Introduction

The thermal fatigue plays an important role during of degradation of interconnection compartments of power electronic devices. The temperature variations resulting from the power cycling has as consequences the stresses and plastic deformations that can affect the microstructure of the materials at the interconnection interfaces of upper metallic parts. Wires and metallization layers more solicited than silicon layers lead to the distortion of material interfaces when the temperature increases, leading to the deformation or degradation of the material surfaces. This will decrease the composite life and leads to an accelerated degradation. The arrangement of grains and grain boundaries is key to understanding the microstructure of metals and composites. When subjected to thermal and mechanical stresses, the variation in surface energies between adjacent grains, confined by the grain boundary, can cause the grains to separate. This phenomenon occurs due to the thermal and mechanical deformation of the grain boundary and the grain groove profile. Such occurrences are commonly observed in the bonding wires utilized in electronic devices.

The studies [

1,

2,

3] have focused on examining the impact of microstructure and physicochemical properties on degradation processes. In literature [

4,

5,

6], three effects were investigated. The first two effects examined the influence of bonding procedures and temperature on crack formation and the microstructure of the interconnection zone. Meanwhile, the third effect explored the relationship between material purity, grain size, and hardness during cycling. The metallization layer, typically around 5μm thick, deposited on the chips undergoes significant distortion compared to materials like silicon when exposed to high temperature. This distortion results in substantial tensile and compressive stresses, leading to notable inelastic strains [

7]. It has been reported that thermomechanical cycling can cause two main types of degradation on the topside of power chips: metallization reconstruction and degradation of bonding contacts [

7,

8,

9]. It is assumed that during cyclic aging, a progressive effect of condensation-evaporation occurs, leading to structural degradation and grooving of the film. However, the precise mechanism of this degradation is not yet fully understood, and further efforts are required to better comprehend the effects of stress parameters on the degradation of contacts between metallization and bond wire. This involves finding a mathematical solution to describe the formation of grain boundary grooving in polycrystalline thin films. Several solutions to this mathematical problem have been proposed in the literature [

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20]. In 1957, Mullins [

10] conducted a study on the thermal effect on the profile of grain boundary grooving, laying the foundation for subsequent research on this phenomenon [

13,

14,

15,

16,

17,

18,

19,

20]. Various studies have focused on the development of this phenomenon, particularly exploring evaporation-condensation, surface diffusion, and formulating the mathematical problem that describes the profile of grain boundary grooving [

10,

11,

12].Some authors [

22] tried to adapt integrable nonlinear evolution equations related to the well-known linearizable diffusion equation to derive a new integrable nonlinear equation which models the surface evolution of anisotropic material accompanying the action of evaporation-condensation and surface diffusion [

22].

A multiple integration technique allowing to solve high-order diffusion equations was proposed by Hristov [

23] based on multiple integration procedures by applying the heat-balance integral method of Goodman and the double integration method of Volkov. Hristov [

24] presented a solution for the linear diffusion models of Mullins’ thermal grooving [

10,

11,

12].

Fourth-order diffusion equations are commonly encountered in various applications, including surface diffusion on solids [

10,

11,

12,

25,

26,

27,

28] and thin film theory [

27,

28]. Unlike second-order diffusion equations, fourth-order equations generally do not satisfy any known maximum principle. Even with simple time-independent linear boundary conditions, evolving solutions tend to generate additional extrema from initially smooth conditions [

29].

Broadbridge [

30] studied the problem of a surface groove by evaporation-condensation governed by

. The depth of a groove at a grain boundary was predicted without any approximation [

30].

Chugunova and Taranets [

31] studied the initial–boundary value problem associated with the fourth-order Mullins equation with initial data. They considered this problem by assuming that the specific free energy of the boundary is lower than the surface free energy. The Mullins equation, originally introduced by Mullins in 1957 [

10], is a model used to analyze the evolution of surface grooves at the grain boundaries of heated polycrystals. Chugunova and Taranets [

31] successfully demonstrated the global existence of weak solutions over time and established that the energy minimizing steady state serves as the global attractor.

Gurtin and Jabbour [

32] developed a regularization theory that incorporates curvature effects, including surface diffusion and bulk-surface interactions. They investigated two specific cases: (i) the interface considered as a boundary between bulk phases or grains, and (ii) the interface between an elastic thin film bonded to a rigid substrate and a vapor phase depositing atoms on the surface [

32].

Huang [

33] conducted isothermal stress relaxation tests on electroplated Cu thin films, considering both passivated and unpassivated films. Based on a kinetic model, Huang [

33] deduced grain-boundary and interface diffusivities and provided numerical and analytical solutions for the coupled diffusion problems. The study also analyzed the impact of surface and interface diffusivities on stress relaxation in polycrystalline thin films, comparing the results to experimental data.

Asai and Giga [

34] considered the surface diffusion flow equation under specific boundary conditions. The problem of Mullins (1957) was proposed to model the formation of surface grooves on the grain boundaries, where the second boundary condition

is replaced by zero slope condition on the curvature of the graph. Asai and Giga solved the initial-boundary problem with homogeneous initial data for construction of a self-similar solution and a solution was proposed by using a semi-divergence structure.

Escher et al. [

35] demonstrated the existence and uniqueness of classical solutions for the motion of immersed hypersurfaces driven by surface diffusion. They focused the surface diffusion proposed by Mullins [

10,

11,

12] to model surface dynamics for phase interfaces when the evolution is governed solely by mass diffusion within the interface. Other studies were devoted to the diffusion problems, grain boundary migration and grain dynamics evolution in materials [

36,

37,

38,

39,

40,

41,

42].

