4.1. Analysis of steering kinematics model for the wheel-track composite vehicle

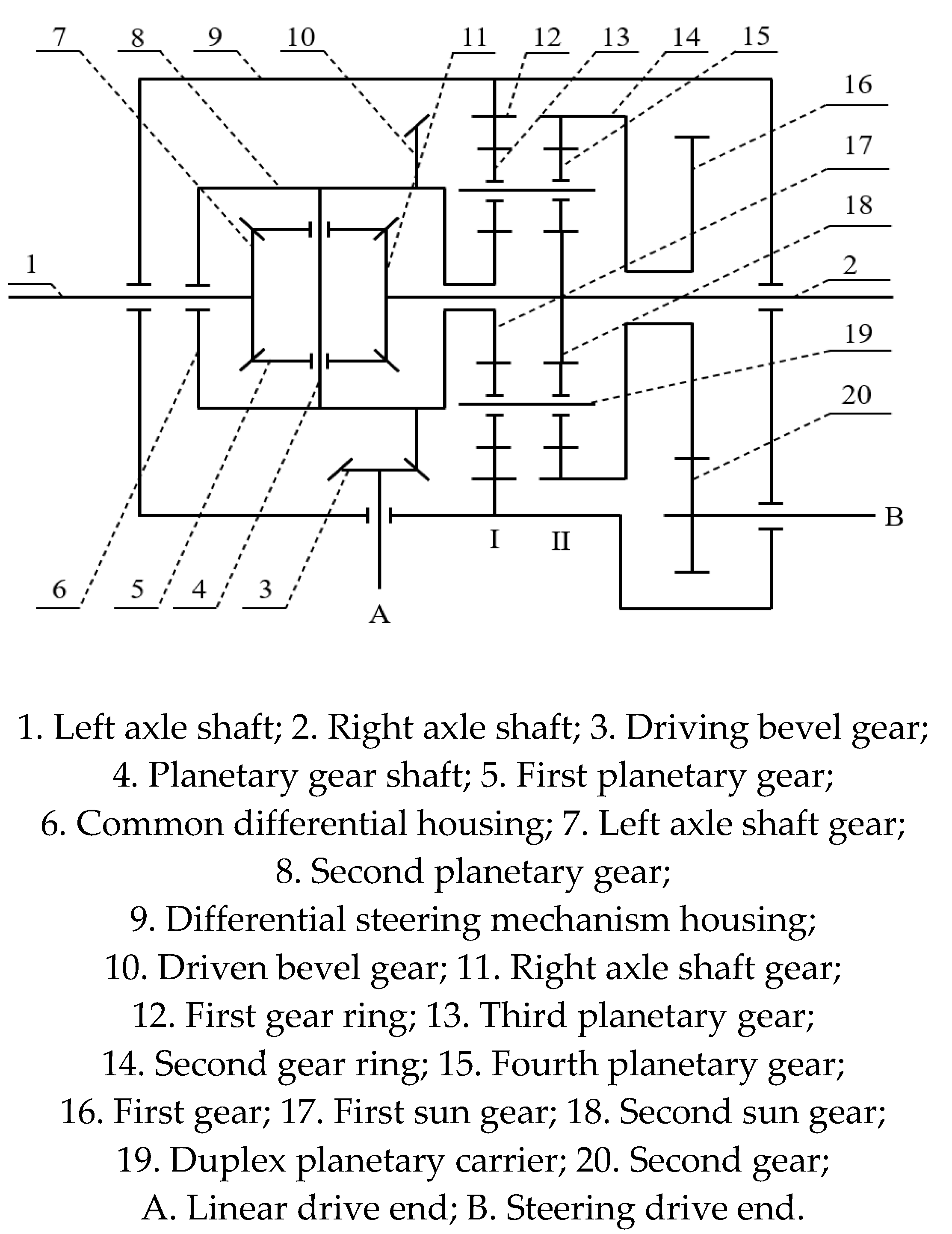

To analyze the steering characteristics of the wheel-track composite vehicle on the horizontal ground, the steering motion model was established as shown in

Figure 6(a). And the following assumptions would be made about the steering motion of the vehicle in the traveling state.

(1) The slow steering speed of the tracked vehicle allowed the effect of centrifugal force during steering to be ignored.

(2) Grounding pressure was evenly distributed.

(3) The tracked vehicle made a steady state uniform steering motion on a horizontal should ground.

(4) The center of gravity of the vehicle was located at the intersection of the axes of symmetry.

