Submitted:

29 August 2023

Posted:

31 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Efficient and effective control schemes based on crowbar controls were designed to cater to the transient effects of rotor current and DC-link voltage throughout grid instabilities, strengthening the LVRT capability of the DFIG and improving the transient performance of the system.

- The proposed method is a promising solution for realizing the LVRT capability, owing to its ability to mitigate the transient effects in generator electromagnetic torque. Moreover, the proposed design is suitable for wind-energy systems due to its the practical implementation.

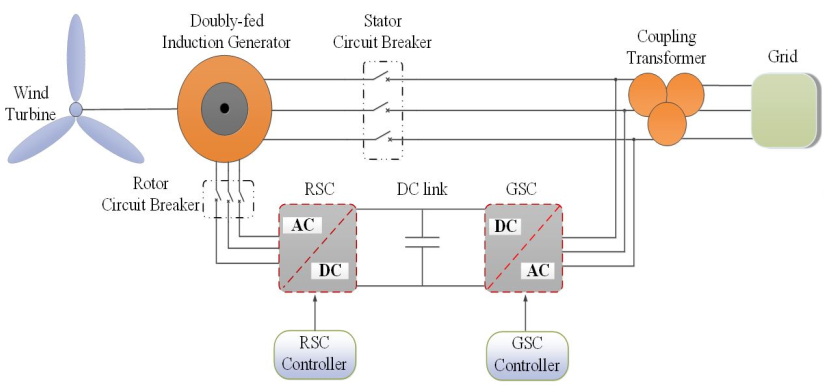

