1. Introduction

The mechanical manufacturing industry is the basic industry of the national economy with the characteristics of resource-intensive, energy-intensive, and labor-intensive [

1]. While creating great social wealth, the mechanical manufacturing industry also results in huge energy and material consumption and generates a large amount of carbon emissions [

2]. A study by Dahmus [

3] shows that the carbon emissions of one CNC machine tool with 22 kW spindle power in one year are equivalent to the carbon emissions of 61 SUVs (20.7 mpg, 12000 miles/year). Meanwhile, the quantity of machining system is enormous which provide the considerable potential to save energy and material consumption. As far as China is concerned, there are about 10 million machine tools in Chinese machining plants, ranked number one in the world [

4]. Moreover, the machining operation of operators consists of a series of activities that also generate tremendous energy consumption and carbon emissions [

5]. Therefore, it is important to assess the sustainability of the machining system considering the energy consumption of the operator, the energy consumption of the machine tool, and the material consumption in machining processes for mechanical manufacturing industry sustainability improvement. As the most common machining system, the CNC milling system is a typical man-machine cooperative system characterized by low energy efficiency and intensive material consumption [

6,

7]. Because modeling and assessing the sustainability of the CNC milling system has been considered to be a crucial approach to improving environmental performance, the first step is to devise applicable assessment methods.

Numerous research works focusing on energy consumption modeling and energy efficiency assessment of machine tools have been carried out. Gutowski et al. [

8] established the total power model for the material removal stage which can be divided into a fixed and a variable part. Mori et al. [

9] classified machine tool energy consumption as energy consumption of standby, energy consumption of positioning, energy consumption of acceleration of the spindle, and energy consumption of feed movement. Li et al. [

10] proposed an improved energy consumption model of the milling process based on thermal equilibrium and empirical modeling. Jia et al. [

5,

11,

12] modeled the energy demand of the machine tools based on therbligs. Kara [

13], Balogun [

14], Cai [

15], Liu [

16], Ghosh [

17] and Heinzel [

18] all employed the SEC (specific energy consumption) as an indicator to measure the energy efficiency of different machining processes. Ma [

19], Liu [

20], and Tuo [

21,

22] investigated the inherent energy performance of machine tools to describe the differences in energy efficiency. In addition, some research works have been conducted to study the material consumption characteristics of the machining systems. Choi et al. [

23] described the resource consumption and environmental emissions of the machining process with the Input-Process-Output (IPO) diagram. Munoz et al. [

24] established a quantitative analysis method to reveal the relation between cutting parameters and cutting tool consumption, material consumption, and cooling liquid consumption in the NC machining process. Liu F et al. [

25] presented a calculation method for the overall utilization rate of material resources in machining systems. Jiang et al. [

26] proposed a multi-objective optimization model in which process cost and cooling liquid consumption are used as objective functions, and cooling liquid flow rate is used as one of the optimization variables. The above studies provide a foundation for assessing the sustainability of machining systems but fail to provide uniform evaluation criteria between energy and materials flows.

Because exergy analysis theory has the ability to quantify both materials and energy flows in one metric, it is a suitable method for assessing the sustainability of machining systems. Gutowski et al. [

27] firstly proposed a thermodynamic framework to analyze the material and energy resources used in 20 manufacturing processes. The research showed that new manufacturing processes primarily generate an increase in material/energy intensity, rather than traditional technologies. Renaldi et al. [

28,

29,

30] provided different definitions of exergy efficiency for subtractive processes, additive processes, and mass-conserving processes. Salman Pervaiz and Mohamed Gadalla [

31,

32] established a physical model of exergy analysis for the metal dry-cutting process. In a dry-cutting experiment, they found that the exergy efficiency of removal is very different from the overall efficiency. Ghandehariun et al. [

33] established the calculating model of exergy loss for the dry turning process and optimized the exergy loss by solving the partial derivative of the model function. In another study, Ghandehariun et al. [

34] provided an exergy efficiency model of drilling processes and analyzed the variation tendency between exergy loss and feed rate by experimental tests. Benjie Li et al. [

35] pointed out that the energy used to maintain the thermal stability of a motorized spindle is useful energy consumption. Based on it, a new energy efficiency model was established under exergy analysis for a high-speed dry hobbing machine. The above research works indicate that exergy analysis is a good method for assessing the sustainability of the CNC milling system.

As a matter of fact, the activities of operators in machining processes also generate massive energy consumption. Regrettably, the energy consumption of the operator in the CNC milling system has often been ignored in most existing research. Therefore, existing methods fail to provide a comprehensive understanding of the sustainability of the CNC milling system. To supply the gap, the energy consumption of the operator from the activities perspective is modeled. The rest of the paper is arranged as follows. The system boundary of exergy loss assessment is defined in

Section 2. The energy consumption models of machine tools and operators are established in

Section 3. The exergy analysis is conducted and the specific exergy loss model is established in

Section 4. A case study conducted on an XH714D machining center is given in

Section 5. Conclusions and future works are proposed in

Section 6.

2. Definition of the system boundary

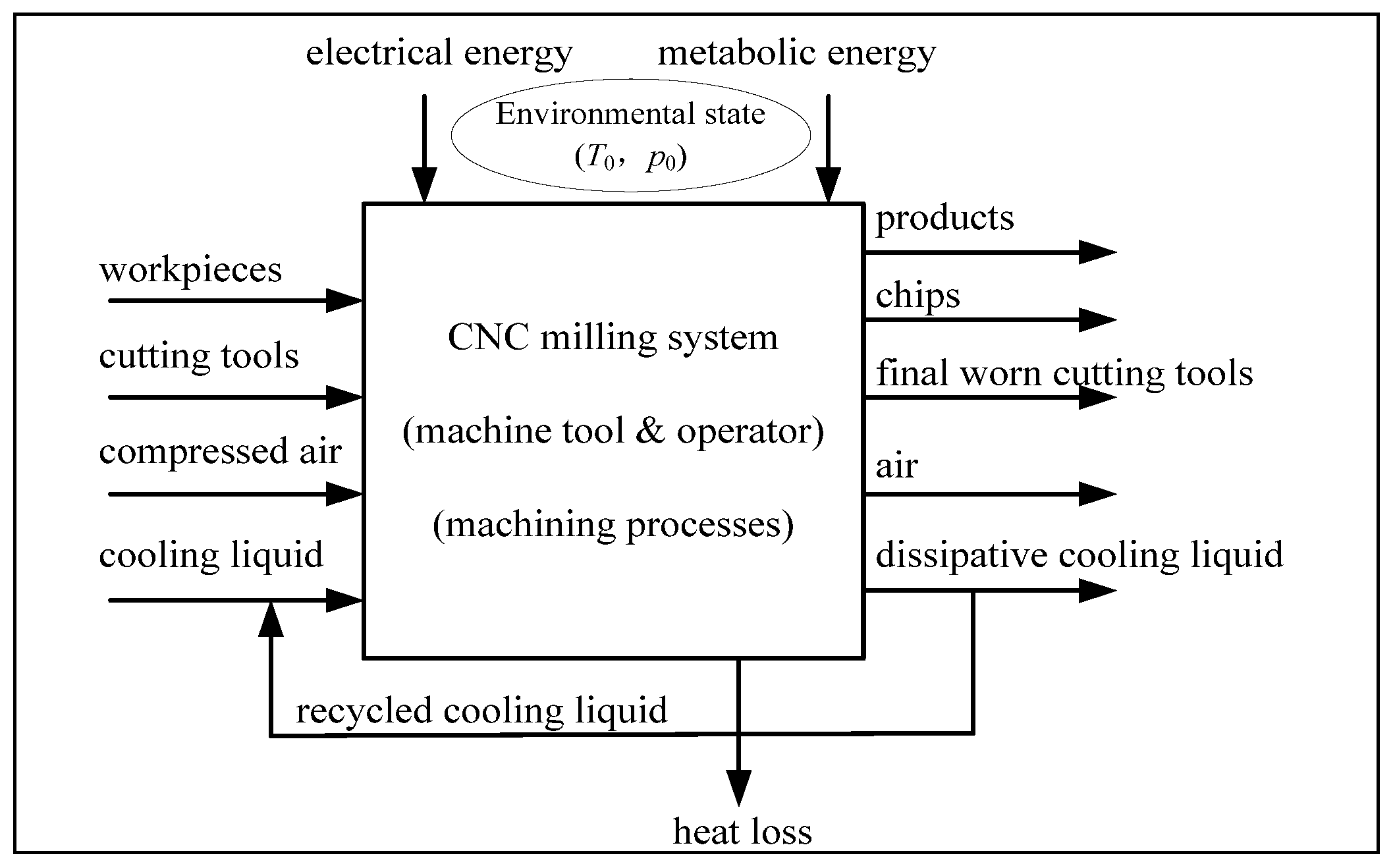

The boundary of the exergy loss assessment method for the CNC milling system is shown in

