Submitted:

27 August 2023

Posted:

29 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Using production technologies that consume less water.

- Decreasing uncontrolled water usage by implementing spray nozzles and reducing leaks.

- Recycling/reusing water efficiently.

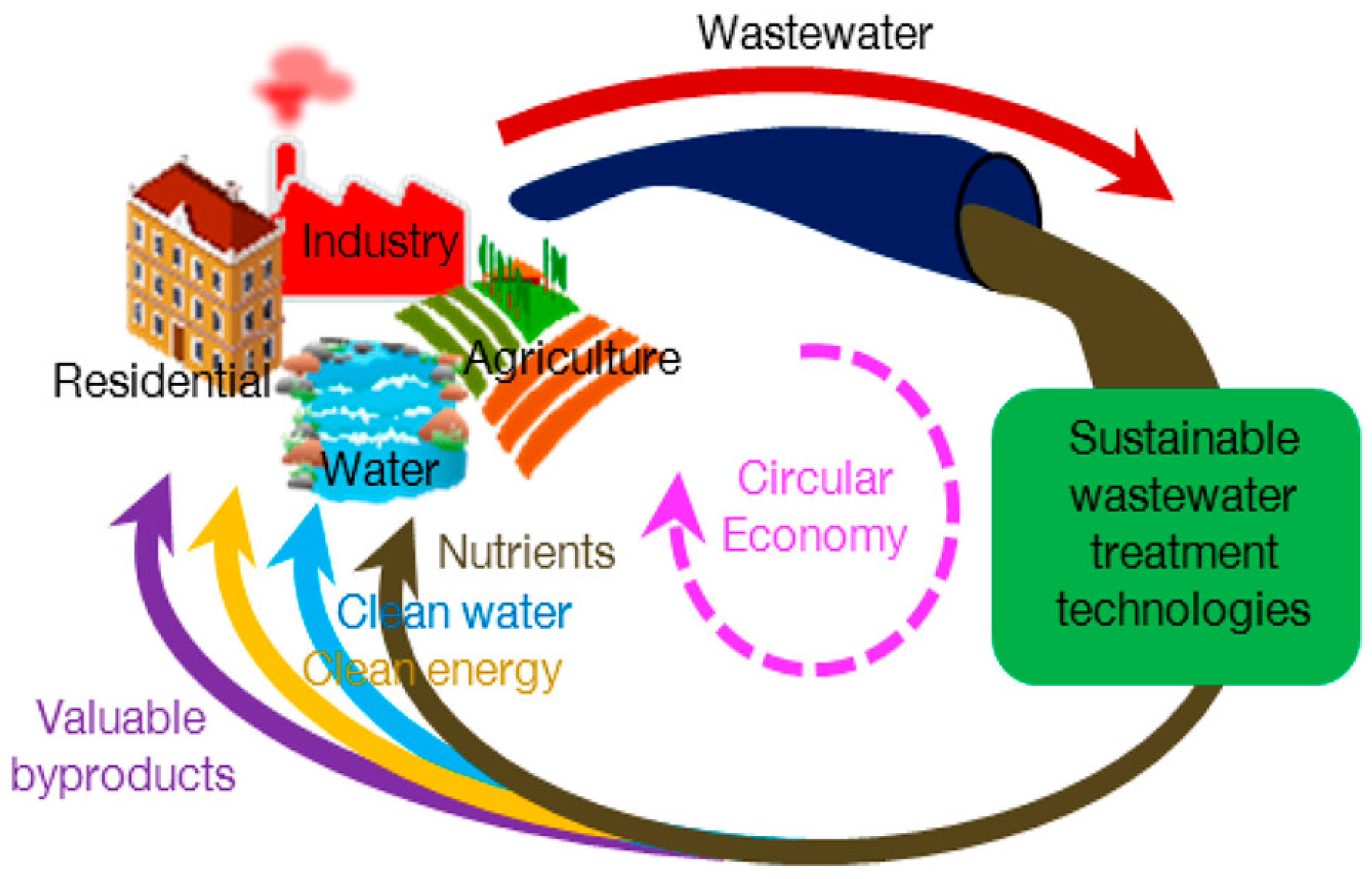

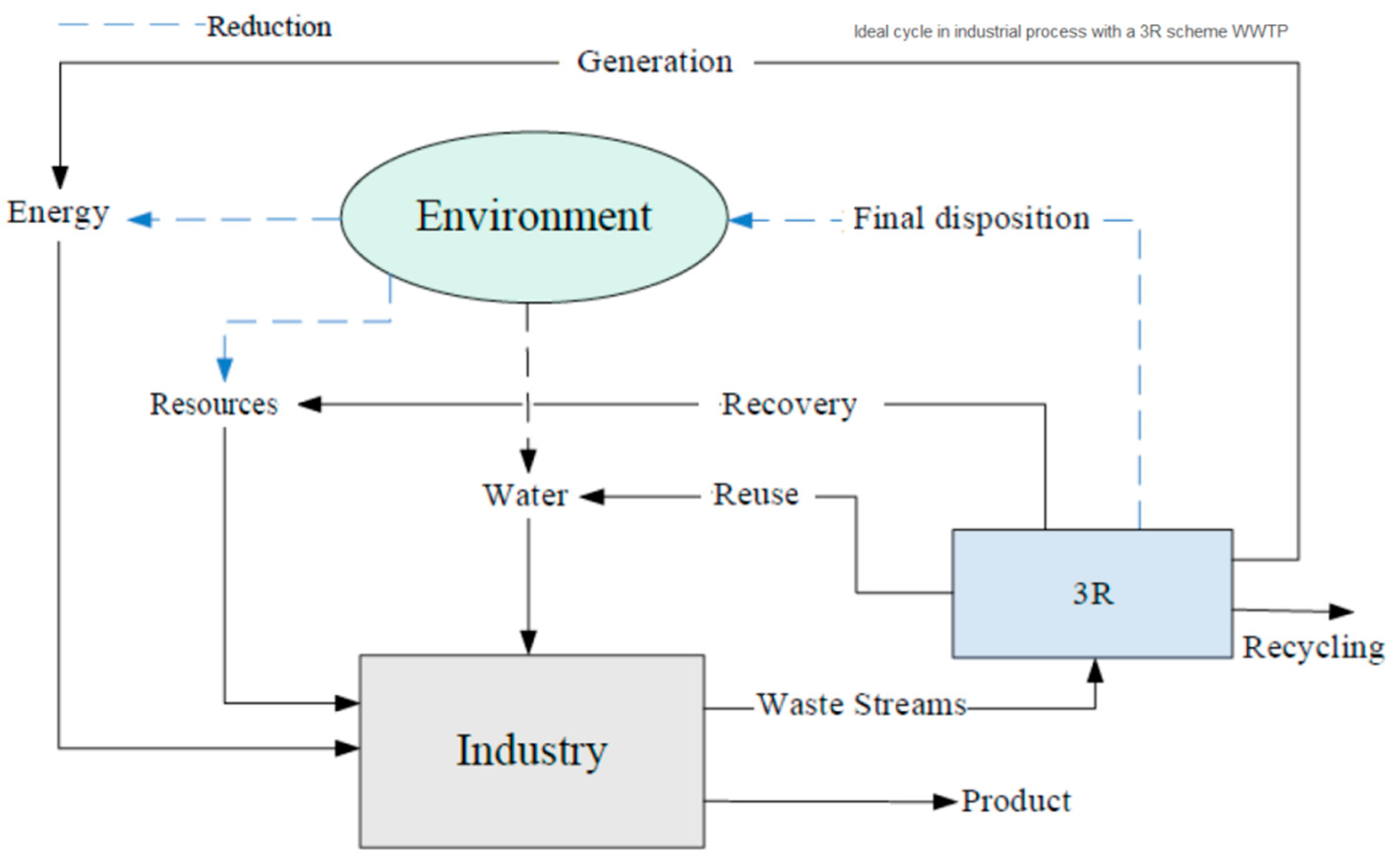

2. Integrated Industrial Wastewater Management

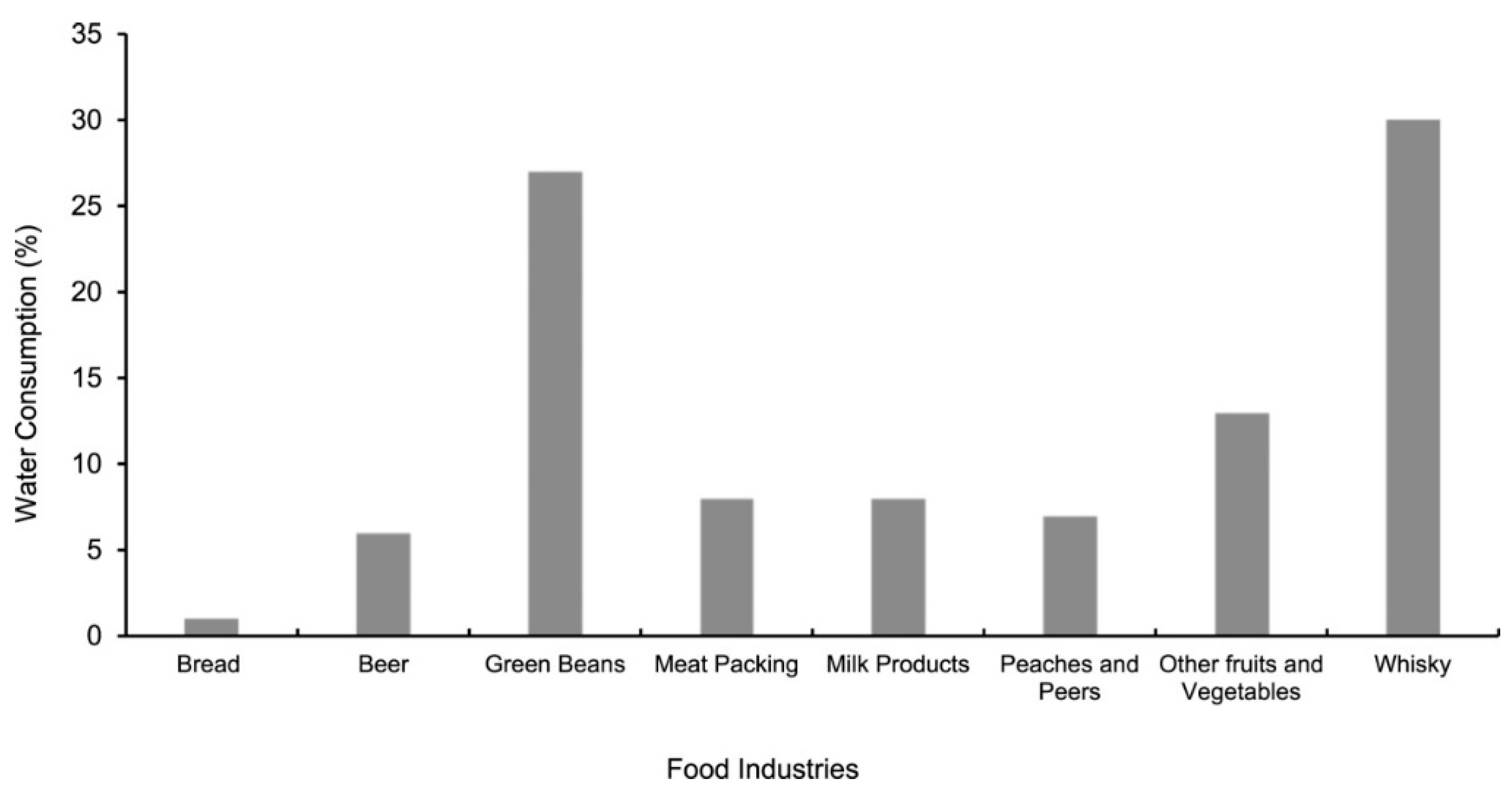

2.1. Food Processing Units

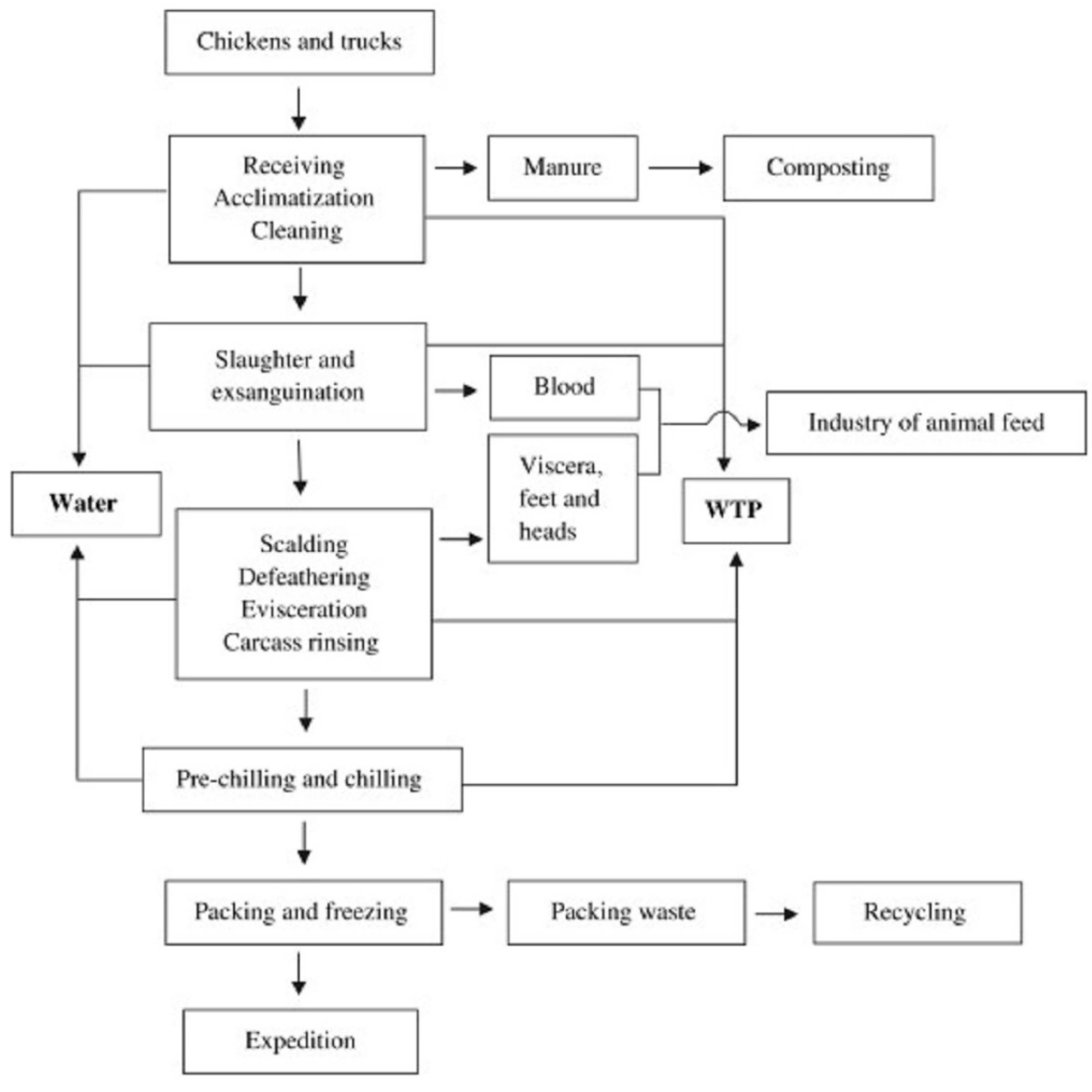

2.1.1. Meat production industries

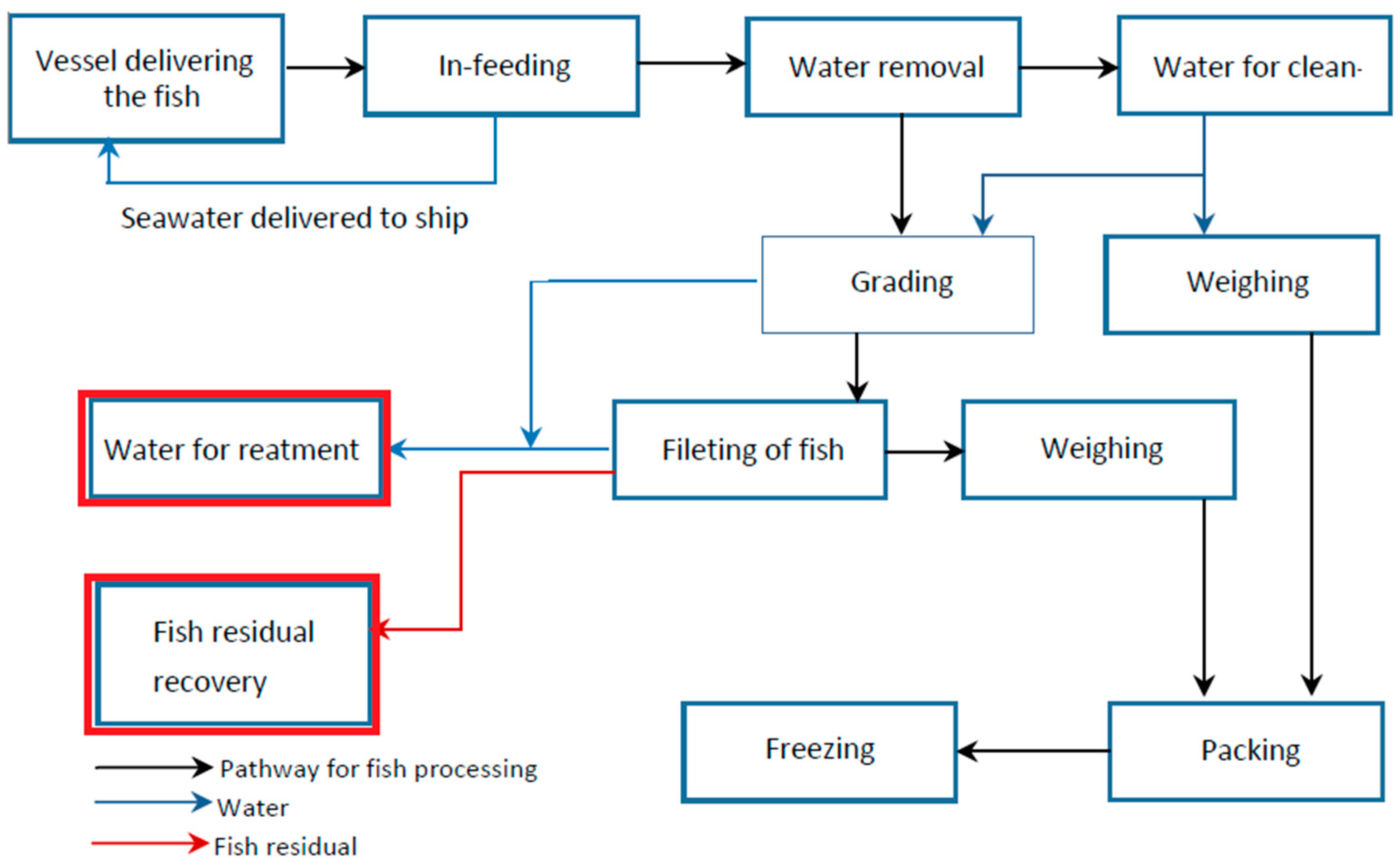

