1. Introduction

Citric acid (C6H8O7) is an organic acid present in citric fruits (orange, lemon,), which can be found in anhydrous form as a white, odorless crystalline powder [

1].

According to [

2], it is a substance that is already widely used in the food and pharmaceutical sectors. In wood it has been applied as a crosslinking agent [

3], as an adhesive in the manufacture of panels [

4] and to improve the dimensional stability of wood composites [

5].

In general, the main changes caused in wood by citric acid are attributed to the esterification reactions caused between the carboxyl groups (-COOH) of the acid, and the hydroxyl groups (-OH) present in the wood structure [

6]. However, studies focusing on the effect of this substance on the properties of wood are still very incipient.

On the other hand, wood modification was already evaluated by many studies using the technique of Fourier-transform infrared spectroscopy – FTIR with focus on the identification of esterification reactions through the evaluation of the peaks of bands 1720-1750 cm-1 and 1200-1300cm-1 [

7,

8], through the technique of scanning electron microscopy, which allows to evaluate the changes provoked on the surface of the material through the analysis of micrographs [

9,

10], and through the technique of pH, which allows to evaluate alteration on the hydrogenonic activity on wood [

11].

Another technique that was widely applied on many studies to evaluate changes on wood in a non-destructive manner is the x-ray densitometry [

12,

13], which allows to obtain a density profile in a rapid an automatized way to verify how the distribution of the substance applied occurs inside of the material.

Lastly, [

14] verified mixed results for the effect of the thermal treatments over the resistance to abrasion, with an increase of the resistance in the radial plane, and a reduction in the tangential plane.

In this context, the present study aimed to evaluate the effect of the application of citric acid on densified boards of Pinus sylvestris, which were measured through the evaluation of the chemical properties (SEM, FTIR and pH), the density profile, and the resistance to abrasion.

2. Materials and Methods

2.1. Wood samples

Timbers of sapwood of Pinus sylvestris. with dimensions of 380 by 15 by 2.8 cm (length x width x thickness) and 0.57 g/cm3 of nominal density were obtained at the carpentry of the Faculty of Forest Sciences and Forest Ecology of the Georg August Universität Göttingen.

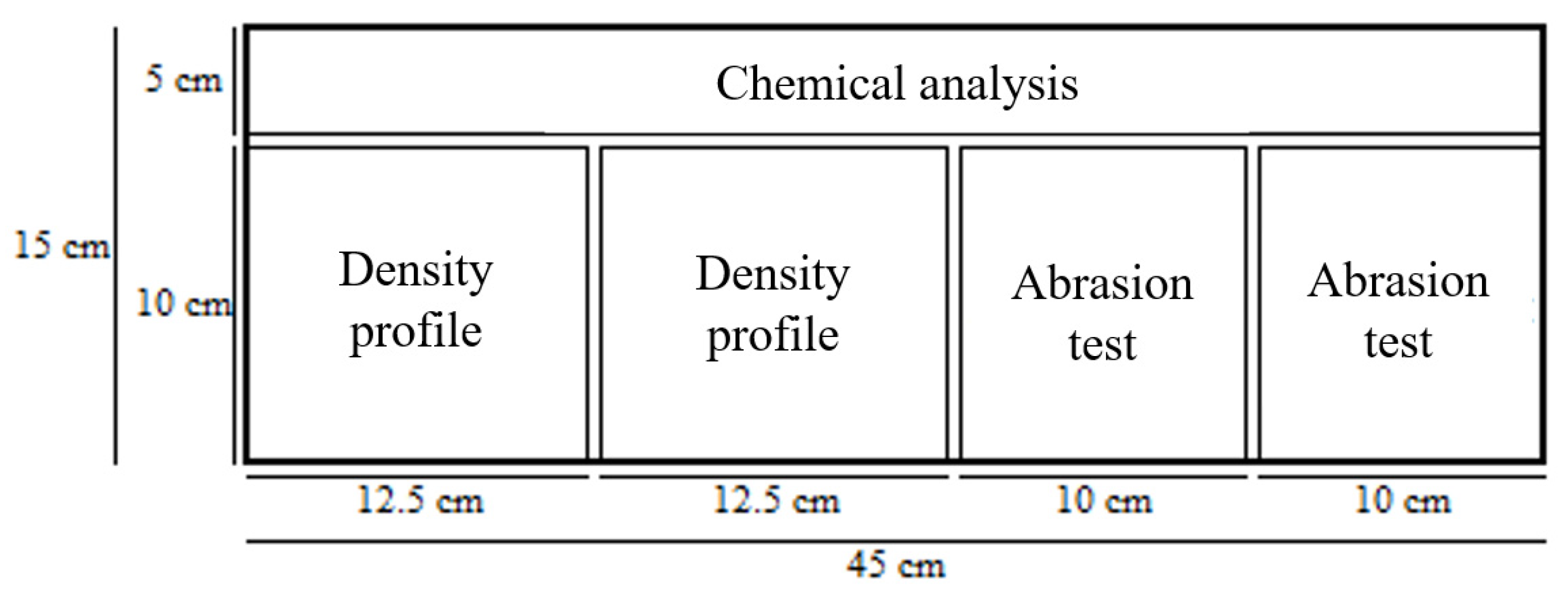

The timbers were sawn into sixteen boards of 15 by 45 by 2.5 cm, conditioned in a climatization room to achieve constant weight.

Figure 1 presents the cutting scheme of the samples and the test blocks for technological characterization.

2.2. Wood samples

The preparation of the solution (CA) was carried out diluting CA in water at room temperature (+ 28

oC), in a 1:1 ratio, according to methodology proposed by [

4].

The application of the CA was carried out using a paint roller to distribute the solution onto one of the surfaces, and subsequent heating in oven at 60oC, for 6 hours, so that CA can react adding functional chemical groups to wood. The amount of CA applied was proportional to the mass of the surface of the sample, considered as a veneer of 150 by 150 by 2.5mm (length x width x thickness).

