1. Introduction

In the production process of agricultural products, the loss rates accumulate throughout the entire production chain, from the harvest to the consumer’s table. This scenario makes it essential to use techniques and technologies that promote the reduction of such losses [

1]. Additionally, to provide conditions that favor the maintenance of product quality, one must know the physical and mechanical properties of the material being worked on for proper use of processing techniques and equipment [

2,

3].

Coffee is one of the products that has an increase in value and export volume due to better quality but may have its flavor, aroma and color altered due to the occurrence of mechanical damage, which affects the desired attributes [

4]. In this context, there has been a strengthening of the industry standards for the production of high-quality coffee, as well as of the institutions that evaluate its excellence and qualify specialty coffees, which influences the sales price of the lots and can favor the reputation of the countries and regions that produce this coffee [

5,

6].

Among the coffee-producing countries, Brazil produces the largest amount, approximately 48 million bags in 2021, which contributes to the gross domestic product (GDP) of the country; furthermore, in 2020, the coffee production in Brazil had an increased contribution to the agribusiness [

7,

8,

9].

However, for coffee to continue contributing effectively to the economic development of Brazil, attention should be given to the damage caused to this fruit due to the mechanical processes, semi-mechanized and mechanized, to which it is subjected from the harvest to the final destination [

10].

[

11] found that one of the ways to alter the mechanical processes of coffee processing that can induce injuries to the fruits is the study and evaluation of scenarios that result in damage to the fruits via computer simulation. mechanical behavior during the storage and harvesting processes for different stages of maturation. In this case, the use of known mechanical properties such as elastic modulus, Poisson coefficient and density is essential to predict the deformation, energy distribution and equivalent stress of the material after compression loads application [

12].

[

13] highlighted that one of the ways to measure the mechanical response of materials is through compression testing and that parameters such as moisture content and force application region can affect the mechanical behavior of the fruit. Hertz theory states that when compression occurs between two solid bodies, they initially touch a single point in the contact region, causing them, after light loading, to deform elastically in the vicinity of the primary contact point [

14]. [

11] highlighted that fruit cells in such a contact area are compressed, while the adjacent cells are subjected to stress, shearing or flexion, with a mechanical response that may be related to the internal structure of the fruit and to the solid biomaterials of tissues and cellular components. Thus, it is important to analyze these responses in fruits with different maturation stages.

In this context, this study aimed to analyze, by means of computer simulation, the deformation, strain energy and von Mises stress of coffee fruit in the mature, semi-ripe and immature maturation stages after being compressed by collapse forces, pointing out the relevance of modeling in obtaining data that can help reduce the compression damage caused during harvesting and storage processes of coffee fruits at different stages of maturation.

2. Literature review

2.1. Coffea arabica L.

Arabica coffee (Coffea arabica L.) belongs to the order Gentianales, family Rubiaceae and genus Coffea and is a shrub native to the region of southwestern Ethiopia, southeastern Sudan and northern Kenya but has been cultivated in other locations, such as in Brazil, where there are approximately 132 cultivars registered with the responsible agencies [

15,

16].

The species Coffea arabica was introduced in Brazilian soil first in Pará, in approximately 1727, and spread throughout Maranhão, Bahia, Rio de Janeiro, São Paulo, Minas Gerais, Paraná and Espírito Santo, occupying a relevant position in the worldwide supply in the twentieth century [

17].

The climatic variety of the regions of Brazil where coffee is grown causes productivity to fluctuate over time, since this crop is sensitive to drought, extreme temperatures and high humidity [

18]. For [

19], the ideal climate for cultivating Arabica coffee should have mild temperatures during the year, at altitudes between 900 and 1200 m and with preferential cultivation in shaded places.

The coffee plant, a shrub of continuous growth that reaches between 2 and 4 m in height, has a cylindrical, yellowish-white stem, with hard wood, dark green leaves, oval, opposite and paired, with white aromatic flowers [

15]. Its phenological cycle takes two years to complete, with the formation of vegetative branches (plagiotropic or transverse), from the orthotropic branches (orthogonal or perpendicular to the soil), containing nodes with auxiliary buds occurring in the first year. In the second year, flowering begins, followed by the formation of pellets, grain expansion, fruit germination and maturation [

20].

During the fruit ripening process, there is a reduction in chlorophyll and an increase in anthocyanins and carotenoids, which, combined with the action of ethylene and the increase in the activity of the enzymes responsible for the softening of the cell wall, transforms the hard, green and rigid fruit into soft fruit [

20]. The degree of maturation together with the size of the beans, which are thinner than Robusta coffee, can reduce harvest efficiency and change the quality of the arabica coffee beverage products, which tend to have a low caffeine content and favorable aroma and flavor [

19,

21].

During the harvesting process, mechanical damage can be caused to the fruit, affecting the quality of the product (coffee) and thus compromising the value and volume of the commercialization [

4]. Therefore, there is a need to search for effective methods to optimize mechanical processing design and minimize these injuries, such as modeling and computational simulation [

11].

2.2. Modeling with finite element method

In the industrial production system, the search for design solutions is performed empirically, by trial and error, based on the designer's experience, something that is time-consuming and costly. However, with technological advancement, the industry has recently used computational modeling to solve such problems [

22].

It was in 1950 in the United States that modeling and simulation was developed, which was initially intended for military use now is also used to support decision-making by evaluating and analyzing real systems through computational models [

23].

[

24] and [

25] suggested that a model can be defined as a set of equations that predict the behavior of a process through approximate representation, with a complexity that depends on the end use. Additionally, [

26] suggested that computational modeling is a multidisciplinary technique to perform simpler and incomplete representations of the analyzed system, using tools to create microsystems. [

27] pointed out that this type of model applies computational techniques and mathematical models and develops codes to understand and analyze complex phenomena and simulate solutions to problems.

Among the benefits of simulation associated with modeling is the possibility of simulating the real world without the need for experiments that require higher costs; this approach is flexible and can be used to improve systems, test concepts before implementing them, and optimize processes and resources [

23,

25]. [

24] highlighted that the main utility of a model is to allow the investigation of the responses of a system under various conditions without modifying the system, i.e., it is able to replace the physical system.

To perform this modeling, it is necessary to define the problem, determine how it can be solved, build the model and analyze the results. During the model construction process, computer-aided design (CAD) tools can be used to numerically, accurately and reliably simulate the projected model [

22,

26].

CAD uses a numerical resource that is based on mathematical formulas to solve problems, following the finite element method (FEM), which was first presented in the 1960s for aeronautical purposes but is now applied in various areas, such as engineering [

22].