2.1.2. Fish and seafood industries

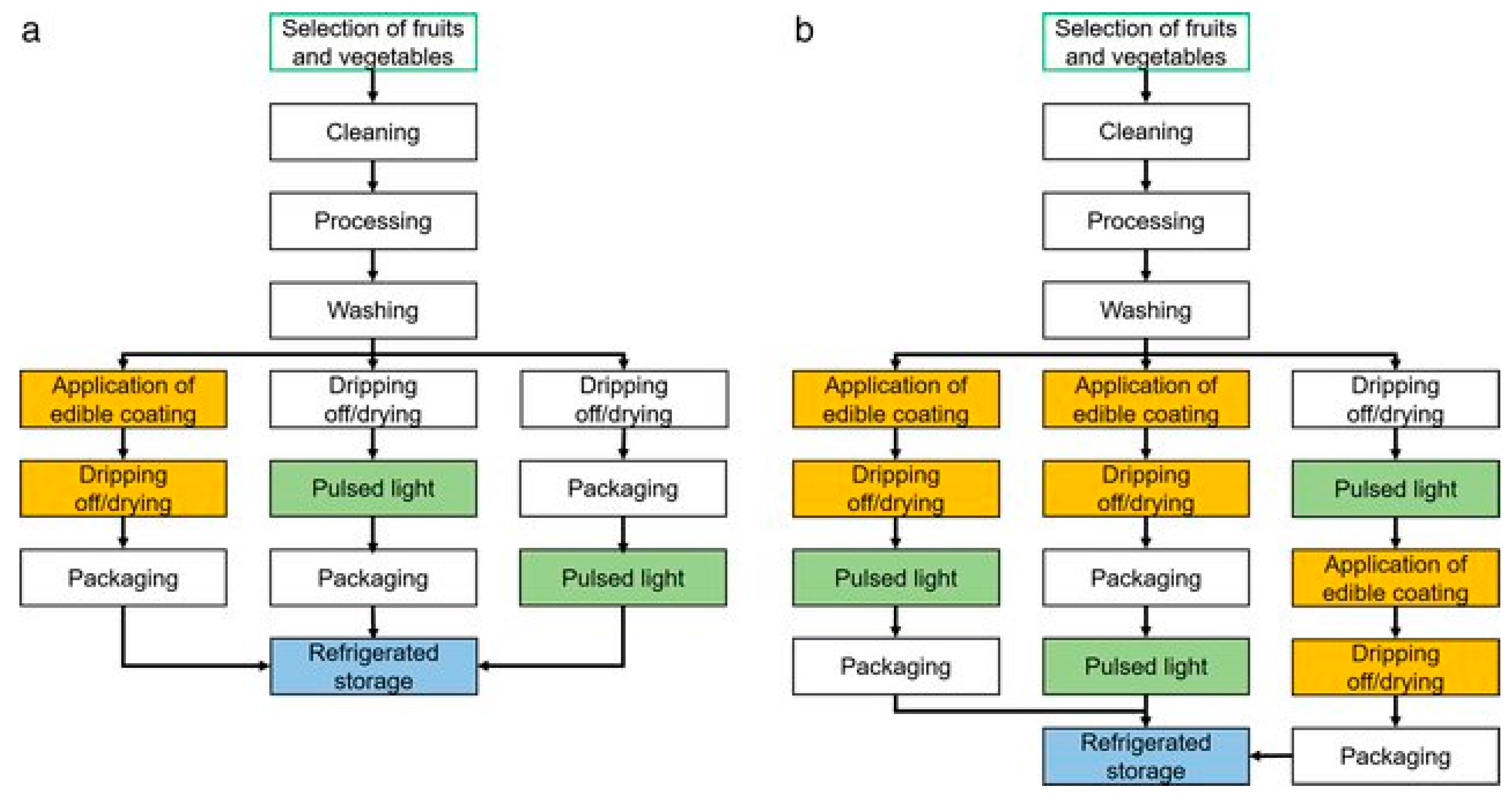

2.1.3. Fruits and vegetable processing industry

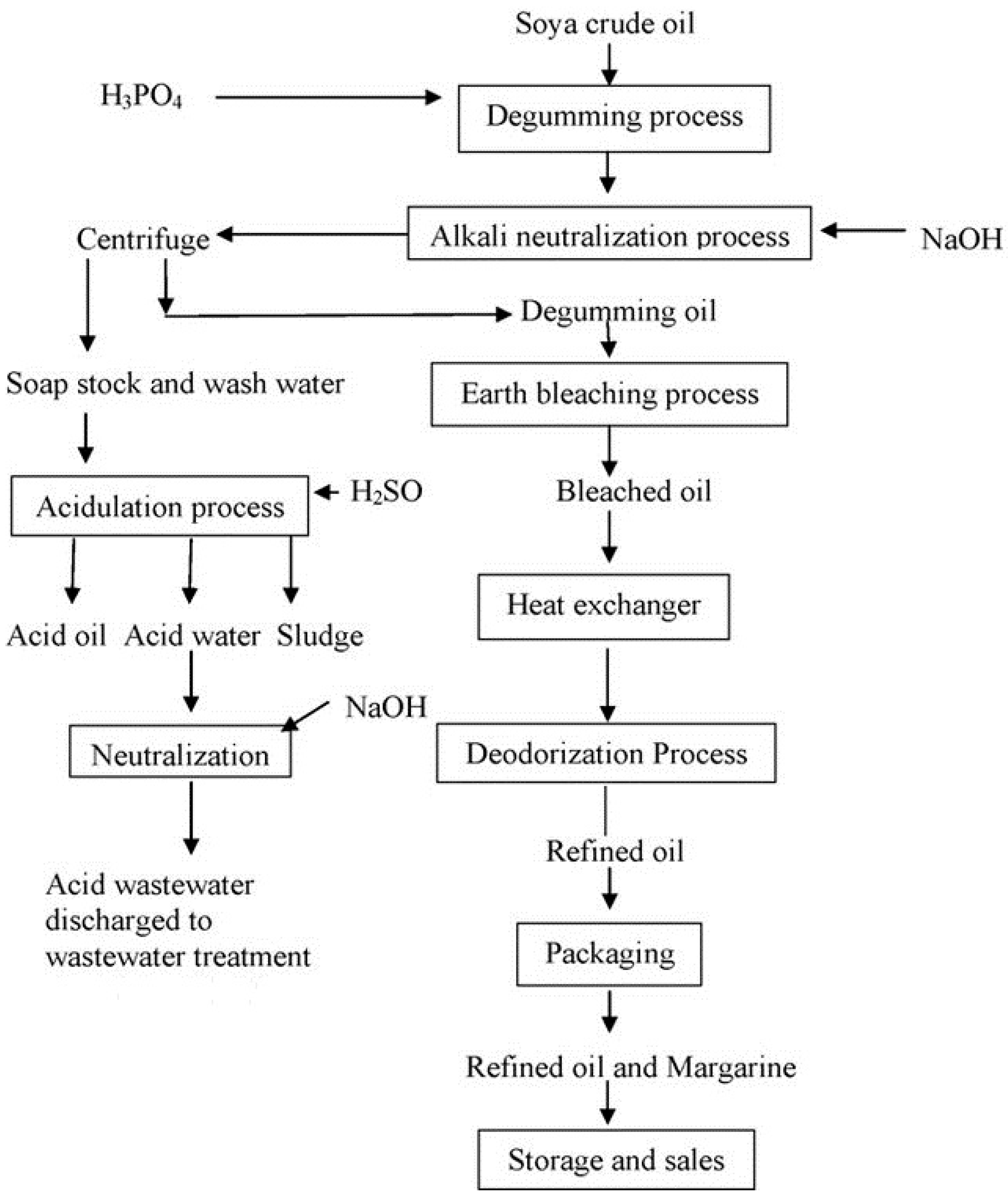

2.1.4. Edible oils industry

2.1.5. Dairy industries

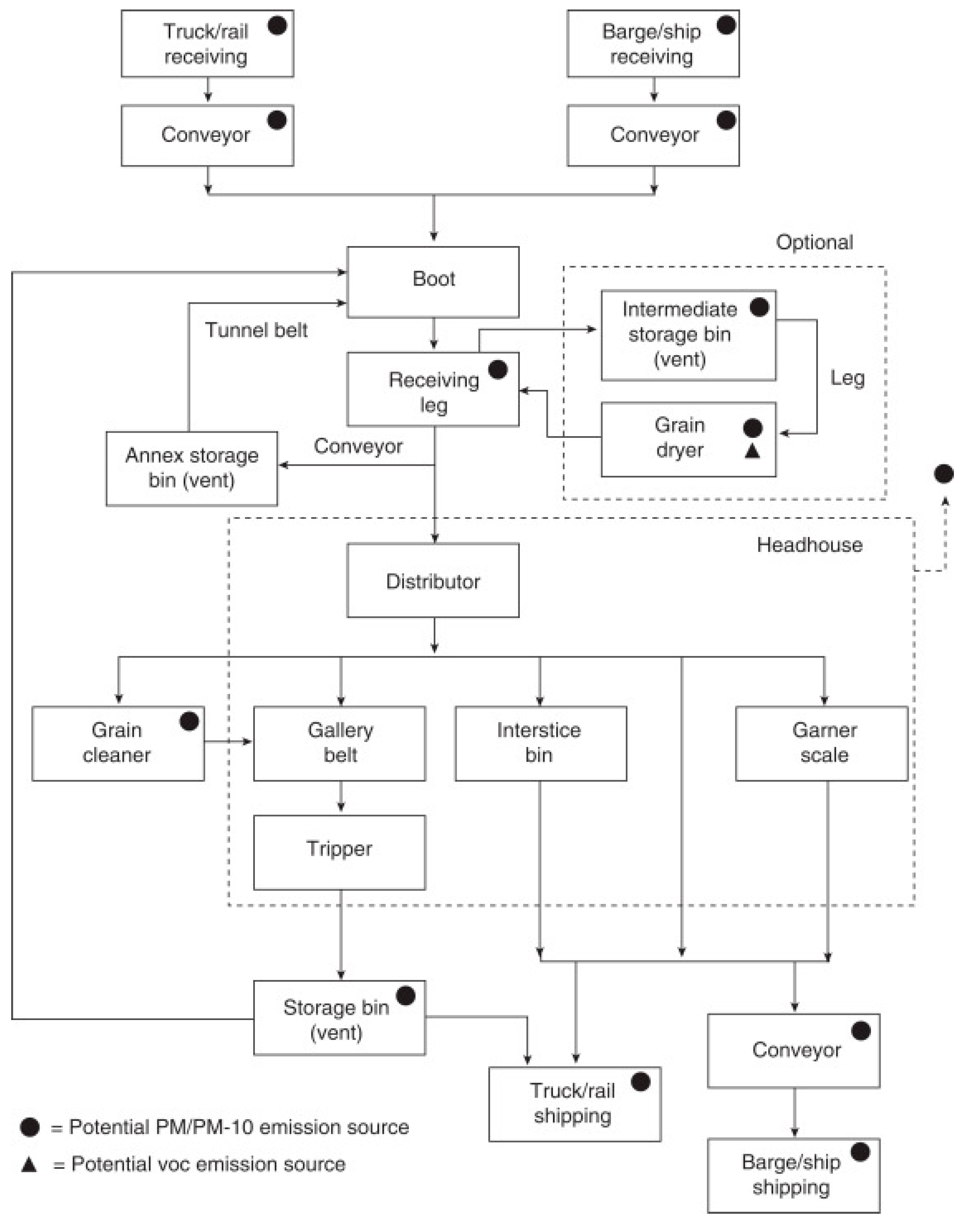

2.1.6. Grain milling industry

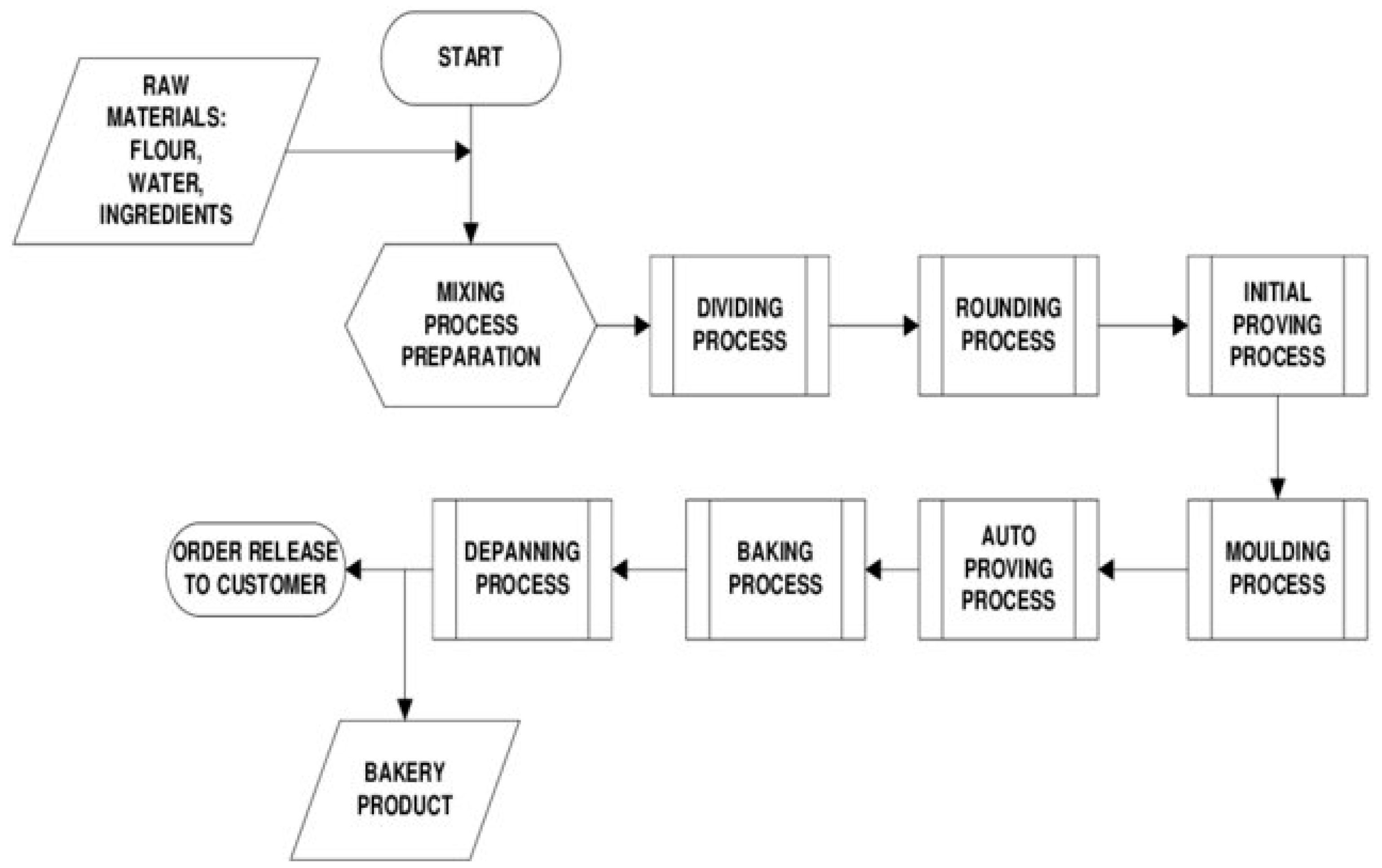

2.1.7. Bakery industry

2.2. Other Food Processing Industries

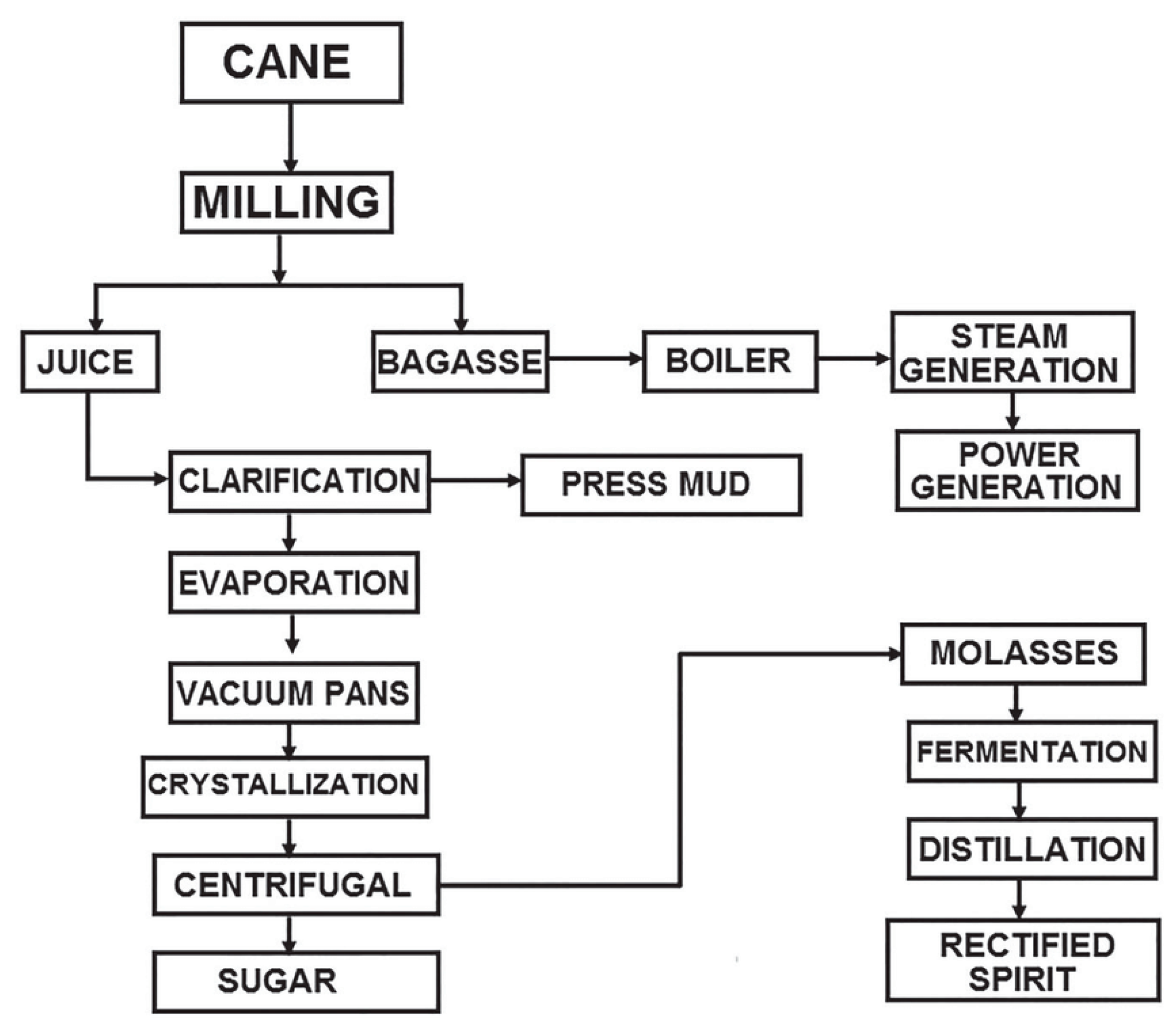

2.2.1. Sugar production

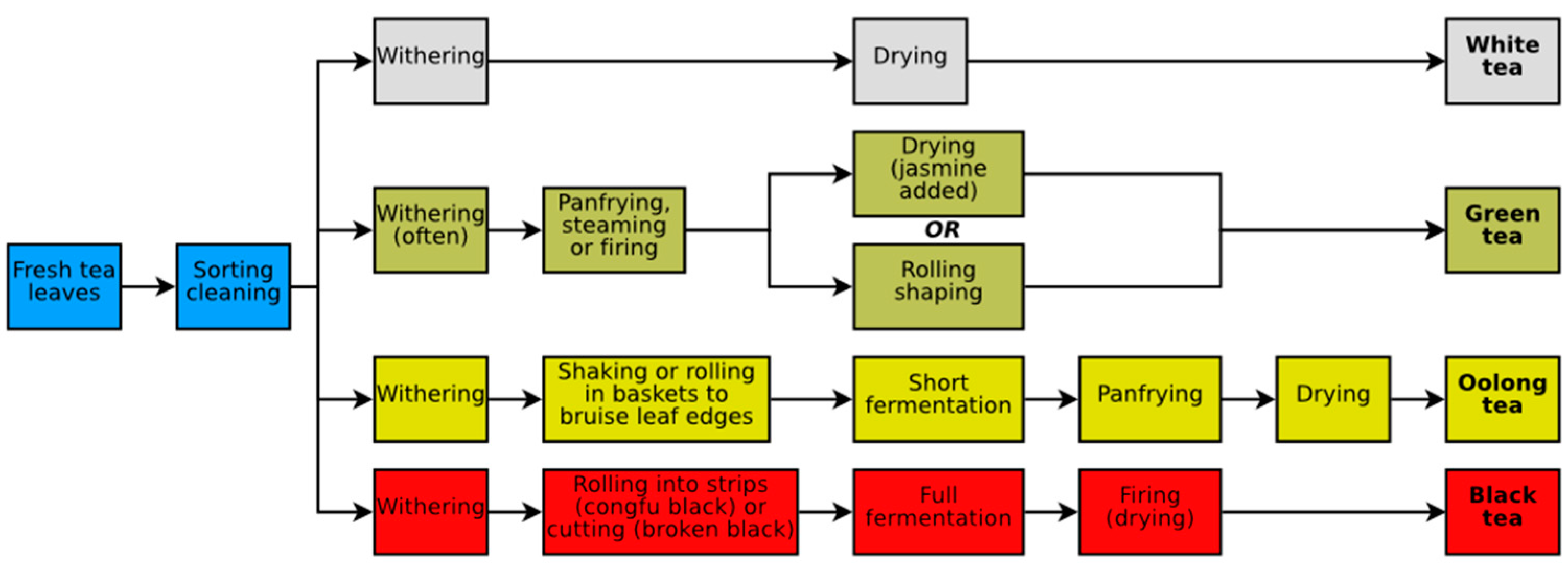

2.2.2. Tea industry

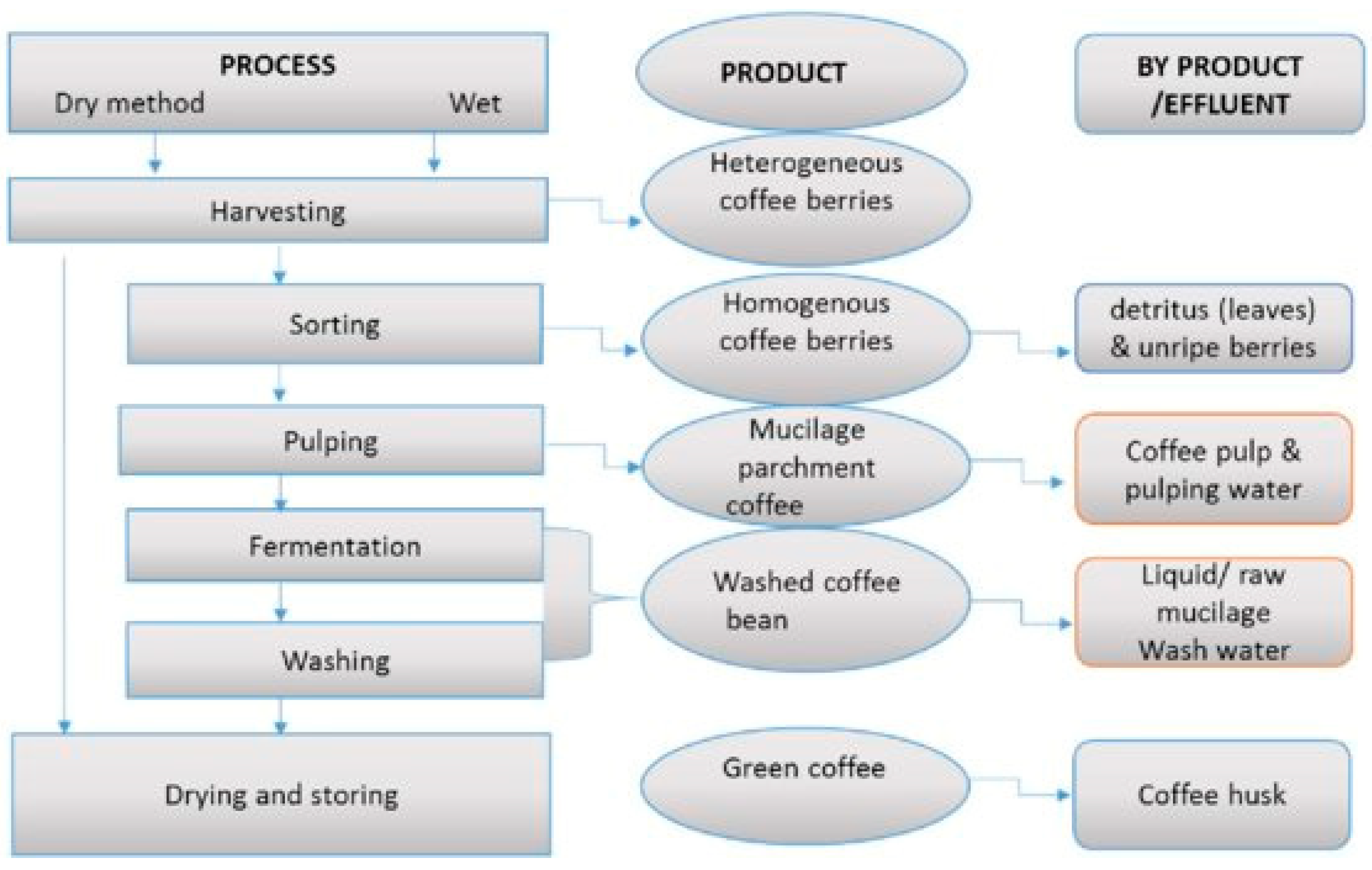