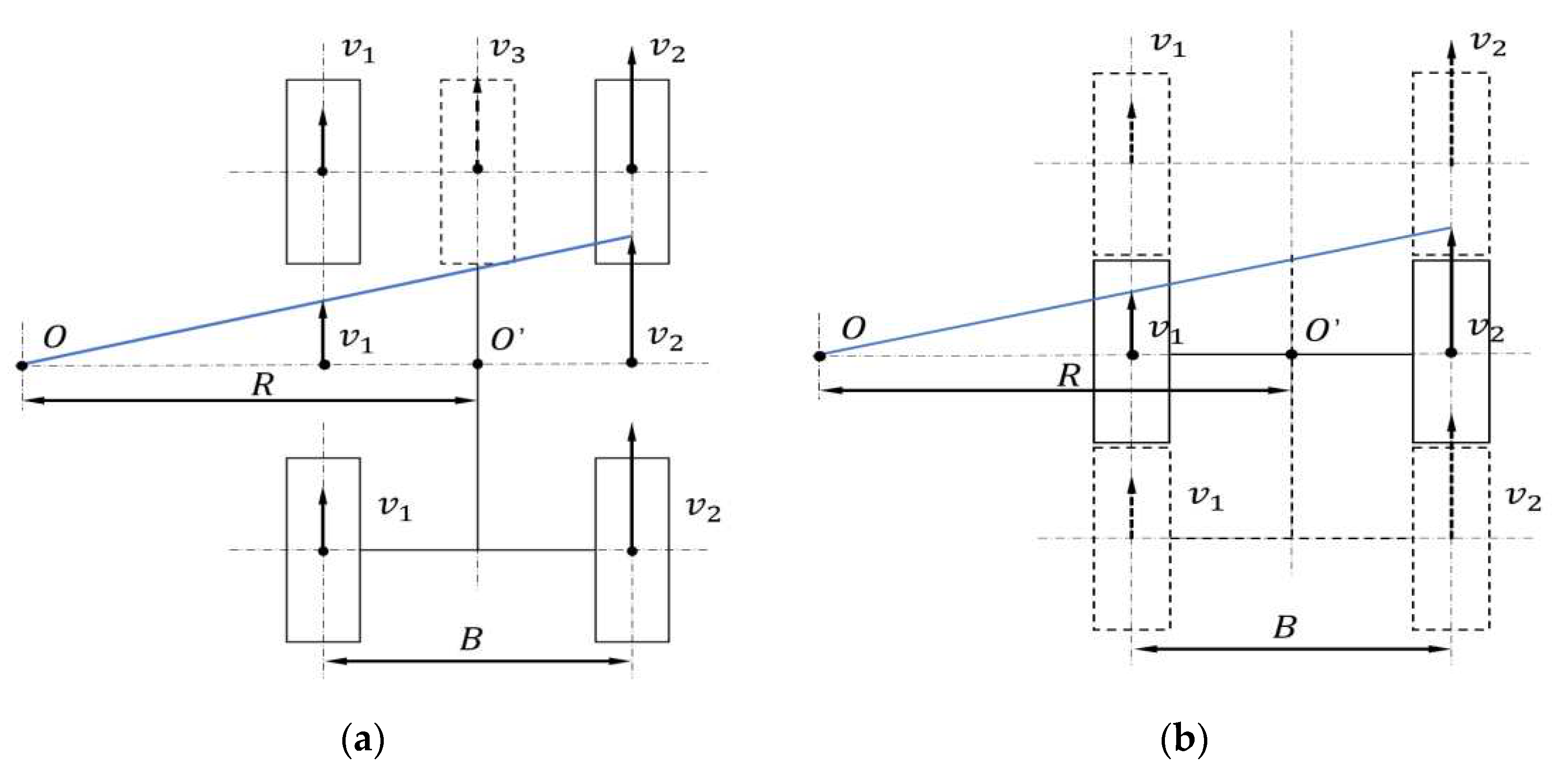

Since the track of the wheel-track composite vehicle was lifted upward during turning, it was equivalent to grounding the wheel, as shown in

Figure 6(b). In order to better explain the differential steering principle of the wheel-track composite vehicle in the presence of the differential steering mechanism with dual driving, the front track was simplified to a wheel. The wheel-track composite vehicle differential steering model was transformed into a three-wheeled vehicle differential steering model to be studied. Assuming that the model was steered to the left, the relationship between the velocities of the wheels on both sides and the steering radius was obtained according to the geometric relationship.

The kinematic model of the whole vehicle was shown in

Figure 6(a). The coordinate system of

xoy was the body coordinate system, where x pointed to the forward direction of the wheel-track composite vehicle.

O point was the vehicle turning center,

O' point was the own rotation center of vehicle,

B point was the distance between the left and right wheel center,

R point was the turning radius of vehicle, and

v1,

v2, and

v3 were the forward speeds of the left wheel, right wheel, and front wheel, respectively.

The relationship between the velocities of the wheels on both sides and the steering radius was obtained according to the geometric relationship as shown in formulas (12) to (13).

In the above formulas,

ω represented the vehicle steering angular velocity. If the angular velocities of the driving wheels on both sides were ω

1 and ω

2 respectively, and the rolling radius of the driving wheels was denoted as r, the traveling speeds of the wheels on both sides were

and

respectively. Thus, the steering angular velocity

ω could be obtained as follows.

The larger the difference in steering angular velocities between the wheels on both sides of the wheel-track composite vehicle, the greater the steering angular velocity ω of the vehicle, resulting in a smaller steering radius R.

Based on the above speed relationship and the kinematic model, the steering radius could be derived from the speed of two wheels.