The FEM, which is also known as finite element analysis, is a numerical method that obtains approximate solutions of problems through the approximation of solutions of partial and ordinary differential equations [

28] and that, with the evolution of processing capacity, can be used to predict the mechanical behavior of organic, nonmetallic and metallic materials, such as vegetables, fruits, agricultural machinery and other implements [

29].

This type of analysis is recommended when the use of analytical methods becomes very complex and would require a considerable amount of time and resources from a professional to solve them [

22]. For this purpose, the FEM is mainly based on the discretization of the system, i.e., it divides the problem domain into smaller regions with simpler geometry to obtain more simplified problems [

28].

In this process, the subregions form a mesh that must define the number of nodes that are present in it and that connect the elements with a simple shape, be it linear, triangular or rectangular. These simplified elements serve as a basis for performing analyses by the FEM with the aid of software capable of predicting the behavior of the system, such as Ansys, Nastran, Procal3D, Rocky DEM and SolidWorks [

22,

28].

3. Materials and Methods

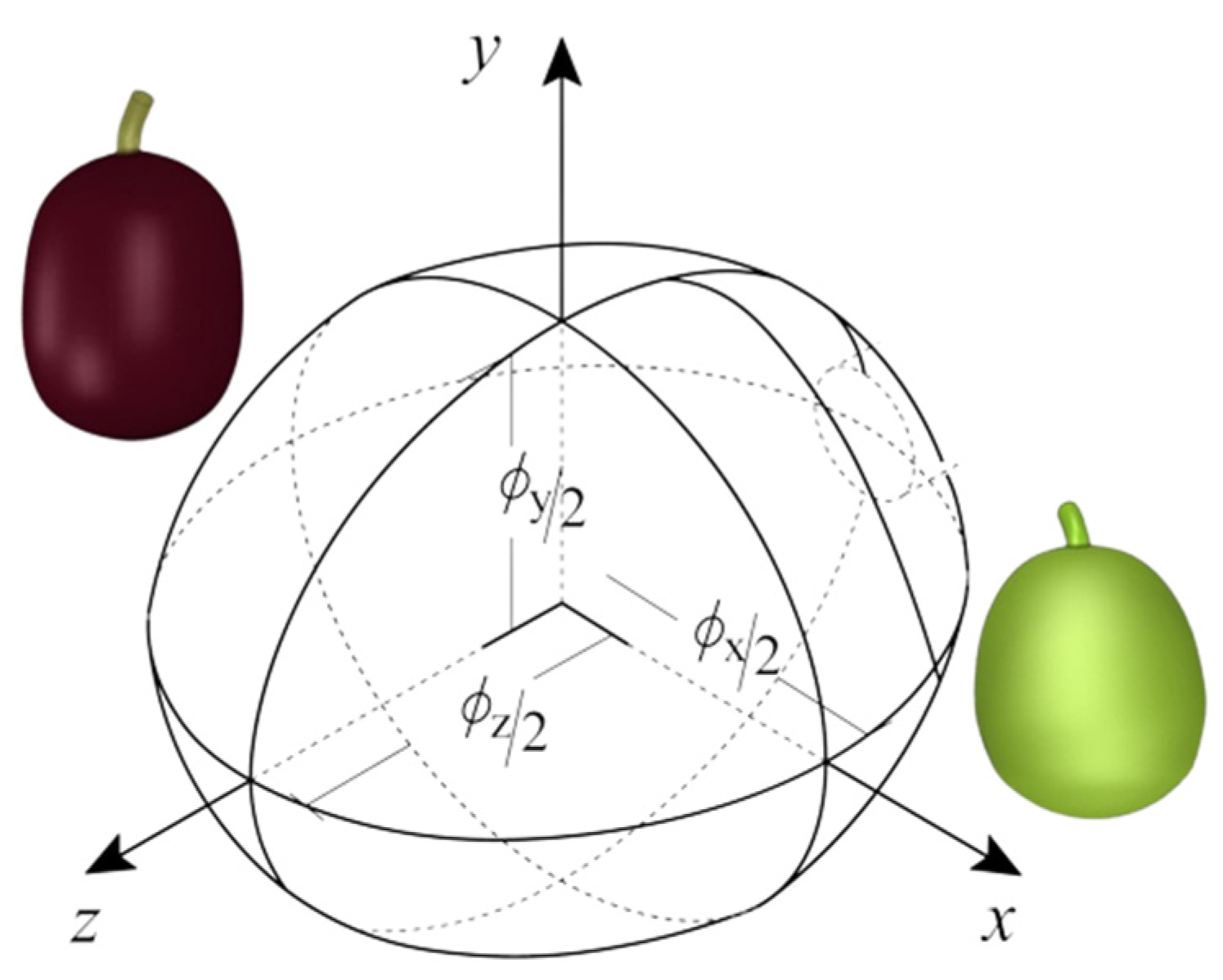

In SolidWorks®, geometric models of coffee fruits in the mature, semi-mature and immature maturation stages were developed (

Figure 1) for later simulation in Ansys® version 14.5. The model considered images from Coffea arabica L. variety Colombia fruits with dimensions comprising the average of those provided by [

30]. Coffee fruits were modeled with approximately 0.013 m in the smallest circumference (x) and 0.017 m in the largest (z), while the peduncle was created by moving a scan of a 2D profile along a 3D sketch path.