2.2.3. Coffee industry

2.3. Different Wastewater Treatment Solutions

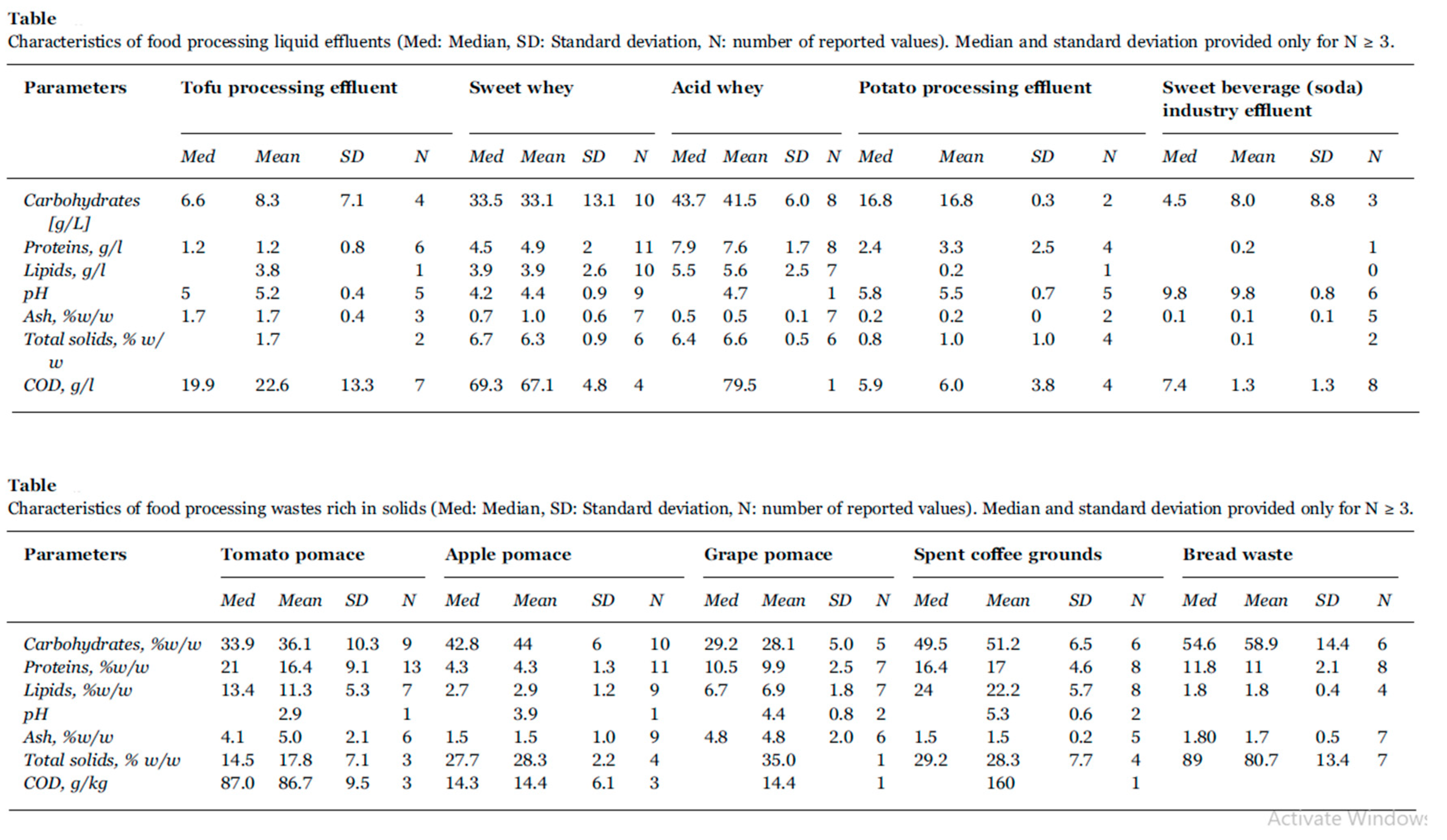

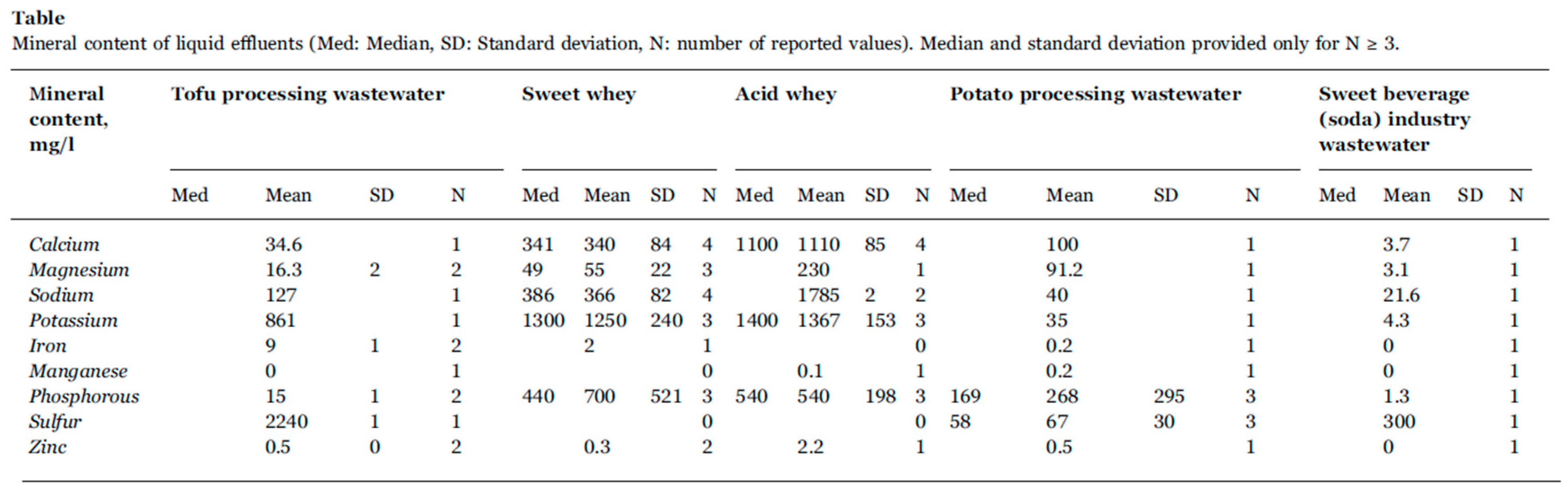

2.3.1. Treatment unit inlet composition

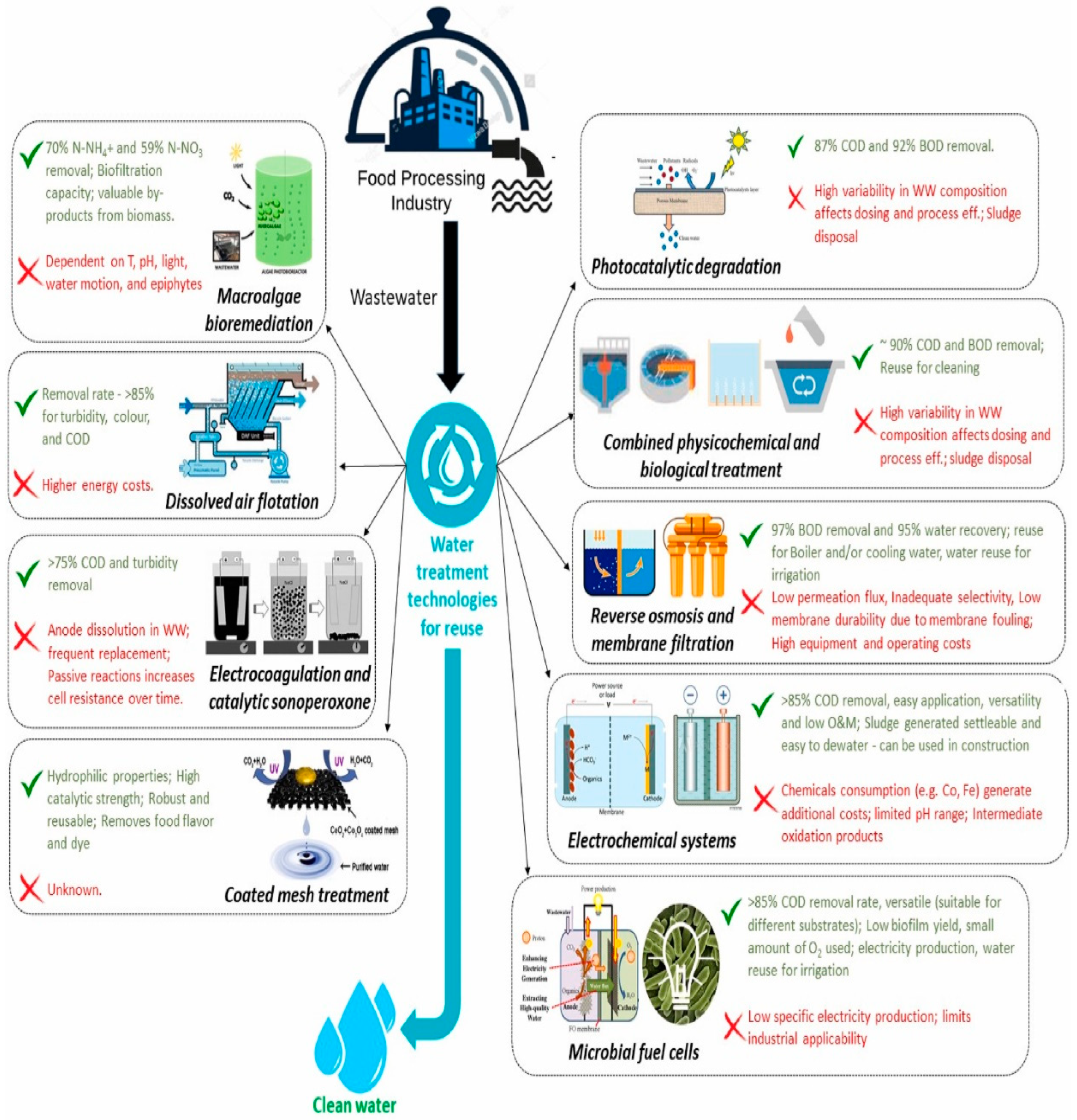

2.3.2. Technologies for food industry wastewater treatment and reuse

2.4. Challenges and factors for selecting the optimum treatment method

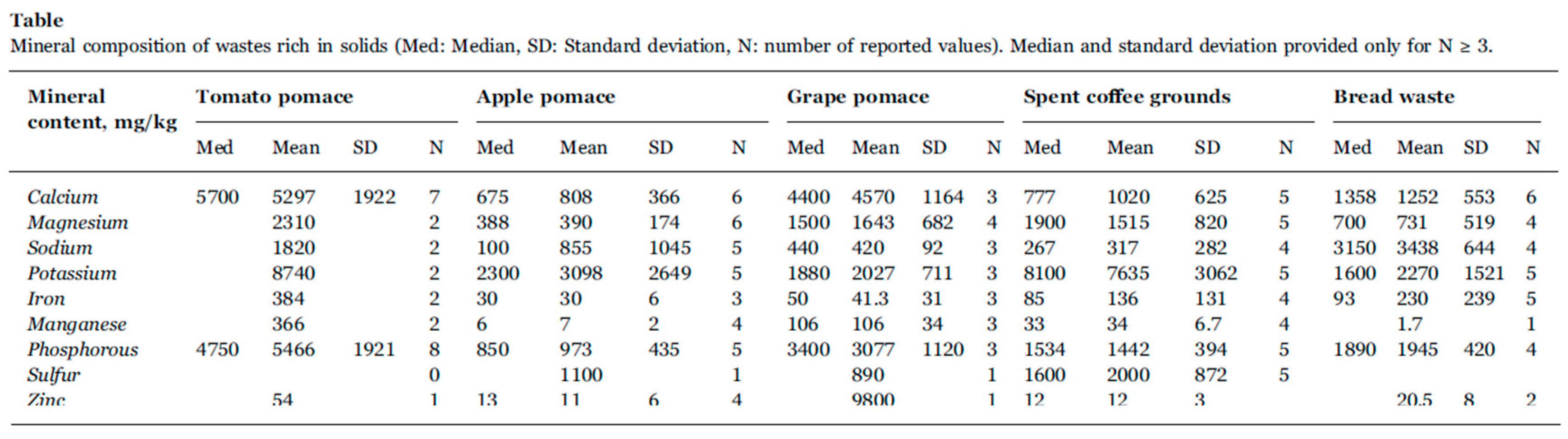

2.4.1. Environmental hazards of industrial wastewater

2.4.2. Water quality

2.5. Development and Integrated Management

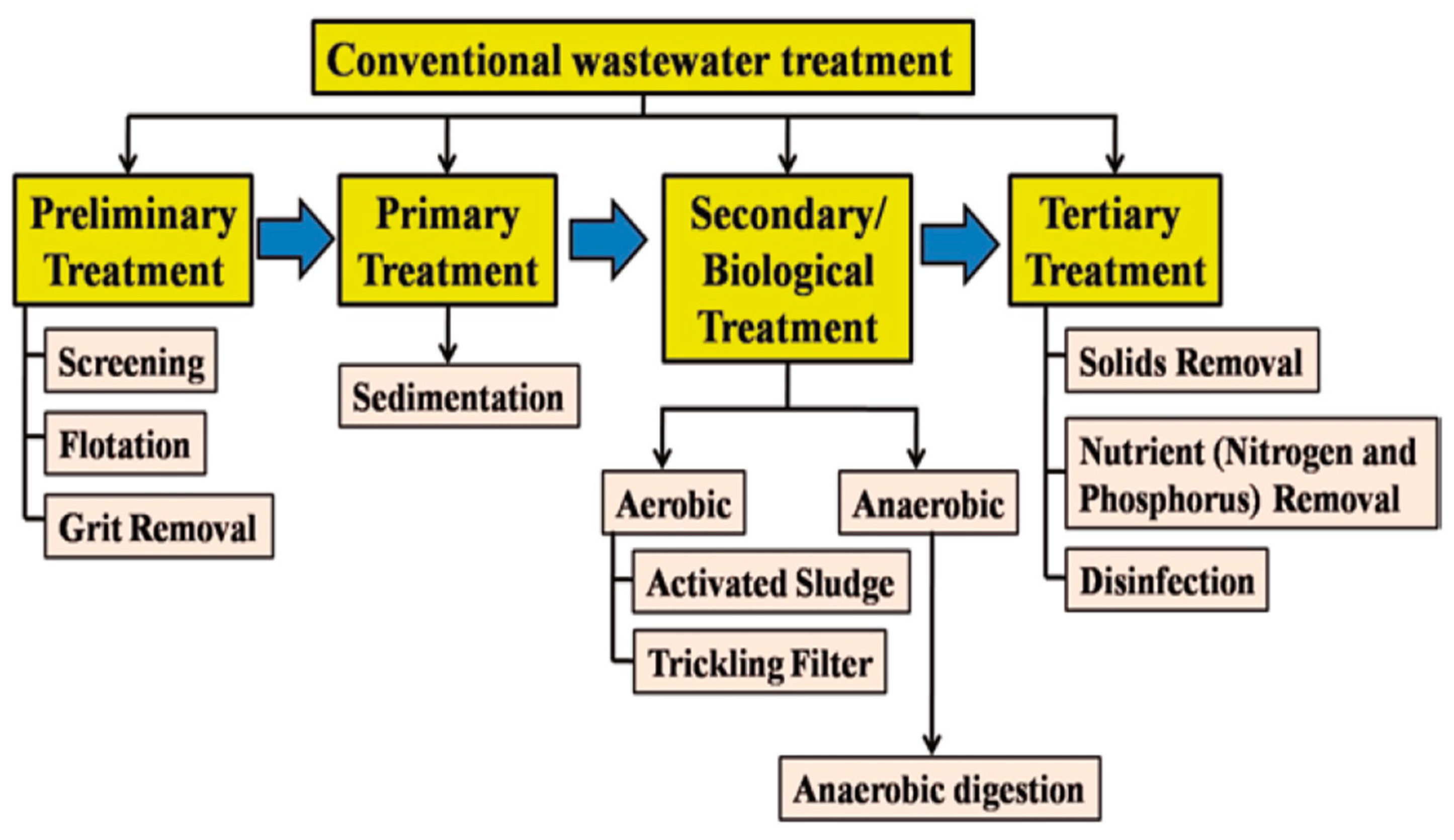