Mullins et al. [

43] have linearized the differential equation by assuming a very small slope at any point of the grain profile. In 1975, Brailsford & Gjostein [

44] derived approximate solutions by studying the influence of surface energy anisotropy on morphological changes occurring by surface diffusion on simply shaped bodies. Wherever a grain boundary intersects the surface of a polycrystalline material, a groove develops. At the root of the groove, a balance between grain-boundary tension and surface tension produces an equilibrium angle [

45]. The difference in chemical potential between the curved surface near the groove’s root and the smoother surface farther away results in material drift.

Tritscher [

46] considered the boundary-value problem concerning the formation of a single groove due to surface diffusion at the junction of a bicrystal, assuming that the grain boundary remains planar.

Martin [

47] extended the original Mullins theory of surface grooving due to a single interface to multiple interacting grooves formed by closely spaced flat interfaces. Martin considered two cases: the first involved simplifying Mullins’ analysis using Fourier cosine transforms instead of Laplace transforms, while the second dealt with an infinite periodic row of grooves. Martin [

40] also solved the problem for two interacting grooves. Analytical solutions for the fourth partial differential equation governing the groove profile in metals have not been found in the literature.

In a previous study [

48], we addressed the mathematical problem associated with the second non-linear partial differential equation in Mullin’s problem. We focused on the case of the evaporation-condensation and provided an exact solution for the geometric profile of grain boundary grooving when materials are subjected to thermal and mechanical stress, as well as fatigue effects.

This paper is devoted to model the grain groove profile governed by the fourth-order partial differential equation in the case of diffusion in thin polycrystalline films. An analytical and exact solution to the Mullins approximated problem, , was given.

Exact resolution of Mullins’ problem

In this section, we propose a new method to resolve the equation (38) by using the following equation:

and by considering the different solutions r in function of u.

Let us consider the following equation valid for all values of

:

To resolve equation (38), we begin by transforming equation (39’) into difference between two perfect squares, therefore, the expression will be transformed into perfect square, if it has a double solution and then his discriminant has to be cancelled.

Now, let us consider the equation:

The discriminant

of this second-degree equation (40) function in r can be written as:

Equation (42) can be written as:

With

and

Putting

and taking

or

one obtains

; and

et

will be the two solutions of the following second-degree equation:

The discriminant of equation (44′):

Can be calculated as a function of u:

Two cases have to be distinguished:

- 1.

First case and

In this case, the solutions of equation (44′) will be given by:

This leads to the solution of equation (43):

This value of

will cancel the discriminant of equation (40)

Therefore, the solution r is given by:

and then:

Consequently, one obtains:

The four solutions of equation (37) can be then obtained from the solutions of the two following 2

nd degree equations:

The discriminants of equations (53) and (54) are given by the respective following expressions:

Two cases can be studied:

Solutions of

Knowing that

is negative because of the condition

, one obtains two conjugate complex solutions:

Solutions of

Where

Let us prove that

can be written as:

, To obtain the sign of

, we have to study the sign of

and then to compare between 1 and

or between

and

.

Let us put

, one obtains:

Equation (61) shows that , this implies that Z decreases for all values of and for and therefore or and .

Therefore, the two other solutions are then given by equations (62) and (63):

Solution of equation (38) for

Now, the final solution, in the case of

, is given by equation (64):

The solution in function of

will be written as:

Boundary conditions

Using of the boundary conditions:

The first condition implies necessary: A

3 = A

4 = 0 and therefore the solution will be given by the following form:

This solution can be written as:

- 2.

Second case and

In this case, one obtains two conjugate complex solutions

and

:

Where

and

and finally

With:

The real solution is given by:

or

This leads to the solution of equation (43):

This value of

λ will cancel the discriminant of equation (39)

The solution is given here by:

Their respective discriminants are given below:

Two cases can be studied for

:

First case:

Here one has

Where

is negative. The two conjugate complex solutions of equation (53) are given below:

Second case:

Here one has and

Let us prove that is negative

can be written as:

Knowing that

;

or

therefore, one obtains:

Now, one writes:

and one obtains:

It is obvious that and then , therefore

The two other conjugate complex solutions are then given by equations (75) and (76)

Now, the final solution in this case when

is negative or when

is given by:

The continuity and derivability of the solution

g(

u) and its derivatives imposed that

Because the function

is not derivable in point

and then, one writes:

In conclusion, one obtains the solutions of the fourth differential equation (37):

For

:

For

:

Satisfying the boundary conditions:

Determination of the problem parameters of the solution for

With the boundary conditions and knowing that for

u = 0,

;

and one obtains:

Where is the groove depth.

Condition on the first derivative

The calculation of the first derivative gave:

with

Knowing that

;

and

, one obtains:

;

;

and then the first derivative

:

At u = 0, ; ; ; , one obtains , and then ; ; and .

The use of the above parameters led to:

The second derivative

One had the second derivative:

To determine the values of and , one needs to determine the second derivative .