Figure 1. Generally, all machining processes consume materials and energy as input sources and produce products as output while discharging waste streams. The CNC milling system is a typical man-machine cooperative system. Therefore, the input energy of the CNC milling system consists of the electrical energy consumption by the machine tool and the metabolic energy by operators during the machining process. The input materials include workpieces, cutting tools, cooling liquid, and compressed air. The output materials are products, chips, final worn cutting tools, recycled and dissipative cooling liquid, and air. In addition, the CNC milling system is running in a specific external environment, such as the temperature (T0) and pressure (P0) of the environment. On the other hand, most of the energy consumption by the activities of the machine tool and operator is dissipated with heat loss.

3. Energy analysis

Usually, the machining process of the CNC milling system can be broken up into seven stages according to the activities of the operator and machine tool. The activities of the operator and machine tool during the seven stages are shown in

Table 1. Consequently, there are two kinds of energy consumption in the CNC milling system: energy consumption of the machine tool and energy consumption of the operator.

3.1. Energy consumption modeling of machine tool

According to the above-mentioned machining process stages, the energy consumption of the machine tool for machining a workpiece can be calculated as:

where

EMT [J] is the energy consumption of the machine tool for machining a workpiece;

EMT, i [J] is the energy consumption of the machine tool during stage

i.

As for the machine tool, stage 5 (executing NC program activity) can be divided into two sub-stages: sub-stage 1 (air cutting activity) and sub-stage 2 (material removal activity). So, the energy consumption of the machine tool during stage 5 can be expressed as:

where

EMT,5-1 [J] is the energy consumption of the machine tool during sub-stage 1 (air cutting activity);

EMT,5-2 [J] is the energy consumption of the machine tool during sub-stage 2 (material removal activity).

The energy consumption of the machine tool during each stage is a function of power and time. The power types of all machining process stages are divided as follows:

(1) Standby power

Standby power is the basic power to keep the machine tool running where the main power is switched on; the electrical control systems and the numerical control system are running. Generally, the value of standby power is a constant, usually measured by experiment. The standby power can be measured as:

where

Pstandby [W] is the machine tool electrical power consumption of standby activity;

Pstandby, i [W] is the

i-th measured value of the machine tool electrical power consumption of standby activity;

N is the number of measured value.

(2) Air-cutting power

Air-cutting power is the machine tool’s electrical power consumption of the air-cutting activity in which the cutting tool moves with the tool path defined in the NC program without material removal. The air cutting power, which consists of four parts: standby power, spindle rotation power, feed power, and cooling liquid supplying power, can be calculated by Equation (4).

where

Pair-cutting [W] is the power consumption of the machine tool during sub-stage 1 (air cutting activity);

Pspindle [W] is the spindle rotation power;

Pfeed [W] is the feed power;

Pcooling [W] is the cooling liquid supplying power treated as a constant value.

In addition, the spindle rotation power follows an approximately linear relationship with the rotational speed, which can be expressed as:

where

n [r/min] is the spindle rotational speed; k1 and b are the specific coefficients of the spindle motor.

Similarly, the feed power follows an approximately linear relationship with the feed rate, which is calculated as:

where

f [mm/min] is the feed rate; k2 and c are the specific coefficients of the feed motor. Based on Equations (4)–(6), the

Pair-cutting can further be written as:

(3) Material removal power

Material removal power is the machine tool’s electrical power consumption of the material removal activity where the cutting tool is in contact with the workpiece and the chips are produced. It can be expressed as:

where

Pmaterial removal [W] is the power consumption of machine tool during sub-stage 2 (material removal activity);

Pcutting [W] is the power consumption in cutting tool tip when cutting the workpiece;

MRR [mm3/s] is the material removal rate; k0 the specific coefficient of cutting force;

ap [mm] is the cutting depth;

ae [mm] is the cutting width. Based on Equations (7)–(9), the Pmaterial removal can further be written as:

In development, the

EMT can be expressed as:

where

ti (

i=1,2,3,4,6,7) [s] is the duration of stage

i;

t5-1 [s] is the duration of sub-stage 1 (air cutting activity);

t5-2 [s] is the duration of sub-stage 2 (material removal activity).

Moreover, according to the NC program,

t5-1 ,

t5-1 and t5can be calculated as:

where

Lair [mm] is the length of the cutting tool moving route during sub-stage 1 (air cutting activity);

Lcutting [mm] is the length of the cutting tool moving route during sub-stage 2 (material removal activity),

t5 [s] is the duration of stage 5.

It's worth noting that the energy consumption in the cutting tool tip used to remove material from the workpiece, ”

Ecutting [J]”, is defined as the effective energy output of the CNC milling system. It can be expressed as:

In consequence, the traditional material removal energy efficiency of the machine tool can be calculated as:

where

ηe is the material removal energy efficiency of the machine tool.

3.2. Energy consumption modeling of the operator

Similarly, the operations of the operator in the machining process can be broken up into seven activities. Each activity also generates massive energy consumption which is often been ignored in previous studies. The energy consumption of the operator is relevant to the activity intensity, the duration of each activity, and the features of the operator such as height and body weight. As a matter of fact, different activities have different intensities that can be characterized by the average energy metabolic rate. On the other hand, the duration of the seven activities is diverse. Therefore, there are huge differences in the energy consumption of the operator during the seven stages. The description and intensity of the seven activities are shown in

Table 2.

The unit of the average energy metabolic rate is 1.0 kcal per minute per m

2 body surface area. The body surface area is the function of the height and body weight of humankind and for Chinese people, it can be calculated as:

where

S [m

2] is the body surface area of the operator;

H [cm] is the height of the operator;

W [kg] is the body weight of the operator.

According to the unit transformation between calories and joules, 1.0 kcal=4184 J, the unit of activity intensity can be transformed as follow:

J·s-1·m-2

It is well known that 1 W = 1 J·s

-1. So, Equation (16) can be transformed as follows:

where

[W·m

-2] is the power consumption of the operator per m

2 body surface area.

According to the above-mentioned analysis, the operator energy consumption for machining a workpiece can be calculated as:

where

EOP [J] is the energy consumption of the operator for machining a workpiece;

EOP, i [J] is the operator energy consumption of activity

i;

Pi [W] is the power consumption of the operator for activity

i.

4. Exergy analysis

Exergy is defined as the maximum obtainable work from a system, also called work potential. Unlike energy which is conserved, exergy is not conserved and it can be destructed in a system based on the second law of thermodynamics. Because there are no chemical reactions taking place in the CNC milling process, the chemical exergy is not taken into account in this study. Additionally, under the environmental temperature T0 (dead state), exergy transfer accompanying heat transfer in and out of the CNC milling system is zero. Therefore, the exergy balance equation of the CNC milling system can be expressed as:

where

Exin [J] is the total exergy inputs to the CNC milling system;

ExMT,in [J]and

ExOP,in [J] represent the electrical exergy and mechanical exergy input respectively;

Exworkpiece,in [J],

Exair,in [J],

Extool,in [J] and

Excooling,in [J] represent input exergies of the workpiece, compressed air, cutting tool, and cooling liquid respectively;

Exair,out [J],

Extool,out [J] and

Excooling,out [J] represent output exergies of air, worn cutting tool and cooling liquid respectively;

Exchip,out [J] is the exergy of chips;

Exloss [J] is the total exergy loss of CNC milling system;

Exproduct,m [J] is the output mass exergy of the finished workpiece;

Exproduct,w [J] is the additional exergy of the finished workpiece and the value of it is equal to the electric energy consumption of machine tool used to remove material from workpiece ”

Ecutting”.