2.5.1. Industrial wastewater treatment levels

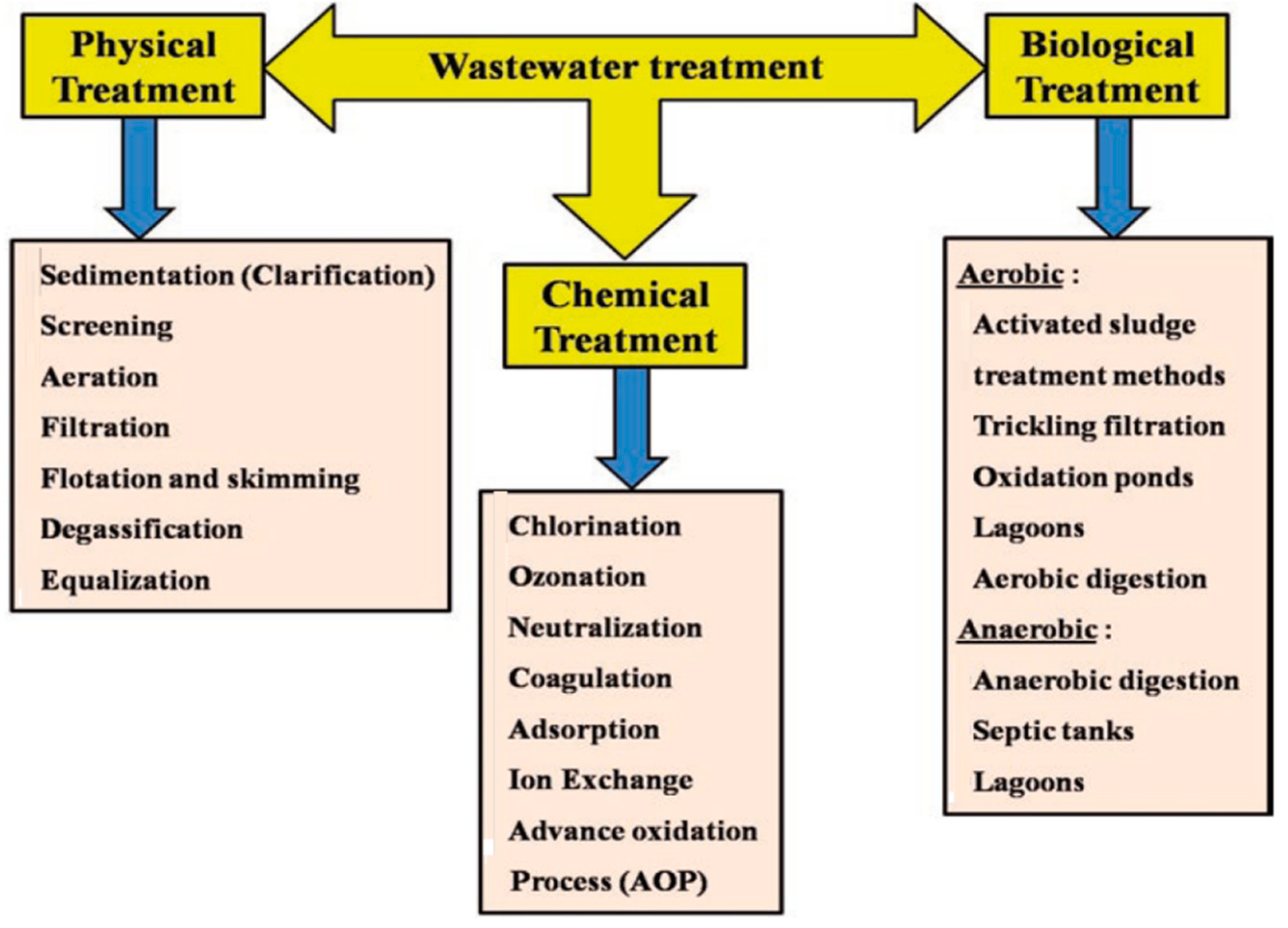

2.5.2. Wastewater Treatment Operations

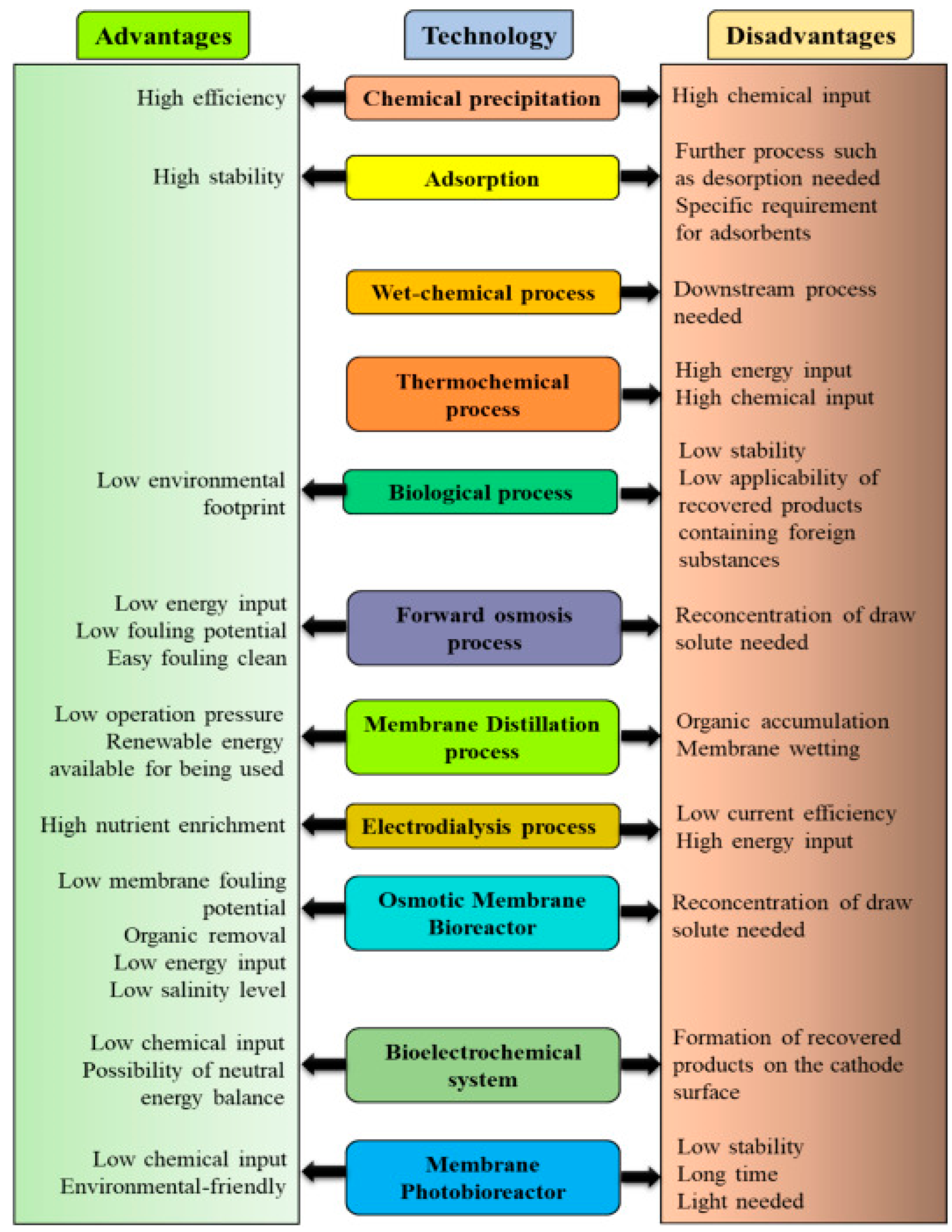

2.5.3. Membrane separation techniques

3. New Integrated Methods and Technologies

3.1. Microbial fuel cells

3.2. Recovery of proteins and lipids

3.3. Recovery of ammonium and phosphate

3.4. Production of biopolymers

3.5. Production of xanthan

3.6. Biogas production by anaerobic digestion

3.7. Heat recovery

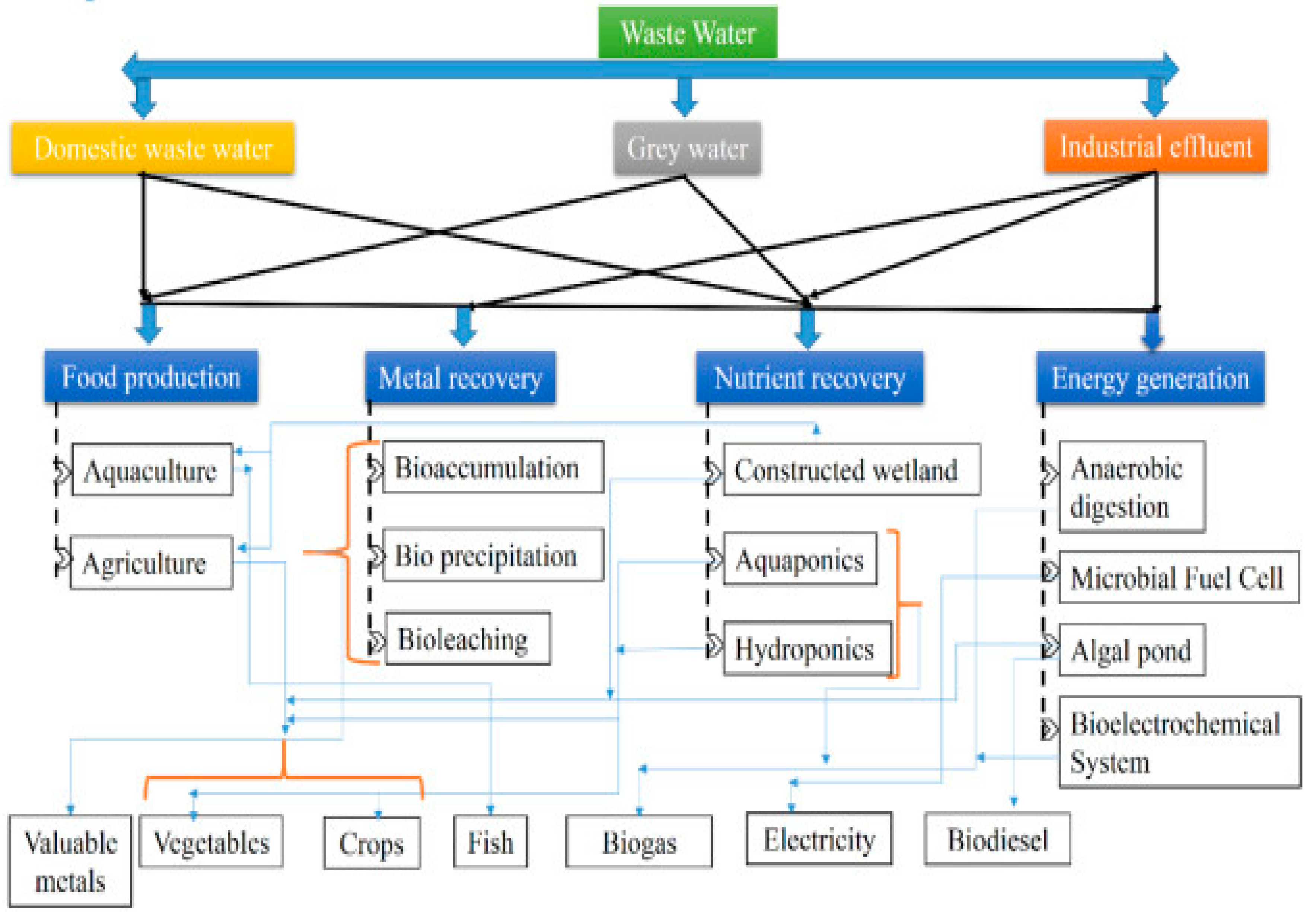

3.8. Mining of resources from wastewater

