1. Introduction

Water is one of the most valuable natural resources of the world and alongside air and soil, they support our environmental ecosystem. It is a vital resource for a variety of human activities from domestic to industrial applications and also provides the living environment for marine biodiversity. Despite this integral support, global industrialization and advancement in technology are associated with the generation of different types of wastewater into our environmental ecosystems. On another hand, the demand for petroleum resources has continued to rise in many parts of the world as a means to increase the economy. This process of petroleum production and refining is also associated with the generation of large volumes of wastewater which contains hazardous pollutants that some of which are highly toxic even at low concentrations (Salem and Thiemann 2022; Al-Khalid and El-Naas 2018). The impact of the environmental pollution caused by petroleum refinery wastewater (PRWW) is widely manifested in different areas including affecting aquatic life, destructing natural land for agricultural production and contaminating groundwater resources (Yu et al., 2017). As a result of this, almost all countries nowadays have environmental regulating agencies and departments which are concerned with the aspect of protecting the environmental ecosystem with the United Nations Environment Programme (UNEP) as the leading environmental authority (Zinicovscaia and Cepoi 2016). But on the other hand, the treatment of petroleum refinery wastewater (PRWW) is also becoming a growing challenge in the petroleum industry due to its complex and dynamic nature. Different treatment techniques including; physical, chemical, biological, or hybrid processes have been employed for the treatment of PRWW in the literature. However, many of these processes have their distinct advantages and disadvantages in terms of efficiency, energy requirements and treatment cost. In light of this, more research work is necessary to explore the most appropriate treatment techniques that are cost-effective as well as environmentally friendly. Therefore, the review article aims to critically provide a fundamental review of the existing knowledge on the conventional, advanced as well as integrated or hybrid treatment techniques of petroleum wastewater reported in the literature and highlight some of the basic challenges or limitations of each technique as well as a discussion for the prospects.

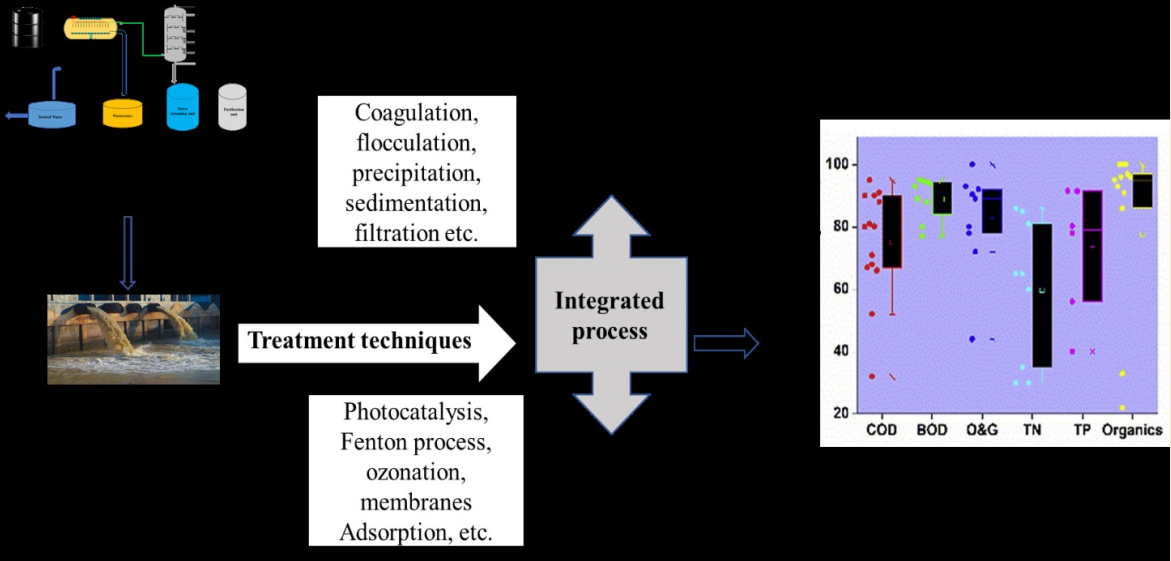

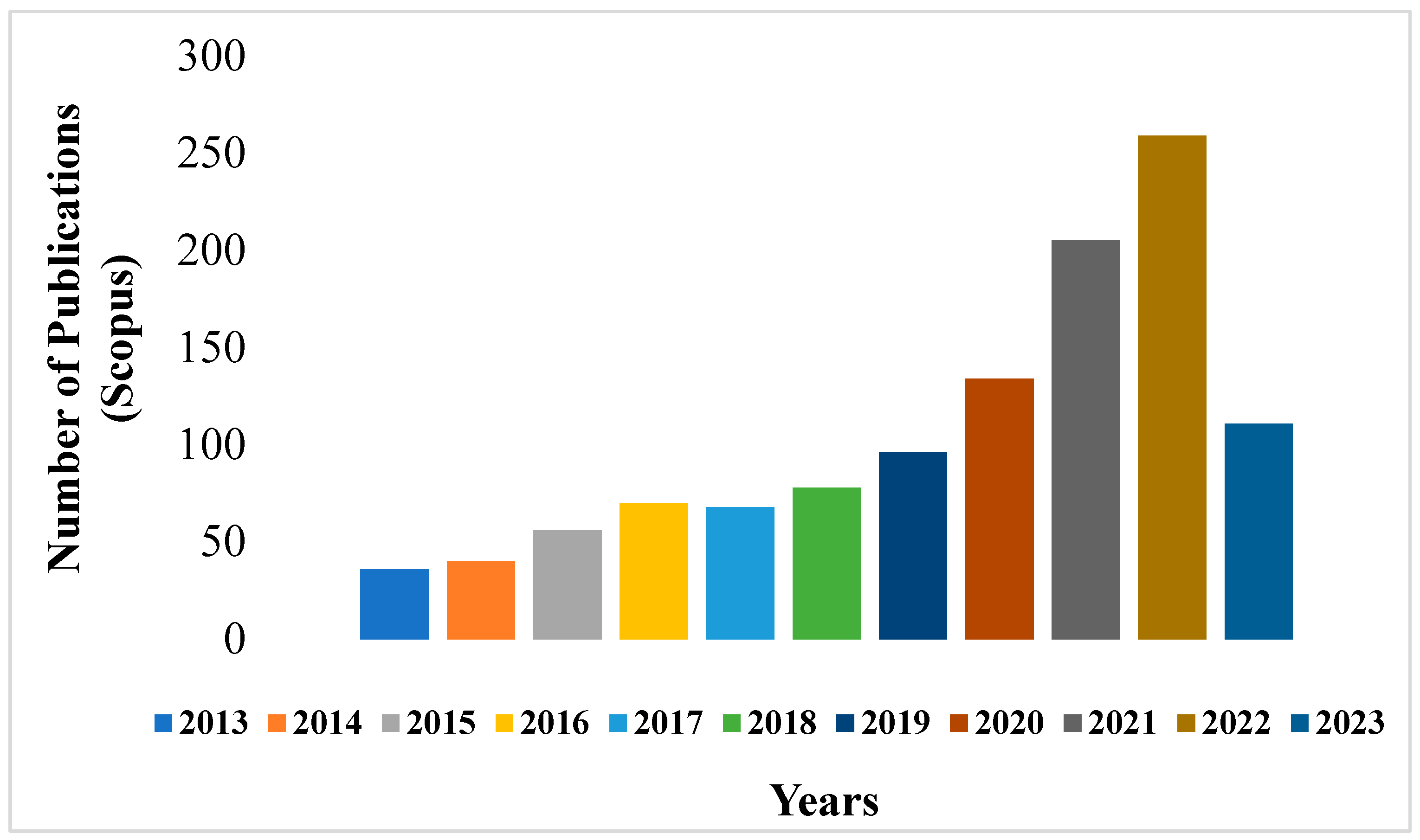

The methodology of the review is set on the search for the findings from recent studies on the conventional and advanced as well the integrated techniques which have been applied to degrade the different pollutants from petroleum refinery wastewater. However, a few articles published from 2012–2015 were also considered as they presented crucial data. The major source of these articles was from the Scopus databases obtained using the search keywords such as “petroleum”, “refinery”, “wastewater pollutants”, “advanced techniques”, “integrated”,” hybrid” and “review”. To determine the range of the available research evidence and identify the literature gap on this theme, a search on the published literature reviews database conducted using the Scopus database for 10 years, between 2013 and May 2023 returned approximately 1,153 papers. About 259 review papers were published in 2022 alone and already 111 reviews were published in the current year 2023 (

Figure 1). The search to find the most effective treatment method in the changing phase of petroleum wastewater has significantly derived much interest leading to more publications within these years. There have been several comprehensive reviews such as (Elmobarak, et al. 2021; Mokif, et al. 2022; Yu, et 2017; Kulkarni, & Goswami, 2015; Aljuboury, et al. 2017; Jain, et al. 2020; Adetunji, & Olaniran, 2021; Kulkarni, 2016; Rahi, et al. 2021; Abbassi & Livingstone, 2018; Asaithambi, et al. 2021 and Thorat & Sonwani, 2022). However, most of these reviews do not provide a combined critical report of both the conventional and recent advanced as well as integrated techniques used for the treatment of refinery wastewater. Hence, this review attempts to fill this gap with a focus on research mostly undertaken from 2015-2023 periods. The data collection involved several steps, starting from the description of the petroleum industry and the refining process, characterization of the petroleum wastewater and determination of its composition. This is followed by a discussion of the conventional techniques and then the reported advanced and integrated treatment methods. Finally, critical conclusion notes and recommendations for future research prospects were presented.

Figure 1.

Number of published review papers on the treatment of petroleum wastewater on the Scopus database from 2013-2023.

Figure 1.

Number of published review papers on the treatment of petroleum wastewater on the Scopus database from 2013-2023.

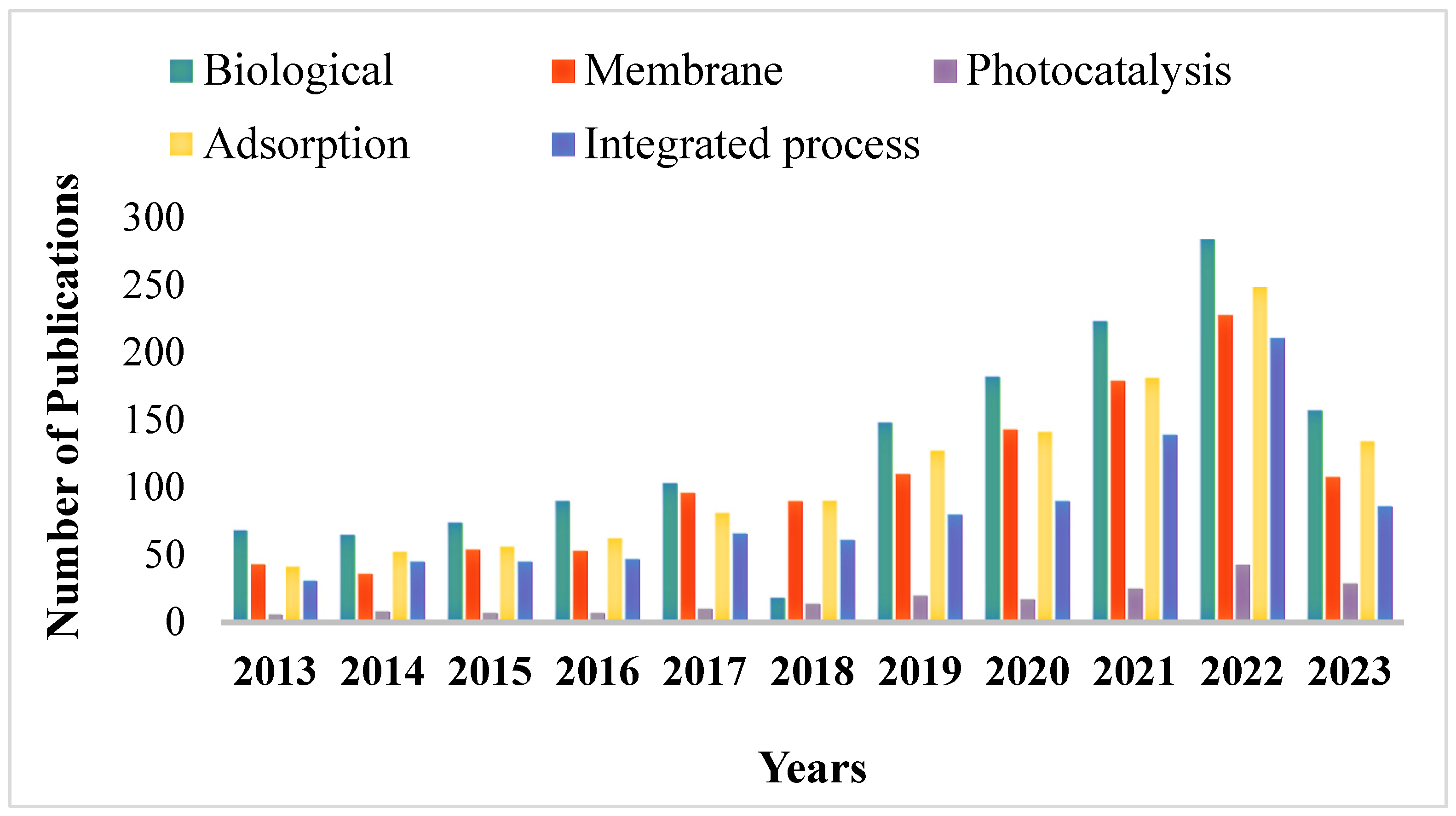

Figure 2.