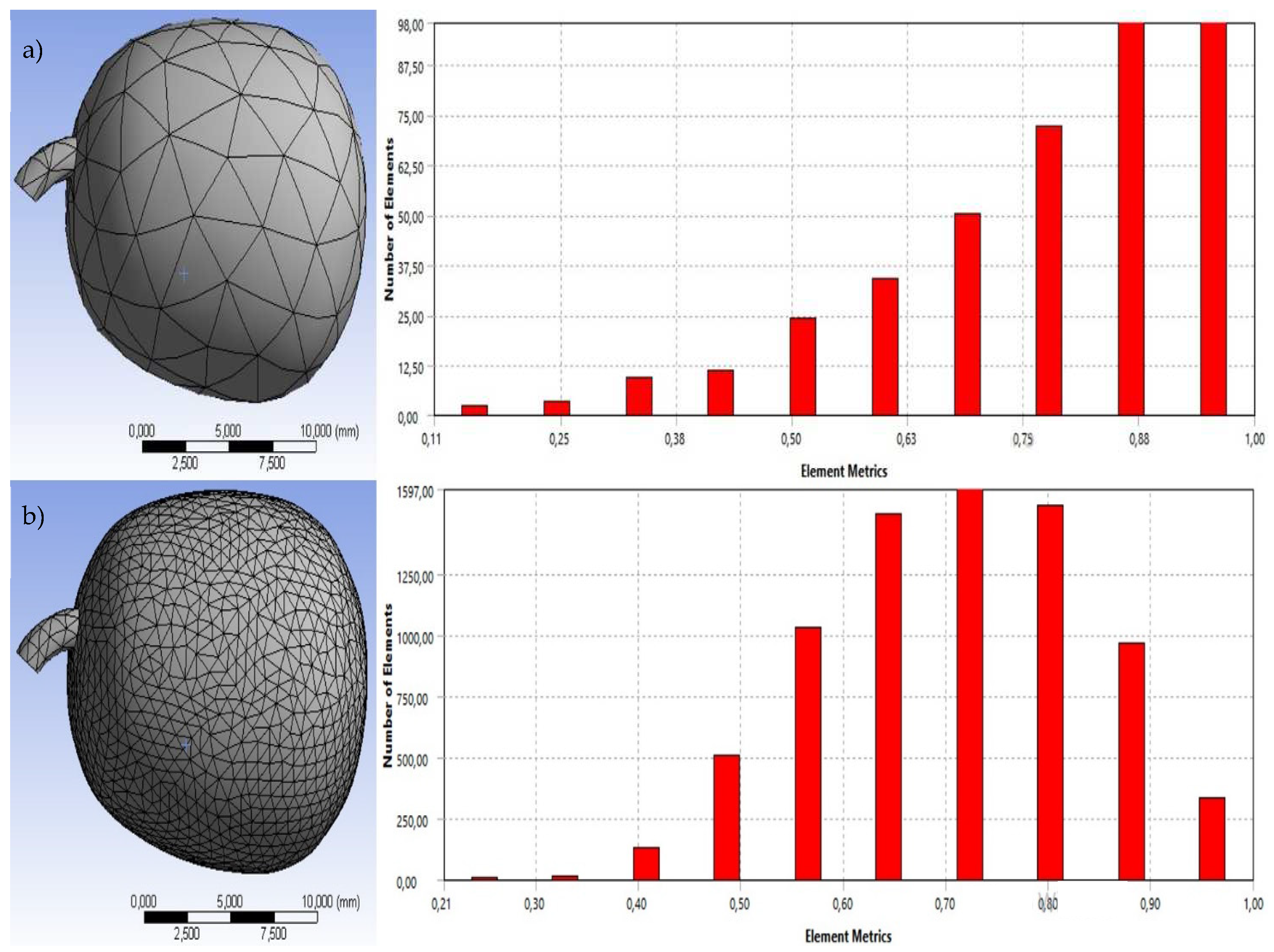

To check the reliability of the numerical analysis, a standard mesh convergence study was performed using the standard mode of the Ansys® software itself, with the use of meshes with different levels of refinement until the best one was found to represent the geometry of the coffee fruit with a greater number of elements and an element quality metric close to 1, a value that, according to [

31], represents a perfect cube for a 3D element. For this purpose, a mesh with 3 mm elements was obtained initially (

Figure 2a), and the final size was 0.7 mm (

Figure 2b). The load intensity and its location (x, y and z) were determined, in addition to the compression points, which were at the side of the model opposite to the of the applied forces. Thus, finite element models with were generated the tetrahedral mesh that best represented the fruit geometry, containing 6725, 13,393 and 9516 second-order elements for the mature, semi-mature and immature maturation stages, respectively.

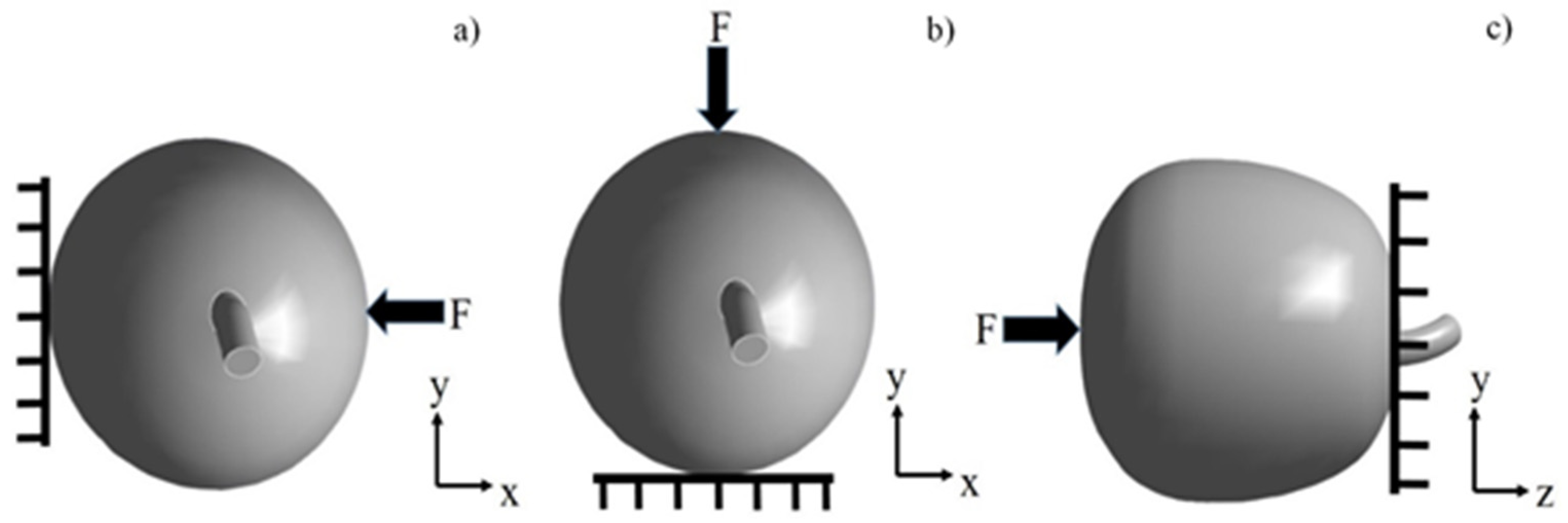

In the search to determine the response of the evaluated structure, numerical simulations were performed in Ansys®, by static structural analysis, compressing the fruit along three directions (x, y and z axis) to establish its deformation (Ɛ), strain energy (μ) and equivalent von Mises stress (σvonMises), according to Equations 1, 2 and 3, respectively.

where Ɛxx = ∂u/∂x , Ɛyy = ∂s/∂y , Ɛzz = ∂w/∂z , Ɛxy = ∂u/∂y + ∂s/∂x, Ɛxz = ∂u/∂z + ∂w/∂x, Ɛyz = ∂s/∂z + ∂w/∂y

where σ =

and dƐ =

In the proposed simulations, it was decided to position a compression support in the opposite direction to the applied force, which is distributed throughout the body, as shown in

Figure 3.

