1. Introduction

The increase in lack of wood for production of wood products, disapproval of part of the public opinion and the media regarding the harvesting of wood from natural forests for economic purposes (sometimes almost hysterical), and demanding the exclusion of more and more forest areas from normal forest management, e.g., by the European Commission, collectively make it that among industries such as the pulp and paper one and wood particle boards one located in Europe, the use of fibrous production intermediates manufactured from non-wood plants may soon be more popular [

1,

2,

3]. This trend is also supported by such facts as:

- these fibrous raw materials (FRMs) have so far been used in these industries to a relatively small extent, and they constitute a fairly large FRMs base,

- they are much better suited for use in the pulp and paper industry than, for example, in the furniture or construction industries,

- the waiting period for straw from non-wood plants is much shorter than in the case of wood,

- in some cases, they show a higher CO2 absorption capacity per ha of cultivation than woodlands [

4].

Taking this into account, a review of the source literature on the use of one of the non-wood raw materials, i.e., industrial hemp, in large-scale European kraft pulp mills was made, taking into account the causal, cultivation, technological, and application aspects of this application. The main purpose of this study is to familiarize the environment of pulp and paper producers with issues concerning industrial hemp as a material for papermaking and to indicate the possibility of better adapting this raw material to this type of application by breeding new papermaking varieties of this plant known for years in Europe.

2. Casual Aspects

2.1. The State of the FRMs bAse of the European Pulp and Paper Industry and the Possibilities of Its Expansion

Forests are a traditional source of wood for papermaking around the world. The surface of the forest land, according to FAO data on a global scale, is decreasing somewhat every year (FAO 2015) [

5]. This is due to unsustainable forest management in some countries, the transformation of forest areas into agricultural lands, forest fires, and damage caused by insects (Wilson and Ward 1996; Watson 2006) [

6,

7]. For this reason, there has been an increasing interest in acquiring wood for papermaking from forest plantations. However, the possibility of obtaining wood from this source is greatest in countries with a warm climate (in Europe, mainly Spain and Portugal) [

8,

9,

10]. In countries located in the northern temperate climate zone, there are shortages of cheap wood for papermaking [

11,

12]. In order to increase the competitiveness of the pulp and paper industry in these countries, forest plantations are also planned, in which poplars, spruces, larches, and birches are cultivated [

13,

14]. An example is the plantation of fast-growing poplar hybrids set up in 2012 in Poland by International Paper in cooperation with GreenWood Resources. The area of these plantations, and therefore the amount of wood from which pulp could possibly be obtained, is small, however, and the quality of the wood is uncertain, which means that it may even be necessary to use it for heat production at pulp mills, as speculated by Duda [

15].

In view of the relatively high prices of primary papermaking pulps, many companies choose waste paper as the main FRM for the production of paper and cardboard [

2]. This FRM, as a result of the development of technology and techniques for upgrading waste paper, can also be processed into relatively good quality pulps [

16,

17]. In 2010, this type of FRM accounted for approximately 45% of the raw material base of the paper industry in the world. Waste paper, however, is also in short supply due to the increasing number of enterprises using it for the production of paper and cardboard, as well as due to the reduction in the amount of graphic paper production [

18].

NFRMs are used for papermaking in a relatively small amount globally (up to approx. 8–10% of papermaking pulps were produced from these FRM in 2010) [

19]. The main reason for this was the easier production of pulps from wood than non-wood FRMs, which is a FRM that is easier to transport, more durable in storage, and contains cells that enable obtaining more balanced and better paper quality. The most important NFRMs used in the production of paper and cardboard in the world include mainly straws from some cereals (wheat, rye, triticale, rice), bagasse, and bamboo [

20,

21,

22]. For example, in the years 1996–1998, these FRMs accounted for about 68% of all the NFRMs consumed in the world for papermaking purposes (cereal straw 46%, bagasse 14%, and bamboo 6%), with the remaining part of the non-wood pulp and paper being made from reeds, cotton linters, esparto, flax, hemp, kenaf, jute, abaca, and sisal fibres ( [

20,

23].

Most of the listed species of non-wood plants used in the world for papermaking, however, do not grow in European countries. Therefore, in these countries, for papermaking, mainly non-wood plants that grow well in northern temperate climate zone can be considered. The obvious NFRM for use in the paper industry of countries located in this zone is the straw of consumption cereals. Its unfavorable feature, however, is the high content of mineral substances, and in some case, the high density of the paper produced from cereal straw pulp. For this reason, the use of straw from other plants that grow well in the temperate climate zone, such as industrial hemp (IH) [

24,

25,

26,

27]

should be taken into account.

2.2. Long Tradition of Cultivation of IH in Europe and Multiple Uses of This Plant in the European Economy

Hemp (Cannabis sativa L.) was one of the first plants commonly grown by humans to obtain fibres for fabric production. It is characterized by rapid growth in northern temperate climatic zone; moderate climatic and soil requirements; capability of growing without the use of large amounts of pesticides and herbicides; and resistance to rodents. The earliest records of the use of this plant originate from Japan and China (years 4500–7000 BCE), from where, probably as a result of population migration, they first reached the Caspian Sea region, and then, ancient Rome and all of Europe, becoming widespread after 500 BCE. After the discovery of America, it also found its way to that continent, where it was widely cultivated until the 1930s. After this period, the size of the crop area of this plant decreased quite rapidly. This was due to the widespread cultivation of cotton; the import of cheaper fibres (abaca, jute) from Asia; the intensive development of technology for producing artificial fibres; and the ban introduced on hemp cultivation due to the possibility of producing narcotic substances from it [

4,

28,

29].

Currently, due to the return to the trend of manufacturing industrial products using natural raw materials, there is increased interest in the cultivation of fibre plants, including industrial hemp (IH) (Pal and Lucia 2019) [

30]. Raw materials obtained from IH can be used for the production of: textiles, haberdashery, and footware [

4,

31,

32,

33,

34]; building materials [

33,

35,

36,

37]; composites (e.g., car parts) [

33,

35,

38,

39]; energy, heat, and fuel [

40]; food (oil, flakes, margarine); cosmetics and pharmaceuticals [

33,

41,

42,

43,

44,

45]; paints and varnishes [

46]; ropes and twines [

4]; as well as papermaking pulp and products [

4,

47,

48]. Also mentioned is the possibility of using IH for removing heavy metals from soils contaminated by industry [

34,

49]. An incentive to increase IH cultivation and processing is also the establishment of subsidies for its cultivation in the EU, as well as research programs financed from European funds and European Union countries’ own resources [

24,

50,

51,

52].

As it turns out, the most profitable for farmers is the cultivation of IH for inflorescences and seeds to obtain essential oil and food products, respectively [

4]. According to Czapluk and Czerniak [

46], in Poland, 82% of farmers’ income from IH cultivation came from dried inflorescences, 13% from seeds, 3% from bast fibres, and 2% from IH straw. The seeds can be sold, used for sowing IH in the next year, or processed into food raw materials like oil, flour, and protein powder, while inflorescences serve as a source of active substances that are then used to make pharmaceuticals, parapharmaceuticals, dietary supplements, and cosmetics [

33,

34,

42,

43,

53]. Burczyk et al. [

43], claim that the amount of inflorescences that can be collected per ha of IH cultivation depends on the sowing density and harvesting period and is usually 1‒4 tons, while the seed yield is about 1‒1.5 tons per ha of cultivation.

The above fact creates an opportunity for the papermaking industry to obtain IH straw for its needs. However, it is possible provided that there is no large interest in this FRM from the part of such industries as textiles, the construction (production of building materials), agriculture (bedding for animals) or energy (e.g. production of pellets).

3. Cultivation Aspect

3.1. Definition of IH

Knowledge of the basic issues regarding the legality of IH cultivation is of great importance for assessing the possibility of its use in the pulp and paper industry. As to the IH, the facts are as follows. IH is a one-year plant belonging to the genus Cannabis sativa L. in which the sum of the content of Δ-9-tetrahydrocannabinols acid (THC) in the dried upper fragments of stalks containing female inflorescences does not exceed 0.2-0.3% of their dry matter harvested in the green state during the flowering period (cultivation of IH with THC content higher than the range given in inflorescences is forbidden in many countries [

53,

55]. In the years 2004–2011 Zachwieja [

56] examined annually the THC content in Polish varieties of IH which never exceeded 0.2%, and in most cases was below 0.1%. However, the problem is that the stalks, leaves, and inflorescences in the initial stage of development do not differ substantially from narcotic hemp. Only in the final stage of development are there differences in the height of growth and in the structure of inflorescences between IH and narcotic hemp (narcotic hemp is shorter and has more branched inflorescences). However, the exact identification of the type of industrial hemp can be done on the basis of the results of THC determination in the plant inflorescences [

57,

58]. Nevertheless, the decision of the United Nations’ Commission for Narcotic Drugs to remove cannabis from the category of dangerous drugs in 2020 [

53] can be considered an important event from the point of view of reducing the reluctance of the pulp and paper industry to use IH straw as a raw material for the production of papermaking pulps and then paper and cardboard.

3.2. The size of the IH Crop Area

In order for IH to be considered a FRM that could play a role in large-scale EKPM, it should account for at least 1% of the FRM used to produce kraft pulp in a standard kraft pulp mill. As we know, such pulp mills are designed most often to produce about 1,000 tons of oven-dried (o.d.) pulp per day, which, with a 50% pulp yield from wood, requires the supply of 2,000 tons of o.d. wood per day. The annual demand for IH straw in this case would therefore be 320 × 20 tons of o.d. IH straw, which gives a demand of 6,400 tons of o.d. IH straw annually. This would require sowing 6,400/8 = 800 ha (assuming the possibility of obtaining only 8 tons of o.d. IH stalks without leaves from one hectare of cultivation). Therefore, the area of IH cultivation in a given country is important. The literature on the subject shows that in the period before the Second World War, as well as immediately after it, the size of the cultivation area of IH was considerable. For example, in Poland, in 1964, about 15,000 hectares of arable land were allocated to IH cultivation. However, the size of the area of these crops in the twentieth century was gradually reduced as a result of the widespread use of synthetic fibres in the textile industry, as well as the increase in profitability of growing consumption cereals, and so in the years 2006–2012 it amounted to only 400–1000 ha [

59], in 2018–2020 increased to about 3000 ha [

60], to decrease again in 2022 to 1700 ha because of the increase in the prices of agricultural products, such as rapeseed, wheat, and corn [

61].