Number of research articles on the treatment of petroleum wastewater based on different treatment techniques on the Scopus database from 2013-2023.

Figure 2.

Number of research articles on the treatment of petroleum wastewater based on different treatment techniques on the Scopus database from 2013-2023.

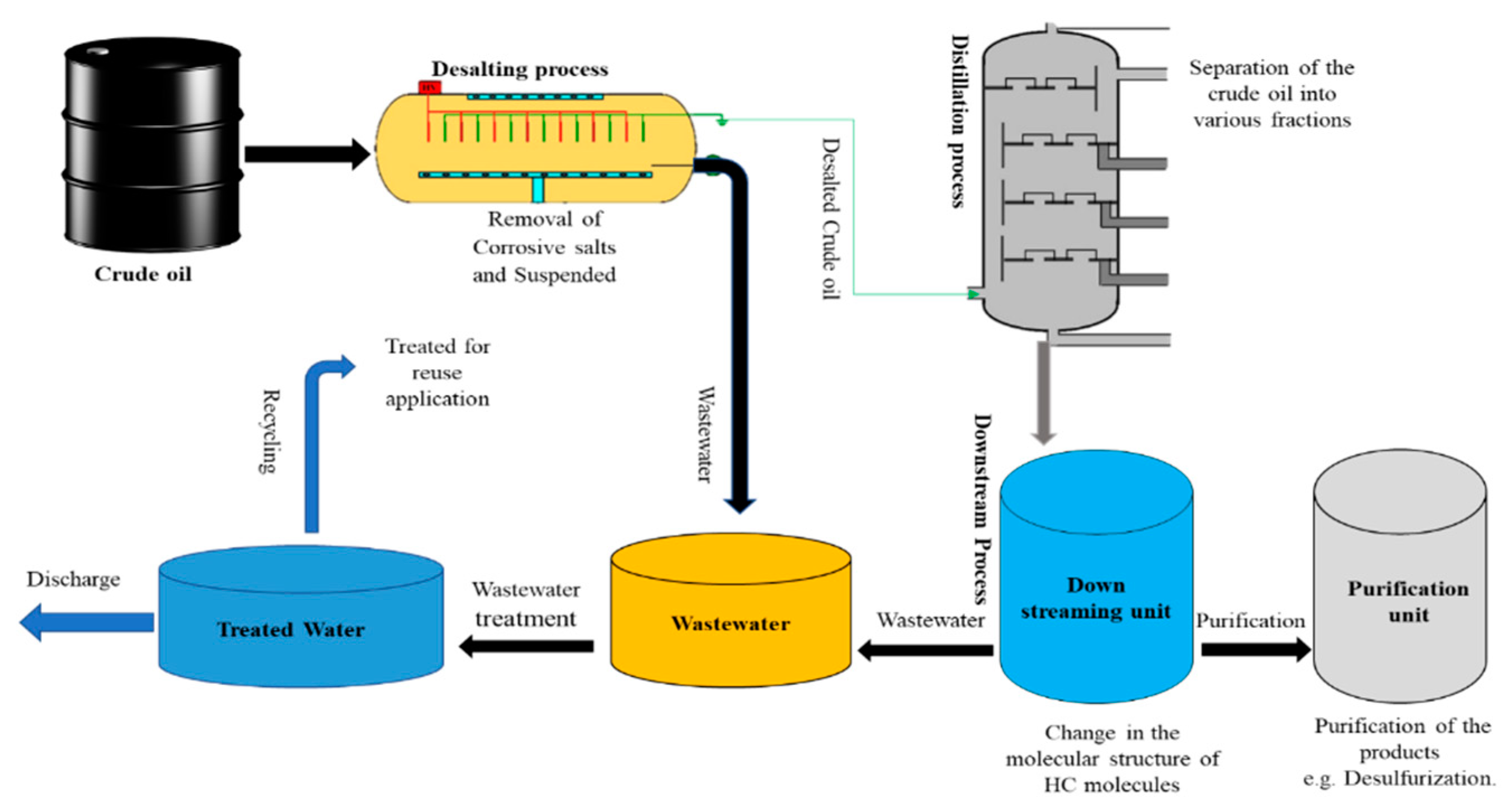

Petroleum refineries are complex industrial systems which are designed to refine crude oil after an exploration into various desired products through distillation, cracking and reforming processes. This categorised the nature of the refining process into three main categories which are separation, conversion and chemical treatment processes (Pinzón-Espinosa 2018). Meanwhile, petroleum is the term used for the unprocessed oil that comes out of the ground source rock during the drilling process and is also called crude oil. It is the fossil fuel that is naturally made from the decaying of plants and animals millions of years ago (Kalair, et al. 2021). During the distillation stage which is also the first refining process, crude oil is separated into its various fractions based on their boiling point temperature to obtain different usable products including solvents, gaseous fuels, gasoline, lubricating oils, grease, waxes and asphalts (Handogo, et al. 2022). A large amount of water is required for the various processes of refining the crude oil including distillation, desalting, hydro heating and cooling. Consequently, these processes generate wastewater which is channelled into a sewer system in most modern petroleum refineries (Rahi et. al. 2021). Meanwhile, the specific industrial operations of every refinery depend on the crude oil type and the choice of refined products. For this basic reason, almost all petroleum oil refineries are unique in their operations and hence, distinctive from one another (IPIECA, 2010). However, water is a basic requirement for the success of many of the industrial operations in every oil refinery. It is used in various applications including cooling, steam generation, crude desalting, distillation as well as hydrocarbon/chemical processing (Al Zarooni and Elshorbagy 2006; Whale et al. 2022). Hence, petroleum refineries generate a large volume of effluent which is characterized by a composition of large quantities of crude oil products, suspended solids, polyaromatic hydrocarbons (PAHs), sulphides, ammonia, phenols, metals and their derivatives (Mustapha, 2018; Diya'uddeen et al., 2011).

Figure 3.

Simplified crude oil refining process and generation of the PRWW.

Figure 3.

Simplified crude oil refining process and generation of the PRWW.

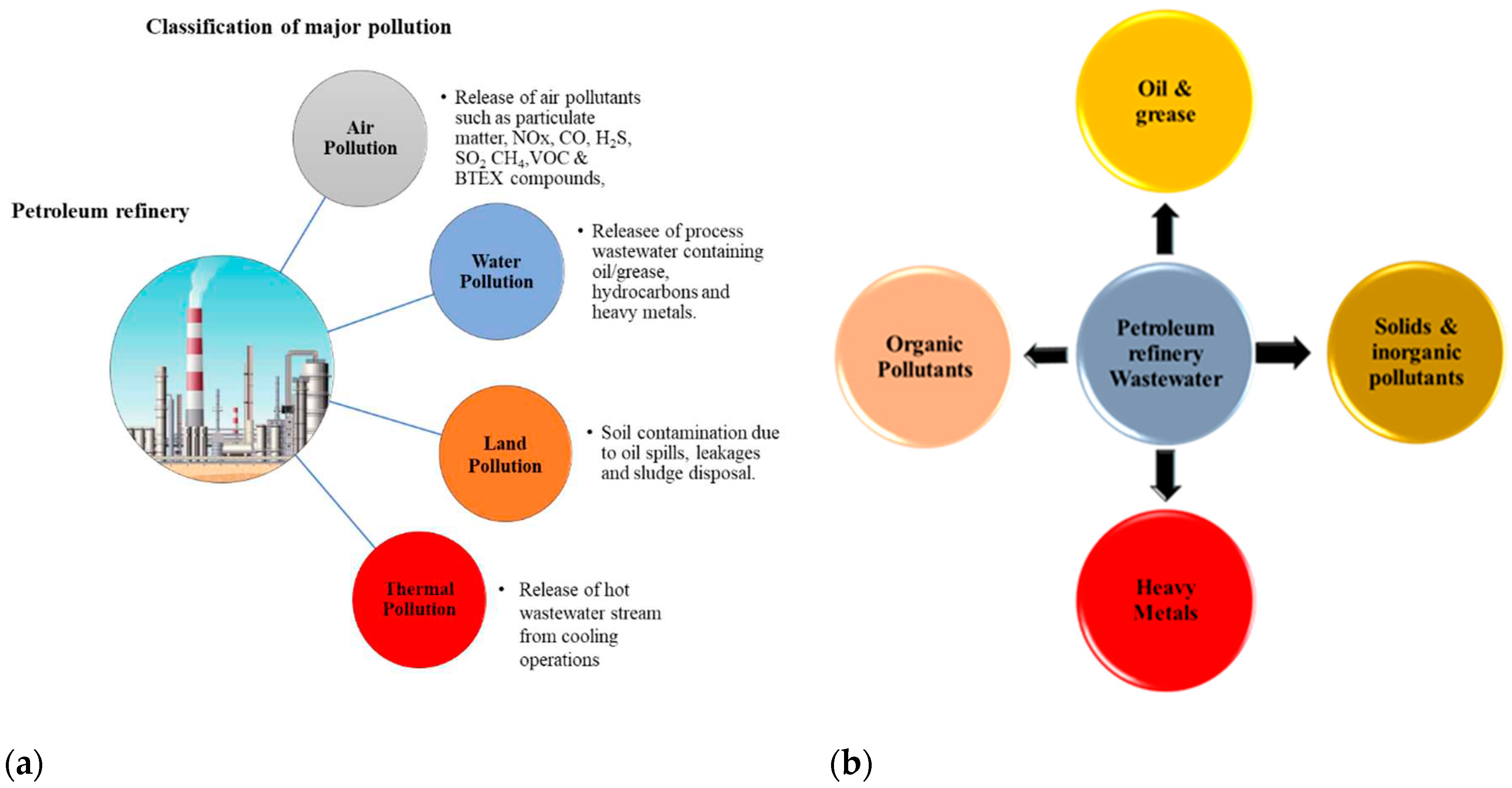

The activities of petroleum refineries usually have the potential to contribute to the contamination of our environmental ecosystem. As a gigantic refining industry, there is associated potential pollution which affects the qualities of the atmosphere, water and land where the industry makes its operations. Toxic air pollutants such as particulate matter (PM), carbon monoxide (CO), nitrogen oxides (NOx), Sulfide (SO2), hydrogen Sulfide (H2S), methane (CH4), BTEX, volatile organic compounds can be released during the petroleum refining process and constitute the major atmospheric pollutants (Polvara, et al. 2021). Soil contamination during the petroleum refining process is usually less significant compared to air and water pollution. However, post-refining practices may eventually lead to oil spills and leakages from pipelines and trucks during the distribution stage of refined petroleum products. The most significant post-refining soil contamination from the petroleum refinery industry comes from the disposal of wastewater sludge in landfills (Islam 2015). The petroleum refining industry generates a large amount of effluents that when released without appropriate treatment can lead to chronic effects on living organisms. It contains a high concentration of toxic recalcitrant substances originating from the composition of the refining crude oil and hence a serious cause of pollution to the receiving environmental ecosystem (Pal, et al. 2016). Studies have shown that the pollutants that are most responsible for living tissue toxicity are; ammonia, Sulfide, cyanide, phenols and hydrocarbons (Daflon, 2015). The contaminants are usually toxic and a major threat to the environment and human health due to their solubility and long accumulation period in living tissues and environmental substrates (Rahi, et al. (2021; Al-Khalid and El-Naas, 2018;) For example, compounds like phenols which is highly soluble in water can be detected from few concentrations up to 7000 mg/L from a PRWW composition. Furthermore, under favourable reaction conditions, phenols can undergo various reactions such as chlorination and methylation thereby producing more toxic recalcitrants including Chlorophenols and cresols (Al-Khalid and El-Naas 2018). Wang et al., (2015) also reported that Naphthenic acids (NAs) are toxic organic contaminants which can pose a serious challenge in the treatment of PRWW using biological processes. They are usually a key indicator for toxicity from the refining process of heavy crude oils accounting for about 15% of the COD concentration and a major recalcitrant for biodegradation. (Misiti, et al. 2013). Similarly, long-period of exposure to phenols and hydrocarbon compounds such as benzene, toluene, ethyl benzene and xylenes (BTEX) can cause leukaemia and tumours in multiple organs especially the lungs and vascular system infections (Ishak, et al. 2012). Marine species such as fishes and all other aquatic living organisms are also affected by petroleum aromatic hydrocarbons (PAHs) leading to their DNA and cardiac systems damage as well as oxidative stress (Pal, et al. 2016). Similarly, the general marine biodiversity can also be affected by thermal pollution as a result of the disposal of hot wastewater effluent from cooling operations which can increase the temperature of the receiving body of water. Lattanzio (2016) also reported that PRWW contaminants can also end up polluting the groundwater aquifers in cases where some petroleum refining industries adopt deep wells injection practices for the disposal of their wastewater. Subsequently, the contaminants from this wastewater infiltrate into the groundwater aquifers over time. Furthermore, PRWW also contains concentrations of different toxic heavy metals which can create cumulative and adverse effects on the biological systems of living species. Cancer, skin rashes, asthma, weight loss and among other symptoms can be observed in human health as a result of exposure to an elevated concentration of heavy metals (Barakat 2011). Meanwhile, due to the highly complex and dynamic nature of the PRWW pollutants, it is usually difficult to understand their complete chemistry and link their toxicity to the receiving environmental ecosystem (Pinzón-Espinosa and Kanda 2020). Therefore, there is a need for toxicity identification and evaluation (TIE) studies in case of pollution due to PRWW to identify the agents responsible for toxicity and evaluate an effective mitigation and management strategy (Daflon, 2025).

