Submitted:

28 August 2023

Posted:

03 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Background

1.2. Problem statement

1.3. Aim of the study

2. Materials and Methods

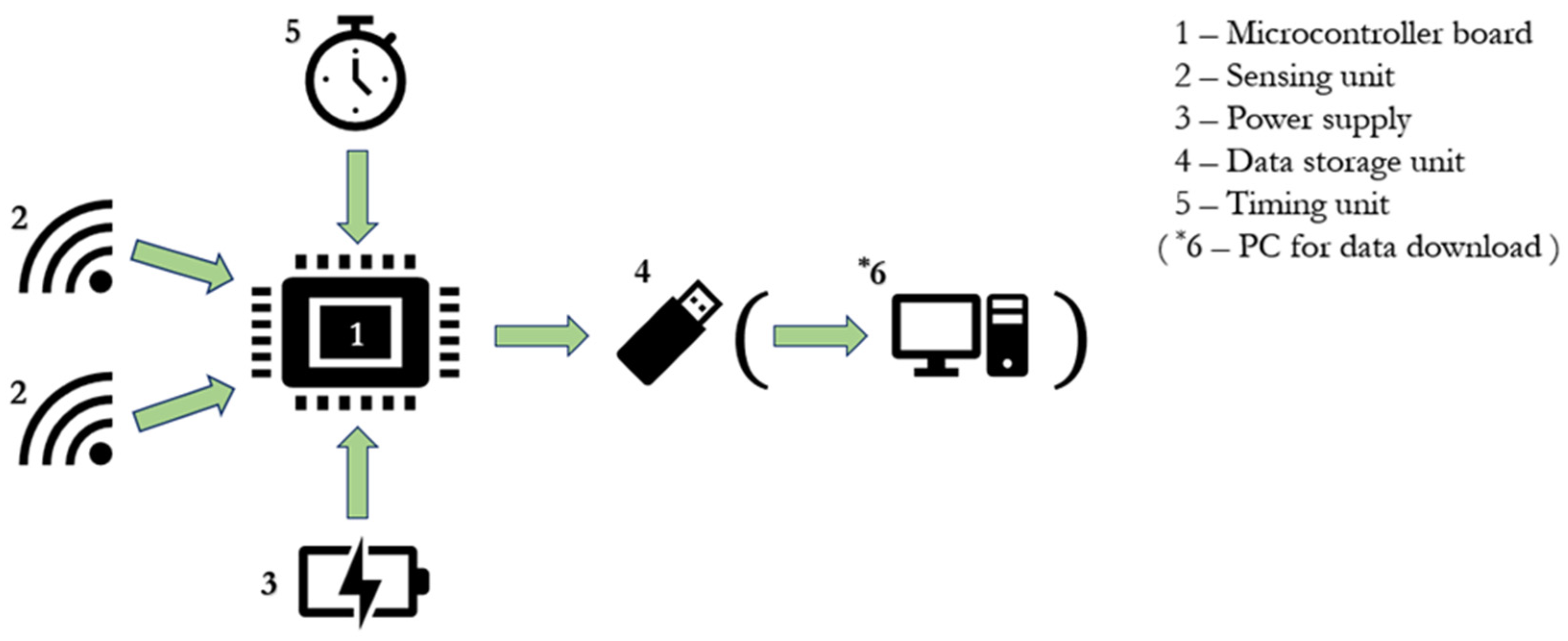

2.1. Design Specification and Concept

2.2. Hardware

2.2.1. Microcontroller

2.2.1.1. Arduino/Elegoo UNO-R3 Board

2.2.2. PMS5003 Sensor

2.2.3. DHT22 Sensor

2.2.4. Real Time Clock DS3231

2.2.5. Micro-SD card adapter

2.2.6. Micro-SD card

2.2.7. Mini PCB Prototype solderable Breadboard

2.2.8. USB type C to USB type B converter

2.2.9. 4 Inch USB C cable

2.2.10. Power Bank

2.2.11. Breadboard jumper wires

2.2.12. Storage lid/airtight container

2.2.13. Hardware acquisition

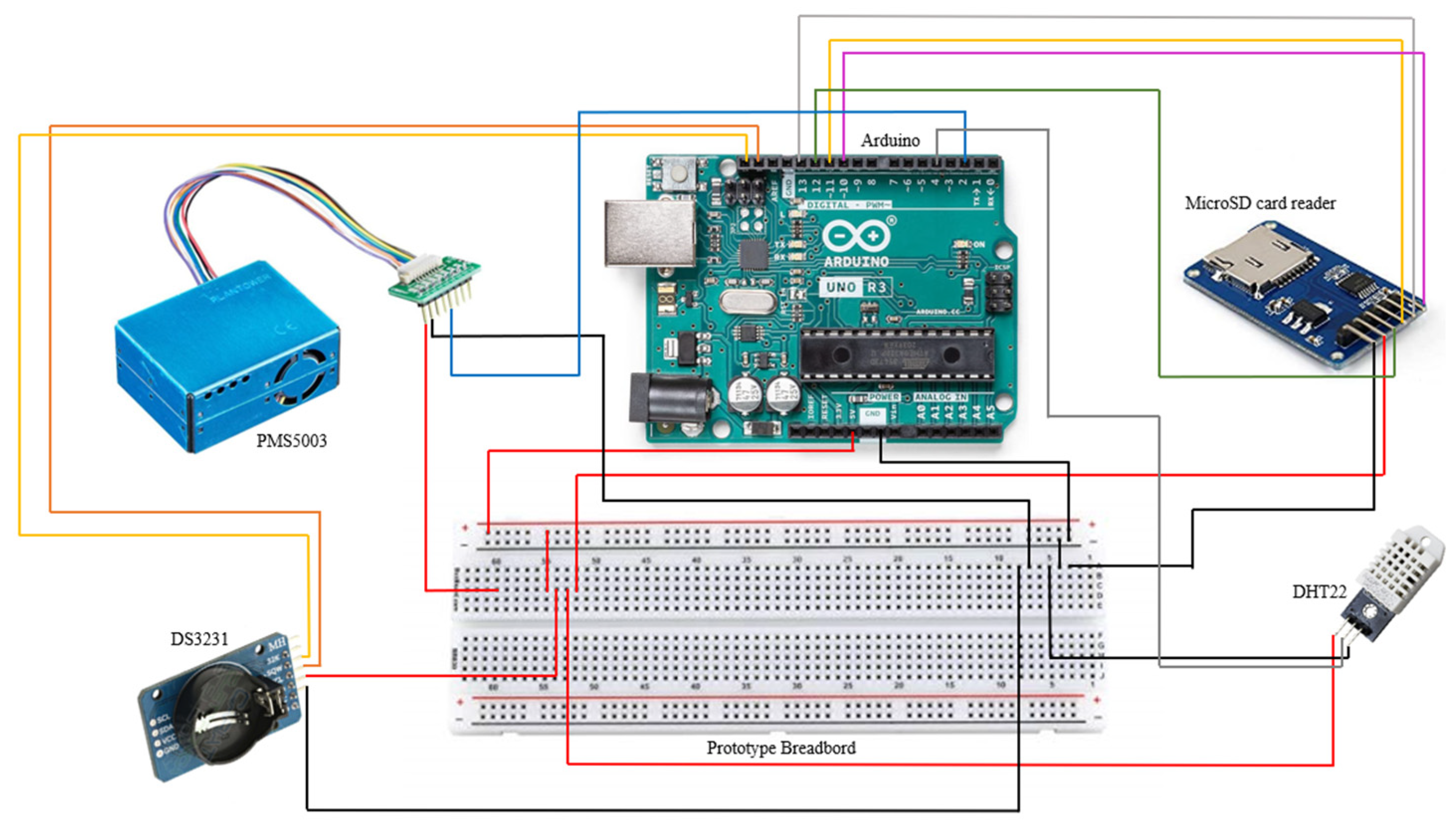

2.3. PIN Connections and Assembling

2.4. Software Design

2.4.1. Arduino IDE

2.4.2. R Code

2.5. Use of the P.ALP

- Once the hardware of the P.ALP is assembled, the operator needs to upload the Arduino sketch (available in the SM) on the microcontroller board, to program it to acquire and save data. This latter operation must be conducted by connecting the board to a computer using the proper cable (provided with the board) and using the Arduino IDE software. For more detail on this operation, you could visit the official tutorial link [46].

- Unplug the microcontroller board from the computer to shut down the P.ALP. At this stage, it is important to remove the micro-SD card from the micro-SD reader and format it.

- Once the formatted micro-SD card is inserted back into the P.ALP the device will be ready to be used.

- To start a monitoring session, turn on the P.ALP, by plugging in the power bank. The device will start measuring automatically. It is critical to take note of the monitoring start time (in 24-hour format—hh:mm:ss) and date (mm/dd/yyyy). This is because every time that the P.ALP is powered take as starting time the one at the last time “step 1” was performed.

- To stop the monitoring session, it is enough to unplug the power bank.

- Data are stored in the micro-SD. The R code (available in the SM) prepared for the use of P.ALP allows the operator to extract the collected data and organize results in two different databases, in which the data are ordered in chronological order with two different time resolutions (1 second and 1 minute). During this operation, it is fundamental to insert in the R-code the correct starting time and date, previously noted, of the monitoring session and to select the correct directory in which we want to work.