As for the world, at least 70 countries cultivate IH for commercial or research purposes. The largest producers of IH are currently Canada, China, the USA, France, and Chile [

34]. The IH acreage in North America and the European Union countries in the last period amounted to about 30 000 − 46 000 ha and about 36 000 − 55 000 ha, respectively, depending on reference, while the worldwide figure was at the level of approximately 200 000 − 220 000 ha [

62,

63]. In the EU, IH cultivation was centered in France (several thousand hectares), Germany, Lithuania, Estonia, the Netherlands, Romania, Italy. and Austria (all countries a number of thousand hectares) [

62].

In recent years, due to the growing fashion for products made of raw materials of natural origin, and following this trend, the legalization of IH cultivation with low THC content, in many countries around the world, many farmers have started growing IH or increased their acreage. However, there are signs that the large supply of IH and the increase in profitability of cultivating cereals have lowers the price of IH and the acreage of this crop has began to decrease in some regions of the world. Other factors may also contribute to this phenomenon. These are: more expensive and less soft and smooth textiles from IH bast fibres in comparison with textiles from cotton and synthetic fibres, low content of CBD (cannabidiol) in IH, higher prices of IH products (e.g., oil).

This suggests that for now IH should yet be treated as a special plant that cannot compete with consumption cereals and that its market still needs several years to mature and stabilize [

64].

3.3. IH Cultivars

In many countries in the world where the cultivation of IH has a long tradition, different varieties of this plant have been grown. These are, for example, the Hungarian varieties Uniko, Kompolti, and Fabriko; French ones: Fibrimon, Férimon, Fédor, Félin, Futura; Romanian ones: Secuieni, Irene, Lovrin, Fibramulta; Finnish ones: Finola and Anka; Russian ones: Kuban, Zenica, Dneprovskaya Odnodomnaya, Zolotonoshskaya, Yuso; Italian ones: Carmagnola, Fibranova, Eletta Campana; Yugoslavian ones: Novosadska konoplja, Spanish ones: Delta-405 and Delta-Llosa; Czech ones: Rastslaviska; and German one: Fasamo [

26,

65].

In Poland, according to the national register of varieties of agricultural plants kept in the Research Center for Cultivar Testing (COBORU) in Słupia Wielka, in 2014, varieties registered included: Beniko, Białobrzeska, Rajan, Tygra, Wojko, and Wielkopolskie [

66].

However, these varieties of IH should be considered as varieties whose main purpose of cultivation is to obtain the largest possible amount of bast fibers for the needs of the textile industry, the largest possible amount of biomass of IH stalks, and the best quality of bast fibers from the point of view of their suitability for the production of clothing.

It is worth noting that recently a need has also been identified for IH varieties capable of yielding more IH seed oil and inflorescenses than the previously known cultivars. These include, for example, the oily variety Henola, which enables you to obtain more seeds than the fibrous IH cultivar Białobrzeskie, and a variety obtained in Italy by start-up Aeroponica Perrotta of unknown name, allowing you to get significantly more CBD than regular IH varieties from inflorescences and roots. Unfortunately, a common, unfavorable feature of these varieties from the point of view of papermaking is a shorter stem and the related lower yield of biomass per hectare of cultivation [

54,

66].

As regards varieties of IH specially bred for the needs of the pulp and paper industry, the number of reports is limited. This is because only Burczyk [

68] reported that the Institute of Natural Fibres and Medicinal Plants in Poznan recently developed a variety of IH with a high yield of biomass per hectare of crops and a 12.5% higher cellulose content compared to the average content of this component in the straw of Białobrzeskie varieties.

3.4. Yields of IH Stalks per ha of Cultivation

The anatomical parts of IH that can be used in papermaking are stalks, woody-core, and bast fibres The amount of dry IH stalks that can be obtained per hectare of cultivation increases with the amount of their dry biomass (i.e., stalks plus leaves). As for the total amount of dry IH biomass from one ha of cultivation, it has been determined by many authors [

24,

25,

27,

52,

69,

70,

71,

72,

73,

74,

75,

76,

77,

78,

79] The yield of dry IH stalks, however, is reported by only a few of them, namely: Struik et al., Bawyer, Pahkala et al., Cosentino et al., and Angelini et al. [

24,

27,

52,

76,

77]. The research by these authors shows that the amount of dry IH stalks, that can be obtained per hectare of cultivation varies from 5 to as much as approx. 22 t per year, depending on the variety of IH; the region in which the crop was located; the fertilization intensity; soil type; and amount of rainfall. For comparison, the annual increase in the volume of spruce trees, European larch, Douglas fir, birch, and various species of genetically modified poplars per 1 hectare of economic plantations in Poland, amounted to approx. 4‒5.2 t; 3.2‒5.5 t; 5.4 t; 2.9 t; and 5.7‒12.3 t of dry wood [

13], respectively. In turn, the amount of dry wheat straw together with leaves and spikes that can be obtained per ha of cultivation in Polish conditions is 2‒7 tons [

75,

80].

In this respect, IH can be competitive in relation to spruce, larch, Douglas fir, birch, and straw of consumption cereals, and genetically modified poplars if the dry biomass yield per hectare is higher than 7 tons and 6‒12 tons per year, respectively.

4. Technological Aspect

4.1. Material and Bulk Densities

One of the significant disadvantages of NFRMs is their lower material and bulk density than wood, which reduces the amount of PFRM that can be transported at one time on a car or rail platform to kraft pulp mills and the amount of PFRM that can be loaded to digester. A comparison of these types of densities of cut IH stalks with the densities of pine, birch and wheat straw was presented in the literature on the subject [

81]. It turned out that the material density of IH stalks was significantly higher than that of wheat straw and slightly lower than that of pine. On the other hand, the bulk densities of IH stalks with and without load (500 g) are similar to those of pine chips, whereas the values of these indices of wheat straw are significantly lower than those of pine chips.

4.2. The Content of Chemical Components in Anatomical Parts of IH Stalks

The content of chemical components in the case of IH should be considered in relation to the different anatomical parts, namely: stalks, bast, technical fibres, and woody-core. Data enabling the comparison of the content of individual chemical components in these parts of IH stalks are presented in

Table 1.

Comparisons of the chemical composition of IH stalks of the Polish variety Białobrzeskie without inflorescences and leaves, the woody-core of this variety separated from stalks, not subjected to the retting process, and technical bast fibres, as well as birch and pine determined with the same analytical methods, are also shown in

Table 2 [

91].

A comparison of the data in

Table 1 and

Table 2 shows that the individual anatomical parts of IH have different contents of chemical components. IH bast has the highest content of cellulose, followed by IH stalks and IH woody-core, while the highest lignin content is in IH woody-core, less in IH stalks, and the least in IH bast. In terms of cellulose content and lignin, IH stalks are a better material for the pulp and paper industry than pine and birch wood.

Table 2 shows that in the selected (without inflorescences and leaves) IH FRMs, the content of mineral substances is 1.2‒1.5% of their dry matter. However, it may well be higher in the unselected ones. A similar tendency may occur in the case of extractives.

4.3. Fibres of IH Stalks

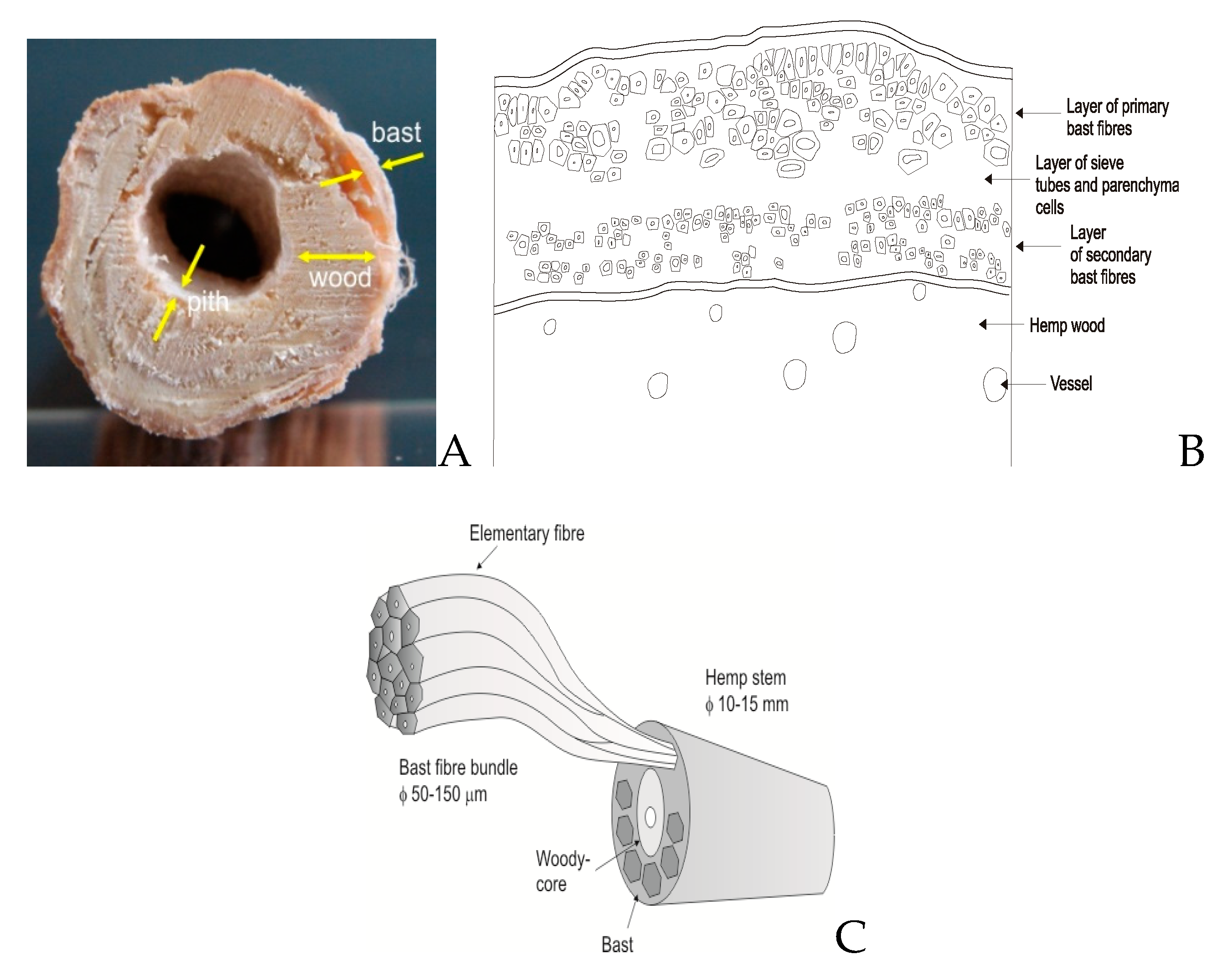

In addition to the biomass yield per hectare of cultivation and the content of individual chemical components, the kind and dimensions of the cells found in IH are of considerable importance to the papermaking industry. The basic elements of the anatomical structure of the IH stalks are: bark, woody-core and pith, the latter lining or filling the hollow core canal of the stalk (

Figure 1).

