Submitted:

25 August 2023

Posted:

29 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

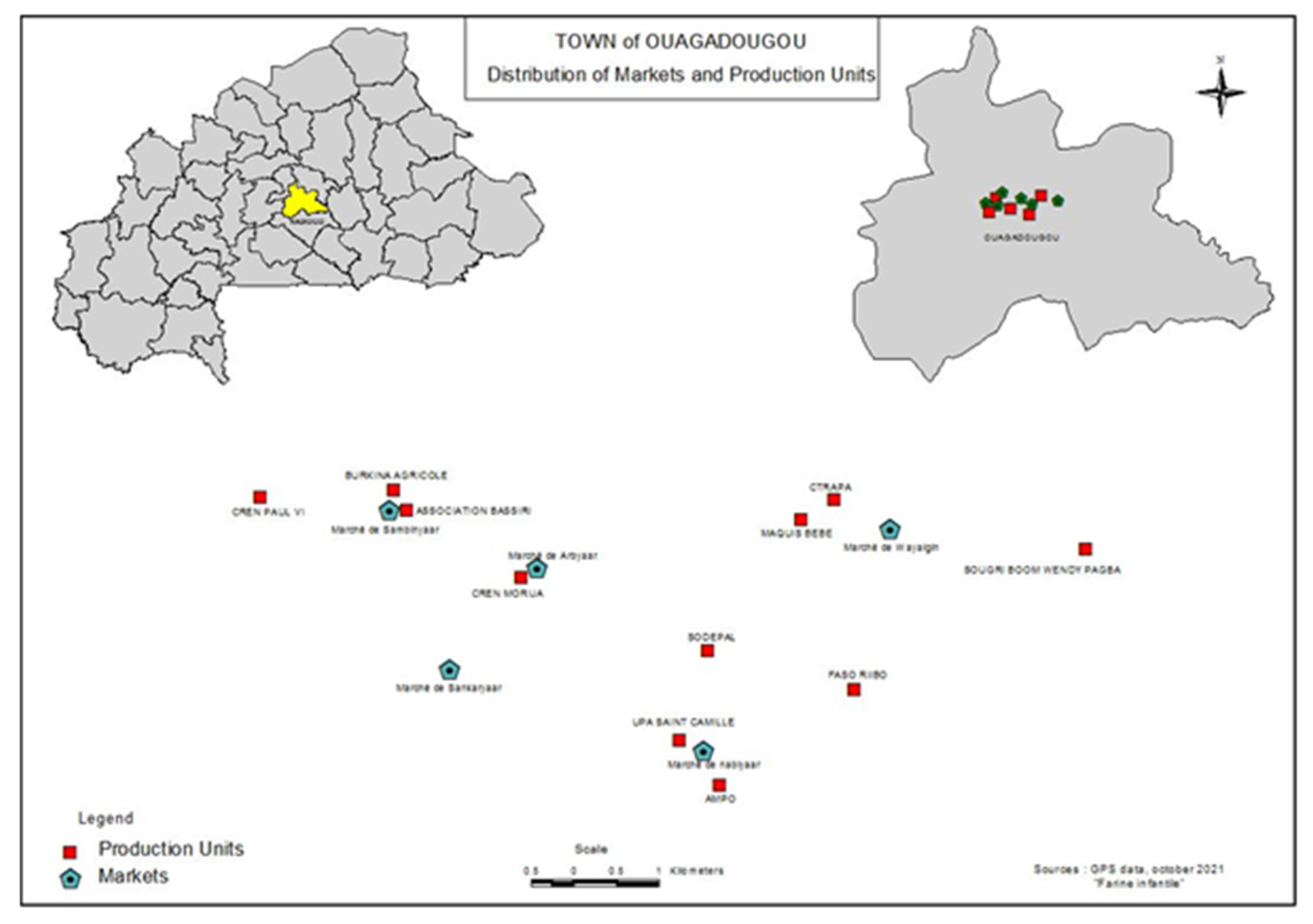

2.1. Study period and sample collection sites

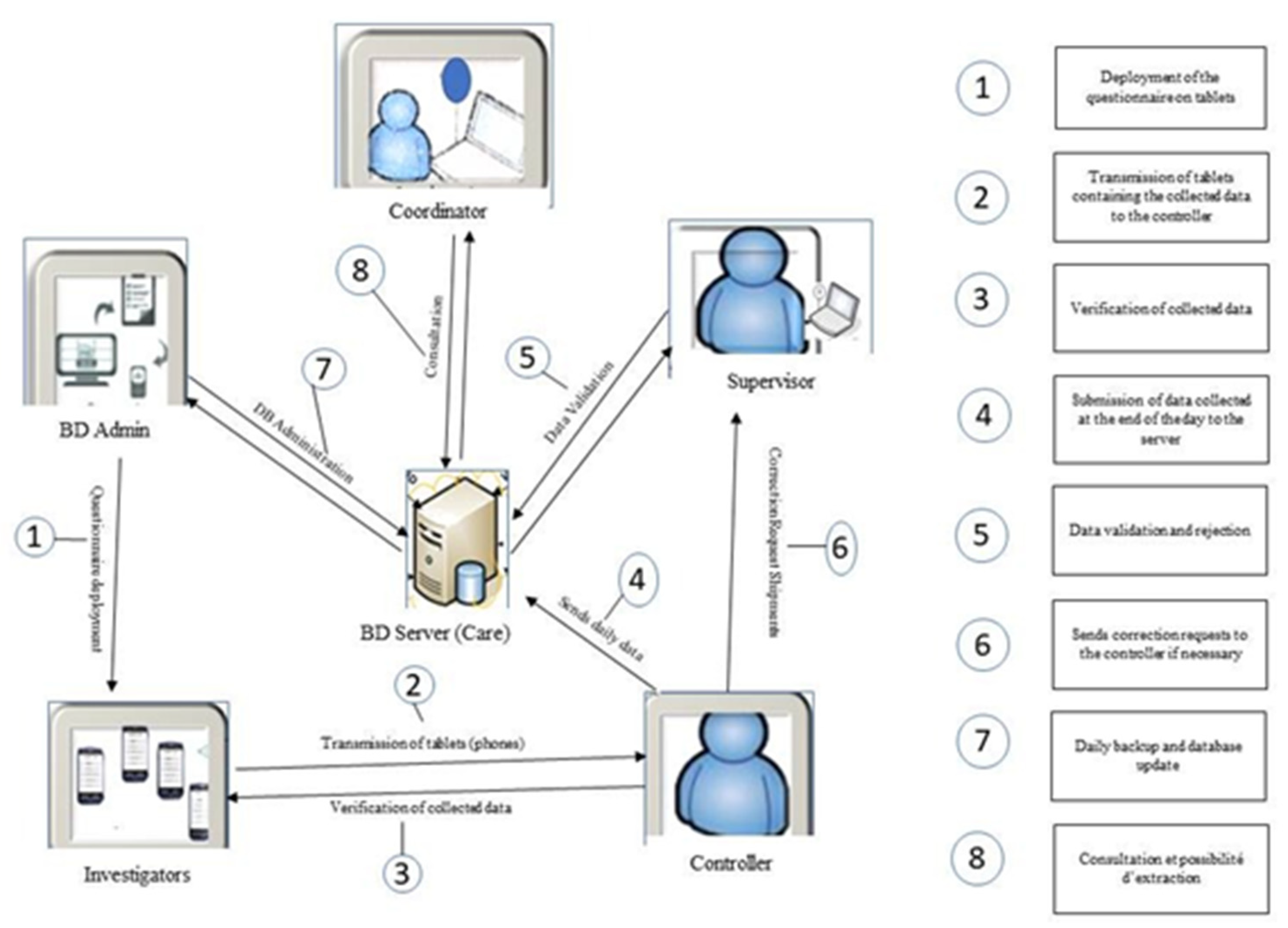

2.2. Conduct of the investigation

2.3. Sample Collection of raw materials and infant flours

2.3.1. Raw materials

2.3.2. Infant flours

3. Results