- Once the databases have been saved on a different storage device, the operator must format the micro-SD card and put it back in the P.ALP. In this way, the device will be ready for the next session which can be performed by repeating the passages starting from Step 4.

3. Further Considerations

3.1. Practical tips for assembling the prototype

3.2. Future Developments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Disclaimers

References

- Zimmerman, N. Tutorial: Guidelines for implementing low-cost sensor networks for aerosol monitoring. J. Aerosol Sci. 2022, 159, 105872. [Google Scholar] [CrossRef]

- Burnett, R.; Chen, H.; Szyszkowicz, M.; Fann, N.; Hubbell, B.; Pope, C.A.; Apte, J.S.; Brauer, M.; Cohen, A.; Weichenthal, S.; et al. Global estimates of mortality associated with longterm exposure to outdoor fine particulate matter. Proc. Natl. Acad. Sci. U. S. A. 2018, 115, 9592–9597. [Google Scholar] [CrossRef]

- Brauer, M.; Freedman, G.; Frostad, J.; Van Donkelaar, A.; Martin, R. V.; Dentener, F.; Dingenen, R. Van; Estep, K.; Amini, H.; Apte, J.S.; et al. Ambient Air Pollution Exposure Estimation for the Global Burden of Disease 2013. Environ. Sci. Technol. 2016, 50, 79–88. [Google Scholar] [CrossRef]

- Lelieveld, J.; Klingmüller, K.; Pozzer, A.; Pöschl, U.; Fnais, M.; Daiber, A.; Münzel, T. Cardiovascular disease burden from ambient air pollution in Europe reassessed using novel hazard ratio functions. Eur. Heart J. 2019, 40, 1590–1596. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.M.; Petersen, M.; Costello, S.; Noth, E.M.; Hammond, K.; Cullen, M.; Van Der Laan, M.; Eisen, E. Occupational exposure to PM2.5 and incidence of ischemic heart disease: Longitudinal targeted minimum loss-based estimation. Epidemiology 2015, 26, 806–814. [Google Scholar] [CrossRef] [PubMed]

- Pearce, T.; Coffey, C. Integrating direct-reading exposure assessment methods into industrial hygiene practice. J. Occup. Environ. Hyg. 2011, 8, D31–D36. [Google Scholar] [CrossRef]

- Cauda, E.; Hoover, M.D. Right Sensors Used Right: A Life-cycle Approach for Real-time Monitors and Direct Reading Methodologies and Data. A Call to Action for Customers, Creators, Curators, and Analysts. | | Blogs | CDC Available online:. Available online: https://blogs.cdc.gov/niosh-science-blog/2019/05/16/right-sensors-used-right/ (accessed on Apr 12, 2021).

- Howard, J.; Murashov, V.; Cauda, E.; Snawder, J. Advanced sensor technologies and the future of work. Am. J. Ind. Med. 2022, 65, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Taborri, J.; Pasinetti, S.; Cardinali, L.; Perroni, F.; Rossi, S. Preventing and monitoring work-related diseases in firefighters: A literature review on sensor-based systems and future perspectives in robotic devices. Int. J. Environ. Res. Public Health 2021, 18. [Google Scholar] [CrossRef]

- Cauda E, Snawder J, Spinazzè A, Cattaneo A, Howard J, C.D. The Challenge for Industrial Hygiene 4.0. A NIOSH Perspective on Direct-Reading Methodologies and Real-Time Monitoring in Occupational Environments. Synerg. 2022.

- Morawska, L.; Thai, P.K.; Liu, X.; Asumadu-Sakyi, A.; Ayoko, G.; Bartonova, A.; Bedini, A.; Chai, F.; Christensen, B.; Dunbabin, M.; et al. Applications of low-cost sensing technologies for air quality monitoring and exposure assessment: How far have they gone? Environ. Int. 2018, 116, 286–299. [Google Scholar] [CrossRef]

- Fanti, G.; Spinazzè, A.; Borghi, F.; Rovelli, S.; Campagnolo, D.; Keller, M.; Borghi, A.; Cattaneo, A.; Cauda, E.; Cavallo, D.M. Evolution and Applications of Recent Sensing Technology for Occupational Risk Assessment: A Rapid Review of the Literature. Sensors 2022, 22. [Google Scholar] [CrossRef]

- Fanti, G.; Borghi, F.; Spinazzè, A.; Rovelli, S.; Campagnolo, D.; Keller, M.; Cattaneo, A.; Cauda, E.; Cavallo, D.M. Features and Practicability of the Next-Generation Sensors and Monitors for Exposure Assessment to Airborne Pollutants: A Systematic Review. Sensors 2021, 21, 4513. [Google Scholar] [CrossRef] [PubMed]

- Howard, J. Algorithms and the future of work. Am. J. Ind. Med. 2022, 65, 943–952. [Google Scholar] [CrossRef]

