1. Introduction

The traditional shipbuilding industry (TSI) has long been a crucial pillar of the global economy, providing essential services for the construction, repair, and maintenance of large vessels. It serves as a strategic sector, supporting vital areas such as transportation, sea trade, fishing, and maritime tourism [

1]. However, in recent years, this industry has encountered numerous challenges when it comes to enhancing the efficiency and performance of its production processes [

2]. The manufacturing process involved in TSI is intricate, demanding seamless coordination among various departments and specialties. Regrettably, the lack of efficiency in the manufacturing cycle persists as a significant issue within the industry. These challenges encompass errors in production planning [

3], inadequate interdepartmental coordination, delays in material delivery, and underutilization of cutting-edge technologies in the process. Consequently, these inefficiencies lead to escalated production costs, diminished productivity, and prolonged project completion [

4].

Meanwhile, the management structure in the TSI predominantly retains its family-oriented nature, with a significant portion of the workforce hailing from large family units [

5]. Moreover, the technology employed in the construction and repair of wooden ships draws heavily from ancestral knowledge and long-standing expertise acquired over generations [

6,

7]. The TSI, specializing in wooden ship production, operates within a traditional framework where tools and production techniques remain simplistic [

8]. The reliance on manual hammers for nail fastening exemplifies the traditional approach, which not only consumes excessive energy but also poses safety risks [

9,

10]. Consequently, this approach leads to challenges in material flow alignment with work process planning [

11], resulting in substantial non-value-added (NVA) activities and suboptimal efficiency in the ship production process [

12]. Additionally, the subpar production line balance further accentuates this condition. Several indicators of an inadequate production line include the absence of well-defined work standards influenced by rudimentary work methods, tools, and technology [

13,

14,

15].

In addition to internal challenges, the TSI is confronted with external pressures to embrace sustainable and environmentally friendly practices. The rising demand for energy-efficient and eco-conscious ships in recent years necessitates the optimization of manufacturing cycles within these industries [

16,

17,

18]. This optimization is vital to enhance production efficiency, minimize environmental impact, and sustain competitiveness in an ever-competitive global market [

19,

20].

Several studies have been conducted to identify and address the challenges associated with enhancing the manufacturing cycle efficiency in the TSI. For instance [

21,

22]. conducted studies that shed light on various challenges faced by the industry, including prolonged lead times, excessive material wastage, inefficient production layouts, and suboptimal workforce management. These findings underline the significance of implementing appropriate strategies and approaches to overcome these challenges and enhance the performance of the production processes. One of the proposed strategies is the integration of efficient management systems such as Lean Manufacturing and Total Quality Management [

23,

24,

25]. Meanwhile, research shows how the application of lean principles can result in significant increases in lead times and productivity in shipyards. In this case, emphasizing value mapping and eliminating waste is important in achieving increased efficiency [

22,

23,

24,

25,

26,

27,

28].

The research presented above underscores the imperative to delve into the in-corporation of streamlined management systems within TSI. Despite the implementation of broad management systems like Lean Manufacturing or Total Quality Management in diverse manufacturing sectors, there persist research voids concerning their tailored implementation and adaptation in the conventional shipbuilding milieu. Hence, it becomes imperative to discern the most efficient and pertinent management practices that can optimize the manufacturing cycle within this industry.

Project Time Deployment (PTD) and Project Cost Deployment (PCD) are two further lean manufacturing techniques that minimize losses by reducing production lead times in Engineer-to-Order (ETO) settings and estimating the effects of prospective (lean) enhancement projects. [

29,

30,

31,

32]. The lean indicator known as Overall Task Effectiveness (OTE) can assist the analyst in defining target task timeframes and locating hidden losses that are responsible for the majority of the observed time spent on manual assembly tasks[

33].

The literature review presented herein underscores the imperative for a holistic approach to optimizing the TSI. Integrating efficient management systems, utilizing advanced technology, and adopting sustainable practices emerge as pivotal strategies to enhance manufacturing cycle efficiency and elevate production process performance[

34,

35]. However, further research is warranted to delve into the practical implementation of these strategies within the context of typical, traditional shipbuilding operations. Moreover, longitudinal studies examining the long-term ramifications of optimization endeavors and the scalability of proposed solutions would yield profound insights into optimizing the manufacturing cycle within the TSI.

With the aforementioned research gap in mind, the primary objective of this article is to address the existing knowledge deficit and present fresh perspectives on optimizing the TSI through heightened manufacturing cycle efficiency. By delving deeper into the integration of management systems, application of advanced technology, and implementation of sustainable strategies, it is anticipated that this article will make a valuable contribution toward the development of a more efficient, sustainable, and competitive TSI.

The utilization of the Manufacturing Cycle Efficiency (MCE) method in the TSI holds paramount importance for enhancing the efficiency and performance of the production process [

36]. The MCE method serves as a valuable tool for measuring the efficiency of the entire manufacturing cycle [

37]; Through a comprehensive analysis of each production step, encompassing waste identification, bottleneck recognition, and interruption assessment, the MCE method facilitates workflow optimization, reduction in lead times, and increased productivity [

38,

39]. Notably, studies conducted by [

40]. demonstrate the efficacy of MCE in identifying nonvalue-added activities and curtail-ing production process duration. Similarly, research conducted b [

41]. reveals the role of MCE in waste reduction and efficiency enhancement within shipyards. By adopting a holistic approach to manufacturing cycle analysis, these studies enable the identification of areas where time and resources are squandered, thereby facilitating the implementation of measures to bolster efficiency. Furthermore, investigations by [

42,

43,

44], indicate that the MCE method can be leveraged to improve shipyard layouts by scrutinizing material flow and production activities and identifying areas requiring layout modifications or enhancements to optimize workflow and mitigate conflicts. The ap-plication of the MCE method also yields benefits in the identification of quality issues and bolsters the effectiveness of quality management. Research by [

45,

46,

47], underscores the significance of comprehending the production process as a whole and employing the MCE method to pinpoint key causes of quality problems, subsequently enabling necessary improvements.