3.1. Infant flour production units in the city of Ouagadougou

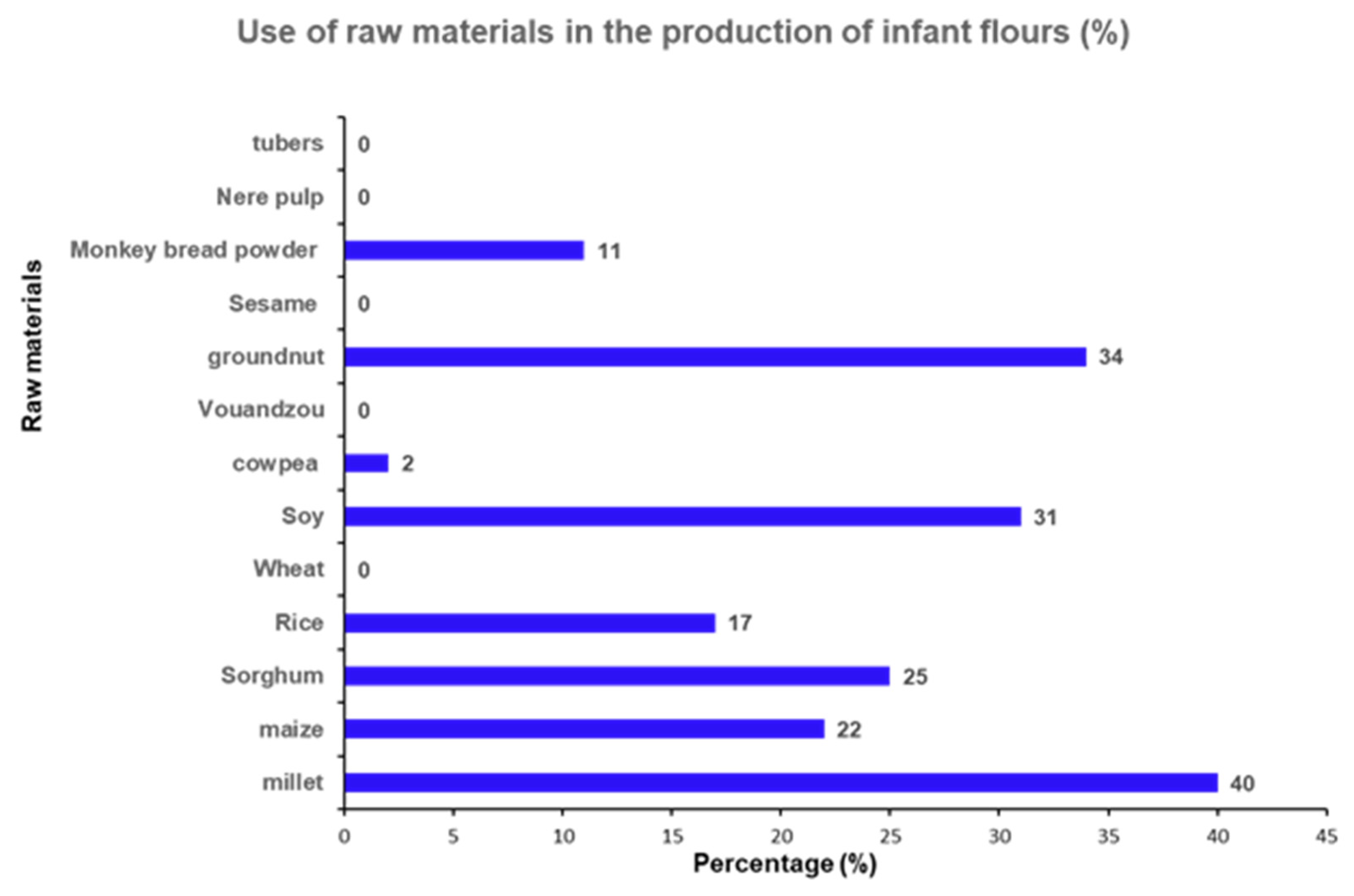

3.2. Raw materials used for the production of infant flours in Ouagadougou

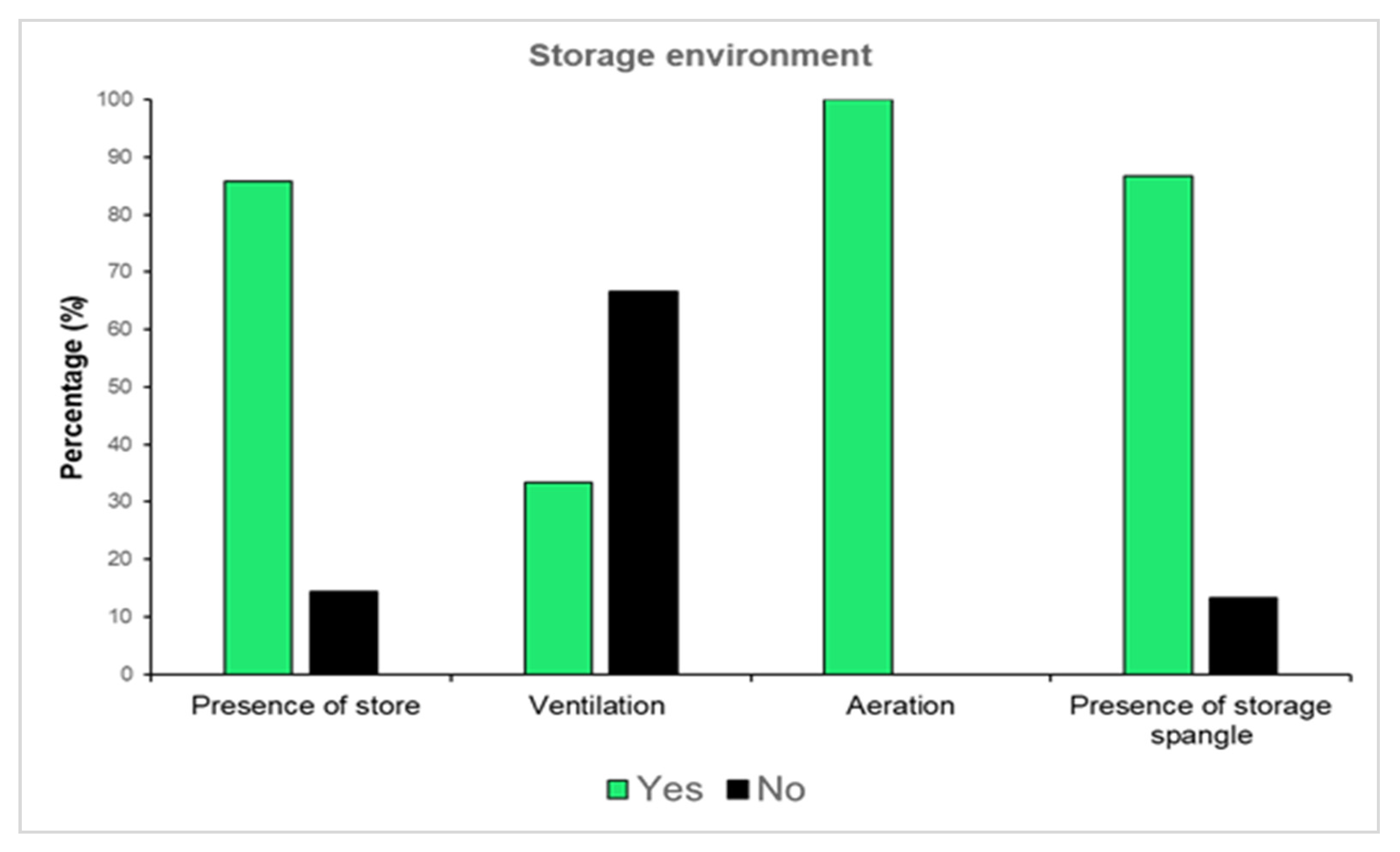

3.3. Storage conditions of raw materials

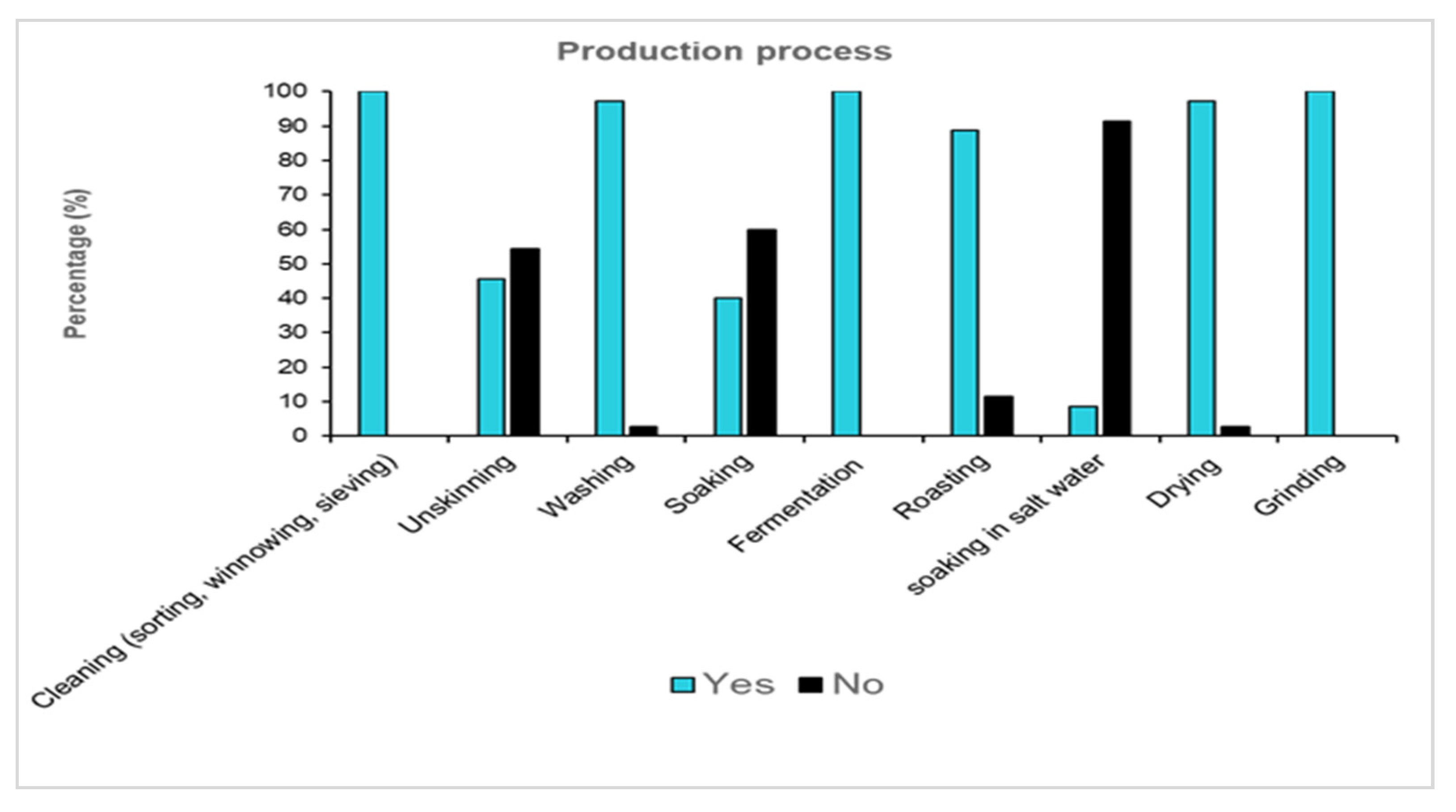

3.4. Infant flour production processes

3.5. Infant flour produced by production units in Ouagadougou

3.5.1. Types of infant flours produced