The second derivative ; let’s put

; therefore,

Knowing that:

, one obtains:

By using

, one obtains:

and therefore:

The other second derivatives are given below:

By calculating the values of the second derivatives at point u = 0:

;

;

; one obtains the following equation:

Condition on the second derivative

The calculation of the third derivative led to:

Let us calculate the third derivative

:

Using

, one obtains:

By using relation:

, one obtains:

And finally, one obtains the third derivative

:

One also calculated the other derivatives:

and

Knowing that the fourth boundary condition and the values of the third derivatives at point u = 0: ; ; ; ; one obtains the following equation:

, therefore:

Consequently, the use of the boundary conditions gave the following linear system composed by four equations with four unknown parameters:

And the the function g and its different derivatives are given at point 0:

Therefore, the solution for

is completely defined by all above parameters:

The values of the different parameters and their derivatives at point

were calculated:

Determination of the problem constants of the solution for

In this case, on has

, with

given by:

The values of the different parameters of the solution

and their derivatives at point

are given below:

One proved that all parameters and derivatives for the two functions

and

are equal and the continuity of the solution and its derivatives is assured, at this point

and consequently at any point of the interval [0, ∞], for:

Now the analytical solution of the fourth order differential equation was completely given and all problem constants were determined.

with

With

and

, the solution can be written as:

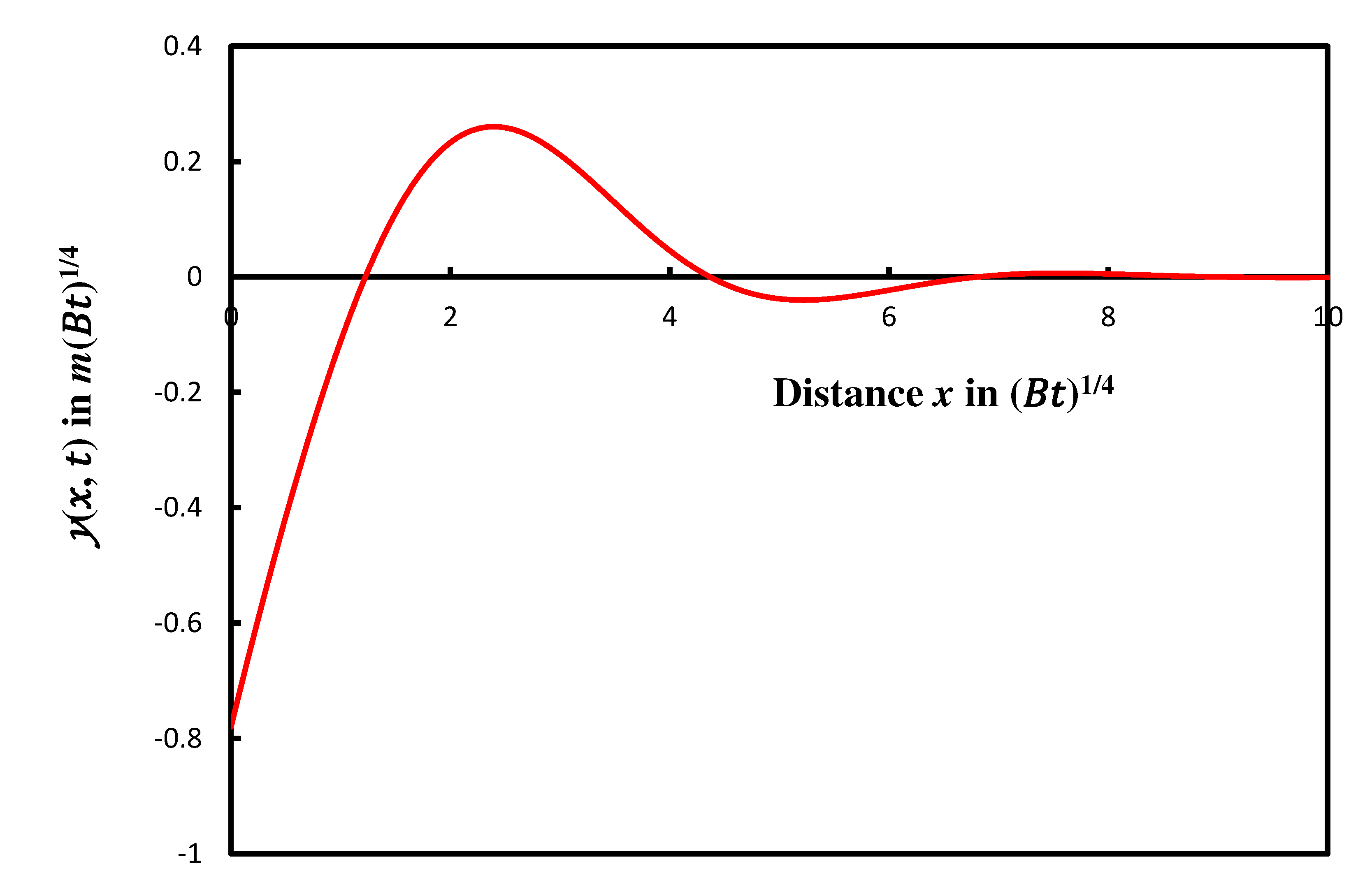

Profile of the groove shape in the diffusion case

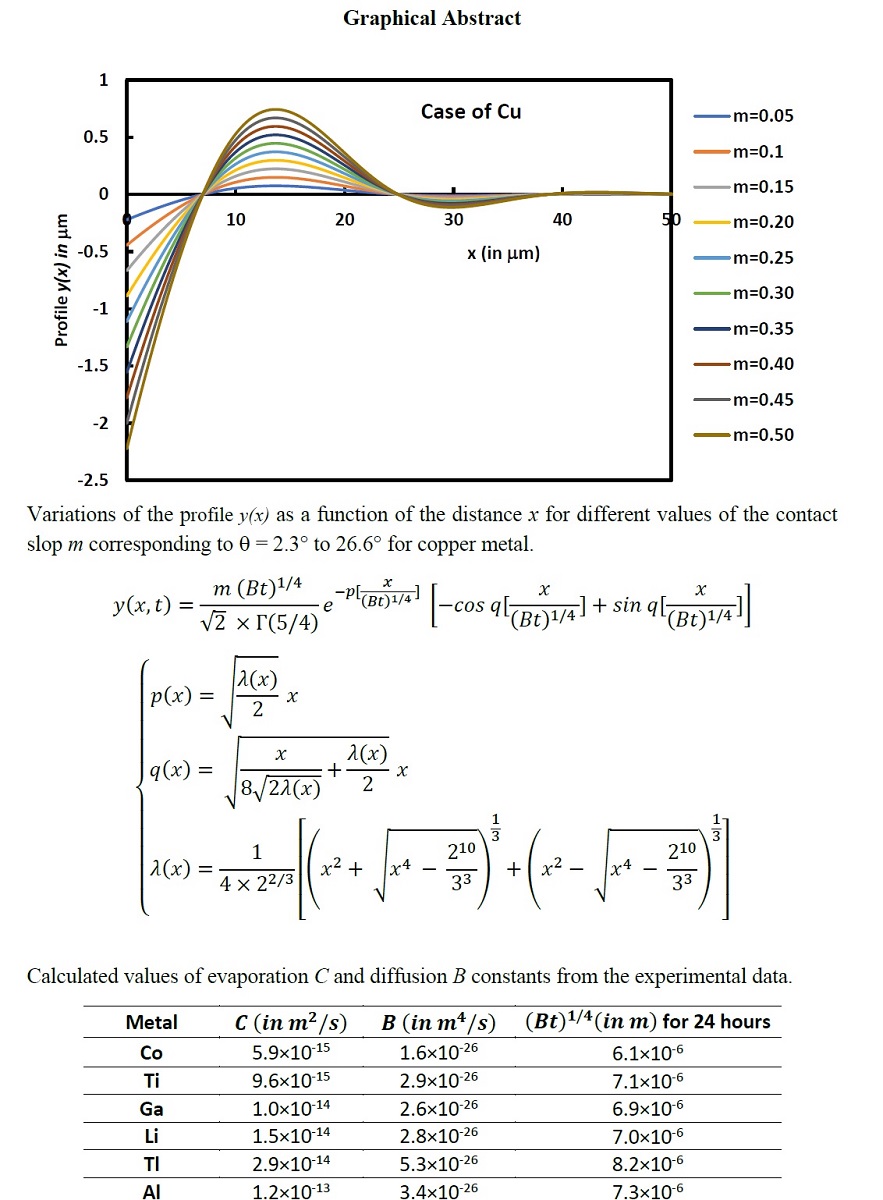

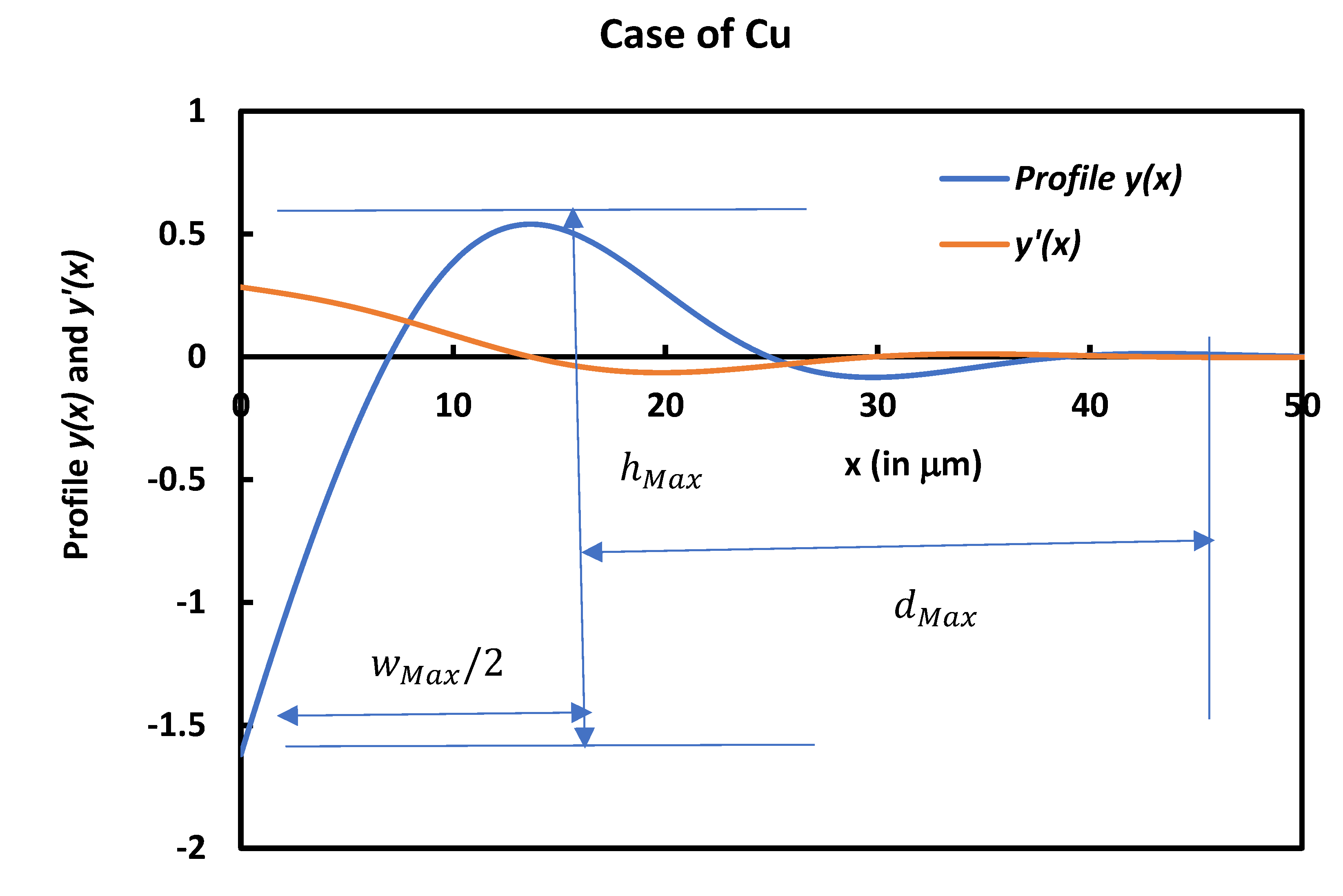

The variations of the profile

as a function of the distance

x from the symmetric axis of the groove are plotted on

Figure 1.

