1. Introduction

Lacquer, a natural coating material for wood, porcelain and metal, is tapped from lacquer trees growing in different regions of East and Southeast Asia: Rhus vernicifera (China, Janpan and Korea), Rhus succedanea (Vietnam, and Taiwan), and Melanorrhoea usitata (Laos, Burma, Thailand and Cambodia) [

1,

2]. The main component of lacquer is a mixture of catechol and phenol derivatives (60-65%), proteins (glycoproteins (2%) and a laccase enzyme (1%)), polysaccharides (7%) and water (30%) [

3]. Lacquer can be polymerized in natural environment when catalyzed by laccase to form film with a three-dimensional network structure [

4,

5], which is very stable and possesses excellent waterproofing, anti-corrosion and anti-microbial properties. Therefore, lacquer is an excellent environment-friendly material.

Lacquer wares have been used and valued highly due to their toughness, durability, waterproofing and beauty for a long time. The history of lacquer use can date back to the Neolithic period, which can be divided into six stages in China. The first is incubation stage, mainly in the Neolithic Age. The second is germination stage, in the Bronze Age, including Xia, Shang and Zhou dynasties. The third is growth stage, in the Iron Age, that is Chunqiu Zhanguo dynasty. The fourth is heyday stage, that is lacquer era, mainly in the Qin and Han dynasties. The fifth is recession stage, in the Buddhist era, ranging from Wei to Tang dynasties. The last is flourishing stage, in porcelain era, which consist of Song, Yuan, Ming and Qing dynasties.[

6] The earliest known Chinese lacquerware is a wooden bow coated with raw lacquer, which was excavated from the Kuahuqiao Culture, more than 8000 years ago [

7]. A red lacquered wooden bowl was unearthed at Hemudu, a Neolithic site in Yangtze River Delta, that can be traced back to 6000-7000 years ago [

8]. Today, lacquerwares are still the most valued and popular handicrafts in the world.

As we known, a number of modern analytical methods have been used to characterize lacquerwares, such as optical microscopy (OM) [

9], scanning electron microscope augmented by energy dispersive X-ray spectrometry (SEM-EDS) [

10], Raman spectroscopy [

11], Fourier transform infrared spectrometry (FTIR) [

12] and pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS) [

13]. A large number of scientific researches have been taken to characterize Asian lacquer, which focused on molecular markers to identify the three lacquer species [

14], the interactions between plant oils and lacquers [

15], and the pathways of lacquers degradation [

16]. Most researches were aimed at one ancient lacquerware, several in one burial, or several in different burials but in same period[

17,

18,

19,

20]. However, few researches about similar lacquered artifacts from different periods and its evolution of lacquering techniques were reported. Lacquer Lian was an important daily necessity in ancient times for Chinese women to store their toiletries, which is very common in unearthed cultural relics. It is a round, straight wall mirror box with three animal feet under it and animal ears beside it, which is popular from Warring States Period to Tang and Song dynasties. In this study, seven Lacquer Lians from Warring States Period, Han Dynasty, Song Dynasty and Yuan Dynasty were analyzed via numerous modern analytical methods to investigate the type of lacquer, pigments, drying oil added to the lacquer and evolution of lacquering techniques.