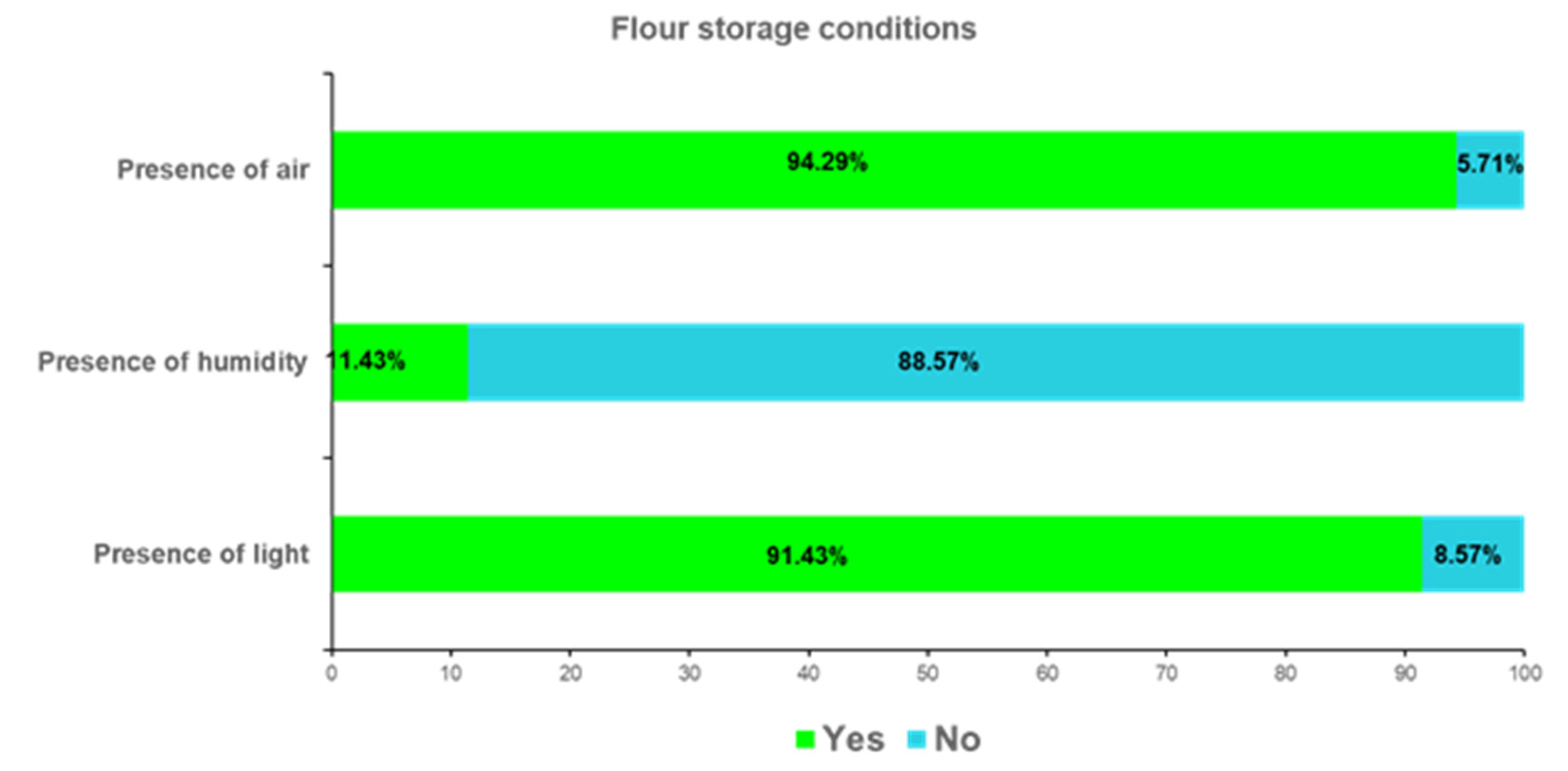

3.5.2. Packaging and storage of infant flours

3.6. Infant flour quality monitoring

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nishida, C.; Uauy, R.; Kumanyika, S.; Shetty, P. The Joint WHO/FAO Expert Consultation on Diet, Nutrition and the Prevention of Chronic Diseases: Process, Product and Policy Implications. Public Health Nutr. 2004, 7, 245–250. [Google Scholar] [CrossRef] [PubMed]