To perform the simulations, known values of properties including the collapse force (F), elastic or Young’s modulus (E), Poisson coefficient (μ) and density determined in other studies (

Table 1), were adopted and it was considered an elastic, homogeneous and isotropic material for simplifications, as stated by Coelho et al., 2015.

The collapse force represents the load acting during the compression of the material that reaches a maximum value upon reaching the greatest resistance of the fruit peel; then, its intensity is reduced upon reaching the pulp, which is milder and is reduced to a minimum after the breakage of the fruit. Young’s modulus, which expresses the rigidity of the material, consists of the ratio between the applied stress and the strain felt by the material, while the Poisson coefficient measures the transverse strain related to the longitudinal direction of the force application [

32,

33].

From the input data and the configuration of the scenarios to be studied, which related the applied compression and the maturation stages of the fruits, it was possible to perform computer simulations to determine the following parameters: total deformation, strain energy distribution and equivalent von Mises stress. In this context, from the results of the simulations, the distributions of the fruit strain, the stress concentration points and the strain energy involved in the process were analyzed.

4. Results

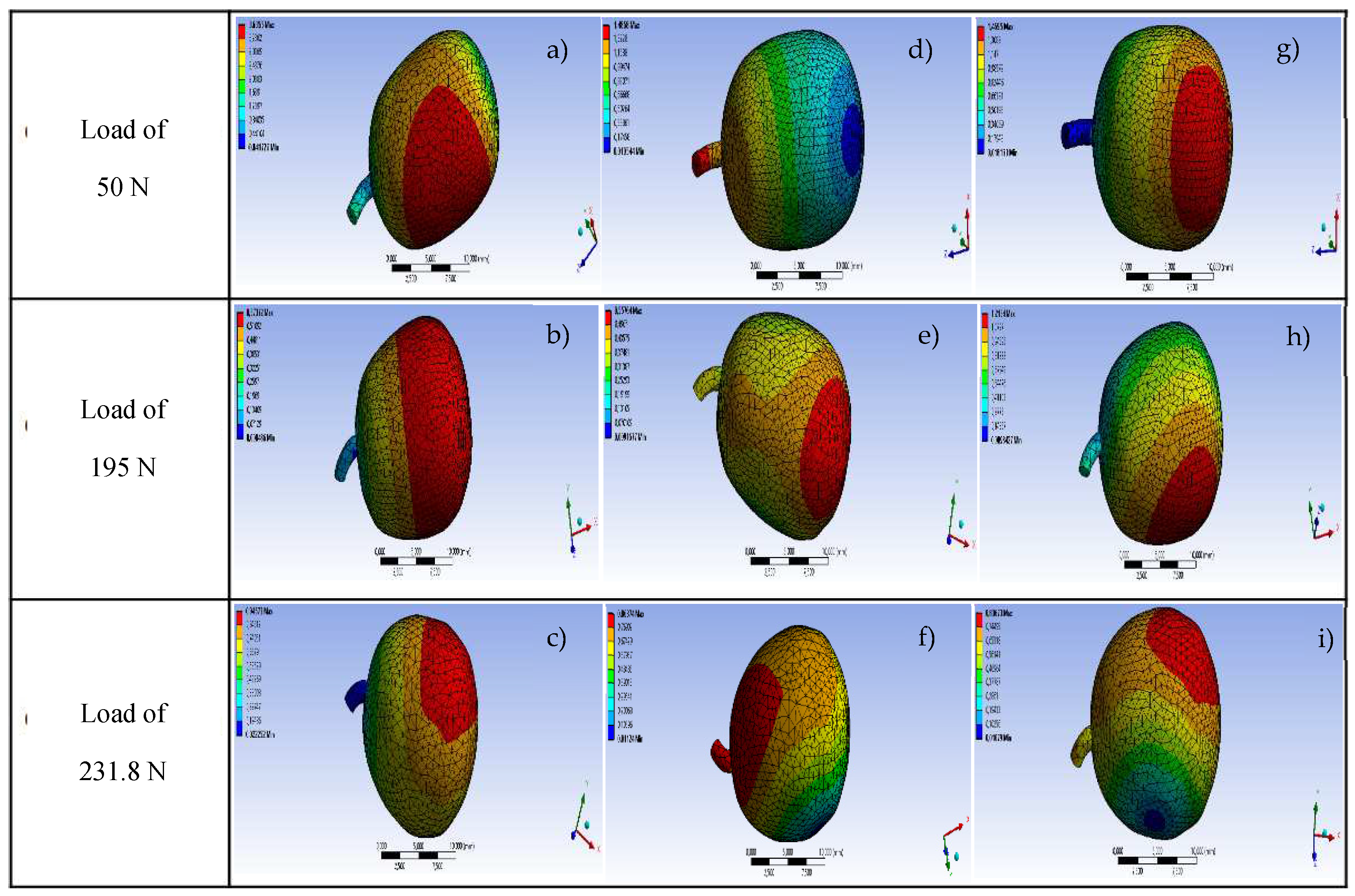

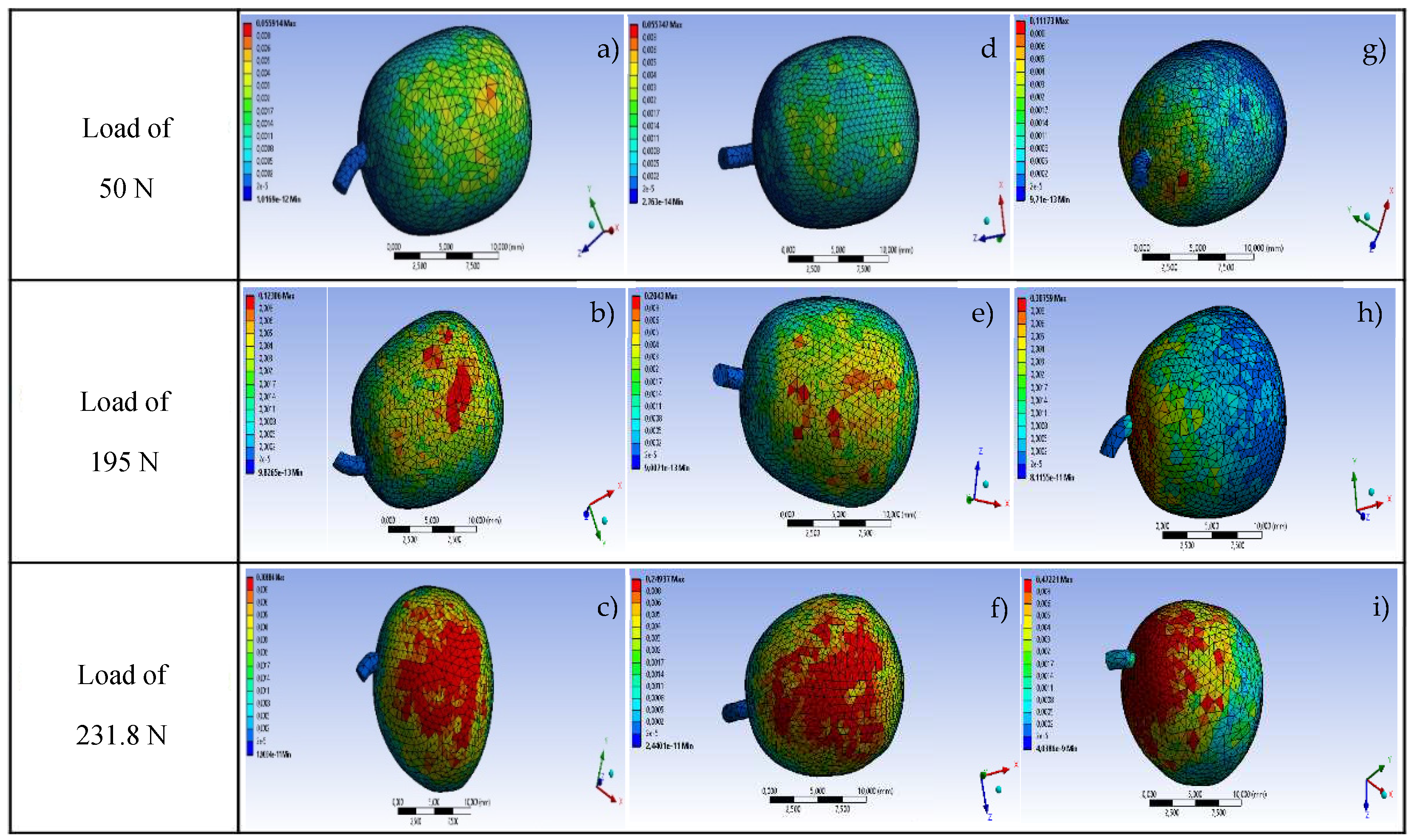

After performing the numerical simulation of the ripe coffee fruit, applying forces in the three directions (x, y and z) and fixing a compression support in the direction opposite to the loading direction, the deformation results were obtained (

Figure 4).