- Koehler, K.A.; Peters, T.M. New Methods for Personal Exposure Monitoring for Airborne Particles. Curr. Environ. Heal. reports 2015, 2, 399–411. [Google Scholar] [CrossRef] [PubMed]

- Apte, J.S.; Messier, K.P.; Gani, S.; Brauer, M.; Kirchstetter, T.W.; Lunden, M.M.; Marshall, J.D.; Portier, C.J.; Vermeulen, R.C.H.; Hamburg, S.P. High-Resolution Air Pollution Mapping with Google Street View Cars: Exploiting Big Data. Environ. Sci. Technol. 2017, 51, 6999–7008. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Lipsky, E.M.; Saleh, R.; Robinson, A.L.; Presto, A.A. Characterizing the spatial variation of air pollutants and the contributions of high emitting vehicles in Pittsburgh, PA. Environ. Sci. Technol. 2014, 48, 14186–14194. [Google Scholar] [CrossRef]

- Zimmerman, N.; Li, H.Z.; Ellis, A.; Hauryliuk, A.; Robinson, E.S.; Gu, P.; Shah, R.U.; Ye, Q.; Snell, L.; Subramanian, R.; et al. Improving correlations between land use and air pollutant concentrations using wavelet analysis: Insights from a low-cost sensor network. Aerosol Air Qual. Res. 2020, 20, 314–328. [Google Scholar] [CrossRef]

- Jain, S.; Presto, A.A.; Zimmerman, N. Spatial Modeling of Daily PM2.5, NO2, and CO Concentrations Measured by a Low-Cost Sensor Network: Comparison of Linear, Machine Learning, and Hybrid Land Use Models. Environ. Sci. Technol. 2021, 55, 8631–8641. [Google Scholar] [CrossRef]

- Giordano, M.R.; Malings, C.; Pandis, S.N.; Presto, A.A.; McNeill, V.F.; Westervelt, D.M.; Beekmann, M.; Subramanian, R. From low-cost sensors to high-quality data: A summary of challenges and best practices for effectively calibrating low-cost particulate matter mass sensors. J. Aerosol Sci. 2021, 158, 105833. [Google Scholar] [CrossRef]

- Hagan, D.; Kroll, J. Assessing the accuracy of low-cost optical particle sensors using a physics-based approach. Atmos. Meas. Tech. Discuss. 2020, 1–36. [Google Scholar] [CrossRef]

- Spinazzè, A.; Fanti, G.; Borghi, F.; Del Buono, L.; Campagnolo, D.; Rovelli, S.; Cattaneo, A.; Cavallo, D.M. Field comparison of instruments for exposure assessment of airborne ultrafine particles and particulate matter. Atmos. Environ. 2017, 154, 274–284. [Google Scholar] [CrossRef]

- Borghi, F.; Spinazzè, A.; Campagnolo, D.; Rovelli, S.; Cattaneo, A.; Cavallo, D.M. Precision and accuracy of a direct-reading miniaturized monitor in PM2.5 exposure assessment. Sensors (Switzerland) 2018, 18, 1–21. [Google Scholar] [CrossRef]

- Fanti, G.; Borghi, F.; Spinazzè, A.; Rovelli, S.; Campagnolo, D.; Keller, M.; Cattaneo, A.; Cauda, E.; Cavallo, D.M.; Pleil, J.D.; et al. Laboratory evaluation of low-cost optical particle counters for environmental and occupational exposures. Sensors 2021, 21, 4513. [Google Scholar] [CrossRef]

- Arduino Arduino UNO R3 Datasheet. Available online: https://docs.arduino.cc/resources/datasheets/A000066-datasheet.pdf (accessed on 11 July 2023).

- Elegoo Elegoo Uno R3 Datasheet. Available online: https://www.elegoo.com/en-it/products/elegoo-uno-r3-board (accessed on 11 July 2023).

- Sayahi, T.; Butterfield, A.; Kelly, K.E. Long-term field evaluation of the Plantower PMS low-cost particulate matter sensors. Environ. Pollut. 2019, 245, 932–940. [Google Scholar] [CrossRef] [PubMed]

- Adafruit DHT22 Datasheet. Available online: https://cdn-shop.adafruit.com/datasheets/Digital+humidity+and+temperature+sensor+AM2302.pdf (accessed on 11 July 2023).

- Analog. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/DS3231.pdf (accessed on 11 July 2023).

- components101. Available online: https://components101.com/sites/default/files/component_datasheet/Micro-SD-Card-Module-Datasheet.pdf (accessed on 11 July 2023).