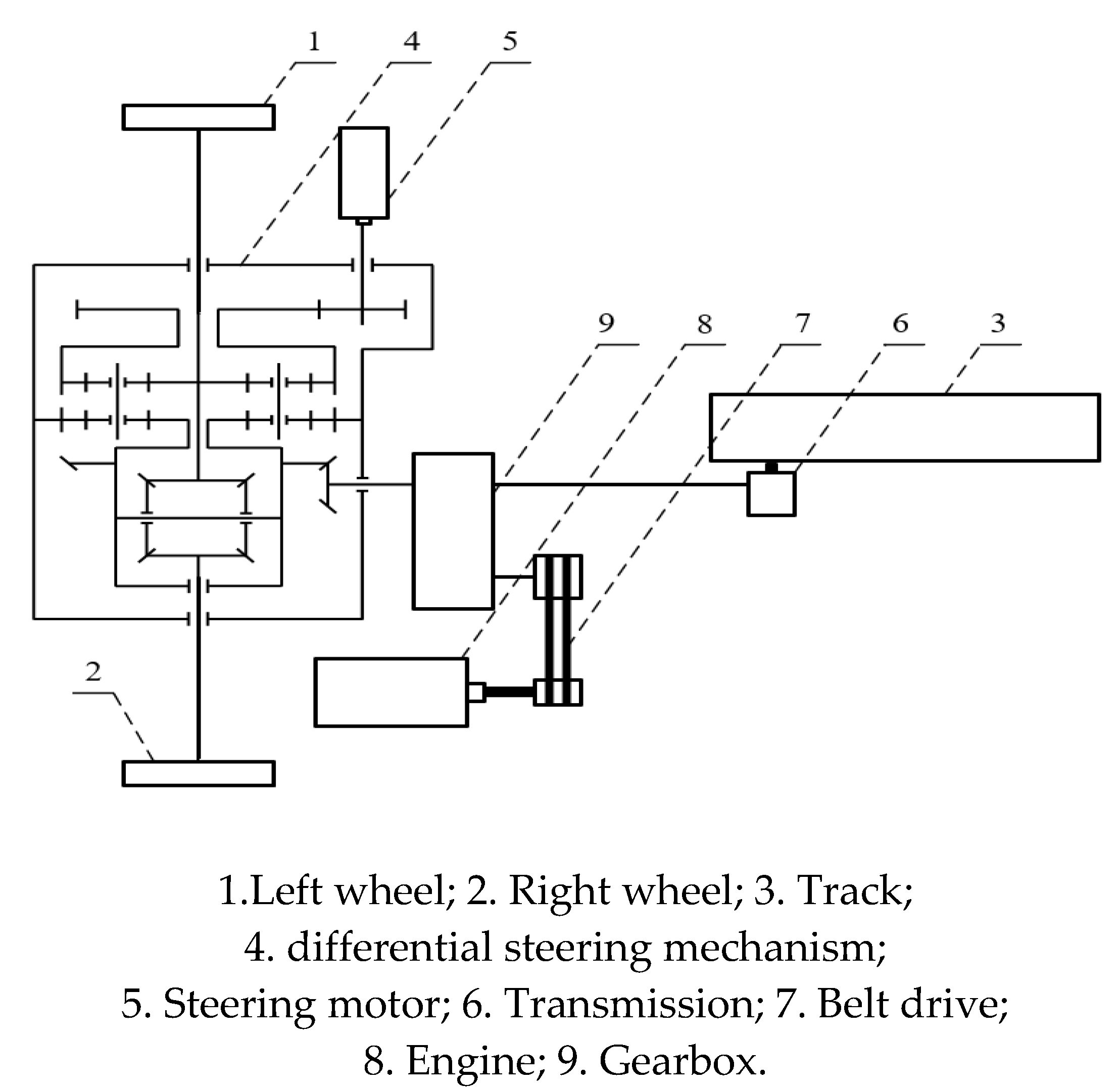

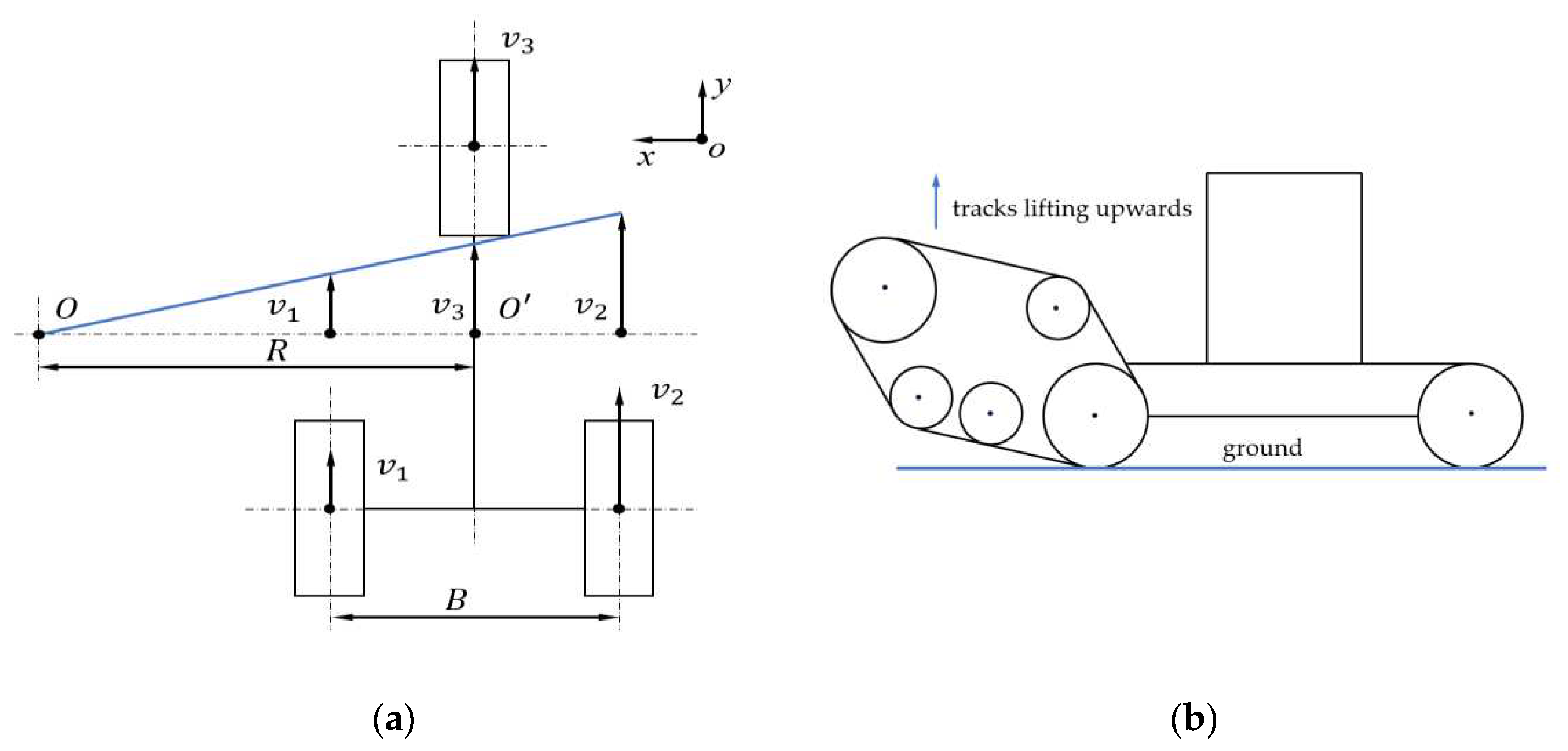

According to formulas (12) to (13) and

Figure 7(a), the effect of converting the front wheels into two wheels on the differential steering of the vehicle was the same, and it would not change the steering radius of the vehicle. The vehicle needed to rely on the differential steering mechanism to achieve differential power distribution between the left and right axle shafts, and the four wheels did not swing during the steering process. In order to explore the impact of the differential steering mechanism on the rotational speeds of the driving wheels on both sides and analyze the relationship between input speed and steering radius, the four-wheel equivalent kinematic model was transformed into a two-wheel kinematic model [

17,

18]. Before and after the equivalence, the wheel rotational speeds and vehicle steering radius were not affected, and the simplified model of vehicle two-wheel steering was shown in

Figure 7(b).

If the rotational speeds of the left and right output axle shafts were known, then

Therefore, the theoretical turning radius of the vehicle could be solved.

(1) As shown in

Figure 8(a), if

, according to

,

and

, then the radius of steering was expressed as follows.

(2) As shown in

Figure 8(b), if

, according to

, then the radius of steering was expressed as follows.

In formulas,

- transmission ratio from the linear drive end to the two axle shafts;

- transmission ratio from the steering drive end to the two axle shafts;

According to formulas (18) and (19), the size of the steering radius could be theoretically derived when the engine input speed and the steering drive motor input speed were known [

5].

; (b) .