The electrical energy consumed by the machine tool and mechanical energy provided by the operator is “high-quality energy” which means can be converted into useful work 100%. So, the electrical exergy and mechanical exergy associated with the machine tool and the operator are expressed as:

What needs to be emphasized is that the material flow in the machining process, although the material flow is consistent with the conservation of mass, the availability of the material is changed. For example, after the material removal process, the workpiece is changed into chips and a product. Compared to the workpiece, the availability of metal chips is reduced. But for the product, the required shape and high dimensional accuracy are obtained which leads to the availability of the product increased.

The above-mentioned exergy balance equation is complex because of numerous input and output factors. It can be simplified from the exergy loss perspective, which can be expressed as Equations (21) and (22):

where

Exloss,energy [J],

Exloss,chips [J],

Exloss,air [J],

Exloss,tool [J] and

Exloss,cooling [J] represent the exergy loss of energy consumption, the exergy loss of chips, the exergy loss of compressed air, the exergy loss of cutting tool wear and the exergy loss of cooling liquid dissipation respectively.

The exergy loss of energy consumption means the total energy consumed by the machine tool and operator except the actual energy computation used to remove the material. The exergy loss of chips is calculated by the exergy consumed in recycling chips to produce workpieces. The exergy loss of compressed air means the exergy loss by pressure loss. The exergy loss of cutting tool wear is the exergy apportionment of tool life. The exergy loss of cooling liquid dissipation can be described as mass exergy transfer. The specific calculation models for different kinds of exergy loss are presented in

Table 3.

In Equation (26),

Ttool [min] is the cutting tool life and it can be obtained as the following empirical formula [

37]:

where

Vc [m/min] is the cutting speed,

fz [mm] is the feed per blade,

ap [mm] is the cutting depth,

ae[mm] is the cutting width.

In order to describe the exergy efficiency of the CNC milling system, specific exergy loss (SEL) is put forward. SEL is defined as the ratio between the total exergy loss and material removal volume. Therefore, SEL is calculated as:

where SEL [J/mm

3] is the specific exergy loss of CNC milling system,

Vchips [mm

3] is the volume of chips. SEL can be used to directly identify the exergy efficiency level of machine processing. The smaller the value of SEL, the more efficient it is, which also means a lower environmental burden.

5. Case study

A three-axis machining center, some workpieces, and an operator form an actual CNC milling system to demonstrate the feasibility of the exergy loss assessment method. The case study consists of two steps. First, a series of cutting experiments were carried out to match the coefficients of the power function, such as the k0, k1, k2, b, and c. Second, a workpiece was machined to demonstrate the exergy loss assessment method.

5.1. Experimental details

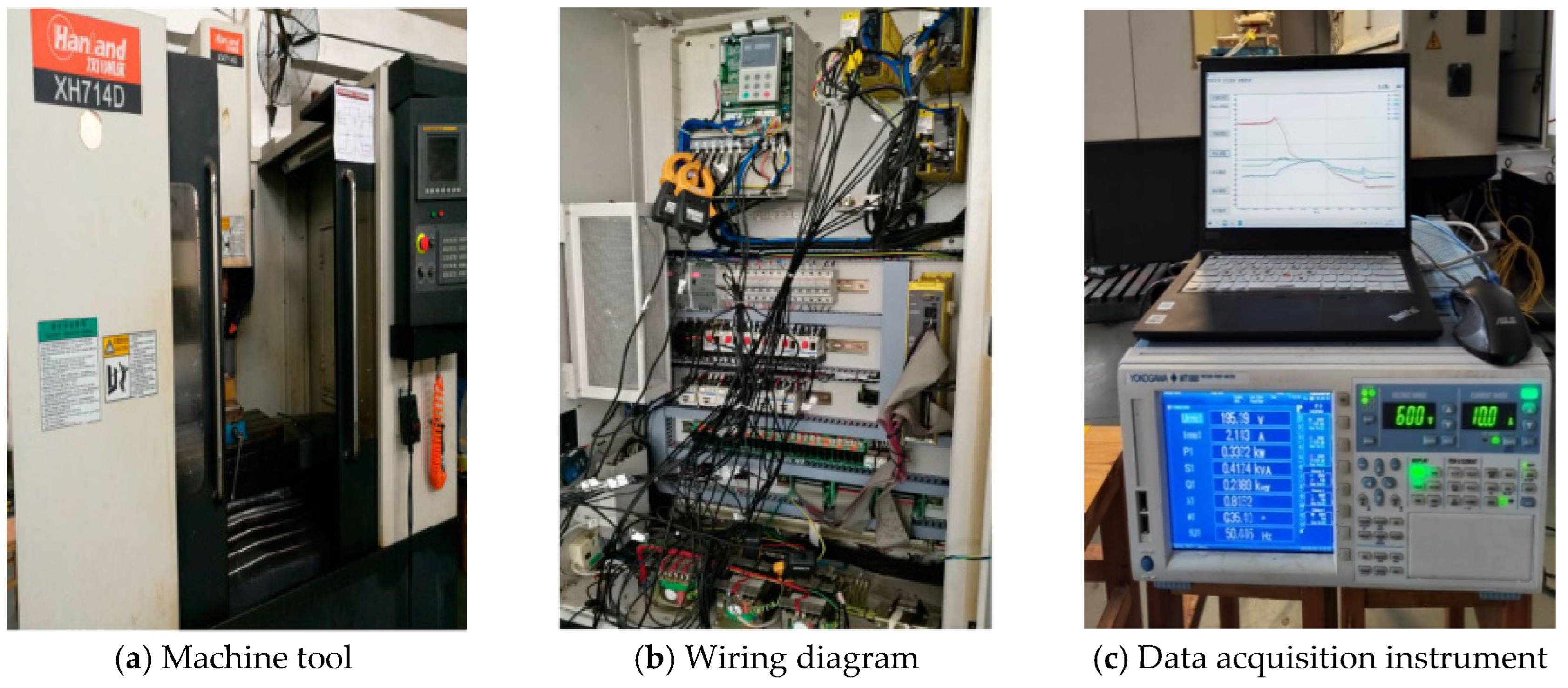

The case study was conducted on an XH714D three-axis machining center made by the Hanchuan CNC Machine Tool Co., Ltd. of China. The power and energy consumption of the machine tool was measured by a Yokogawa WT1800 power analyzer. The power sensor was installed in the electric cabinet and it measured the main power input as shown in

Figure 2. The main parameters of the machine tool are listed in

Table 4. The information about the operator is listed in

Table 5.

