of Autonomous Transport Systems Considering AI-Powered Cyberattacks and Protection. Entropy 2023, 25, 1123. https://doi.org/10.3390/e25081123. [CrossRef]

- Yogesh K. et al. Metaverse beyond the hype: Multidisciplinary perspectives on emerging challenges, opportunities, and agenda for research, practice, and policy, International Journal of Information Management, Volume 66, October 2022, 102542, https://doi.org/10.1016/j.ijinfomgt.2022.102542. [CrossRef]

- Yue Liu et al., Materials discovery and design using machine learning, Journal of Materiomics, Volume 3, Issue 3, September 2017, Pages 159-177, https://doi.org/10.1016/j.jmat.2017.08.002. [CrossRef]

- Worku, M.Y. Recent Advances in Energy Storage Systems for Renewable Source Grid Integration: A Comprehensive Review. Sustainability 2022, 14, 5985. https://doi.org/10.3390/su14105985. [CrossRef]

- Mariotti, Nicole, et al. "Recent advances in eco-friendly and cost-effective materials towards sustainable dye-sensitized solar cells." Green Chemistry 22.21 (2020): 7168-7218. [CrossRef]

- Bachs-Herrera, Anna, et al. "Biomass carbon mining to develop nature-inspired materials for a circular economy." Science 26.4 (2023). [CrossRef]

- Kazakova, E.; Lee, J. Sustainable Manufacturing for a Circular Economy. Sustainability 2022, 14, 17010. https://doi.org/10.3390/su142417010. [CrossRef]

- de Oliveira, Roger Assis, et al. "Transdisciplinary competency-based development in the process engineering subjects: A case study in Brazil." Education for Chemical Engineers 44 (2023): 133-154. [CrossRef]

- Bozdag, Ayse Asli. “Aismosis and the pas de deux of human-AI interaction: Exploring the communicative dance between society and artificial intelligence.” Online Journal of Communication and Media Technologies 13.4 (2023): e202340.

- Singh, Gurjeet. “artificial intelligence in the sustainable energy industry: status quo, challenges, and opportunities.” Era International Journal of multidisciplinary research (jar) 9.5 (2023): 234-237. [CrossRef]

- Almusaed, A.; Almssad, A.; Homod, R.Z.; Yitmen, I. Environmental Profile on Building Material Passports for Hot Climates. Sustainability 2020, 12, 3720. https://doi.org/10.3390/su12093720. [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. https://doi.org/10.3390/en15145221. [CrossRef]

- Grabowska, S., Saniuk, S. & Gajdzik, B. Industry 5.0: improving humanization and sustainability of Industry 4.0. Scientometrics 127, 3117–3144 (2022). https://doi.org/10.1007/s11192-022-04370-1. [CrossRef]

- Wang, Baicun, et al. “Human Digital Twin in the Context of Industry 5.0.” Robotics and Computer-Integrated Manufacturing 85 (2024): 102626.https://doi.org/10.1016/j.rcim.2023.102626. [CrossRef]

- Ehab, A.; Heath, T. Exploring Immersive Co-Design: Comparing Human Interaction in Real and Virtual Elevated Urban Spaces in London. Sustainability 2023, 15, 9184. https://doi.org/10.3390/su15129184. [CrossRef]

- De Giovanni, P. Sustainability of the Metaverse: A Transition to Industry 5.0. Sustainability 2023, 15, 6079. https://doi.org/10.3390/su15076079. [CrossRef]

- Destouet, Candice, et al. “Flexible job shop scheduling problem under Industry 5.0: A survey on human reintegration, environmental consideration, and resilience improvement.” Journal of Manufacturing Systems 67 (2023): 155-173. https://doi.org/10.1016/j.jmsy.2023.01.004. [CrossRef]

- Rosak-Szyrocka, Joanna, Justyna Żywiołek, and Muhammad Shahbaz, eds. Quality Management, Value Creation, and the Digital Economy. Taylor & Francis, 2023.

- Yitmen, I.; Almusaed, A.; Alizadehsalehi, S. Investigating the Causal Relationships among Enablers of the Construction 5.0 Paradigm: Integration of Operator 5.0 and Society 5.0 with Human-Centricity, Sustainability, and Resilience. Sustainability 2023, 15, 9105. https://doi.org/10.3390/su15119105. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).