2. Experimental

2.1. Archaeological Samples

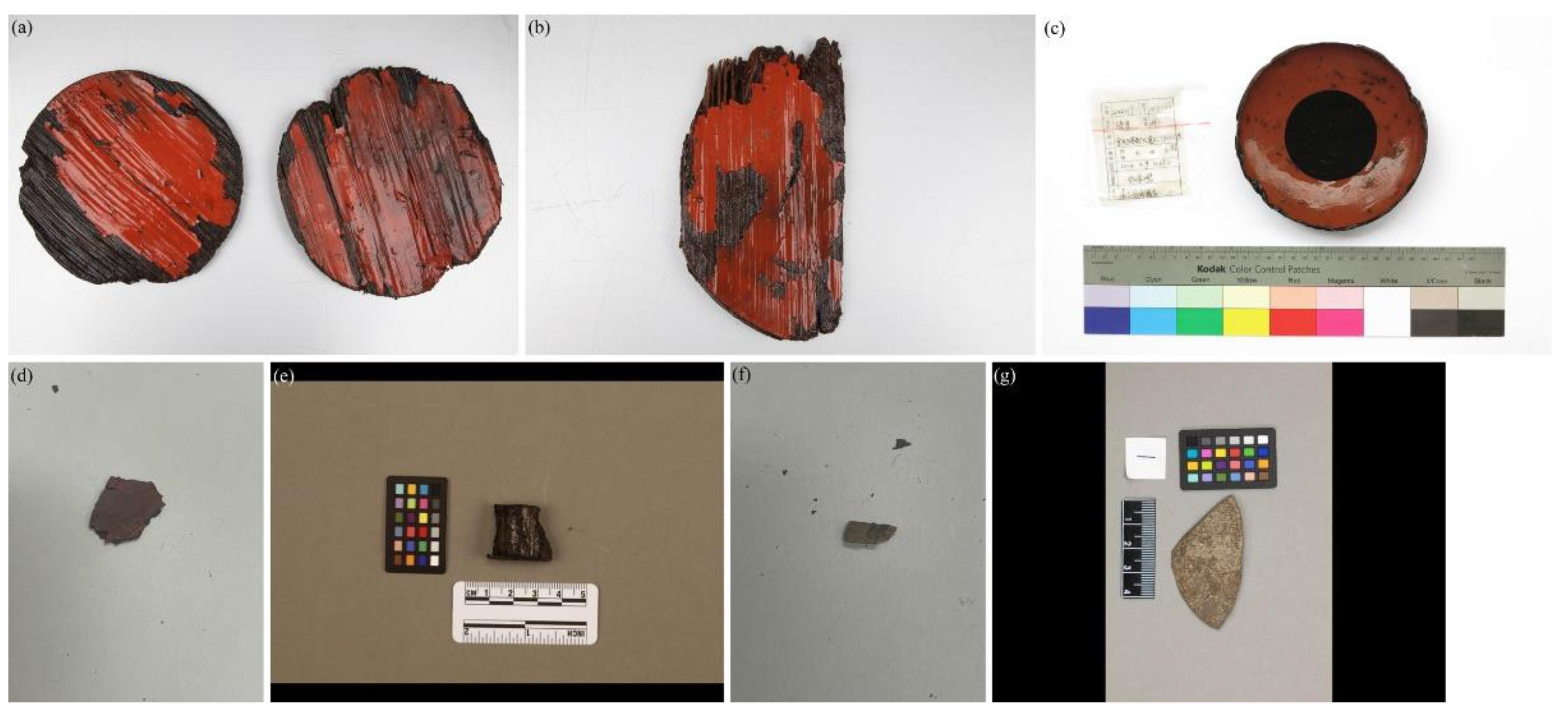

Seven fragment samples of Lacquer Lian used in this study were supplied by Jingzhou Museum, Yangzhou Museum, Changzhou Museum and Jinsha site Museum, respectively. Two of the samples dated back to Warring States Period unearthed from Jigongshan and Yangjiashan tomb, Hubei Province, respectively. Two samples were traced back to Han Dynasty from Tianhui town tomb and Fenghuang mountain tomb, Sichuan Province. Two samples dated back to Song Dynasty supplied by Yangzhou Museum and Changzhou Museum, respectively. The last one was traced back to Yuan Dynasty provided by Yangzhou Museum. The detailed information of each sample is shown in

Table 1 and

Figure 1.

2.2. Analysis Methods

2.2.1. Cross-Section Observations

Lacquer samples were embedded in epoxy resin and the surface was polished by dry sandpapers (up to 12000#) after the epoxy resin was completely cured. The cross-section observations were carried out with an optical microscope (Axio Scope A1, Zeiss, Germany) under blue light (BL).

2.2.2. Raman Spectroscopy

Micro confocal Raman spectrometer (LabRAM HR Evolution, HORIBA, France) was used to determine the mineral pigment in the lacquer film layers.

2.2.3. Thermally Assisted Hydrolysis and Methylation Pyrolysis Coupled with Gas Chromatography/Mass Spectroscopy (THM-Py-GC/MS)

The pyrolysis-gas chromatography/ mass spectroscopy measurements were carried out using a PY-3030D pyrolyzer (Frontier Lab, Japan) attached to a GCMS-QP2020 gas chromatograph mass spectrometer (Shimadzu, Japan). A stainless-steel capillary column (0.25mm i.d. × 30m) coated with 0.25μm of 100% dimethylpolysiloxane was used for separation. The online-methylation with additions of less than 1mg sample and 5μL 25% aqueous solution of tetramethyl ammonium hydroxide was used to obtain methylated phenolic hydroxyl groups. The sample was pyrolyzed at 500℃ for 0.2min. The temperatures of pyrolyzer and GC interface was 300℃. The initial temperature of gas chromatograph oven was set to 50℃, hold at this temperature for 5min, and then increased from 50℃ to 300℃ at 4℃/min. The temperature of gas chromatograph oven was then maintained at a constant temperature of 300℃ for 15.5min. The temperatures of the injector and ion source were set to 300℃ and 230℃, respectively. Helium was used as the carrier gas at a flow rate of 1.0mL/min with a split ratio of 1:20. The electron ionization energy for mass spectroscopy was 70eV, and scanning range were from m/z 10 to 600 with full scan mode. Compounds were identified by comparisons between mass spectroscopy and NIST library.