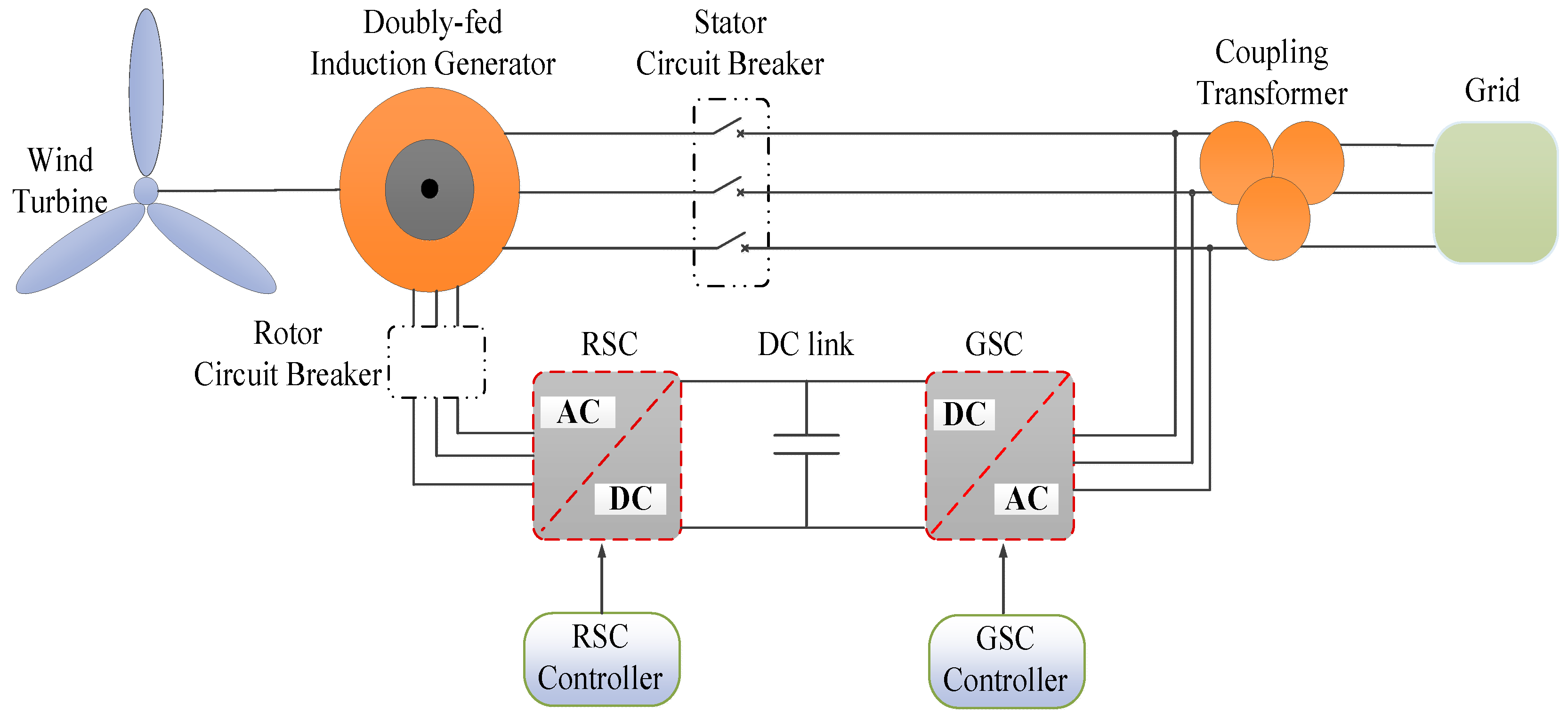

2. Overview of a DFIG-WT System

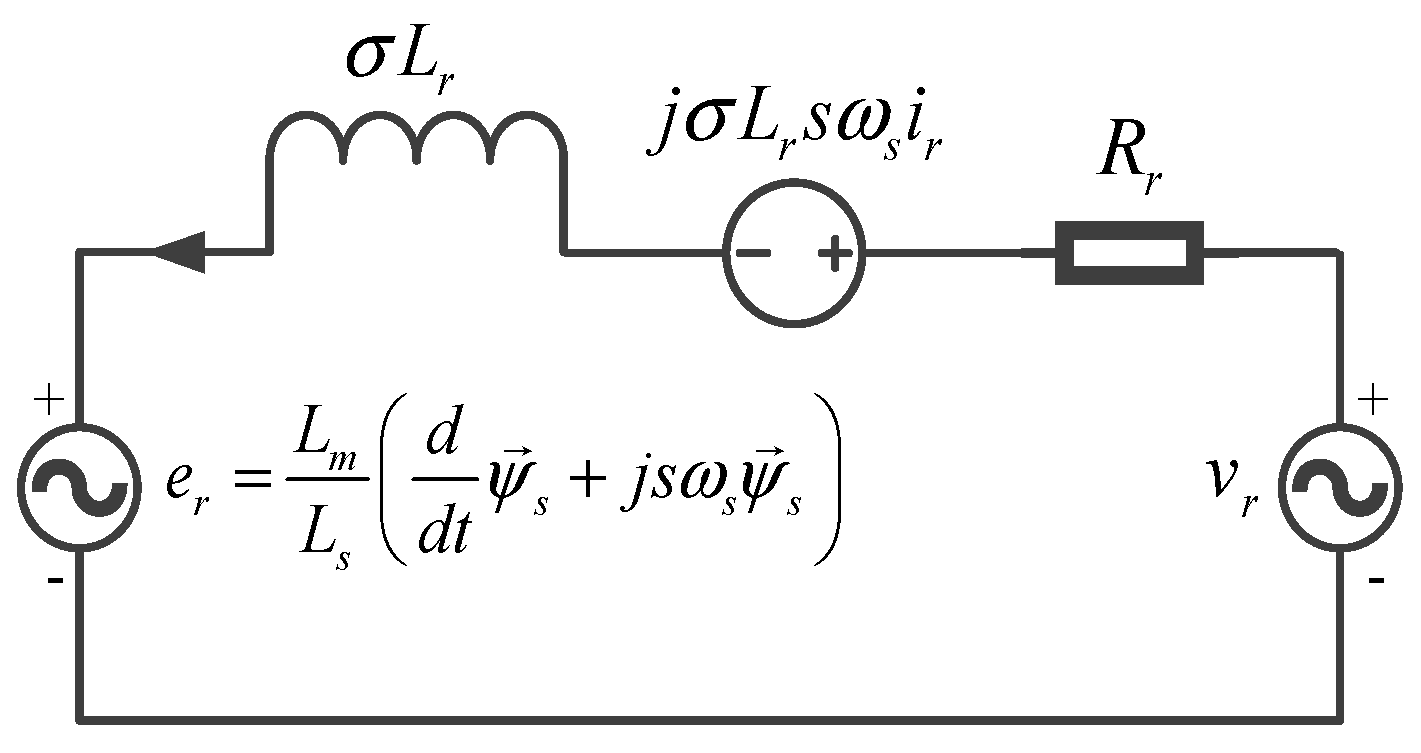

3. Modeling and Analysis of a DFIG

3.1. DFIG Dynamical Model

3.2. Steady-State Analysis of DFIG

3.3. Transient Analyses of DFIG

3.3.1. Symmetrical Grid Faults

3.3.2. Asymmetrical Grid Faults

4. Proposed Control Schemes

4.1. Proposed Control Scheme for LVRT Enhancement

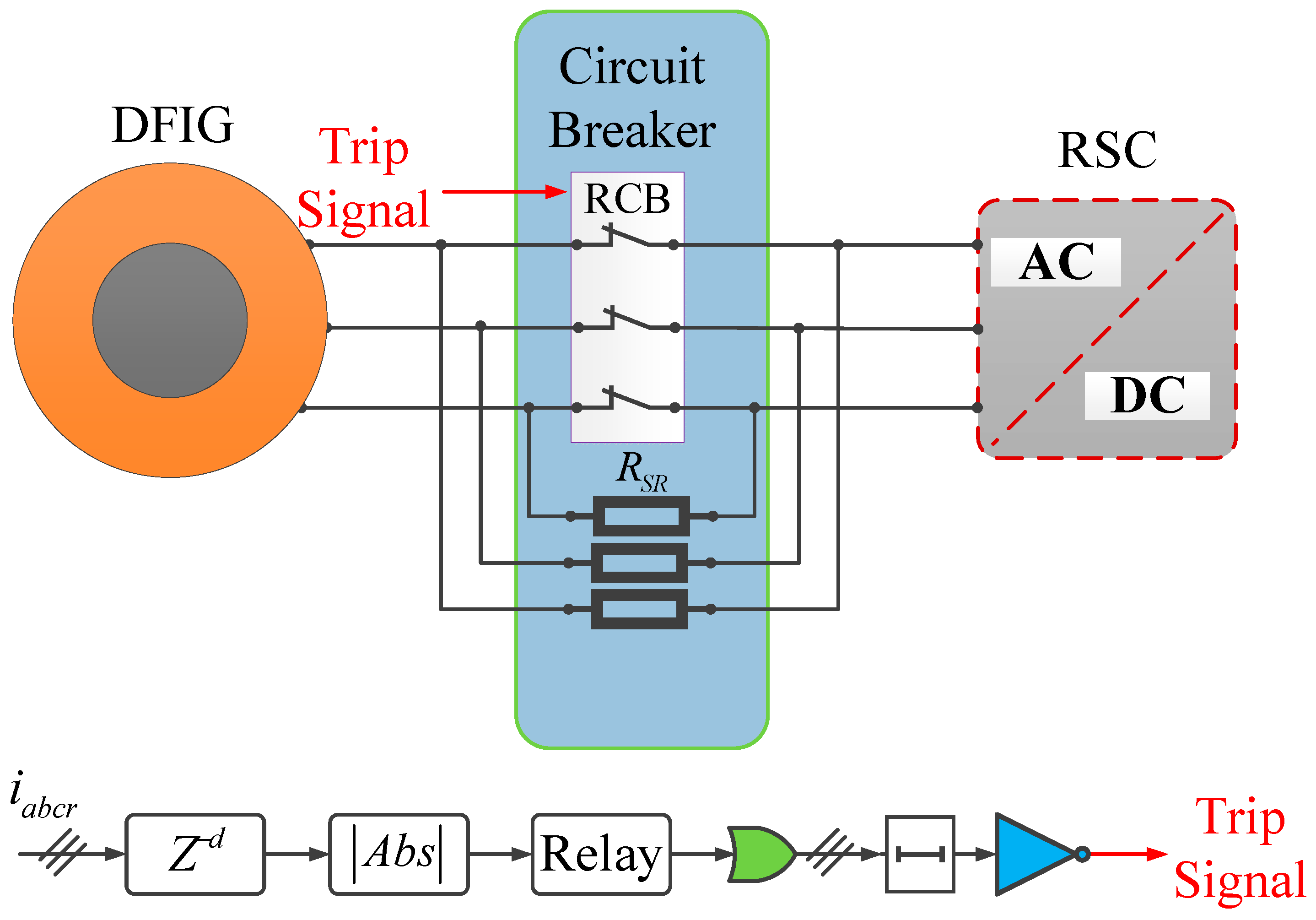

4.1.1. Control Structure of Crowbar at Rotor-side

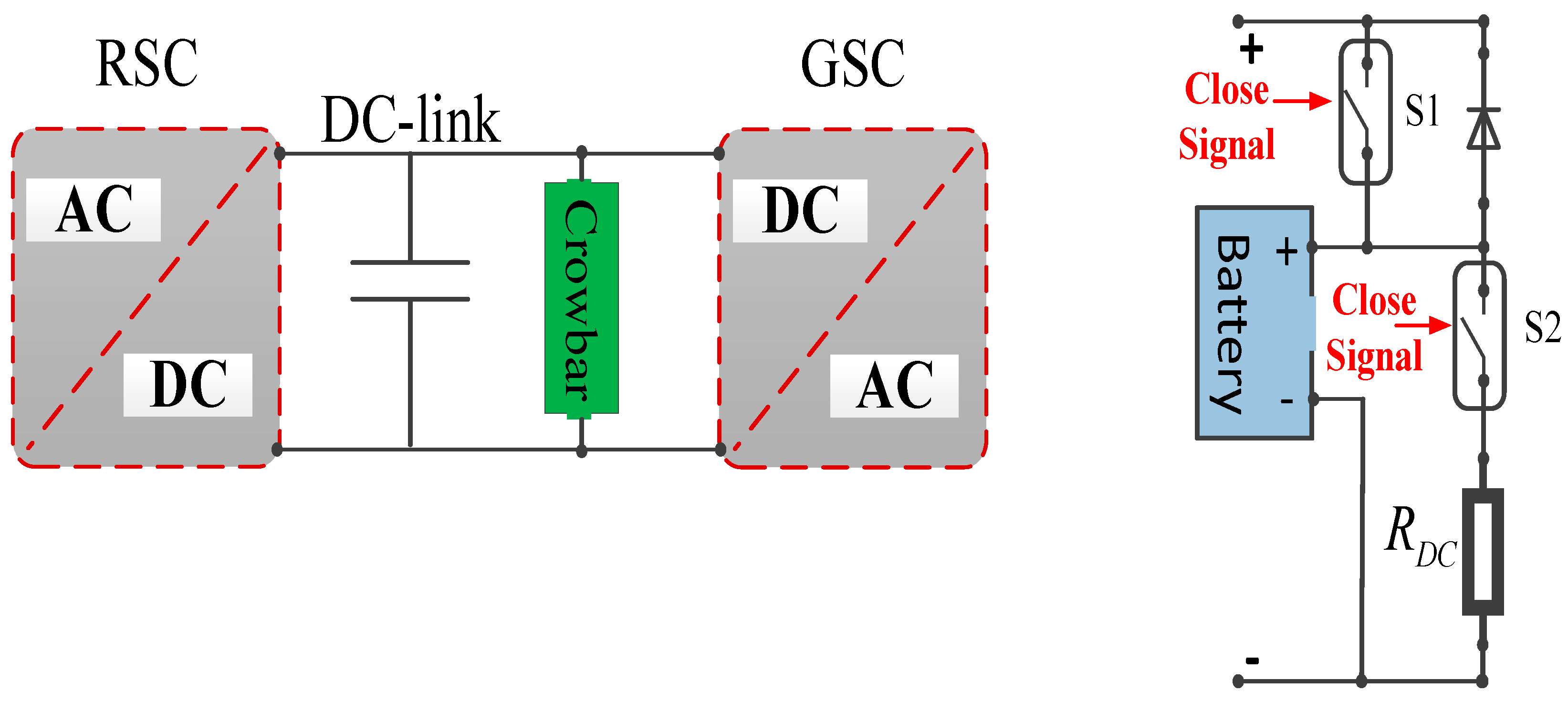

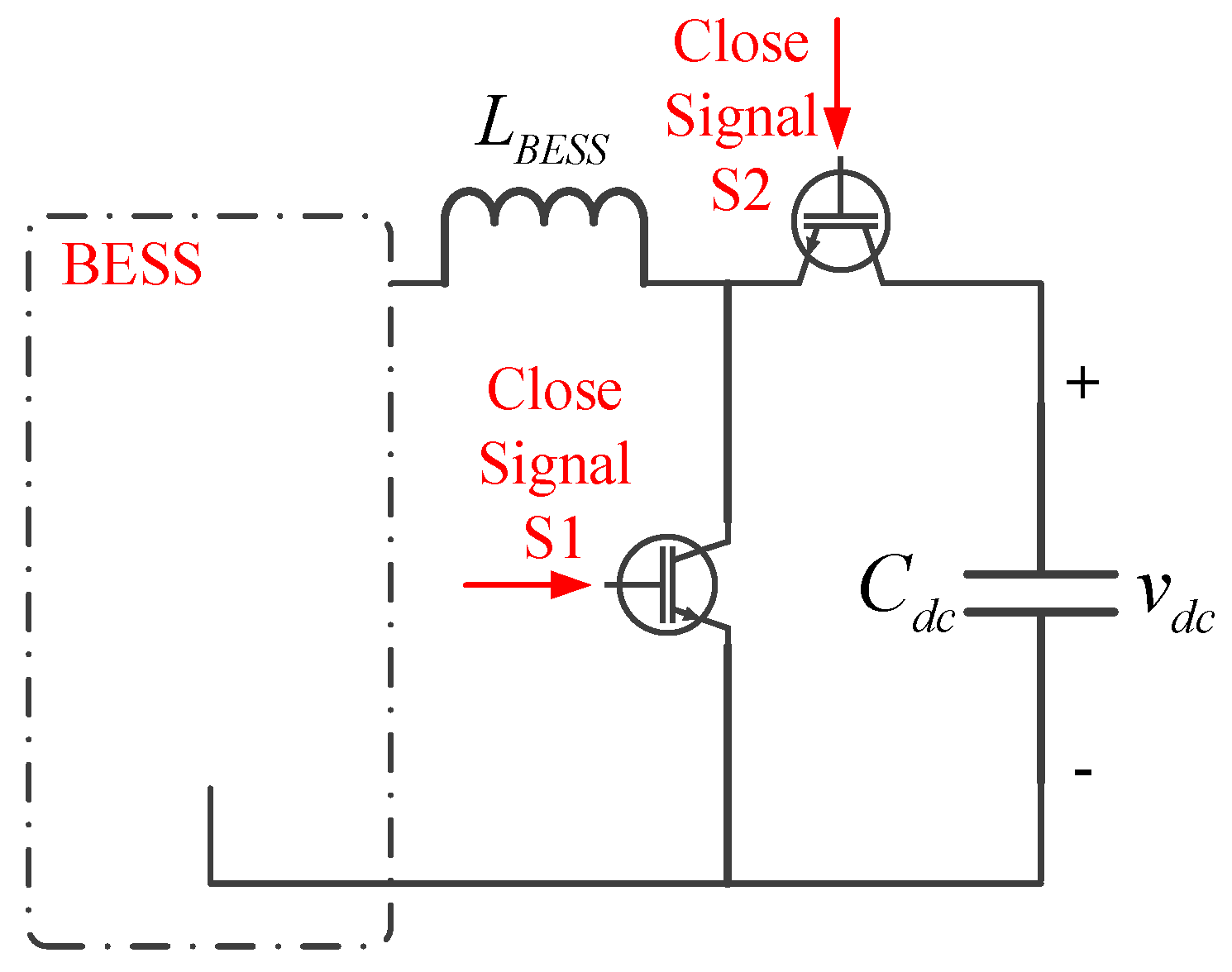

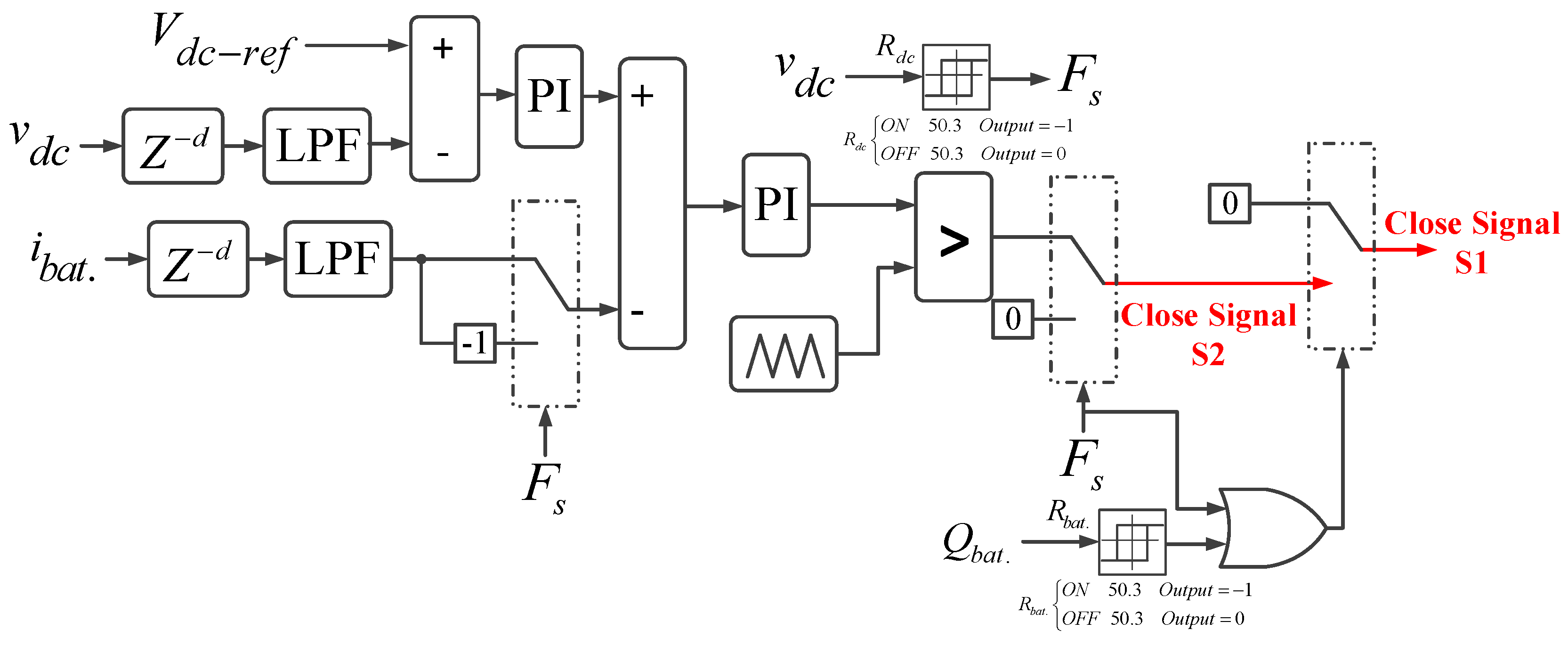

4.1.2. Control Structure of Crowbar at DC-link

5. Estimation of BESS Capacity for LVRT

6. Results and Discussions