2.3. Thermomechanical treatment

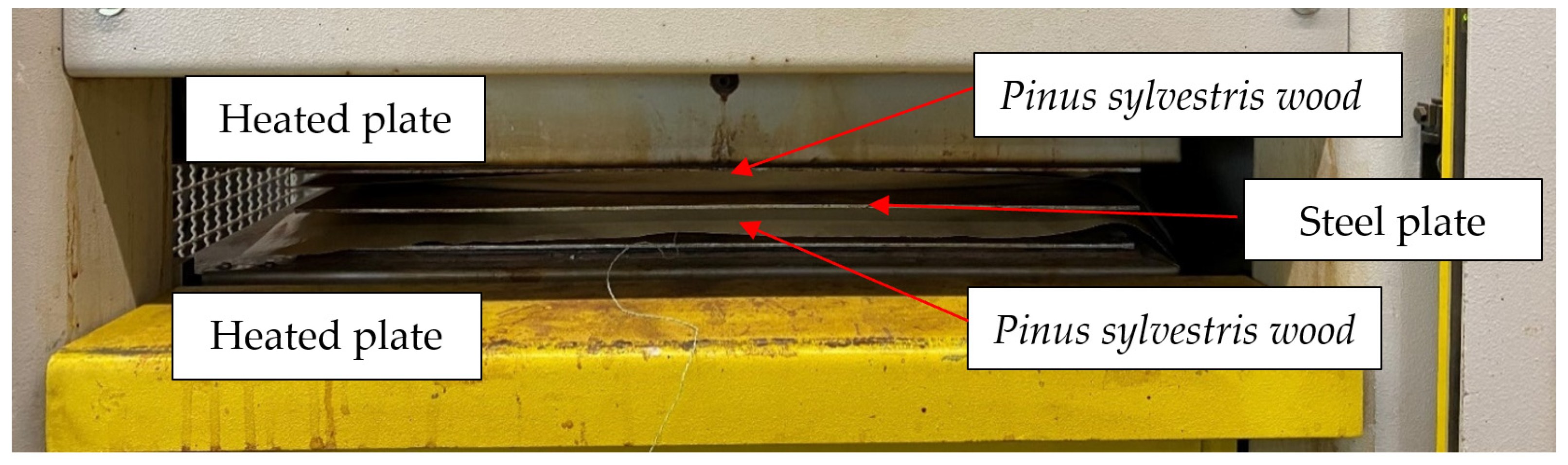

The application of the thermo-mechanical treatment on the samples of Pinus sylvestris was carried out in the carpentry of the Faculty of Forest Sciences and Forest Ecology, located in the Georg August Universität Göttingen, where it was possible to use a press with the following characteristics: pressing area of 60 by 60cm, load capacity of 400 kN, electric resistance heating, and control panel for temperature, time and pressure adjustment.

A steel plate (

Figure 2) with dimensions of 60 x 60 x 0.5 cm (length x width x thickness) was placed between the samples to isolate one of the surfaces of the material, allowing this way to apply the thermomechanical treatment on only one of the sides.

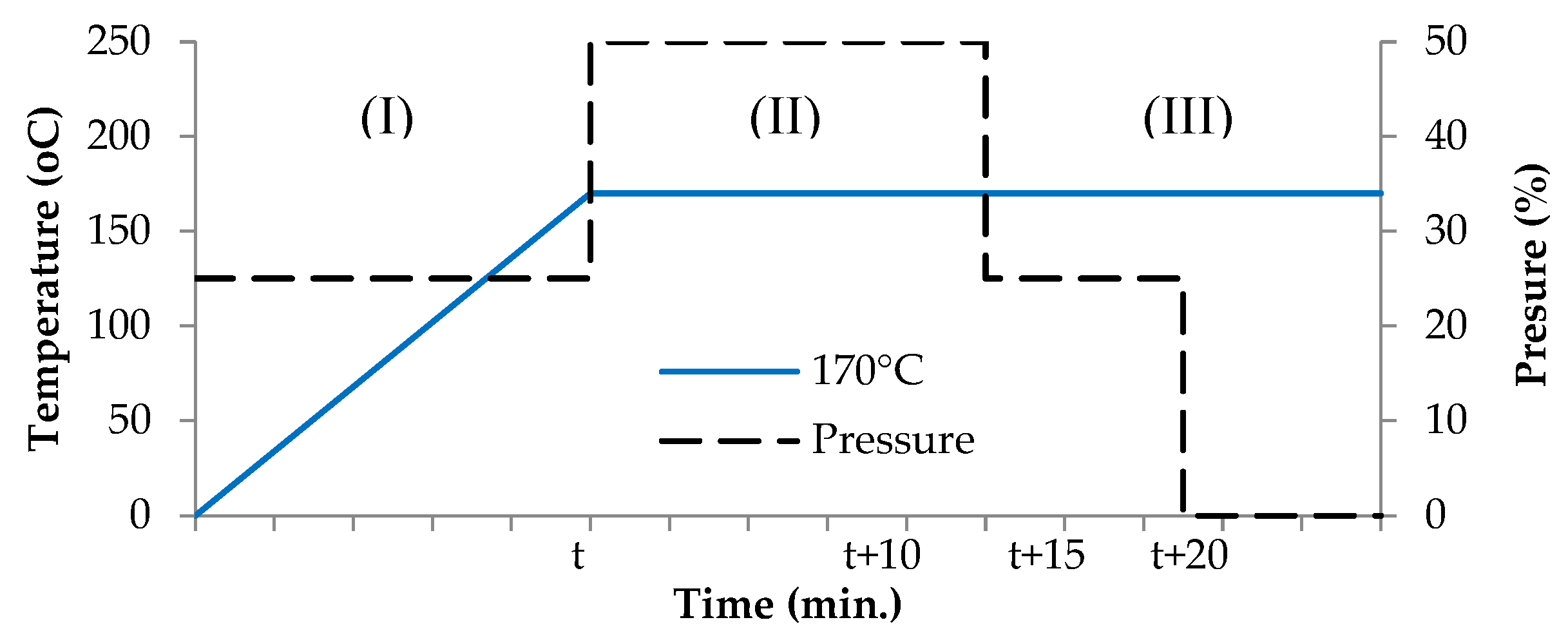

This way, the treatment was divided in three steps:

- (I)

Heating – initial temperature to treatment temperature (170oC) and half of the full pressure (1.3MPa);

- (II)

Treatment – treatment temperature (170oC) and full pressure (2.6MPa) over a period of 10 minutes;

- (III)

Post-treatment – treatment temperature (170oC) and half pressure release (1.30MPa) over a period of 5 minutes, and with all pressure released over a period of 5 minutes.

2.4. Chemical characterization

2.4.1. Fourier transform infrared spectroscopy

The spectroscopy test was performed using a BRUKER Alpha spectrophotometer and the mid-infrared range (MIR), whose range covers waves from 4000cm-1 to 300cm-1, with a resolution of 1cm-1¸ with the aid of a diffuse reflectance accessory. To obtain the samples, it was necessary to obtain small veneers from the material, which were clamped in the spectrometer.

The measurements were carried out on 3 different points per sample for both control and treated samples, generating spectra in absorbance mode. This way, using the OPUS software, the spectra was generated with the average of ten measurements for each treatment. For comparison, it was used the methodology proposed by [

15], which consists on the normalization of the average spectra in relation to the band height of 906 cm-1, assigned by [

16] to the wagging motion of the hydrogen atom on the C-1 position of the glucose ring in cellulose, which doesn’t suffers alteration after heat application.

2.4.2. Scanning electron microscopy

The Scanning Electron Microscopy test was realized using a PHENOMWORLD Phenom XL spectrometer, which allowed to obtain high resolution images of all samples prior to and after applying the evaluated treatments.

The images were obtained using a voltage of 15Kv of tension, a scale of 200 µm, and a magnification of 300x. For this, it was necessary to prepare 4 samples (1 x 1 x 1 cm3) for each treatment, which were covered by a layer of gold and silver with vacuum impregnation.

2.4.3. pH

The pH test was performed using a INOLAB 7110 ph meter, which allowed to verify changes on the acidity of wood prior to and after applying the evaluated treatments. For this, it was necessary to prepare 3 samples (5 x 5 x width of treatment cm3).

The pH was measured through the evaluation of the activity of the hydrogen ion, which was measured by placing an electrode on the surface of the sample, according to the following steps:

(i) Deposition of a drop of water over the wood surface;

(ii) Placement of the electrode in the wet area;

(iii) Measurement of the pH after 2 minutes of the placement of the electrode to allow the stabilization of the parameter.

2.5. Density profile

The density profile analysis was carried out through X-ray micro-computed tomography (XμCT) using a Grecon densityprofiler and the mid-infrared range (MIR), whose range covers waves from 4000cm-1 to 800cm-1, with a resolution of 1cm-1¸ with the aid of a diffuse reflectance accessory.