The bark, whose share in the IH stalks is from 30 to 35% by weight [

69] is made of peel and bast. The bast consists of the surrounding layers (pericycle) and the proper phloem. Bundles of primary (technical) bast fibres are surrounded by parenchyma cells, while the bundles of secondary fibres, located closer to the core of the stalk (

Figure 1B), are surrounded by the parenchymatous-conductive tissue (parenchyma cells and sieve tubes) [

94,

95]. Fišerova et al. [

87] state that the primary bast fibres account for 70% of all bast fibres, are much longer, and have a lower lignin content compared to secondary fibres.

The bast fibres, unlike wood, are multi-cell formations built of a large number of elementary fibres (

Figure 1C) (Szałkowski 1967; Westenbroek et al. 1999) [

93,

94]. The binding substance of these fibres is a natural resin (vegetable gum), the main components of which are pectins, as well as lignin, hemicelluloses, and polyuronides [

31,

94,

96,

97]. Data on the morphological properties of IH technical fibres was presented by Cierpucha et al. [

31]. According to these authors, the length of these fibres ranges from 80 to 300 cm (usually 120 cm), while the length of IH elementary fibres ranges from 5 to 55 mm (usually 15‒25 mm). As mentioned above, in addition to the appropriate primary fibres, the bark of the IH stalk also contains a certain amount of fibres that are of little use for textile purposes, called secondary fibres. Unlike the useful IH fibres, they are shorter, wider, more intertwined, and more fragile [

31].

According to Lisson et al. (2001), the length of these fibres is around 2 mm, while their width is around 17 μm, i.e., about 50% less than primary ones.

The "secondary" fibres are formed from the moment of the creation of flower buds to their maturation stage (so later than the "primary" fibres) [

94]. Most of these fibres occur in the lower part of the IH stalks [

57]. Their share in the phloem is 10‒45% [

69].

The IH stalk contains two next layers, i.e., IH woody-core and pith (

Figure 2). From the point of view of its use in papermaking, the IH woody-core layer has a certain importance. In the process of extracting the bast fibres, the woody inner layer, after breakage, is referred to as shives or hurds. IH shives, due to their different colour and content of mould, IH fibres, leaves and, dust, are available on the market under the names "white shives", "grey shives", "fibred shives", and "defibred shives" [

99]. Account should therefore be taken of the possibility of their various usefulness for papermaking. The IH woody-core layer is made of IH wood fibres (libiforms), vessels and parenchyma cells [

94,

95]. The pith of the IH stalks is made of parenchyma cells. In the wide part of the stalks the cells of the core dry up and cover the core channel wall with a thin layer; in the stalks of young plants and the upper parts of mature plants, they can fill the entire interior of the stalk [

94].

Separation of the elementary fibres from the technical fibres is a process used in the textile industry. This is not an easy process due to the presence of substances cement fibres together [

100]. However, degradation of these substances in the processes used in pulp mills, such as the kraft pulping, should not pose major difficulties.

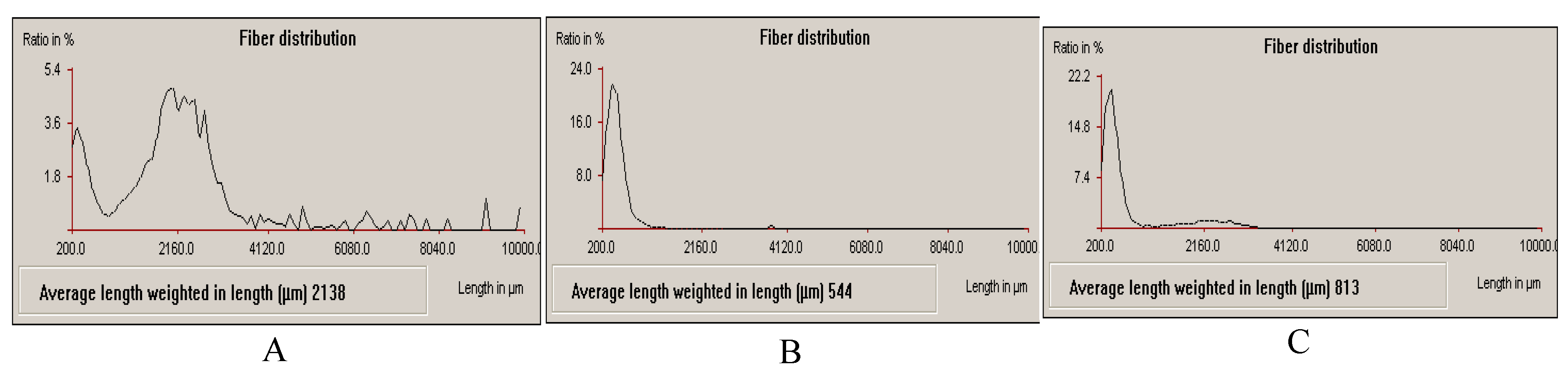

Figure 3 shows the distribution of fibre lengths contained in pulps from IH bast and IH woody-core mechanically separated from each other.

As seen in

Figure 2A, in the range of fibre lengths of 0.2‒10.0 mm, the IH bast pulp contains a fraction of short fibres or other cells with with a maximum fibre length of about 0.3 mm, a fraction of fibres of medium length (0.5‒4.1 mm) of probably secondary bast fibres and a fraction of long bast fibres with a length of 4‒10 mm and more. Due to the measuring range of the MorFi apparatus (0.2‒10 mm) in Figure 4A there is no data regarding the content of the long bast fibres in the IH bast with a length between 10‒55 mm, which are too long for papermaking (given possible problems with the spinning of these fibres, the possibility of their wrapping on the screening devices, and the negative impact of these fibres on the formation of paper). The solution to the problem of the presence of 10‒55 mm IH bast fibres in IH stalks pulp is to cut the IH stalks into appropriate sections before pulping. The effect of cutting these stalks into 3‒6 mm sections on the distribution of the fibre length in the kraft pulp is presented in Figure 4C [

101]. The figure shows that the pulp from IH stalks cut into 3‒6 mm sections does not show the presence of long bast fibres longer than 4 mm, and that the average fibre length of the pulp is approx. 0.8 mm. It contains two fractions of fibres with an average length of approx. 0.5 mm (fibres of IH woody-core) and approx. 2.2 mm (different bast fibres). Similar values of the length of IH woody-core fibres have been reported by Correia et al., de Jong et al.) and Lisson et al. [

82,

85,

98].

4.4. Pulping Methods and Their Effects (Yield of Pulp and Pulp Properties)

From a review of the literature concerning papermaking, it appears that IH FRMs (stalks, phloem, and wood) can be processed so far into fibrous papermaking pulps using many pulping methods, such as: soda [

69,

82,

102,

103,

104,

105,

106]; soda anthraquinone (Soda-AQ) [

87,

107]; soda-oxygen [

83,

105]; soda- or potassium-peroxide [

105,

108]; kraft [

83,

90,

91,

105,

107]; kraft with the addition of anthraquinone (Kraft-AQ) [

105]; kraft-NaBH4 [

89]; organosolv [

84,

110,

111]; neutral-sulfite [

109,

112]; alkaline-sulfite [

105]; thermomechanical and cold-soda (CS) [

98]; alkaline-peroxide (APXP) [

85]; chemithermomechanical [

86,

113]; and sulfite [

83,

105,

108].