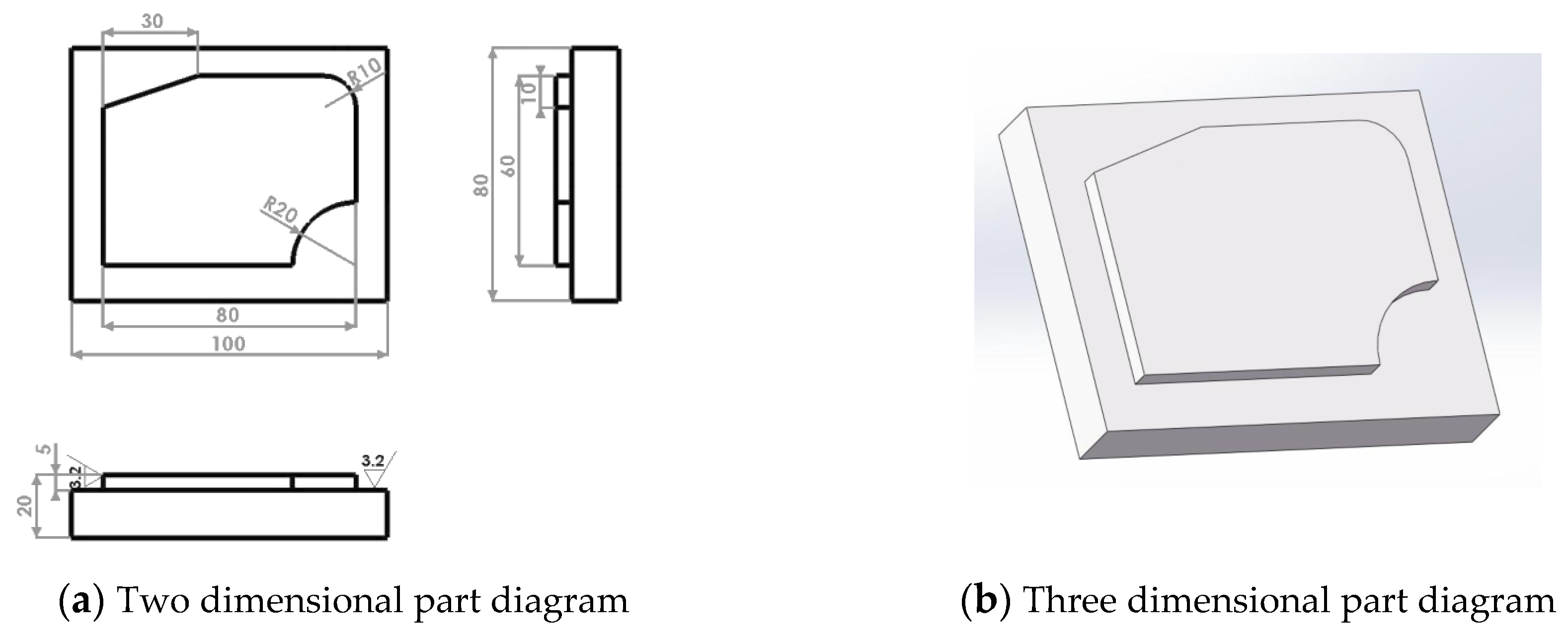

Furthermore, the workpiece with the dimensions 100✕80✕22 mm was used for face milling experiments. The material of the workpiece is medium-carbon steel (C45). The part drawing of the final product is shown in

Figure 3.

According to the dimensions of the workpiece and the part drawing of the product, a face milling cutting tool and a shank cutting tool were used in the upper surface machining and the lug boss machining. The main parameters of the face milling cutting tool and the shank cutting tool are listed in

Table 6. Moreover, the process card was made by the operator as shown in

Table 7. Based on the process card, the NC program was written by the operator.

In this case study, the temperature (T0) and pressure (P0) of the environment were 298.15 K and 0.1 MPa respectively. The density, melting temperature, and energy consumption per unit of material smelting of chips were 7.85 g/cm3,1808.15 K, and 9 MJ/kg respectively. For compressed air, the flow rate, pressure, and molar gas constant (R) were 0.2 m3/min, 0.7 MPa, and 8.314 J/(mol·K) respectively. The specific exergy of the cutting tool was 401.5 MJ/kg and there were two tool noses for one blade of the face milling cutting tool. The specific exergy of the cooling liquid was 42.287 MJ/kg and the dissipation rate was 0.00368 g/s.