For this, it was necessary to prepare samples (50 x 50 x width of treatment mm3), which were inserted on the machine in a way that the X-ray ran longitudinally through the sample, and the density profile was obtained in the radial direction. The density profile was obtained using a resolution of 0.05 mm and a voltage of 33kV.

2.6. Abrasion test

The resistance to abrasion test was performed in accordance to [

17], using a Taber Abraser. For this, 5 test blocks of 10 by 10cm (length x width) for each treatment were exposed to a load of 1000g, velocity of 60 rotations per minute (rWL), and 1000 cycles.

The wear rate (WR) was calculated in accordance to Equation 1.

Where: WR = wear rate (%); Mi = initial mass (g); Mf = final mass (g); N = number of cycles.

The abrasion rate (Δt) was calculated in accordance to Equation 2.

Where: Δt = abrasion rate (%); ti = initial thickness (mm); tf = final thickness (mm).

3. Results

3.1. Thermomechanical treatment

Table 1 presents the specific mass of

Pinus sylvestris before and after the application of the treatments, and the average values of compression rate (CR), densification rate (DR) and mass loss (ML).

The application of citric acid led to a significant improvement of the DR, with an increase between 17.43% (CA5%) and 45.29% (CA10%) when compared to the samples densified without citric acid.

On the other hand, the CR presented a tendency of increase due to the application of citric acid, with an improvement of 7.21% and 15.70% for the amounts of 5% and 10% of the substance, respectively.

The ML presented a significant difference for all treatments evaluated, with a tendency of reduction of the property between 7.65% and 9.91% as a consequence of the application of the citric acid.

Lastly, the specific mass presented a significant difference for the samples treated with CA10% when compared to the samples densified without citric acid, and with CA5%. This improvement was a consequence of a higher reduction in the width of the sample, represented by a higher CR (29.17%), and a lesser ML (7.18%) than the other treatments.

3.2. Chemical analysis

3.2.1. Fourier transform infrared spectroscopy

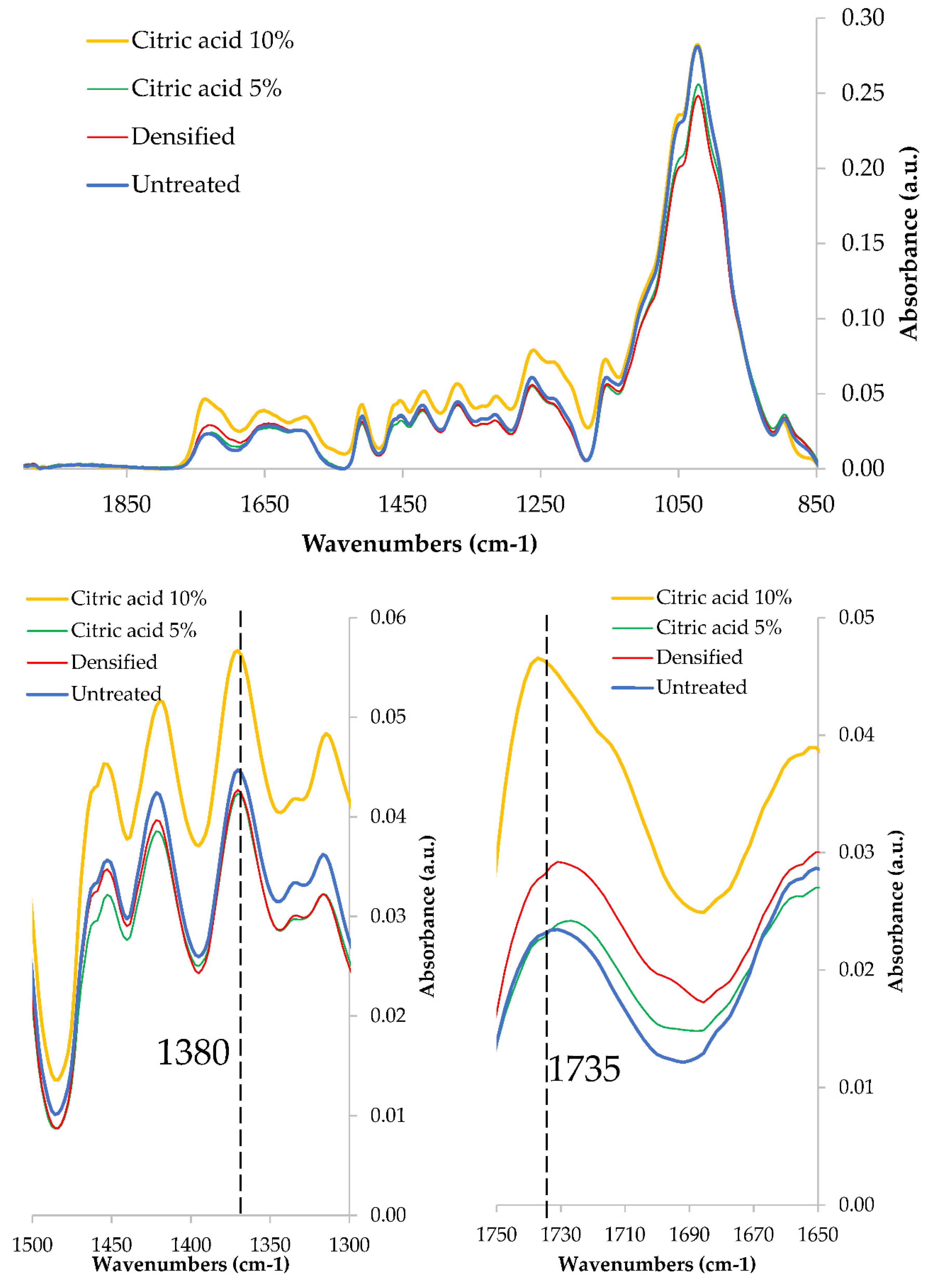

Figure 4 shows the spectra for all evaluated treatments, which were obtained using the Fourier-transform infrared spectroscopy technique. The analysis of these spectra aimed to identify evidence of esterification reactions, considering as hypothesis a possible link between the hydroxyl groups of wood, and carboxyl groups of citric acid.

By analyzing the spectra it was possible to observe two different patterns by having the spectrum of the untreated sample as a reference. For the densified and 5% of Citric acid treatments, a decrease in the height of the peaks was observed.

On the other hand, it was possible to verify that on the treatment of 10% of citric acid, the behavior was opposite, with the spectra presenting higher heights in both spectra (1374 cm-1 and 1735 cm-1) when compared to untreated wood.

Focusing on the effect of the citric acid, it is possible to observe that the higher concentration of citric acid (10%) resulted in a higher esterification rate. According to the height of the peaks in both spectra (1374 cm-1 and 1735 cm-1) it is possible to infer not only that there was a greater amount of esterification reactions, but also that this higher amount of reactions was able to partially compensate the thermal degradation promoted by the thermo-mechanical treatment.