4. Water Management Framework

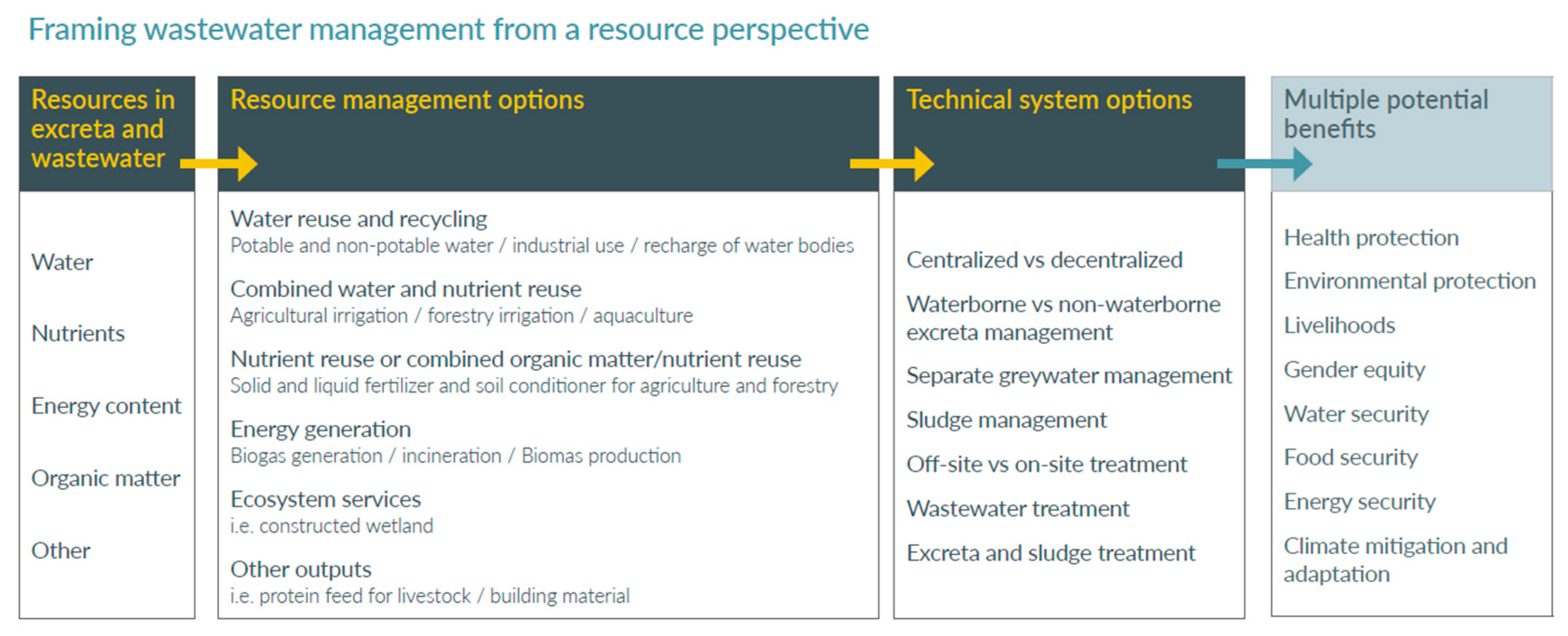

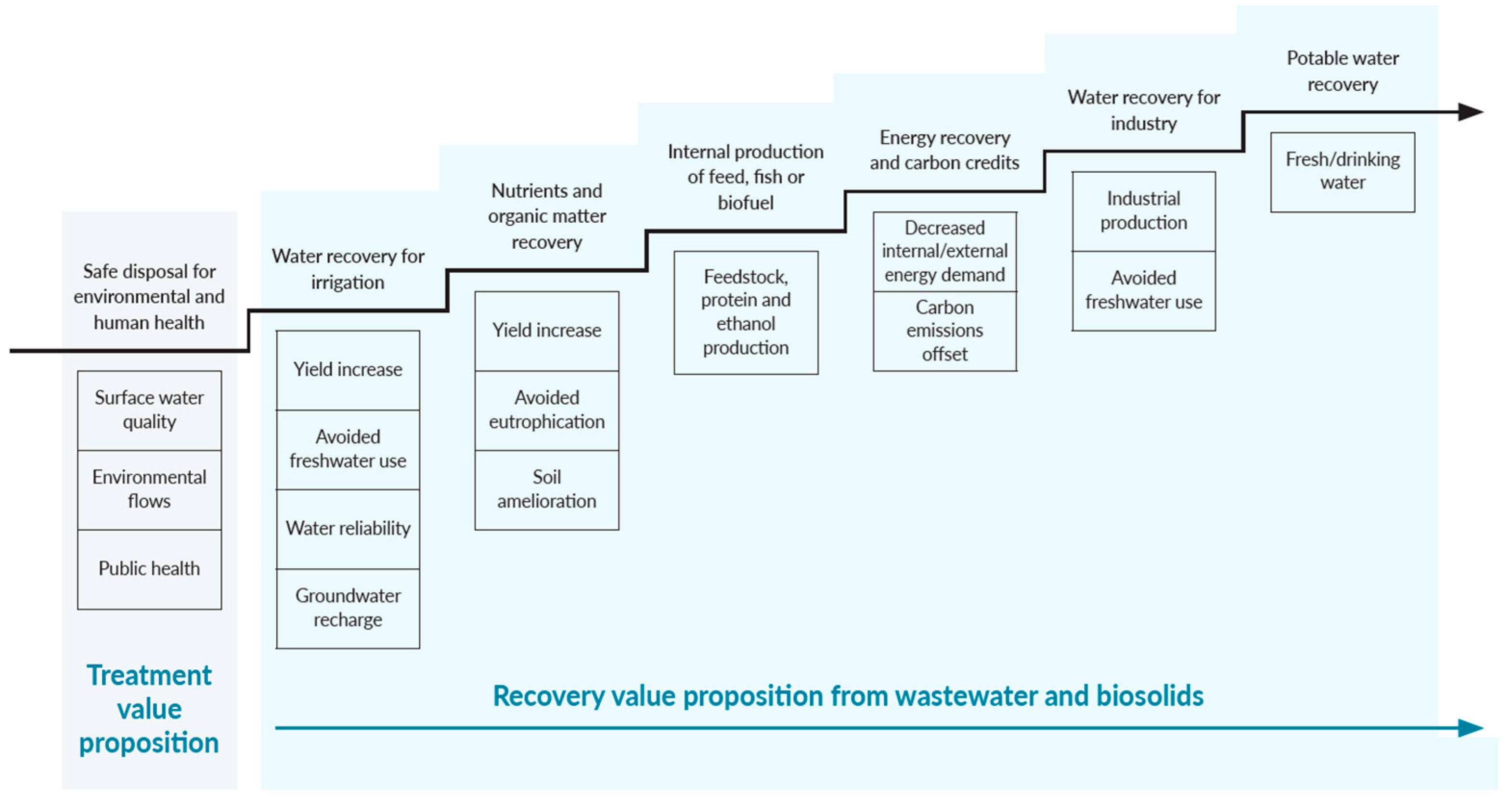

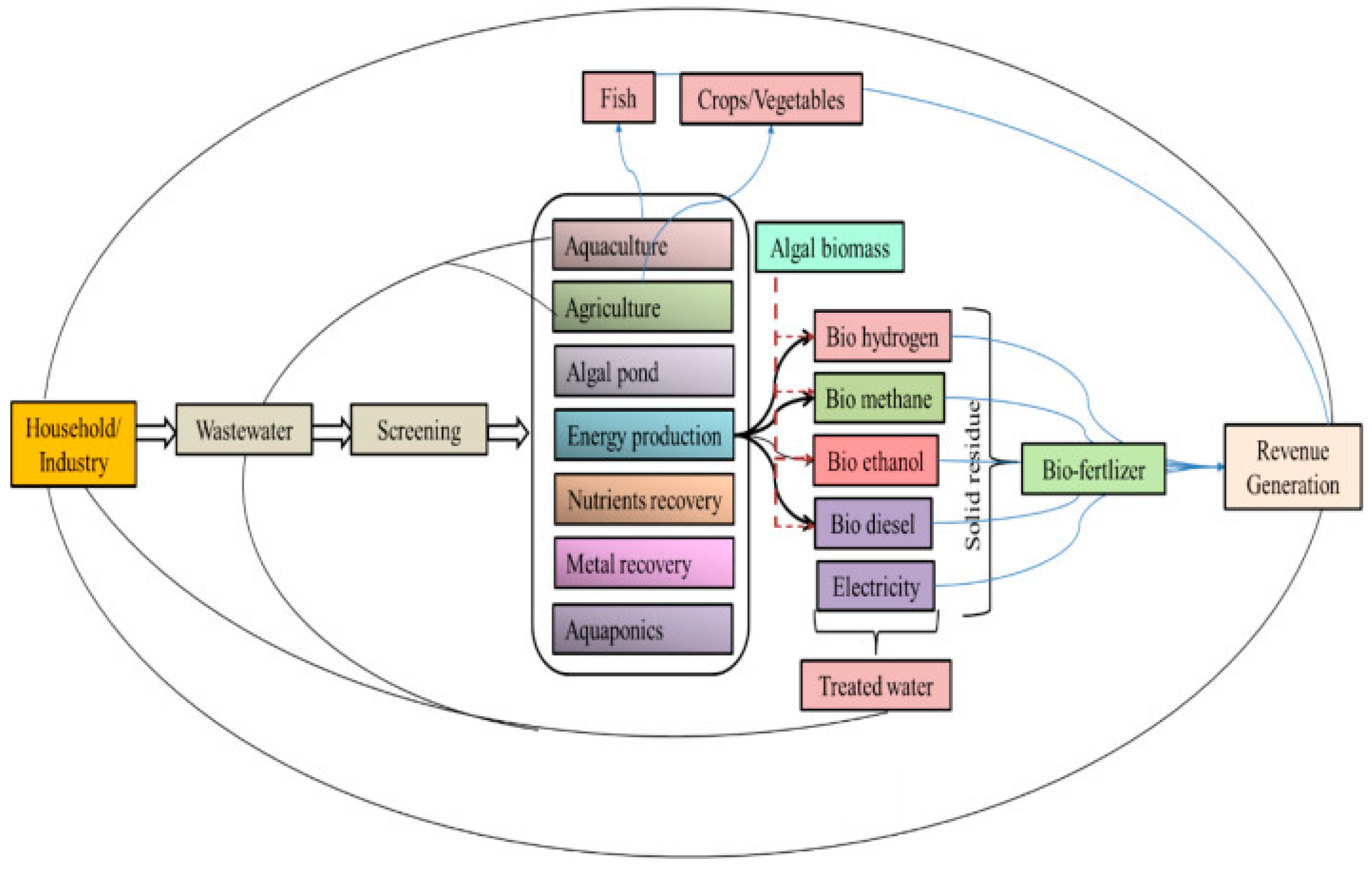

4.1. Resource recovery

5. Case Studies

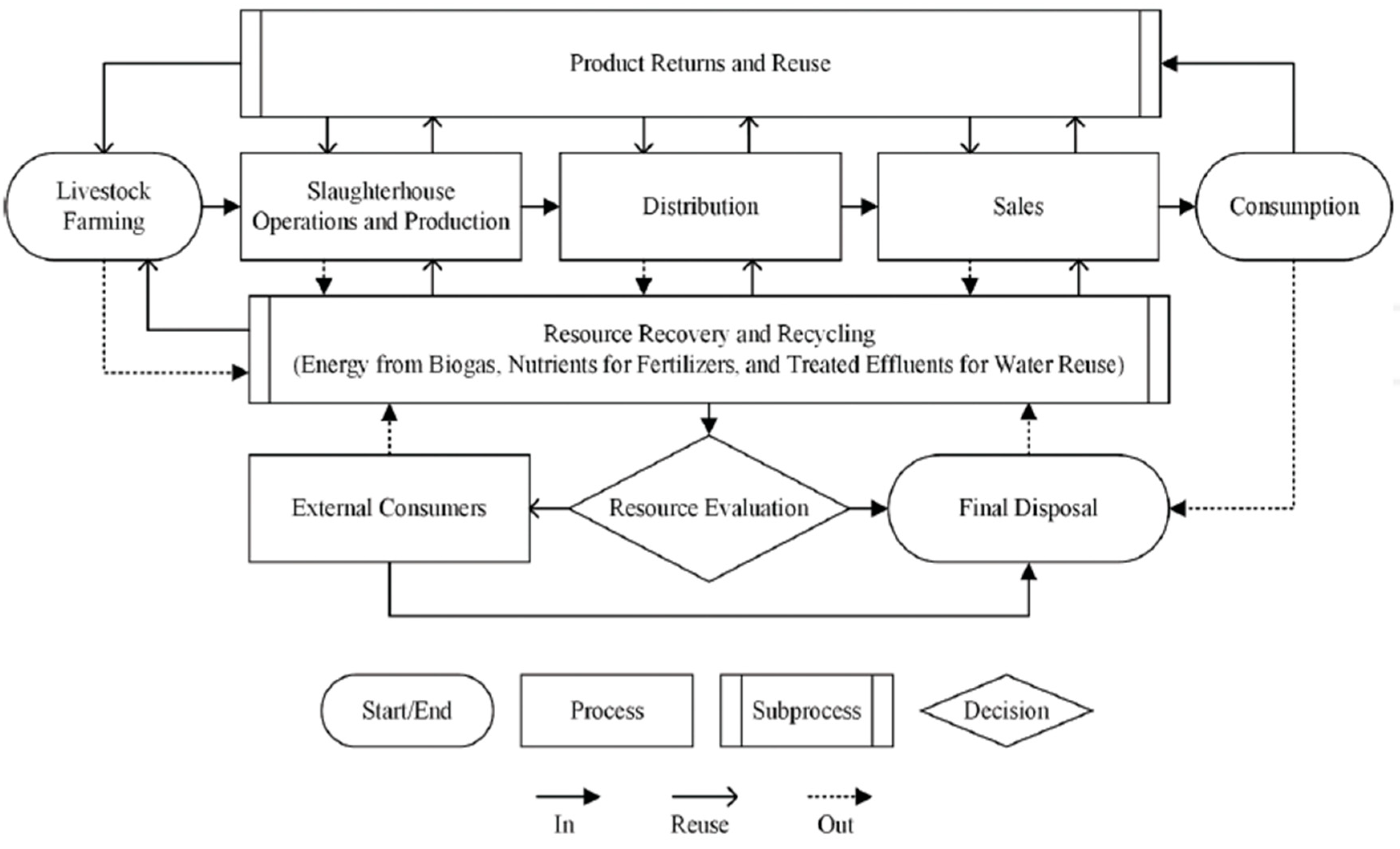

5.1. Slaughterhouse wastewater management and resource recovery

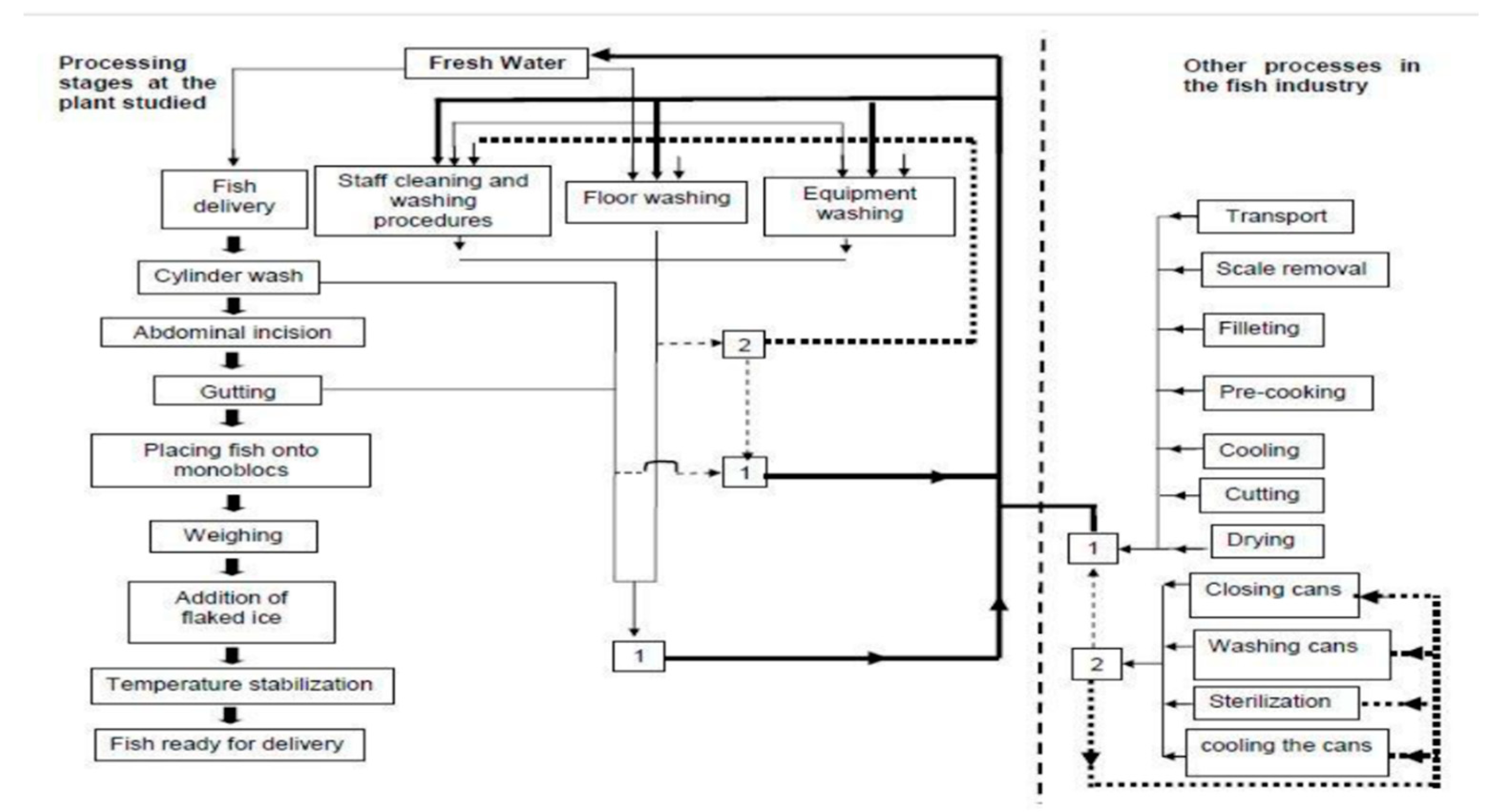

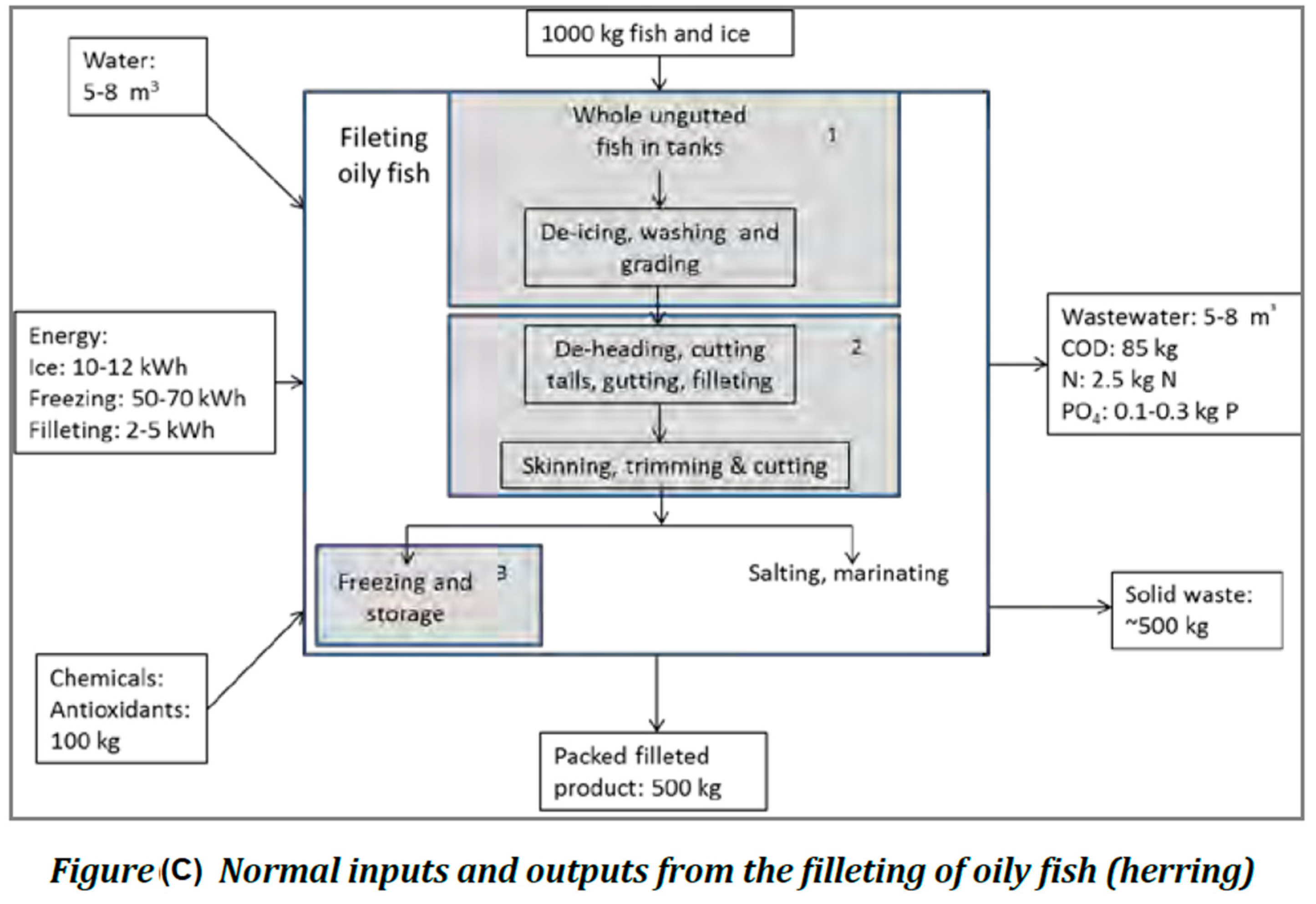

5.2. Recycling and reuse of fish processing [149,150]

6. Conclusions

Funding

Institutional Review Board Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| BAT | Best available technologies |