- Arduino Arduino Uno. Available online: https://www.amazon.com/Arduino-A000066-ARDUINO-UNO-R3/dp/B008GRTSV6/ref=sr_1_1_sspa?crid=999CU1B5V2W&keywords=arduino+uno+r3&qid=1676451837&sprefix=arduino+uno+r3%2Caps%2C162&sr=8-1-spons&psc=1&smid=AA57DDZKZUZDL&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUFUMkwxQU1KS (accessed on 7 July 2023).

- Elegoo ELEGOO UNO R3. Available online: https://www.amazon.com/ELEGOO-Board-ATmega328P-ATMEGA16U2-Compliant/dp/B01EWOE0UU/ref=sr_1_2_sspa?crid=999CU1B5V2W&keywords=arduino+uno+r3&qid=1676451856&sprefix=arduino+uno+r3%2Caps%2C162&sr=8-2-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyS0pFMlNBWjJUOT (accessed on 7 July 2023).

- Plantower PMS5003. Available online: https://www.amazon.com/whiteeeen-PMS5003-Quality-Sensor-Breakout/dp/B09BQZP2CY/ref=sr_1_4?keywords=pms5003+sensor&qid=1676451890&sprefix=pms5003%2Caps%2C158&sr=8-4 (accessed on 7 July 2023).

- Aosong DHT22. Available online: https://www.amazon.com/Tangyy-Digital-Temperature-Humidity-Raspberry/dp/B08QHW9TS8/ref=sr_1_14?crid=398VDVFLD7R1J&keywords=dht22+sensor&qid=1676452000&sprefix=dht22+sensor%2Caps%2C172&sr=8-14 (accessed on 7 July 2023).

- Dorhea RTC DS3231. Available online: https://www.amazon.com/AT24C32-Replace-Arduino-Batteries-Included/dp/B07Q7NZTQS/ref=sr_1_3?keywords=rtc+module+ds3231&qid=1676452099&sprefix=RTC%2Caps%2C178&sr=8-3 (accessed on 7 July 2023).

- Amazon MicroSD Card Adapter. Available online: https://www.amazon.com/Module-Storage-Adapter-Interface-Arduino/dp/B07PFDFPPC/ref=sr_1_1_sspa?crid=3J64W5XEBJW79&keywords=micro+sd+card+adapter+arduino&qid=1676452177&sprefix=micro+sd+card+adapter+arduino%2Caps%2C161&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUX (accessed on 7 July 2023).

- Transcend MicroSD Card. Available online: https://www.amazon.com/Transcend-TS1GUSD-Micro-Secure-Digital-Card/dp/B000FVGM3I/ref=sr_1_18?keywords=microsd+card+1gb&qid=1676452219&sprefix=microsd+card+1%2Caps%2C172&sr=8-18 (accessed on 7 July 2023).

- Qunqi Prototype Board. Available online: https://www.amazon.com/Qunqi-point-Experiment-Breadboard-5-5×8-2×0-85cm/dp/B0135IQ0ZC/ref=sr_1_6?keywords=breadboard&qid=1676452355&sprefix=bread%2Caps%2C158&sr=8-6 (accessed on 7 July 2023).

- ElectroCookie Solderable BreadBoard. Available online: https://www.amazon.com/ElectroCookie-Solderable-Breadboard-Electronics-Gold-Plated/dp/B081MSKJJX/ref=sr_1_13?crid=1UJYWBPN3 × 0HS&keywords=solderable+breadboard+pcb&qid=1676452498&sprefix=solderable+breadboard+%2Caps%2C293&sr=8-13 (accessed on 7 July 2023).

- Qianrengyang USB type C to B converter. Available online: https://www.amazon.com/QIANRENON-Adapter-Printer-Electric-Synthesizer/dp/B09L64XZFW/ref=sr_1_32_sspa?crid=B9VXZADWILR5&keywords=usb+C+to+USB+B&qid=1676452653&sprefix=usb+c+to+usb+b%2Caps%2C194&sr=8-32-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzVzEyV1E0R (accessed on 7 July 2023).

- CableCreation USB type C to A cable. Available online: https://www.amazon.com/CableCreation-Braided-Compatible-MacBook-Resistance/dp/B01CZVEUIE/ref=sr_1_13?keywords=1inch+usb+c+cable&qid=1676452736&sprefix=usb+C+to+USB+A+1i%2Caps%2C185&sr=8-13 (accessed on 7 July 2023).

- Charmast PowerBank. Available online: https://www.amazon.com/dp/B07JYYRT7T?ref=nb_sb_ss_w_as-reorder-t1_ypp_rep_k0_1_19&=&crid=2DX1XOP04RH2X&sprefix=power%2Bbank%2B10400mah&th=1 (accessed on 7 July 2023).