Through a comprehensive analysis of the manufacturing cycle, encompassing waste, bottlenecks, and disruptions, the MCE method proves instrumental in augmenting efficiency, minimizing lead times, enhancing quality, and optimizing overall production management. The application of the MCE method empowers shipyards to attain superior production process performance, bolster competitiveness, and yield substantial advantages for the TSI.

This article aims to make a significant research contribution toward optimizing the TSI and enhancing the performance of its production processes. Firstly, it will meticulously identify and analyze the primary challenges encountered by the industry in terms of manufacturing cycle efficiency. Secondly, it will present an array of strategies and steps that TSI can adopt to enhance the efficiency of its manufacturing cycle. Thirdly, it will expound upon the manifold benefits derived from optimizing the manufacturing cycle within the TSI. Fourthly, this article will offer insights into recent technological advancements and industry practices that can be applied effectively within the traditional shipbuilding context. Fifthly, it will emphasize the pivotal role of sustainability aspects [

48] in optimizing the TSI. By providing practical guidance and novel insights, this article endeavors to empower the TSI in its pursuit of improved manufacturing cycle efficiency and enhanced production process performance.

As a result, the paper presents a method of improving the efficiency of production processes in TSI, aiding in addressing prevailing challenges and fostering sustainable and innovative development in the future.

2. Materials and Methods

The type of research used is descriptive research. Descriptive research is done by examining job analysis and activities on an object. Initial preparations were made to complete this research by conducting a literature study, namely by collecting relevant material, compiling an analytical framework and settlement model, collecting secondary data, and preparing the primary data requirements in survey activities at TSI. In this descriptive study, data collection was obtained from observations, library research, and field research in the form of interviews with sources who had confirmed they knew the information needed by researchers or direct observation of the actual situation within the company. The selected informants are stakeholders who have a stake in the implementation, and who know deeply about the production process at TSI, the conditions of the existing production process will be analyzed, and recommendations for improvement are sought to increase the productivity of the production system and reduce waste in the production process.