- OMS PRINCIPES DIRECTEURS POUR L’ALIMENTATION DES ENFANTS AGES DE 6 A 24 MOIS QUI NE SONT PAS ALLAITES AU SEIN; 2006; p. 44;

- Olive, F.; Mouquet Rivier, C.; Fioroni, N.; Bichard, A.; Boulle-Martinaud, N.; Kaboré, C.; Denizeau, M.; Zagré, N.M.; Le Dain, A.S.; Ndiaye, N.F.; et al. La filière des farines infantiles produites localement dans six pays sahéliens : Burkina Faso, Mali, Mauritanie, Niger, Sénégal, Tchad : rapport de l’étude “La filière des farines infantiles produites localement dans 6 pays sahéliens” réalisée de juillet 2019 à janvier 2020; Paris: Unesco, 2020; p. p. 164 p.; [Google Scholar]

- Størmer, F.C. [Significance of mycotoxins for health--present and past]. Tidsskr. Den Nor. Laegeforening Tidsskr. Prakt. Med. Ny Raekke 1993, 113, 1061–1063. [Google Scholar]

- RGPH Cinquième Recensement Général de la Population et de l’Habitation du Burkina Faso; 2019; p. 136;

- Bougma, S.; Oboulbiga, E.B.; Tarnagda, B.; Zongo, O.; Kaboré, B.; Ouedraogo, H.S.; Songré-Ouattara, L.T.; Savadogo, A. Evaluation de La Qualité Physico-Chimique et Microbiologique de Quelques Farines Infantiles Locales Vendues à Ouagadougou, Burkina Faso. 2022.