Figure 4.

(a) Major environmental pollution from the petroleum refining industry. (b) Major classification of PRWW contaminants.

Figure 4.

(a) Major environmental pollution from the petroleum refining industry. (b) Major classification of PRWW contaminants.

Since water is a vital and necessary component of the petroleum refinery industry as it is required in various applications, the generation of oily wastewater is always an inevitable aspect of the industry value chain (Whale et al. 2022). Petroleum refinery wastewater (PRWW) effluents are the aqueous form of the waste generated from the crude oil refining process (Bastos, et al. 2021). And the characteristics of the PRWW effluents are very much dependent on the type of crude oil being processed, the refinery plant configuration and the operation procedures (Diya'uddeen et al., 2011; Nacheva, 2011). Hence, it is composed of a diverse range of toxic compounds, such as oil and grease, phenols, sulphides and ammonia, constituting the major source of environmental pollution. Obotey Ezugbe, (2020) reported that for every single barrel of crude oil being processed it generates approximately about 10 barrels of petroleum wastewater. Furthermore, several literature data have indicated that about 1.6 times the volume of refined crude oil is generated as wastewater (Ali, A.M et al. 2017; Al-Khalid and El-Naas, 2018; Rahi, Jaeel and Abbas, 2021). The current global output for PRWW is about 33.5 Mbps from the existing 85 Mbps of crude oil production. And this global output is expected to increase by about 32% by 2030 (Rahi, Jaeel and Abbas, 2021). Precisely, a minimum of about 60-90 gallons of water (approximately 246–341 L) is reported to be used in other to process one barrel of crude oil (El-Naas, Alhaija and l-Zuhair, 2014). These reported data indicate that there is a huge amount of PRWW effluents from the petroleum industry continually being produced and discharged into the world’s main water bodies. As a result, an effective approach must be developed to discharge regulatory requirements and for recycling purposes. Petroleum refinery wastewater (PRWW) is usually characterized by a high level of BOD and COD, suspended and dissolved solids, floating and emulsified oils, metal derivatives, Sulfides, as well as various organic and inorganic contaminants. The wastewater effluents are also usually rich in aromatic organic compounds such as; phenols and polyaromatic hydrocarbons (PAHs), (Aziz and Sabbar (2013); Al Zarooni and Elshorbagy (2006)). The transport fate of these contaminants when discharged into the environment also depends on the conditions and hydrodynamics of the receiving water and the environmental ecosystem (Wake, 2005). Hence, periodic monitoring and evaluation of the quality of the receiving environment for PRWW are required to protect living organisms from the toxicity of these pollutants. Hence, while there is a need for highly efficient and economically vibrant treatment technologies, PRWW effluents on the other hand are considered the main cause of environmental pollution (Beni, et al. 2023).

2. Characterization of Petroleum Refinery Wastewater

The composition of a typical PRWW usually depends on the crude oil qualities as well as the complexity and process configuration of the petroleum refining industry. Petroleum crude oil is a complex mixture of hydrocarbon compounds of different carbon chains and other toxic organics such as phenols, they usually constitute the major organic pollutants in petroleum wastewater (Al-Khalid and El-Naas, 2018). According to Diya’uddeen, et al. (2011) and Whale, et al. (2022), the most significant contaminants that are of environmental concern from PRWW generally include; oil, Phenols, suspended solids, metals, ammonia, dissolved minerals and substances which are responsible for oxygen level depletion as a measure of the biological oxygen demand (BOD) and chemical oxygen demand (COD). Generally, the pollutants from PRWW can be classified into; a) oil and grease b) organic pollutants (which includes the hydrocarbons, organic compounds and all other BOD contaminants) c) inorganic pollutants (including; ammonia, nitrogen, phosphorus, chlorides and other inorganic salts) and d) Heavy metals (Aljuboury et al., 2017; Tengrui

et al., 2007). Therefore, PRWW treatment facilities are usually designed to be capable of the removal of both organic and inorganic contaminants. A typical PRWW effluent is usually characterized by high BOD and COD as a result of the overall distribution of the aliphatic and aromatic hydrocarbons, grease and emulsified oils, ammonia, cyanides and other inorganic substances from the crude oil composition. These contaminants constitute the major environmental pollution as a result of PRWW disposal. It is usually rich in hydrocarbons of three main classes which include; a) The Paraffins comprising low-chain carbon atoms such as Methane (CH4), Ethane (C2H6) and Propane (C3H8); Secondly; b) The Naphthene such as dimethyl cyclopentane and cyclohexane; and c) The aromatic compounds comprising of the benzene compounds and its derivatives (Bayona, et al. 2015). The aromatics are the unsaturated hydrocarbon containing at least one or more benzene ring and their derivatives generally referred to as BTEX (Benzene, Toluene, Ethyl Benzene and Xylene) which are mostly toxic in nature to both human and aquatic species (Tang et al. 2009; Bayona, et al. 2015). Hence, a typical PRWW effluent is usually characterized by high BOD and COD as a result of the overall distribution of the aliphatic and aromatic hydrocarbons, grease and emulsified oils, ammonia, cyanides and other inorganic substances from the crude oil composition (Pinzón-Espinosa, 2018; Al Zarooni and Elshorbagy, 2006). Average reported values for BOD and COD were up to 400 mg/l and 600 mg/l respectively (Al-Khalid and El-Naas, 2018; Pinzón-Espinosa, 2018; Aziz and Sabbar, 2013). Rahi, et al. (2021) reported about 150–250 mg/l, 300–600 mg/l, and 20–200 mg /l for BOD, COD and oils concentrations in desalted PRWW effluent respectively. They further revealed that the level of oil concentration can reach up to 5000 mg/l in the effluents from the bottom of tanks with about 1-100mg/l benzene concentration. Similarly, Elmobarak, et al. (2021) reported a COD concentration of 1200 mg/l in their review of the treatment of PRWW. However, El-Naas, Alhaija and l-Zuhair, (2014) have also reported a COD value in the range of 3600–5300 mg/l. Aljuboury et al., (2017) reported an average concentration of 20 mg/l for Sulphide concentration. A review summary of the characterization of a typical PRWW effluent presented in

Table 2 from different regions of the world shows that concentrations of the pollutants vary significantly from one location to the other. Different level of COD concentration was reported with the lowest being 112 mg/L from Brazil up to 74,800 mg/L from Doha, Qatar. Similarly, the concentrations of heavy metals reported from the literature also varies significantly where some metals like Cadmium is not even detected in some case. The variations in concentrations of the effluent qualities must be attributed to the dynamic complexity of the wastewater which is also related to the difference in the crude oil composition as well as the process configuration of the petroleum refining industry. Overall, these studies have proved the heterogenicity nature of the PRWW effluent. Therefore, advancement in the development of new techniques which would allow the complete identification and proper treatment of emerging contaminants is a major aspect concerning this theme. Due to its high environmental impact, discharge limits for the concentration of the various parameters are always established in every petroleum refining industry for policy compliance (Tetteh and Rathilal 2020). Different review papers and research articles on PRWW including (Diya’uddeen et al. 2011; Aljoubory & Senthilkumar 2014; Radelyuk et al. 2019; Qaderi and Abdolalian 2022; and Eldos, et al. 2022) have reported the discharge standard of the PRWW effluent quality. Based on the reviews, the average effluent qualities reported for pH, BOD, COD, Oil/grease, phenols and total organic carbon (TOC) are 6-9, < 20 mg/l, < 200 mg/l, < 10 mg/l, < 0.25 mg/l, and < 75 mg/l respectively.

Table 1: Characteristics of typical petroleum refinery wastewater reported from the literature.

Table 2.

Concentrations of some heavy metal concentration from typical refinery wastewater.

Table 2.

Concentrations of some heavy metal concentration from typical refinery wastewater.

|

.