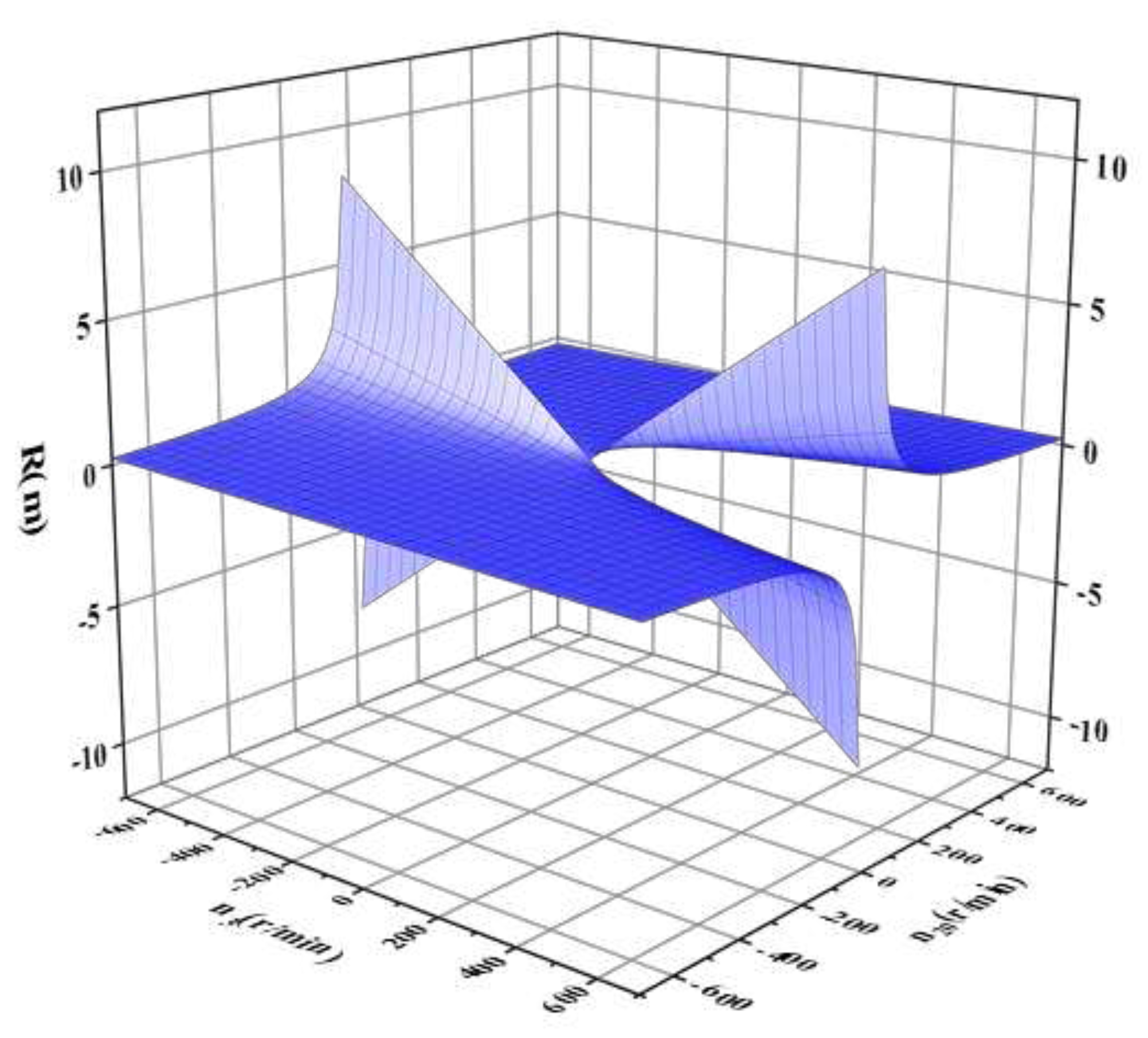

The relationship between the steering radius and the rotational speed of both driving ends was shown in

Figure 9. It could be seen that the size of the steering radius increased with the increase of the input speed of the linear drive end and decreased with the increase of the input speed of the steering drive motor. The steering radius increased sharply when the input speed of the steering drive end tended to 0. The steering radius

R was continuous in the interval (-10,10) m, indicating that the wheel-track composite vehicle equipped with the power differential steering mechanism could achieve an arbitrary continuous steering radius.

, the steering drive end speed of .

In order to verify the accurate steering capability of the differential steering mechanism for the wheel-track composite vehicle, the steering radius of the vehicle was investigated using the rotational speeds of the two drive ends of the differential steering mechanism as power inputs.