5.2. Results and discussion

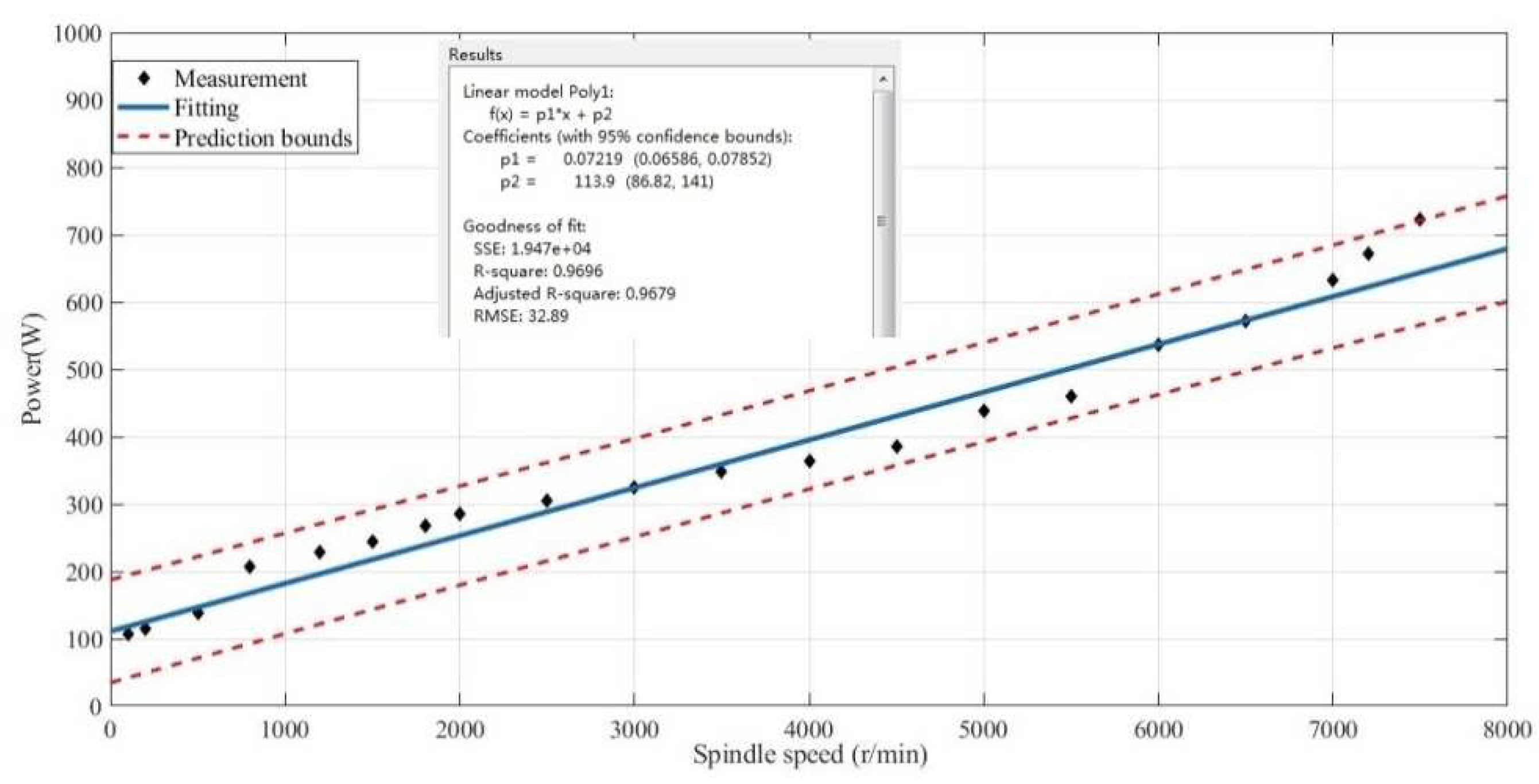

(1) The coefficients of the power model for the machine tool

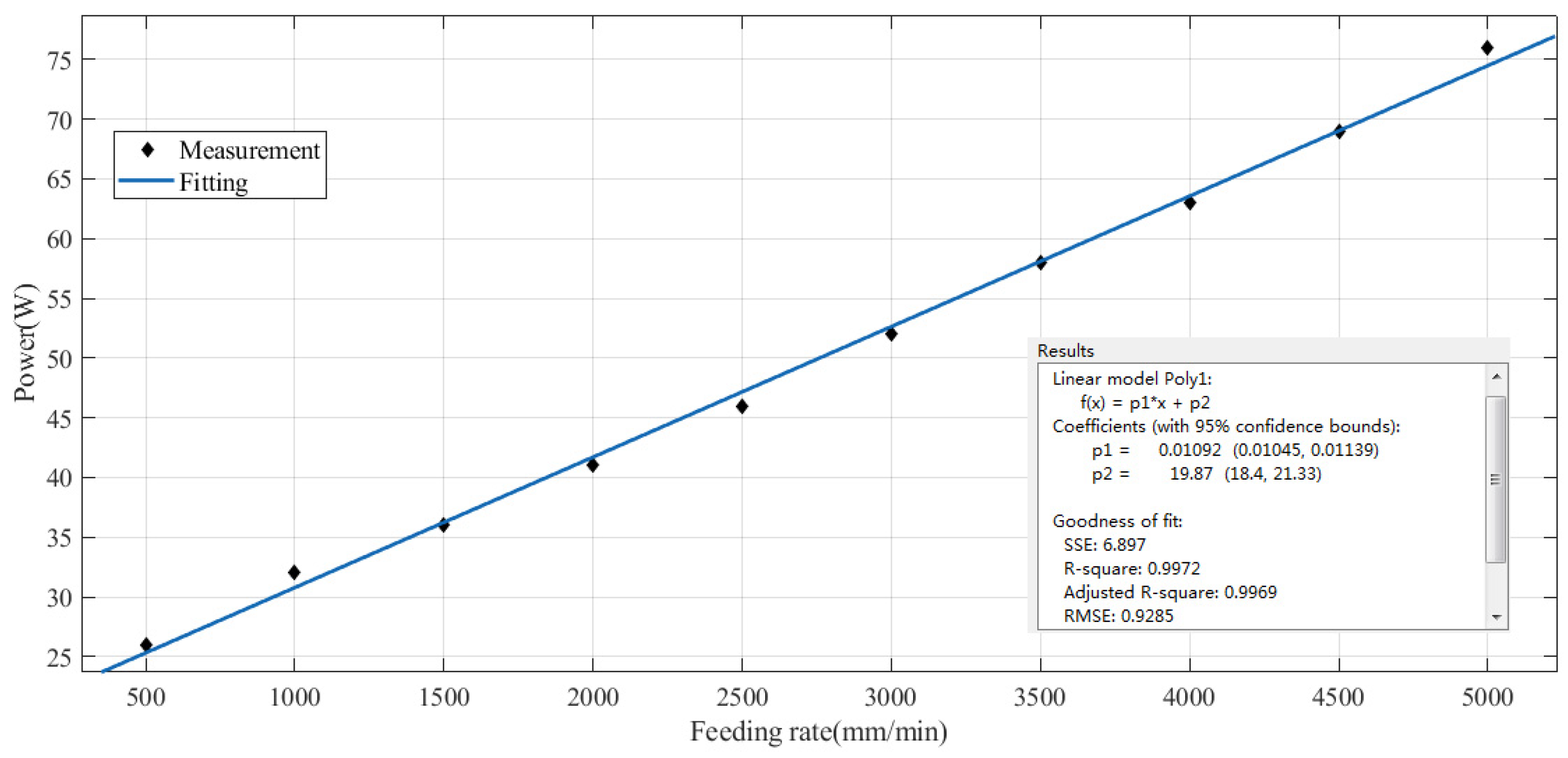

Based on experimental testing and data collection, the standby power was 525W on average and the cooling liquid supplying power was 40W on average. Based on the fitting lines shown in

Figure 4, the spindle rotation power is a function of spindle rotation speed. The fitting result is shown in Table 9.

As for the feed power, it was measured only along the X-axis. With the same situation (the same servo motor and mechanical transmission structure) as the X-axis, the feed power function of the Y-axis was considered the same as the X-axis. The feed power consumption of the Z-axis was ignored owing to low power consumption and low variability. The power consumption for the X-axis or Y-axis movements at defined feed rates is shown in

Figure 5 and the fitting result is shown in Table 9.

The power consumption in the cutting tool tip,

Pcutting (acquired by subtracting air-cutting power from the material removal power), was measured by L

9 orthogonal array tests with four factors and three levels as shown in

Table 8. The fitting result is shown in

Table 9.

(2) Energy consumption analysis for machine tool and operator

Table 10 shows the durations and the energy consumption calculated by energy models for the machine tool and operator in seven machining stages. It can be seen that the energy consumption of the machine tool for machining the workpiece shown in

Figure 3 is 758211 J and the energy consumption of the operator is 169750 J. The energy consumption of the operator is also enormous and should not be ignored. For the machine tool, the results show that most of the energy is consumed in sub-stage 2, sub-stage 1, and stage 3. The values are 324830 J, 194506 J, and 163800 J respectively. As for the operator, the results show that most of the energy is consumed in stage 3, stage 5, and stage 2. The values are 72871 J, 52585 J, and 17289 J respectively. The energy consumption in cutting tool tip ”

Ecutting” is calculated as 139626 J with Equation (13) and the traditional energy efficiency of machine tool “

ηe” is calculated as 18.42% with Equation (14). It means that the XH714D three-axis machining center is energy-inefficient in machining the workpiece because abundant electrical energy is consumed in sub-stage 1 and stage 3.

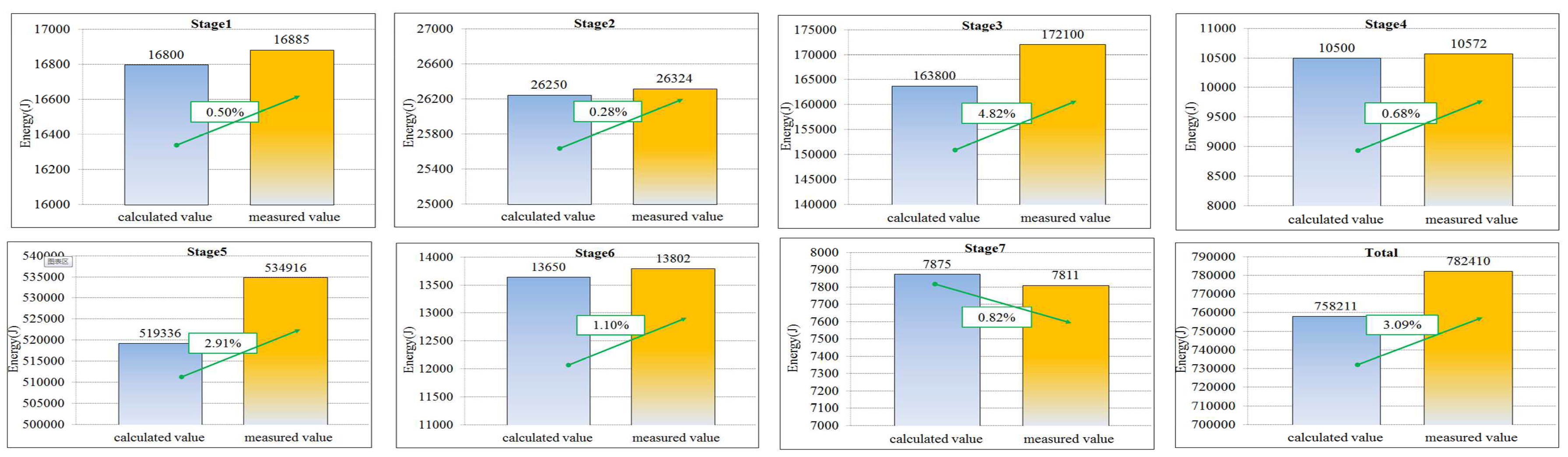

To demonstrate the accuracy of the above-mentioned energy models, the relative errors of calculated and measured values were selected as shown in

Figure 6. It can be seen that the total error between the calculated and measured value of energy consumption of the machine tool in this case study is 3.09%. The maximum error which appears in stage 3 is 4.82%. The main reason for this is that in this paper the machine tool is supposed in a standby state during stage 3. But in fact, the machine tool has other activities resulting in extra energy consumption such as spindle rotating, X-axis feeding, Y-axis feeding, Z-axis feeding, etc. The proposed energy consumption models of the machine tool provide an efficient calculation method with high accuracy of 97%.