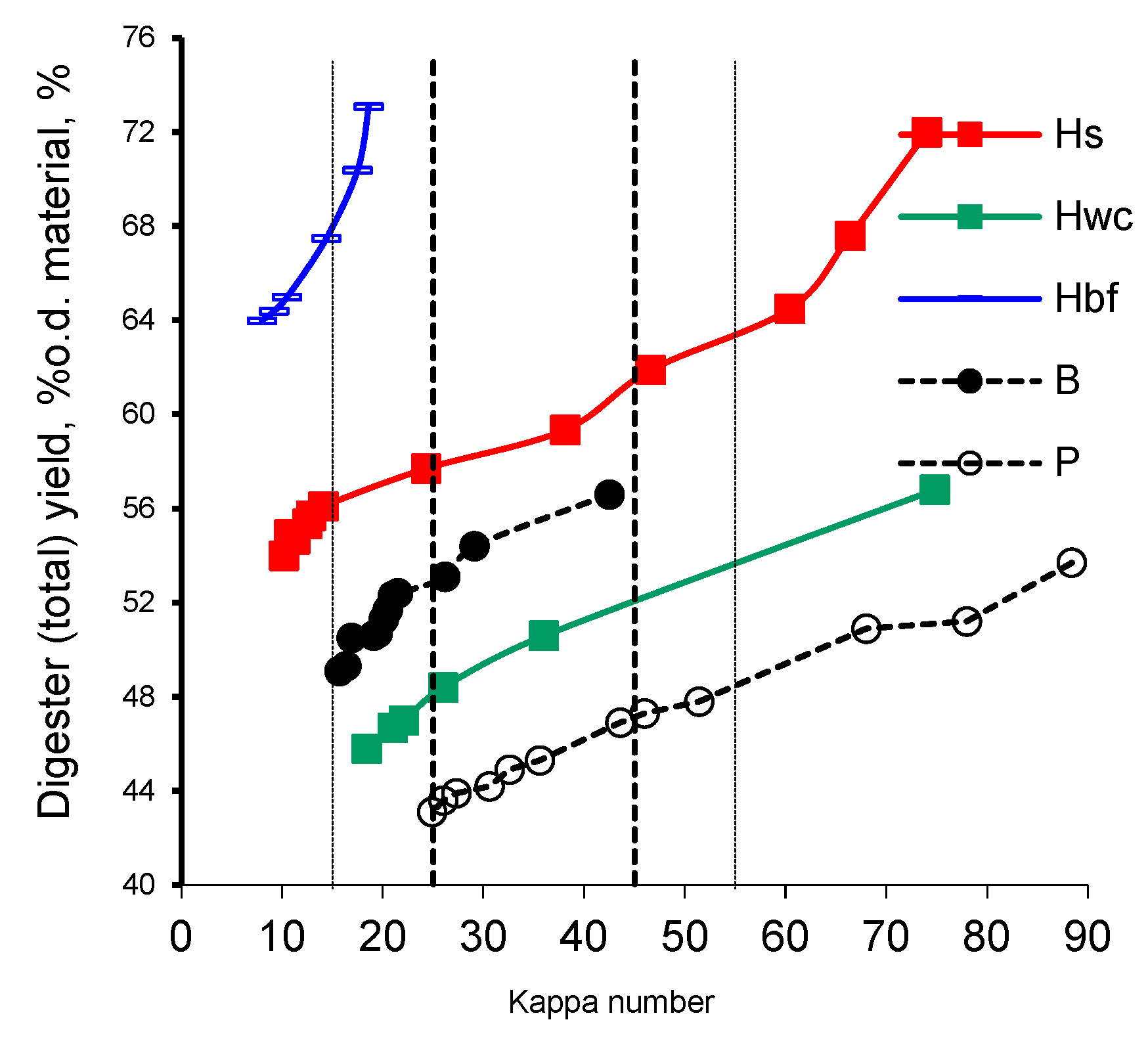

As for the pulps containing low content of residual lignin, research shows that the digesters’ (total) yield of kraft pulps intended for bleaching (easily-bleachable grade, kappa number ~20) and for, e.g., production of sack paper (hard grade, kappa number ~50) from IH stalks is in the range of 56‒70%, while from the IH woody-core it is clearly lower (40‒52%) [

82,

84,

87,

91,

103,

105,

106]. On the other hand, the yield of pulps made of IH bast fibres reported to be higher, in the range of 60‒85% [

84,

91,

105,

108].

The issue of the yield of unbleached kraft pulps from IH FRM (stalks, woody-core and bast fibres) is well illustrated in

Figure 3.

These data indicate that by subjecting IH stalks, woody-core and bast fibers from the Białobrzeskie variety to kraft pulping, it is possible to obtain bleachable grade and sack grade kraft pulps from these FRMs with yields 46–54%, 56–64% and 64–74%, respectively, in their KN range of 20–60 units. The yields of ECF (Elemental Chlorine-Free) bleached kraft pulps from IH stalks, woody-core and bast fibres were also determined. The first one turned out to be higher than the yield of bleached birch kraft pulp by 5%, the second one was higher than the yield of bleached pine kraft pulp by 3%, and the third one (pulp obtained from IH bast fibres through its oxygen delignification and ECF bleaching) was higher than the mentioned birch and pine kraft pulps by 37 and 43%, respectively [

114,

115].

As for the strength properties of IH pulps, studies showed the possibility of achieving a medium or very good (60‒100 N⋅m/g) level of tensile strength of handsheets made from IH stalks pulp [

84,

87,

89,

105,

106,

116], very good (70‒90 N⋅m/g) tensile strength level of IH woody-core pulp [

103,

116], and low or medium (30‒65 N⋅m/g) tensile strength level of IH bast fibers or IH bast pulps [

84,

115,

116].

Also interesting is the resistance to tearing of handsheets of pulps from individual anatomical parts of IH stalks. The values of this characteristic of IH bast fibres pulp or IH bast pulp are high (11‒30 mN⋅m2/g) [

84,

116], while for handsheets made from IH woody-core pulp they are very low (2‒6 mN⋅m2/g) [

84,

103,

116]. This characteristic of IH pulps from IH stalks has intermediate values, but for moderate beating they may also be high (9‒21 mN⋅m2/g) [

87,

116].

Other noteworthy features of IH kraft pulps that are important for the quality of paper are: the high bulk from IH bast fibres or IH bast pulps; the good bulk of IH stalks pulp (comparable to the bulk of pine kraft pulp i.e., higher than birch kraft pulp); the good opacity of IH woody-core pulp and IH stalks pulp; the rapid increase in tensile strength of IH woody-core pulp; the semolina-like consistency of the suspension of this pulp; a high content of α-cellulose in the ECF bleached pulp from IH bast fibres; and the possibility of a negative influence of the presence of IH bast fibres in fibre composition of paper on its formation [

116].

As it turned out, the properties of IH pulps can be explained well using the values of the length of the bast and woody-core fibres; the number of fibres in these pulps; and the fibres’ flexibility/conformability index (F/CI) calculated by dividing the fibre width by their cell wall thickness (

Table 3).

5. Application Aspect

5.1. Compatibility of Devices Used in EKPM with IH FRMs and IH Pulps

A relatively small number of examples of making pulp and paper from IH on an industrial scale in Europe are available in the literature on the subject. These are the use of IH bast fibers for the production of special papers (e.g., cigarette paper) [

47,

117] and IH stalks for the production of bleached pulp, probably used for the production of similar types of products in UK, USA, Germany, France, and Spain (Kane 2000, Gibson 2007) [

48,

118]. There is no data available on the specific features of the equipment used in pulp and paper mills for processing IH FRMs into pulp and producing paper using IH pulps. Although the functioning of papermaking plants producing niche hemp papermaking products proves that it is possible in industrial conditions to process much longer or much shorter IH fibers in pulp and paper devices, it should be expected that in large-scale EKPM prepared for the processing of wood fibres, problems may occur when IH long fibres will appear in the production system, such as, e. g.:

- clogging of the extraction sieves of the digesters by IH bast fibres,

- spinning of these fibres on rotating elements of pumps, defibrators, mixers, etc.

- clogging of the sieve openings of screen sorters and washing devices by them,

- hindering the circulation of the pulping liquor in the chip column of the digester.

Certainly, one of the possibilities for solving this problem is the production of pulp and paper from mixtures of wood and properly cut IH stalks with a relatively small share of these stalks in the mixture of FRM, which causes too long and too short IH fibers to be dispersed in the suspension of wood fibers [

119,

120].

A more rational solution in this respect, however, seems to be grow a variety of IH with a significantly lower length of fibers in the bast (e.g., as in kenaf) and somewhat (e.g., by 0,15–0,3) higher in the IH woody-core (e.g., such as in eucalyptus wood).

5.2. Comparison of Ease of Processing of IH FRMs into Kraft Pulps

The lignin content in IH stalks suggests a higher ease of processing them into kraft pulp than many kinds of pulpwood because it is lower (by approx. 2%) in former FRM. Research results confirm this statement, because IH stalks can be pulped into 25 kappa kraft pulp with approx. 15% active alkalis dosed on o.d. FRM, while birch wood requires approx. 18% of these alkalis on o.d. wood [

91].

Considering the ease of processing IH woody-core into kraft pulp based on the lignin content in it (approx. 26%), it can be assessed as intermediate between hardwood and softwood, with a shift towards hardwood due to the possible better susceptibility of IH lignin for delignification, due to its non-woody nature (non-wood FRM as a rule can be pulped easier than wood) [

91].

IH bast fibers, due to their lowest lignin content, are the IH FRM with the greatest ease of processing into papermaking pulps with low lignin content because only oxygen delignification and bleaching can be used for their processing into such pulps [

91].

When considering the ease of processing IH stalks and bast fibers into kraft pulps in EKPM, one should also take into account the need to cut these FRMs more finely in order to shorten the length of the bast fibers, as opposed to the usual cutting into 2-3 cm sections of cereal straw, Miscanthus giant, Virgina mallow or kenaf, which may make processing IH more difficult than processing the listed alternatives to IH FRM.

5.3. The Effect of Replacing Part of the Wood with Hemp Raw Materials on the Yield of Kraft Pulp and Paper Properties

In terms of yield, IH kraft pulps from IH stalks can be included in the group of FRM, which gives unbleached kraft pulp with a total yield similar to that of European aspen (Populus tremula) unbleached kraft pulp, and therefore one of the highest among kraft pulps from wood (approx. 57% at KN of pulp 20) [

81]. Such pulp yield from IH stalks is a significantly advantageous feature in comparison with pulps from classic types of wood from which kraft paper pulps are made, i.e., birch and pine (yields at the KN 25 are 53 and 44%, respectively) (

Figure 3). It is due to the presence of IH bast fibers with a high cellulose content in IH stalks and a lower lignin content in them. Replacing part of the wood with IH stalks should therefore positively affect the yield of pulp from the mixture of FRMs.

Data analysis of the subject literature indicates that IH stalks pulp can have the best papermaking properties among IH pulps [

114], because they are at the level of the properties of pulps from some traditional pulpwood used in EKPM [

121,

122]. For example, the bleached IH stalks kraft pulp obtained from IH stalks cut into 3-6 mm fragments is characterized by a tensile index similar to bleached pine kraft pulp, a somewhat higher tear resistance and bulk than bleached kraft pulp from wood, and a light scattering ability and opacity that is comparable with bleached birch kraft pulp after beating. These properties of IH stalks kraft pulp result from the dimensional characteristics of its fibers and its chemical composition. For example, the high ability of the fibers of this pulp to bond with each other (high tensile strength index) can be explained by the presence of thin-walled fibres of woody-core in it, while its high resistance to tearing can be explained by the presence of long and stiff IH bast fibers (

Table 4). Comparing the average fibre length of IH stalks pulp from IH stalks cut into 3-6 mm fragments, one can state that it is higher than or comparable to the average fibre length of kraft pulps from certain acacia and eucalyptus varieties [

123,

124,

125] and comparable to or somewhat lower than the average fibre length of birch kraft pulp [

124,

125].