- Atsa’am, D.D.; Oyelere, S.S.; Balogun, O.S.; Wario, R.; Blamah, N.V. K-Means Cluster Analysis of the West African Species of Cereals Based on Nutritional Value Composition. Afr. J. Food Agric. Nutr. Dev. 2021, 21, 17195–17212. [Google Scholar] [CrossRef]

- DN Table de composition des aliments du Burkina Faso. <b>2005</b>, 39. DN Table de composition des aliments du Burkina Faso. 2005, 39.

- Amoin, A.; Agbo, E.A.; Dago, A.G.; Gbogouri, A.G.; Brou, D.K.; Dago, G. Comparaison Des Caractéristiques Nutritionnelles et Rhéologiques Des Bouillies Infantiles Préparées Par Les Techniques de Germination et de Fermentation. Int. J. Biol. Chem. Sci. 2015, 9, 944–953. [Google Scholar] [CrossRef]

- Rémond, D.; Walrand, S. Les Graines de Légumineuses: Caractéristiques Nutritionnelles et Effets Sur La Santé. Innov. Agron. 2017, 60, np. [Google Scholar]

- Cissé, I. Caractérisation Des Propriétés Biochimiques et Nutritionnelles de La Pulpe de Baobab Des Espèces Endémiques de Madagascar et d’Afrique Continentale En Vue de Leur Valorisation. PhD Thesis, Montpellier SupAgro, 2012.

- Augustin, N.-N.; Pierre, N.N.; Antoine, L.K.; Marcel, M.-M.; Adrien, K.-M. Evaluation Des Facteurs Antinutritionnels de Quelques Génotypes de Haricot Commun (Phaseolus Vulgaris L.) Biofortifié. 2017.

- Sarwar Gilani, G.; Wu Xiao, C.; Cockell, K.A. Impact of Antinutritional Factors in Food Proteins on the Digestibility of Protein and the Bioavailability of Amino Acids and on Protein Quality. Br. J. Nutr. 2012, 108 Suppl 2, S315–332. [Google Scholar] [CrossRef]

- de Andrade Cairo, R.C.; Silva, L.R.; Bustani, N.C.; Marques, C.D.F. Iron Deficiency Anemia in Adolescents; a Literature Review. Nutr. Hosp. 2014, 29, 1240–1249. [Google Scholar] [PubMed]

- Tesfaye, T.S.; Tessema, F.; Jarso, H. Prevalence of Anemia and Associated Factors among “Apparently Healthy” Urban and Rural Residents in Ethiopia: A Comparative Cross-Sectional Study. J. Blood Med. 2020, 89–96. [Google Scholar] [CrossRef] [PubMed]

- Nadjet, G.-T.; Noureddine, B.; Didi, O.E.H.M. Les Mycotoxines: Un Danger de Santé Public. Algerian J. Arid Environ. “AJAE” 2016, 6. [Google Scholar]

- BENLAMEUR, Z. Les Ravageurs Des Denrées Stockées et Leur Impact Sur La Santé Humaine. PhD Thesis, ENSA, 2016.

- Badenhausser, I.; Lallemand, J. Se Passer Des Pesticides En Agriculture? In Proceedings of the Conference CPO; 2017.

- Barouki, R. Risque de Cancer Du Sein et Estrogènes: Actualités: Xéno-Estrogènes et Cancer Du Sein. 28° Journ. Société Fr. Sénologie Pathol. Mammaire Lille FRA 2006-11-08 Cancers Sein Localisés Nouv. Prat. Lille 8-10 Novembre 2006Early Breast Cancer New Pract. 2006. [Google Scholar]

- Anjarwalla, P.; Belmain, S.; Sola, P.; Jamnadass, R.; Stevenson, P.C. Guide Des Plantes Pesticides. World Agrofor. Cent. ICRAF Nairobi Kenya 2016. [Google Scholar]

- Cissokho, P.S.; Gueye, M.T.; Sow, E.H.; Diarra, K. Substances Inertes et Plantes à Effet Insecticide Utilisées Dans La Lutte Contre Les Insectes Ravageurs Des Céréales et Légumineuses Au Sénégal et En Afrique de l’Ouest. Int. J. Biol. Chem. Sci. 2015, 9, 1644–1653. [Google Scholar] [CrossRef]

- Bruce, A.C.C.; KAYODE, A.P. Aptitude Au Stockage de Quelques Farines Infantiles à Base de Ressources Alimentaires Locales Du BENIN. 2017.