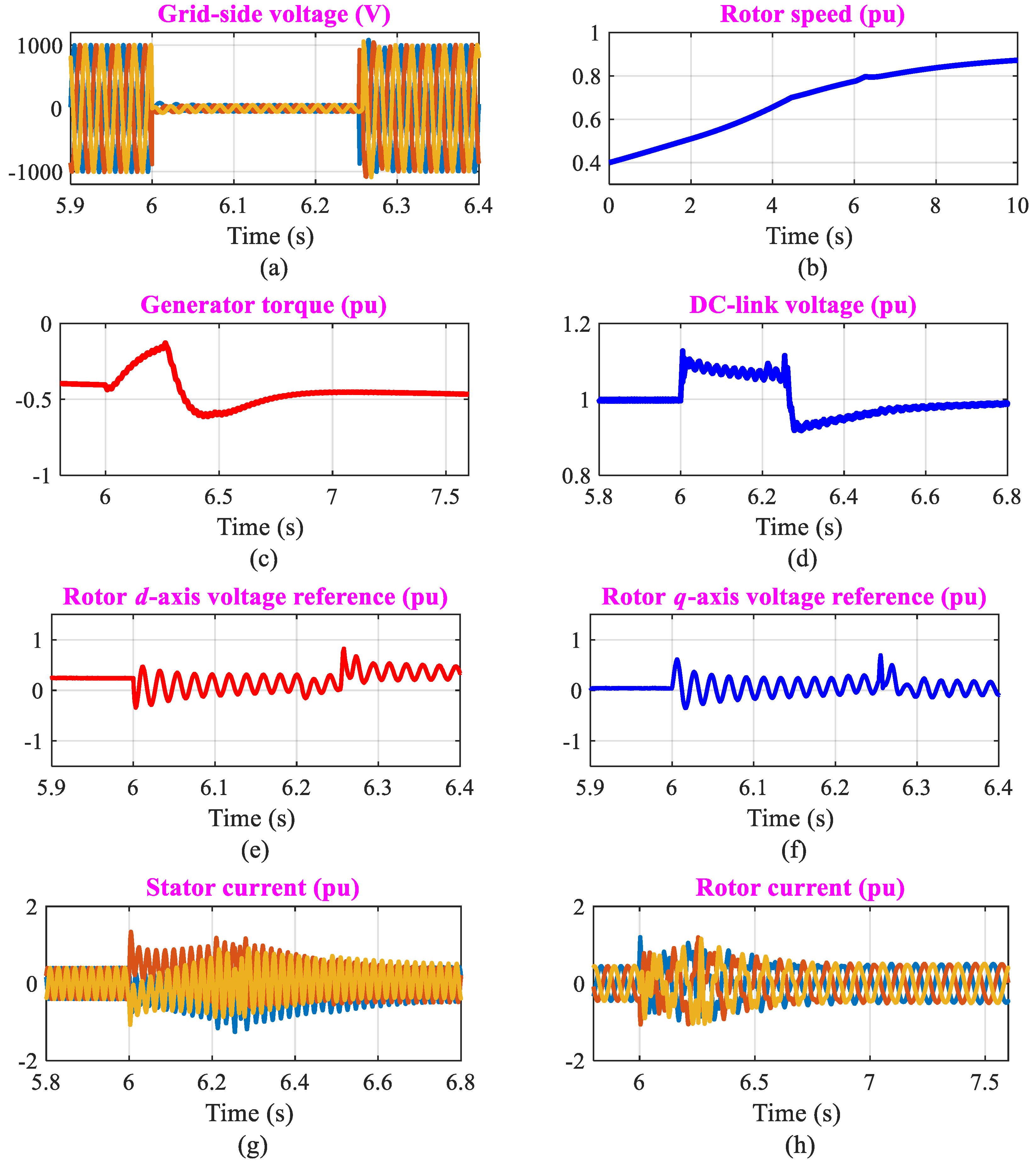

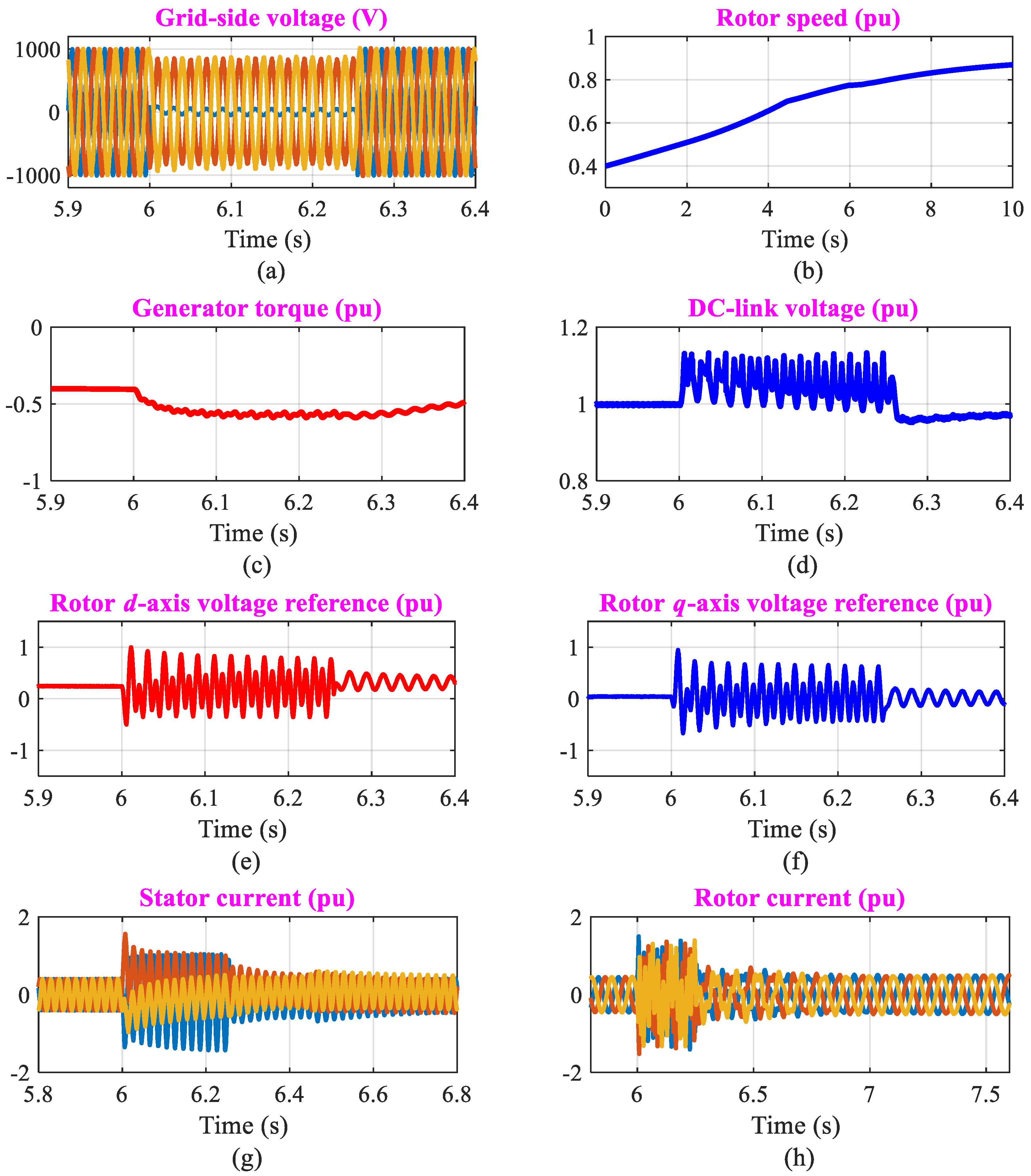

6.1. Performance of the Proposed Control Scheme for Symmetrical Grid Fault

6.2. Performance of the Proposed Control Scheme for Asymmetrical Grid Fault

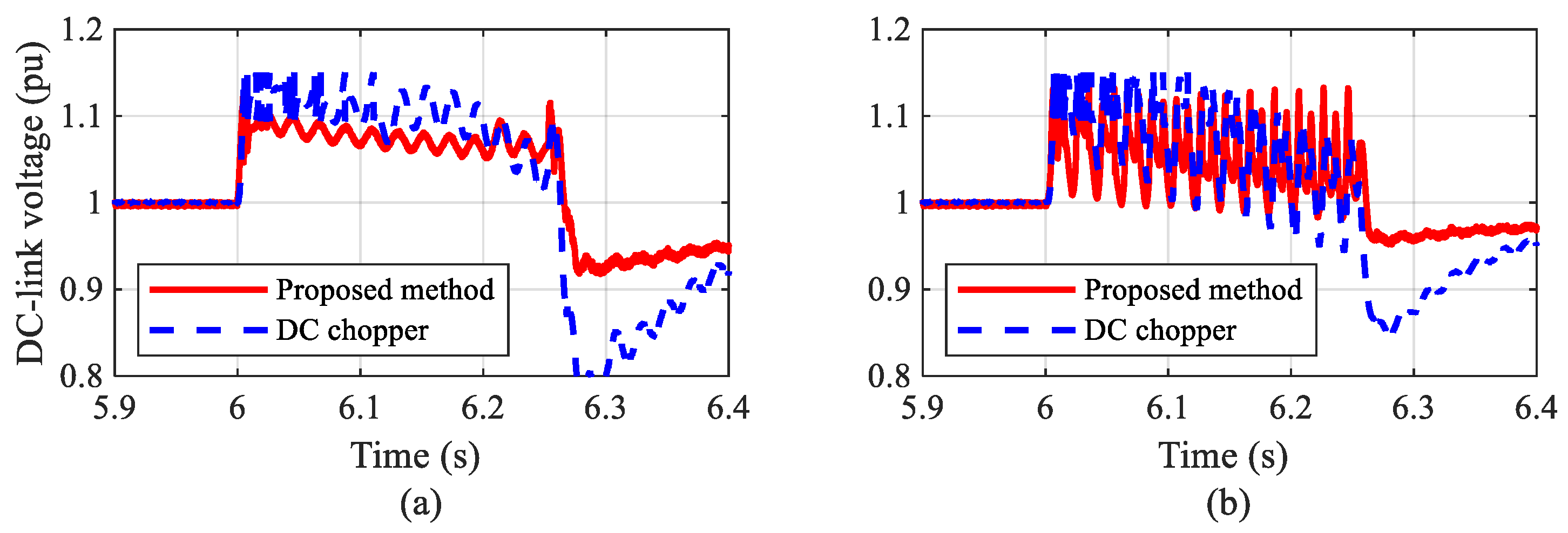

6.3. Performance Comparison

7. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Value | Unit |

|---|---|---|

| Generator rated power | 1.5 | MW |

| Rated stator voltage | 690 | V |

| Rated frequency | 50 | Hz |

| Pole-pair number | 2 | Nos. |

| Stator winding resistance | 2.65 | mΩ |

| Stator leakage inductance | 0.1687 | mH |

| Rotor winding resistance | 2.63 | mΩ |

| Rotor leakage inductance | 0.1337 | mH |