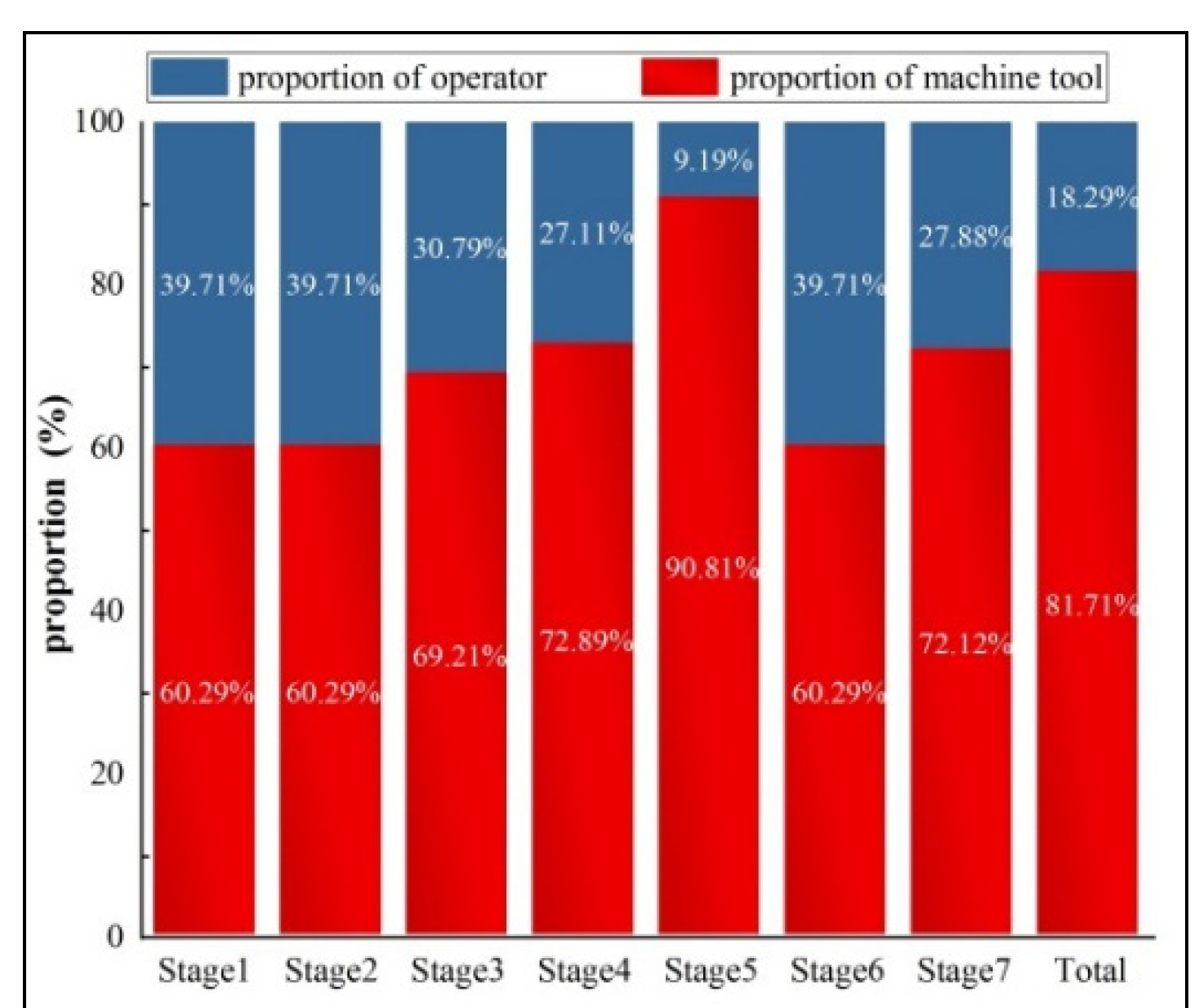

A deeper analysis of the proportions of energy consumption between the machine tool and operator during the seven stages is conducted. As shown in

Figure 7, for stage 1, 2, and 6, the proportions of energy consumption for the operator are all 39.71%. The main reason for this is that during stage 1, 2, and 6, the machine tool is in the state of standby, at the same time the activity intensity of the operator are equal. Meanwhile, for stage 3, 4, and 7, the proportions of energy consumption for the operator are 30.79%, 27.11%, and 27.88%, respectively. The proportion of energy consumption for the operator during stage 5 is relatively low (9.19%). It is because the activity of the machine tool is executing the NC program during stage 5 and the energy consumption is very significant (519336 J). But, the activity of the operator is only standing still. Consequently, the power consumption of the operator is relatively low (112.6 W) and the energy consumption is only 52585 J. What needs to be pointed out is that the energy consumption of the operator accounts for 18.29% of the total energy consumption of the CNC milling system for machining the product. Obviously, the energy consumption of the operator should be taken into account if aiming for accurate and fine exergy loss assessment.

(3) Exergy loss analysis

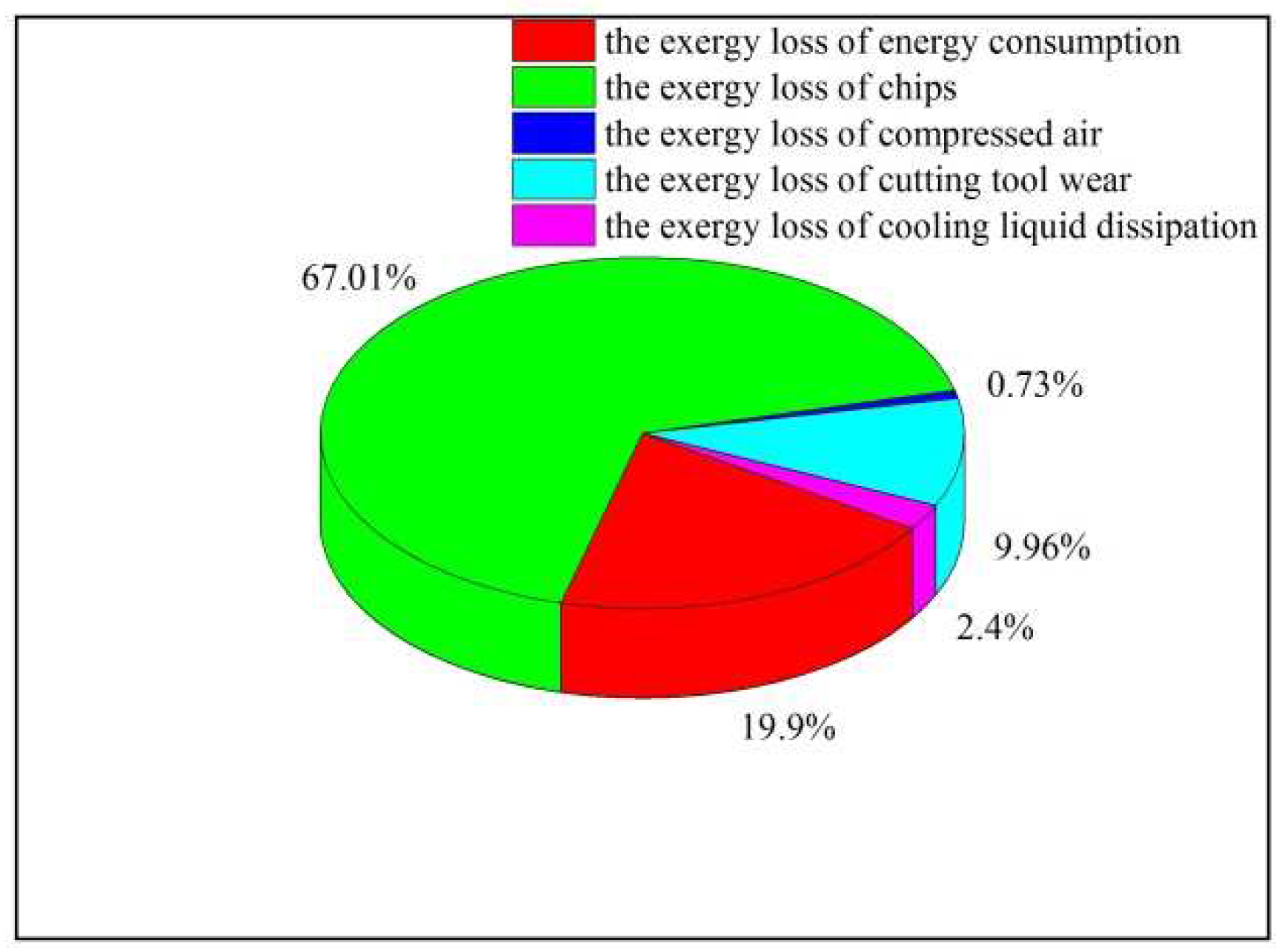

Based on the experiments and calculations of exergy loss models, the values of all kinds of exergy loss are shown in