It is worth noting that the resistance to tearing of the pulp from IH stalks can be programmed to a certain extent at the stage of initial cutting of these stalks by using their shorter or longer sections for pulping. This may make it possible to obtain pulp whose tear resistance exceeds the value of this feature of pine pulp, which in turn creates the possibility of using it to improve this feature of pulps with low value, e.g. waste paper pulps, i.e., as a “healing” pulp. However, it seems that this kind of work has not yet been done.

The values of IH stalks kraft pulp properties, in the case when this pulp is obtained from IH stalks cut into 3-6 mm, and the average fiber length of such pulp do not indicate that it could cause application difficulties in the production of paper and its further processing, but such difficulties can cause long IH bast fibers contained in such pulp. These difficulties may apply to the formation of paper. The observations made by the author of this publication suggest that the presence of such fibers in the pulp may impair this property of the paper. It seems that this effect of IH bast fibers could be limited by proper cutting of IH stalks. However, this can be difficult due to the tendency for the IH bast to separate from the woody-core of IH stalks under mechanical forces, such as those applied to them when they are fed into the cutter. The other possibilities to reduce the adverse effect of IH bast fibers on paper formation are: maintaining a small proportion of IH stalks pulp in the paper, and artificial reduction of the length of elementary fibers in IH bast e.g. to the level of fiber length in kenaf bast, which involves the need to breed a new variety of hemp.

The yield of kraft pulps from IH woody-core can be described as having an intermediate value (i.e., approx. 47.5%) at kappa number 25 between that of birch pulp (53%) and pine pulp (44%) (

Figure 3). Replacing a part of birch or pine wood with IH woody-core should therefore lead to a decrease in the kraft pulp yield from a mixture with the first of the listed wood species and an increase in the case of a mixture with the second of them. Replacing part of the birch or pine wood with IH woody-core is therefore less favorable in terms of pulp yield from the FRMs mixes than replacing part of the wood with IH stalks [

119].

In the IH woody-core kraft pulp evaluation from the application point of view, its ability to dewater on the paper machine screen and the influence of the short length and thin cell wall fibres on the properties of paper should be considered. The determinations of properties of IH woody-core pulp indicate that it should dewater on the paper machine wire worse than pulps made of birch and pine (Shopper-Riegler freeness in unbeaten state – 28 ºSR vs. 13, and 14 ºSR, respectively) and should give the paper high: breaking strength, light scattering ability (opacity), and density of handsheets, but low: specific volume (bulk) and tear resistance [

116]. This results is due to: the very high content of fibers in 1 gram of pulp (32 mln), the short fiber length (0,5 mm), and thin cell wall of fibres (

Table 4) [

114]. This type of pulp is suitable for the production of thin papers that require high opacity and tensile strength (e.g., bible paper, paper for cash registers). However, other types of paper, e.g. printing and packaging ones, may require a larger bulk to obtain greater stiffness and greater fiber length and cell wall thickness to obtain greater tear resistance, which IH woody-core pulp cannot provide. This type of pulp is therefore less versatile than IH stalks pulp.

When evaluating the yield of pulp from IH bast fibers it can be stated that when the proper production method of cellulose pulp from these fibres is used, it significantly exceeds the yield of kraft pulps from wood. With the processing of these fibers consisting only of oxygen delignification and ECF bleaching, a fully bleached pulp can be obtained from these fibers with a yield of as much as 85% [

115].

As for the properties of IH bast fibre pulp one can state that it is characterized by high tear resistance and high bulk, but a low breaking length and low ability to scatter light, which result from the low number of fibers in 1 g of this pulp, the low content of hemicelluloses (dominance of rigid cellulose-cellulose connections in the structure of the handsheet) and the relatively thick cell walls of these fibers. As in the case of pulp from cut IH stalks, in the case of IH bast fibres pulp, there is also a problem with the uneven paper formation of handsheets produced from this pulp. Probably the main reason for this is the large differences in the length of the fibers in it [

114,

116].

The high bulk and tear strength of bleached IH bast fibres pulp, as well as the high α-cellulose and low hemicellulose content of this pulp, make it a potential fibrous material for the production of high-bulk specialty papers (e.g., filtracyjnych); improvement of the bulk and tear index of pulps characterized by low values of these properties (e.g., waste paper pulps); and chemical processing (as dissolving pulp).

Taking above mentioned data into consideration, it seems that the best way to introduce IH into EKPM is to replace part of the wood with IH stalks mainly because pulp from these stalks enables obtaining the most balanced paper properties and properties similar to those of kraft pulps, especially pine, additionally allowing to increase the pulp yield from a mixture of wood and IH stalks by 2-3% at the 20% share of IH stalks in the mixture [

119].

5.4. Competition from Other Non-Wood FRMs

5.4.1. Cereal Straw

One of the most obvious alternatives to wood for the production of papermaking pulps in Europe is straw from cereals mainly wheat, rye, and triticale. In terms of availability, it is much better than IH. For example, it is reported that cultivation of consumption cereals in Poland in the last 20 years enabled the country to obtain from 23 to 35 million tons of straw of cereals (including corn and rape) per year, a significant part of which was used in agriculture for bedding, fodder, and soil fertilization, resulting in a surplus of 25–32% of this amount [

80,

126,

127]. However, straw is also considered an alternative FRM for generating thermal energy in the form of bales, briquettes and pellets. Nevertheless, the use of even several thousand tons of such straw for papermaking purposes could significantly reduce the interest in using industrial IH stalks for this purpose. Cereal straw can also be considered as a more competitive FRM than IH in terms of pulp properties, due to the lack of long IH fibers, which, as mentioned earlier, can cause spinning problems and deteriorate paper formation if IH pulp constitutes a significant part of fiber composition of the paper and these fibres will not cut properly. So far, however, the use of cereal straw for papermaking purposes in EKPM has been very small. This is mainly due to the difficulties encountered in the case of joint processing of wood and cereal straw resulting from: its faster pulping than wood; the content of a large number of fine cells in it with a large specific surface; and the content of a much larger amount of mineral substances in it that pass into the post-pulping liquor and cause difficulties on the stage of its processing in the alkali recovery department, e.g. of kraft pulp mills. In this regard, IH stalks fare better, because they contain fewer high-surface area cells and mineral substances than straw.

In terms of minimizing problems with: the spinning of IH bast fibers at the stage of processing IH stalks into unbleached and bleached kraft pulps; the formation of paper obtained from IH stalks pulp, and the too low tear resistance of IH woody-core pulp, the competitiveness of these stalks and IH woody-core in relation to cereal straw would certainly be improved by a significant reduction in the length of IH bast fibers in the IH stalks and its increase in the case of IH woody-core. However, this requires the breeding of a new type of IH, which one might call a papermaking variety.

5.4.2. Miscanthus Giganteus

Miscanthus giganteus can be considered one of the competitors to IH when used for papermaking purposes. As it turned out, although it is a plant originating from Asia, it can be cultivated with good results in Europe. Its advantages over IH are: approximately similar high stalks yield per hectare of cultivation as IH; no need for annual sowing (gaining biomass is possible for 15-20 years after establishing the plantation); and the lack of long bast fibers and related runnability processing problems in EKPM and the ones related to paper properties [

128,

129]. As far as Poland is concerned, the problem in the case of Miscanthus, from a papermaking point of view is like it is in the case of IH, i.e. the small area of cultivation of this plant (in 2011, about 4,000 ha, Cichorz et al. 2014 [

130]). The other problems are that: the main purpose of this crop’s cultivation is to use it to obtain thermal energy (e.g., pellet production) due to less problems with grinding Miscanthus straw than IH stalks [

131], and a high content of leaves in the former straw (approx. 26–36%) less useful for the production of paper pulp than stalks [

132]. Overall, however, the plant appears to be more competitive compared to industrial IH for paper purposes due to the lack of long bast fibers and higher fiber length in the woody part of the stem than in the case of IH.

5.4.3. Virginia Mallow (Sida Hermaphrodita)

Virginia mallow, similarly to Miscanthus gigantheus, is a perennial plant (use period of 15-20 years), resistant to frosts and droughts, with low fertilization requirements, and with a somewhat lower ash content than cereal straw (2.3–2.7%). Significant features of the V. mallow from the point of view of papermaking are: the height of the stems, sometimes even up to approx. 4 m (in Poland, 2.2–2.9 m), and its considerable width, from 5 to even 33 mm (in Poland 12.1-12.9 mm). In the climatic conditions of Poland, yields of V. mallow per hectare of cultivation amounted to approx. 9-22 tons (in Poland 7–15 tonnes) of stalks and leaves at their humidity of 23–30% and unknown content of leaves in biomass [

133,

134]. Preliminary studies of the length distribution of V. mellow fibers in the kraft pulp carried out in Poland showed that the average length of wood pulp fibres of this plant is low and about the same as in IH woody-core pulp (i.e., approximately 0.5 mm), while the average length of bast pulp fibers of this plant is approx. 2 mm in the range of fibre lengths from 0.5 to 6 mm, and the share of phloem in the lower part of the stem is approx. 14%.

5.4.4. Kenaf (Hibiscus Cannabinus)

Kenaf is a plant that grows in countries with a warm climate and high rainfall. During 6–8 months of growth, the kenaf reaches a height of 0.90 to 6.0 m and a diameter of 2.5 to 5.0 cm. With dense planting, the kenaf stems do not produce large branching. The annual harvest of kenaf straw is large, even up to 30 t/ha. In research conducted by Grabowska et al. [

73], kenaf plantations established in Poland (and therefore in the temperate climate zone) gave a similar amount of biomass (stalks and leaves) per hectare of cultivation as IH of the Białobrzeskie variety, i.e., about 14 tons. Kenaf, however, turned out to be much more susceptible to adverse weather conditions than IH, which was manifested by the inhibition of growth of this plant during periods of low temperatures and lack of rainfall. However, research on the possibility of growing kenaf in the temperate climate zone is worth continuing, because this plant has an advantage over IH due to the fact that bast fibers of this plant pulp down into single elementary fibers, which are characterized by a range of fiber lengths (0.2–6 mm) much closer to the range of hardwood and coniferous wood fibers [

135,

136] than IH fibers (2–55 mm). As a result, better processability of kenaf in devices designed for wood processing in EKPM and semi-chemical and mechanical pulp mills can be expected than in industrial IH stalks and better paper formation.

5.5. Price Factor

Table 2 contains the prices of IH FRMs, pulpwood and other non-wood FRMs expressed in EUR.