3. Results and Discussion

3.1. Cross-Sectional Analysis

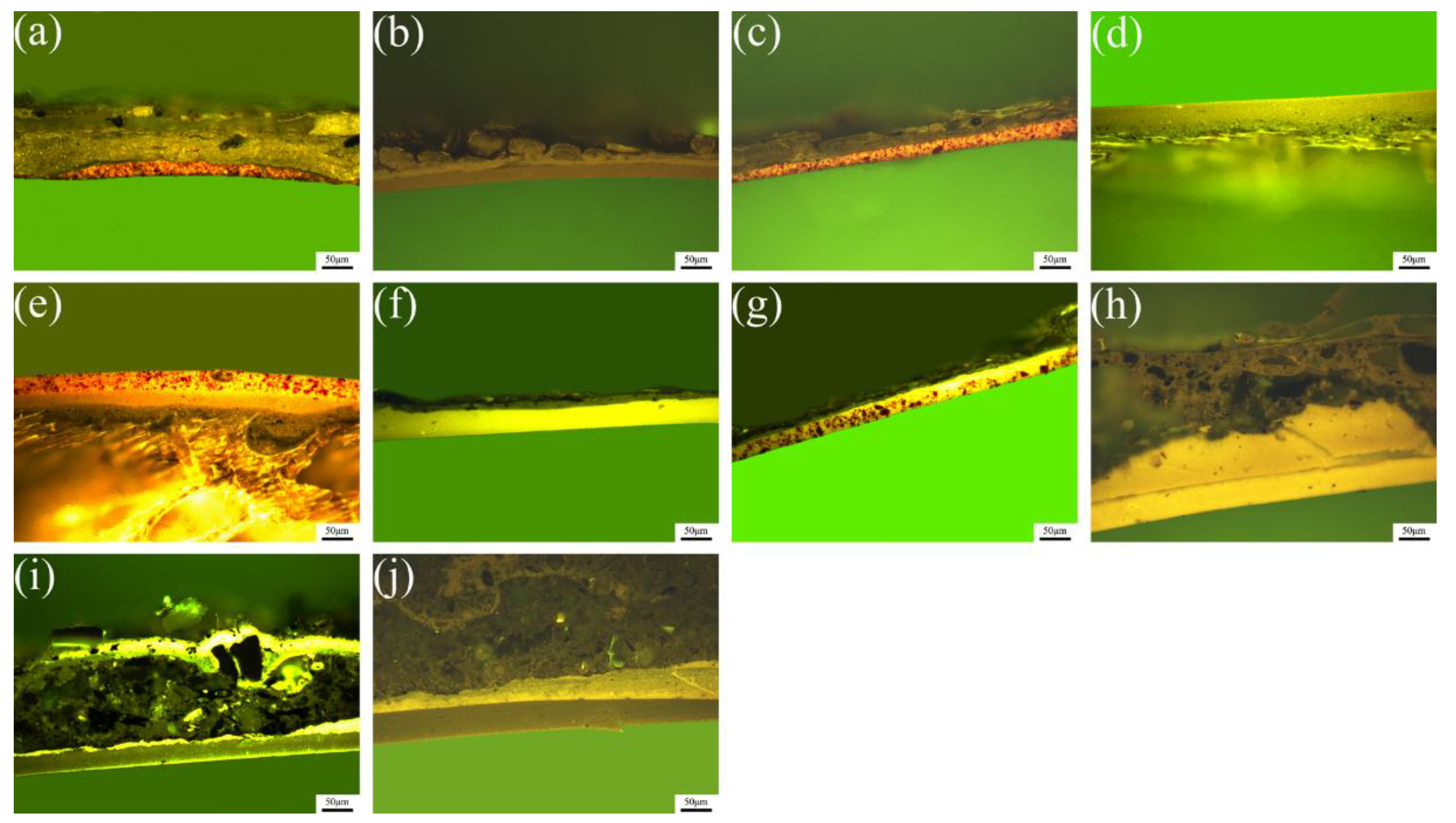

The morphology of the cross-sections of seven samples were examined by optical microscope. As shown in

Figure 2, their cross-sections showed similar three-layer structures, including a colored paint layer with red pigment or a surface finish layer, an undercoat layer and a ground layer. The detailed thickness of lacquer films of the analyzed archaeological samples is shown in

Table 2.

The colored paint layer, known as a mixture of pigment, drying oil and lacquer liquid, was not only used to decorate the lacquerwares, but also could increase the covering power of the lacquer film, prevent ultraviolet rays from penetrating the lacquer film, and delay the aging of the lacquer film. It is located on the top layer of lacquerware, as shown in

Figure 2a,c,e,g). The undercoat layer under the surface layer, which was usually a mixture of lacquer and drying oil, was used to cover defects on the next layer, such as the second layer in

Figure 2. It can also be used as the surface finish layer for the original color of raw lacquer, as shown in

Figure 2b,d,f,h,i,j. A mixture of clay, lacquer and oil, known as the ground layer, was used to fill the pores of lacquer bodies, as shown in

Figure 2.

As shown in

Figure 2, the lacquering techniques of Lacquer Lian had undergone minimal changes from Warring States Period to Yuan Dynasty. Firstly, the ground layer was painted on the lacquer bodies to fill the pores. Secondly, the undercoat layer was used to cover the defects of the ground layer. Lastly, a colored layer or a lacquer layer was used as the surface finish layer to decorate the lacquerware. However, the thickness of the same layer in different eras varied greatly, for instance, the red colored layer became thicker from Warring States Period to Han Dynasty, as shown in

Table 2.

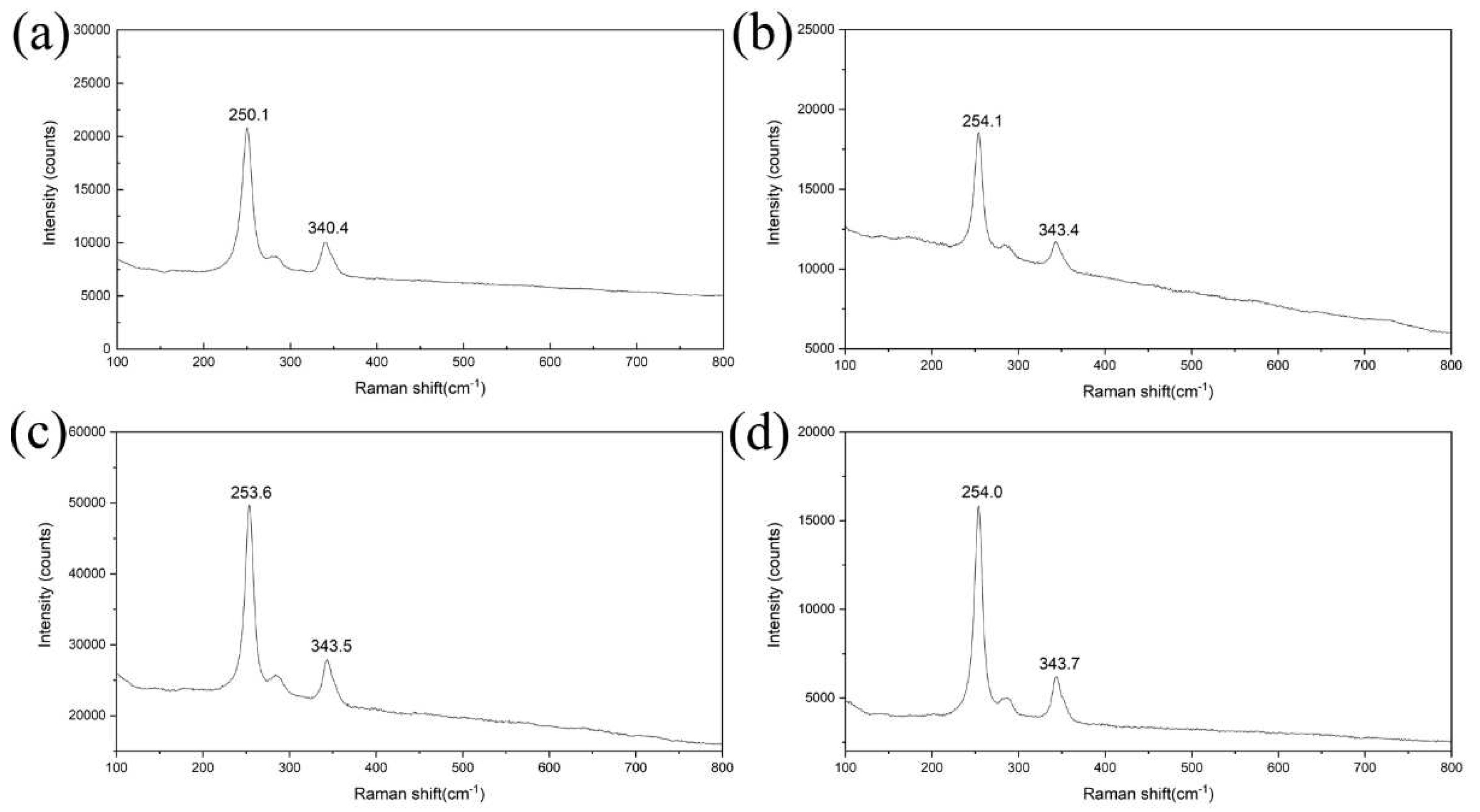

3.2. Pigment Analysis

According to Xiushilu, cinnabar, red ochre and crimson melanterite could make red lacquer. Raman analysis was used to clarify the minerals in the red pigments.