- Elegoo Jumper Wires. Available online: https://www.amazon.com/Elegoo-EL-CP-004-Multicolored-Breadboard-arduino/dp/B01EV70C78/ref=sr_1_1_sspa?keywords=elegoo+jumper+wires&qid=1676452915&sprefix=elegoo+jum%2Caps%2C168&sr=8-1-spons&psc=1&smid=A2WWHQ25ENKVJ1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUFJWFJFTU (accessed on 7 July 2023).

- LocknLock Airtight Box. Available online: https://www.amazon.com/dp/B0000AN4CP?ref=nb_sb_ss_w_as-reorder-t1_ypp_rep_k1_1_9&=&crid=2KEARWEAWN9ZM&=&sprefix=airtight+ (accessed on 7 July 2023).

- Arduino Arduino IDE. Available online: https://docs.arduino.cc/software/ide-v1/tutorials/arduino-ide-v1-basics (accessed on 7 July 2023).

- Arduino Arduino IDE Instructions. Available online: https://support.arduino.cc/hc/en-us/articles/4733418441116-Upload-a-sketch-in-Arduino-IDE (accessed on 7 July 2023).

- Karagulian, F.; Barbiere, M.; Kotsev, A.; Spinelle, L.; Gerboles, M.; Lagler, F.; Redon, N.; Crunaire, S.; Borowiak, A. Review of the Performance of Low-Cost Sensors for Air Quality Monitoring. Atmosphere (Basel). 2019, 10, 506. [Google Scholar] [CrossRef]

- Boniardi, L.; Borghi, F.; Straccini, S.; Fanti, G.; Campagnolo, D.; Campo, L.; Olgiati, L.; Lioi, S.; Cattaneo, A.; Spinazzè, A.; et al. Commuting by car, public transport, and bike: Exposure assessment and estimation of the inhaled dose of multiple airborne pollutants. Atmos. Environ. 2021, 262. [Google Scholar] [CrossRef]

- Borghi, F.; Fanti, G.; Cattaneo, A.; Campagnolo, D.; Rovelli, S.; Keller, M.; Spinazzè, A.; Cavallo, D.M. Estimation of the inhaled dose of airborne pollutants during commuting: Case study and application for the general population. Int. J. Environ. Res. Public Health 2020, 17, 1–14. [Google Scholar] [CrossRef]

- Ruiter, S.; Bard, D.; Ben Jeddi, H.; Saunders, J.; Snawder, J.; Warren, N.; Gorce, J.-P.; Cauda, E.; Kuijpers, E.; Pronk, A. Exposure Monitoring Strategies for Applying Low-Cost PM Sensors to Assess Flour Dust in Industrial Bakeries. Ann. Work Expo. Heal. 2023, 1–13. [Google Scholar] [CrossRef]

- Ruiter, S.; Kuijpers, E.; Saunders, J.; Snawder, J.; Warren, N.; Gorce, J.-P.; Blom, M.; Krone, T.; Bard, D.; Pronk, A.; et al. Exploring Evaluation Variables for Low-Cost Particulate Matter Monitors to Assess Occupational Exposure. Int. J. Environ. Res. Public Health 2020, 17, 8602. [Google Scholar] [CrossRef]

- Clements, A.; Duvall, R.; Greene, D.; Dye, T. The Enhanced Air Sensor Guidebook; Washington, DC, 2022.

- Fanti, G.; Cody, W.; Borghi, F.; Campagnolo, D.; Justin, P.; Cattaneo, A.; Spinazzè, A.; Cavallo, D.M.; Cauda, E. In-Lab Testing of a Self-Made Multiparameter Prototype based on Low-Cost Dust sensors using a Marple Camber; 39th Italian Congress of occupational and environmental hygiene: Arenzano—GE; ISBN 978-88-86293-44-0.