| BOD5 | Biological oxygen demand |

| CHP | Combined heat and power |

| COD | Chemical oxygen demand |

| HAB | Harmful algal blooms |

| IWW | Industrial Waste works |

| MFC | Microbial fuel cell |

| MPA | Maximum permissible amount |

| O&G | Oil and grease |

| SBR | Sequence Batch Reactor |

| SGD | Sustainable development goals |

| TN | Total nitrogen |

| TP | Total phosphorus |

| TS | Total solids |

| TDS | Total dissolved solids |

| TSS | Total suspended solids |

| UASB | Up-flow anaerobic sludge blankets |

| WWTPs | Wastewater treatment plants |

| UF | Ultrafiltration |

| RO | Reverse Osmosis |

| NF | Nanofiltration |

| RFBB | Ring Fixed Bed Bioreactor |

| EC | Electro-coagulation |

| HCPB | Hollow-centered packed bed |

| MBR | Membrane bioreactor |

| FPWs | Food process wastewater |

| IM | Integrated Management |

| CE | Circular Economy |

| VA | Value Added |

| RR | Resource Recovery |

| 4R | Reduce, Reuse, Recycle, And Recover |

| SWW | Slaughterhouse wastewater |

| SC | Supply chain |

| WHO | World Health Organization |

| UNICEF | United Nations International Children’s Emergency Fund |

| UNEP | United Nations Environment Program |

| WWW | Worldwide Water |

References

- D.L. Sedlak, The past, present, and future of the world's most vital resource Water, 2019, 4.

- Water.org, Water crisis - learn about the global water crisis Available at 2021. https://water.org/our-impact/water-crisis.

- CDC, Global wash fast facts. Centers of Disease Control and Prevention Available at 2021. https://www.cdc.gov/healthywater/global/wash_statistics.html.

- P. Singh, Why Delhi is staring at a water crisis - Delhi News - times of India Available at: 2018. https://timesofindia.indiatimes.com/city/delhi/why-delhi-is-staring-at-a-water-crisis/articleshow/64228440.cms.

- P. Vergine, C. Salerno, A. Libutti, L. Beneduce, G. Gatta, G. Berardi, A. Pollice Closing the water cycle in the agro-industrial sector by reusing treated wastewater for irrigation J. Clean. Prod., 2017, 164 pp. 587-596.

- FAO The state of food and Agriculture 2020, Available at (2021) http://www.fao.org/state-of-food-agriculture/en.

- M. Barbera, G. Gurnari, Wastewater Treatment and Reuse in the Food Industry, Springer Briefs Molecu. Sci (2018). [CrossRef]

- Mateus, J. Torres, W. Marimon-Bolivar, L. Pulgarin, Implementation of magnetic bentonite in food industry wastewater treatment for reuse in agricultural irrigation, Water Resour. Ind. (2021), Article 100154. [CrossRef]

- European Commission, Drinking water legislation – Environment, Available at (2021) https://ec.europa.eu/environment/water/water-.

- Water, Wastes Digest, Heineken pledges to reduce water use. https://www.wwdmag.com/industrial-wastewater-recyclingreuse/heineken-pledges-reduce-water-use (2021).

- Piesse, M. (2020). Global water supply and demand trends point towards rising water insecurity. Future Directions International, APO. https://www.futuredirections.org.au/publication/global-water-supply-and-demand-trends-point-towards-rising-water-insecurity/.

- Awange, J. (2021). Lake Victoria monitored from space. Springer.

- Negm, A. M., Omran, E.-S. E., & Abdel-Fattah, S. (2018). Update, conclusions, and recommendations for the “unconventional water resources and agriculture in Egypt. In A. M. Negm (Ed.), Unconventional water resources and agriculture in Egypt (pp. 509–532). Springer.

- Awad Abouelata AM, Abdallah SMA, Sorour MH, Shawky NA, Abdel-Fatah MA. Modification and ionic stimulation of hollow fiber membrane by electric field for water treatment. J Appl Polym Sci. Vol. 37(39), 49190, pp 1 -10, (2020). [CrossRef]

- Oki, T., & Quiocho, R. E. (2020). Economically challenged and water scarce: identification of global populations most vulnerable to water crises. International Journal of Water Resources Development, 36, 416–428. [CrossRef]

- Darban, A., Shahedi, A., Taghipour, F., & Jamshidi-Zanjani, A. (2020). A review on industrial wastewater treatment via electrocoagulation processes. Current Opinion in Electrochemistry, 22, 154–169. [CrossRef]

- Malik, S. N., Ghosh, P. C., Vaidya, A. N., & Mudliar, S. N. (2020). Hybrid ozonation process for industrial wastewater treatment: Principles and applications: A review. Journal of Water Process Engineering, 35, 101193. [CrossRef]

- Meneses, Y. E., Stratton, J., & Flores, R. A. (2017). Water reconditioning and reuse in the food processing industry: Current situation and challenges. Trends in Food Science & Technology, 61, 72–79. [CrossRef]

- Nguegan, C. A., & Mafini, C. (2017). Supply chain management problems in the food processing industry: Implications for business performance. Acta Commercii, 17, 1–15. [CrossRef]

- Aderibigbe DO, Giwa AA, Bello IA (2017) Characterization and treatment of wastewater from food processing industry: A review. Imam J Appl Sci 2:27–36.

- Mona A. Abdel-Fatah, S. I. Hawash, and H. H. Shaarawy; Cost-effective Clean Electrochemical Preparation of Ferric Chloride and its Applications, Egyptian Journal of Chemistry, Vol. 64(7): pp 3841 – 3851, (2021). [CrossRef]

- Saxena, G., Purchase, D., & Bharagava, R. N. (2020). Environmental hazards and toxicity profile of organic and inorganic pollutants of tannery wastewater and bioremediation approaches. In G. Saxena & R. N. Bharagava (Eds.), Bioremediation of industrial waste for environmental safety (pp. 381–398). Springer. [CrossRef]

- Shahid, M., Khalid, S., Murtaza, B., Anwar, H., Shah, A. H., Sardar, A., Shabbir, Z., & Niazi, N. K. (2020). A critical analysis of wastewater use in agriculture and associated health risks in Pakistan. Environmental Geochemistry and Health, 1–20. Advance online publication. [CrossRef]

- Udugama, I. A., Petersen, L. A., Falco, F. C., Junicke, H., Mitic, A., Alsina, X. F., Mansouri, S. S., & Gernaey, K. V. (2020). Resource recovery from waste streams in a water-energy-food nexus perspective: Toward more sustainable food processing. Food and Bioproducts Processing, 119, 133–147. [CrossRef]

- Narasimmalu, A., & Ramasamy, R. (2020). Food Processing Industry Waste and Circular Economy. IOP Conference Series: Materials Science and Engineering. 955, 012089.

- Morseletto, P. (2020). Targets for a circular economy. Resources, Conservation and Recycling, 153, 104553. [CrossRef]

- Dantas, T., de-Souza, E., Destro, I., Hammes, G., Rodriguez, C., & Soares, S. (2021). How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustainable Production and Consumption, 26, 213–227. [CrossRef]

- Pukšec, T., Foley, A., Markovska, N., & Duić, N. (2019). Life cycle to Pinch Analysis and 100% renewable energy systems in a circular economy at sustainable development of energy, Water and Environment Systems 2017. Renewable and Sustainable Energy, 108, 572–577. [CrossRef]

- Skouteris, G., Ouki, S., Foo, D., Saroj, D., Altini, M., Melidis, P., Cowley, B., Ells, G., Palmer, S., & O'Dell, S. (2018). Water footprint and water pinch analysis techniques for sustainable water management in the brick-manufacturing industry. Journal of Cleaner Production, 172, 786–794. [CrossRef]

- Wong, C. Y., Foo, D. C., & Sin, L. T. (2020). Design and optimization of water recovery system for a polylactide production process. Process Integration and Optimization for Sustainability, 4, 149–161.

- Foo, D. C., El-Halwagi, M. M., & Tan, R. R. (2017). Process integration for sustainable industries. In M. Abraham (Ed.), Encyclopedia of sustainable technologies (pp. 117–124). Elsevier Science.

- Valencia-Arredondo, J. A., Hernández-Bolio, G. I., Cerón-Montes, G. I., Castro-Muñoz, R., & Yáñez-Fernández, J. (2020). Enhanced process integration for the extraction, concentration and purification of di-acylated cyanidin from red cabbage. Separation and Purification Technology, 238, 116492. [CrossRef]

- Nemati-Amirkolaii, K., Romdhana, H., & Lameloise, M.-L. (2019). Pinch methods for efficient use of water in food industry: A survey review. Sustainability, 11, 4492. [CrossRef]

- Varbanov, P. S., Klemeš, J. J., & Wang, X. (2018). Methods optimization, Process Integration and modelling for energy saving and pollution reduction. Energy, 146, 1–3. [CrossRef]

- Ashraf Amin, Gh. Al Bazedi, Mona A. Abdel-Fatah; Experimental study and mathematical model of coagulation/sedimentation units for the treatment of food processing wastewater, Ain Shams Engineering Journal. Vol. 12(1): pp 195-203, (2021). [CrossRef]

- FAO. (2019). In Angel Gurria & Jose Graziano da Silva (Eds.), Food and Agriculture Organization of the United Nations agricultural outlook 2019–2028. (pp. 166–180). FAO.

- Fornarelli, R., Bahri, P., & Moheimani, N. (2017). Utilization of microalgae to purify waste streams and production of value added products. Australian Meat Processor Corporation.

- Abdel-Fatah, M.A., Hawash, S.I., Abd El Maguid, A., Treatment of Meat Processing Wastewater Using Coagulation and Sedimentation Techniques, ARPN Journal of Engineering and Applied Sciences, (2020), 15(23), pp. 2812–2819.

- https://ift.onlinelibrary.wiley.com/doi/full/10.1111/1541-4337.12782#crf312782-bib-0100.

- FAO. (2018b). The state of world fisheries and aquaculture 2018–meeting the sustainable development goals. Fisheries and Aquaculture Department, Food and Agriculture Organization of the United Nations, Rome.

- Renuka, V., Remya, S., Jha, A., & Joseph, T. (2019). Nature and composition of fish processing industrial waste and handling protocols. Veraval Research Centre of ICAR-Central Institute of Fisheries Technology.

- Bell, J. D., Sharp, M. K., Havice, E., Batty, M., Charlton, K. E., Russell, J., Adams, W., Azmi, K., Romeo, A., Wabnitz, C. C. C., Andrew, N. L., Rodwell, L., Gu'urau, S., & Gillett, R. (2019). Realising the food security benefits of canned fish for Pacific Island countries. Marine Policy, 100, 183–191. [CrossRef]

- Ching, Y. C., & Redzwan, G. (2017). Biological treatment of fish processing saline wastewater for reuse as liquid fertilizer. Sustainability. [CrossRef]

- Compton, M., Willis, S., Rezaie, B., & Humes, K. (2018). Food processing industry energy and water consumption in the Pacific north-west. Innovative Food Science & Emerging Technologies, 47, 371–383.

- Fenech, M., Amaya, I., Valpuesta, V., & Botella, M. A. (2019). Vitamin C content in fruits: Biosynthesis and regulation. Frontiers in Plant Science. [CrossRef]

- Honglin Chen, Hua Zhang, Jinhu Tian, John Shi, Robert J. Linhardt, Tian Ding Xingqian Ye, and Shiguo Chen, Recovery of High Value-Added Nutrients from Fruit and Vegetable Industrial Wastewater, (2019) Institute of Food Technologists®. [CrossRef]

- K. Valta1, P. Damala1, V. Panaretou1, E. Orli1, K. Moustakas1, M. Loizidou, Review and Assessment of Waste and Wastewater Treatment from Fruits and Vegetables Processing Industries in Greece, Waste Biomass Valor (2017) 8:1629–1648. [CrossRef]

- Tapera, M. (2019). Towards greener preservation of edible oils: a mini-review. Asian Journal of Applied Chemistry Research, 4(1), 1–8. [CrossRef]

- Khillari, S. (2020). Edible oil and fat market size. Share| Global Research Report.

- Pacheco, P., Schoneveld, G., Dermawan, A., Komarudin, H., & Djama, M. (2020). Governing sustainable palm oil supply: Disconnects, complementarities, and antagonisms between state regulations and private standards. Regulation & Governance, 14, 568–598. [CrossRef]

- Sun, Z., Scherer, L., Tukker, A., & Behrens, P. (2020). Linking global crop and livestock consumption to local production hotspots. Global Food Security, 25, 100323. [CrossRef]

- Ochando-Pulido, J.M.; Corpas-Martínez, J.R.; Martinez-Ferez, A. About two-phase olive oil washing wastewater simultaneous phenols recovery and treatment by nanofiltration. Process Saf. Environ. Prot. 2018, 114, 159–168. [CrossRef]

- Cassano, A., Conidi, C., Galanakis, C., & Castro-Muñoz, R. (2016). Recovery of polyphenols from olive mill wastewaters by membrane operations. In A. Figoli, A. Cassano & A. Basile (Eds.), Membrane technologies for biorefining (pp. 163–187). Elsevier. [CrossRef]

- Gotor, A. A., & Rhazi, L. (2016). Effects of refining process on sunflower oil minor components: a review. OCL, 23, D207. [CrossRef]

- Kerr, W. L. (2019). Food drying and evaporation processing operations. In M. Kutz (Ed.), Handbook of farm, dairy and food machinery engineering (pp. 353–387). Elsevier.

- Trichia, E., Luben, R., Khaw, K.-T., Wareham, N. J., Imamura, F., & Forouhi, N. G. (2020). The associations of longitudinal changes in consumption of total and types of dairy products and markers of metabolic risk and adiposity: findings from the European Investigation into Cancer and Nutrition (EPIC)–Norfolk study, United Kingdom. The American Journal of Clinical Nutrition, 111, 1018–1026.