It was observed that the maximum deformation values of the ripe fruit were 3.63 mm mm−1, 1.49 mm mm−1 and 1.47 mm mm−1, while those of the semi-ripe fruit were approximately 0.57 mm mm−1, 0.55 mm mm−1 and 1.21 mm mm−1, and those of the immature fruit were 0.94 mm mm−1, 0.86 mm mm−1 and 0.84 mm mm−1, corresponding to the application of loading in the x, y and z directions.

These values were applied opposite to the direction of the applied loading, to simulate crushing of the fruit, which can generate perceptible deformation on the sides of the fruit, corroborating the study by [

34], who affirm the occurrence of transverse expansion in elastic material after compression, coinciding with Hertz theory, which states that deformation remains in the vicinity of the body after compression.

The results obtained suggest that, except for the semi-ripe fruit, the smallest deformations were obtained by compressing the fruit in the direction of the z axis, corroborating the study by [

35], who found lower firmness in the fruit peel when compressed in the direction of this same axis.

Notably, the largest deformation was found in the ripe fruit, with a tendency for less mature fruit to present smaller deformations. This behavior was predictable because, according to [

30], the more mature the outer layer of the fruit, the less the resistance, according to [

36], during maturation, the cells grow and the cell wall thickness decreases, reducing this mechanical property; and according to [

37], a higher water content is present in ripe fruit, compared to the semi-ripe and immature maturation stages, making the fruit more flexible, resulting in a lower force required for collapse. Thus, the deformation of more mature fruit will be greater. This lower collapse force and greater deformation in wetter fruit is similar to the findings of [

38].