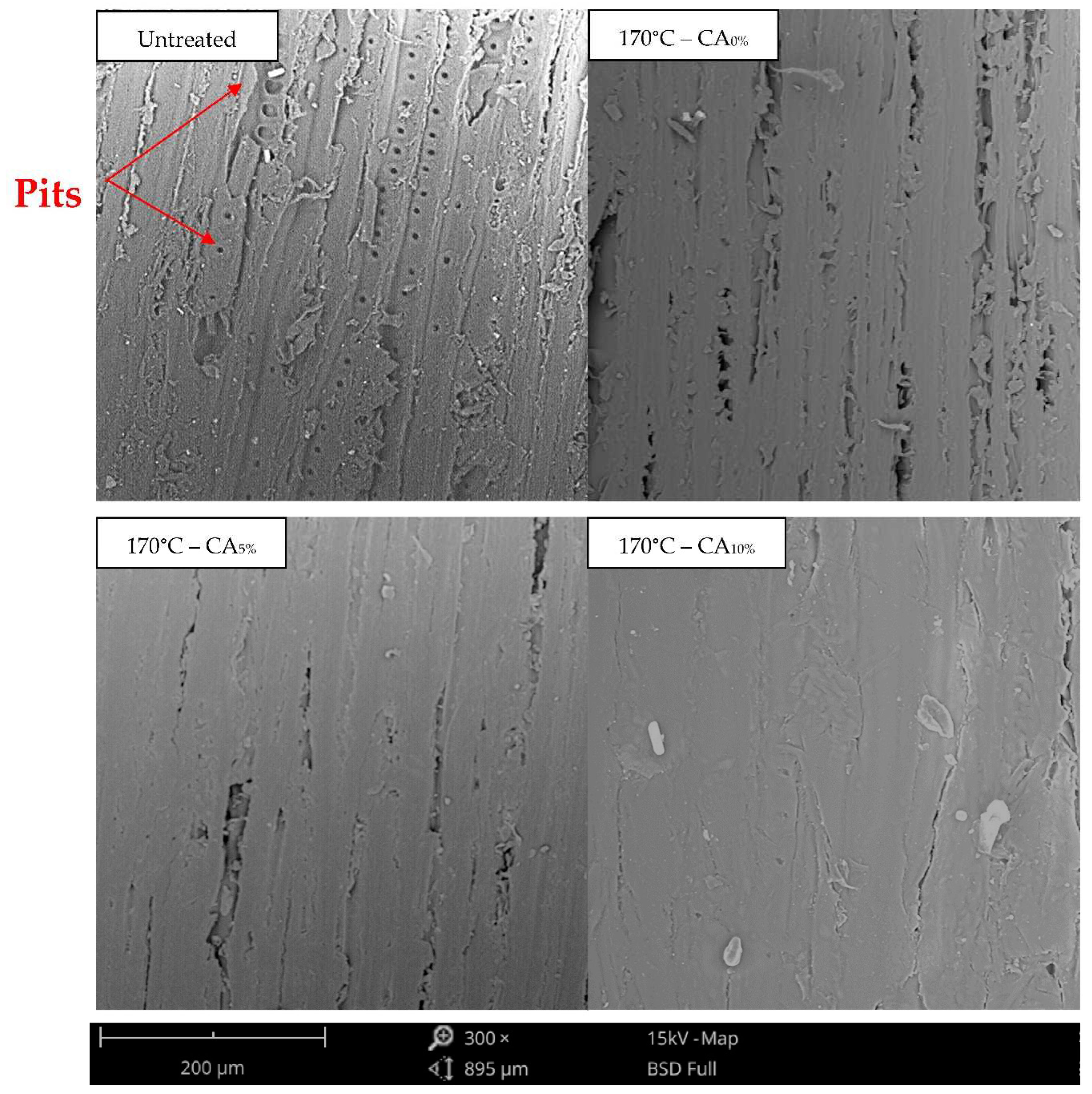

3.2.2. Scanning electron microscopy

Figure 5 presents the surface of

Pinus sylvestris wood for each treatment evaluated, which were obtained using the Scanning electron microscopy technique.

From the pictures, it was possible to verify that the untreated Pinus sylvestris wood (control) presents a very irregular and porous surface, with many pits and valleys.

Evaluating the effect of the densification, it was possible to observe that the application of the thermomechanical treatment had as a main consequence the reduction on the number of apparent pits.

Regarding the effect of the citric acid, it was possible to observe that the substance acted as a film, revesting the surface and reducing considerably the number of valleys, when compared to the densified wood without citric acid. Considering the amount of citric acid applied, it was possible to verify that the largest amount of citric acid (10%) presented a better coating when compared to the lowest amount of the substance (5%), so that the valleys were almost totally covered.

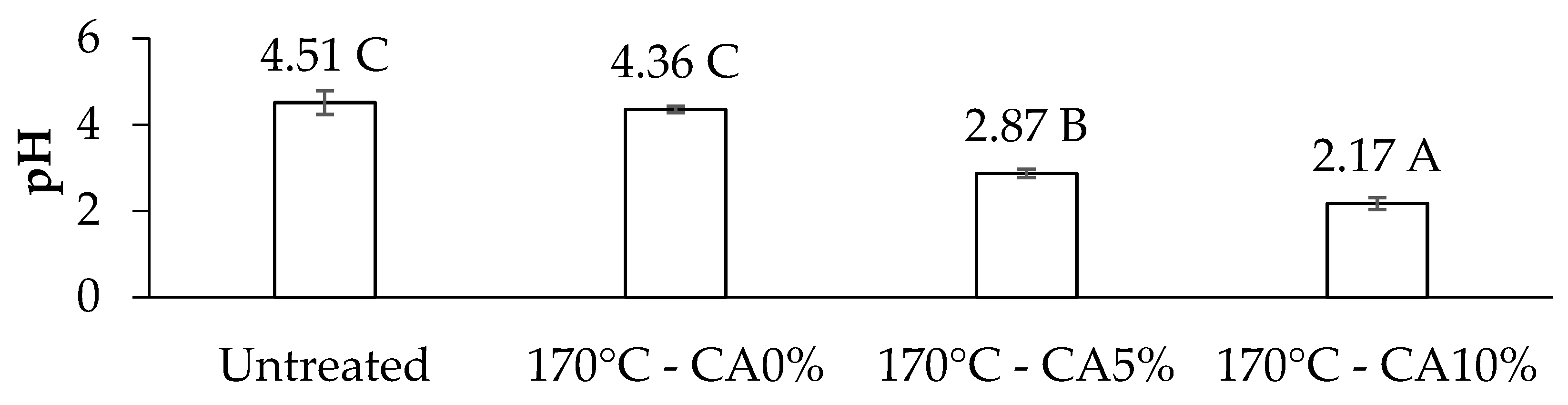

3.2.3. pH

Figure 6 presents the average pH of

Pinus sylvestris for each treatment evaluated.

The pH showed a significant difference for all the evaluated treatments. When compared to the untreated wood (control), all the treatments applied promoted a reduction in pH and, consequently, an increase in acidity on the wood surface.

Evaluating the effect of the densification, it was possible to observe that the thermomechanical treatment caused a non-significant reduction on pH (3.52%).

On the other hand, evaluating the effect of the citric acid, it was possible to observe that the combined treatment presented a significant reduction in pH, of the order of 36.36% and 51.86% for the amounts of 5% and 10% of citric acid, respectively.