|

Parameters |

|

| Location of PRWW |

pH |

BOD (mg/L) |

COD (mg/L) |

TSS (mg/L) |

TDS (mg/L) |

TOC (mg/L) |

NH3 (mg/L) |

Phenols (mg/L) |

Sulphides (mg/L) |

Oil & grease (mg/l) |

Reference |

| Kurdistan region-Iraq. |

7.74 |

155 |

485 |

600 |

800 |

- |

13.7 |

3.5 |

- |

17.36 |

Aziz and Fakhrey (2016). |

| Guangdong China |

---- -- |

1198 |

2554 |

- |

- |

610.93 |

81.2 |

- |

- |

-- |

Dai, et al. (2020) |

| Isfahan, Iran |

6.7 |

174 |

450 |

150 |

- |

119 |

- |

- |

- |

870 |

Saber, et al. (2014) |

| Japan |

8.3–8.9 |

- |

3600–5300 |

30–40 |

3.8–6.2 |

- |

|

11–14 |

- |

- |

El-Naas, et al. (2014) |

| Rawalpindi, Pakistan. |

9.2 |

- |

970 |

42.3 |

1,220 |

- |

|

|

- |

- |

Ul haq, et al. (2020) |

| Nigeria |

7.2 |

107.3 |

232.7 |

86.2 |

276 |

- |

0.7 |

0.17 |

- |

2.9 |

Mustapha, (2018) |

| Not reported |

8.0 |

718 |

1494 |

75 |

- |

-- |

- |

70 |

142 |

- |

Jafarineja (2017). |

| India |

8.0 |

195 |

480 |

315 |

- |

- |

- |

13.8 |

16.8 |

94 |

Ibrahim et al. (2013) |

| Doha, Qatar |

8.3–8.7 |

- |

3970–4745 |

30–40 |

3800–6200 |

|

|

8–10 |

- |

- |

El-Naas, et al. (2016) |

| Mathura, India |

7.82 |

- |

310 |

- |

1910 |

-- |

-- |

- |

- |

- |

Khatoon & Malik, (2021) |

| Republic of Iraq |

8.2 |

23 |

- |

31 |

- |

- |

0.81 |

20.7 |

- |

- |

Aziz and Sabbar (2013) |

| Qatar |

7.8 |

44,300 |

74,800 |

2010 |

41,600 |

5490 |

- |

- |

- |

- |

Eldos, et al. (2022) |

| Arzew, Algeria |

7.3 |

- |

330 |

253.3 |

-- |

391 |

9.5 |

- |

- |

- |

Ghezali, et al. (2022) |

| Sines, Portugal |

7.2 |

- |

1179 |

- |

74 |

-- |

- |

257 |

0.18 |

217 |

Bastos, et al. (2021) |

| Niger Delta, Nigeria |

8.0 |

138 |

350 |

60 |

2100 |

- |

- |

7.35 |

- |

14.75 |

Nkwocha, et al. (2013) |

| Brazil |

8.0 |

8.6 |

112 |

|

930 |

- |

0.7 |

|

- |

- |

Daflon, et al. (2015) |

| Heavy Metals |

|

| Cadmium |

Chromium |

Copper |

Lead |

Manganese |

Iron |

Zinc |

Arsenic |

Mercury |

Nickel |

Reference |

| <0.005 –0.2 |

0.02–1.1 |

<0.002–1.5 |

<0.004–175 |

– |

<0.1–100 |

0.01–35 |

0.01–35 |

<0.001–0.002 |

– |

Elmobarak, et al. (2021) |

| – |

<0.01 |

<0.01 |

0.04 |

0.58 |

5.14 |

0.75 |

<0.4 |

<0.15 |

0.02 |

Khatoon and Malik, (2021) |

| 0.045 |

0.022 |

– |

0.03 |

– |

– |

– |

– |

– |

0.176 |

Hashemi, et al. (2018) |

| ND |

– |

– |

0.0135 |

– |

0.253 |

0.33 |

– |

– |

– |

Wokoma and Edori (2017) |

| – |

1.225 |

0.005 |

0.47 |

– |

– |

0.45 |

– |

– |

– |

Olayebi and Adebayo (2017) |

| < 0.001 |

0.06 |

– |

– |

0.149 |

2.535 |

1.133 |

– |

– |

– |

Igbagara and Ntekim (2021) |

| 0.031 |

2.33 |

0.86 |

2.06 |

– |

2.28 |

7.56 |

|

|

1.03 |

Ghezali, et al. (2022a) |

| 0.054 |

0.025 |

|

0.031 |

– |

0.775 |

0.75 |

– |

– |

0.188 |

Stanley, et al. (2017) |

| 0.026 |

0.04 |

0.03 |

0.01 |

– |

0.88 |

0.03 |

|

– |

– |

Ghezali, et al. (2022b) |

| 5.93 |

– |

– |

– |

– |

– |

– |

2.78 |

1.05264 |

– |

Ugboma, et al. (2020) |

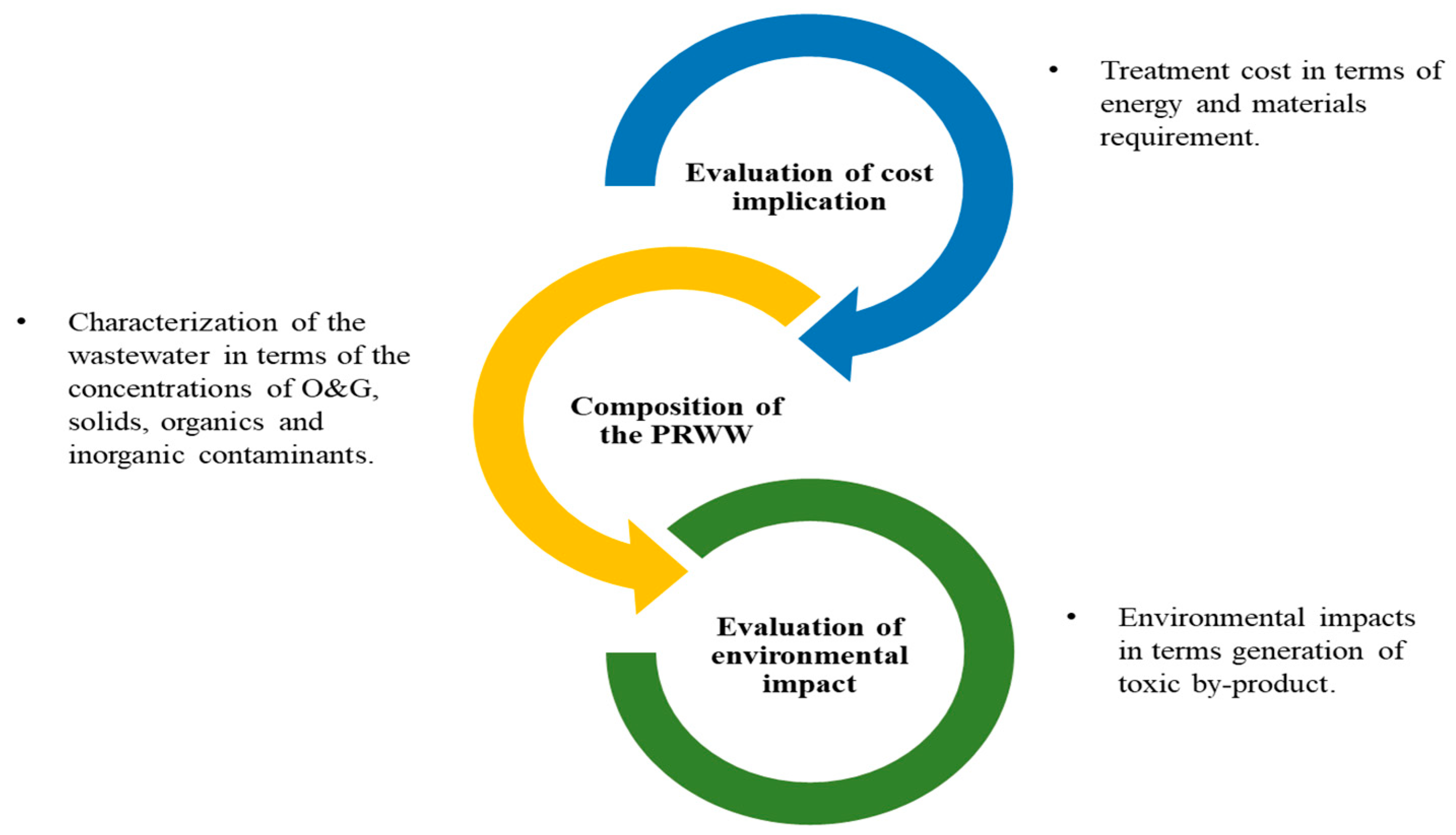

3. Treatment of Petroleum Refinery Wastewater

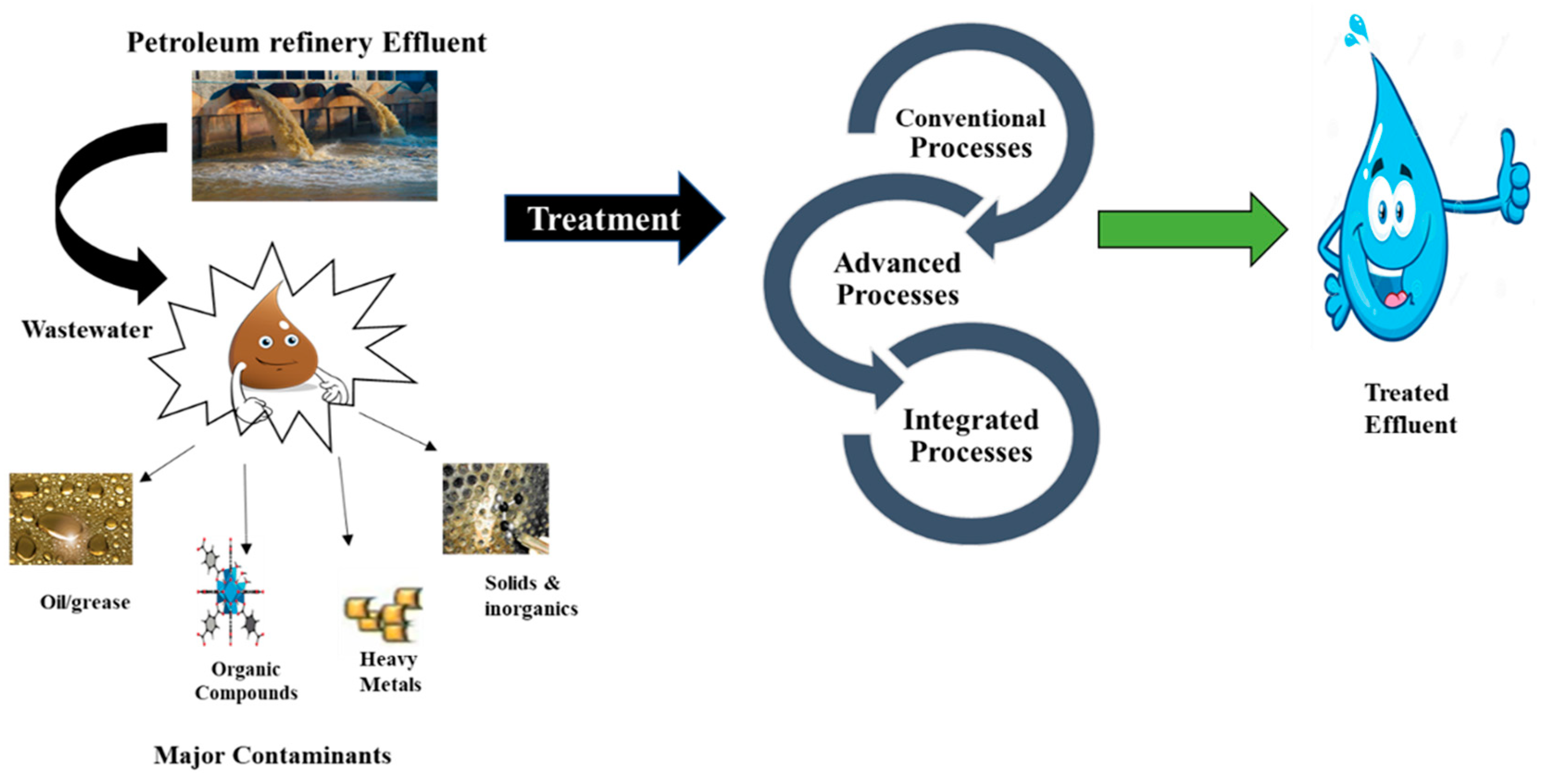

For the fact that petroleum wastewater contains toxic contaminants which are a source of a major threat to the environmental ecosystem, hence it is necessary to receive the appropriate treatment before disposal and to meet the regulatory requirement. Given this, there are various treatment techniques reported in the literature for the treatment of PRWW (Petrowiki, 2018). However, while some already established technologies are efficient in terms of their treatment, cost and energy requirement, others are associated with high energy and maintenance costs and hence as such are not environmentally friendly. Therefore, efficiency assessment in terms of energy requirements, flexibility to treat various contaminants, and level of waste generation as a by-product at the end of the treatment process is very critical in the development and application of any treatment technology (Amakiri et al. 2022). Generally, the treatment of PRWW has two main stages; The pre-treatment stage; is used to reduce the contaminants loads such as oil, grease, and suspended solids. Secondly, the degradation of the pollutants to an acceptable discharge limit (Diya’uddeen, et al. (2011; Aljuboury et al., 2017; Al-Khalid and El-Naas, 2018). Some of the reported treatment techniques in the literature include; biological processes (Tong, et al. 2013; Wang, et al. 2016; Vendramel, et al. 2015; El-Naas 2014; Wang, et al. 2021), coagulation process (Dehghani, 2016; Singh, et al. 2020; Zueva, et al. 2020), adsorption process (El-Naas 2014), membrane processes (Ratman, et al. 2020; Estrada-Arriaga, et al. 2016; Razavi, et al. 2015; Hashimi, et al. 2018 and Kusworo, et al. 2021), chemical oxidation (Nogueira, et al. 2016; Rubio-Clemente), advanced oxidation process (AOPS) (Coelho, et al. 2006; Chen, et al. 2015; Ebrahiem, et al. 2017 Zhang, et al. 2006). In most cases, the determination of the treatment efficiency of these techniques focuses on the efficiency in the removal of the BOD, COD, oils & grease, phenols, Sulphates, TOC as well as concentration of heavy metals. Based on this, advanced oxidation processes such as Fenton-oxidation and photocatalysis are nowadays receiving more attention due to their high capability in the degradation of recalcitrant petroleum contaminants (Aljuboury et al., 2017). Many advances in treatment technologies have been achieved in recent years which can be attributed to advancements in the application of technology in the area of material sciences and dynamic approach to the treatment of the phase of modern and complex pollutants (Abuhasel, et al. 2021). In this paper, a review of the works previously reported using conventional methods as well as advanced and integrated treatment techniques would be discussed.

Figure 5.

Composition of petroleum refinery wastewater and major classification of treatment techniques.

Figure 5.

Composition of petroleum refinery wastewater and major classification of treatment techniques.

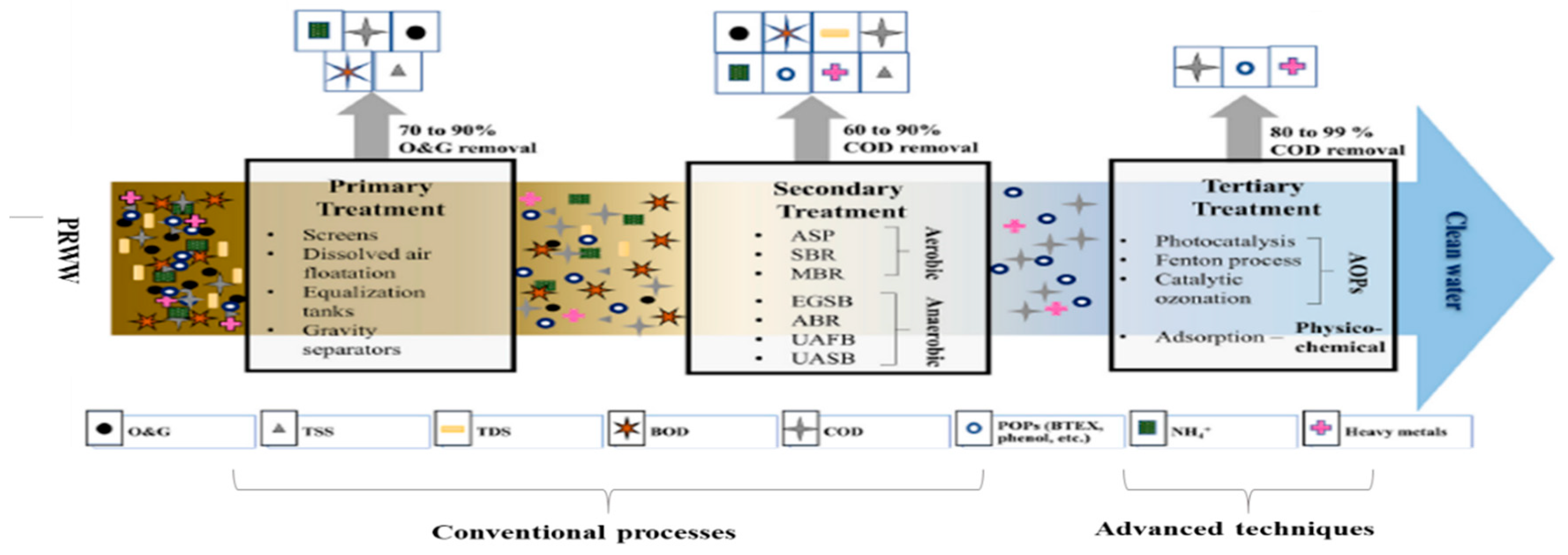

3.1. Conventional Treatment Techniques

Petroleum wastewater effluent can be treated using either conventional, advanced or integrated treatment processes. The conventional treatment techniques include a sequence of mechanical and physicochemical processes, followed by biological treatment of usually activated sludge treatment units. The sequence of the conventional treatment techniques is divided into four; (a) Pre-treatment (b) Primary treatment (c) Secondary treatment (c) Tertiary treatment. Although, the pre-treatment stage is sometimes regarded as part of the primary treatment where the majority of the suspended solids are separated and removed with the help of gravity, sedimentation and filtration processes (Radelyuk, et al. 2019). Conventional techniques have been widely used since the beginning of the 20th century and mainly consist of a combination of physical, chemical, and biological processes. According to Yu, et al. (2017), conventional techniques for the treatment of PRWW include; flotation, coagulation, biological treatment and membrane separation technology. However, these techniques are usually associated with various limitations including, low efficiency, high capital operating cost as well as low sensitivity to emerging complex organic contaminants (Varjani, et al. 2019). Toxic recalcitrant pollutants from hydrocarbon source such as Naphthenic acids (NAs) usually remains a considerable challenge in the treatment of PRWW using biological processes. Furthermore, due to the low efficiency and operational limitations of the conventional techniques, it makes it necessary to adopt more robust advanced treatment systems. The advanced treatment systems which include; advanced oxidation processes, (such as photocatalysis, Fenton-oxidation, and electrochemical processes) have been reported to provide more efficient treatment and less production of waste by-products that may also require further treatment. Alternatively, the use of an integrated or hybrid system which combines two or more advanced processes is also nowadays receiving more attention to provide the most effective treatment for the removal of oil and other hazardous pollutants from petroleum wastewater (Adetunji and Olaniran 2021).