The study of the solution reveals a damped sinusoidal profile of the groove with an infinity of maxima, minima and zeros of the solutions. The oscillations can be easily observed in our solution. Mullins mentioned that it is questionable, however, that these oscillations could be observed due to the progressively decreasing amplitude of g. Here, we proved the superiority of our analytical solution that can predict the all oscillations, their amplitudes, the zero, the maxima and minima of the groove profile.

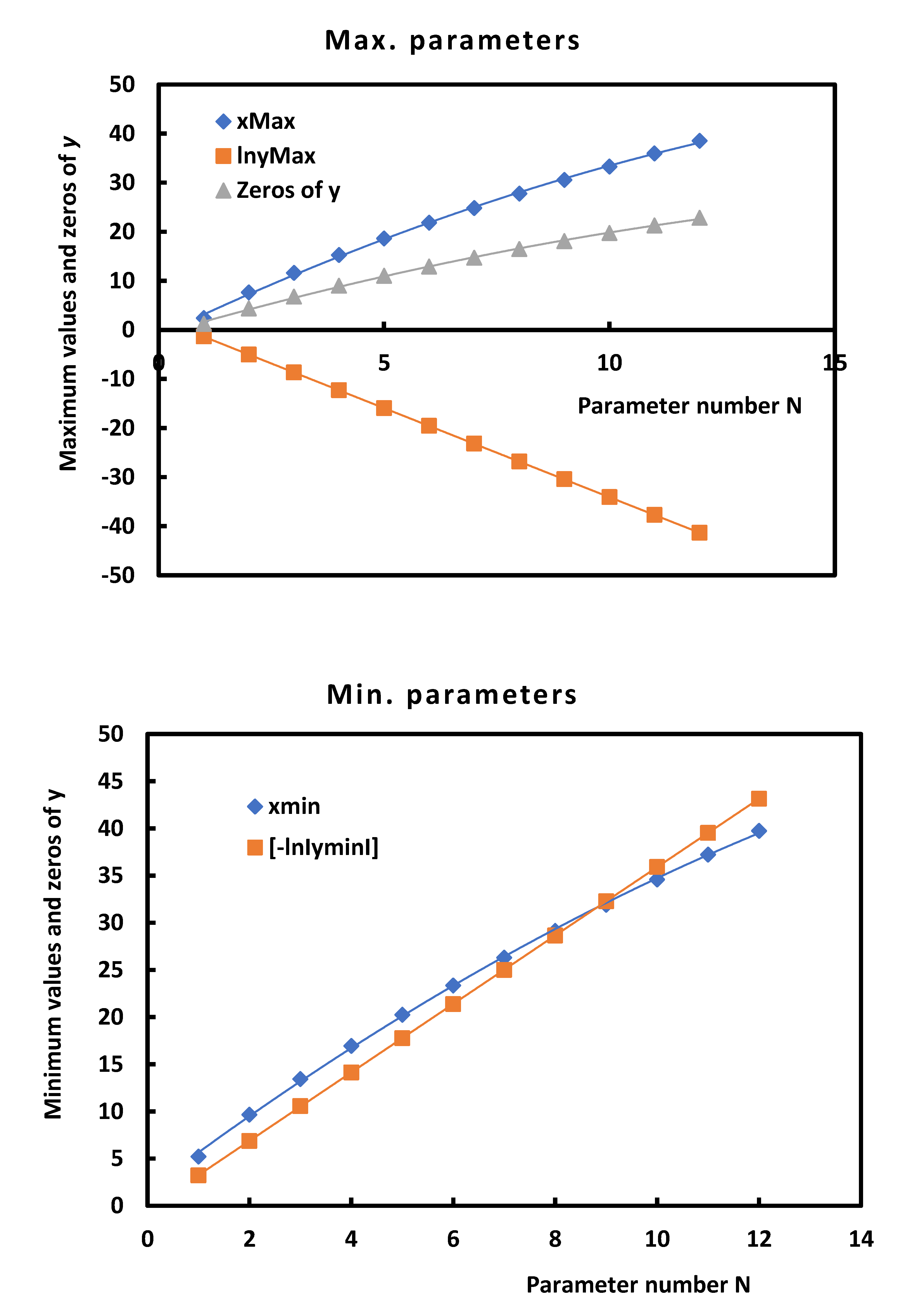

As example, we gave on

Table 1 the 12 first values of the groove shape parameters and on

Table 2 the distance between two consecutive maxima and minima for the first 12 numbers.

We observed that

decreases towards zero when x increases to the infinity as well as the absolute value of

(

Table 1). This will decrease the distance between two consecutive maxima and minima when the distance x increases.

Equations given in

Table 3 showed the properties of damped sinusoidal functions and the pseudo-periodicity of the various groove parameters and the strong correlations between them showing at the same time the infinity of the number of these different parameters.

On

Table 4, we gave the various results obtained by our analytical solution and the Mullins’s results.