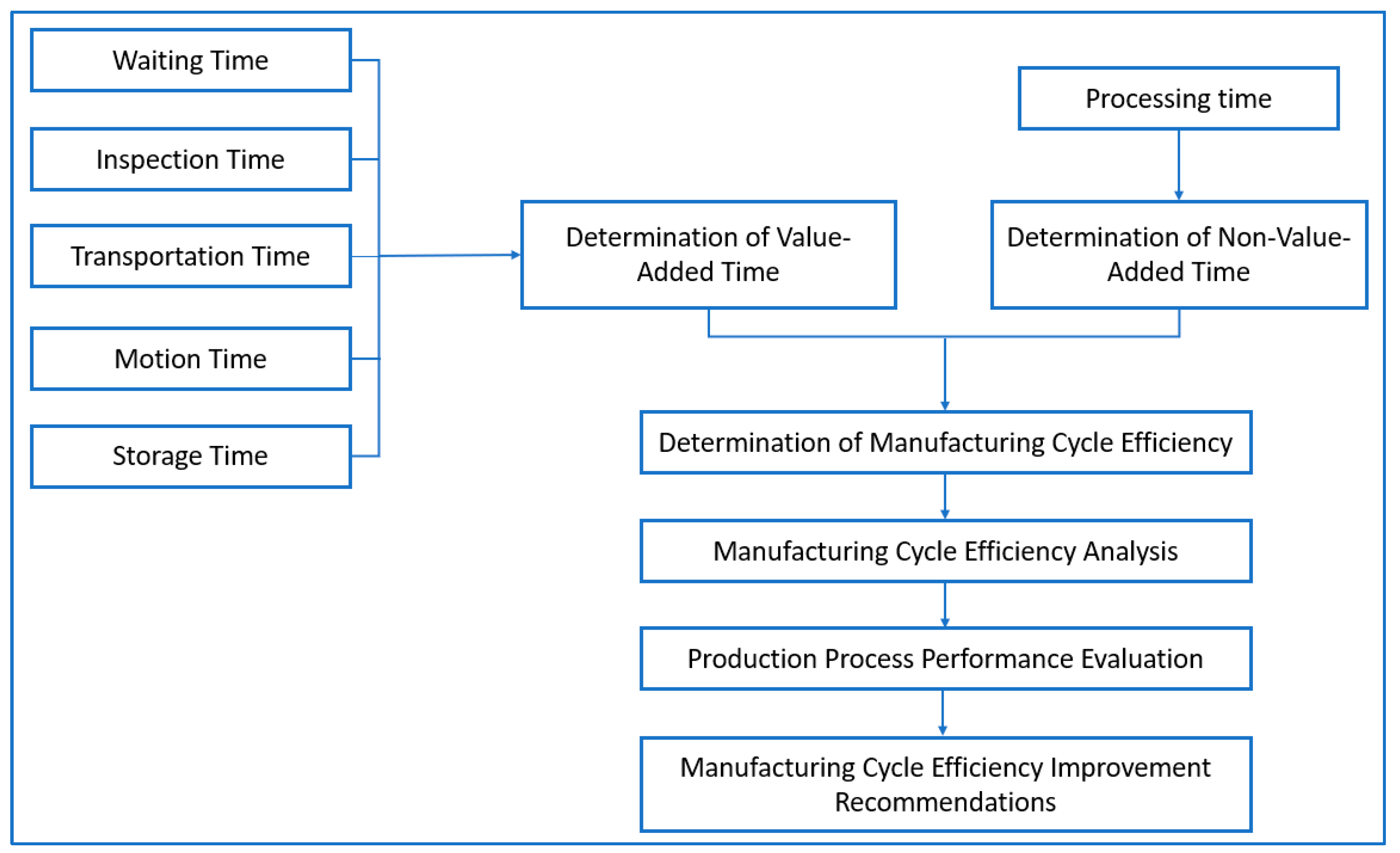

The conceptual framework of research is a relationship or connection between one concept to another concept of the problem to be studied. This conceptual framework is useful for connecting or explaining at length a topic to be discussed. This framework is obtained from the concept of science/theory that is used as the basis for research obtained in the literature review or if one might say the researcher is a summary of the literature review which is connected by lines according to the variables studied. The conceptual framework is an arrangement of logical constructs arranged in order to explain the variables studied. This framework is formulated to explain the construction of the flow of logic to study empirical reality systematically. The following conceptual framework in this study can be seen in

Figure 1.

Data processing with the tools used according to their respective functions.

a. NVA identification

At this stage, the waste that often occurs in the production process is weighted. Direct interviews were carried out with the parties involved in the study implementation focused on the production division, which consisted of 5-7 people to carry out the weighting. The results of this identification obtained nonvalue-added time (NVAT).

b. Process Activity Mapping

Process Activity Mapping is used to describe the production system (starting from how to order to finished goods as a whole) along with the value stream that exists in the company, so that later an overview of the information flow and physical flow of the existing system is obtained, identifying where NVA occurs, and describing leads time required based on each characteristic of the process that occurs.

c. MCE measurement

MCE is a metric used to measure the overall efficiency of a production process. MCE describes the extent to which the production process can produce value-added output in one production cycle. The determination of MCE involves calculating the ratio between Value-Added Time (VAT) and Total Cycle Time (TCT). TCT is the time actually used to convert raw materials into finished products by adding value to the product.

In determining the MCE, the following steps can be followed:

- VAT identification: Identification and in-depth analysis of all the steps or operations that add direct value to the product. VAT involves operations that actually transform raw materials into finished products by giving the product new characteristics, uses, or features.

- Calculate VAT: Calculate the total time spent on those value-added steps. VAT can be measured in relevant time units, such as minutes or hours.

- Identification: Identification and analysis of all time elements involved in the production cycle, which consists of processing time (PT), including waiting time (WT), transportation time (TT), motion time (MT), inspection time (IT), storage time (ST), and other time that does not provide direct added value.

- Calculate TCT: Calculate the total time required from start to finish of the production cycle, including all-time elements identified in the previous step. The formula for calculating MCE is shown in the following equation:

A high MCE indicates that the production process experiences little waste and most of the time is used for value-added activities. Conversely, a low MCE indicates significant time wastage in the production cycle. MCE can be used as a tool to identify and reduce unnecessary time wastage in production processes. By increasing MCE, companies can achieve higher efficiencies, reduce production costs, increase productivity, and improve customer satisfaction with faster delivery times.

3. Results

In a study, collecting data is essential to resolving issues. Additionally, data-gathering techniques play a critical role in obtaining accurate data. The data has been obtained in this study through several data collection methods including recording traditional shipyard companies in one Village Nort of Morocco; historical data and observing operators’ work such as paying attention to the length of time operators change stations while working.

3.1. Waiting time

Waiting time is an activity in which raw materials and products in the process use up time and resources in waiting for the next process. Data collection from waiting time activities at shipbuilding production stations is known through direct observation and interviews with workers who are TSI. The waiting time in the traditional shipbuilding process at TSI starts with the installation of the keel wood and is then followed by the waiting time for other installations. Data collection from waiting time activities at shipbuilding production stations is known through direct observation and interviews with shipyard workers which can be seen in

Table 1.

Based on

Table 1, it is explained that almost the entire average waiting time in traditional shipbuilding at TSI is 24 hours and several other waiting times are longer, namely 24-32 hours. Whereas in the installation of keel wood, there is no waiting time because the installation of keel wood is the first time and only one in the shipbuilding process. Since any material can be used in shipbuilding, and the operator hasn't started using it yet, this period is defined as waiting time. The waiting time data shown in the table above is used to calculate MCE.

3.2. Transportation time

This includes transportation time, namely the activity of moving from the first storage station (warehouse) to the shipbuilding location and then forming and processing it into materials for use in shipbuilding. A certain transportation time is sometimes required in each production process. However, precise sequencing of activities, tasks, and application of technology is required, which can significantly eliminate transportation time. The calculation is done by adding up all the activities included in the transportation time. The time is obtained by calculating using a stopwatch and using the camera instrument. an overview of the operator's task transfer activities at the shipyard production station is known through direct observation and can be seen in

Table 2.