Figure 6.

General overview of the PRWW treatment techniques. (Jain, et al. 2020).

Figure 6.

General overview of the PRWW treatment techniques. (Jain, et al. 2020).

3.1.1. Physicochemical Processes

The physicochemical processes are a set of techniques that combines both physical and chemical properties of the PRWW in the removal of pollutants. The physical part may include the use of filtration, floatation, adsorption and sedimentation while the chemical part includes precipitation and coagulation processes (Aljuboury et al. 2017)

3.1.2. Flotation Sedimentation and Filtration

The physical PRWW treatment processes are the sets of techniques such as screening, floatation, sedimentation and gravity separation that do not require the application of biological or chemical changes during the treatment processes (Aljuboury et al., 2017). They usually constitute the primary treatment processes to reduce the waste load before proceeding to the secondary treatment units (Ahmad et al. 2016). A typical example is the course screening, sedimentation, floatation, and filtration in the removal of large particles, sediments as well as fine grains from the PRWW (Shuokr and Sazan, 2021). The sedimentation process is used for the separation of water and oil due to the density difference between the oil and water. Hence, a significant density difference is required to provide an optimum separation. Oil and water sedimentation can be mechanically achieved using separators such as the API separator which operates on the principle of specific gravity difference to allow the settlement of heavy oil and pollutants (Varjani, et al. 2020). Diffused air flotation (DAF) is achieved by introducing fine air bubbles to enhance the formation of a scum layer between the oil and the water for easy separation. The technique is achieved by introducing air under pressure which would bring the pollutants to rise to the top surface. High levels of total suspended solids, colloids as well as some immiscible liquids are significantly reduced during this stage as they can reduce treatment efficiency and even cause damage to treatment facilities (Renault et al., 2009). Abuhasel, et al. (2021), DAF techniques enhanced by nanobubbles systems were applied along with surfactants in other to reduce the surface tension of the oil concentration. About 90% oil separation efficiency was reported using this system more than the traditional DAF system. Floatation and gravity separation were usually used as the first stage separation process to remove floating and dispersed oil efficiently. However, they are not efficient in terms of the separation of emulsified oil (Abuhasel, et al. 2021; Le et al. 2013). Li, et al. (2013) reported that Wang (2007) applied diffused floatation process to a sedimentation tank of PRWW with an influent oil concentration of 3000-14000 mg/l. An average effluent oil concentration of 300 mg/l with a minimum value of 97 mg/l was achieved using the process. Wang et al. (2015) reported that most conventional physicochemical techniques especially floatation and sedimentation processes do not yield more than 16% to 24% efficiency in the removal of organic aromatic pollutants. Furthermore, high maintenance costs and increased energy consumption were also among the major disadvantages of the DAF system.

3.1.3. Coagulation/Flocculation

The use of coagulants to form flocs as a result of coagulation is also another physicochemical treatment process for the removal of pollutants from PRWW. Iwuozor (2019) reported that coagulants are generally polyelectrolytes or synthetic organic polymers with high molecular which form multi-charged poly nuclear complexes in solution that makes flocs and settle easily. Coagulation processes were reported to be effective to treat heavy metals and high-level concentrations of organic pollutants. Hassan et al., (2012) reported that coagulation/flocculation are the most popular techniques for the removal of pollutants related to turbidity, colour, and TSS. However, it is an inappropriate technology for the complete treatment of organic pollutants, but it is an efficient conventional treatment process used before membrane and biological processes to eliminate or reduce the level of non-biodegradable organic pollutants (Aljuboury et al. 2017). The coagulation process is also reported to remove dissolved and emulsified oils. It is also greatly influenced by pH, coagulant dose and settling time (Sukmana et al. 2021). Aluminium and iron salt coagulants such as aluminium sulfate (alum), ferrous sulfate and ferric chloride were among the most widely used coagulants (Lal and Garg 2019). The function of the coagulant is to promote the agglomeration or accumulation of the wastewater particle by reducing the surface charges of the electrostatic particles. Different investigations have indicated the ability of the coagulation process in the treatment of PRWW. Zueva et al. (2020) reported research conducted to prove the petroleum wastewater treatment capabilities of Ca (OH)2 and Al2(SO4)3. Under optimum conditions, the removal efficiencies of turbidity, total hydrocarbons and COD were 100%, 90% and 70% respectively.

Table 3.

Petroleum refinery wastewater treatment by coagulation.

Table 3.

Petroleum refinery wastewater treatment by coagulation.

| |

Experimental conditions |

Reference |

| Coagulant |

pH |

Dosage |

Tempt. (°C) |

Time (Min) |

Pollutants removed |

Removal efficiency (%) |

|

| Ca (OH)2 and Al2(SO4)3 |

7.3 |

0.43 mg/L. |

NR |

NR |

Turbidity |

100 |

Zueva et al. (2020) |

| |

|

|

|

|

TOC |

90 |

|

| |

|

|

|

|

COD |

70 |

|

| CuSO4+FeCl3 |

7.1 |

0.20 g/L |

NR |

NR |

COD |

76.77 |

Singh and Kumar (2020) |

| |

|

|

|

|

Turbidity |

89.47 |

|

| |

|

|

|

|

TDS |

94.16 |

|

| |

|

|

|

|

Colour |

95.29 |

|

| Land snail shells (LSS) |

6 |

0.1 g/L |

NR |

30 |

Turbidity |

90 |

Ovuoraye, et al. (2022) |

| Ca (OH)2-based coagulant |

|

|

|

|

Turbidity |

95.1 |

Benouis et al. (2020) |

| |

|

|

|

|

Hydrocarbons |

90.4 |

|

3.1.4. Adsorption Using Conventional Adsorbents

The adsorption process is both a conventional and advanced treatment technique depending upon the adsorbent material. Conventional adsorbent materials such as activated carbon, zeolites and silica are been used for a long time in the treatment of PRWW. These are called conventional adsorbent materials. Nowadays, adsorption techniques (using both conventional and non-conventional adsorbents) are one of the most commonly studied techniques for most industrial wastewater treatment due to their simplicity and lower treatment cost (Cai, et al. 2019). Additionally, besides its effectiveness and economic advantage, the adsorption technique is sometimes a reversible process where adsorbents can be regenerated simply through an appropriate desorption process (Gkika, et al. 2022). The adsorption process can occur between a combination of systems such as; solid-liquid, solid-gas, liquid-gas, and liquid-liquid (Sukmana et al. 2021). Parameters affecting adsorption process efficiency include; pH, temperature, contact time and adsorbent porosity and dose. The pH factor affects the ability of the hydrogen ions in the solution and their interaction with the functional groups and the metal ions (Afroze et al. 2016).

Adsorbents with high porosity tend to have a high surface area as well as high adsorption capacity (Ballav, et al. 2018). Activated carbons, polymeric organic resins (such as ion exchange resins) and inorganic adsorption materials such as zeolites, silica gel, as well as activated alumina, were all classified as conventional adsorbents. Meanwhile, industrial or agricultural by-products such as rice husk and sawdust were categorized as non-conventional adsorbents (Crini, et al. 2019). Various adsorbent materials derived from agricultural or industrial by-products originating from natural material or modified biopolymers were reported to be used for the removal of heavy metals (Barakat 2011). Mahmoud et al. (2013) have reported the application of activated carbon, natural clay and sawdust for the treatment of petroleum wastewater from Kuwait Gulf Oil Company (KGOC). The sorption capacities reported are; 15.52 mg/g, 16.23 mg/g and 12.91 mg/g for the activated carbon, natural clay and sawdust respectively at 100 min. equilibrium time. Jun et al. (2020) investigated the adsorption potential and efficiency of palm kernel shells (PKS) as biomass integrated with iron oxide and zeolite. The analysis revealed that the optimized PKS can remove colour (83.1%) and COD (67.2%) within a contact time of 30 minutes. Similarly, Kassob and Abbar (2022) also investigated the COD removal efficiency of an activated carbon fixed-bed column operated at a batch recirculation mode using petroleum wastewater from Iraq's Al-Diwaniyah petroleum refinery plant. At an optimal condition and pH of 5.7, 80% activated carbon parking and 73 adsorption time, 96.70% COD removal efficiency was recorded.

Table 4.

Petroleum refinery wastewater treatment by adsorption.

Table 4.

Petroleum refinery wastewater treatment by adsorption.

| sssss |

Experimental conditions |

|

|

| Adsorbent |

pH |

Dosage |

Tempt. (°C) |

Time (Min) |

Pollutants removed |

Removal efficiency (%) |

Reference |

| Activated carbon (AC), natural clay (NC) and sawdust (SD) |

7 |

NC 18.96 mg/g,

AC 16.25 mg/g & SD 14.11 mg/g. |

NR |

100 |

Colour |

83.1 |

Mahmoud et al. (2013) |

| |

|

|

|

|

COD |

67.2 |

|

| Activated carbon fixed-bed column |

5.7 |

80% Parking |

25±2 |

73 |

COD |

96.7 |

Kassob and Abbar (2022) |

| Synthesised nanorods ZnO/SiO2 via the sol–gel |

|

|

|

|

Pb2+

|

85.06 |

Shaba, et al. (2022) |

| |

|

|

|

|

Cd2+

|

84.12 |

|

| Functionalized mesoporous material with amine groups (NH2-MCM-41) |

7 |

0.4 g/L |

|

50 |

PAHs |

85.7 |

Kalash and Albayati (2021) |

| ZnO/Fe3O4 nanocomposite |

NR |

0.08 g |

30 |

900 |

Cu2+

|

92.99% |

Shaba et al. (2023). |

| |

|

|

|

|

Cr6+

|

77.60% |

|

3.1.5. Membrane Processes

Membrane technology has been in existence since around the 18th century for the treatment of wastewater. It is a physicochemical treatment technology that is gaining more acceptance and is also efficient in the treatment of organic matter. Membranes are used as a selective barrier in the separation of two phases through semi-permeable pore space by restriction of movement between components (Obotey Ezugbe, 2020). According to Obotey Ezugbe, (2020) and Aljuboury et al., (2017), membranes can be generally classified into two main types; organic membranes (usually made from organic polymers) and inorganic membranes (made from silica, metals, zeolites, or ceramics). Depending on their pore sizes, membranes can be used for microfiltration ultrafiltration or nanofiltration (Barakat 2011; Moslehyani, et al. 2015). A high level of concentrate generation which subsequently leads to membrane fouling is the major drawback in the membrane treatment systems (Chun, et al. 2017). Ratman et al. (2020) reported the application of a Polyether sulfone (PES) membrane consisting of zinc oxide (ZnO) nanoparticles followed by UV irradiation for the pre-treatment of RWW. The result showed pre-treatment enhanced rejections up to 18.6%, 16.7%, and 87.1%, for total dissolved solids, chemical oxygen demand, and Ammonia respectively. Hashimi et al. (2018) used micellar-enhanced ultrafiltration (MEUF) for the treatment of heavy metals at Kermanshah Oil Refinery and the result showed 96%, 95%, 92% and 86% removal efficiency for nickel, lead, cadmium and chromium respectively. Sodium Dodecyl Sulfate (SDS) was used as a surfactant and added to the effluent to enhance complex formation that can trap the heavy metals. Kusworo, et al (2021) utilised Polysulfone (PSf) membrane with improved efficiency using zinc oxide (ZnO) nanoparticles and reported rejection values of 70.21% for TDS and 74.68% for COD. Similarly, Kusworo, et al. (2022) have reported a study using a Polysulfone-Nano TiO2 Hybrid membrane coupled with an ozonation process as a pre-treatment for the removal of TDS, COD, and phenols. The ozonation process enhanced the membrane permeate capacity by up to 96% and improved the pollutant removal efficiency by up to 77%. They further reported that the ozonation process also reduces the fouling of the membrane and increases surface resistance by up to 21%. Although, ozonation itself is a costly process, utilising a hybrid process that can reduce the concentration of pollutants before membrane filtration can enhance membrane efficiency and reduce fouling which is a major problem with membrane applications.

Table 5.

Petroleum refinery wastewater treatment by membrane process.

Table 5.

