Submitted:

24 August 2023

Posted:

25 August 2023

You are already at the latest version

Abstract

Keywords:

Introduction

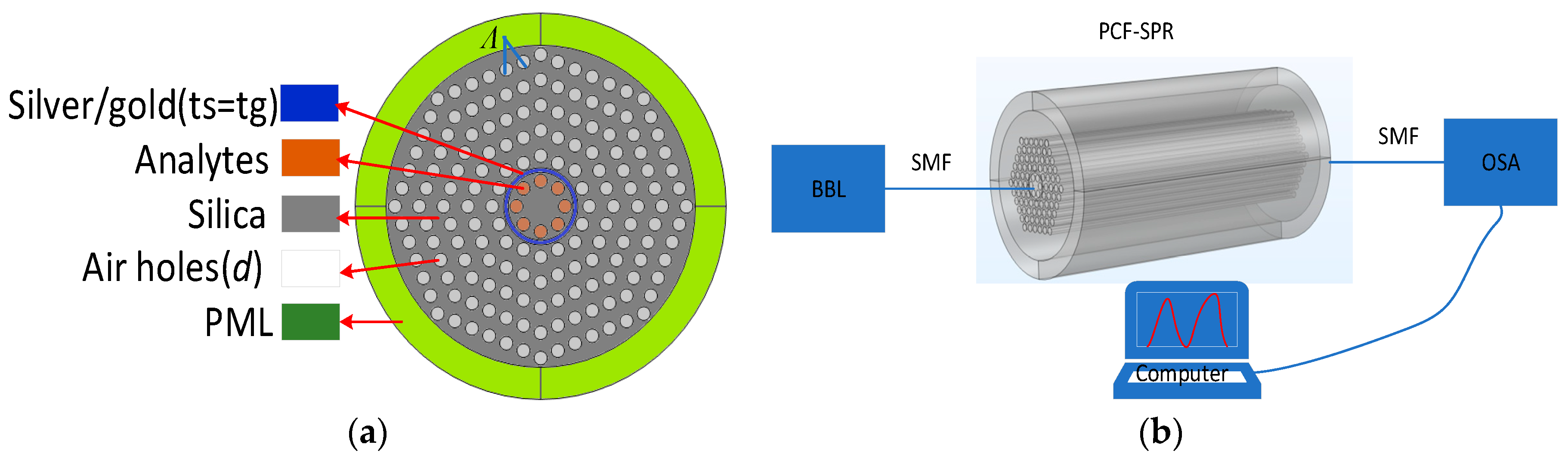

Geometrical Structure and Design

Materials and Methodology

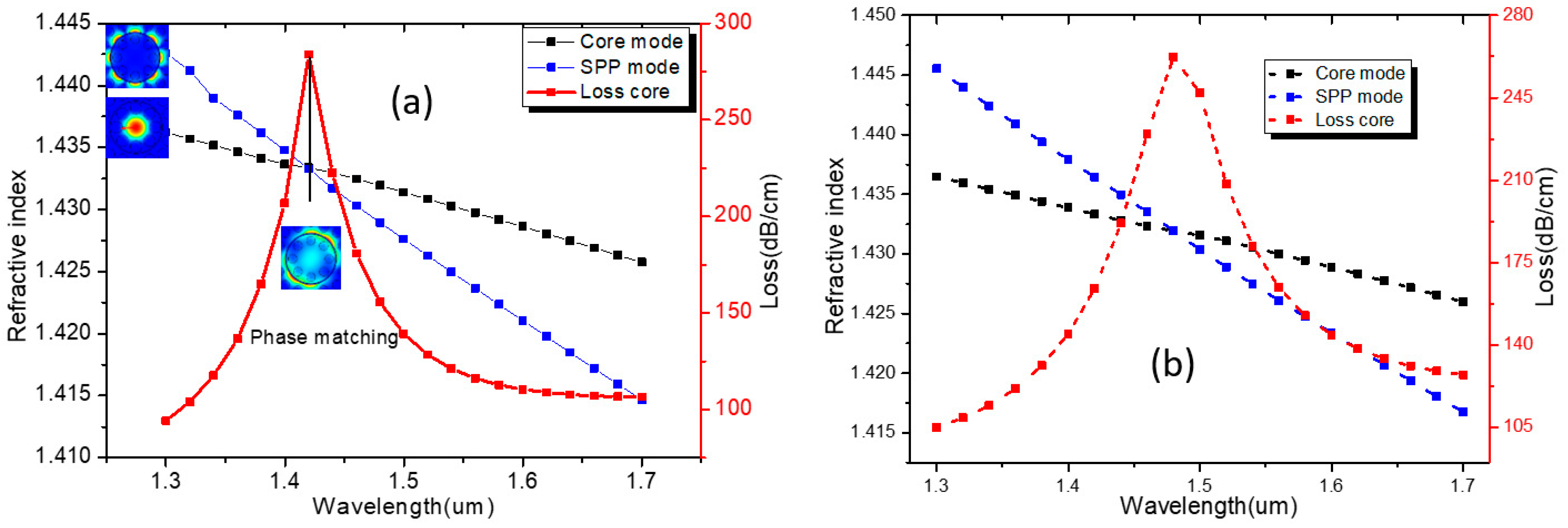

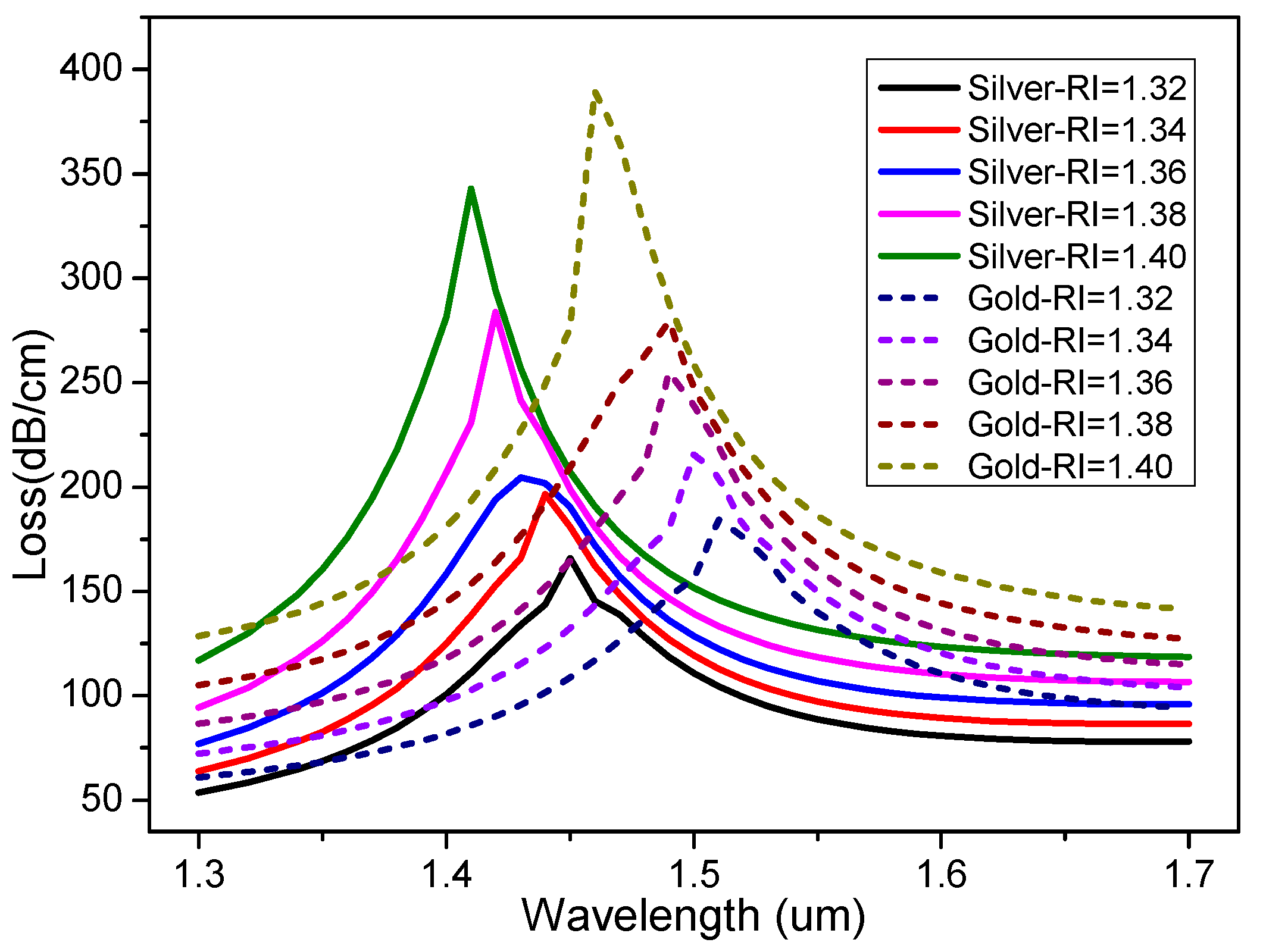

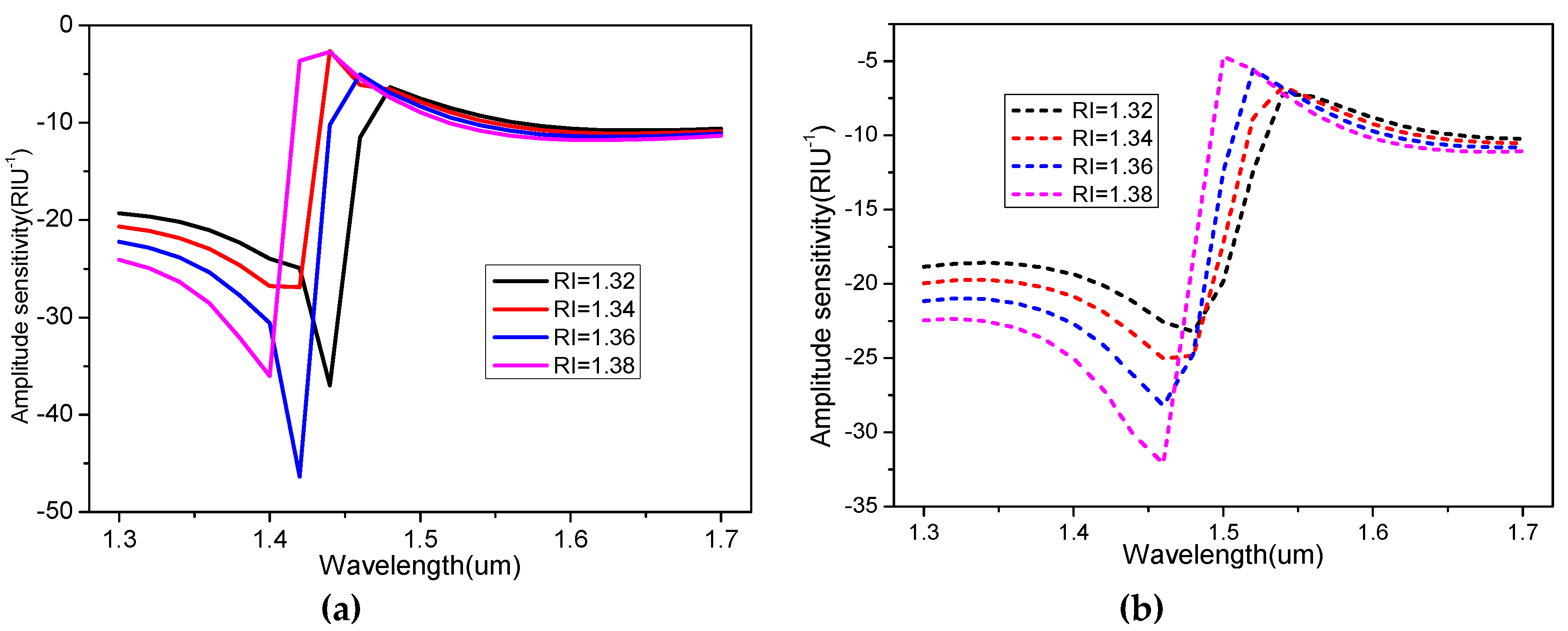

Results and Discussions

Conclusions

Data Availability Statement

Acknowledgment

Conflicts of Interest

References

- Al Mahfuz, M.; Hossain, M.A.; Haque, E.; Hai, N.H.; Namihira, Y.; Ahmed, F. A Bimetallic-Coated, Low Propagation Loss, Photonic Crystal Fiber Based Plasmonic Refractive Index Sensor. Sensors 2019, 19, 3794. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Cardona, N.; Reyes-Vera, E.; Torres, P. High Sensitivity Refractive Index Sensor Based on the Excitation of Long-Range Surface Plasmon Polaritons in H-Shaped Optical Fiber. Sensors 2020, 20, 2111. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Yang, L.; Su, W.; Wang, F.; Sun, T.; Liu, Q.; Mu, H.; Chu, P.K. Numerical analysis of a photonic crystal fiber based on a surface plasmon resonance sensor with an annular analyte channel. Opt. Commun. 2017, 382, 162–166. [Google Scholar] [CrossRef]