| Magnetizing inductance | 5.4749 | mH |

| Rotational inertia | 3 | s |

References

- Salama, H.S.; Vokony, I. Voltage and Frequency Control of Balanced/Unbalanced Distribution System Using the SMES System in the Presence of Wind Energy. Electricity 2021, 2, 205–224. [Google Scholar] [CrossRef]

- Ali, M.A.S.; Mehmood, K.K.; Kim, C.-H. Full operational regimes for SPMSG-based WECS using generation of active current references. Int. J. Electr. Power Energy Syst. 2019, 112, 428–441. [Google Scholar] [CrossRef]

- Huang, Q.; Zou, X.; Zhu, D.; Kang, Y. Scaled current tracking control for doubly fed induction generator to ride through serious grid faults. IEEE Trans. Power Electron. 2016, 31, 2150–2165. [Google Scholar] [CrossRef]

- Alsmadi, Y.M.; et al. Detailed investigation and performance improvement of the dynamic behavior of grid-connected DFIG-based wind turbines under LVRT conditions. IEEE Trans. Ind. Appl. 2018, 54, 4795–4812. [Google Scholar] [CrossRef]

- Firouzi, M.; Gharehpetian, G.B. LVRT performance enhancement of DFIG-based wind farms by capacitive bridge-type fault current limiter. IEEE Trans. Sustain. Energy 2018, 9, 1118–1125. [Google Scholar] [CrossRef]

- Ali, M.A.S.; Mehmood, K.K.; Baloch, S.; Kim, C.-H. Wind-Speed Estimation and Sensorless Control for SPMSG-Based WECS Using LMI-Based SMC. IEEE Access 2020, 8, 26524–26535. [Google Scholar] [CrossRef]