The parabolic approximation of the groove profile obtained by Mullins was valid for

, whereas, our approximation more precise is valid for

(from the origin until the first maximum of the groove shape). On the other hand, the error committed by Mullins calculations on the abscissa of the first maximum the zero of the function y and the first inflexion point is about 7%, while that on the ordinate of the profile maximum exceeds 25%. On

Table 4, we were able, on the contrary of Mullins results, to give more information on the various maxima, minimas, zeros and positive and negative inflexion points of the grove shape profile.

If we notice

and

the depths of the groove taken from the bottom of the grove respectively to its first maximum and minimum, one can write:

The separation distance between two consecutive maxima

or minima

was given in

Table 2 proving the variation of this distance as a function of optima number N. One obtained the interpolated expressions on

Table 5:

Table 5 clearly showed that the ratio is independent from the time, for example, we can give this ratio for the first maximum:

Table 6 showed a certain deviation of Mullins results with respect to those of the analytical solution proposed in this paper, that can reach 12% in the case of the first maximum of the groove shape. However, Mullins did not give any additional information on the other maxima, minima, zeros of the solution and the various inflexion points, while our solution gave more complete information on the different parameters of the groove and also proposed many correlations that can be very useful for the readers.

Here, some information on the coordinates of the positive and negative inflexion points are given on

Table 7.

Competition between evaporation and diffusion

When studying the evolution of grain boundary groove profiles in the cases of the evaporation/condensation and surface diffusion, Mullins [

10] assumed that: (1) the surface diffusivity and the surface energy,

, were independent of the crystallographic orientation of the adjacent grains and (2) the tangent of the groove root angle, γ, is small compared to unity. Mullins also supposed an isotropic material. The assumption (tan

θ << 1) was used in all papers’ Mullins to simplify the study of the mathematical partial differential equation. The polycrystalline metal was supposed (3) in quasi-equilibrium with its vapor. The interface properties don’t depend on the orientation relative to the adjacent crystals. The grooving process was described by Mullins using the macroscopic concepts (4) of surface curvature and surface free energy. The matter flow (5) is neglected out of the grain surface boundary.

The mathematical equation governing the evaporation-condensation problem can be written here as:

where

C(

T) a constant of the problem depending on the temperature T, given by:

where

γ is the isotropic surface energy,

the vapor pressure at temperature

T in equilibrium with the plane surface of the metal characterized by a curvature

c = 0,

ω is the atomic volume,

m is molecular mass,

μ the coefficient of evaporation and

k is the Boltzmann constant.

We remember here the analytical solution of the evaporation case without any approximation [our paper] given by

and

By combining the two phenomena of diffusion and evaporation/condensation, one writes:

With the approximation postulated by Mullins supposing that

one can write:

Let’s put

the profile area. One can write the rate of change of profile area:

The Mullins’ approximation supposed that

and

. In a previous paper [ref], we studied the case of evaporation without this approximation and obtained at the origin the following relations:

In such case, on obtains:

This relationship provides clear evidence that the rate of change of the profile area is influenced by both evaporation and diffusion, contrary to Mullin’s prediction which states that and is independent of surface diffusion.

Calculation of the profile area

from below to above the original surface

By using the differential equation:

Where

is the first zero of the function

g.

If

σ is the profile area transferred from below to above of the original surface by surface diffusion alone divided by the profile area lost by evaporation, one can write:

With

, one has

and one deduces:

If we suppose that the contact angle is small or

(for Theta < 18°) we obtain:

Our relation proved that

depends on the temperature, at contrary of the relation obtained by Mullins:

Indeed, in this relation, there is no direct effect of the temperature. To compare between the two previous expressions, we supposed that

and obtained:

This calculation yielded a ratio of

, indicating an overestimation compared to the value proposed by Mullins.

Table 8 and

Table 9 provide two examples comparing the results obtained using the two methods for Au and Mg metals.

We observed that the profile areas corresponding to Au and Mg are overestimated by the Mullins method (about 2.5 times greater than our new values). On the other hand, the calculated ratio of the profile area lost by evaporation of Au and Mg is equal to:

This proved that whatever the time, the evaporation of Au is times more important than that of Mg. However, the diffusion of Mg particles is greater than that of Au.

The same procedure was used to determine the values of the profile area lost by evaporation of some common metals (

Table 10).

These interesting results of the

Table 10 gave the following order of the various metals by increasing profile area:

On

Table 11, we gave the obtained values of the two constants

C and

B of evaporation and diffusion for the different metals.