- Kamrunnahar, Q.M.; Mou, J.R.; Momtaj, M. Dual-core gold coated photonic crystal fiber plasmonic sensor: Design and analysis. Results Phys. 2020, 18, 103319. [Google Scholar] [CrossRef]

- Yu, H.; Peng, Y.; Yang, Y.; Li, Z.Y. Plasmon-enhanced light–matter interactions and applications. Comput. Mater. 2019, 5, 1–14. [Google Scholar] [CrossRef]

- Yan, X.; Li, B.; Cheng, T.; Li, S. Analysis of High Sensitivity Photonic Crystal Fiber Sensor Based on Surface Plasmon Resonance of Refractive Indexes of Liquids. Sensors 2018, 18, 2922. [Google Scholar] [CrossRef]

- Sharma, A.K.; Jha, R.; Gupta, B.D. Fiber-optic sensors based on surface plasmon resonance: A comprehensive review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar] [CrossRef]

- Sharma, A.K.; Pandey, A.K.; Kaur, B. A Review of advancements (2007–2017) in plasmonics-based optical fiber sensors. Opt. Fiber Technol. 2018, 43, 20–34. [Google Scholar] [CrossRef]

- Lv, W.; Yao, J.; Wang, R.; Luan, N. Surface plasmon resonance sensor based on D-shaped microstructured optical fiber with hollow core. Opt. Express 2015, 23, 8576–8582. [Google Scholar]

- Jin, W.; Li, X.; Wu, S.; Fu, X.; Fu, G.; Bilal, M.M.; Bi, W. Highly sensitive temperature sensing probes based on liquid cladding elliptical micro/nanofibers. Opt. Express 2020, 28, 20062–20073. [Google Scholar] [CrossRef]

- Bilal, M.M.; Bi, W.; Jaleel, F.; Luwen, Y.; Sohail, M.N.; Irshad, M.; Madni, H.A. Magnetic fluid-based photonic crystal fiber for temperature sensing. Opt. Eng. 2019, 58, 072008. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Bozorgzadeh, F.; Ghorbani, M. Designing magnetic field sensor based on tapered photonic crystal fibre assisted by a ferrofluid. Sci. Rep. 2021, 11, 1–9. [Google Scholar]

- Bilal, M.M.; Bi, W.; Liu, X.; Yang, L.; Wa, J.; Madni, H.A. Magnetic field sensor based on the magnetic fluid infiltration into the cladding air holes of the solid-core photonic crystal fiber. Opt. Eng. 2019, 58, 096107. [Google Scholar] [CrossRef]

- Gamal, Y.; Younis, B.M.; Hegazy, S.F.; Badr, Y.; Hameed, M.F.O.; Obayya, S.S.A. Highly Sensitive Multi-Functional Plasmonic Biosensor Based on Dual Core Photonic Crystal Fiber. IEEE Sens. J. 2022, 22, 6731–6738. [Google Scholar] [CrossRef]

- Abdelghaffar, M.; Gamal, Y.; El-Khoribi, R.A.; Soliman, W.; Badr, Y.; Hameed, M.F.O.; Obayya, S.S.A. Highly sensitive V-shaped SPR PCF biosensor for cancer detection. Opt. Quantum Electron. 2023, 55, 1–20. [Google Scholar] [CrossRef]

- Han, Y.; Gao, J.; Lu, J.; Li, Y.; Liu, Y. D-shaped photonic crystal fiber plasmonic refractive index sensor based on gold grating. Appl. Opt. 2018, 57, 5268–5272. [Google Scholar]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt Mater 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Liu, Q.; Lv, J.; Yi, Z.; Liu, C.; Liu, W.; Fu, H.; Hu, C.; Lv, Y.; Wu, X.; Yang, L.; et al. HE1,1 mode excited surface plasmon resonance for high-sensitivity sensing by photonic crystal fibers. JOSA A 2023, 40, 35–44. [Google Scholar]