- Zhu, D.; et al. Feedforward current references control for DFIG-based wind turbine to improve transient control performance during grid faults. IEEE Trans. Energy Convers. 2018, 33, 670–681. [Google Scholar] [CrossRef]

- Haidar, A.M.A.; Muttaqi, K.M.; Hagh, M.T. A coordinated control approach for DC link and rotor crowbars to improve fault ride-through of DFIG-based wind turbine. IEEE Trans. Ind. Appl. 2017, 53, 4073–4086. [Google Scholar] [CrossRef]

- Xiao, S.; Yang, G.; Zhou, H.; Geng, H. An LVRT control strategy based on flux linkage tracking for DFIG-based WECS. IEEE Trans. Ind. Electron. 2013, 60, 2820–2832. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, J.; Zhou, S. Improved demagnetization control of a doubly-fed induction generator under balanced grid fault. IEEE Trans. Power Electron. 2015, 30, 6695–6705. [Google Scholar] [CrossRef]

- Ali, M.A.S.; Mehmood, K.K.; Baloch, S.; Kim, C.-H. Modified rotor-side converter control design for improving the LVRT capability of a DFIG-based WECS. Electr. Power Syst. Res. 2020, 186, 106403. [Google Scholar] [CrossRef]

- Li, X.-M.; Zhang, X.-M.; Lin, Z.-W.; Niu, Y.-G. An improved flux magnitude and angle control with LVRT capability for DFIGs. IEEE Trans. Power Syst. 2018, 33, 3845–3853. [Google Scholar] [CrossRef]

- Majout, B.; et al. Improvement of PMSG-based wind energy conversion system using developed sliding mode control. Energies, 2022, 15, 1625. [Google Scholar] [CrossRef]