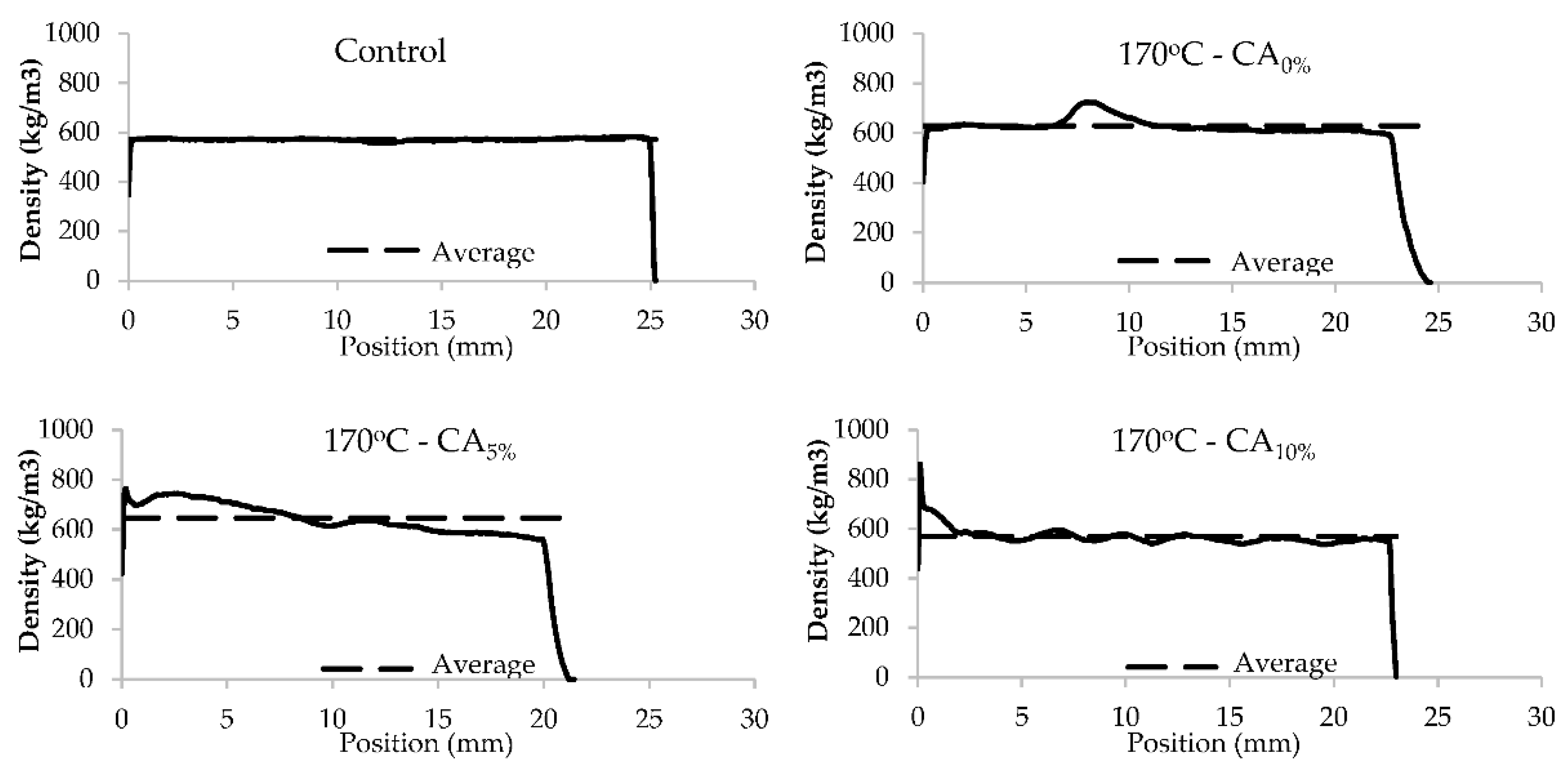

3.3. Density profile

Figure 7 presents the density profile of

Pinus sylvestris sapwood for each treatment evaluated.

This way, it was possible to verify that the untreated wood presented a very homogeneous and close to the average line of 0.56 g/cm3.

Evaluating the effect of the densification, it was possible to verify that the thermomechanical treatment provoked a peak of density (0.76 g/cm3) close to the position 7.5mm. Making a visual analysis of the sample, it was possible to verify that the increase of density was a consequence of a change in the direction of the growth rings.

Lastly, for the treatments modified citric acid it was possible to verify a similar pattern on both concentrations (5% and 10%), where the peak of density did not occur in the middle of the sample, but in the region where the substance was applied, reaching peaks of density of 0.76 g/cm3 (CA5%) and 0.86 g/cm3 (CA10%).

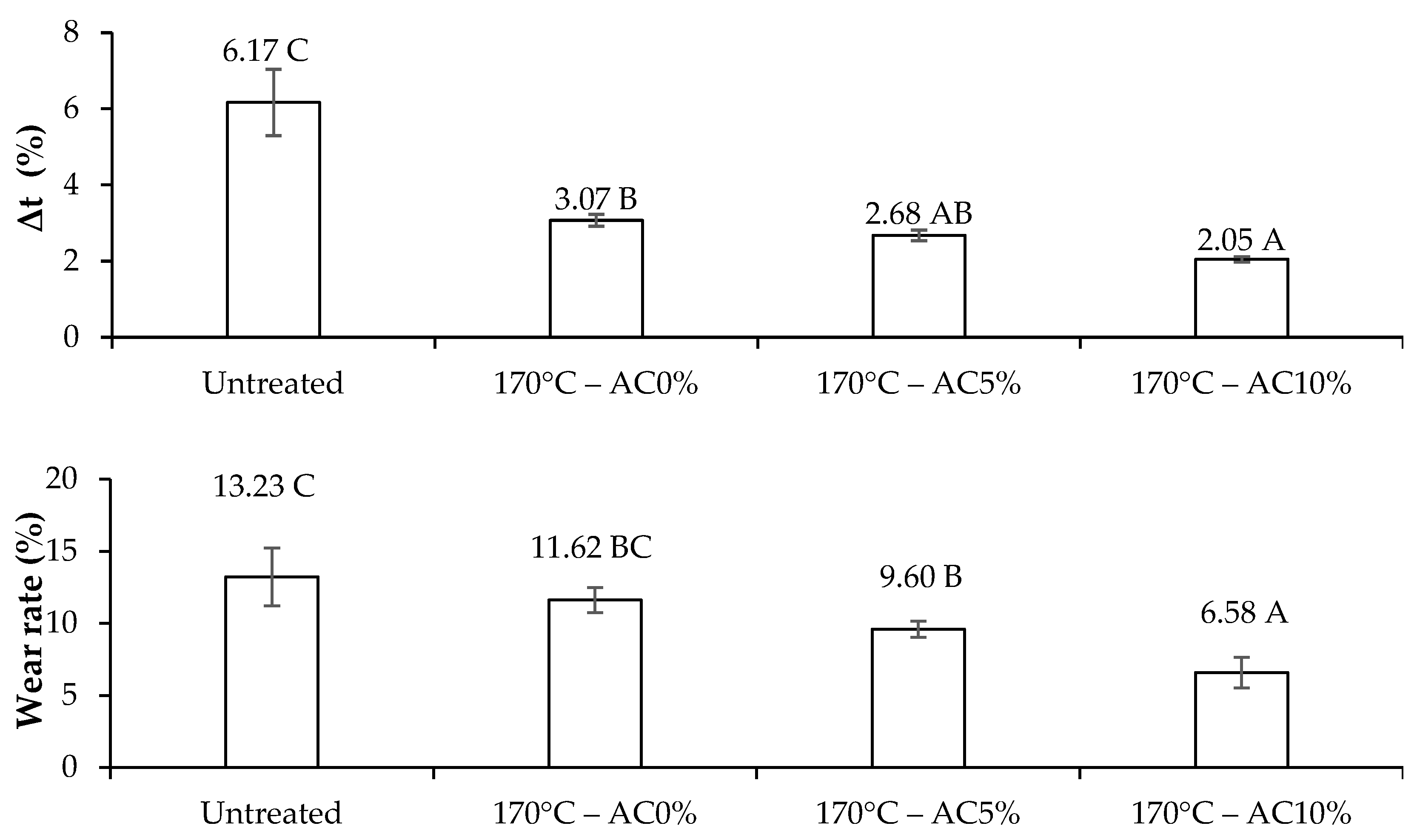

3.4. Abrasion test

Figure 8 presents the abrasion (Δt) and wear rate (WR) of

Pinus sylvestris for each treatment.