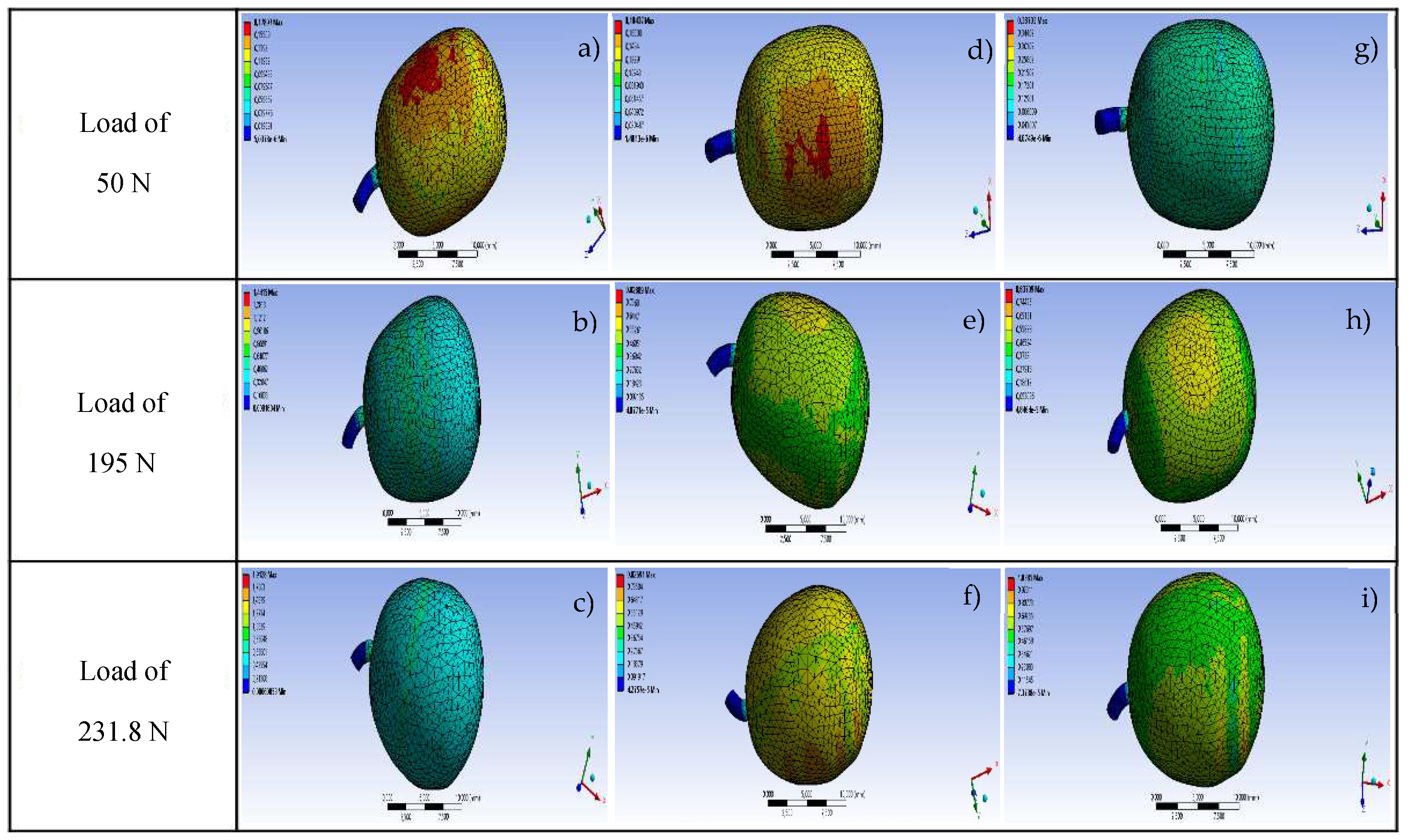

When analyzing the strain energy distribution, it was observed that in the ripe fruit, the maximum values were 0.06 mJ, 0.05 mJ and 0.11 mJ, corresponding to the application of force in the x, y and z directions, while in the semi-ripe fruit, they were 0.31 mJ, 0.20 mJ and 0.12 mJ, corresponding to the application of force in the x, y and z directions; in the immature fruit, the maximum results were 0.47 mJ, 0.25 mJ and 0.31 mJ, corresponding to the application of force in the x, y and z directions (

Figure 5), where the compression support was fixed.

For the immature fruit, the values of the strain energy distribution exceeded those found in the ripe and semi-ripe fruit, which occurred due to the greater resistance to deformation found in this stage of maturation.

It was also possible to observe that for the mature stage, when compressing the coffee fruit in the direction of the peduncle (z axis), the higher the strain energy applied, the greater the distance was between the points of force application and the compression support in this direction of application.

This result corroborates that of a study by [

39] with strawberry, in which the longitudinal compression of the fruit required a greater force and consequently a higher strain energy, compared to the transverse compression.

Regarding the von Mises stress results, the maximum values for the application of force in the x, y and z directions were 0.18 MPa, 0.18 MPa and 0.39 MPa, respectively (

Figure 6). These results also demonstrate that the highest von Mises stress values were located in the fruit end regions (close to the peduncle), meaning that there was a higher stress concentration and, consequently, a higher probability of collapse there, therefore, direct contact of the fruit detachment mechanism with this region should be avoided during harvesting.

When analyzing the von Mises stress for the semi-ripe fruit, it was observed that the maximum values obtained when applying force along the x, y and z axes were approximately 1.44 MPa, 0.83 MPa and 0.83 MPa, respectively. These values were higher than those of ripe fruits due to the greater internal resistance to the application of external force (compression) inherent to this maturation stage, it can be inferred that during harvest by harvester stems, these find less resistance in mature fruits, making them more susceptible to damage.

When analyzing this property in the immature fruit, it was observed that concomitant to the ripe and semi-ripe fruit, the maximum values for the application of force in the x, y and z directions were 1.91 MPa, 0.83 MPa and 1.04 MPa, and were higher where the compression support was fixed, meaning a higher concentration of this property in these locations, making them points of higher probability of collapse. It was also clear that it was at this stage of maturation that the highest tensions occurred, corroborating the results of [

40], who also found maximum values for immature fruit.

5. Conclusions

The numerical simulation of the coffee fruit compression process made it possible to verify that the more mature the fruit is, the greater the mean deformation (2.20 mm mm-1, 0.78 mm mm−1 and 0.88 mm mm−1, corresponding to ripe, semi-ripe and immature fruit), the lower the mean strain energy (0.07 mJ, 0.21 mJ and 0.34 mJ, corresponding to mature, semi-ripe and immature fruit) and the lower the mean equivalent von Mises stress (0.25 MPa, 1.03 MPa and 1.25 MPa, corresponding to ripe, semi-ripe and immature fruit), and these properties can be used to direct the harvest and storage system of the fruit, avoiding losses due to mechanical damage by compression.

The performance of this type of analysis, besides reducing the time and professional resources used to solve problems, shows itself as an alternative to help improve the mechanized harvesting techniques, by indicating how the strain energy and the von Mises stress impact the fruit in the various stages of maturity. These data can provide more adequate indicators for machine regulation, which would minimize the injuries caused during harvesting.

For future works, it is proposed to analyze damages during the processing of the grain in the decassary, spittened, drying, roasted, etc. and how it can be related with other variables such as moisture, the temperature to which it is subjected during toasted. This can help the improvement of technological process as the quality control of the fruit that is processed in each of the stages of maturation.

Author Contributions

Conceptualization, J.S.P., R.R.M. and E.T. de A.; Data curation, J.S.P.; Formal analysis, J.S.P. and R.R.M.; Investigation, J.S.P., R.R.M., E.T. de A., F.L.S. and L.S.M; Methodology, J.S.P., R.R.M. and E.T. de A.; Project administration, R.R.M.; Supervision, R.R.M.; Visualization, J.S.P., R.R.M., E.T. de A., F.L.S. and L.S.M; Writing – original draft, J.S.P., R.R.M., E.T. de A. , F.L.S. and L.S.M; Writing – review & editing, J.S.P., R.R.M., E.T. de A., F.L.S. and L.S.M.

Funding

This research was funded by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - CAPES, grant number 001.

Acknowledgments

The authors greatly acknowledge CAPES, CNPq and Fapemig for providing funding for this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rosa, C.I.L.F.; Moribe, A.M.; Yamamoto, L.Y.; Sperandio, D. Pós-colheita e comercialização. In Hortaliças-fruto [online]. Brandão Filho, J.U.T.; Freitas, P.S.L.; Berian, L.O.S.; Goto, R. (Org.), EDUEM, Brazil, 2018 2018, 489–526. [CrossRef]

- Munyendo, L.; Njoroge, D.; Hitzmann, B. The Potential of Spectroscopic Techniques in Coffee Analysis—A Review. Processes 2021, 10, 71. [Google Scholar] [CrossRef]

- de Oliveira, V.C.; Mendes, F.Q. TÉCNICAS DE PRESERVAÇÃO PÓS-COLHEITA DE FRUTAS E HORTALIÇAS: UMA REVISÃO NARRATIVA. In Ciência e Tecnologia de Alimentos: Pesquisa e Práticas Contemporâneas, 2nd ed. Cordeiro, C.A.M.; Silva, E.M. da; Barreto, N.S.E. (Org.), AREPB, Brasil, 2021 718–733. [CrossRef]