3.3. Inspection time

Inspection activities are carried out in each production process. The calculation made is the sum of all activities starting from the beginning to the end of traditional shipbuilding. The description of the work activities at TSI is known through direct observation when the operator is working, by looking at and checking the work being done one by one. A description of the inspection time activities can be seen in

Table 3.

3.4. Motion time

Motion time in the production process refers to the time required to carry out physical movements or human activities that are not required in the production process. Movements that are inefficient or non-value-added can take up valuable time and resources without contributing significantly to product value. An overview of work activities at TSI is known through direct observation when the operator is working, by looking at and checking one by one the work being done. An overview of moving time activity can be seen in

Table 4.

3.5. Storage time

Storage time is an activity that uses time and resources, as long as products and raw materials are stored as inventory. This storage time is due to the storage process, both raw materials before the production process finally starts or finished goods stored in the warehouse as inventory. The following is a description of the length of time storage of raw materials at TSI which can be seen in

Table 5.

3.6. Processing time

Processing time in the traditional shipbuilding production process refers to the time required to complete a particular operation or stage in shipbuilding. Traditional ships involve complex processes and involve various stages, from planning to construction and completion. Processing time includes the time required to perform special operations such as cutting, welding, assembling structures, painting, and so on. The following is an overview of the length of processing time for traditional shipbuilding at TSI which can be seen in

Table 6.

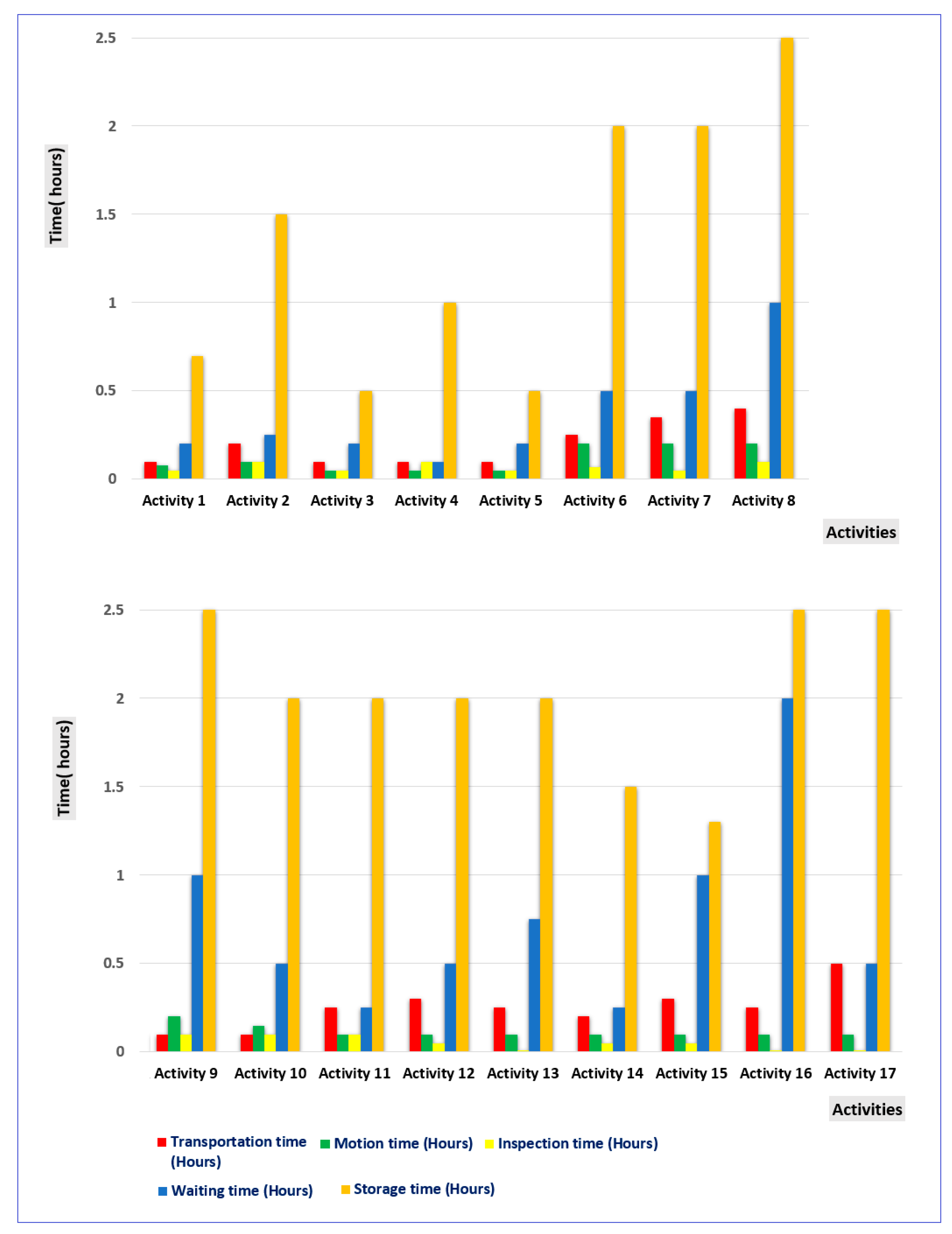

The Graph in

Figure 2 illustrates the correlation between traditional shipbuilding activities and different nonvalue-added time factors.