Figure 3 shows Raman spectra of the red pigments. All the four red pigments show the similar Raman spectra, with peaks at about 254cm

-1 and 343cm

-1, which are characteristic bands of cinnabar. Due to its excellent color, gloss and anti-corrosion properties, cinnabar is the best choice for making red lacquer.

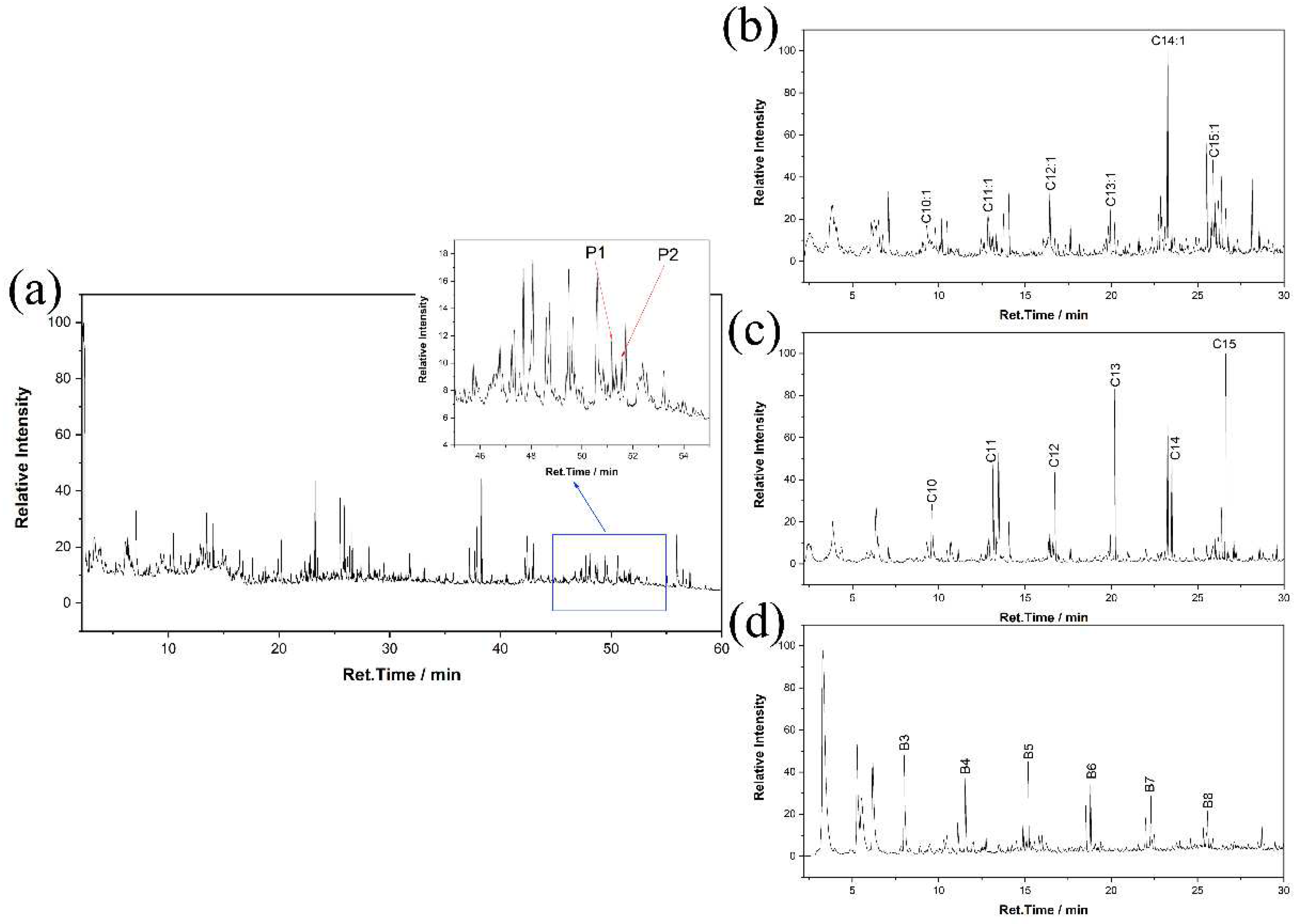

3.3. Lacquer Film Analysis

In order to identify the type of lacquer and oil in different layers of the seven samples, THM-Py-GC/MS analysis was carried out. All the seven samples show similar chromatographic profiles, only the chromatographic profiles of red layer of sample 1 was presented in

Figure 4, and the rest were shown in Appendix A. Supplementary data. The presence of lacquer was assessed by using EICs, as shown in

Figure 4. Characteristic pyrolysis products have been confirmed and summarized in Table 3. The aliphatic hydrocarbons (C, m/z 55and 57,

Figure 4b,c) present from 1-Decene (C9:1) to 1-Pentadecene (C15:1), peaking at 1-Tetradecene (C14:1), and present from Decane (C10) to Pentadecane (C15), peaking at Pentadecane (C15); the alkylbenzenes (B, m/z 91,

Figure 4d) show decreasing profile from benzene propyl- (B3) to benzene octyl- (B8). These results are identical to those of urushi [

21]. In addition, 1,2-Dimethoxy-3-pentadec-8-enylbenzene (P1, 3-pentadecenyl-catechol) and 1,2-Dimethoxy-3-pentadecylbenzene (P2, 3-pentadecyl-catechol) have been detected in the red layer as shown in Table 3, both the components are characteristic components of urushi [

22,

23].