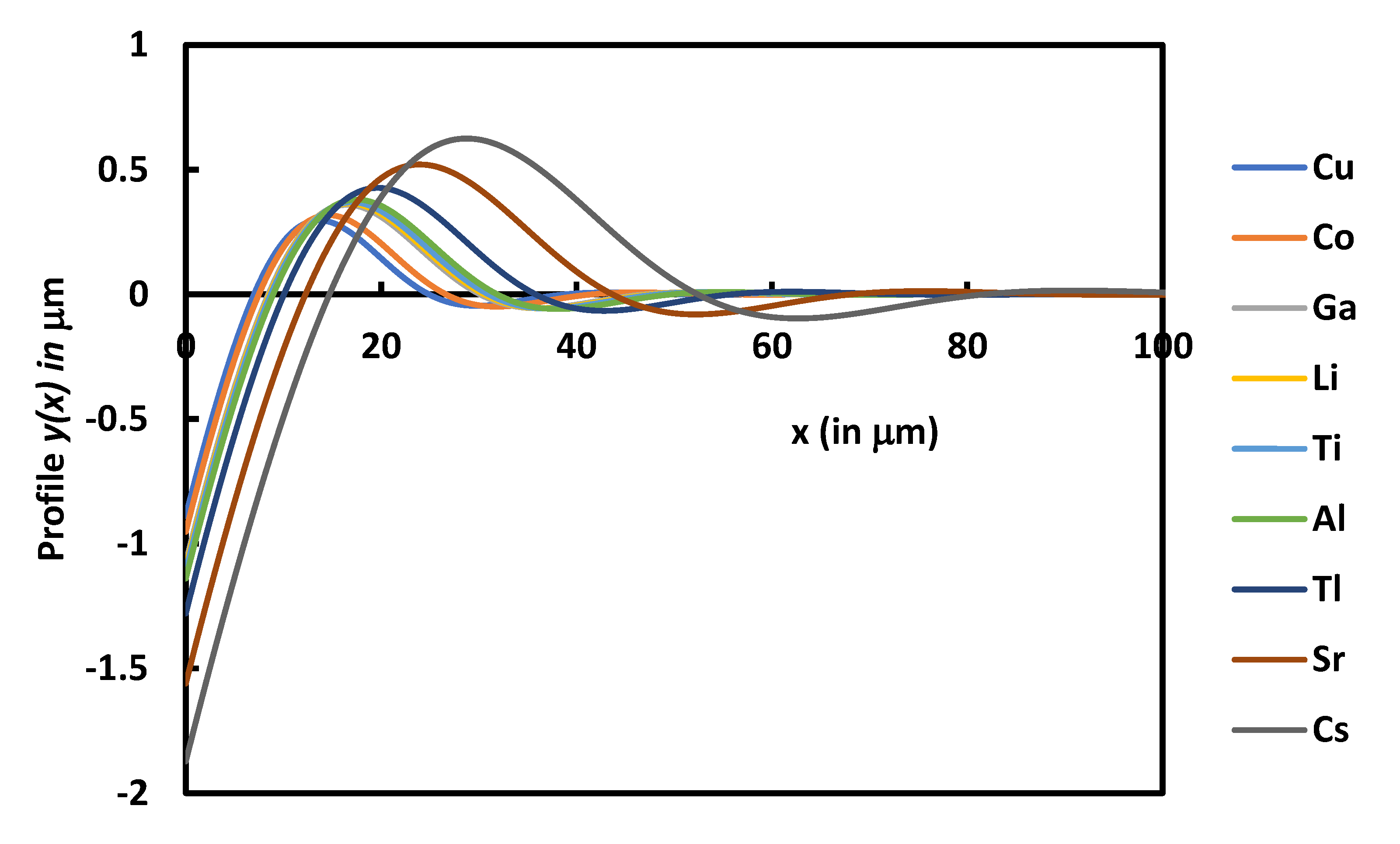

The constant of evaporation

C decreases from the cobalt element Co to cesium by respecting the following increasing order:

Whereas, this order changes for the constant of diffusion that increases from Cu to Cs with the following order:

Another important conclusion concerns the larger value of constant C with respect to B. It is shown that the value of C is about 1012 times greater that of B. This led to conclude that the diffusion can be neglected relative to evaporation.