The samples of Pinus sylvestris without treatment presented the highest abrasion and wear rate between all the evaluated conditions.

Considering the effect of the thermomechanical treatment, the densified samples presented a significant difference in comparison with the untreated samples, with an average reduction of 50.21% for Δt, and 16.70% for WR.

On the other hand, considering the effect of citric acid, it was possible to verify a significant increase on the performance of both properties when compared to untreated and densified samples, with an average reduction of 61.65% for Δt, and 42.00% for WR.

Additionally, it was possible to verify that the application of a higher amount of citric acid (10%) promoted a better performance on both properties, although being significantly different only for WR.

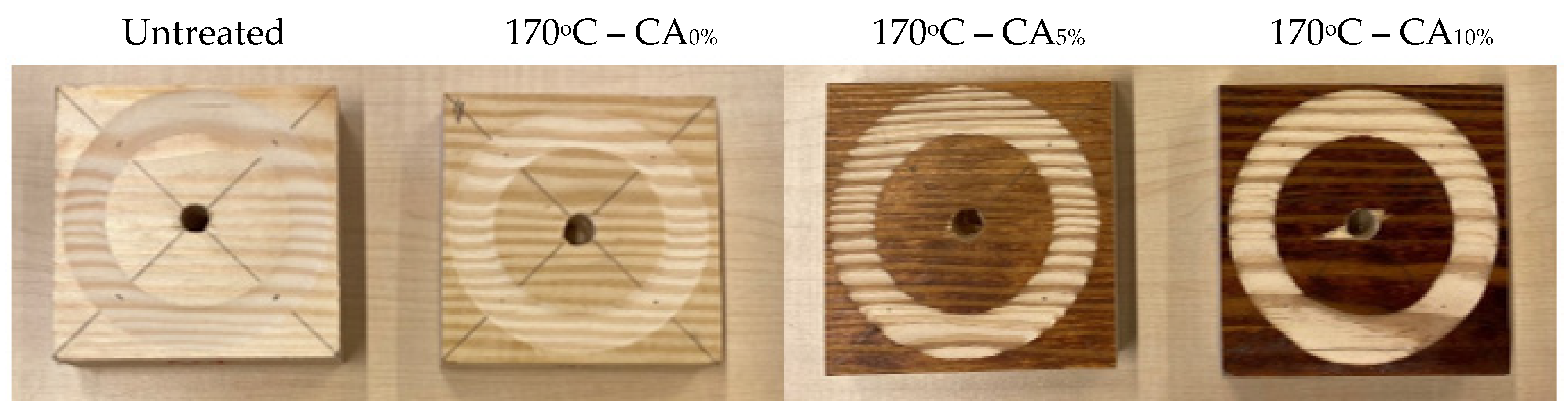

Lastly, when considering the visual aspect (

Figure 9) it was possible to observe that the abrasion is noticeable in all the evaluated treatments. In this context, it was possible to verify that although the citric acid promoted a reduction on abrasion by through a smaller reduction in thickness and mass loss, the technique applied was not enough efficient to penetrate deeper layers of wood.

4. Discussion

4.1. Thermomechanical treatment

When considering the effect of the thermomechanical treatment on the Densification rate (DR), different results were found by [

18] and [

19] who applied thermomechanical treatment on boards of

Pinus sylvestris and

Pinus elliotti and verified a DR between 83% and 93%. In this context, [

20] states that the increase of the specific mass of wood after the application of thermomechanical may be associated to many factors such as temperature, time and pressure applied.

Therefore, the divergence of results may be associated to the pressure applied on the present study, since the samples were exposed to similar temperatures, but with a pressure of 2.6 MPa, while the authors applied pressures of 6 MPa and 4.9 MPa, respectively.

For the effect of the thermomechanical treatment on the Compression rate (CR) the results corroborate with [

21], who applied thermomechanical treatment on wood of

Pinus sylvestris at a temperature of 150°C for a period of 10 minutes. According to the same authors, the variation presented by CR is mainly associated to the presence of internal tensions that are generated inside the cellular structure during the compression, and the loss of humidity due to the exposure to high temperatures, being both factors responsible for the spring-back behavior on wood after densification.

Lastly, the effect of the citric acid on the Mass loss matches with the results obtained by [

10] who verified that the application of citric acid promoted a reduction of the permeability of boards of

Pinus strobus. Therefore, this behavior suggest that the application of the substance may have acted as a barrier, making it difficult for water to exit during the heating stage (1st stage of the thermomechanical treatment), thus reducing the ML presented by the treatments.

4.2. Chemical analysis

4.2.1. Fourier transform infrared spectroscopy

In this context, emphasis was given to two specific peaks: one between the 1725 cm-1 and 1740 cm-1 bands, related to the stretching of carbonyl groups (C=O) in the esters of wood polymers and citric acid [

22]; and the other one found in the 1374 cm-1 spectra, which according to [

23] is related to the polysaccharides (C-H bonds of CH3 groups) that are deformed in carbohydrates.

According to [

24], authors who applied thermal treatments on wood of

Pinus pinaster, the reduction on the peaks is associated to thermal degradation of polysaccharides and weight loss presented on wood as a consequence of the exposure of the material to high temperatures (170

oC).

This result corroborates with [

24] and [

25], who verified an increase of esterification reactions after applying citric acid on wood panels of

Sorghum bicolor L. Monech and

Vitis vinifera L., respectively.

4.2.2. Scanning electron microscopy

The result of the untreated samples corroborates with [

26], authors that evaluated the microstructure of

Pinus sylvestris sapwood and observed that it is a species with a very porous and irregular surface, with many apparent pits, characteristics that are typical of low-density pinewood.

For the effect of the thermomechanical treatment the result corroborates with [

9], who evaluated the effect of densification on the microstructure of

Populus tomentosa wood and verified a reduction in the number of pits per unity of area. Similar result was obtained by [

27], who applied a thermomechanical treatment on

Pinus sylvestris wood and verified a reduction on the wood porosity.

In this context, [

28] states that the densification of wood through the thermomechanical treatment leads to the occurrence of morphological changes such as the reduction of pits and valleys, which are compressed by the pressure applied on press. Finally, for the effect of the citric acid the observed results corroborate with [

10], authors that applied citric acid on

Pinus strobus and

Pinus contorta wood and verified a considerably reduction on the porosity of both species. According to [

29], this behavior is a consequence of the capacity of citric acid of stablish chemical bonds between the carboxyl groups (-COOH) available on its structure and the free hydroxyl groups (-OH) available on wood structure, process that is known as ester bonds.