Table 2.

Prices (in EUR) of IH FRM, pulpwood and other non-wood FRMs (without transport costs).

Table 2.

Prices (in EUR) of IH FRM, pulpwood and other non-wood FRMs (without transport costs).

| FRM |

Dry hemp stalks without leaves |

Dry hemp hurds (woody-core) |

Dry hemp bast fibres |

Birch and pine pulpwood |

Cereal straw (wheat) |

Misc. gigant. stalks |

V. mellow stalks |

| Source |

Year |

1st, 2nd or 3rd class of purity |

- |

- |

- |

- |

- |

| [137] |

2011 |

122 |

275 |

782 |

- |

|

- |

- |

| Various references |

2013-2023 |

90-1353)

|

79, 213 and 3821); 4638)

|

514-7718)

|

160-1702)

|

417)-514)

|

100-1205) |

1076)

|

The data in

Table 2 shows lower price for IH stalk straw than cleaned IH woody-core and bast fibres. The high prices of the latter two FRM probably result from the high demand for them from the production of hemp-lime-cement concrete and the lot of work needed to separate IH bast fibers from the stalks, with their low share in this stalk. So, in terms of price, IH stalks turned out to be the best FRM for papermaking among the IH FRMs. As can be seen in

Table 2, their price per ton is even lower than the price of wood in Poland. Unfortunately, IH stalks are two times more expensive compared to wheat straw, but their price can be comparable to the price of Miscanthus giant stalks and Virginia mallow stalks.

6. Conclusions

When assessing the practical possibility of using straw from a specific type of non-wood papermaking plant in large-scale EKPM, causal, cultivation, technological, and application aspects should be taken into account.

Analyzing the causal factors for considering IH as a FRM for the pulp and paper industry, it can be concluded that there are currently reasons to increase the scope of use of pulps from NFRMs in them as FRMs extending the raw material base of these mills and enabling: the reduction of tree felling for papermaking purposes or the use of the wood of these trees for other, non-papermaking applications, including in particular those enabling the retention of CO2 stored in wood for a longer time than in the case of paper and cardboard (e.g. furniture, roof truss). An important casual factor in favor of the use of IH for papermaking purposes is also the fact that IH is a plant very well known in Europe and well adapted to the conditions of the northern temperate climate zone. Unfortunately, IH stalks and their anatomical parts (bast fibers, woody-core) can be used for other purposes than papermaking, which may create strong competition for their applications in the production of papermaking pulps.

The analysis of cultivation factors indicates that the disadvantages of IH as a potential FRM for papermaking are: the need to register its cultivation; its still small area resulting from the developmental nature of IH products; the need for its annual sowing; and the lack of varieties with the length of bast fibers and IH woody-core more similar to the length of the wood fibers. On the other hand, the advantages are: no need to use plant protection and anti-weed chemical agents; good resistance of the plant to low rainfall (a deep root system); and a relatively high yield of stalks per hectare of cultivation every year.

From the point of view of papermaking, the following technological factors draw attention: the material and bulk density of IH stalks which are more similar to wood than cereal straw; greater ease of obtaining kraft pulps from IH than in the case of wood; the possibility of obtaining unbleached and bleached pulps from IH FRMs by several methods used for their production from wood; and the unfavorable one: the presence in IH stalks of two types of fibers that differ diametrically in their dimensional properties and ability to bond with each other.

As for the application factors, the analysis showed that IH stalks are the best FRM for large-scale EKPM. These stalks are the cheapest IH FRMs; they can be noticeably easier processed into bleached kraft pulp than hardwood and softwood due to their lower lignin content; with a higher yield of pulp (in the case of bleached kraft pulp by 3% and 11% than from birch and pine wood, respectively); with paper properties more similar to the properties of wood pulps than in the case of woody-core pulps and IH bast fibers.

The analysis of the criterion of competitiveness of other non-wood FRM growing well in Europe in relation to IH showed a higher competitiveness of wheat straw in terms of availability (hundreds of times greater) and price (2–3 larger) over hemp stalks and a higher competitiveness of Miscanthus giganteus stalks and wheat straw in terms of the composition of fibres fraction in them. These FRM, unlike IH, do not contain long bast fractions and much less short fibers (this is especially evident in the case of Miscanthus). In this type of comparison, the fibrous composition of Virginia mellow can be described as intermediate, because the pulp from its stalks does not contain long bast fibers, but contains a similar amount of short fibers as the pulp obtained from IH stalks. For this reason Miscanthus giganteus stalks, wheat straw and Virginia mallow are more competitive than an industrial IH in terms of compatibility with equipment used in EKPM and paper formation uniformity. The situation in this aspect could be changed by having a industrial IH variety with a much shorter length of fibers in IH bast and a slightly longer (e.g., by 0.2–0.3 mm) length of fibers in IH woody-core.

References

- Serrano, O. Forest products—supply and demand. Przegl. Papiern. 1999, 55, 788–794. [Google Scholar]

- McNutt, J.A.; Rennel, J. The future of fibre in tomorrow’s world. PPI 1997, 39, 48–49. [Google Scholar]

- Karus, M. Official founding of the “European Industrial Hemp Association (EIHA)” and the 3rd International Hemp Conference. J. Ind. Hemp 2006, 11, 69–72. [Google Scholar] [CrossRef]

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- FAO. Global Forest Products Facts and Figures. 2015. Available online: http://www.fao.org/3/a-i6669e.pdf.

- Wilson, R.A.; Ward, M.R. Biotechnology holds the key as world demand soars. PPI 1996, 38, 41–43. [Google Scholar]

- Watson, P. The mountain pine beetle epidemic: Changing the face of the BC industry. Pulp Pap-Canada, 2006, 107, 12–16. [Google Scholar]

- Toland, J. Veracel sets new standards. PPI 2006, 48, 22–25. [Google Scholar]

- Häggblom, R. Advanced forest-sector expertise in South America. Paperi Puu 2004, 86, 208–209. [Google Scholar]

- Ryan, R. Europeans head down under. PPI 2008, 48, 35–37. [Google Scholar]

- Toppinen, A.; Toivonen, R.; Tilli, T. Growing the wood industry in the Baltic Sea Area. Paperi Puu 2004, 86, 128–129. [Google Scholar]

- Fornalski, Z. Conditions for the development of the paper industry in Poland. Fibrous Materials. Przegl. Papiern. 2008, 64, 233–242. [Google Scholar]

- Bodył, M. Wood outside the forest. The Voice of Forest 2009, 10, 10–12. (In Polish) [Google Scholar]

- McLaren, J. A glut now, but what about future supplies? PPI 1996, 38, 41–43. [Google Scholar]

- Duda, S. The largest plantation of energy trees in Europe. Przegl. Papiern. 2012, 68, 186–187. (In Polish) [Google Scholar]

- Robinson, B.; Hartwell, P. Deinking pulp grows up to be more sophisticated. PPI 1997, 37, 35–37. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Pulping and bleaching OCC. Part II. Oxygen delignification and bleaching, APPITA J. 2011, 64, 94. [Google Scholar]

- Björkman, M. Why invest in pulp in a digital world? PPI 2014, 56, 14–16. [Google Scholar]

- Bride, J. Australia& NewZealand Pulp & Paper Industry Guide, APPITA, 2012.

- Paavilainen, L. European prospects for using nonwood fibres. PPI 1998, 40, 61–66. [Google Scholar]

- Xiaorong, N.; Oinonen, H. Non-wood is still the main virgin fibre. Paperi Puu 2007, 89, 284–286. [Google Scholar]

- Zhu, A. Straw: The eco-friendly choice. PPI 2008, 50, 25–27. [Google Scholar]

- Atchison, J.E. Twenty-five years of global progress in non-wood plant fibre repulping. TAPPI J. 1996, 79, 87–95. [Google Scholar]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of fibre hemp (Cannabis sativa L.) in Europe. Ind. Crop Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Pahkala, K.; Syrjälä, H.; Pahkala, E. Northern limits to hemp production in Europe. J. Ind. Hemp 2008, 13, 104–116. [Google Scholar] [CrossRef]

- Jankauskiene, Z.; Gruzdeviene, E. Beniko and Bialobrzeskie—industrial hemp varieties in Lithuania. Proc. of the 7th Int. Sci. and Pract. Conf., vol. 1, Rezeknes Augstskola, RA Izdevniciba, 2009.

- Angelini, L.G.; Tavarini, S.; Di Candilo, M. . Performance of new and traditional fiber hemp (Cannabis sativa L.) cultivars for novel applications: Stem, bark, and core yield and chemical composition. J. Nat. Fibers 2016, 13, 238–252. [Google Scholar] [CrossRef]

- Ehresing, D.T. Feasibility of industrial hemp production in the United States Pacific Northwest. Agricultural Experiment Station, Oregon State University, Station Bulletin 681, 1998.

- Anonymous. Industrial hemp in the United States: Status and market potential, USDA Report, Washington, DC, 2000.