- Morshed, M.J.; Fekih, A. A new fault ride-through control for DFIG-based wind energy systems. Electr. Power Syst. Res. 2017, 146, 258–269. [Google Scholar] [CrossRef]

- Geng, H.; Liu, C.; Yang, G. LVRT capability of DFIG-based WECS under asymmetrical grid fault condition. IEEE Trans. Ind. Electron. 2013, 60, 2495–2509. [Google Scholar] [CrossRef]

- Xie, D.; et al. A comprehensive LVRT control scheme for DFIG wind turbines with enhanced reactive power support. IEEE Trans. Power Syst. 2013, 28, 3302–3310. [Google Scholar] [CrossRef]

- Ali, M.A.S. Enhanced transient performance of wind-driven PMSG: A revised control structure of wind-power converters. Adv. Electr. Comput. Eng. 2022, 2, 61–70. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Zhou, M.; Li, C.; Lv, Y. ; Double impedance-substitution control of DFIG based wind energy conversion system. Energies, 2022, 15, 5739. [Google Scholar] [CrossRef]

- Ma, Y.; et al. Modeling and transient stability analysis for Type-3 wind turbines using singular perturbation and Lyapunov methods. IEEE Trans. Ind. Electron. 2022, 1–1. [Google Scholar] [CrossRef]

- Dang., H.P.; Pico, H.N.V. Blackstart and fault ride-through capability of DFIG-based wind turbines. IEEE Trans. Smart Grid 2022, 1–1. [Google Scholar] [CrossRef]

- Jalilian., A.; Naderi, S.B.; Negnevitsky, M.; Hagh, M.T.; Muttaqi, K.M. Controllable DC-link fault current limiter augmentation with DC chopper to improve fault ride-through of DFIGURE. IET Renew. Power Gener 2017, 11, 1304–1304. [Google Scholar] [CrossRef]

- Tabosa da Silva, P.L.; Rosas, P.A.C.; Castro, J.F.C.; Marques, D.d.C.; Aquino, R.R.B.; Rissi, G.F.; Neto, R.C.; Barbosa, D.C.P. Power Smoothing Strategy for Wind Generation Based on Fuzzy Control Strategy with Battery Energy Storage System. Energies 2023, 16, 6017. [Google Scholar] [CrossRef]

- Rashid, G.; Ali, M.H. Nonlinear control-based modified BFCL for LVRT capacity enhancement of DFIG-based wind farm. IEEE Trans. Energy Convers. 2017, 32, 284–295. [Google Scholar] [CrossRef]

- Hossain., M.A.; et al. Protecting DFIG-based multi-machine power system under transient-state by nonlinear adaptive backstepping controller-based capacitive BFCL. IET Gener. Transm. Distrib. 2022, 16, 4528–4528. [Google Scholar] [CrossRef]

- Padmaja, A.; et al. Design of capacitive bridge fault current limiter for low-voltage ride-through capacity enrichment of doubly fed induction generator-based wind farm. Sustainability 2021, 13, 6656. [Google Scholar] [CrossRef]

- Sadi, M.A.H.; AbuHussein, A.; Shoeb, M.A. Transient performance improvement of power systems using fuzzy logic controlled capacitive-bridge type fault current limiter. IEEE Trans. Power Syst. 2020, 36, 323–335. [Google Scholar] [CrossRef]

- Gounder., Y.K..; Nanjundappan, D.; Boominathan, V. Enhancement of transient stability of distribution system with SCIG and DFIG based wind farms using STATCOM. IET Renew. Power Gener. 2016, 10, 1171–1180. [Google Scholar] [CrossRef]

- Shen, Y.-W.; et al. Advanced auxiliary control of an energy storage device for transient voltage support of a doubly fed induction generator. IEEE Trans. Sustain. Energy 2016, 7, 63–76. [Google Scholar] [CrossRef]

- Wessels, C.; Gebhardt, F.; Fuchs, F.W. Fault ride-through of a DFIG wind turbine using a dynamic voltage restorer during symmetrical and asymmetrical grid faults. IEEE Trans. Power Electron. 2011, 26, 807–815. [Google Scholar] [CrossRef]

- Wang, X.; Peng, L. Dynamic voltage equalization control of D-STATCOM under unbalanced grid faults in low-voltage network. IEEE Trans. Power Electron. 2022, 1–14. [Google Scholar] [CrossRef]

- Xiao, F.; Xia, Y.; Zhang, K.; Zhang, Z.; Yin, X. Fault characteristics analysis of DFIGWT in whole LVRT process considering control strategy switching between RSC and crowbar. Int. J. Electr. Power Energy Syst. 2023, 145, 108615. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Xu, D.; Chen, W.; Zhu, N. Advanced Control of Doubly Fed Induction Generator for Wind Power Systems; Wiley-IEEE Press: Piscataway, NJ, USA, 2018. [Google Scholar]

- Abad, G.; Lopez, J.; Rodriguez, M.; Marroyo, L.; Iwanski, G. Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation; Wiley-IEEE Press: Piscataway, NJ, USA, 2011. [Google Scholar]

- Wu, B.; Lang, Y.; Zargari, N.; Kouro, S. Power Conversion and Control of Wind Energy Systems; Wiley-IEEE Press: Piscataway, NJ, USA, 2011. [Google Scholar]

- Noubrik, A.; Chrifi-Alaoui, L.; Bussy, P.; Benchaib, A. Analysis and simulation of a crowbar protection for DFIG wind application during power systems disturbances. J. Mech. Eng. Autom. 2011, 1, 303–312. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).