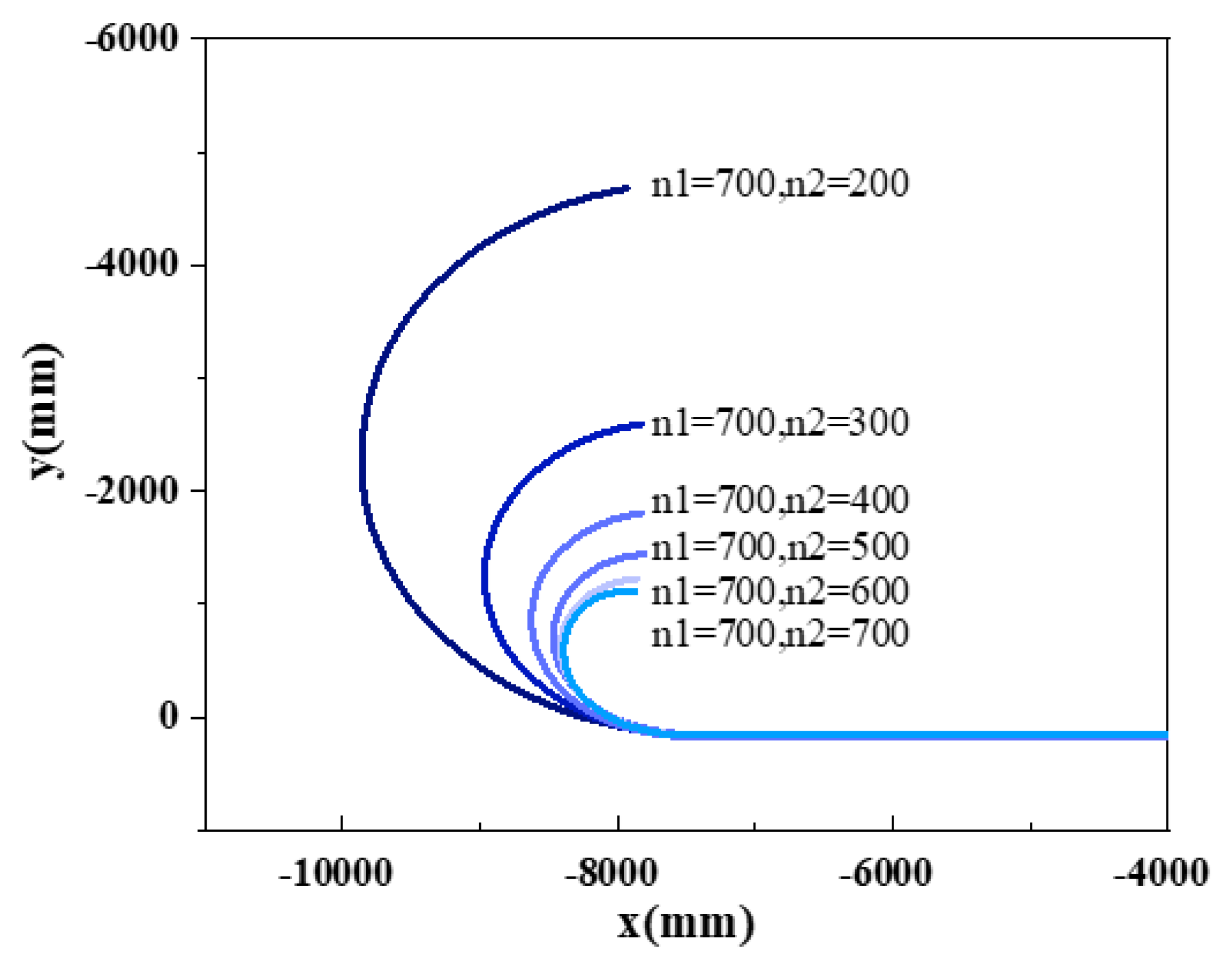

Under the land surface, setting the coefficient of static friction of the pavement to 0.8 and the coefficient of dynamic friction to 0.7. When the input speed of linear drive end was 700 rad/s, the input speed of steering drive end was respectively taken as 100, 200, 300, 400, 500, 600 and 700 rad/s, to observe the change of steering radius of the wheel-track composite vehicle under different working conditions, as shown in

Figure 10.

From the

Figure 10, the steering radius decreased with the increase of the speed of the steering drive end when the speed of the linear drive end was a constant value, and the wheel-track composite vehicle could achieve any continuous steering radius, which were consistent with the theoretical analysis and simulation results. Therefore, as long as the input speed of the two power sources were set reasonably, the vehicle could realize the steering of any continuous radius.