Petroleum refinery wastewater treatment by membrane process.

| No. |

Membrane |

Pollutants removed |

Removal Efficiency (%) |

Reference |

| 1 |

Polyether sulfone (PES) membrane consisting of zinc oxide (ZnO) nanoparticles |

TDS |

18.6 |

Ratman et al. (2020) |

| |

|

COD |

16.7 |

|

| |

|

Ammonia |

87.1 |

|

| 2 |

Micellar-enhanced ultrafiltration (MEUF) |

Nickel |

96 |

Hashimi et al. (2018) |

| |

|

Lead |

95 |

|

| |

|

Cadmium |

92 |

|

| |

|

Chromium |

86 |

|

| 3 |

Polysulfone zinc oxide (ZnO) nanoparticles to PSf membrane |

TDS |

70.21 |

Kusworo, et al (2021) |

| 4 |

|

COD |

74.68 |

|

| |

Polysulfone-Nano TiO2 Hybrid Membrane |

TDS |

77% |

Kusworo, et al. (2022) |

| |

|

COD |

77.2 |

|

| |

|

Phenols |

78.5 |

|

| |

|

|

|

|

3.2. Chemical Processes

3.2.1. Chemical Precipitation & Ion Exchange

Chemical processes utilize the application of chemical reactions in the treatment of wastewater contaminants. Neutralization, ozonation, ion exchange and oxidation processes were among the most widely used chemical processes in the treatment of RWW (Aziz and Fakhrey 2016). Neutralization consists of the use of an acid or base such as lime to adjust the pH level (Aljuboury et al. 2017). Generally, chemical precipitation is one of the most widely used conventional treatment processes for the removal of heavy metal concentrations from inorganic effluents (Barakat, 2011). In the precipitation process, heavy metal ions from the PRWW react with suitable chemicals to form insoluble participates which can be further separated by a sedimentation or filtration process (Zinicovscaia and Cepoi 2016). It is relatively a simple and less costly technique which can be used for the removal of metals and sulphides. The coagulation precipitation method is broadly used with the help of chemical precipitants such as Ca (OH)2 and NaOH (Qasem, et al 2021). Alnakeeb and Rasheed (2021) have reported the application of BaCl2 and Al (OH)3 in the treatment of PRWW from Al-Doura Refinery in Iraq. High sulphate removal efficiency was obtained with BaCl2 over Al (OH)3 and concluded that aluminium hydroxide is unsuitable for PRWW with neutral pH and low sulphate concentrations. Meanwhile, Barium salts are highly insoluble and hence making them an excellent precipitant for sulphate ions. Altaş and Büyükgüngör (2008), also reported the use of Ca (OH)2 as precipitant together with Fe2+ ions and obtained (96–99%) and (50–80%) removal efficiencies for Sulfide and COD respectively. Alternatively, precipitation can also be achieved using sodium or calcium carbonates in which classical carbonates are formed. Habte et al. (2020) investigated the Removal of Cadmium and Lead via carbonation of aqueous Ca (OH)2 derived from eggshell and found the results to be efficient for obtaining very low concentrations of the heavy metals. About 99.99% and 99.63% treatment efficiency for Cd2+ and Pb2+ were obtained at an optimum condition of 3 g/L dosages of Ca (OH)2, the initial metal concentration of 100 mg/L and the CO2 flow rate of 1 L/min. The study has provided evidence for the application of Ca (OH)2 derived from an eggshell for the treatment of heavy metals. Furthermore, the impact of carbonation to enhance calcium hydroxide-based precipitation can be an attractive method for the capture and utilization of CO2 as a greenhouse gas. However, the formation of large sludge and the effect of pH is the main disadvantage of the precipitation process (Park et al. 2014). Furthermore, precipitation performance is also mostly affected by a high-level concentration of chlorides from the wastewater. High chlorine concentration usually favours the formation of hydroxo salts precipitates instead of the typical heavy metal hydroxides (Stec, et al. 2020). From their review of about 185 articles from 1988–2010, Fu and Wang (2011) stated that ion exchange, adsorption and membrane filtration were the most widely studied methods for the treatment of heavy metals. The potential recovery of the metal, higher selectivity, and lower sludge production are among the main advantages of the ion exchange technique. The main principle of the technique is the exchange of ions in a chemically equivalent amount between a resin (usually a solid) and an electrolytic solution (Zinicovscaia and Cepoi 2016). Generally, ion-exchange resins are applied in the isolation of rare metals, regeneration of metal wastes desalination as well as softening process (Sillanpää and Shestakova 2017). The resin materials can be natural such as inorganic zeolites or synthetically produced organic resins (Qasem, et al 2021).

Table 6.

Treatment of petroleum refinery wastewater by precipitation.

Table 6.

Treatment of petroleum refinery wastewater by precipitation.

| |

Experimental conditions |

|

| Precipitant |

pH |

Dosage |

Tempt. (°C) |

Time (Min) |

Pollutants removed |

Removal efficiency (%) |

Reference |

| BaCl2 and Al (OH)3 |

7 |

0.36 g/L |

NR |

15 |

Sulphate ion |

|

Alnakeeb and Rasheed (2021) |

| Ca (OH)2 and Fe2+ ions |

5 |

40 mg/L |

NR |

NR |

Sulfide |

97.5 |

Altaş and Büyükgüngör (2008) |

| |

|

|

|

|

COD |

65 |

|

| Ca (OH)2 derived from eggshell |

NR |

3 g/L |

NR |

NR |

Cd 2+

|

99.99 |

Habte et al. (2020) |

| |

|

|

|

|

Pb 2+

|

99.63 |

|

3.3. Biological Processes

The biological processes utilize the use of the microbial activity of living organisms such as bacteria to decompose or degrade organic contaminants. The four major groups of biological treatment processes are aerobic, anaerobic, anoxic (the process by which nitrate is converted biologically into nitrogen gas in the absence of oxygen), or a combination of the three. The principal applications for these processes are removing carbonaceous organic matter (measured in BOD, COD, or TOC), nitrification, denitrification, or stabilization (Roy and Saha 2021). There are various biological processes which have been reported to be effective in treating PRWW among which the activated sludge process is the most widely used (Elmobarak et al. 2021). However, there is little removal efficiency of petroleum hydrocarbons and large sludge production, but at least up to 60%-90% COD removal efficiency was observed in many biological treatments of PRWW (Jain et al. 2020). Based on the requirement, the general application of biological treatments can be grouped into two main classes; aerobic and anaerobic methods where the latter is widely used due to its simplicity and high efficiency (Aljuboury et al. 2017). Furthermore, anaerobic digestion produces methane gas as renewable energy and requires less space and generates lower sludge than the aerobic process. Pretreatment processes such as flotation, flocculation, sedimentation, and filtration are usually applied in the treatment of PRWW to eliminate free oil and gross solids as well as increase biodegradability (Ghimire and Wang 2018). Different reactor systems of the aerobic process have been reported to treat PRWW including; the traditional activated sludge (ASP), contact stabilization active sludge, membrane bioreactor (MB), biological aerated filter (BAF), moving bed biofilm reactor (MBBR), sequence batch reactor (SBR) etc. Bioreactors adopted for PRWW are generally categorised into suspended growth, attached growth or hybrid processes advanced treatment (Pal et al. 2016). Shuokr and Sazan (2021) have reported that high COD removal efficiency of up to 78% and 94% for total organic carbon and oil degradation were achieved using aerobic biological treatment. Rasheed and Muthukumar (2010) preserved a PRWW sample with an initial COD of 40000 mg/l and a pH of 5.4 under a deep freeze for a limited number of days before undertaking biological treatment using sequencing batch bioreactor (SBR) with sonication pre-treatment for 30 minutes. The investigation revealed that there is a significant decrease in COD with an increase in time. An industrial scale granular sludge bed bioreactor and aerobic activated sludge treatment (EGSB-BR) were developed by Liang et al. (2019) to RWW and the overall COD and petrochemical removal efficiencies of the plant are 85.6 % and 81.5 %, respectively. El-Naas et al. (2016) investigated a three-step pilot plant process consisting of biological treatment in a spouted bed bioreactor (SBBR) unit for the treatment of highly contaminated RWW in which they achieved 96% COD removal and nearly 100% Phenols degradation. Vendramel (2015) utilized the capability of an aerobic submerged fixed-bed reactor (ASFBR) to treat a high organic strength RWW and found COD, dissolved organic carbon and TSS removal efficiencies at 91%, 90% and 92%, respectively. About 90% reduction in the ammonium level was also obtained.

Table 7.

Treatment of petroleum refinery wastewater by biological process.

Table 7.

Treatment of petroleum refinery wastewater by biological process.

| No. |

Biological process/reactor |

COD (%) |

TOC (%) |

Phenols (%) |

TSS (%) |

Reference |

| 1. |

Aerobic biological treatment |

78 |

94 |

|

|

Shuokr and Sazan (2021) |

| 2. |

Granular sludge bed bioreactor and aerobic-activated sludge treatment (GSB-BR) |

85.6 |

|

|

|

Liang et al. (2019) |

| 3. |

Spouted bed bioreactor (SBBR) |

96 |

|

|

|

El-Naas et al. (2016) |

| |

|

|

|

100 |

|

|

| 4. |

Aerobic submerged fixed-bed reactor (ASFBR) |

91 |

|

|

92 |

Vendramel (2015) |

3.4. Advanced Treatment Processes

The problem of low treatment efficiency and high operational costs and among others in most conventional treatment processes have led to the need to adopt more advanced treatment technologies. Alternatively, the use of a hybrid system which combines two or more processes is sometimes effective for the removal of oil and other hazardous pollutants from petroleum wastewater (Adetunji and Olaniran 2021).

3.4.1. Adsorption Using Modified Adsorbents

With the advancement in the field of material science and the need for an effective and low-cost adsorbent, many natural and synthetic materials have been tested for the adsorption of pollutants from wastewater of different industrial effluents. Although the selection of an appropriate adsorbent with a suitable property is also indispensable to obtaining the maximum adsorption capacity, the adsorption technique is often seen as the best choice in the treatment of different types of wastewater among the available treatment options. This is for the fact that it is regarded as the most simple and fitting treatment technique (Vikrant & Kim 2019). Furthermore, the adsorption technique is also believed to be the optimal method for crude oil spill clean-up because of its relatively low cost and high effectiveness. Various oil hydrophobic adsorbents exist, such as natural sorbents, organic polymers (synthetic), and mineral materials (inorganic) are nowadays generated from a variety of sources that can be used to treat oily PRWW (Sabir, 2015). For example, Abdeen & Moustafa (2016) have reported their study for the adsorption of crude oil from wastewater on a crosslinked poly (vinyl alcohol) hydrogel (HPVA) and its foam (HPVAF). The macroporous adsorbent of HPVAF was prepared by adding CaCO3 and epichlorohydrin which act as the pore-forming agent and crosslinker, respectively. The adsorption ability of the two materials was assessed using the gravimetric method where the HPVAF carrier demonstrated an improvement in hydrocarbon trapping than the HPVA. The crude oil removal ability of the HPVAF was approximately 82% at a pH of 3. Meanwhile, the removal percentage is higher at pH 3 and 9 compared with pH 7. This study confirms the potential ability of using HPVA and HPVAF films as crude oil adsorbents from oily PRWW especially in an open marine environment. It also proved the good ability of calcium carbonate as a pore-forming agent in the preparation of hydrogel adsorbents. However, there is a need for low or high pH concentrations for the effective use of the HPVA and HPVAF hydrogel films. Similarly, Li, et al. (2022) also reported the use of hydrogel composite produced by freezing–thawing process using chitosan, polyvinyl alcohol, and carbon black as the raw materials and used for oil/water separation. The prepared hydrogel displayed oil repellence and water affinity properties and when submerged in oil was able to separate oil/water mixtures efficiently. After 25 oil–water separation cycles, the hydrogel-coated filter still had a separation efficiency of over 98%. Furthermore, they also reported that due to its super hydrophilicity and active functional groups, it was able to effectively absorb dye molecules dissolved in water. Li, et al. (2021) similarly reported the synthesis of a highly hydrophobic and self-recoverable hydrogel sponge prepared from cellulose nanofibrils (CNFs), N-alkylated chitosan (NCS), and poly (vinyl alcohol) (PVA) for oil/water separation. The interconnected microstructure CNF/NCS/PVA hydrogel was found to have 96% porosity. The hydrogel sponge effectively separates oil/water mixtures and water-in-oil emulsions with high separation efficiency and good stability in various acidic, saline and mechanical conditions. They further maintained that it can absorb various organic solvents with an absorption capacity of about 19.05–51.08 times its original weight. Similarly, Xue, et al. (2019) have also conducted a study to separate oil/water mixture in a highly acidic, alkaline, and salty condition using a porous calcium alginate/Ag nanoparticle (Ca-ALG/Ag) hydrogel film with super hydrophilic and underwater superoleophobic properties which is fabricated through an eco-friendly process. The synthesis of the Ca-ALG hydrogel film was conducted by combining ionic cross-linking of Ca+ ions and soluble NaCl salt-template method and also incorporating the Ag nanopar ticles into the alginate matrix by a simple reduction process. NaCl crystals were used as templates and sifted on the ALG solution films which can be easily removed by water. The ALG/NaCl composites were quickly immersed in CaCl2 solution and sonicated at the same time. The NaCl crystals pierced through the ALG film and dissolved in water gradually and generating a macro-pore structure. They finally reported that the oil/water separation efficiency of the Ca-ALG/Ag hydrogel film was above 98%. Polyvinyl alcohol and formaldehyde hydrogel composite sponges (PVF/PVF) were also synthesised from a study conducted by Zheng, et al. (2023) for the treatment of oily wastewater. Although the prepared hydrogels sponge shows almost 100% oil removal efficiency, it could effectively only remove oil emulsion under the action of gravity with a maximum flux of 2.9 × 105 L m-2h−1 bar−1. The hydrogel has displayed excellent reusability after use and recovered simply by washing. Tai, et al. (2022) reported the development of a superhydrophobic composite aerogel-prepared leached carbon black waste (LCBW) obtained from industrial waste and polyvinyl alcohol (PVA) via conventional freeze-casting and followed by a surface coating. The synthesised PVA/LCBW aerogel was used as a selective adsorbent for different oils and organic solvents and showed an adsorption capacity of about 35 times its original weight. It can also be reused repeatedly and recovered easily through a simple drying process. The maximum removal efficiency was obtained from a PVA/LCBW combination ratio of 1 and 0.5 wt % PVA. This corresponds to the highest water contact angle of 156.7 ± 2.9°. Regarding oil/water emulsion separation using porous materials such as hydrogels, the two most important key points for consideration are 1) proper average pore size and 2) the wettability of the adsorbent. This important property simply describes the level of hydrophilicity and hydrophobicity of the adsorbent material. The superoleophobicity and wettability of the hydrogel adsorbents protect them from fouling by oils, thus making them better performance in the removal of oil concentrations and reuse of materials (Zhang, et al. 2020). Sha, et al. (2021) developed a polyvinyl alcohol-formaldehyde (PVA-PVF) sponges with harmonious pore size through a crosslinking reaction of polyvinyl alcohol (PVA) in the polyvinyl alcohol-formaldehyde (PVF) and under acidic condition. They further stated that the use of PVA containing chitosan, diatomite and sodium alginate (SA) can effectively decrease the average pore size of PVF from approximately 75 μm to 23 μm along with a few hundred nanometres pore channels while maintaining porosity above 73.4%. The oil/water emulsion separation efficiency can reach up to 97.40% with a high-water flux of 2.40 × 104 L m−2 h−1 bar−1.