- Janssen, E., & Swinnen, J. (2019). Technology adoption and value chains in developing countries: Evidence from dairy in India. Food Policy, 83, 327–336. [CrossRef]

- Bortoluzzi, A. C., Faitão, J. A., Di Luccio, M., Dallago, R. M., Steffens, J., Zabot, G. L., & Tres, M. V. (2017). Dairy wastewater treatment using integrated membrane systems. Journal of Environmental Chemical Engineering, 5, 4819–4827. [CrossRef]

- Owusu-Sekyere, E., Jordaan, H., & Chouchane, H. (2017). Evaluation of water footprint and economic water productivities of dairy products of South Africa. Ecological Indicators, 83, 32–40. [CrossRef]

- Atasoy, M., Eyice, O., & Cetecioglu, Z. (2020). A comprehensive study of volatile fatty acids production from the batch reactor to anaerobic sequencing batch reactor by using cheese processing wastewater. Bioresource Technology, 311, 123529. [CrossRef]

- Wang, Y., & Serventi, L. (2019). Sustainability of dairy and soy processing: a review on wastewater recycling. Journal of Cleaner Production, 237, 117821. [CrossRef]

- Chen, Z., Luo, J., Hang, X., & Wan, Y. (2018). Physicochemical characterization of tight nanofiltration membranes for dairy wastewater treatment. Journal of Membrane Science, 547, 51–63. [CrossRef]

- Falahati, F., Baghdadi, M., & Aminzadeh, B. (2018). Treatment of dairy wastewater by graphene oxide nanoadsorbent and sludge separation, using In Situ Sludge Magnetic Impregnation (ISSMI). Pollution, 4, 29–41. [CrossRef]

- Afsharnia, M., Kianmehr, M., Biglari, H., Dargahi, A., & Karimi, A. (2018). Disinfection of dairy wastewater effluent through solar photocatalysis processes. Water Science and Engineering, 11, 214–219. [CrossRef]

- Bruguera-Casamada, C., Araujo, R. M., Brillas, E., & Sirés, I. (2019). Advantages of electro-Fenton over electrocoagulation for disinfection of dairy wastewater. Chemical Engineering Journal, 376, 119975. [CrossRef]

- Jaltade, A. S., Mokadam, A. M., & Gulhane, M. L. (2020). Treatment of dairy wastewater using the Fenton's oxidation process (FOP). In V. Sivasubramanian & S. Subramanian (Eds.), Global challenges in energy and environment (pp. 131–137). Springer. [CrossRef]

- Panahi, A. H., Meshkinian, A., Ashrafi, S., Khan, M., Naghizadeh, A., Abi, G., & Kamani, H. (2020). Survey of sono-activated persulfate process for treatment of real dairy wastewater. International Journal of Environmental Science and Technology, 17, 93–98. [CrossRef]

- Chandra, R., Castillo-Zacarias, C., Delgado, P., & Parra-Saldívar, R. (2018). A biorefinery approach for dairy wastewater treatment and product recovery towards establishing a biorefinery complexity index. Journal of Cleaner Production, 183, 1184–1196. [CrossRef]

- Daneshvar, E., Zarrinmehr, M. J., Koutra, E., Kornaros, M., Farhadian, O., & Bhatnagar, A. (2019). Sequential cultivation of microalgae in raw and recycled dairy wastewater: microalgal growth, wastewater treatment and biochemical composition. Bioresource Techno, 273, 556–564. [CrossRef]

- Kumar, A., Sharma, S., Shah, E., Parikh, B., Patel, A., Dixit, G., Gupta, S., & Divecha, J. (2019). Cultivation of Ascochloris sp. ADW007-enriched microalga in raw dairy wastewater for enhanced biomass and lipid productivity. International Journal of Environmental Science and Technology, 16, 943–954. [CrossRef]

- Daneshvar, E., Zarrinmehr, M. J., Hashtjin, A. M., Farhadian, O., & Bhatnagar, A. (2018). Versatile applications of freshwater and marine water microalgae in dairy wastewater treatment, lipid extraction and tetracycline biosorption. Bioresource Technology, 268, 523–530. [CrossRef]

- Ozturk, A., Aygun, A., & Nas, B. (2019). Application of sequencing batch biofilm reactor (SBBR) in dairy wastewater treatment. Korean Journal of Chemical Engineering, 36, 248–254. [CrossRef]

- USDA. (2020). Grain: World markets and trade; world production, markets, and trade reports. United States Department of Agriculture.

- Bavar, M., Sarrafzadeh, M.-H., Asgharnejad, H., & Norouzi-Firouz, H. (2018). Water management methods in food industry: Corn refinery as a case study. Journal of Food Engineering, 238, 78–84. [CrossRef]

- Vaibhav Shrivastava, Izba Ali, Makid Maskawat Marjub, Eldon R. Rene, Ailén María Florencia Soto, (2022). Wastewater in the food industry: Treatment technologies and reuse potential, Chemosphere, Volume 293, 2022, 133553. [CrossRef]

- Nougadère, A., Sirot, V., Cravedi, J.-P., Vasseur, P., Feidt, C., Fussell, R. J., Hu, R., Leblanc, J.-C., Jean, J., & Rivière, G. (2020). Dietary exposure to pesticide residues and associated health risks in infants and young children–results of the French infant total diet study. Environment International, 137, 105529. [CrossRef]

- Struk-Sokolowska, J., & Tkaczuk, J. (2018). Analysis of bakery sewage treatment process options based on COD fraction changes. Journal of Ecological Engineering, 19(4), 226–235. [CrossRef]

- Mohan, S., Vivekanandhan, V., & Priyadharshini, S. (2017). Performance evaluation of modified UASB Reactor for treating bakery effluent. International Journal of Applied Environmental Sciences, 12, 1883–1894.

- Vistanti, H., Malik, R. A., & Mukimin, A. (2020). Performance of a full-scale anaerobic digestion on bakery wastewater treatment: Effect of modified distribution system. Jurnal Riset Teknologi Pencegahan Pencemaran Industri, 11, 12–18. [CrossRef]

- Abdel-Fatah, M.A., Sherif, H.O., Hawash, S.I., Design parameters for waste effluent treatment unit from beverages production, Ain Shams Engineering Journal, (2017), 8(3), pp. 305–310. [CrossRef]

- Carboneras, M. B., Cañizares, P., Rodrigo, M. A., Villaseñor, J., & Fernandez-Morales, F. J. (2018). Improving biodegradability of soil washing effluents using anodic oxidation. Bioresource Technology, 252, 1–6.

- Hubertus, G. (2019). OECD-FAO agricultural outlook 2019–2028. OECD Publishing Paris.

- FAO. (2018a). OECD-FAO agricultural outlook 2018–2027.

- Asgharnejad, H., & Sarrafzadeh, M.-H. (2019). Studying the process of sugar extraction from sugarcane and proposing solutions to reduce water consumption through water reuse. Journal of Water and Wastewater Science and Engineering (JWWSE), 4, 50–60.

- Peiter, F.S.; Hankins, N.P.; Pires, E.C. Evaluation of concentration technologies in the design of biorefineries for the recovery of resources from vinasse. Water Res. (2019), 157, 483–497. [CrossRef]

- Zhang, L., Ho, C. T., Zhou, J., Santos, J. S., Armstrong, L., & Granato, D. (2019). Chemistry and biological activities of processed Camellia sinensis teas: A comprehensive review. Comprehensive Reviews in Food Science and Food Safety, 18, 1474–1495. [CrossRef]

- FAO. (2020). http://www.fao.org/faostat.

- Cassano, A., Conidi, C., Ruby-Figueroa, R., & Castro-Muñoz, R. (2018). Nanofiltration and tight ultrafiltration membranes for the recovery of polyphenols from agro-food by-products. International Journal of Molecular Sciences, 19, 351. [CrossRef]

- Piotr Konieczka, P., Aliaño-González, M. J., Ferreiro-González, M., Barbero, G. F., & Palma, M. (2020). Characterization of Arabica and Robusta coffees by ion mobility sum spectrum. Sensors, 20, 3123. [CrossRef]

- Gasper, D., Shah, A., & Tankha, S. (2019). The framing of sustainable consumption and production in SDG 12. Global Policy, 10, 83–95. [CrossRef]

- Amos, R., & Lydgate, E. (2019). Trade, transboundary impacts and the implementation of SDG 12. Sustainability Science, 15, 1699–1710. [CrossRef]

- Momblanch, A., Papadimitriou, L., Jain, S. K., Kulkarni, A., Ojha, C. S., Adeloye, A. J., & Holman, I. P. (2019). Untangling the water-food-energy-environment nexus for global change adaptation in a complex Himalayan water resource system. Science of the Total Environment, 655, 35–47. [CrossRef]

- Buabeng-Baidoo, E., Mafukidze, N., Pal, J., Tiwari, S., Srinivasan, B., Majozi, T., & Srinivasan, R. (2017). Study of water reuse opportunities in a large-scale milk processing plant through process integration. Chemical Engineering Research and Design, 121, 81–91. [CrossRef]

- Ahmad, T., Guria, C., Mandal, A., (2020). A review of oily wastewater treatment using ultrafiltration membrane: A parametric study to enhance the membrane performance. J. Water Process Eng. 36, 101289. [CrossRef]

- Balla, W. H., Rabah, A. A., & Abdallah, B. K. (2018). Pinch analysis of sugarcane refinery water integration. Sugar Tech, 20, 122–134. [CrossRef]

- Francisco, F. S., Mirre, R. C., Calixto, E. E., Pessoa, F. L., & Queiroz, E. M. (2018). Water sources diagram method in systems with multiple contaminants in fixed flowrate and fixed load processes. Journal of Cleaner Production, 172, 3186–3200. [CrossRef]

- Castro-Muñoz, R. (2020b). Retention profile on the physicochemical properties of maize cooking by-product using a tight ultrafiltration membrane. Chemical Engineering Communications, 207, 887–895. [CrossRef]

- Pichardo-Romero, D., Garcia-Arce, Z. P., Zavala-Ramírez, A., & Castro-Muñoz, R. (2020). Current advances in biofouling mitigation in membranes for water treatment: an overview. Processes, 8, 182. [CrossRef]

- Javadinejad, S., Mariwan, R., Hamah, A., & Jafary, S. F. (2020). Analysis of gray water recycling by reuse of industrial wastewater for agricultural and irrigation purposes. Journal of Geographical Research, 3, 20–24.

- Swati Hegde, Jeffery S. Lodge, Thomas A. Trabold, Characteristics of food processing wastes and their use in sustainable alcohol production, Renewable and Sustainable Energy Reviews, Volume 81, Part 1, (2018), Pages 510-523. [CrossRef]

- Hemalatha, M.; Sravan, J.S.; Min, B.; Venkata Mohan, S. Microalgae-biorefinery with cascading resource recovery design associated to dairy wastewater treatment. Bioresour. Technol. (2019), 284, 424–429. [CrossRef]

- Kaushik, A.; Basu, S.; Raturi, S.; Batra, V.S.; Balakrishnan, M. Recovery of antioxidants from sugarcane molasses distillery wastewater and its e_ect on biomethanation. J. Water Process Eng. (2018), 25, 205–211.

- Wenjie Dong, Xiaorong Gu, Yu Shu1, Dingyi Cao, Jingyi Yu, Mona A. Abdel-Fatah, Hailu Fu, Pulse electrocoagulation combined with a coagulant to remove antimony in wastewater, Journal of Water Process Engineering, Vol 47, June (2022), 102749. [CrossRef]

- Hailu Fu, Lingling Zhong, Ziyao Yu, Wenxiang Liu, Mona A. Abdel-Fatah, Jinye Li, Mingzhang, Jie Yu, Wenjie Dong, Sang Soo, Lee; Enhanced adsorptive removal of ammonium on the Na+/Al3+ enriched natural zeolite, Separation and Purification Technology, Volume 298, 1 October (2022), 121507. [CrossRef]

- Amann, A.; Zoboli, O.; Krampe, J.; Rechberger, H.; Zessner, M.; Egle, L. Environmental impacts of phosphorus recovery from municipal wastewater. Resour. Conserv. Recycl. (2018), 130, 127–139. [CrossRef]

- Bouzas, A.; Martí, N.; Grau, S.; Barat, R.; Mangin, D.; Pastor, L. Implementation of a global P-recovery system in urban wastewater treatment plants. J. Clean. Prod. (2019), 227, 130–140. [CrossRef]

- Y. Zhang, C. Zhang, Y. Qiu, B. Li, H. Pang, Y. Xue, X. Huang, Wastewater treatment technology selection under various influent conditions and effluent standards based on life cycle assessment, Resour. Conserv. Recycl., 154 (2020). [CrossRef]

- Castro-Muñoz, R., Díaz-Montes, E., Cassano, A., & Gontarek, E. (2020a). Membrane separation processes for the extraction and purification of steviol glycosides: an overview. Critical Reviews in Food Science and Nutrition, 1–23. [CrossRef]

- Abdel-Fatah, M.A., (2018). Nanofiltration systems and applications in wastewater treatment. Ain Shams Eng. J. 9, 3077–3092. [CrossRef]

- M. Faragò, A. Damgaard, J.A. Madsen, J.K. Andersen, D. Thornberg, M.H. Andersen, M. Rygaard From wastewater treatment to water resource recovery: environmental and economic impacts of full-scale implementation Water Res., 204 (2021), Article 117554.

- S. Guerra-Rodríguez, P. Oulego, E. Rodríguez, D.N. Singh, J. Rodríguez-Chueca, Towards the implementation of circular economy in the wastewater sector: challenges and opportunities, Water, 12 (5) (2020), p. 1431.

- Kiselev, E. Magaril, R. Magaril, D. Panepinto, M. Ravina, M.C. Zanetti, Towards circular economy: evaluation of sewage sludge biogas solutions, Resources, 8 (2) (2019), p. 91. [CrossRef]

- D. Cecconet, D. Molognoni, A. Callegari, A.G. Capodaglio Agro-food industry wastewater treatment with microbial fuel cells: energetic recovery issues Int. J. Hydrogen Energy, 43 (1) (2018), pp. 500-511.

- S. Firdous, W. Jin, N. Shahid, Z.A. Bhatti, A. Iqbal, U. Abbasi, Q. Mahmood, A. Ali The performance of microbial fuel cells treating vegetable oil industrial wastewater Environ. Technol. Innovat., 10 (2018), pp. 143-151.

- S. Maddalwar, K.K. Nayak, M. Kumar, L. Singh Plant microbial fuel cell: opportunities, challenges, and prospects Bioresour. Technol., 341 (2021), Article 125772.

- G.G. Kurup, B. Adhikari, B. Zisu Recovery of proteins and lipids from dairy wastewater using food grade sodium lignosulphonate Water Resour. Ind., 22 (2019), Article 100114.

- Z. Zhao, R. Xue, L. Fu, C. Chen, F. Ndayisenga, D. Zhou Carbon dots enhance the recovery of microalgae bioresources from wastewater containing amoxicillin Bioresour. Technol., 335 (2021), Article 125258.

- M. Kumar, Y. Sun, R. Rathour, A. Pandey, I.S. Thakur, D.C. Tsang Algae as potential feedstock for the production of biofuels and value-added products: opportunities and challenges Sci. Total Environ., 716 (2020), Article 137116.

- T.D.P. Nguyen, D.H. Nguyen, J.W. Lim, C.K. Chang, H.Y. Leong, T.N.T. Tran, T.B.H. Vu,T.C, Nguyen, P.L. Show Investigation of the relationship between bacteria growth and lipid production cultivating of microalgae Chlorella vulgaris in seafood wastewater Energies, 12 (12) (2019), Article 2282.

- W.S. Chai, W.G. Tan, H.S.H. Munawaroh, V.K. Gupta, S.H. Ho, P.L. Show Multifaceted roles of microalgae in the application of wastewater biotreatment: a review Environ. Pollut., 269 (2021), Article 116236.

- M.M.T. Zin, D. Tiwari, D.J. Kim Maximizing ammonium and phosphate recovery from food wastewater and incinerated sewage sludge ash by optimal Mg dose with RSM J. Ind. Eng. Chem., 86 (2020), pp. 136-143.

- K.C. Kedwell, M.K. Jørgensen, C.A. Quist-Jensen, T.D. Pham, B. Van der Bruggen, M. L. Christensen Selective electrodialysis for simultaneous but separate phosphate and ammonium recovery Environ. Technol., 42 (14) (2021), pp. 2177-2186.

- Malila, R.; Lehtoranta, S.; Viskari, E.L. The role of source separation in nutrient recovery—Comparison of alternative wastewater treatment systems. J. Clean. Prod. (2019), 219, 350–358. [CrossRef]

- Wu, Y.; Luo, J.; Zhang, Q.; Aleem, M.; Fang, F.; Xue, Z.; Cao, J. Potentials and challenges of phosphorus recovery as vivianite from wastewater: A review. Chemosphere (2019), 226, 246–258. [CrossRef]

- S.K. Wang, X. Wang, Y.T. Tian, Y.H. Cui Nutrient recovery from tofu whey wastewater for the economical production of docosahexaenoic acid by Schizochytrium sp. S31 Sci. Total Environ., 710 (2020), Article 136448.

- M. Micari, M. Moser, A. Cipollina, A. Tamburini, G. Micale, V. Bertsch, Towards the implementation of circular economy in the water softening industry: a technical, economic and environmental analysis Cleaner Prod., 255 (2020). [CrossRef]

- M. Amini, H. Yousefi-Massumabad, H. Younesi, H. Abyar, N. Bahramifar Production of the poly-hydroxy-alkanoate biopolymer by Cupriavidus necator using beer brewery wastewater containing maltose as a primary carbon source J. Environ. Chem. Eng., 8 (1) (2020), Article 103588.

- Z. Trivunović, I. Mitrović, V. Puškaš, B. Bajić, U. Miljić, J. Dodić Utilization of wastewaters from red wine technology for xanthan production in laboratory bioreactor J. Food Process. Preserv. (2021), Article 15849.

- Z. Rončević, J. Grahovac, S. Dodić, D. Vučurović, J. Dodić Utilisation of winery wastewater for xanthan production in stirred tank bioreactor: bioprocess modelling and optimization Food Bioprod. Process., 117 (2019), pp. 113-125.

- M. Kumar, S. Dutta, S. You, G. Luo, S. Zhang, P.L. Show, A.D. Sawarkar, L. Singh, D.C. Tsang A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge J. Clean. Prod. (2021), pp. 127-143.

- Mishra, M. Kumar, N.S. Bolan, A. Kapley, R. Kumar, L. Singh Multidimensional approaches of biogas production and up-gradation: opportunities and challenges Bio-resour. Technol., 338 (2021), Article 125514.

- G. Choi, H. Kim, C. Lee Long-term monitoring of a thermal hydrolysis-anaerobic co-digestion plant treating high-strength organic wastes: process performance and microbial community dynamics Bioresour. Technol., 319 (2021), pp. 124-138.

- M. Dębowski, M. Zieliński, M. Kisielewska, J. Kazimierowicz Evaluation of anaerobic digestion of dairy wastewater in an innovative multi-section horizontal flow reactor Energies, 13 (9) (2020), p. 2392.

- N.I.H.A. Aziz, M.M. Hanafiah, S.H. Gheewala A review on life cycle assessment of biogas production: challenges and future perspectives in Malaysia Biomass Bioenergy, 122 (2019), pp. 361-374.

- K. Kavouras Moving the Needle: Exploring Thermal Savings at Heineken by Targeting on Waste Heat Recovery Systems Master's thesis University of Twente (2020).

- Başaran, A., Yılmaz, T. & Çivi, C. Application of inductive forced heating as a new approach to food industry heat exchangers. J Therm Anal Calorim 134, 2265–2274 (2018). [CrossRef]

- K. Garver The latest in heat exchangers for food processing Process Expo (2016).

- Morales-arrieta S, Okoye PU, Ang R (2021) Recycling industrial wastewater for improved carbohydraterich biomass production in a semi-continuous photo-bioreactor: Effect of hydraulic retention time. J Environ Manage 284(January):2–10.

- Smol M, Adam C, Preisner M (2020) Circular economy model framework in the European water and wastewater sector. J Mater Cycles Waste Manage 22(3):682–697.

- Carus M and Dammer L (2018). The “Circular Bioeconomy” Concepts, Opportunities and Limitations. Ind. Biotechnol. 14(2) pp 83- 91.

- López-Gómez, J.P.; Venus, J. Potential role of sequential solid-state and submerged-liquid fermentations in a circular bioeconomy. Fermentation (2021), 7, 76. [CrossRef]

- Gomes, D.; Cruz, M.; de Resende, M.; Ribeiro, E.; Teixeira, J.; Dominques, L. Very high gravity bioethanol revisited: Main challenges and advances. Fermentation (2021), 7, 38. [CrossRef]

- 2022; 143. Europe Sustainable Development Report (2022).