3.7. MCE Determination

Determining the MCE value begins with identifying the time that does not have added value or NVAT which consists of WT, TT, MT, IT, and ST. Equation (1) can be used to calculate the NVAT value. The results of these calculations are shown in

Table 7. Furthermore, to determine the values of TCT, VAT, and MCE respectively, equations (2), (3), and (4) can be used. This calculation uses the data contained in

Table 1 -

Table 6, while the results of this calculation are shown in

Table 7.

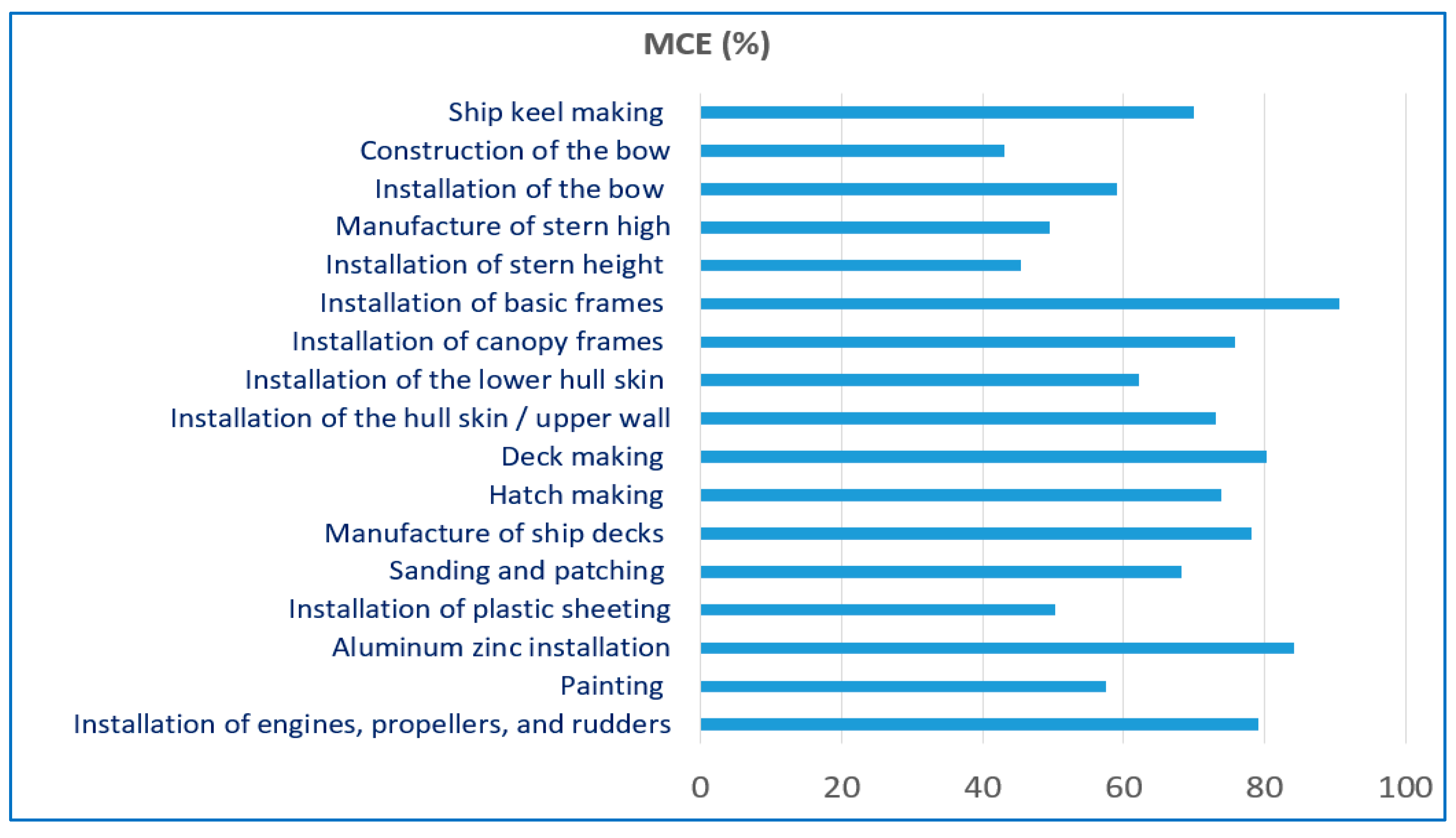

Based on the calculations presented in

Table 7, the obtained TCT value is 364.21 hours. Additionally, the MCE value achieved a percentage of 67.08%. These results indicate that the traditional shipbuilding production process at TSI still exhibits a significant amount of waste, as evidenced by the identified NVAT value of 44.98 hours derived from WT, TT, MT, IT, and ST activities at TSI. For a more comprehensive understanding of the correlation between the MCE value and each specific work activity in traditional shipbuilding at TSI, please refer to

Figure 3.

4. Discussion

In this Discussion sub-chapter, we will delve into a comprehensive analysis of the significant findings previously presented. We aim to expand our understanding of the implementation and significance of the research results within a broader context. Through open-mindedness and critical evaluation, we can identify patterns, trends, and potential alternative explanations that contribute to strengthening the validity of our findings. Let us embark on an exploration of diverse perspectives and generate valuable insights to advance knowledge and shape future research directions.