Table 11. The exergy loss of energy consumption, chips, compressed air, cutting tool wear, and cooling liquid dissipation are 603131 J, 2031404 J, 22023 J, 301868 J, and 2673 J, respectively. Furthermore, the specific exergy loss is calculated as 88.04 J/mm

3 with Equation (29). It means that 88.04 J energy is degenerated or destructed for unit material removal of the workpiece, which includes electrical energy consumption by machine tool, the metabolic energy consumption by operators and material flows consumption, and needs to be reduced for sustainable manufacturing.

The proportion distributions of exergy loss are shown in

Figure 8. In this case, the proportions of exergy loss in five parts in descending order are that the exergy loss of chips accounts for 67.02%, the exergy loss of energy consumption accounts for 19.90%, the exergy loss of cutting tool wear accounts for 9.96%, the exergy loss of cooling liquid dissipation accounts for 2.40% and the exergy loss of compressed air accounts for 0.73%. Obviously, the top three are the exergy loss of chips, energy consumption, and the cutting tool wear.

Generally, the higher the proportion of exergy loss, the greater potential for the total exergy efficiency increasing it is. It can be found that the reduction of the generation of chips is the most effective way to improve the exergy efficiency because it dominates the total exergy loss. In order to reduce the exergy loss of chips, three suggestions have been proposed. Firstly, blanks or workpieces which have similar features in shape and size as the products are selected to reduce the amount of material removed during processing. Secondly, during the product design stage, the lower exergic value materials replace the higher exergic value materials to reduce the exergy loss of chips. Thirdly, use additive manufacturing techniques whenever possible. The exergy loss of energy consumption is the second largest. It is understood that great potential for improvement can also be realized by reducing energy consumption for machine tools and operators. At present, related scholars have done a lot of research on reducing the electrical energy consumption for machine tools, but research about energy consumption evaluation and optimization for operators is very rare which will be one of our future study work. The third largest exergy loss is the exergy loss of cutting tool wear. It is suggested that reduction of the exergy loss of cutting tool wear can be achieved by using wear-resistant blades and choosing suitable cutting parameters to improve the life of the cutting tool. The exergy loss of cooling liquid dissipation and compressed air are both relatively low, therefore they have the lowest promotion potential.

6. Conclusions

CNC milling system is a man-machine cooperative system that is characterized by low energy efficiency and intensive material consumption. However, the energy consumption of the operator in a CNC milling system is often ignored in most existing research. Therefore, existing methods fail to provide a comprehensive understanding of the sustainability of the CNC milling system. In this paper, an exergy loss assessment method based on the second law of thermodynamics is proposed to investigate the sustainability of the CNC milling system, where the energy consumption of the operator, the energy consumption of the machine tool, and material flows are taken into consideration. The energy consumption of the operator, the energy consumption of the machine tool, traditional energy efficiency, exergy loss, and specific exergy loss are characterized by a mathematical modeling approach. In order to demonstrate the feasibility of the proposed method, a case study was carried out on a three-axis machining center (XH714D). The results showed that the energy consumption of the operator and the machine tool are 169750 J and 758211 J respectively. The energy consumption of the operator accounts for 18.29% of the total energy consumption. The exergy loss of energy consumption, chips, compressed air, cutting tool wear, and cooling liquid dissipation are 603131 J, 2031404 J, 22023 J, 301868 J, and 2673 J, respectively. Furthermore, the specific exergy loss is calculated as 88.04J/mm3. The proposed method can bring the following advantages: (i) the energy consumption of the operator is considered and modeled; (ii) detailed power and energy consumption models of all machining process stages are established for the energy evaluation of the machine tool; (iii) a novel exergy efficiency model (SEL) is established to investigate the comprehensive sustainability performance of CNC milling system; and (iv) exergy efficiency improving potentials can be found by exergy loss analysis. The proposed method is also applicable to other machining systems.

In future work, an effective measurement experiment for the energy consumption of operators will be conducted. Exergy efficiency improvement is another important issue. The optimization models of SEL will be thoroughly studied based on this paper.

Author Contributions

Conceptualization, Z.F. and H.Z.; methodology, Z.F.; validation, Y.Y., Y.G. and X.D.; investigation, W.L.; resources, H.Z.; writing—original draft preparation, Z.F.; writing—review and editing, H.Z.; supervision, H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, Grant number 51775392, and 51975432.

Acknowledgments

The authors acknowledge the support and inspiration of the Wuhan University of Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| List of symbols |

|

|

| ap |

the cutting depth [mm] |

MRR |

the material removal rate [mm3/s] |

| ae |

the cutting width [mm] |

n |

the rotation speed of spindle [r/min] |

| b |

the coefficient of the spindle motor |

nair |

the amount of substance of consumed compressed air [mol] |

| c |

the coefficient of the feed motor |

N |

the number of measured value |

| echips |

energy consumption for per unit of material smelting of chips [MJ/kg] |

Ntool |

the number of tool noses for one blade |

| etool |

the specific exergy of cutting tool [MJ/kg] |

P |

the pressure of compressed air [MPa] |

| ecooling |

The specific exergy of cooling liquid [MJ/kg] |

P0

|

the pressure of environment [MPa] |

| EMT |

the machine tool energy consumption for machining a workpiece [J] |

Pstandby |

the machine tool electrical power consumption of standby activity [W] |

| EMT,i |

the machine tool energy consumption of stage i [J] |

Pstandby,i |

the i-th measured value of the machine tool electrical power consumption of standby activity [W] |

| EMT,5-1 |

the machine tool energy consumption of sub-stage 1 [J] |

Pair-cutting |

the power consumption of machine tool during sub-stage1 [W] |

| EMT,5-2 |

the machine tool energy consumption of sub-stage 2 [J] |

Pmaterial removal |

the power consumption of machine tool during sub-stage 2 [W] |

| Ecutting |

the energy consumption in cutting tool tip used to remove material from workpiece [J] |

Pspindle |

the spindle rotation power [W] |

| EOP |

the operator energy consumption for machining a workpiece [J] |

Pfeed |

the feed power [W] |

| EOP, i |

the operator energy consumption of activity i [J] |

Pcooling |

the cooling liquid supplying power [W] |

| Exloss, energy |

the exergy loss of energy consumption [J] |

Pcutting |

the power consumption in cutting tool tip when cutting the workpiece [W] |

| Exloss, chips |

the exergy loss of chips [J] |

rcooling |

the dissipation rate of cooling liquid [g/s] |

| Exloss, air |

the exergy loss of compressed air [J] |

R |

the molar gas constant |

| Exloss, tool |

the exergy loss of cutting tool wear [J] |

S |

the body surface area of the operator [m2] |

| Exloss, cooling |

the exergy loss of cooling liquid dissipation [J] |

SEL |

the specific exergy loss [J/mm3] |

| f |

the feed rate [mm/min] |

ti |

the duration of machining stage i [s] |

| fz |

the feed per blade [mm] |

t5-1 |

the duration of sub-stage 1 [s] |

| H |

the height of the operator [cm] |

t5-2 |

the duration of sub-stage 2 [s] |

| k0 |

the specific coefficient of cutting force |

T0

|

the temperature of environment [K] |

| k1 |

the coefficient of the spindle motor |

Tchips |

the melting temperature of chips [K] |

| k2 |

the coefficient of the feed motor |

Ttool |

the life of cutting tool [min] |

| Lair |

the length of cutting tool moving route during sub-stage1[mm] |

Vc |

the cutting speed [m/min] |

| Lcutting |

the length of cutting tool moving route during sub-stage2 [mm] |

Vchips |

the volume of chips [mm3] |

| mchips |

the weight of the chips [kg] |

W |

the body weight of the operator [kg] |

| mtool |

one blade weight [kg] |

z |

the number of teeth |

| mcooling |

the weight of dissipated cooling liquid |

ηe |

the traditional material removal energy efficiency of machine tool |

References

- PANG, ZQ.; LIU, M. Research on the Current States and Measures of the Investment in the Equipment Manufacturing Industry in Gansu Province. Journal of Lanzhou Commercial College [in Chinese]. 2008, 24, 72–79. [Google Scholar]