- Abreu, G.F.; Pereira, C.C.; Malta, M.R.; Clemente, A.C.S.; Coelho, L.F.S.; Rosa, S.D.V.F. Alterações na coloração de grãos de café em função das operações pós-colheita. Coffee Sci 2015, 10, 429–436. [Google Scholar] [CrossRef]

- Bastian, F.; Hutabarat, O.S.; Dirpan, A.; Nainu, F.; Harapan, H.; Bin Emran, T.; Simal-Gandara, J. From Plantation to Cup: Changes in Bioactive Compounds during Coffee Processing. Foods 2021, 10, 2827. [Google Scholar] [CrossRef] [PubMed]

- Gumecindo-Alejo, A.L.; Sánchez-Landero, L.A.; Ortiz-Ceballos, G.C.; Cabrera, C.R.C.; Alvarado-Castillo, G. Factors related to coffee quality, based on the “Cup of Excellence” contest in Mexico. Coffee Sci. 2021, 16, 1–10. [Google Scholar] [CrossRef]

- CNA – Confederação da Agricultura e Pecuária do Brasil (2020). PIB do Agronegócio alcança participação de 26,6% no PIB brasileiro em 2020. Available online: https://www.cnabrasil.org.br/boletins/pib-do-agronegocio-alcanca-participacao-de-26-6-no-pib-brasileiro-em-2020#_ftn1 (accessed on 26 November 2021).

- CONAB - Companhia Nacional de Abastecimento (2020). Boletim da Safra de Café: Tabela de dados - Estimativas da Produção e Colheita de janeiro. Available online: https://www.cnabrasil.org.br/boletins/pib-do-agronegocio-alcanca-participacao-de-26-6-no-pib-brasileiro-em-2020#_ftn1 (accessed on 13 de June 2022).

- ICO – International Coffee Organization (2021). Trade statistics tables: Coffee production by exporting countries. Available online: https://www.ico.org/prices/po-production.pdf (accessed on 26 November 2021).

- Coelho, A.L.D.F.; Santos, F.L.; Pinto, F.A.C.; De Queiroz, D.M. Determinação das propriedades geométricas, físicas e mecânicas do sistema fruto-pedúnculo-ramo do cafeeiro. 2015, 19, 286–292. [CrossRef]

- Li, Z.; Miao, F.; Andrews, J. Mechanical Models of Compression and Impact on Fresh Fruits. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1296–1312. [Google Scholar] [CrossRef]

- Gazzola, J.; Fabbro, M.D. ; Biasi,.R.; Cardoso, K.C.; Rodrigues, S.; Enes, A.M. PROPRIEDADES MECÂNICAS DOS MATERIAIS BIOLÓGICOS. 2021, 507–524. [CrossRef]

- Freccia, C.S.; Ramos, A.P.; Peres, L.G.; Vitto, D.C.; Carlos, E.B.; Cardoso, L.S.; Palhano, W.C.; Schimidt-Bellini, J.; Seibert, E. Aplicação de danos mecânicos e seus efeitos na qualidade pós-colheita de frutas cítricas. Rev Técnico Científica – IFSC 2012, 3.

- Melo Neto, J.V.; Silva, G.C. Avaliação experimental para detecção da elipsoide de Hertz em um alojamento de célula de carga para pontes de pesagem. J Ind Prod Eng 2019, 2, 39–54. [Google Scholar]

- de Carvalho, C.N.; Oliveira, Y.R.; da Silva, P.H.; de Abreu, M.C. Coffea arabica L.: potencialidades e ações medicinais. Rev. Intertox de Toxicol. Risco Ambient. e Soc. 2018, 11. [Google Scholar] [CrossRef]

- Terceiro, M.G.; Meirelles, F.C.; Cavalcante, A.G.; Mingotte, F.L.C.; Lemos, L.B. Caracteres morfológicos de cafeeiro de porte baixo no primeiro ano de formação em Jaboticabal-SP. 2019, 62. 62. [CrossRef]

- Queiroga, V.P.; Gomes, J.P.; Melo, B.A.; Albuquerque, E.M.B. Cultivo do café (Coffea arabica L.) orgânico sombreado para produção de grãos de alta qualidade. 1nd ed., Editora Científica Digital, Brazil, 2021. pp. 507-524.

- Silva, G.R.; Neto, A.T.d.S.; Costa, J.E.; de Podestá, G.S.; Junior, S.L.d.S. Desenvolvimento inicial de cultivares de Coffea arabica L. no Brejo Paraibano. Res. Soc. Dev. 2021, 10. [Google Scholar] [CrossRef]

- Alves, G.S.P.; Coelho, A.P.; Lemos, L.B. Crescimento vegetativo, produtividade e qualidade pós-colheita de cultivares de café de porte baixo em região de baixa altitude. Rev. Agroecossistemas 2021, 13, 63–83. [Google Scholar] [CrossRef]

- Negreiros, V.M.V.; Nascentes, R.F.; Nascentes, M.C.B. Efeitos da aplicação de regulador vegetal na maturação e na qualidade de bebida dos frutos do café. Revista AGROFIB 2019, 1, 13–24. [Google Scholar]

- Graciano, P.D.; Siquieroli, A.C.S.; Assis, G.A.; Junior, L.D.F.; Fernandes, M.I.S.; Paiva, C.R. ESTÁDIOS DE MATURAÇÃO DE CULTIVARES DE Coffea arabica L. EM MONTE CARMELO-MG E SUAS CARACTERÍSTICAS SENSORIAIS. 2019, 17. [Google Scholar] [CrossRef]

- Vieira, D.F.; Coelho, R.C.; Dias, M.J.; Neto, A.M.S.; Fontes, W.A. Elementos Finitos para o Dimensionamento de uma Viga Perfil “I” Utilizada em um Pórtico Móvel. 2019, 13, 31–44. [CrossRef]

- Andrade, L.O.; Junior, J.F.d.S.; Rodrigues, T.V.; de Carvalho, G.D.G. Modelagem e simulação no estudo de melhoria da capacidade produtiva em uma empresa de serviços de lavanderia na cidade de passos. Rev. de Tecnol. Apl. 2020, 9, 38–62. [Google Scholar] [CrossRef]

- Franco, I.C. Modelagem e Simulação: do processo de atendimento cardiológico em um posto de saúde visando menor tempo de espera do paciente. J. Eng. Exact Sci. 2021, 7. [Google Scholar] [CrossRef]

- Santos, A.A.; Fagundes, C.H.; Ferreira Junior, J.S.; Rodrigues, T.V.; Sanjulião, L.K.A.F.; Borges, V.J.P. Pós-colheita e comercialização. 2018, 489–526. [CrossRef]