4.1. Production Process Performance Evaluation

Based on the findings of the MCE research, the calculation results show that the performance of the traditional shipbuilding production process at TSI has a lot of wasteful activities, so it needs to be repaired. Based on the findings, the average MCE value was 67.08%. This MCE value is indeed not so bad. However, there is no universally permitted minimum value for MCE. The MCE value that is considered good or optimal can vary depending on the industry, product type, complexity of the production process, and company goals. However, in general, the higher the MCE value, the more efficient the production process is. As a general guide, companies often strive to achieve as large an MCE as possible, ideally close to 100%. In this case, most of the time spent in the production cycle is time that adds value to the product.

However, keep in mind that very high MCE values may be difficult to achieve with absolute certainty as some wastage or bottleneck factors may remain in the production process. Factors such as waiting time, transportation, or repair of defects may not be completely eliminated. In addition, each company must consider the balance between MCE and other factors such as production costs, flexibility, order completion speed, and customer satisfaction. In some cases, achieving an MCE that is too high may not be practical or business profitable. In practice, companies often compare their MCE with previous internal performance or with similar companies in the same industry to determine how far they have achieved production process efficiency. The company's goal then is to continue to improve its MCE over time through efforts to eliminate waste and increase operational efficiency.

Therefore, to get the optimal MCE value, it is necessary to improve the production process at TSI. Based on the results of calculating the MCE value with various percentage ranges related to activity, can be seen in

Table 8.

Based on

Table 8, what needs to be improved is activities that have a low % MCE range, namely the range of 40% - 60% with a total of six activities. Therefore, it must be evaluated in detail, whether the causes of these six activities contribute to the low % MCE value in the traditional shipbuilding production process at TSI. So, to see which wastage factors cause these activities to contribute to the MCE value, therefore a correlation calculation is carried out between MCE and NVAT which consists of WT, TT, MT, IT, and ST, the correlation values are obtained as shown in

Table 9.

4.2. Improvement recommendations

Building upon the evaluation results from the preceding sub-chapter, recommendations for enhancements are put forth for six activities falling within the % MCE range of 40% - 60%, with the goal of reducing non-value-added time waste based on correlation values exhibiting a moderate relationship within the range of 0.4 - 0.599. Specifically, the areas that require improvements are the time parameters associated with inspection and storage, which lack added value. These improvement recommendations have been summarized and presented in

Table 10.

5. Conclusions

Conclusions This research on optimizing the traditional shipyard industry and enhancing manufacturing cycle efficiency has provided valuable insights into improving production process performance. Through an analysis of the industry's challenges, including production planning errors, coordination issues, material delivery delays, and limited technology integration, it is evident that implementing efficient management systems and utilizing tools such as the Manufacturing Cycle Efficiency (MCE) methods are essential.

By adopting efficient management systems like Lean Manufacturing and Total Quality Management, shipyards can eliminate non-value-added activities, simplify processes, and reduce waiting times. The application of the MCE method enables a comprehensive analysis of production processes, facilitating the identification of waste, bottlenecks, and interruptions, thus optimizing workflows.

Future Research Plans To further advance the optimization of the traditional shipyard industry, future research should focus on the practical implementation of these recommendations in real-world shipbuilding contexts. Longitudinal studies evaluating the long-term impact of optimization efforts and assessing the scalability of proposed solutions would provide valuable insights.

Furthermore, future research should explore the integration of advanced technologies and innovative practices within the traditional shipbuilding industry. Investigating the use of digitalization, automation, robotics, and data analytics can lead to significant improvements in manufacturing cycle efficiency and overall production process performance.

Additionally, examining the role of sustainability practices, such as eco-friendly materials, energy-efficient processes, and waste reduction strategies, is crucial for the industry's long-term viability and environmental responsibility. By conducting these future research studies, the traditional shipyard industry can continue to enhance manufacturing cycle efficiency, improve production process performance, and stay competitive in the evolving global maritime sector.

References

- Soh, M. C., Shamsuddin, S. M., & Hasan, S. (2019). A new framework for dynamical resources planning system in the shipbuilding industry. International Journal of Advances in Soft Computing and Its Applications, 11(1).

- Sukisno, & Singgih, M. L. (2019). Location Selection Analysis for New Shipyard Using Integration of DEMATEL and ANP: A Case Study (PT IKI). IOP Conference Series: Materials Science and Engineering, 598(1). [CrossRef]

- Z. Benmamoun, H. Hachimi, and A. Amine, “Comparison of Inventory Models for Optimal Working Capital; Case of Aeronautics Company,” International Journal of Engineering, vol. 31, no. 4, pp. 605–611, Apr. 2018.