4.2.3. pH

The

Pinus sylvestris sapwood without treatment presented an average pH of 4.51, a result very close to that observed by [

30], who verified a pH of 4.6 for untreated

Pinus roxburghii wood.

The result for the effect of the thermomechanical treatment differs from [

11], who verified a significant reduction of pH (3.5 – 4) of

Pinus radiata wood after the application of thermal treatments, due to the occurrence of reactions that led to the production of acetic and formic acid. In this context, the different result may be associated to the temperature chosen (170°C), which may have been insufficient to promote greater changes in the wood surface.

Lastly, the results for the effect of the citric acid corroborates with [

31], who verified a reduction in the pH of the wood of Fagus sylvatica because of the application of citric acid. According to [

32], such reduction in pH observed in wood is the result of esterification reactions between the hydroxyls of the material and the carboxyls of citric acid, thus generating a new structure with greater availability of protons.

4.3. Density profile

Several studies with

Pinus sylvestris have referred that wood of this species can present foreign bodies such as knots [

33], and resin bags [

34], capable of significantly increase the density of wood. Therefore, the obtained results suggest that the obtained samples of

Pinus sylvestris sapwood did not contain such bodies.

Additionally, it was not possible to verify any difference between earlywood and latewood on the obtained density profile, differing from the results obtained by [

35], who were able to verify this difference on

Pinus sylvestris wood using the X-ray tomography technique. However, this result may be associated with the resolution applied in the equipment which may have not been sufficient to detect such differences.

For the effect of the thermomechanical treatment, it was possible to observe that the increase of density did not occur homogeneously through the sample, but due to a peak of density which was 20% higher than the average curve (0,63 g/cm3). This result corroborates with [

36], who applied thermomechanical treatment on

Pinus sylvestris and verified the formation of peaks of density along the sample.

According to [

37], who applied thermomechanical treatment on boards of

Populus tomentosa, the lower density in the surface of the sample may be associated to the loss of moisture that occurs when the wood was in contact with the hot plates of the press.

Lastly, the result for the effect of the citric acid corroborates with [

13], who evaluated the effect of citric acid, applied using impregnation chamber, on the density profile of sapwood of

Pinus sylvestris and verified the formation of peaks next to the edge of the sample suggest a higher accumulation of the substance in the surface of the material.

In addition, these results suggest that the citric acid may have acted as a barrier, preventing the exit of moisture present in the innermost layers of the material and, consequently, increased the density of the most superficial layer. Such behavior corroborates a study carried out by [

10], who verified a reduction in the permeability of

Pinus strobus L wood through citric acid impregnation.

4.4. Abrasion test

The result for abrasion test on untreated samples of

Pinus sylvestris corroborates with [

38], who verified an abrasion rate of 6.00% for the sapwood of

Pinus sylvestris without any treatment.

For the effect of the thermomechanical treatment, similar result was observed by [

39], who registered an increase in the resistance to abrasion after applying thermomechanical treatment on boards of

Paulownia spp., with a reduction of weight loss between 40.00% and 75%, according to the pressure applied.

According to [

40], the resistance of abrasion may be associated to the specific mass of the material, so that higher density materials also tend to present greater resistance to abrasion.

Lastly, for the effect of the citric acid it was not possible to find any results in the literature evaluating the effect of this substance on the abrasion resistance of wood. However, when considering the effect of chemical modification of wood, [

38] verified an increase of the abrasion resistance after promoting acetylation reaction on boards of

Fagus sylvatica, and [

41] obtained similar results by promoting furfurylation reaction on boards of

Pinus radiata.

5. Conclusion

The combination between thermomechanical treatment and citric acid presented a significant improvement on the chemical and surface properties, on the density profile, and on the resistance to abrasion of Pinus sylvestris sapwood.

The application of a higher concentration of citric acid (10%) may be justified by the better result presented on the chemical analysis, on the density profile, and on the abrasion resistance of Pinus sylvestris sapwood.

Lastly, when considering the visual aspect, the application of the citric acid provoked an intense darkening of the surface for the same temperature applied, changing it color from a light yellow color to dark brown.

Author Contributions

Conceptualization, M.C, C.M. and H.M.; methodology, C.M., H.M., L.C. and J.M.; K.K. and A.M.; software, M.C., K.K. and A.M.; validation, M.C., K.K. and A.M.; formal analysis, C.M., H.M., L.C. and J.M.; investigation, M.C.; writing—original draft preparation, M.C.; writing—review and editing, M.C.; supervision, C.M. and H.M.; funding acquisition, C.M. and H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and Deutscher Akademischer Austauschdienst (DAAD) agencies.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Lee, S.H.; Tahir, M.D.P.; Lum, W.C.; Tan, L.P. A review on citric acid as green modifying agent and binder for wood. Polymers 2020, 12, 1692. [Google Scholar] [CrossRef] [PubMed]

- Ciriminna, R.; Meneguzzo, F.; Delisi, R.; Pagliaro, M. Citric acid: emerging applications of key biotechnology industrial product. Chem. Central J. 2017, 11, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Vukusic, S.B.; Katovic, D.; Schramm, C.; Trajkovic, J.; Sefc, B. Polycarboxylic acids as non-formaldehyde anti-swelling agents for wood. Holzforschung 2006, 60, 439–444. [Google Scholar] [CrossRef]

- Del Menezzi, C.; Amirou, S.; Pizzi, A.; Xi, X.; Delmotte, L. Reactions with Wood Carbohydrates and Lignin of Citric Acid as a Bond Promoter of Wood Veneer Panels. Polymers 2018, 10, 833. [Google Scholar] [CrossRef] [PubMed]

- Amirou, S.; Pizzi, A.; Delmotte, L. Citric acid as waterproofing additive in butt joints linear wood welding. Eur. J. Wood Wood Prod. 2017, 75, 651–654. [Google Scholar] [CrossRef]

- Essoua, G.G.E.; Blanchet, P.; Landry, V.; Beauregard, R. Pine Wood Treated with a Citric Acid and Glycerol Mixture: Biomaterial Performance Improved by a Bio-byproduct. BioResources 2016, 11. [Google Scholar] [CrossRef]

- Kusumah, S.S.; Umemura, K.; Yoshioka, K.; Miyafuji, H.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind. Crop. Prod. 2016, 84, 34–42. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Kawai, S. Characterization of wood-based molding bonded with citric acid. J. Wood Sci. 2011, 58, 38–45. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood (Populus tomentosa). J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

- Berube, M.-A.; Schorr, D.; Ball, R.J.; Landry, V.; Blanchet, P. Determination of In Situ Esterification Parameters of Citric Acid-Glycerol Based Polymers for Wood Impregnation. J. Polym. Environ. 2017, 26, 970–979. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Kegel, E.; Stevens, M. Optimisation of a two-stage heat treatment process: durability aspects. Wood Sci. Technol. 2006, 41, 31–57. [Google Scholar] [CrossRef]

- Gaitán-Alvarez, J.; Berrocal, A.; Lykidis, C.; Moya, R.; Mantanis, G.I. Furfurylation of tropical wood species with and without silver nanoparticles: Part II: Evaluation of wood properties. Wood Mater. Sci. Eng. 2021, 18, 112–119. [Google Scholar] [CrossRef]

- Kurkowiak, K.; Emmerich, L.; Militz, H. Sorption behavior and swelling of citric acid and sorbitol (SorCA) treated wood. Holzforschung 2021, 75, 1136–1149. [Google Scholar] [CrossRef]

- Aytin, A.; Korkut, S.; As, N.; Ünsal. ; Gündüz, G. Effect of Heat Treatment of Wild Cherry Wood on Abrasion Resistance and Withdrawal Capacity of Screws. Drv. Ind. 2015, 66, 297–303. [Google Scholar] [CrossRef]

- Pastore, T.C.M. Studies of the effect of ultraviolet radiation on wood by RAMAN (FT-RAMAN), diffuse reflectance in the infrared (DRIFT) and visible (CIE-L*a*b*) spectroscopy. Thesis, Universidade de Brasília, 2014.