4.2. Fitting the steering radius of the wheel-track composite vehicle

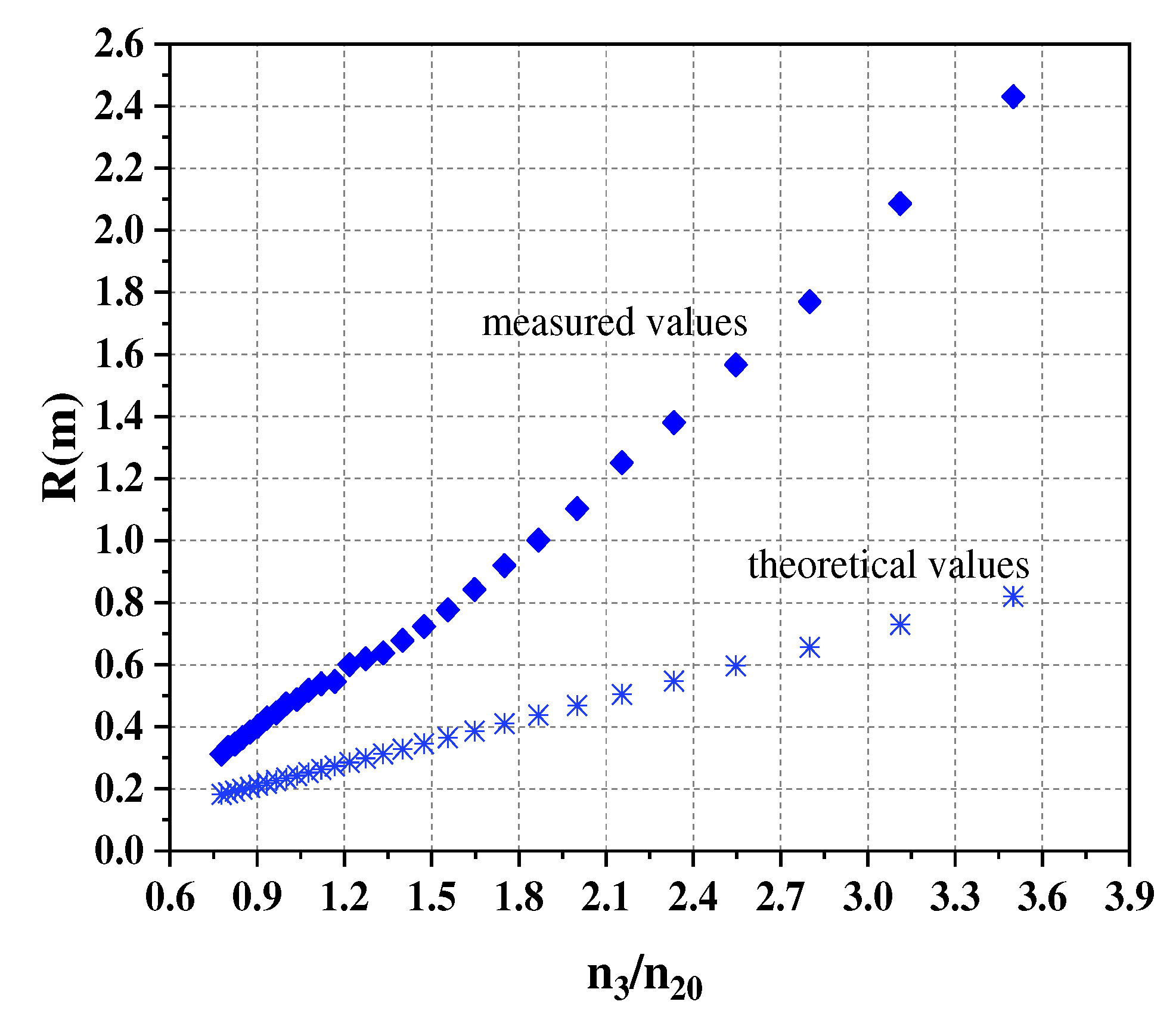

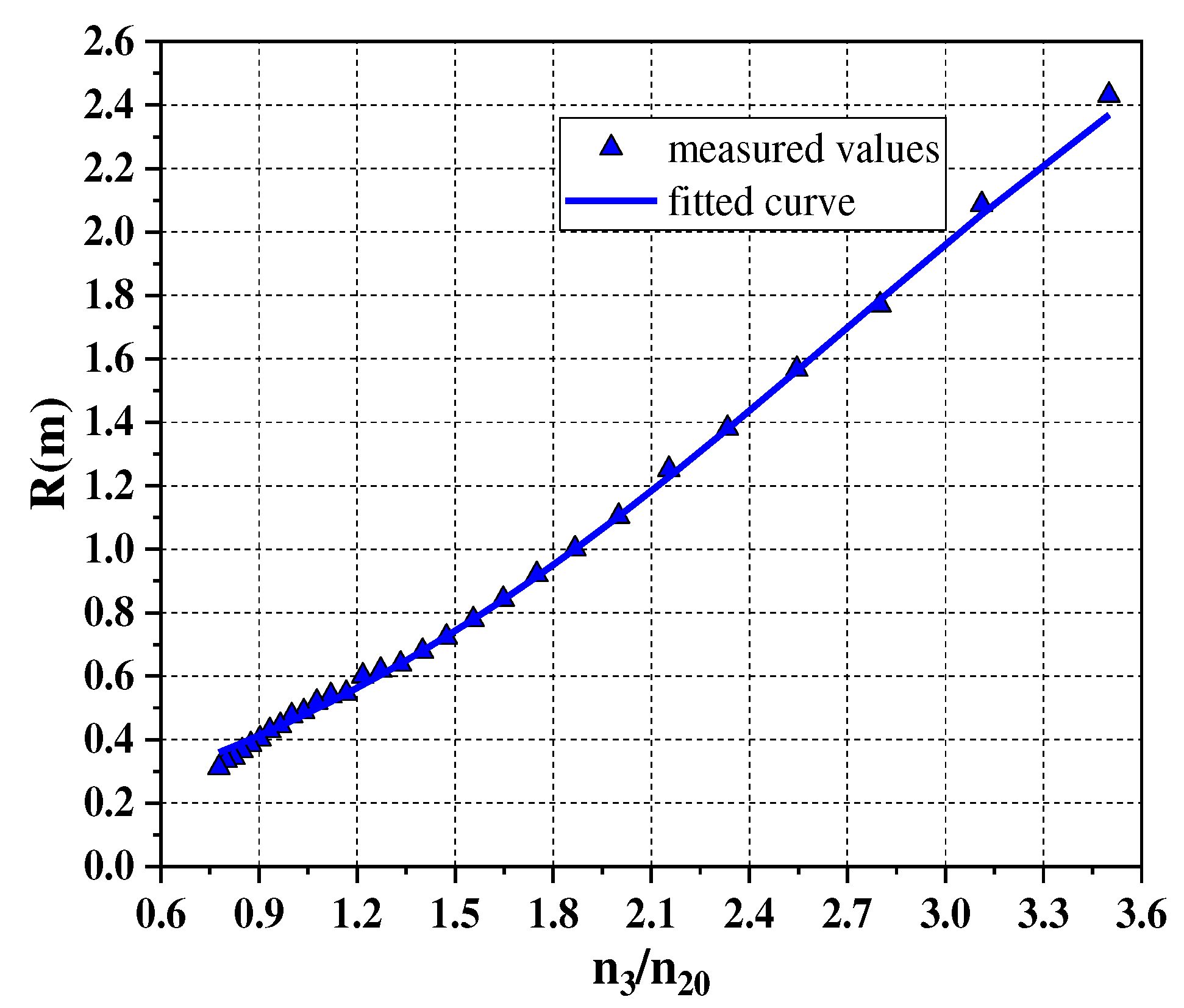

The speed of the two output shafts obtained from simulation were substituted into the formula of theoretical steering radius and the theoretical values were calculated. Comparing with the measured values of the same input speed ratio, it was found that the measured values were larger than the theoretical values, as shown in

Figure 11. The measured values exceeded the theoretical values due to limitations in road adhesion during the steering of the wheel-track composite vehicle, resulting in the occurrence of slip and yaw phenomena on the vehicle's faster side.

Indeed, it was necessary to apply suitable driving or braking forces to the wheels during the steering of the wheel-track composite vehicle at varying speeds. The outer wheels consistently functioned as the driving force, resulting in a continuous sliding state. Conversely, the inner wheels could serve as either driving or braking forces, leading to potential slippage and sliding. Taking into consideration the occurrence of slip and slide, the actual steering radius was determined by the following equation [

16].

Wherein, and represented the outer and inner wheel slip rates, respectively.

As slip was present, the steering radius of the wheel-track composite vehicle was consistently greater than the steering radius in the absence of slip. It implied that slip contributed to an increase in the steering radius of the wheel-track combination vehicle.

Due to the practical challenges in measuring the slip rate, the aforementioned formula posed difficulties in accurately calculating the actual turning radius. This paper conducted experimental measurements of several actual steering radii, which were then compared and analyzed in relation to their theoretical counterparts. Based on the theoretical formula, a fitting process was performed to derive a formula for calculating the actual steering radius under identical ground conditions [

16].

Formulas (18) and (19) could be expressed as the following function.

In the function,

- theoretical turning radius(m);

- ratio of linear input speed to steering input speed of the power differential steering mechanism, that is, ;

- constant coefficient, that is, ;

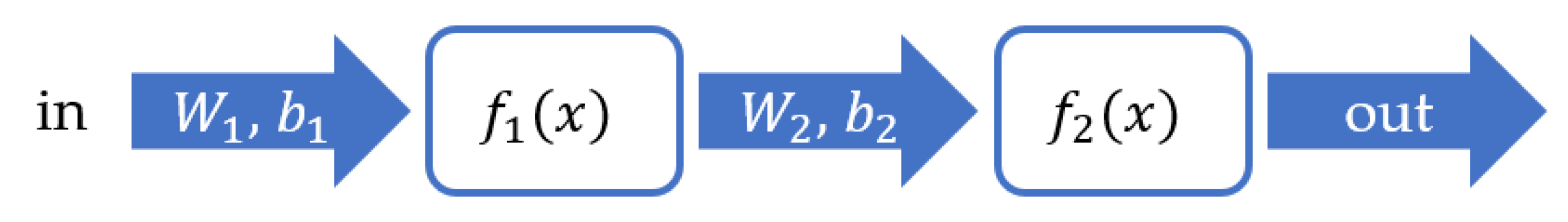