- Fitriadi, F., & Ayob, A. F. M. (2022). Identifying the Shipyard Waste: An Application of the Lean Manufacturing Approach. International Journal of Global Optimization and Its Application, 1(2). [CrossRef]

- Fitriadi, F., Faisal, A., & Ayob, M. (2023). Continuous Improvement Strategy in Traditional Shipyard Industry: A Holistic Approach towards Sustainability. Journal of Optimization in Industrial Engineering, 16, 255–268. [CrossRef]

- Misra, S. C. (2015). Design principles of ships and marine structures. Design Principles of Ships and Marine Structures, 1–461. [CrossRef]

- Rizwan, T., Rizki, A., Salsabila, U., Muhammad, M., Maulana, R., Chaliluddin, M. A., Affan, J. M., Thaib, R., Suhendrianto, S., & Muchlis, Y. (2021). Literature review on shipyard productivity in Indonesia. Depik, 10(1). [CrossRef]

- Zazzaro, C., Liebner, H., Soriente, A., Ferraioli, G., & Purnawibawa, A. G. (2022). The Construction of an Historical Boat in South Sulawesi (Indonesia): The Padewakang. Journal of Maritime Archaeology, 17(4), 507–557. [CrossRef]

- Astuti, R. D., Susmartini, S., & Kinanthi, A. P. (2017). Improving the work position of worker based on manual material handling in rice mill industry. AIP Conference Proceedings, 1902(1), 20043. [CrossRef]

- Holtermann, A., Krause, N., Van Der Beek, A. J., & Straker, L. (2017). The physical activity paradox: six reasons why occupational physical activity (OPA) does not confer the cardiovascular health benefits that leisure time physical activity does. Br J Sports Med Month, 0(0). [CrossRef]

- M. Elkhechafi, Z. Benmamoun, H. Hachimi, A. Amine, and Y. Elkettani, “Firefly Algorithm for Supply Chain Optimization,” Lobachevskii Journal of Mathematics, vol. 39, no. 3, pp. 355–367, Apr. 2018. [CrossRef]

- Tasdemir, C., & Gazo, R. (2019). Validation of Sustainability Benchmarking Tool in the Context of Value-Added Wood Products Manufacturing Activities. Sustainability 2019, Vol. 11, Page 2361, 11(8), 2361. [CrossRef]

- Martín-Navarro, A., Sancho, M. P. L., & Medina-Garrido, J. A. (2020). Business process management systems in port processes: A systematic literature review. International Journal of Agile Systems and Management, 13(3), 258–278. [CrossRef]

- Schulze, F., & Dallasega, P. (2021). Barriers to lean implementation in engineer-to-order manufacturing with subsequent assembly on-site: state of the art and future directions. Https://Doi.Org/10.1080/09537287.2021.1888159, 34(1), 91–115.

- Vidal-Balea, A., Blanco-Novoa, O., Fraga-Lamas, P., Vilar-Montesinos, M., & Fernández Caramés, T. M. (2022). A Collaborative Industrial Augmented Reality Digital Twin: Developing the Future of Shipyard 4.0. Lecture Notes of the Institute for Computer Sciences, Social- Informatics and Telecommunications Engineering, LNICST, 442 LNICST, 104–120. [CrossRef]

- Ferreira, F. de A. L., Scavarda, L. F., Ceryno, P. S., & Leiras, A. (2018). Supply chain risk analysis: a shipbuilding industry case. Https://Doi.Org/10.1080/13675567.2018.1472748, 21(5), 542–556. [CrossRef]

- Jasmi, M. F. A., & Fernando, Y. (2018). Drivers of maritime green supply chain management. Sustainable Cities and Society, 43, 366–383. [CrossRef]

- Zhou, Y. , Li, X., & Yuen, K. F. (2023). Sustainable shipping: A critical review for a unified framework and future research agenda. Marine Policy, 148, 105478. [CrossRef]

- Ghatorha, K. S. , Sharma, R., & Singh, G. (2022). Lean Manufacturing Through PDCA: A Case Study of a Press Manufacturing Industry. 167–187. [CrossRef]

- Vaidya, S. , Ambad, P., & Bhosle, S. (2018). Industry 4.0 – A Glimpse. Procedia Manufacturing, 20, 233–238. [CrossRef]

- Praharsi, Y. , Jami’in, M. A., Suhardjito, G., & Wee, H. M. (2021). The application of Lean Six Sigma and supply chain resilience in maritime industry during the era of COVID-19. International Journal of Lean Six Sigma, 12(4), 800–834. [CrossRef]

- Z. Benmamoun, W. Fethallah, M. Ahlaqqach, I. Jebbor, M. Benmamoun, and M. Elkhechafi, “Butterfly Algorithm for Sustainable Lot Size Optimization,” Sustainability, vol. 15, no. 15, p. 11761, Jul. 2023. [CrossRef]

- Aleksandrova, S. V. , Vasiliev, V. A., & Letuchev, G. M. (2018). Digital Technology and Quality Management. Proceedings of the 2018 International Conference “‘Quality Management, Transport and Information Security, Information Technologies’”, IT and QM and IS 2018, 18– 21. [CrossRef]

- Sá, J. C. , Vaz, S., Carvalho, O., Lima, V., Morgado, L., Fonseca, L., Doiro, M., & Santos, G. (2020). A model of integration ISO 9001 with Lean six sigma and main benefits achieved. Https://Doi.Org/10.1080/14783363.2020.1829969, 33(1–2), 218–242.

- Santos Bento, G. dos, & Tontini, G. Developing an instrument to measure lean manufacturing maturity and its relationship with operational performance 2018 Https://Doi.Org/10.1080/14783363.2018.1486537, 29(9–10), 977–995.

- Kunkera, Z., Tošanović, N., & Štefanić, N. (2022). Improving the Shipbuilding Sales Process by Selected Lean Management Tool. Machines 2022, Vol. 10, Page 766, 10(9), 766.