- WHO and UNICEF, (2019). [CrossRef]

- U.N, Sustainable Development Goal 6: Synthesis Report (2018) on Water and Sanitation, United Nations Publications, United States of America.

- UNESCO, The United Nations World Water Development Report 2019: Wastewater, The Untapped Resource, WWAP (United Nations World Water Assessment Programme), (2020).

- W.H.O, World Health Organization Media Centre Fact Sheet: Drinking Water, (2019). https://www.who.int/news-room/fact-sheets/detail/drinking-water.

- Robina Farooq, Zaki Ahmad, Slaughterhouse Wastewater: Treatment, Management, and Resource Recovery, May (2017). In book: Physico-Chemical Wastewater Treatment and Resource Recovery, Chapter: 8 Publisher: InTech Open Access Publisher. [CrossRef]

- Luana Ferraciolli, Danielle de Bem Luiz, Liliana Naval, Potential for reuse of effluent from fish-processing industries, (2017). [CrossRef]

- Ahmed, Z. (2019). Treatment and reuse of wastewater of fish processing industry. U.S.- Pakistan Center for Advanced Studies in Water (USPCAS-W), MUET, Jamshoro, Pakistan.

| Product | Wastewater (m3/ton) | COD (kg/m3) |

| Dairy | 6.5 | 1.5–5.2 |

| Fish | 13 | 2.5 |

| Meat and poultry | 13 | 2–7 |

| Sugar refining | 11 | 1–6 |

| Starch | 11 | 1.5–42 |

| Fruits, vegetables, and juices | 21 | 2–10 |

| Vinegar | 28.5 | 0.7–3 |

| Meat | COD mg/L | BOD5 mg/L | TN mg/L | TSS mg/L | O&G mg/L |

| Beef | 4220 | 1209 | 427 | 1164 | na |

| Poultry | 950 | 400 | 80 | 240 | 120 |

| Pork | 4310 | na | 275 | 1240 | 125 |

| Method | Parameter | Removal efficiency (%) |

| Up-flow anaerobic sludge blanket (UASB) | COD | 78–80 |

| Oil and grease (O&G) | 68–70 | |

| Coagulation / Floatation | Total Solid (TS) | 85 |

| O&G | 85 | |

| BOD | 62–78.8 | |

| COD | 74.6–79.5 | |

| Algal Treatment | (NH3–N) | 68.75–90.38 |

| Total Nitrogen (TN) | 30.06–50.94 | |

| Total Phosphorus (TP) | 69 | |

| TN | 67 | |

| COD | 91 | |

| A2O Bioreactor | TP | 83.48 |

| TN | 90.48 | |

| COD | 98.33 | |

| Algal Treatment | BOD | 97 |

| COD | 94 | |

| TP | 94 | |

| Anaerobic Baffled Reactor withActivated Sludge | Total Organic Carbon (TOC) | 85 |

| TN | 72 | |

| Total Suspended Solids (TSS) | >95 | |

| Algal Treatment | NH3–N | 89.74–99.03 |

| Phosphate (PO43–) | 92.39–99.93 | |

| Sequence Batch Reactor (SBR) | COD | 98 |

| BOD | 97 | |

| TSS | 89 | |

| TN | 91 | |

| TP | 86 |

| Parameter | R (1) | R (2) | R (3) |

| BOD5 (mg/L) | – | 3163 | 858 |

| COD (mg/L) | 1518 ± 584.4 | 3325 | – |

| Total Nitrogen (mg/L) | 112 ± 34.5 | 410 | – |

| Turbidity (NTU)) | – | – | 64.9 |

| TSS (mg/L) | 418 ± 487.2 | 703 | 770 |

| pH | 7.67 | 7 | 5.5–8.5 |

| Product | Water requirement (m3/hr. per ton of raw fish) | ||||

| Thawing and washing | Cooking and can washing | Sterilization | Other | Total | |

| Tuna | 8 | 4 | 12 | 8 | 32 |

| Sardine | 6 | 4 | 12 | 6 | 28 |

| Salmon | – | 4 | 10 | 2 | 16 |

| Shrimps | – | 8 | 6 | 2 | 16 |

| Product | BOD5 (mg/L) |

COD (mg/L) |

Conductivity (mS·cm−1) | TSS (mg/L) |

TN (mg/L) |

| Tuna | 4569 | 8313 | 24.8 | 3150 | 471 |

| Tuna | 3300 | 5553 | 9.21 | 1575 | 440 |

| Shrimp | 980 | 1595 | na | 443 | 63 |

| Sardine | 1065 | 1320 | 12.3 | 4903 | 36 |

| Treatment process | Parameter | Removal % |

| Crystallization | COD | 40.1 |

| TSS | 21.6 | |

| TN | 93.8 | |

| Sedimentation / Floatation | BOD5 | 90 |

| COD | 60 | |

| TSS | 95 | |

| NH4+-N | 50 | |

| Ultrafiltration (UF) | BOD5 | 24.4 |

| COD | 35.2 | |

| Reverse Osmosis (RO)/ UV Disinfection | DOC | 99.9 |

| O&G | 99.8 | |

| TSS | 98.4 | |

| Hetero-trophics | 100 | |

| Ring Fixed Bed Bioreactor (RFBB) | BOD | 77 |

| COD | 80 | |

| NH4+-N | 42 | |

| Algal Treatment | COD | 99.9 |

| TDS | 19.4 | |

| NH4+-N | 93.1 | |

| Moving Bio-Bed Reactor / UASB / Fluidized Immobilized Catalytic Carbon Oxidation / Chemo Autotrophic Activated Carbon | COD | 99 |

| Protein | 99 | |

| Lipid | 100 | |

| O&G | 100 |

| Parameter | R (1) | R (2) | R (3) |

| COD (mg/L) | 22,300 | 21,040 | 10,913 |

| BOD5 (mg/L) | 14,300 | 13,900 | 6900 |

| TS (mg/L) | 12,400 | 4590 | 2100 |

| TN (mg/L) | 220 | na | 252 |

| TP (mg/L) | 46 | 512.4 | 20.8 |

| Method | Parameter | Removal (%) |

| Aqueous phase reforming | COD | 79.7 |

| TOC | 94.9 | |

| Fenton | COD | 70.2 |

| Polyphenol | 36.1 | |

| Electrocoagulation | COD | 66 |

| Color | 98 | |

| Fenton / Coagulation | COD | 80 |

| Turbidity | 99 | |

| TSS | 95 | |

| Up-flow anaerobic stage reactor and Activated sludge | COD | 97.5 |

| BOD5 | 99.2 | |

| TSS | 94.5 | |

| O&G | 98.9 | |

| Aerobic with Coagulation | COD | 99.6 |

| Turbidity | 94.4 | |

| Immobilized Cell Bioreactor | COD | 89.5 |

| Plasma | COD | 93.3 |

| Endotoxin | 90.2 |

| Oil | Water requirement per ton of produced oil (m3) | Wastewater generated per ton of seed (m3) |

| Palm | 2.450 | 0.87 |

| Soybean | 3.365 | 8.5 |

| Rapeseed | 1.860 | 0.85 |

| Parameter | Palm oil | Soybean oil | Rapeseed oil |

| pH | 3.4–5.2 | 4.2 | 6.3–7.2 |

| BOD5 (mg/L) | 10,250–43,750 | 4340 | 4300–4650 |

| COD (mg/L) | 15,000–100,000 | 17,000 | 13,800–15,000 |

| TS (mg/L) | 5000–54,000 | 6700 | 3800–4100 |

| TN (mg/L) | 180–1400 | na | na |

| TP (mg/L) | 180 | na | 62 |

| O&G (mg/L) | 4000 | 1550 | 3600–3900 |

| Method | Oil | Parameter | Removal (%) |

| Magnetic field + Adsorption | Palm | Color | 39 |

| TSS | 61 | ||

| COD | 46 | ||

| Microbial fuel cells + Biological aerated filters | Palm | NH3–N | 93.6 |

| COD | 96.5 | ||

| UASB–Hollow-centered packed bed (HCPB) | Palm | COD | 86.7 |

| UASB-HCPB | Palm | BOD | 90 |

| COD | 88 | ||

| Flocculation | Palm | TSS | 82.97 |

| Turbidity | 88.62 | ||

| COD | 53.23 | ||

| Color | 91.76 | ||

| Algal Treatment | Palm | COD | 71 |

| Fenton advanced oxidation process (AOP) | Palm | COD | 85 |

| Electrocoagulation - Peroxidation | Palm | Color | 96.8 |

| TSS | 100 | ||

| COD | 71.3 | ||

| SBR | Palm | BOD5 | 96 |

| COD | 98 | ||

| TSS | 99 | ||

| Ultrafiltration + Adsorption | Palm | TDS | 47.1 |

| TSS | 71.2 | ||

| COD | 42.3 | ||

| BOD5 | 63.2 | ||

| Turbidity | 63.3 | ||

| Algal Treatment | Palm | TN | 86 |

| Phosphate | 85 | ||

| TOC | 77 | ||

| COD | 48 | ||

| The integrated 2-phase anaerobic reactor | Soybean | COD | 80 |

| Yeast Treatment | Soybean | COD | 94.7 |

| Internal circulation-anoxic/oxic coupling reactor |

Soybean | COD | 90 |

| TN | 98 | ||

| Continuous aerobic/anaerobic in MBBR | Soybean | COD | 94.4 |

| TN | 76 | ||

| Algal treatment | Soybean | COD | 77.8 |

| TN | 89 | ||

| Electrocoagulation and Electro-oxidation |

Rapeseed | CODs | 99 |

| TSS | 100 | ||

| DOC | 95 | ||

| Electrochemical Peroxidation | Rapeseed | CODs | 77 |

| TSS | 100 | ||

| DOC | 86 | ||

| Photo-Fenton | Rapeseed | COD | 80 |

| TOC | 70 | ||

| Hybrid TiO2 /UV/ultrafiltration |

Rapeseed | COD | 82 |

| O&G | 86 | ||

| Microbial fuel cell | Vegetable | COD | 90 |

| TSS | 64 | ||

| Phosphate | 73.6 | ||

| Turbidity | 91.5 |

| Dairy product | Water consumption | Unit |

| Milk and dairy drinks | 0.5–4.1 | L W/L milk |

| Cheese | 0.6–2.9 | L W/L milk |

| Powdered products | 0.1–2.7 | L W/L milk |

| Frozen milk products | 15.7 | L W/kg of product |

| Cream | 3.3 | L W/kg of product |

| Butter | 4 | L W/kg of product |

| Yogurt and fluid products | 1.2 | L W/kg of product |

| Parameter (mg/L) | Range | Average |

| COD | 1906–2513 | 2131 |

| BOD5 | 1372–1809 | 1536 |

| TN | 246–297 | 273 |

| TP | 55–73 | 60 |

| TN | 218–241 | 233 |

| NO3–-N | 22–48 | 38 |

| Method | Parameter | Treatment (%) |

| Algal Treatment | COD | 76.77 |

| TN | 92.15 | |

| Phosphate | 100 | |

| COD | 95.1 | |

| NO3–-N | 79.7 | |

| TP | 98.1 | |

| TDS | 22.8 | |

| Algal Treatment | COD | 64.47 |

| TN | 86.21 | |

| Phosphate | 89.83 | |

| SBBR | COD | 81.8 |

| Phosphate | 94 | |

| NH3-N | 85.1 | |

| SBR | COD | 63.5 |

| Phosphate | 88 | |

| NH4+-N | 66 | |

| UAASB | COD | 71.27 |

| Phosphate | 96.54 | |

| NH4+-N | 95.88 | |

| Airlift reactor with aerobic granular sludge | COD | 81–93 |

| BOD | 85–94 | |

| TN | 52–80 | |

| Combined UASB and Membrane bioreactor (MBR) | COD | 95–99 |

| Hybrid MBR | COD | 95 |

| MBR | COD | 94.1 |

| BOD | 98 | |

| NH4+-N | 100 | |

| Floating activated sludge | COD | 77 |

| Up-flow anaerobic/aerobic/anoxic bioreactor | COD | >90 |

| TN | >50 | |

| TP | >50 | |

| Aerobic sequencing batch flexible fiber biofilm reactor | COD | 98 |

| TSS | 99 | |

| Airlift bioreactor | COD | 99 |

| TN | 79 | |

| TP | 63 |

| Grain | Water requirement (m3 per ton of grain) | Wastewater generation (m3 per ton of grain) |

| Corn | 4 | 3.6 |

| Wheat | 0.07 | 0.06 |

| Rice | 1.3 | 0.3 |

| Grain | Process | BOD5 (mg/L) | COD (mg/L) | TSS (mg/L) | TDS (g/L) | O&G (mg/L) | pH |

| Corn | Wet | 26,000 | 106,600 | – | 109 | – | 5.2 |

| Wheat | Wet | 614 | 1680 | 818 | 1.8 | 1038 | 7 |

| Wheat | Dry | 80 | 154 | 94 | 0.3 | Nil | 7.5 |

| Rice | Wet | 1200 | 1350 | 1100 | 0.7 | – | 7.5 |

| Grain | Technology | Wastewater | Parameter | Removal efficiency (%) |

| Wheat | Filtration+ centrifugation+ filtration column + UV | Washing wastewater | BOD | 45 |

| DO | 71 | |||

| Conductivity | 13 | |||

| Turbidity | 82 | |||

| Wheat | Ozone oxidation | Total wastewater | Phenols | 80 |

| Wheat | Coagulation | Total wastewater | Turbidity | 98 |

| Corn | micro-electrolysis + two-phase anaerobic-aerobic + electrolysis | Oxidized modified starch wastewater | COD | 96 |

| Corn | Internal circulation anaerobic + two-stage AO biochemical + modified Fenton | Starch wastewater | COD | 99.8 |

| NH3-N | 98.7 | |||

| TN | 99 | |||

| Corn | Sedimentation + microfiltration + reverse osmosis | Starch washing wastewater | TSS | 99.3 |

| TS | 99.6 | |||

| BOD | 100 | |||

| Corn | Algal treatment | Cationic starch wastewater | TSS | 80 |

| TP | 33 | |||

| Rice | Ultrafiltration | Total wastewater | COD | 63 |

| Color | 67 | |||

| Rice | Algal treatment | Parboiled rice wastewater | TP | 93.9 |

| NH3-N | 100 | |||

| BOD | 98.7 | |||

| COD | 91.6 | |||

| TDS | 93.5 | |||

| Rice | Algal treatment | Total wastewater | TP | 68.12 |

| TN | 49.32 |

| Parameter, (mg·L−1) | [103] | [106] | [107] |

| pH | 6 | 4.7–5.1 | 3.5–3.8 |

| TSS | 1180 | 6000 | 881–1124 |

| TDS | 3600 | ||

| BOD | 2250 | 3200 | 1603–3389 |

| COD | 5700 | 7000 | 3984–9672 |

| TN | 60–90 | 36 | |

| TP | 30–100 | 7 | |

| O&G | 96 | 820 |

| Method | Stage | Parameter | Removal efficiency (%) |

| Electrochemical treatment | Pre-treatment | COD | 6–8 |

| Turbidity | 32–98 | ||

| Constructed wetland | Biological treatment | TKN | 57 |

| TP | 65 | ||

| BOD | 92 | ||

| TSS | 69 | ||

| O&G | 99 | ||

| UASB | Biological treatment | COD | 83.1 |

| UASB | Biological treatment | COD | 92 |

| Parameter | Beet | Cane |

| CODt (mg/L) | 6621 ± 113.2 | 965–11,640 |

| CODs (mg/L) | 6165 ± 517.1 | 799–10,640 |

| BOD (mg/L) | 3837 | 1939–2347 |

| TKN (mg/L) | 10 | 20–43 |

| TP (mg/L) | 2.7 | 3–31 |

| TSS (mg/L) | 665 ± 21.2 | 288–5030 |

| VSS (mg/L) | 335 ± 7.1 | 110–1990 |

| pH | 6.82 | 4.4–4.6 |

| Parameter | R(1) | R(2) |

| Turbidity (NTU) | 11,549 | 9210 |

| COD (mg/L) | 9850 | 628 |

| BOD5 (mg/L) | na | 193.4 |

| TSS (mg/L) | 8945 | na |

| TOC (mg/L) | 5057 | na |

| pH | na | 6.69 |

| Conductivity (μS·cm−1) | na | 317 |

| Type | pH | BOD5 (g/L) | COD (g/L) | TS (g/L) | TP (mg/L) | TN (g/L) |

| Arabica | 3.9–4.1 | 3.6–15.2 | 6.2–31.5 | 5.4–13.4 | 5–8.8 | 0.1–0.12 |

| Robusta | 4.1–4.6 | 10.8–13.2 | 15–18.1 | 6.3–12 | 4–7.3 | 0.02–0.04 |

| Wastewater | Method | Parameter | Removal efficiency (%) |

| Sugar | UASB | COD | 78–82 |

| Sugar | Electrochemical | COD | 84 |

| Turbidity | 86 | ||

| Sugar | Anaerobic granular sludge | COD | 92–95 |

| Sugar | Electrochemical peroxidation | COD | 65 |

| COD | 64 | ||

| TOC | 66 | ||

| TOC | 63 | ||

| Sugar | Chemical oxidation+ electro-oxidation | COD | 81 |

| Turbidity | 83.5 | ||

| Sugar | Electrochemical reactor | COD | 90 |

| Turbidity | 93.5 | ||

| Sugar | Algal treatment | COD | 37.91 |

| BOD | 25.69 | ||

| TDS | 48.51 | ||

| Turbidity | 39.2 | ||

| Tea | Membrane treatment | Turbidity | > 99.9 |

| COD | > 99.9 | ||

| TOC | > 99.9 | ||

| Tea | Photo-Fenton | COD | 88–99.3 |

| Tea | UV photo-Fenton | TOC | 96 |

| COD | 100 | ||

| Polyphenol | 97 | ||

| Tea | Adsorption + AOP | Color | 98 |

| Coffee | UV photo-Fenton | TOC | 93 |

| Coffee | Photo-Fenton + UASB | BOD | 95 |

| Coffee | Chemical flocculation + AOP | COD | 87 |

| Coffee | Adsorption | COD | 99 |

| BOD | 99 | ||

| Coffee | Membrane treatment | COD | 97 |

| Conductivity | 99 | ||

| Coffee | Chemical coagulation + electro-oxidation | TOC | 95 |

| COD | 97 | ||

| Coffee | Fenton's + coagulation | TOC | 76.2 |

| COD | 76.5 | ||

| BOD | 66.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).