- Pal, L.; Lucia, L.A. Renaissance of industrial hemp: A miracle crop for a multitude of products. BioResources 2019, 14, 2460–2464. [Google Scholar]

- Cierpucha, W.; Kozłowski, R.; Mańkowski, J.; Waśko, J.; Mańkowski, T. Applicability of flax and hemp as raw materials for production of cotton-like fibres and blended yarns in Poland. Fibres Text. East. Eur. 2004, 12, 13–18. [Google Scholar]

- Sadelnik, N. Properties of hemp fibre cottonised by biological modification of hemp hackling noils. Fibres Text. East. Eur. 2004, 12, 58–60. [Google Scholar]

- Ahmed, A.T. M. F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Helyion 2022, 8, e08753. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, X.; Guo, Y.; Qiu, C.; Long, S.; Wang, Y.; Qiu, H. Industrial hemp—An old but versatile bast fiber crop. J. Nat. Fibres 2022, 19, 6269–6282. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pach, J.; Burgstaller, C. Chemically treated hemp fibres to reinforce polymers. Polimery 2011, 56, 817–822. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Monte, M.C.; Savastano, H.; Mutje, P.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage, and product properties. Ind. Crops Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef]

- Brzyski, P.; Fic, S. . Characteristics of lime-hemp composite and its use in construction industry. Constr. Architecture 2015, 14, 11–19. (In Polish) [Google Scholar] [CrossRef]

- Madsen, B.; Lilholt, H. Physical and mechanical properties of unidirectional plant fibre composites—an evaluation of the influence of porosity. Composites Sci. Technol. 2003, 63, 1265–1272. [Google Scholar] [CrossRef]

- Pervaiz, M.; Sain, M. , Ghosh, A. Evaluation of the influence of fibre length and concentration on the mechanical performance of hemp fibre reinforced polypropylene composites. J Nat Fibers 2006, 2, 67–84. [Google Scholar] [CrossRef]

- Burczyk, H. , Kowalski, M.; Kowalska, M. Energy suitability of the new variant of "Wielkopolskie" hemp. Agricultural Advisory Issues 2011, 2, 119–122. (In Polish) [Google Scholar]

- Vogl, C.R.; Mölleken, H.; Lisek-Wolf, G.; Surböck, A.; Kobert, J. Hemp (Cannabis sativa L.) as a resource for green cosmetics. J. Nat. Fibres 2004, 9, 51–68. [Google Scholar] [CrossRef]

- Kaniewski, R.; Konczewicz, W. Steam distillation of essential oils from hemp panicles. J. Nat. Fibers 2005, 2, 91–92. [Google Scholar] [CrossRef]

- Burczyk, H.; Kaniewski, R.; Konczewicz, W.; Kryszak, N.; Turowski, J. Hemp is a source of essential oils. The Puławski Diary Notebook 2009, 151/I, 37–47. [Google Scholar]

- Makowiecka, M.; Wielgus, K. Therapeutic Potential of Cannabinoids-perspectives for the future. J. Nat. Fibers 2014, 11, 283–311. [Google Scholar] [CrossRef]

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial hemp (Cannabis sativa) as an emerging source for value-added functional food, ingredients and nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Czapluk, M.; Czerniak, A. Development of the industrial hemp cultivation and processing market in Poland; Insight Politika Press: Warszawa, Poland, 2020. [Google Scholar]

- MacLeod, M. Nonwood fiber: Number 2, and trying harder. TAPPI J. 1988, 71, 50–55. [Google Scholar]

- Kane, M. Problem getting fiber? Hemp is at hand. PPI 2000, 42, 33–35. [Google Scholar]

- Baraniecki, P.; Kozłowski, R. Heavy Metal Polluted Areas as a Source of Alternative Raw Material for Pulp. J. Nat. Fibers 2005, 1, 79–82. [Google Scholar] [CrossRef]

- Ranalli, P. Hemp in Italy. J. Ind. Hemp 2002, 7, 139–141. [Google Scholar] [CrossRef]

- Sladkỳ, V.; Široká, M. Czech hemp and national industry program. J. Ind. Hemp 2007, 12, 81–85. [Google Scholar] [CrossRef]

- Cosentino, S.L.; Rigi, E.; Testa, G.; Scordia, D.; Copani, V. Evaluation of European developed fibre hemp genotypes (Cannabis sativa L.) in semi-arid Mediterranean environment. Ind. Crops Prod. 2013, 50, 312–324. [Google Scholar] [CrossRef]

- Siudem, P.; Wawer, I.; Paradowska, K. Cannabis and cannabinoids. Contemp. Pharm. 2015, 8, 1–8. [Google Scholar]

- Sorrentino, G. Introduction to emerging industrial applications of cannabis (Cannabis sativa L.). Rendiconti Lincei. Fisiche e Naturali 2021, 32, 233–234. [Google Scholar] [CrossRef]

- Grabowska, L.; Burczyk, H.; Baraniecki, P.; Kozak, J.; Strybe, M. Maintenance breeding of Polish hemp cultivar Beniko. J. Nat. Fibers 2008, 5, 208–217. [Google Scholar] [CrossRef]

- Zachwieja, J. The content of tetrahydrocannabinol in Polish cultivars of fibrous hemp in 2004–2011. J. Nat. Fibers 2013, 10, 297–308. [Google Scholar] [CrossRef]

- Grabowska, L.; Heller, K. Cultivation of flax and hemp in ecological farms. Training materials as part of the project: Ecologization of agrotouristic farms in Podlasie province. Białystok-Sulin, 17-19.03.09., 2009.

- Rochalska, M.; Pyrzyna, P. Fibrous hemp – the plant of diversified applications. Plant Breeding and Seed Production 2010, 4, 23–28. (In Polish) [Google Scholar]

- Spychalski, G. Selected factors of fibrous plant production in Poland. J. Nat. Fibers 2014, 11, 225–241. [Google Scholar] [CrossRef]

- FARMER. How much hemp was yielded in 2021? Available online: https://www.farmer.pl/produkcja-roslinna/inne-uprawy/jak-plonowaly-konopie-w-roku-2021,116557.html.

- Kowalski, M. Less and less Polish hemp. Available online: https://kombinatkonopny.pl/coraz-mniej-polskich-konopi. 2022.

- CBS—Cannabis Business Plan. 2020. Global Hemp Market. Available online: https://cannabusinessplans.com/global-hemp-market/.

- EU—European Commission. Agriculture and Rural Development. Hemp. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based- products/hemp_en (accessed on 10 March 2023).

- Wenig, S. Hemp Boom Is Over. What Now? Available online: https://www.pewtrusts.org/en/research-and-analysis/blogs/stateline/2021/07/09/the-hemp-boom-is-over-what-now.

- De Meijer, E. Fibre hemp cultivars: A survey of origin, ancestry, availability and brief agronomic characteristics. Available online: http://www.internationalhempassociation.org/jiha/iha02207.html.

- Wilegusz, K. Cultivation of hemp and oilseeds. Centrum Doradztwa Rolniczego w Brwinowie Press, 2020.

- Burczyk, H.; Oleszak, G. Oilseed hemp (Cannabis sativa L var. oleifera) grown for seeds, oil, and biogas. Probl. Agric. Eng. 2016, 94, 109–116. (In Polish) [Google Scholar]

- Burczyk, H. Production and use of annual plant biomass for the needs of renewable energy. Agricultural Advisory Issues 2010, 4, 71–83. (In Polish) [Google Scholar]

- Van der Werf, H.M.G.; Van der Veen, J.E.; Bouma, A.T.M.; Ten Cate, M. Quality of hemp (Cannabis sativa L.) stems as raw material for paper. Ind. Crops Prod. 1994, 2, 219–227. [Google Scholar] [CrossRef]

- Di Bari, V.; Campi, P.; Colucci, R.; Mastrorilli, M. Potential productivity of fibre hemp in southern Europe. Euphytica 2004, 140, 23–32. [Google Scholar] [CrossRef]

- Burczyk, H.; Kowalski, M.; Plawuszewski, M. Trends and methods in hemp breeding in Poland. J. Nat. Fibers 2005, 2, 25–33. [Google Scholar] [CrossRef]

- Grabowska, L.; Koziara, W. The Effect of Nitrogen Dose, Sowing Density and Time of Harvest on Development and Yields of Hemp Cultivar Bialobrzeskie. J. Nat. Fibers 2006, 2, 1–17. [Google Scholar] [CrossRef]

- Grabowska, L.; Konczewicz, W.; Oleszak, G.; Jakimcio-Turowski, J. Assessment of the economic value of kenaf. Problemy Inżynierii Rolniczej 2009, 1, 137–143. [Google Scholar]

- Burczyk, H.; Grabowska, L.; Strybe, M.; Konczewicz, W. Effect of sowing density and date of harvest on yields of industrial hemp. J. Nat. Fibers 2009, 6, 204–218. [Google Scholar] [CrossRef]

- Burczyk, H. Production of biomass for renewable energy from annual plants. Plant Breeding Seed Prod. 2010, 4, 13. (In Polish) [Google Scholar]

- Bowyer, J.L. Industrial hemp (Cannabis sativa L.) as a papermaking raw material in Minnesota: Technical. Economical and environmental considerations, 2001.

- Prade, T.; Svensson, S.E.; Andersson, A.; Mattsson, J.E. Biomass and energy yield of industrial hemp grown for biogas and solid fuel. Biomass Bioenerg. 2011, 35, 3040–3049. [Google Scholar] [CrossRef]

- Finnan, J.; Styles, D. Hemp: A more sustainable annual energy crop for climate and energy policy. Energ. Policy 2013, 58, 152–162. [Google Scholar] [CrossRef]

- Jankauskienė, Z.; Gruzdevienė, E. Screening of Industrial Hemp (Cannabis sativa L.) cultivars for biomass yielding capacities in Lithuania. J. Nat. Fibers 2015, 12, 368–377. [Google Scholar] [CrossRef]

- Kurzydłowska, I.; Rachoń, L. The technical potential of straw as a raw material energy sector in Lubelskie Voivodship. Autobusy Technika, Eksploatacja, Systemy Transportowe 2012, 13, 81–84. [Google Scholar]

- Danielewicz, D.; Kmiotek, M.; Surma-Ślusarska, B. Comparison of some properties of selected non-wood plants and wood species and unbleached kraft pulps from these materials. J. Nat. Fibres 2021, 18, 1296–1306. [Google Scholar] [CrossRef]

- Correia, F.; Roy, D.N.; Goel, K. Chemistry and delignification kinetics of Canadian industrial hemp. J. Wood Chem. Technol. 2001, 21, 97–111. [Google Scholar] [CrossRef]

- Kovacs, I.; Rab, A.; Rusznak, I.; Annus, S. Hemp (Cannabis sativa) as a possible raw material for the paper industry. Cell. Chem. Technol. 1992, 26, 627–635. [Google Scholar]

- Zomers, F.H.A.; Gosselink, R.J.A.; Van Dam, J.E.G.; Tjeerdsma, B.F. Organosolv pulping and test paper characterization of fiber hemp. TAPPI J. 1995, 78, 149–155. [Google Scholar]

- DeJong, E.; van Roekel, G.J.; Snijder, M.H.B.; Zhang, Y. Towards industrial application of bast fibre pulps. Pulp Pap-Canada 1999, 100, 19–22. [Google Scholar]

- Stupińska, H.; Madaj, R. Production of fiber pulps from non-wood raw materials—annual plants. Proc. of International Scientific-Technical Conference Progress’96, Łódź 1996.