- Ware, L.Y.; Durand, N.; Nikiema, P.A.; Alter, P.; Fontana, A.; Montet, D.; Barro, N. Occurrence of Mycotoxins in Commercial Infant Formulas Locally Produced in Ouagadougou (Burkina Faso). Food Control 2017, 73, 518–523. [Google Scholar] [CrossRef]

- Olagunju, O.; Mchunu, N.; Durand, N.; Alter, P.; Montet, D.; Ijabadeniyi, O. Effect of Milling, Fermentation or Roasting on Water Activity, Fungal Growth, and Aflatoxin Contamination of Bambara Groundnut (Vigna Subterranea (L.) Verdc). Lwt 2018, 98, 533–539. [Google Scholar] [CrossRef]

- Furbeyre, H.; Guillevic, M.; Chesneau, G.; Labussière, E. Effets Du Dépelliculage et de l’extrusion Sur La Valeur Nutritionnelle de La Graine de Féverole Chez Le Porc En Croissance. In Proceedings of the 52. Journées de la Recherche Porcine; IFIP-Institut du Porc; 2020; pp. 87–92. [Google Scholar]

- Mariscal-Landı́n, G.; Lebreton, Y.; Sève, B. Apparent and Standardised True Ileal Digestibility of Protein and Amino Acids from Faba Bean, Lupin and Pea, Provided as Whole Seeds, Dehulled or Extruded in Pig Diets. Anim. Feed Sci. Technol. 2002, 97, 183–198. [Google Scholar] [CrossRef]

- Razafindrazaka, V.L. Elaboration et évaluation d’une stratégie d’amélioration de l’alimentation de complément des jeunes enfants à Brickaville (côte Est de Madagascar). 2006, 215.

- Ndamobissi, R. La Malnutrition Des Enfants Dans Les Pays Du Sahel et de La Corne de l’Afrique: Défis Sociodémographiques et Politiques (Burkina Faso, Niger, Sénégal, Ethiopie, Ghana). Malnutrition Enfants Dans Pays Sahel Corne Afr. 2018, 1–256. [Google Scholar]

- Tou, E.H.K.-P. Caractérisation et Amélioration Du Procédé Traditionnel de Préparation de La Bouillie de Mil Fermenté, Ben-Saalga, Utilisée Comme Aliment de Complément Au Burkina Faso. 2006.

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; Van Geem, K.M.; Ragaert, K.; De Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef] [PubMed]

- SOMAKOU, M. APPRECIATION DE LA QUALITE NUTRITIONNELLE DE LA FARINE INFANTILE CERESO OUANDO ET EVALUATION DE L’EFFET DE LA CUISSON-EXTRUSION SUR LA FARINE; EPAC/UAC, 2017.

- Grodji Albarin, G.; Mandoué Stephanie, B.; Dogoré Yolande, D.; Kouakou, B. Elaboration d’une Farine Infantile Composée à Base d’ingrédients Locaux de Côte d’Ivoire : Quelles Stratégies d’enrichissement En Acides Gras Polyinsaturés Oméga 3 ? 2019, 13.

- Rohner, F.; Leyvraz, M.; Konan, A.G.; Esso, L.J.C.E.; Wirth, J.P.; Norte, A.; Adiko, A.F.; Bonfoh, B.; Aaron, G.J. The Potential of Food Fortification to Add Micronutrients in Young Children and Women of Reproductive Age – Findings from a Cross-Sectional Survey in Abidjan, Côte d’Ivoire. PLOS ONE 2016, 11, e0158552. [Google Scholar] [CrossRef] [PubMed]

| Flour fortification, breakdown of production units by type and use of store treatment pesticides | Type of flours and packaging | ||||||||||||||

| Flour fortification | Breakdown of production units by type | Use of store treatment pesticides | Type of flours | Type of packaging | |||||||||||

| YES | NO | Artisanal | CREN | Semi-industrial | YES | NO | weaning | recovery | Plastic sachet and cardboard package | Aluminum complex sachet (Doypa type) | Simple sachet | Métallic box | |||

| NIF | 21 | 5 | NPU | 3 | 3 | 5 | 7 | 4 | NIF | 10 | 16 | 3 | 1 | 10 | 12 |

| P (%) | 80 | 20 | 27.27 | 27.27 | 45.45 | 66 | 34 | 37.14 | 62.86 | 11.43 | 2.86 | 40 | 45.71 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).