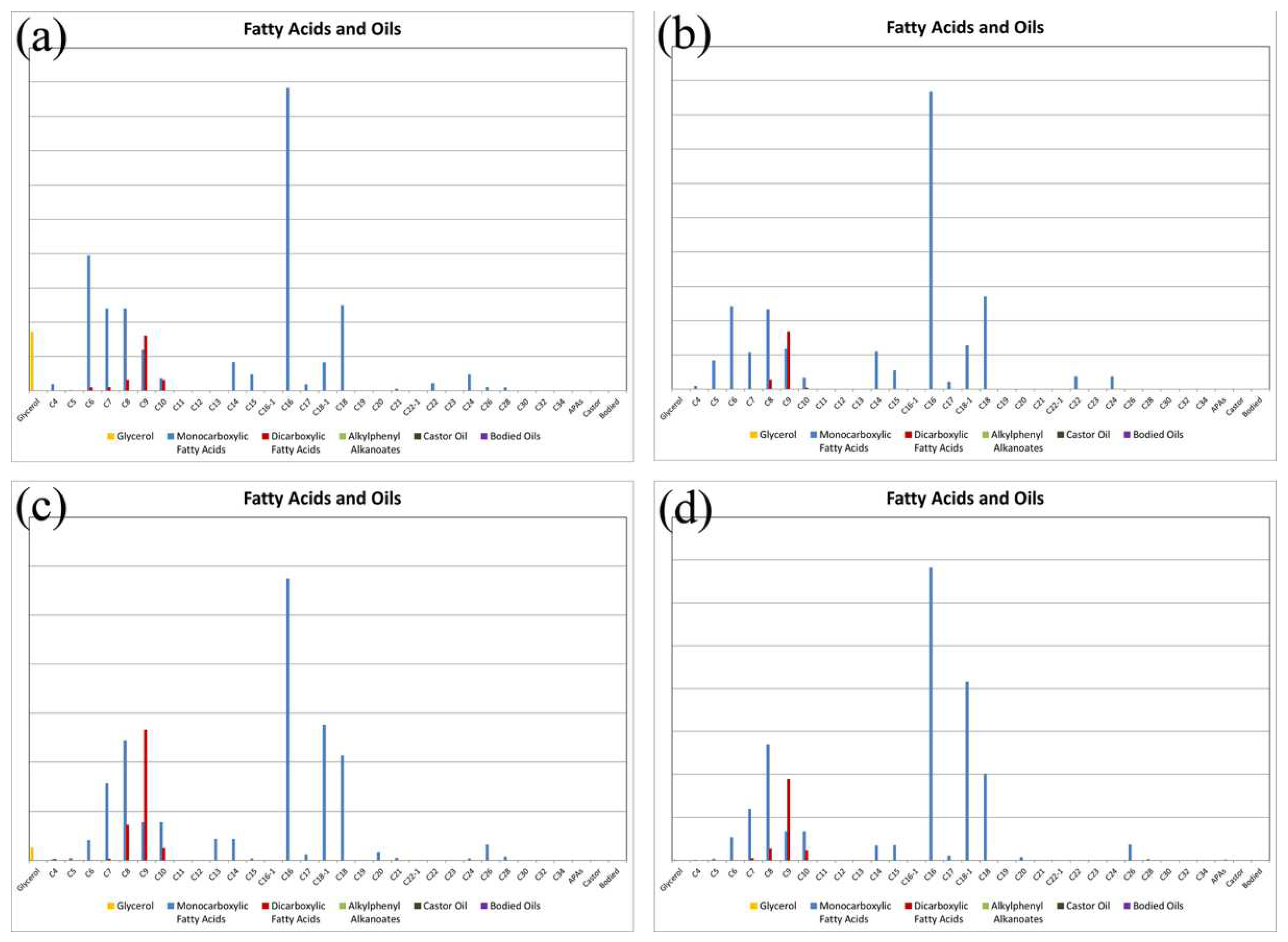

Figure 5 shows the relative concentration of fatty acids detected from red layers. It can be seen that a large number of mono-carboxylic acids and di-carboxylic acids were detected, especially nonanedioic acid (C8) and octanedioic acid (C9), which are the typical pyrolytical and aging products of dying oil. These results indicate that drying oil has been used in the red layer. Lacquer could be easily mixed with pigments by drying oil to get colorful lacquerwares.