- Fišerova, M.; Gigac, J.; Illa, A. Soda-AQ pulping of hemp stalks and pulp properties. Pap. Celul. 2013, 68, 10–13. [Google Scholar]

- Kopania, E.; Wietecha, J.; Ciechańska, D. Studies on isolation of cellulose fibres from waste plant biomass. Fibres Text. East. Eur. 2012, 20, 167–172. [Google Scholar]

- Tutuş, A.; Karataş, B.; Çiçekler, M. Pulp and paper production from hemp by modified kraft method. In Proceedings of the 1st International Mediterranean Science and Engineering Congress (IMSEC 2016), Adana, Turkey, 26–28 October 2016. [Google Scholar]

- Baptista, C.; Santos, N.; Rosa, M. Portuguese hemp plant as raw material for papermaking. Athens J. Sci. 2020, 7, 15–20. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Processing of industrial hemp into papermaking pulps intended for bleaching. Fibres Text. East. Eur. 2010, 18, 110–114. [Google Scholar]

- Amaducci, S. ; John Wiley and Sons, Ltd.: UK, 2000.processing. In Industrial application of natural fibres; John Wiley and Sons, Ltd.: UK, 2000. [Google Scholar]

- Westenbroek, A.; van Roekel, G.; de Jong, E. Compressibility of hemp bast fibres. Nordic Pulp Pap. Res. J. 1999, 14, 336–344. [Google Scholar] [CrossRef]

- Szałkowski, Z. Basics of chemical technology of raw materials and bast fibers. Light and Food Industry Publisher. Warsaw, Poland, 1967.

- Surewicz, W. Fundamentals of technology of fibrous pulps. WNT, Warszawa 1971.

- Urbańczyk, G.W. Science about fibre. WNT Press, Warsaw, Poland, 1985.

- Thygesen, A.; Daniel, G.; Lilholt, H.; Thomsen, B.A. Hemp fiber microstructure and use of fungal defibration to obtain fibers for composite materials. J. Nat. Fibers 2006, 2, 19–37. [Google Scholar] [CrossRef]

- Lisson, S.N.; Banham, P.W.; Mendham, N.J. Studies of hemp and flex properties as a feedstock for Australian newsprint production. APPITA J. 2001, 54, 449–456. [Google Scholar]

- Garnier, W.; Nieddu, M.; Barbier, M.; Kurerk, B. The dynamics of the French hemp system and its stakeholders. J. Ind. Hemp 2007, 12, 67–87. [Google Scholar] [CrossRef]

- Kozłowski, R.; Mańkowski, J.; Kubacki, A.; Kołodziej, J. Effective decortication system of hemp and flax fibre. Polish Flax 2004, 2, 40–50. (In Polish) [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Characterisation of bleached hemp pulps with the use of computer image analysis method. Fibres Text. East. Eur. 2011, 19, 96–101. [Google Scholar]

- De Groot, B.; Van Dam, J.E.G.; Van T’Riet, K. Alkaline pulping of hemp woody core: Modelling of lignin, xylan and cellulose extraction and degradation. Holzforschung 1995, 49, 332–342. [Google Scholar] [CrossRef]

- De Groot, B.; Van der Kolk, J.C.; Van Dam, J.E.G.; Van T’Riet, K. Papermaking characteristics of alkaline hemp-woody-core pulps. TAPPI J. 1999, 82, 107–112. [Google Scholar]

- Correia, F.; Roy, D.N.; Goel, K. Pulping of Canadian industrial hemp (Cannabis sativa L.). Pulp Pap.- Canada 1998, 99, 39–41. [Google Scholar]

- Dutt, D.; Upadhyaya, J.S.; Malik, R.S.; Tyagi, C.H. Studies on the pulp and papermaking characteristics of some Indian non-woody fibrous raw materials. Cell Chem. Technol. 2005, 39, 115–128. [Google Scholar]

- Dutt, D.; Tyagi, C.H. Studies on Impomena carnea and Cannabis sativa as an alternative pulp blend for softwood: Optimization of soda pulping process. J. Sci. Ind. Res. 2010, 69, 460–467. [Google Scholar] [CrossRef]

- Correia, F.; Roy, D.N.; Chute, W. Hemp chemical pulp: A reinforcing fibre for hardwood kraft pulps. Pulp Pap-Canada 2003, 104, 51–54. [Google Scholar]

- Bączyńska, K.; Madaj, R.; Stupińska, H. Production of pulp from long-fibre annual plants by eco-friendly method. International Conference PROGRESS'93, 27–30.09.1993, Lodz, Poland, 1993.

- Dutt, D.; Upadhyaya, J.S.; Tyagi, C.H. Studies on Hibiscus cannabinus, Hibiscus sabdariffa and Cannabinus sativa pulp to be substitute for softwood pulp-Part. 2: SAS AQ and NSSC-AQ delignification process. BioResources 2010, 5, 2137–2152. [Google Scholar] [CrossRef]

- Tjeerdsmaa, B.F.; Zomers, F.H.A.; Wilkinson, C.E.; Sierra-Alvarez, R. Modelling of organosolv pulping of hemp. Holzforschung 1994, 42, 415–422. [Google Scholar] [CrossRef]

- Barberà, L.; Pèlach, M.A.; Pérez, I.; Puig, J.; Mutjé, P. Upgrading of hemp core for papermaking purposes by means of the organosolv process. Ind. Crop Prod. 2011, 34, 865–872. [Google Scholar] [CrossRef]

- Winczakiewicz, A. Can we use hemp for making cigarette paper? Przegl. Papiern. 1964, 20, 1994–197. (In Polish) [Google Scholar]

- Stupińska, H.; Palenik, J.; Kopania, E.; Malinowski, T.; Wójcik, M.; Czepczyński, A. Bleached fibrous pulp from hemp straw. Proceedings of International Scientific-Technical Conference Progress’05, 05-08.2005. Lodz, Poland, 2005.

- Danielewicz, D. OCC and industrial hemp as fibrous raw materials for production of bleached papermaking pulps. Science Notebooks 2013, 1176. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Oxygen delignification and bleaching of industrial hemp pulps. Fibres Text. East. Eur. 2011, 19, 84–88. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Properties and fibre characterization of bleached hemp, birch and pine pulps: A comparison. Cellulose 2017, 24, 5173–5186. [Google Scholar] [CrossRef]

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, processing and applications for fibres, shivs, seeds and flowers. EIHA. 2016. Available on-line: http://eiha.org/media/2016/05/16-05-17-European-Hemp-Industry-2013.pdf.

- Gibson, K. Hemp paper. J. Ind. Hemp 2007, 12, 115–121. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Bleached kraft pulps from blends of wood and hemp. Part I. Demand of alkali, yields of pulps, their fractional composition and fibre properties. Fibres Text. East. Eur. 2019, 27, 112–117. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Bleached kraft pulps from blends of wood and hemp. Part II. Structural, optical and strength properties. Fibres Text. East.. Eur. 2019, 27, 111–116. [Google Scholar] [CrossRef]

- Fišerova, M. , Gigac, J.; Balberčák, J. Relationship between fibre characteristics and tensile strength of hardwood and softwood kraft pulps. Cell. Chem. Technol. 2010, 44, 249–253. [Google Scholar]

- Fišerova, M.; Gigac, J. Comparison of hardwood kraft pulps fibre characteristics and tensile strength. Cell. Chem. Technol. 2011, 45, 627–631. [Google Scholar]

- Mohlin, U.-B.; Hornatowska, J. Fibre and sheet properties of Acacia and Eucalyptus. APPITA J. 2006, 59, 225–239. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B. Application of computer image analysis method for characterisation of papermaking pulps. Cell. Chem. Technol. 2010, 44, 285–291. [Google Scholar]

- Paavilainen, L. Quality-competitiveness of Asian short-fibre raw materials in different paper grades. Pap. Puu. 2000, 82, 156–161. [Google Scholar]

- Jarosz, Z. Technical potential of straw in Poland and environmental effects of its alternative use. Roczniki Naukowe Stowarzyszenia Ekonomistów Rolnictwa i Agrobiznesu.

- Hryniewicz, M.; Grzybek, A. Surplus straw available for use in 2016. Probl. Agric. Eng. 2017, 3, 15–31. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B.; Żurek, G.; Martyniak, D. Selected grass plants as biomass fuels and raw materials for papermaking. Part I. calorific value and chemical composition. BioResources 2015, 10, 8539–8551. [Google Scholar] [CrossRef]

- Danielewicz, D. ; Surma-Ślusarska. Miscanthus × giganteus stalks as a potential non-wood raw material for the pulp and paper industry. Influence of pulping and beating conditions on the fibre and paper properties. Ind. Crops Prod. 2019, 141, 111744. [Google Scholar] [CrossRef]

- Cichorz, A.; Gośka, M.; Litwiniec, A. Perennial grasses of the genus Miscanthus—potential source of renewable energy. Biuletyn Instytutu Hodowli i Aklimatyzacji Roślin 2014, 247, 133–151. [Google Scholar] [CrossRef]

- Igliński, B.; Chichorz, M.; Skrzatek, M.; Buczkowski, R. Energy potential of biomass on fallow lands and wastelands in Poland. Inżynieria i Ochrona Środowiska 2018, 21, 79–81. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B.; Żurek, G.; Martyniak, D. Selected grass plants as biomass fuels and raw materials for papermaking. Part II. BioResources 2015, 10, 8552–8564. [Google Scholar] [CrossRef]

- Borkowska, H.; Molas, R.; Skiba, D. Plonowanie ślazowca pensylwańskiego w wieloletnim użytkowaniu. Acta Agrophysica 2015, 22, 5–15. [Google Scholar]

- Tworkowski, J.; Szczukowski, S.; Stolarski, M.J.; Kwiatkowski, J.; Graban, Ł. Fragm. Agron. 2014, 31, 115–125.

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santos, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant material and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- Villar, J.C.; Revilla, E.; Gómez, N.; Carbajo, J.M.; Simón, J.V. Improving the use of kenaf for kraft pulping by using mixtures of bast and core fiber. Ind. Crops Prod. 2009, 29, 301–307. [Google Scholar] [CrossRef]

- IWNiRZ Prywatna korespondencja z, J. Kołodziejem pracownikiem IWNiRZ w Poznaniu, 2011.

- Alba-Hemp. Available online: www.alba-hemp.com.