- Rodrigues, G.O.; Simonetto, E.D.O.; Dalmolin, L.C.; Modro, N.R.; De Barros, R.S. Uso da modelagem computacional para comparativo entre adição de diferentes percentuais de biodiesel no transporte de resíduos sólidos urbanos. Estud. do CEPE 2019, 80–98. [Google Scholar] [CrossRef]

- Batista, R.C.; Gomes, M.d.N. Modelagem computacional aplicada como uma tecnologia no currículo de engenharia mecânica. Revista Mundi Engenharia, Tecnologia e Gestão 2020, 5, 238-01. 5. [CrossRef]

- Carneiro, R.D.S.; Carneiro, R.D.S.; da Silva, K.F. Método dos elementos finitos para a análise de estruturas: comparativo entre solução exata e soluções aproximadas pelo método de Galerkin. 2020, 5, 407–428. [CrossRef]

- Souza, V.H.S.; Dias, G.L.; Santos, A.A.R.; Costa, A.L.G.; Santos, F.L.; Magalhães, R.R. Evaluation of the interaction between a harvester rod and a coffee branch based on finite element analysis. Comput. Electron. Agric. 2018, 150, 476–483. [Google Scholar] [CrossRef]

- Tinoco, H.A.; Ocampo, D.A.; Peña, F.M.; Sanz-Uribe, J.R. Finite element modal analysis of the fruit-peduncle of Coffea arabica L. var. Colombia estimating its geometrical and mechanical properties. Comput. Electron. Agric. 2014, 108, 17–27. [Google Scholar] [CrossRef]

- Kohnke, P. (Ed.) , 1999. ANSYS: Theory Reference. 11. ed. Canonsburg: [s.n.].

- Couto, S.M.; Batista, C.d.S.; Devilla, I.A.; Paim, V.T. Características de frutos de café sob compressão. 2002, 6, 117–122. [CrossRef]

- Silva, E.P.; Projeto estrutural de uma colhedora de café operando em terrenos declivosos. Doctoral thesis. Federal University of Lavras - Brazil, 2018. Available online: http://repositorio.ufla.br/handle/1/32274 (accessed on 26 November 2021).

- Pallottino, F.; Costa, C.; Menesatti, P.; Moresi, M. Assessment of the mechanical properties of Tarocco orange fruit under parallel plate compression. J. Food Eng. 2011, 103, 308–316. [Google Scholar] [CrossRef]

- Vieira, D.A.d.P.; Caliari, M.; de Souza, E.R.B.; Júnior, M.S.S. Mechanical resistance, biometric and physicochemical characteristics of tomato cultivars for industrial processing. Food Sci. Technol. 2019, 39, 363–370. [Google Scholar] [CrossRef]

- Neto, A.F.; Almeida, F.D.A.C.; Olivier, N.C.; Dantas, A.C.S.; Irmão, M.A.S. Mechanical behavior of pumpkin fruits subjected to compression during maturation. 2013, 43, 223–231. [CrossRef]

- Chakespari, A.G.; Rajabipour, A.; Mobli, H. Strength Behavior Study of Apples (cv. Shafi Abadi & Golab Kohanz) under Compression Loading. Mod Appl Sci 2010, 4, 173–182. [Google Scholar]

- Martins, B.D.A.; Ferraz, A.C.D.O.; Schmidt, F.L. Physical characteristics of baru tree fruit aimed at kernel extraction. Semin. Ciências Agrárias 2017, 38, 1865–1874. [Google Scholar] [CrossRef]

- Linhares, J.A.; Castillo, B.; Londoño, M.T. Characterization of the mechanical properties of the sweet passion fruit (Passiflora ligularis Juss). Agron Colomb 2013, 31, 208–214. [Google Scholar]

- Santos, F.L.; de Queiroz, D.M.; Valente, D.S.M.; Coelho, A.L.D.F. Simulation of the dynamic behavior of the coffee fruit-stem system using finite element method. Acta Sci. Technol. 2015, 37, 11. [Google Scholar] [CrossRef]

Figure 1.

3D model of coffee fruits with dimensions on axes x (φx), y (φy) e z (φz).

Figure 1.

3D model of coffee fruits with dimensions on axes x (φx), y (φy) e z (φz).

Figure 2.

Second order tetrahedral mesh refinement applied to coffee fruits with elements size of 3 mm (a) and 0.7 mm (b).

Figure 2.

Second order tetrahedral mesh refinement applied to coffee fruits with elements size of 3 mm (a) and 0.7 mm (b).

Figure 3.

Loads applied to coffee fruit planes in x axis (a), y axis (b) and z axis (c).

Figure 3.

Loads applied to coffee fruit planes in x axis (a), y axis (b) and z axis (c).

Figure 4.

Total deformation (mm.mm−1) of ripe, semi-ripe and immature coffee fruits when subjected to loads of 50 N, 195 N and 231.8 N in x (a, b, c), y (d, e, f) and z (g, h, i), directions, respectively.

Figure 4.

Total deformation (mm.mm−1) of ripe, semi-ripe and immature coffee fruits when subjected to loads of 50 N, 195 N and 231.8 N in x (a, b, c), y (d, e, f) and z (g, h, i), directions, respectively.

Figure 5.

Strain energy distribution (mJ) in the ripe coffee fruit when subjected to loads of 50 N, 195 N and 231.80 N in x (a, b, c), y (d, e, f) and z (g h, i) directions, respectively, and compressed in the opposite load direction.

Figure 5.

Strain energy distribution (mJ) in the ripe coffee fruit when subjected to loads of 50 N, 195 N and 231.80 N in x (a, b, c), y (d, e, f) and z (g h, i) directions, respectively, and compressed in the opposite load direction.

Figure 6.

Von Mises equivalent stress distribution (MPa) in the ripe coffee fruit when subjected to loads of 50 N, 195 N and 231.80 N in x (a, b, c), y (d, e, f) and z (g h, i) directions, respectively, and compressed in the opposite load direction.

Figure 6.

Von Mises equivalent stress distribution (MPa) in the ripe coffee fruit when subjected to loads of 50 N, 195 N and 231.80 N in x (a, b, c), y (d, e, f) and z (g h, i) directions, respectively, and compressed in the opposite load direction.

Table 1.

Mechanical properties of coffee fruit in the mature, semi-ripe and immature stages of maturation.

Table 1.

Mechanical properties of coffee fruit in the mature, semi-ripe and immature stages of maturation.

| Property |

Fruit |

Source |

| Mature |

Semi-mature |

Immature |

| Collapse force (N) |

50 |

195.00 |

231.80 |

[32] |

| Density (kg m−3) |

1020 |

1087 |

1130 |

[10] |

| Young’s modulus (Pa) |

2930000 |

19570000 |

15820000 |

| Poisson coefficient (dimensionless) |

0.27 |

0.25 |

0.24 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).