Although there are many non-conventional adsorbent materials such as those developed from biopolymers or hydrogels that have been used in the application of wastewater treatment, only a few studies were reported using biopolymers and hydrogels in the treatment of real PRRW samples. Moreover, most of the reported studies were conducted on a small laboratory scale. Hence, there is a need for further research on this to theme understand the suitability of these materials for PRWW treatment in practical applications.

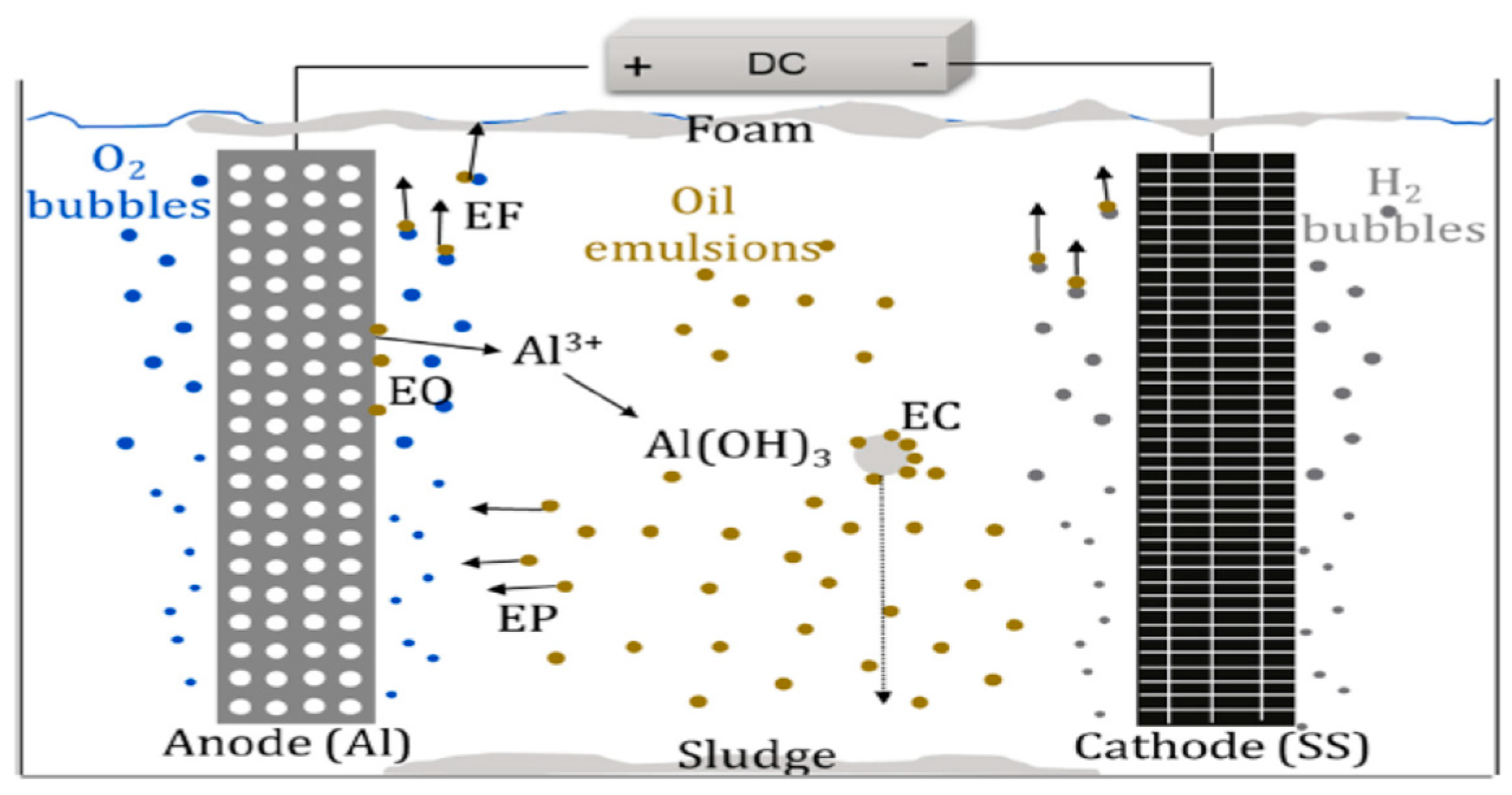

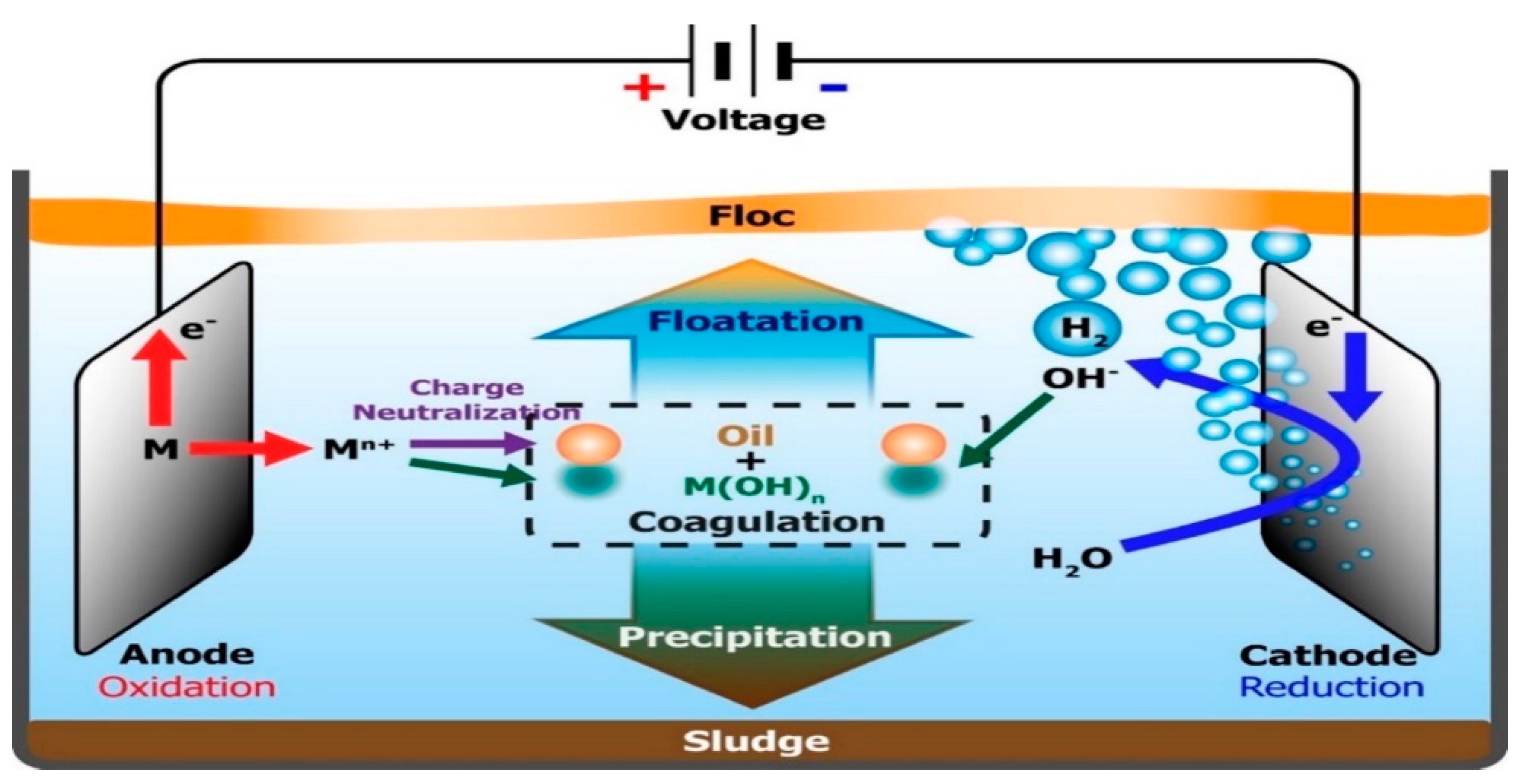

3.4.2. Electrochemical Technology

Electrochemical technology is nowadays a promising treatment technology for the removal of organic pollutants from PRWW using the application of electric currents supplied to electrodes. This technology can occur in the forms of electrocoagulation, electro-floatation electro-oxidation, electro-Fenton electrodialysis, electrodeposition, and electrode ionization etc. (Treviño-Reséndez 2021; Khalifa et al. 2022). Adetunji and Olaniran (2021) reported that electrochemical technologies are usually affected by operating conditions such as; current density, pH, electrode materials, temperature and concentration and structure of phenols. For the fact that no chemical addition is needed and less waste generation, electrochemical processes were considered green technologies which are simple to operate and combine with other technologies (Khalifa et al. 2022). The average estimated time for an electrochemical treatment process to treat PRWW is about 5-6 hours. However, most of the studies conducted on electrochemical treatment were lab-scale technologies with only a few evaluated at a pilot scale. Hence, there is a need for more efforts to determine the applicability of the prototype technology of the system to establish its viability (Ibrahim et al. 2022). Furthermore, there is no universally accepted electrochemical treatment technology for the treatment of highly contaminated RWW, but hybrid application with other treatment processes (such as biological and physicochemical processes) may prove the required efficiency and more work is needed in this direction (Treviño-Reséndez 2021; Ibrahim et al. 2022)

Figure 7.

Electrochemical cell showing the different electrochemical processes. (Khalifa et al. 2022). DC: Direct current. EF: Electro-flotation. EC: Electrocoagulation EO: Electrooxidation. A: Aluminium. EP: electrophoresis.

Figure 7.

Electrochemical cell showing the different electrochemical processes. (Khalifa et al. 2022). DC: Direct current. EF: Electro-flotation. EC: Electrocoagulation EO: Electrooxidation. A: Aluminium. EP: electrophoresis.

Electro Floatation (EF)

This is an advanced and enhanced form air floatation process which carries floating pollutants to the surface by buoyancy and gas bubbles (usually oxygen and hydrogen gases) produced as a result of the electrolysis of water (Khalifa et al. 2022). Unlike the conventional DAF which depends on the solubility of oxygen and nitrogen in the wastewater, in electro floatation oxygen and hydrogen gas bubbles were formed at the surface of the anode and cathode respectively. Although it can be used as a separate process, it is usually combined with coagulation, flocculation, or both to remove pollutants by skimming (Mickova 2015). The efficiency of the EF process is dependent on the current density, pH of solution and temperature. Furthermore, it differs from conventional air floatation in that it provides uniform and finely dispersed gas bubbles and requires little space and less operation cost (Adetunji and Olaniran 2021). While the choice of the electrode material is very vital for a successful implementation of EF, Titanium-based inert anodes in the form of dimensional stable anodes (DAS) are the most dominantly used anodes (Mohtashami and Shang 2019). Alam and Shang (2017) studied the treatment of synthetic oil sand tailing using a batch cell electro-flotation reactor made up of stainless steel mesh cathode and Ti-IrO2 mesh anode. At an optimum current density of 150 A/m2, about 90% oil flotation efficiency was achieved.

Electrocoagulation (EC)

Electrocoagulation is one of the most prominent electrochemical processes employed for the treatment of oily wastewater such as PRWW and is efficient for the removal of a colloidal immiscible form of pollutants of less than 10 micrometres (Khalifa et al. 2022). This technology involves an in-situ release of appropriate coagulant (such as aluminium or iron species) from a metal electrode with the application of an electric current leading to the electrolytic dissolution of metal ions. The process would result in a simultaneous formation of hydroxyl ions and hydrogen gas production while the coagulant aggregate and precipitates suspended solids (Adetunji and Olaniran 2021). Among the advantages of this technology are simple and automated operation, lower sludge volume and no chemical requirement except for pH control (Merma et al. 2020). Akkaya (2022) reported the use of aluminium and iron cathode electrodes from scrap metals disposed by different industries for the electrocoagulation process of PRWW under an optimum condition of 6.30 pH, current density of 22 mA/cm2 and exposure time of 39 minutes. The process obtained COD and phenol removal efficiencies of 91.18% and 91.46%, respectively. The three-step pilot plant process reported by El-Naas et al. (2016) consisting of an electro-coagulation unit has resulted in the best performance to enhance COD and suspended solids removal. The plant achieved a 96% reduction of COD and a 100% reduction of phenol and cresols concentrations. El-Ashtoukhy et al. (2013), also utilised a fixed-bed electrochemical reactor for the electrocoagulation of phenolic compounds in a real RWW sample. They reported 100 per cent phenol removal efficiency for 3 mg/l in two hours. Gousmi et al. (2016), similarly reported the application of iron and aluminium electrodes in an electrolytic reactor to determine the treatment efficiencies of COD and turbidity from synthetic PRWW. The process revealed 83.52% and 99.94% removal efficiencies for COD and turbidity respectively. The major drawback of this system especially when used separately often yields a lower efficiency in a high concentration of oily wastewater. Thus, it is commonly combined in an integrated process with other methods. Furthermore, it involves the application of electrochemical cells, where electrodes are dipped into oily wastewater, and determine their potential current difference being applied (Elmobarak, 2021).