- Shafkat, A. Analysis of a gold coated plasmonic sensor based on a duplex core photonic crystal fiber. Sens. Biosensing Res. 2020, 28, 100324. [Google Scholar] [CrossRef]

- Mittal, S.; Sharma, T.; Tiwari, M. Surface plasmon resonance based photonic crystal fiber biosensors: A review. Mater. Today Proc. 2021, 43, 3071–3074. [Google Scholar] [CrossRef]

- Weng, S.; Pei, L.I.; Wang, J.; Ning, T.; Li, J. High sensitivity D-shaped hole fiber temperature sensor based on surface plasmon resonance with liquid filling. Photonics Res. 2017, 5, 103–107. [Google Scholar] [CrossRef]

- Khalil, A.E.; El-Saeed, A.H.; Ibrahim, M.A.; Hashish, M.E.; Abdelmonem, M.R.; Hameed, M.F.O.; Azab, M.Y.; Obayya, S.S.A. Highly sensitive photonic crystal fiber biosensor based on titanium nitride. Opt. Quantum Electron. 2018, 50, 1–12. [Google Scholar] [CrossRef]

- Kaur, V.; Singh, S. A dual-channel surface plasmon resonance biosensor based on a photonic crystal fiber for multianalyte sensing. J. Comput. Electron. 2019, 18, 319–328. [Google Scholar] [CrossRef]

- Yasli, A.; Ademgil, H.; Haxha, S.; Aggoun, A. Multi-Channel Photonic Crystal Fiber Based Surface Plasmon Resonance Sensor for Multi-Analyte Sensing. IEEE Photonics J. 2020, 12, 6800515. [Google Scholar] [CrossRef]

- Islam, A.; Haider, F.; Ahmed, R.; Aoni, R.A. Plasmonic photonic biosensor: In situ detection and quantification of SARS-CoV-2 particles. Opt. Express 2022, 30, 40277–40291. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rana, M.M.; Anower, M.S.; Rahman, M.S.; Paul, A.K. Design and analysis of photonic crystal fiber-based plasmonic microbiosensor: An external sensing scheme. SN Appl. Sci. 2020, 2, 1–11. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Rifat, A.A.; Rana, S.; Ali, S. A Highly Sensitive Gold-Coated Photonic Crystal Fiber Biosensor Based on Surface Plasmon Resonance. Photonics 2017, 4, 18. [Google Scholar] [CrossRef]

- Al Mahfuz, M.; Hossain, M.A.; Haque, E.; Hai, N.H.; Namihira, Y.; Ahmed, F. Dual-Core Photonic Crystal Fiber-Based Plasmonic RI Sensor in the Visible to Near-IR Operating Band. IEEE Sens. J. 2020, 20, 7692–7700. [Google Scholar] [CrossRef]

- Bilal, M.M.; López-Aguayo, S.; Szczerska, M.; Madni, H.A. Multi-functional sensor based on photonic crystal fiber using plasmonic material and magnetic fluid. Appl. Opt. 2022, 61, 10400–10407. [Google Scholar] [CrossRef]

- Ramola, A.; Van, V.; Singh, S.; Shakya, A.K. Design of an ultra-sensitive bimetallic anisotropic PCF SPR biosensor for liquid analytes sensing. Opt. Express 2022, 30, 9233–9255. [Google Scholar]

- Zha, F.; Li, J.; Sun, P.; Ma, H. Highly sensitive selectively coated D-shape photonic crystal fibers for surface plasmon resonance sensing. Phys. Lett. A 2019, 383, 1825–1830. [Google Scholar] [CrossRef]

- Sharif, V.; Pakarzadeh, H. High-performance surface plasmon resonance fiber sensor based on cylindrical vector modes. Sci. Rep. 2023, 13, 1–9. [Google Scholar]

- Sharif, V.; Pakarzadeh, H. Terahertz Hollow-Core Optical Fibers for Efficient Transmission of Orbital Angular Momentum Modes. J. Light. Technol. 2021, 39, 4462–4468. [Google Scholar] [CrossRef]

- Ayyanar, N.; Raja, G.T.; Sharma, M.; Kumar, D.S. Photonic Crystal Fiber-Based Refractive Index Sensor for Early Detection of Cancer. IEEE Sens. J. 2018, 18, 7093–7099. [Google Scholar] [CrossRef]