- Shahsavar, A. , Sadeghi, J. K., Shockley, J., & Ojha, D. (2021). On the relationship between lean scheduling and economic performance in shipbuilding: A proposed model and comparative evaluation. International Journal of Production Economics, 239, 108202. [CrossRef]

- Sharma, S. , & Gandhi, P. J. (2017). Scope and Impact of Implementing Lean Principles & Practices in Shipbuilding. Procedia Engineering, 194, 232–240. [CrossRef]

- Bertolini, M., M. Braglia, L. Marrazzini, and M. Neroni. Project Time Deployment: a new lean tool for losses analysis in Engineer-to-Order production environments, International Journal of Production Research, (2022), 60 (10): 3129-3146.

- Braglia, M., M. Frosolini, M. Gallo, and L. Marrazzini.. “Lean Manufacturing Tool in Engineering-to-Order Environment: Project Cost Deployment.” International Journal of Production Research, (2019) 57 (6): 1825–1839.

- Braglia, M. , Gallo, M. & Marrazzini, L. A lean approach to address material losses: materials cost deployment (MaCD). Int J Adv Manuf Technol, (2021), 113, 565–584. [CrossRef]

- Matt, D. T. “Adaptation of the Value Stream Mapping Approach to the Design of Lean Engineer-to-Order Production Systems: A Case Study.” Journal of Manufacturing Technology Management, (2014), 25 (3): 334–350,.

- Braglia, M. , Gabbrielli, R. and Marrazzini, L. "Overall Task Effectiveness: a new Lean performance Indicator in engineer-to-order Environment", International Journal of Productivity and Performance Management, Vol. 68 No. 2, pp. 407-422 (2019). [CrossRef]

- Jebbor, Z. Benmamoun, H. Hachimi, Y. Raouf, M. Haqqi, and M. Akikiz, “Improvement of an Assembly Line in the Automotive Industry: A Case Study in Wiring Harness Assembly Line,” in Advances in Transdisciplinary Engineering, L.-C. Tang, Ed., IOS Press, 2023, pp. 62–71. [CrossRef]

- Y. Raouf, Z. Benmamoun, H. Hachimi, I. Jebbor, M. Haqqi and M. Akikiz, "Towards a Smart and Sustainable Industry: Cycle Time optimization," 2023 3rd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Mohammedia, Morocco, 2023, pp. 1-7. [CrossRef]

- Braglia, M. , Frosolini, M., Gabbrielli, R., Marrazzini, L. Process Engineering and Optimization. In: Zijm, H., Klumpp, M., Regattieri, A., Heragu, S. (eds) Operations, Logistics and Supply Chain Management. Lecture Notes in Logistics. Springer, Cham, (2019). [CrossRef]

- da Silva, A. F. , Marins, F. A. S., Dias, E. X., & Ushizima, C. A. (2020). Improving manufacturing cycle efficiency through new multiple criteria data envelopment analysis models: an application in green and lean manufacturing processes. Https://Doi.Org/10.1080/09537287.2020.1713413, 32(2), 104–120.

- Karim, A., & Arif-Uz-Zaman, K. (2013). A methodology for effective implementation of lean strategies and its performance evaluation in manufacturing organizations. Business Process Management Journal, 19(1), 169–196. [CrossRef]

- Swarnakar, V. , Singh, A. R., Antony, J., Tiwari, A. K., & Cudney, E. (2021). Development of a conceptual method for sustainability assessment in manufacturing. Computers & Industrial Engineering, 158, 107403. [CrossRef]

- Zhang, Y. , Lei, Z., Han, S., Bouferguene, A., & Al-Hussein, M. (2020). Process-Oriented Framework to Improve Modular and Offsite Construction Manufacturing Performance. Journal of Construction Engineering and Management, 146(9), 04020116. [CrossRef]

- Ding, L. li, Lei, L., Wang, L., Zhang, L. fu, & Calin, A. C. (2020). A novel cooperative game network DEA model for marine circular economy performance evaluation of China. Journal of Cleaner Production, 253, 120071. [CrossRef]

- Centobelli, P., Cerchione, R., Murino, T., & Gallo, M. (2016). Layout and material flow optimization in digital factory. International Journal of Simulation Modelling, 15(2), 223–235. [CrossRef]

- Jerin Leno, I. , Saravanasankar, S., & Ponnambalam, S. G. (2012). Layout Design for Efficient Material Flow Path. Procedia Engineering, 38, 872–879. [CrossRef]

- Purnamasari, I. , Adhimursandi, D., & Nadir, M. (2018). Optimalisasi manufacturing cycle effectivieness (mce) terhadap pengelolaan value added activities dan non value added activities dalam meningkatkan efisiensi produksi. JURNAL MANAJEMEN, 10(1), 29–37. [CrossRef]

- Tao, F. , Cheng, J., Qi, Q., Zhang, M., Zhang, H., & Sui, F. (2018). Digital twin-driven product design, manufacturing and service with big data. International Journal of Advanced Manufacturing Technology, 94(9–12), 3563–3576. [CrossRef]

- Tao, F. , Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal of Manufacturing Systems, 48, 157–169. [CrossRef]

- Yan, J. , Meng, Y., Lu, L., & Li, L. (2017). Industrial Big Data in an Industry 4.0 Environment:.

- Z. Benmamoun, W. Fethallah, S. Bouazza, A. A. Abdo, D. Serrou, and H. Benchekroun, “A framework for sustainability evaluation and improvement of radiology service,” Journal of Cleaner Production, vol. 401, p. 136796, May 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).