Figure 8.

Mechanism of electrocoagulation process for oil removal. (An, et al. 2017).

Figure 8.

Mechanism of electrocoagulation process for oil removal. (An, et al. 2017).

Electrooxidation (EO)

This is an advanced form of chemical oxidation process which involves the generation of the oxidants that oxidize the pollutants through the application of electric current (Adetunji and Olaniran 2021). The EO process is sometimes considered as part of the AOPs from a broad perspective but only the oxidation process here occurs on the surface of the anode electrode as opposed to direct oxidation in the latter (Khalifa et al. 2022). The efficiency of the EO process is affected by operating conditions such as the current density and electrode activity as well as pollutants diffusion rate (Adetunji and Olaniran 2021). Ibrahim et al. (2013) reported an electrochemical oxidation process for the treatment of RWW effluent with optimized conditions of 30 mA/cm2 current density, pH 8, supporting electrolyte 2g/l, and operation time of 120 minutes. Ruthenium oxide-coated Titanium and stainless steel served as the anode and cathode respectively. were estimated. FTIR analysis was conducted to determine the removal of pollutants by electrooxidation degradation and 92% COD removal efficiency was estimated. The efficacy of lead oxide reinforced on tantalum (Ta/PbO2) and boron-doped diamond (BDD) anodes contained in an electrolytic batch cell were determined by Gargouri et al. (2014) for the treatment of oily wastewater. At different current densities of 30, 50 and 100 mA/cm2 COD removal efficiency of 85% and 96% were obtained after 11 and 7 hours respectively.

Table 8.

Treatment of petroleum refinery wastewater by an electrochemical process.

Table 8.

Treatment of petroleum refinery wastewater by an electrochemical process.

| |

|

Removal Efficiency |

|

| Electrodes/reactor |

Process |

COD (%) |

Phenols (%) |

Oil (%) |

Reference |

| Porous graphite electrodes. |

EFen |

95.9 |

|

|

Fahim and Abbar (2020) |

| Electrochemical reactor with Ti-IrO2 mesh anode |

EF |

|

|

90 |

Alam and Shang (2017) |

| Aluminium and iron cathode electrodes from scrap metals |

EC |

91.18 |

91.46 |

|

Akkaya (2022) |

| Fixed-bed electrochemical reactor |

EC |

|

100 |

|

El-Ashtoukhy et al. (2013) |

| Aluminium electrodes in an electrolytic reactor |

EC |

83.5 |

|

|

Gousmi et al. (2016), |

| Ruthenium oxide-coated Titanium and stainless steel |

EO |

92 |

|

|

Ibrahim et al. (2013) |

| Lead oxide reinforced on tantalum (Ta/PbO2) and boron-doped diamond (BDD) anodes |

EO |

96 |

|

|

Gargouri et al. (2014) |

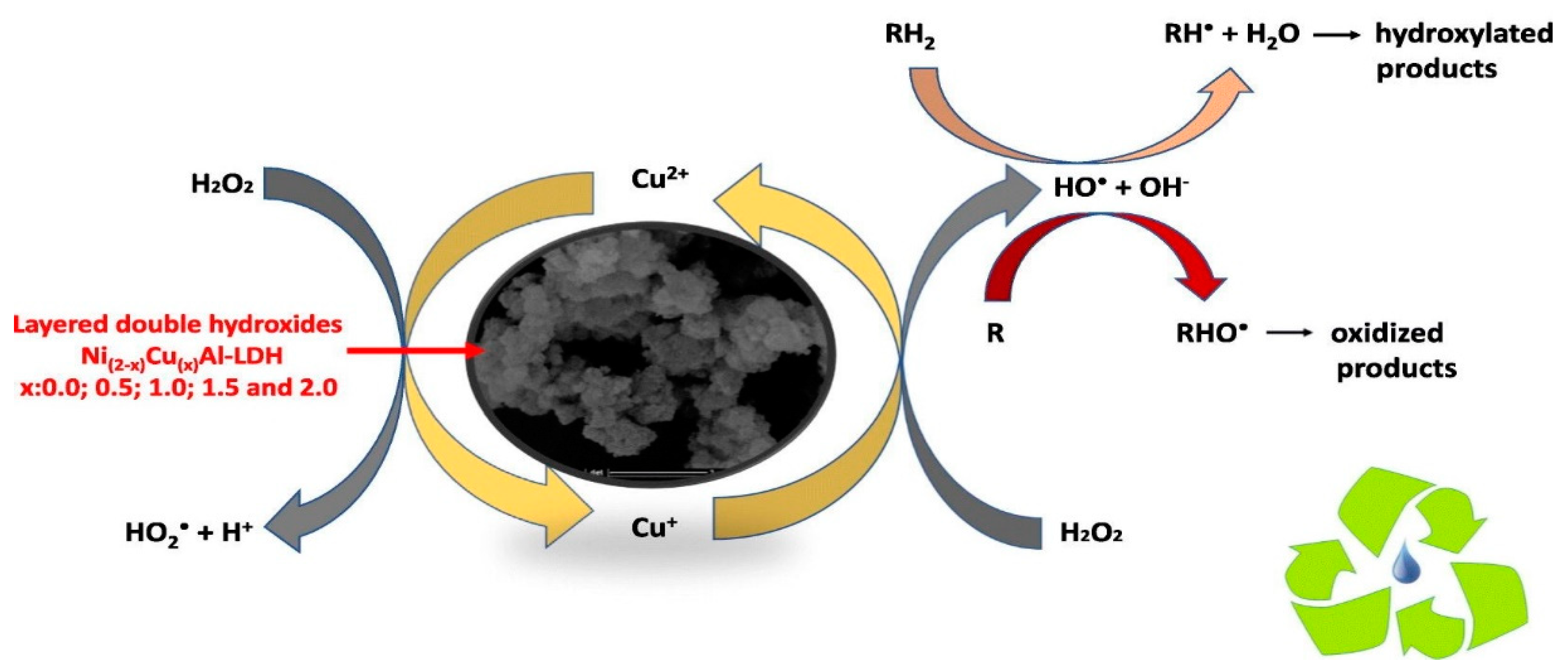

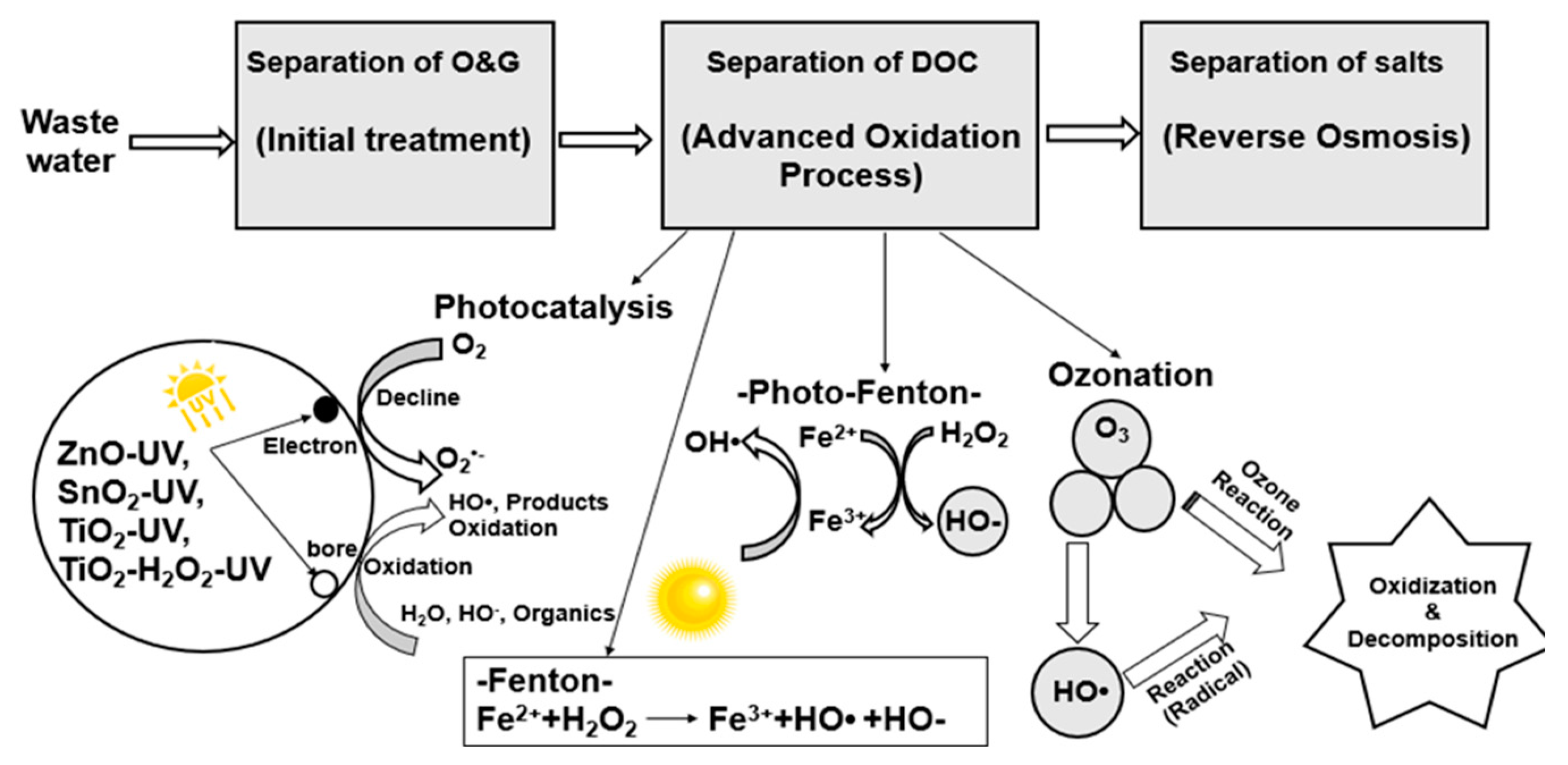

3.4.3. Advanced Oxidation Processes

The chemical oxidation techniques are a set of treatment processes which can be broadly classified into two types; conventional chemical treatments and advanced oxidation processes (Almomani, et al. 2016). Advanced oxidation processes are highly efficient techniques used in the treatment of different types of wastewater including petroleum industry wastewater, toxic effluents from pharmaceutical industries wastewaters, etc. In previous years, several works have been reported in the literature been conducted to examine the efficiency of the advanced oxidation processes in the treatment of different wastewaters containing recalcitrant and toxic pollutants (Elmobarak et al. 2021). Advanced oxidation processes (AOPs) are a category of chemical treatment methods that produce free hydroxyl radical groups with strong oxidant potential and are capable of degrading contaminants. The most commonly employed AOPs in the treatment of RPWW include; Fenton and Photo-Fenton oxidation reaction processes, electrochemical oxidation, ozonation processes (O3), as well as heterogeneous photocatalytic oxidation (Elmobarak et al. 2021; Khalifa et al. 2022). The AOPs are nowadays gaining more attention as they are environmentally friendly techniques with less generation of hazardous by-products and have shown high treatment efficiencies in the removal of organic compounds even at low concentrations (Tetteh et al. 2020). The treatment capability is attributed to the strong hydroxyl radical (-OH) which has strong reactivity towards organic compounds and colour degradation potential (Palaniandy and Feroz 2019). Based on this, AOPs have been reported as an efficient treatment technology for the reduction of COD, odour, colour other specific pollutants as well as sludge treatment. It can also be used in combination with biological treatment processes as a non-selective integrated chemical oxidant with high efficiency in removing toxic organic compounds such as phenols. Wang et al. (2019) also reported that AOPs are usually rapid processes with high treatment efficiency and little residual production but on the other hand associated with high energy requirements. Azizah and Widiasa (2018) investigated the application of H2O2/UV and H2O2/UV/O3 configurations for the treatment of PRWW with high phenol concentration. High phenol degradation of about 93.75% was achieved using H2O2/UV/O3 configuration with 1000 ppm concentration of H2O2 after 120 minutes. Several studies have also shown more than 90% COD and Phenol removal efficiencies from the application of the H2O2-based advanced oxidation process. Similarly, de Oliveira, et al. (2020) have reported their study in which they synthesised TiO2 nanoparticles assisted by microwave, from titanium tetrachloride and water, and used it as a catalyst subjected to photodegradation under UV-C irradiation using promising UF-Permeate from a Membrane Bioreactor. TOC and total nitrogen (TN) removal efficiencies were 32 % and 67 %, respectively, under a pH of 10 and catalyst concentration of 100 mg /L in a reaction time of 90 minutes. Furthermore, the catalyst shows stability after 4 different cycles of application and the data obtained is promising to prove the capability of the catalyst in the removal of recalcitrant organic pollutants of the UF-Permeate from a Membrane Bioreactor which can also reduce fouling in downstream polishing processes. Most of the reviews (Elmobarak et al. 2021; Palaniandy and Feroz 2019; Adetunji and Olaniran 2021; Aljuboury et al. 2017; Khalifa et al. 2022) have shown best treatment experimental results obtained using the AOPs than conventional methods.

Fenton-Oxidation