In this paper, a two-layer neural network consisting of one neuron in each layer was constructed. The function of the neuron in the first layer was a linear function, and the second layer was a sigmoid function, as shown in

Figure 12. A more ideal prediction was obtained after several training sessions, and the curve fitting was shown in

Figure 13. For the training of the first layer, the weight value was set as

, and the threshold was assigned as

. For the training of the second layer, the weight value was set as

, and the threshold was assigned as

.

The fitting function could be obtained as follows.

In the function,

- weights of linear functions, and ;

- thresholds of linear functions, and ;

- weights of the sigmoid function, and ;

- thresholds of the sigmoid function, and .

The actual steering radius fitting formula was as follows.

In the formula,

R - actual turning radius(m);

- ratio of linear input speed to steering input speed.

The aforementioned formula represented the mathematical expression for the steering radius of the wheel-track combination vehicle equipped with the differential steering mechanism that was designed in this paper for the land surface. The actual steering radius was based on the speed ratio between the linear drive end and the input speed of the steering drive end of the power differential steering mechanism as the independent variable.

This formula showed that the steering radius decreases as the steering drive end increases for a constant value of the linear drive end. The larger the speed ratio between the linear drive end and the steering drive end input speed, the larger the steering radius, which was consistent with the simulation results of differential steering for the wheel-track composite vehicle.

As shown in

Table 2, a total of 9 test datasets were selected and compared against the fitted formula for the actual steering radius. The results indicated that the relative error between the steering radius values obtained from the actual fitting formula and the corresponding test values was less than 3.53% when the speed ratio exceeded 0.8. The fitting formula had good accuracy and stability, and the difference between the formula calculation and the test result was within the acceptable range. This method could also be used to calculate the steering radius of the vehicle under other complex road conditions.