- Cai, W.; Liu, F.; Zhou, X.; Xie, J. Fine energy consumption allowance of workpieces in the mechanical manufacturing industry. Energy 2016, 114, 623–633. [Google Scholar] [CrossRef]

- Dahmus, J.; Gutowski, T. An Environmental Analysis of Machining. ASME 2004 International Mechanical Engineering Congress and Exposition, California, USA, –19 2004, pp. 653–652. 13 November.

- Liu, S.; Liu, F.; Hu, S.; Yin, Z. Energy Survey of Machine Tools: Separating Power Information of the Main Transmission System During Machining Process. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 445–455. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Li, M.; Li, Z. Energy modeling method of machine-operator system for sustainable machining. Energy Convers. Manag. 2018, 172, 265–276. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, T.; Dai, Y.; Qu, S.; Zhao, J. Energy consumption considering tool wear and optimization of cutting parameters in micro milling process. Int. J. Mech. Sci. 2020, 178, 105628. [Google Scholar] [CrossRef]

- Han, F.; Li, L.; Cai, W.; Li, C.; Deng, X.; Sutherland, J.W. Parameters optimization considering the trade-off between cutting power and MRR based on Linear Decreasing Particle Swarm Algorithm in milling. J. Clean. Prod. 2020, 262. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 2006, pp. 623–628.

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Li, L.; Yan, J.; Xing, Z. Energy requirements evaluation of milling machines based on thermal equilibrium and empirical modelling. J. Clean. Prod. 2013, 52, 113–121. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S. Therblig-based energy supply modeling of computer numerical control machine tools. J. Clean. Prod. 2014, 65, 168–177. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Lv, J.; Liu, Y.; Ren, D.; Zhang, Z. Therblig-embedded value stream mapping method for lean energy machining. Energy 2017, 138, 1081–1098. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Balogun, V.A.; Edem, I.F.; Adekunle, A.A.; Mativenga, P.T. Specific energy based evaluation of machining efficiency. J. Clean. Prod. 2016, 116, 187–197. [Google Scholar] [CrossRef]

- Cai, W.; Liu, F.; Hu, S. An analytical investigation on energy efficiency of high-speed dry-cutting CNC hobbing machines. Int. J. Sustain. Eng. 2017, 11, 412–419. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Y. A hybrid approach to integrate machine learning and process mechanics for the prediction of specific cutting energy. CIRP Ann. 2018, 67, 57–60. [Google Scholar] [CrossRef]

- Ghosh, S.; Chattopadhyay, A.; Paul, S. Modelling of specific energy requirement during high-efficiency deep grinding. Int. J. Mach. Tools Manuf. 2008, 48, 1242–1253. [Google Scholar] [CrossRef]

- Heinzel, C.; Kolkwitz, B. The Impact of fluid supply on energy efficiency and process performance in grinding. CIRP Ann. 2019, 68, 337–340. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Gong, Q.; Hon, K.K.B. A novel energy efficiency grade evaluation approach for machining systems based on inherent energy efficiency. Int. J. Prod. Res. 2020, 59, 6022–6033. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Z.; Wang, X.; Li, X.; Wang, X.V.; Tuo, J. A generalized method for the inherent energy performance modeling of machine tools. J. Manuf. Syst. 2021, 61, 406–422. [Google Scholar] [CrossRef]

- Tuo, J.; Liu, F.; Liu, P.; Zhang, H.; Cai, W. Energy efficiency evaluation for machining systems through virtual part. Energy 2018, 159, 172–183. [Google Scholar] [CrossRef]

- Tuo, J.; Liu, F.; Liu, P. Key performance indicators for assessing inherent energy performance of machine tools in industries. Int. J. Prod. Res. 2018, 57, 1811–1824. [Google Scholar] [CrossRef]

- Choi, A.C.K.; Kaebernick, H.; Lai, W.H. Manufacturing processes modelling for environmental impact assessment. J. Mater. Process. Technol. 1997, 70, 231–238. [Google Scholar] [CrossRef]

- Munoz, A.A.; Sheng, P. An analytical approach for determining the environmental impact of machining processes. J. Mater. Proc. Technol. 1995, 53, 736–758. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, H.; Wu, P.; Cao, H. A model for analyzing the consumption situation of product material resources in manufacturing systems. J. Mater. Process. Technol. 2002, 122, 201–207. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhou, F.; Zhang, H.; Wang, Y.; Sutherland, J.W. Optimization of machining parameters considering minimum cutting fluid consumption. J. Clean. Prod. 2015, 108, 183–191. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Branham, M.S.; Dahmus, J.B.; Jones, A.J.; Thiriez, A.; Sekulic, D.P. Thermodynamic Analysis of Resources Used in Manufacturing Processes. Environ. Sci. Technol. 2009, 43, 1584–1590. [Google Scholar] [CrossRef] [PubMed]

- Renaldi; Kellens, K. ; Dewulf, W.; Duflou, JR. Exergy Efficiency Definitions for Manufacturing Processes. Glocalized Solutions for Sustainability in Manufacturing: Proceedings of the 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, May 2–4 2011; pp. 329–334. [Google Scholar]

- Renaldi; Kellens, K. ; Dewulf, W.; Duflou, JR. On the Implementation of Exergy Efficiency Metrics in Discrete Manufacturing System: The Dissipative Nature of Production Processes. The 19th CIRP International Conference on Life Cycle Engineering, Berkeley, 2012; pp. 545–550. [Google Scholar]

- Renaldi; Kellens, K. ; Dewulf, W.; Duflou, JR. Resource efficiency assessment of discrete manufacturing processes: Comparison between energy- and exergy-based metrics. Proceedings of EcoDesign 2011 International Symposium, 2011; pp. 645–650. [Google Scholar]

- Salman, P; Mohamed, G. Exergy analysis of metal cutting processes. Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, Arizona, USA, -17 2016, IMECE2016-68035, pp. 1–8. 11 November.

- Salman, P; Mohamed, G. Exergy analysis of a machining operation using finite element (fe) assisted simulations. Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, -15 2018, IMECE2018-88494, pp. 1–9. 9 November.

- Amirmohammad, G.; Yousef, N.; Hossam, K.; Nassir, N. Investigation of sustainability in machining processes: exergy analysis of turning operations. Int. J. Exergy 2015, 17, 1–15. [Google Scholar]

- A, Ghandehariun. ; A, Hosseini.; I, Deiab.; H.M.A, Hussein. Sustainability investigation of drilling: exergy analysis of conventional and peck drilling approaches. Int. J. Exergy 2016, 21, 369–382.

- Li, B.; Cao, H.; Hon, B.; Liu, L.; Gao, X. Exergy-based Energy Efficiency Evaluation Model for Machine Tools Considering Thermal Stability. Int. J. Precis. Eng. Manuf. Technol. 2020, 8, 423–434. [Google Scholar] [CrossRef]

- Wang, CF. Modeling and Experimental Study on Tool Wear Life in High-speed Milling. Manufacturing Technology & Machine Tool [in Chinese]. 2008, 11, 84–87. [Google Scholar]

- Wu, DL.; Zhou, YF. Preliminary study on classification method of physical labor intensity in machinery manufacturing enterprises. JIDIAN ANQUAN [in Chinese]. 2005, 11, 7–13. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).