- Horn, B.A.; Qiu, J.; Owen, N.L.; Feist, W.C. FT-IR Studies of Weathering Effects in Western Redcedar and Southern Pine. Appl. Spectrosc. 1994, 48, 662–668. [Google Scholar] [CrossRef]

- Astm-D4060. Standard test method for Abrasion Resistance of Organic Coatings by the Taber Abraser. ASTM International: West Conshohoken, United states of America, 1995.

- Ulker, O.; Imirzi, O.; Burdurlu, E. The effect of densification temperature on some physical and mechanical properties of Scots pine (Pinus sylvestris L.). BioResources 2012, 7, 5581-5592. BioResources 2012, 7. [Google Scholar] [CrossRef]

- Pertuzzatti, A.; Missio, A.L.; Cademartori, P.H.G.; Santini, E.J.; Haselein, C.R.; Berger, C.; Gatto, D.A.; Tondi, G. Effect of Process Parameters in the Thermomechanical Densification of Pinus elliottii and Eucalyptus grandis Fast-growing Wood. BioResources 2017, 13, 1576–1590. [Google Scholar] [CrossRef]

- Kutnar, A.; Šernek, M. Densification of wood. Zbornik gozdarstva in lesarstva 2007, 53–62. [Google Scholar]

- Pelit, H.; Sönmez, A.; Budakçı, M. Effects of ThermoWood® process combined with thermo-mechanical densification on some physical properties of Scots pine (Pinus sylvestris L. ). BioResources 2014, 9, 4552–4567. [Google Scholar] [CrossRef]

- Brum, S.S.; Bianchi, M.L.; Silva, V.L.; Gonçalves, M. Preparação e caracterização de carvão ativado produzido a partir de resíduos do beneficiamento do café. Química Nova 2008, 31, 1048–1052. [Google Scholar] [CrossRef]

- Michell, A.; Higgins, H. Infrared spectroscopy in Australian forest products research. CSIRO Forestry: Melbourne, Australia, 2002.

- Esteves, B.; Marques, A.V.; Domingos, I.; Pereira, H. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. 15. [CrossRef]

- Santos, J.; Pereira, J.; Escobar-Avello, D.; Ferreira, I.; Vieira, C.; Magalhães, F.D.; Martins, J.M.; Carvalho, L.H. Grape Canes (Vitis vinifera L.) Applications on Packaging and Particleboard Industry: New Bioadhesive Based on Grape Extracts and Citric Acid. Polymers 2022, 14, 1137. [Google Scholar] [CrossRef] [PubMed]

- Barman, D.N.; Haque, A.; Hossain, M.; Paul, S.K.; Yun, H.D. Deconstruction of Pine Wood (Pinus sylvestris) Recalcitrant Structure Using Alkali Treatment for Enhancing Enzymatic Saccharification Evaluated by Congo Red. Waste Biomass- Valorization 2018, 11, 1755–1764. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Morén, T.; Hagman, O.; Cloutier, A.; Fang, C.-H.; Elustondo, D. Anatomical properties and process parameters affecting blister/blow formation in densified European aspen and downy birch sapwood boards by thermo-hygro-mechanical compression. J. Mater. Sci. 2013, 48, 8571–8579. [Google Scholar] [CrossRef]

- efc, B.; Trajković, J.; Hasan, M.; Katović, D. Dimensional stability of wood modified by citric acid using different catalysts. Drvna industrija et al. 2009, 60, 23–26. [Google Scholar]

- Poonia, P.K.; Tripathi, S. Effect of microwave heating on ph and termite resistance of Pinus roxburghii wood. 2018. [Google Scholar] [CrossRef]

- Mubarok, M.; Militz, H.; Dumarçay, S.; Gérardin, P. Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci. Technol. 2020, 54, 479–502. [Google Scholar] [CrossRef]

- Feng, X.; Xiao, Z.; Sui, S.; Wang, Q.; Xie, Y. Esterification of wood with citric acid: The catalytic effects of sodium hypophosphite (SHP). Holzforschung 2013, 68, 427–433. [Google Scholar] [CrossRef]

- As, N.; Goker, Y.; Dundar, T. Effect of Knots on the physical and mechanical properties of scots pine. Wood Research 2006, 51, 51–58. [Google Scholar]

- Kozakiewicz, P.; Jankowska, A.; Mamiński, M.; Marciszewska, K.; Ciurzycki, W.; Tulik, M. The Wood of Scots Pine (Pinus sylvestris L.) from Post-Agricultural Lands Has Suitable Properties for the Timber Industry. Forests 2020, 11, 1033. [Google Scholar] [CrossRef]

- Campbell, R.; McCarroll, D.; Loader, N.J.; Grudd, H.; Robertson, I.; Jalkanen, R. Blue intensity in Pinus sylvestris tree-rings: developing a new palaeoclimate proxy. Holocene 2007, 17, 821–828. [Google Scholar] [CrossRef]

- Belt, T.; Rautkari, L.; Laine, K.; Hill, C.A.S. Cupping behaviour of surface densified Scots pine wood: the effect of process parameters and correlation with density profile characteristics. J. Mater. Sci. 2013, 48, 6426–6430. [Google Scholar] [CrossRef]

- Tu, D.; Su, X.; Zhang, T.; Fan, W.; Zhou, Q. Thermo-mechanical Densification of Populus tomentosa var. tomentosa with Low Moisture Content. BioResources 2014, 9, 3846–3856. [Google Scholar] [CrossRef]

- Brischke, C.; Ziegeler, N.; Bollmus, S. Abrasion resistance of thermally and chemically modified timber. Drvna industrija: Znanstveni časopis za pitanja drvne tehnologije 2019, 70, 71–76. [Google Scholar] [CrossRef]

- Li, H.; Jiang, X.; Ramaswamy, H.S.; Zhu, S.; Yu, Y. High-Pressure Treatment Effects on Density Profile, Surface Roughness, Hardness, and Abrasion Resistance of Paulownia Wood Boards. Trans. ASABE 2018, 61, 1181–1188. [Google Scholar] [CrossRef]

- Swaczyna, I.; Kedzierski, A.; Tomusiak, A.; Cichy, A. Hardness and wear resistance tests of the wood species most frequently used in flooring panels. Forestry and Wood Technology et al. 2011, 76, 82–87. [Google Scholar]

- Liu, M.; Lyu, S.; Cai, L.; Peng, L.; Tang, J.; Huang, Z.; Lyu, J. Performance improvement of radiata pine wood by combining impregnation of furfuryl alcohol resin and densification for making fretboard materials. Ind. Crop. Prod. 2021, 172, 114029. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).