| Unit Number | Unit Name | Components (Model, Manufacturer) |

Cost ($) * |

|---|---|---|---|

| 1 | Microcontroller board unit # | Elegoo UNO-R3 Board | 16.99 |

| 2 | Sensing unit | PMS5003 | 35.99 |

| DHT22 | 8.99 | ||

| 3 | Power supply unit | Power-Bank | 10.99 |

| 4 | Data storage unit | Micro-SD card adapter; | 12.99 |

| Micro-SD card | 14.79 | ||

| 5 | Timing unit | DS3231 | 8.99 |

| Generic hardware | |||

| Prototype board | 5.99 | ||

| (Solderable board) | 9.99 | ||

| USB type C to B converter | 8.99 | ||

| USB type C to A cable | 7.99 | ||

| Jumper wires | 6.98 | ||

| Airtight container | 11.50 | ||

| Total Cost | |||

| The minimum cost of one prototype | 151.81 | ||

| Arduino Uno R3 Components | Specification |

|---|---|

| Microcontroller | ATmega328P |

| Operating Voltage | 5V |

| Input Voltage recommended | 7-12V |

| Input Voltage limit | 6-20V |

| Digital I/O PINs | 14 (6 of those provide also PWM output) |

| Analog Input PINs | 6 |

| DC Current for I/O PINs | 20 mA |

| DC Current for 3.3V PINs | 50 mA |

| Flash Memory (Microcontroller) | 32 KB |

| SRAM (Microcontroller) | 2 KB |

| EEPROM (Microcontroller) | 1 KB |

| Clock Speed | 16 MHz |

| Built-in LEDs | 13 |

| Parameter | Index | Unit |

|---|---|---|

| Range of measurement | 0.3-1.0; 1.0-2.5; 2.5-10 | µm |

| Effective Range (PM2.5) | 0-500 | µg/m3 |

| Maximum Range (PM2.5) | 1000 | µg/m3 |

| Resolution | 1 | µg/m3 |