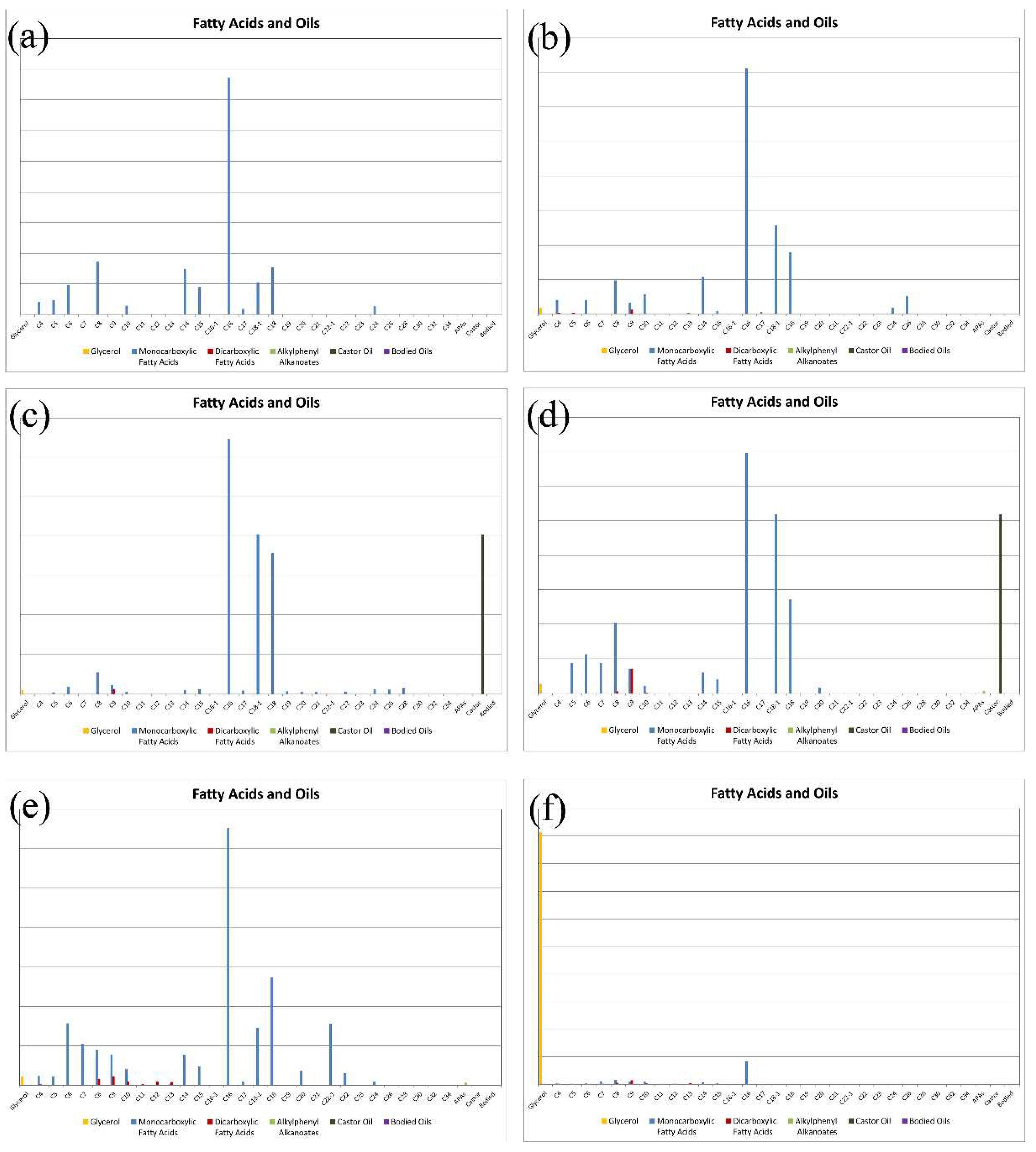

Figure 6 shows the relative concentration of fatty acids detected from black layers. There is no drying oil in black layers of Lacquer Lian from Warring States Period, as shown in

Figure 6a,b. Castor oil were detected in black layers of lacquerwares from Han Dynasty and Song Dynasty, which is one kind of drying oil, as shown in

Figure 6c,d.

Figure 6e,f indicate that there is drying oil in the black layers of lacquerwares from Song Dynasty and Yuan Dynasty. Drying oil can slow the hardening process of lacquer and increase the luster and flexibility of the lacquer to improve the quality of lacquerwares.

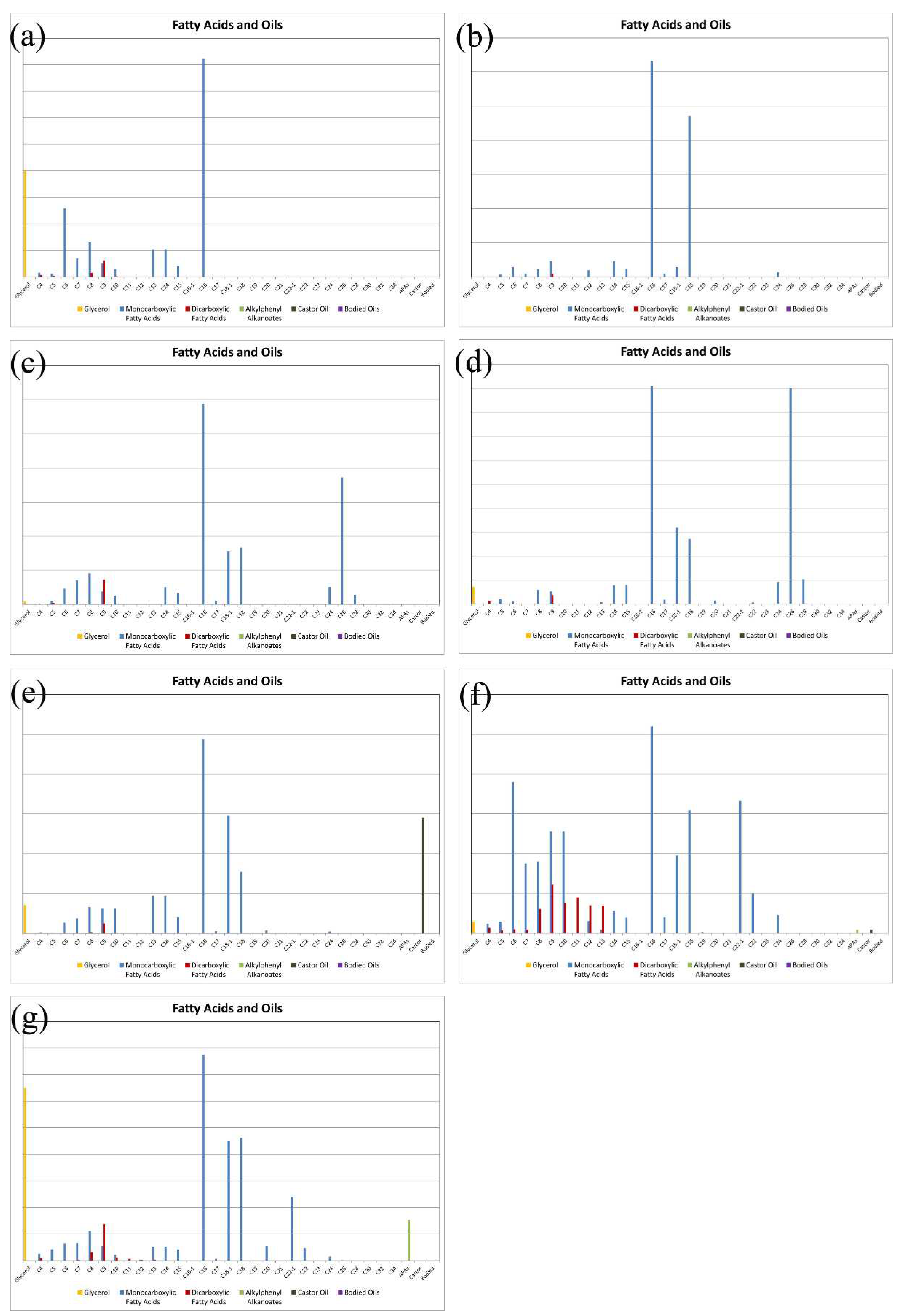

The relative concentration of fatty acids detected from ground layers is shown in

Figure 7. Drying oil was used in the ground layer for Sample 1, but not for Sample 2, as shown in

Figure 7a,b.