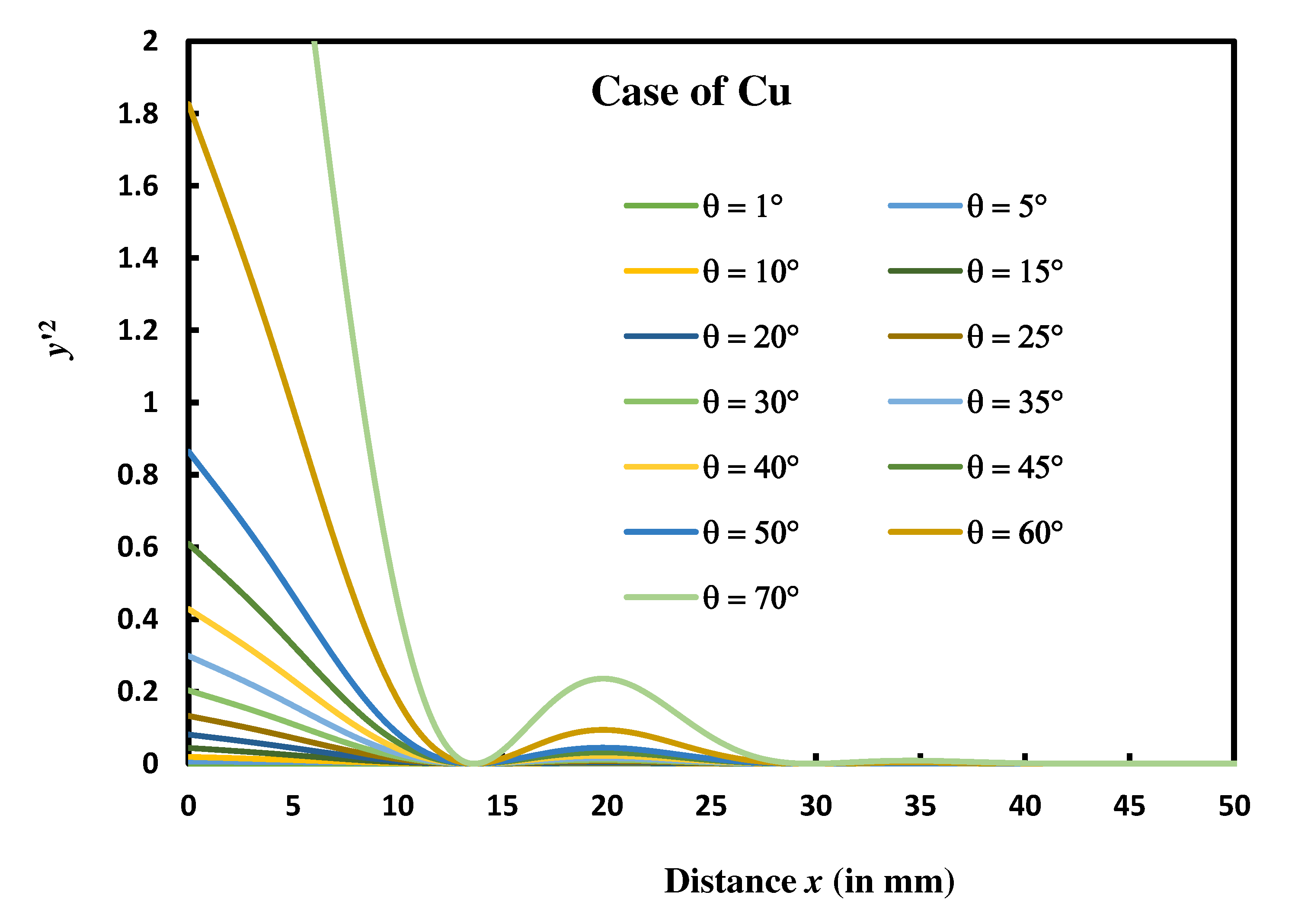

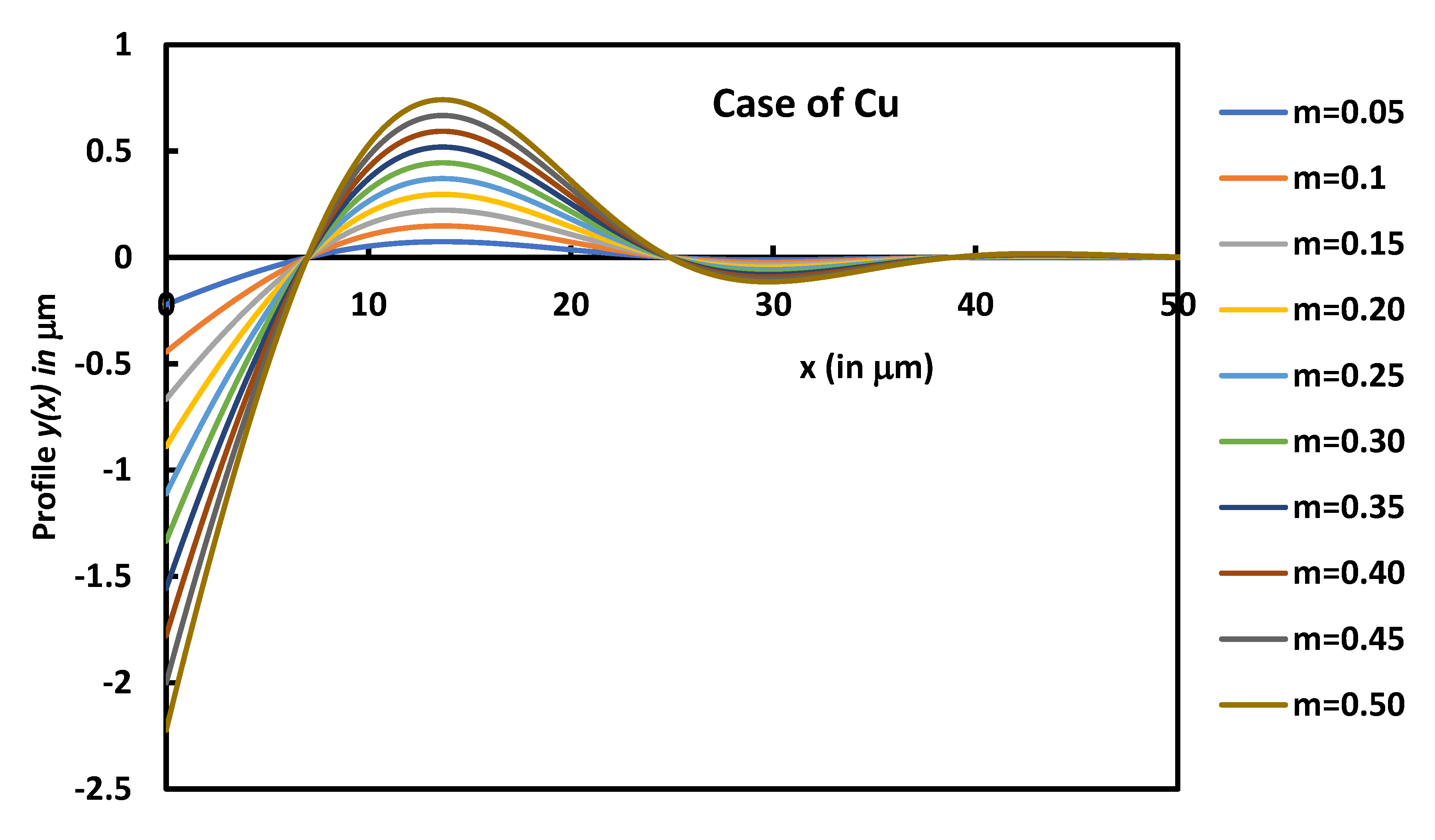

The depth of the groove

In many experiments, it was proved that the depth groove can vary from 0.1mm to several 10 mm in the case of diffusion depending on the metal thermal properties and on the width of the groove. In order to understand the thermal behavior of diffusion of the various elements, let’s take the typical example where m = 0.20 and calculate the corresponding depth

of the groove for metals (

Table 12).

Knowing that the width

of the groove is given by:

One deduced the value of

for the different metals presented on

Table 13.