- Ahmed, K.; Jabin, M.A.; Paul, B.K. Surface plasmon resonance-based gold-coated biosensor for the detection of fuel adulteration. J. Comput. Electron. 2020, 19, 321–332. [Google Scholar] [CrossRef]

- Ahmed, K.; Haque, M.J.; Jabin, M.A.; Paul, B.K.; Amiri, I.S.; Yupapin, P. Tetra-core surface plasmon resonance based biosensor for alcohol sensing. Phys. B Condens. Matter 2019, 570, 48–52. [Google Scholar] [CrossRef]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt Mater 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Rifat, A.A.; Rana, S.; Ahmed, K.; Ahmed, R.; Subbaraman, H.; Abbott, D. Spiral photonic crystal fiber-based dual-polarized surface plasmon resonance biosensor. IEEE Sens. J. 2018, 18, 133–140. [Google Scholar] [CrossRef]

- S. Akter and S. M. Abdur Razzak, Highly sensitive open-channels based plasmonic biosensor in visible to near-infrared wavelength. Results Phys. 2019, 13, 102328. [Google Scholar] [CrossRef]

- Zuhayer, A.; Shafkat, A. Design and analysis of a gold-coated dual-core photonic crystal fiber bio-sensor using surface plasmon resonance. Sens. Biosensing Res. 2012, 33, 100432. [Google Scholar] [CrossRef]

- Sakib, M.N.; Hossain, M.B.; Al-tabatabaie, K.F.; Mehedi, I.M.; Hasan, M.T.; Hossain, M.A.; Amiri, I.S. High performance dual core D-shape PCF-SPR sensor modeling employing gold coat. Results Phys. 2019, 15, 102788. [Google Scholar] [CrossRef]