Figure 7c,d shows that drying oil was widely used in ground layers in Han Dynasty. Castor oil was detected in the ground layer of Sample 5 (

Figure 7e). Since methyl alkylphenyl alkanoate (APAs) is the marker component of boiled tung oil, it could be concluded that boiled tung oil was used in the ground layer of Sample 6 and Sample 7 based on the results of

Figure 7f,g.

4. Conclusions

Seven Lacquer Lians from Warring States Period, Han Dynasty, Song Dynasty and Yuan Dynasty were comprehensively investigated using a scientific analytical approach. The cross-section photos indicated that Lacquer Lian included pigment layer, undercoat layer and ground layer, and lacquering techniques had undergone minimal changes from Warring States Period to Yuan Dynasty. Raman analysis clarified that the red pigment was cinnabar. The THM-Py-GC/MS results indicated that all lacquerwares were coated with lacquer sap collected from a Rhus vernicifera lacquer tree. Drying oil was mixed with lacquer sap to increase luster and elastic of lacquer film. Boiled tung oil was found in the ground layer of lacquerwares from Song Dynasty and Yuan Dynasty. This study will provide a better understanding of the evolution of Chinese lacquering techniques and lacquering materials.

Author Contributions

The first author, Hao Wu, carried out the Raman experiments of the samples, analyzed the data and designed the article. The second author, Yang Zhao, carried out THM-Py-GC/MS of the samples. The third author, Beisong Fang, provided archaeological samples and their archaeological information. Corresponding author and the fourth author, Jingren Dong, designed the article and funded the research.

Acknowledgments

This work was financially supported by the the National Key R&D Program of China [No. 2019YFC1520300].

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- N. Niimura, T. Miyakoshi, J. Onodera, T. Higuchi, Characterization of Rhus vernicifera and Rhus succedanea lacquer films and their pyrolysis mechanisms studied using two-stage pyrolysis-gas chromatography/mass spectrometry, Journal of Analytical and Applied Pyrolysis 37(2) (1996) 199-209. [CrossRef]

- N. Niimura, T. Miyakoshi, J. Onoderra, T. Shiguchi, Structural studies of Melanorrhoea usitate lacquer film using two-stage pyrolysis/gas chromatography/mass spectrometry, Rapid Communications in Mass Spectrometry 10(14) (1996) 1719-1724.

- D. Tamburini, I. Bonaduce, M.P. Colombini, Characterization and identification of urushi using in situ pyrolysis/silylation–gas chromatography–mass spectrometry, Journal of Analytical and Applied Pyrolysis 111 (2015) 33-40. [CrossRef]

- 4. J. Kumanotani, Urushi (oriental lacquer) — a natural aesthetic durable and future-promising coating, Progress in Organic Coatings 26(2) (1995) 163-195. [CrossRef]

- R. Lu, Y. Kamiya, T. Miyakoshi, Applied analysis of lacquer films based on pyrolysis-gas chromatography/mass spectrometry, Talanta 70(2) (2006) 370-376. [CrossRef]

- M. Sung, J. Jung, R. Lu, T. Miyakoshi, Study of historical Chinese lacquer culture and technology – Analysis of Chinese Qin-Han dynasty lacquerware, Journal of Cultural Heritage 21 (2016) 889-893. [CrossRef]

- M. Wu, B. Zhang, L. Jiang, J. Wu, G. Sun, Natural lacquer was used as a coating and an adhesive 8000 years ago, by early humans at Kuahuqiao, determined by ELISA, Journal of Archaeological Science 100 (2018) 80-87. [CrossRef]

- M. Wu, Y. Zhang, B. Zhang, L. Li, Study of colored lacquerwares from Zenghou Yi Tomb in Early Warring States, New Journal of Chemistry 45(21) (2021) 9434-9442. [CrossRef]

- L. Zheng, L. Wang, X. Zhao, J. Yang, M. Zhang, Y. Wang, Characterization of the materials and techniques of a birthday inscribed lacquer plaque of the qing dynasty, Heritage Science 8(1) (2020). [CrossRef]

- X. Ma, Y. Shi, H. Khanjian, M. Schilling, M. Li, H. Fang, D. Cui, I. Kakoulli, Characterization Of Early Imperial Lacquerware From The Luozhuang Han Tomb, China, Archaeometry 59(1) (2017) 121-132. [CrossRef]

- L.F.C. de Oliveira, H.G.M. Edwards, R.L. Frost, J.T. Kloprogge, P.S. Middleton, Caput mortuum: spectroscopic and structural studies of an ancient pigment, Analyst 127(4) (2002) 536-541. [CrossRef]

- X. Li, X. Wu, Y. Zhao, Q. Wen, Z. Xie, Y. Yuan, T. Tong, X. Shen, H. Tong, Composition/structure and lacquering craft analysis of Wenzhou Song dynasty lacquerware, Analytical Methods 8(35) (2016) 6529-6536. [CrossRef]

- X. Hao, H. Wu, Y. Zhao, T. Tong, X. Li, C. Yang, Y. Tang, X. Shen, S. Liu, H. Tong, Scientific investigation of the lacquered wooden coffin of Xiang Fei excavated from Eastern Royal Tombs of the Qing Dynasty, New Journal of Chemistry 41(18) (2017) 9806-9814. [CrossRef]

- D. Tamburini, D. Sardi, A. Spepi, C. Duce, M.R. Tinè, M.P. Colombini, I. Bonaduce, An investigation into the curing of urushi and tung oil films by thermoanalytical and mass spectrometric techniques, Polymer Degradation and Stability 134 (2016) 251-264. [CrossRef]

- T. Honda, R. Lu, R. Sakai, T. Ishimura, T. Miyakoshi, Characterization and comparison of Asian lacquer saps, Progress in Organic Coatings 61(1) (2008) 68-75. [CrossRef]

- D. Tamburini, G. Pescitelli, M.P. Colombini, I. Bonaduce, The degradation of Burmese lacquer (thitsi) as observed in samples from two cultural artefacts, Journal of Analytical and Applied Pyrolysis 124 (2017) 51-62. [CrossRef]

- Y. Fu, Z. Chen, S. Zhou, S. Wei, Comparative study of the materials and lacquering techniques of the lacquer objects from Warring States Period China, Journal of Archaeological Science 114 (2020) 105060. [CrossRef]

- K. Yuasa, T. Honda, R. Lu, T. Hachiya, T. Miyakoshi, Analysis of Japanese ancient lacquerwares excavated from Jōmon period ruins, Journal of Analytical and Applied Pyrolysis 113 (2015) 73-77. [CrossRef]

- S. Wei, V. Pintus, V. Pitthard, M. Schreiner, G. Song, Analytical characterization of lacquer objects excavated from a Chu tomb in China, Journal of Archaeological Science 38(10) (2011) 2667-2674. [CrossRef]

- X. Wang, X. Hao, Y. Zhao, T. Tong, H. Wu, L. Ma, X. Shen, H. Tong, Systematic study of the material, structure and lacquering techniques of lacquered wooden coffins from the Eastern Regius Tombs of the Qing Dynasty, China, Microchemical Journal 168 (2021) 106369. [CrossRef]

- D. Tamburini, I. Bonaduce, E. Ribechini, C. Gallego, J. Perez-Arantegui, Challenges in the data analysis of Asian lacquers from museum objects by pyrolysis gas chromatography/mass spectrometry, JOURNAL OF ANALYTICAL AND APPLIED PYROLYSIS 151 (2020). [CrossRef]

- 22. N. Niimura, Determination of the type of lacquer on East Asian lacquer ware, International Journal of Mass Spectrometry 284(1-3) (2009) 93-97.

- M.R. Schilling, A. Heginbotham, H. van Keulen, M. Szelewski, Beyond the basics: A systematic approach for comprehensive analysis of organic materials in Asian lacquers, STUDIES IN CONSERVATION 61 (2016) 3-27. [CrossRef]

Figure 1.

Images of lacquer fragments of a) - b) Warring States Period, c) – d) Han Dynasty, e) – f) Song Dynasty and f) Yuan Dyansty.

Figure 1.

Images of lacquer fragments of a) - b) Warring States Period, c) – d) Han Dynasty, e) – f) Song Dynasty and f) Yuan Dyansty.

Figure 2.

Cross-sectional photos of a) Sample 1, b) Sample 2 (black), c) Sample 2 (red), d) Sample 3 (black), e) Sample 3 (red), f) Sample 4 (black), g) Sample 4 (red), h) Sample 5, i) Sample 6 and j) Sample 7 under blue light.

Figure 2.

Cross-sectional photos of a) Sample 1, b) Sample 2 (black), c) Sample 2 (red), d) Sample 3 (black), e) Sample 3 (red), f) Sample 4 (black), g) Sample 4 (red), h) Sample 5, i) Sample 6 and j) Sample 7 under blue light.

Figure 3.

Raman spectra of red pigments of a) Sample 1, b) Sample 2, c) Sample 3, and d) Sample 4.

Figure 3.

Raman spectra of red pigments of a) Sample 1, b) Sample 2, c) Sample 3, and d) Sample 4.

Figure 4.

Chromatographic profiles obtained by THM-Py–GC/MS of red layer of sample 1: (a) total ion pyrogram; (b) m/z 55 extracted ion pyrogram; (c) m/z 57 extracted ion pyrogram; (d) m/z 91 extracted ion pyrogram.

Figure 4.

Chromatographic profiles obtained by THM-Py–GC/MS of red layer of sample 1: (a) total ion pyrogram; (b) m/z 55 extracted ion pyrogram; (c) m/z 57 extracted ion pyrogram; (d) m/z 91 extracted ion pyrogram.

Figure 5.

The relative concentration of fatty acids in red layers of (a) Sample 1, (b) Sample 2, (c) Sample3, and (d) Sample 4.

Figure 5.

The relative concentration of fatty acids in red layers of (a) Sample 1, (b) Sample 2, (c) Sample3, and (d) Sample 4.

Figure 6.

The relative concentration of fatty acids in black layers of (a) Sample 2, (b) Sample 3, (c) Sample4, (d) Sample 5, (e) Sample 6 and (f) Sample 7.

Figure 6.

The relative concentration of fatty acids in black layers of (a) Sample 2, (b) Sample 3, (c) Sample4, (d) Sample 5, (e) Sample 6 and (f) Sample 7.

Figure 7.

The relative concentration of fatty acids in ground layers of (a) Sample 1, (b) Sample 2, (c) Sample3, (d) Sample 4, (e) Sample 5, (f) Sample 6 and (g) Sample 7.

Figure 7.

The relative concentration of fatty acids in ground layers of (a) Sample 1, (b) Sample 2, (c) Sample3, (d) Sample 4, (e) Sample 5, (f) Sample 6 and (g) Sample 7.

Table 1.

Detailed information of the analyzed archaeological samples.

Table 1.

Detailed information of the analyzed archaeological samples.

| Sample No. |

Dynasty |

Provenance |

| 1 |

Warring States Period |

Hubei, China |

| 2 |

Warring States Period |

Hubei, China |

| 3 |

Han Dynasty |

Sichuan, China |

| 4 |

Han Dynasty |

Sichuan, China |

| 5 |

Song Dynasty |

Jiangsu, China |

| 6 |

Song Dynasty |

Jiangsu, China |

| 7 |

Yuan Dynasty |

Jiangsu, China |

Table 2.

The detailed thickness of lacquer films of the analyzed archaeological samples.

Table 2.

The detailed thickness of lacquer films of the analyzed archaeological samples.

| Sample |

Color |

Layer 1 (μm) |

Layer 2 (μm) |

| 1 |

red |

21.6 |

56.7 |

| 2 |

black |

21.6 |

28.1 |

| red |

19.2 |

22.7 |

| 3 |

black |

40.8 |

- |

| red |

29.9 |

23 |

| 4 |

black |

39 |

11.7 |

| red |

27.6 |

5.1 |

| 5 |

black |

43.8 |

78.9 |

| 6 |

black |

31.6 |

9.9 |

| 7 |

black |

45.3 |

35.1 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).