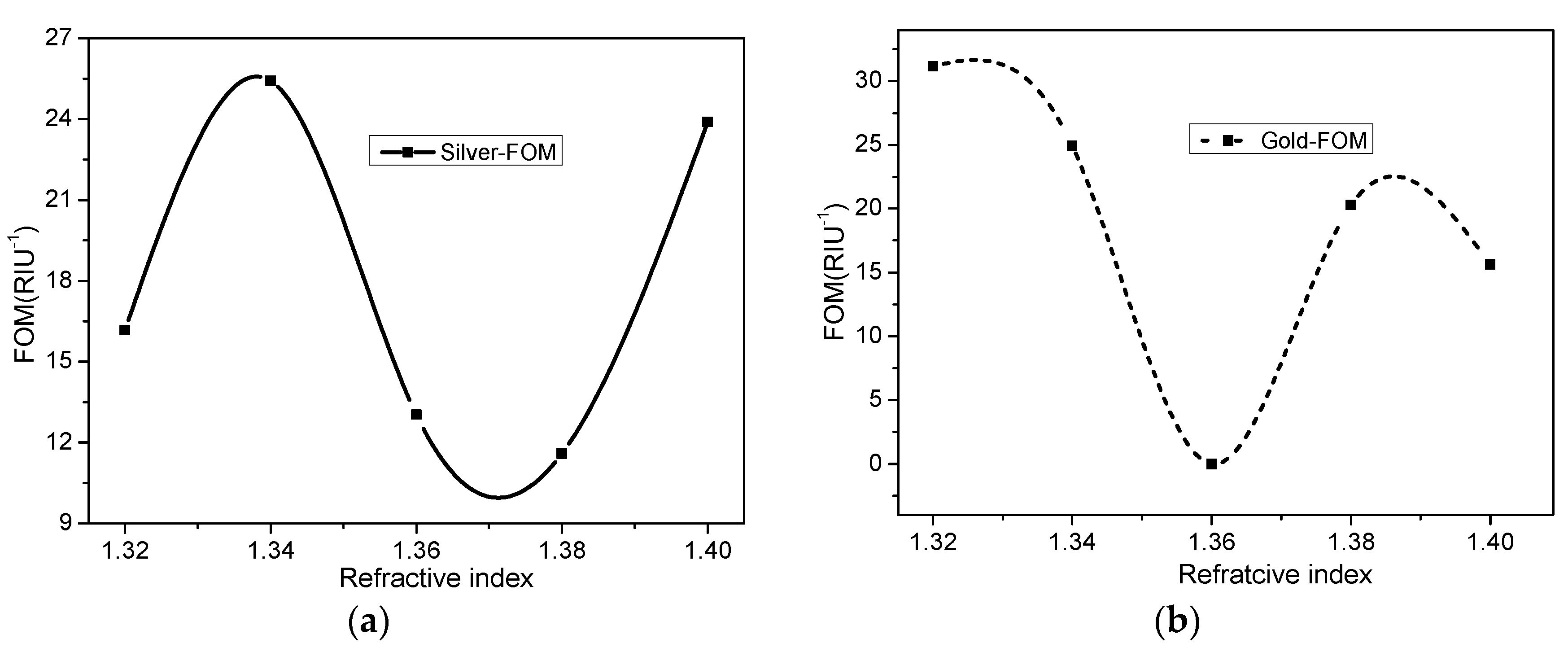

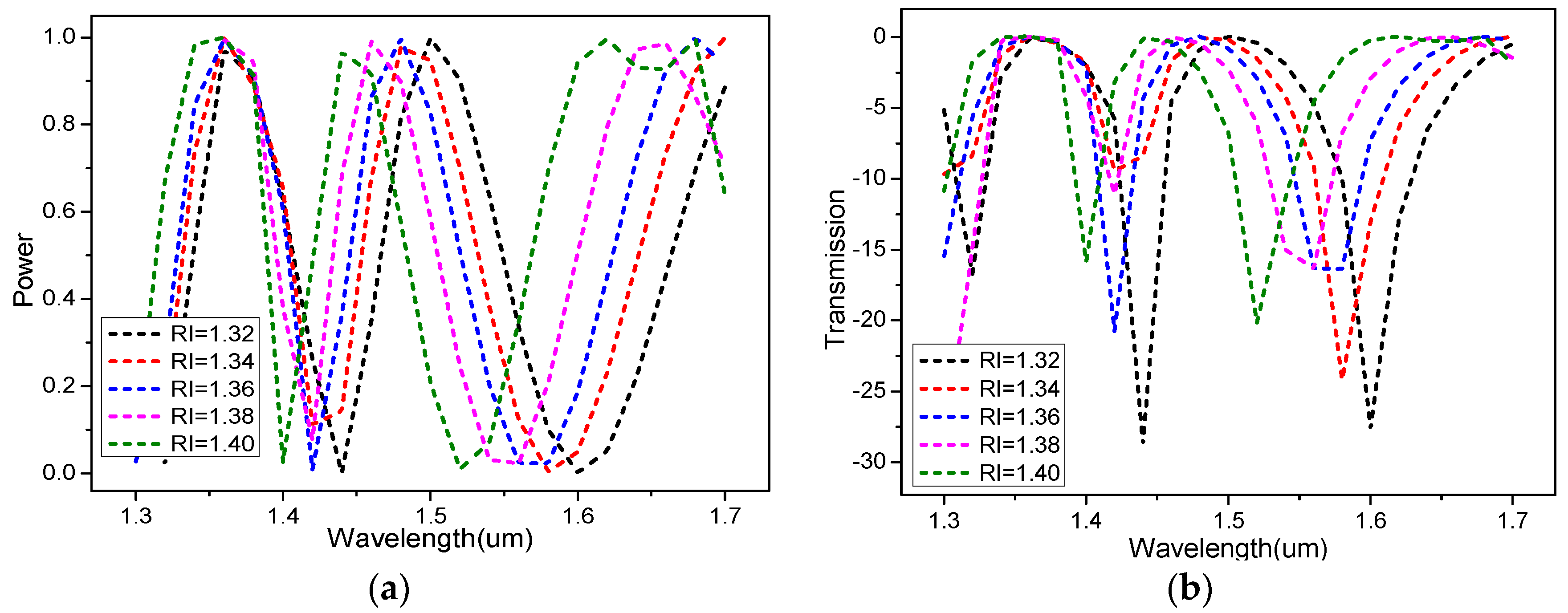

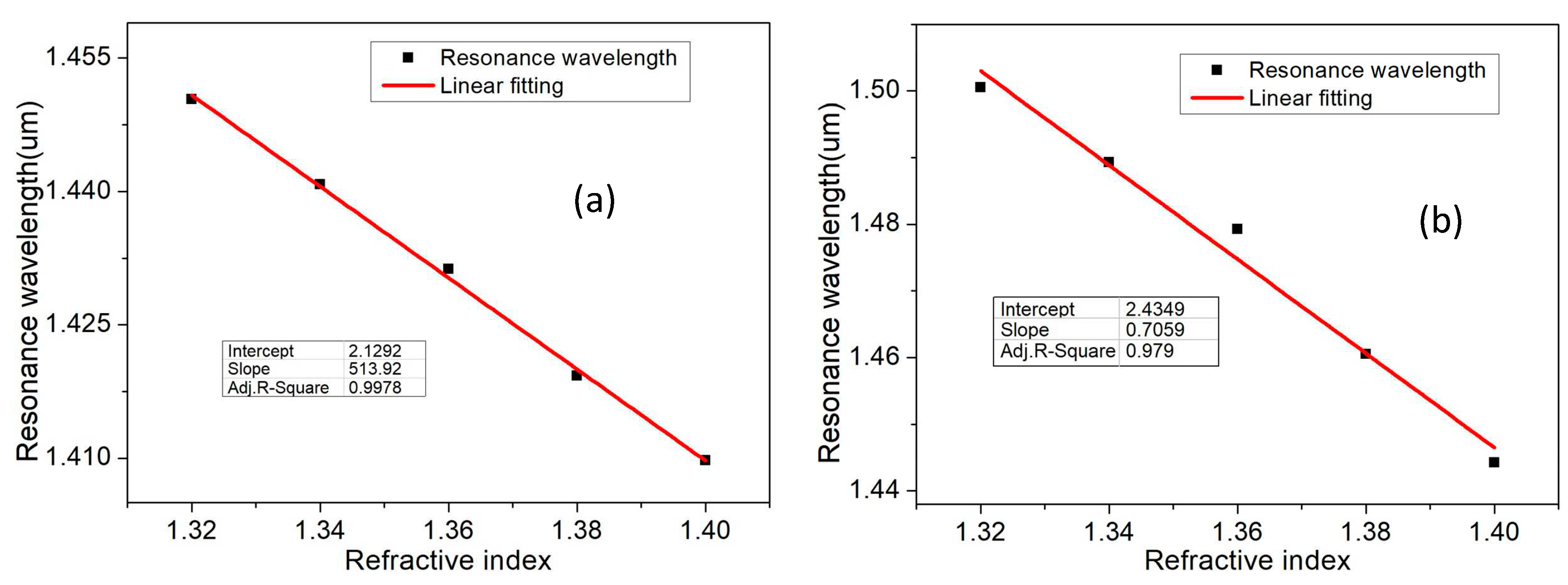

| RI | λpeak[μm] | Sλ[μm/RIU] | R[RIU] | AS[RIU-1] | FOM [RIU-1] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| silver | gold | silver | gold | silver | gold | gold | gold | |||

| 1.32 | 1.451 | 1.519 | 1.100 | 1.151 | 0.010 | 0.0145 | -36 | -23 | 16 | 31 |

| 1.34 | 1.439 | 1.502 | 1.074 | 1.121 | 0.007 | 0.0106 | -27 | -24 | 25 | 24 |

| 1.36 | 1.430 | 1.490 | 1.052 | 1.096 | 0.010 | 0.0087 | -46 | -27 | 12 | -0.2 |

| 1.38 | 1.420 | 1.481 | 1.029 | 1.073 | 0.010 | 0.0111 | -35 | -32 | 11 | 20 |

| 1.40 | 1.409 | 1.469 | 1.006 | 1.049 | ---- | ---- | ---- | ---- | 23 | 15 |

| RI range | WS | AS [RIU-1] | R [RIU] | FOM [RIU-1] | Ref |

|---|---|---|---|---|---|

| 1.33-1.37 | 4200 nm/RIU | 300 | 3.33×10-5 | ---- | [37] |

| 1.33-1.38 | 4600 nm/RIU | 420 | 2.17×10-5 | ---- | [38] |

| 1.33-1.40 | 5000 nm/RIU | 396 | 2.0×10-5 | 47 | [39] |

| 1.35-1.40 | 8000 nm/RIU | 1443 | 12.2×10-6 | ---- | [40] |

| 1.45-1.48 | 8000 nm/RIU | 700 | 1.78×10-5 | 138 | [41] |

| 1.32-1.40 | 513 μm/RIU | -46 | 0.0145 | 31 | Proposed work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).