| Standard Volume | 0.1 | L |

| Single Response Time | <1 | s |

| DC Power Supply | 5.0 (from 4.5 to 5.5) | V |

| Active Current | ≤100 | mA |

| Standby Current | ≤200 | µA |

| Working Temperature | From -10 to +60 | °C |

| Working Humidity | From 0 to 99 | % |

| Dimensions | 50 × 38 × 21 | mm |

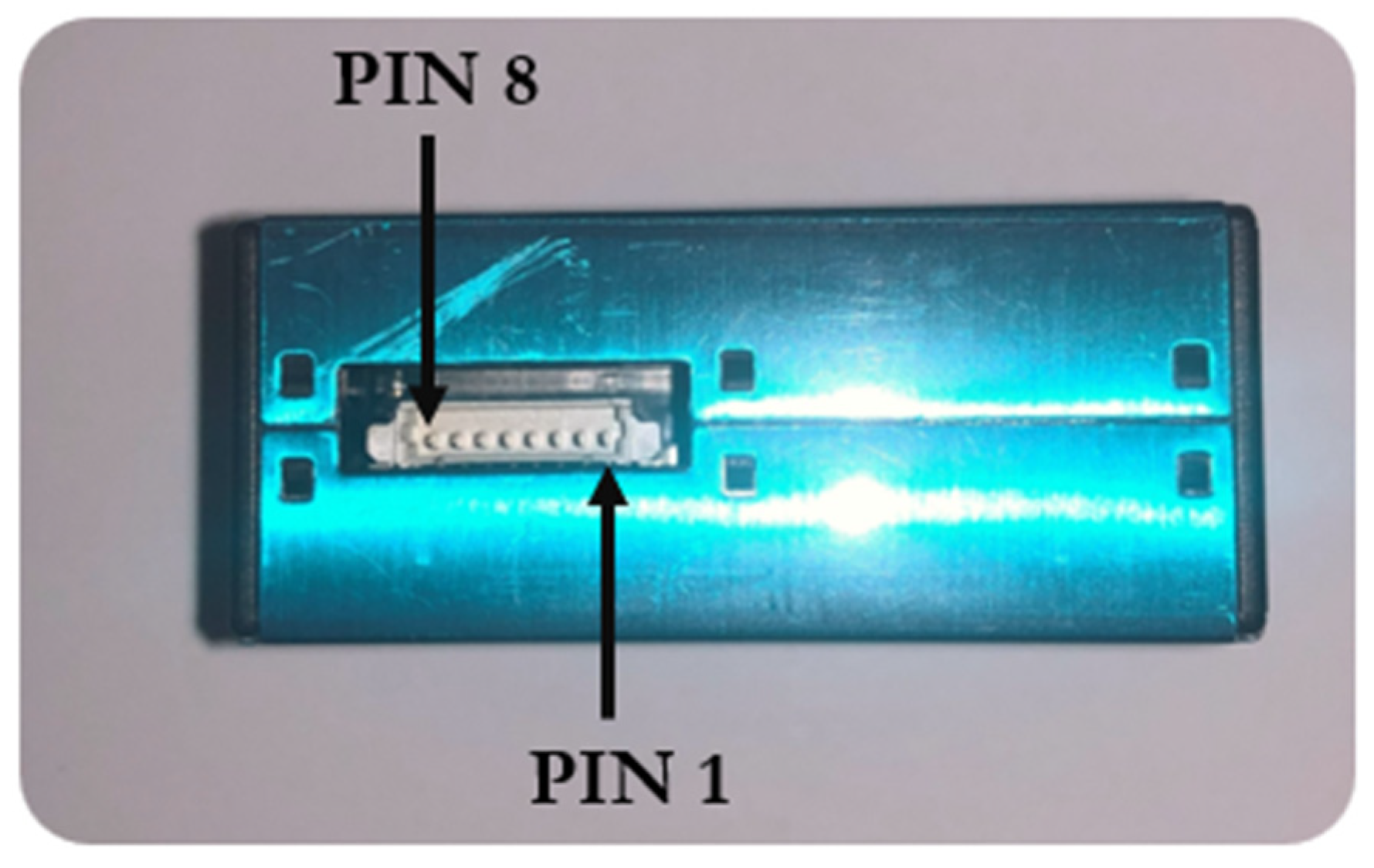

| PIN * | Code | Specification |

|---|---|---|

| 1 | VCC | Positive power 5V |

| 2 | GND | Negative power |

| 3 | SET | Set PIN/TTL level at 3.3V |

| 4 | RX | Serial port receiving PIN TTL level at 3.3V |

| 5 | TX | Serial port sending PIN TTL level at 3.3V |

| 6 | RESET | Module reset signal/TTL level at 3.3V |

| 7 | NC | n.d. |

| 8 | NC | n.d. |

| Parameter | Specification |

|---|---|

| Power supply | 3.3-6V DC |

| Output signal | Digital via a single bus |

| Sensing element | Polymer capacitor |

| Operating range humidity | From 0 to 100 RH% |

| Operating range temperature | From -40 to 80 °C |

| Accuracy humidity | ±2%RH |

| Accuracy temperature | ±0.5 °C |

| Resolution humidity | 0.1%RH |

| Resolution temperature | 0.1 °C |

| Sensing period | 2s |

| Dimensions | 22 x 28 x 5mm |

| PIN * | Description |

|---|---|

| 1 | VCC (+5V) |

| 2 | Signal |

| 3 | GND |

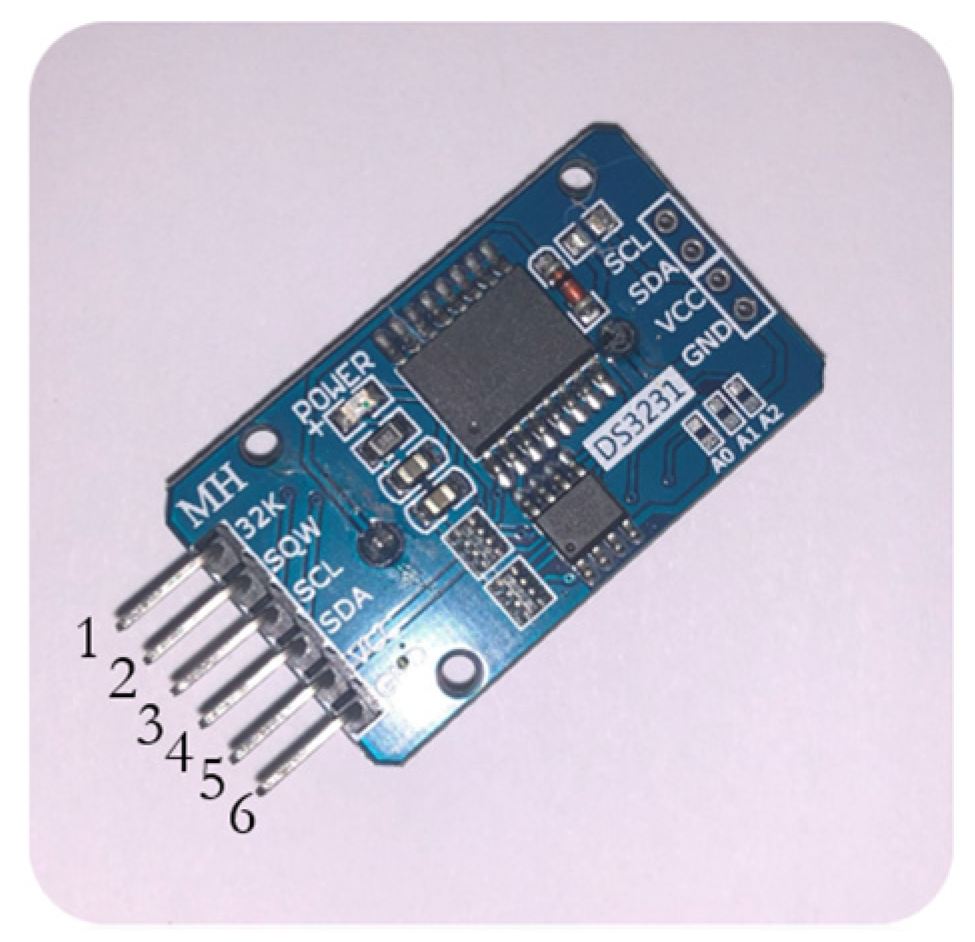

| Parameter | Specification |

|---|---|

| Power Supply | 2.3-5.5V DC |

| Pullup voltage | 5.5V |

| Max voltage at SDA | 0.3V |

| Max voltage at SCL | 0.3V |

| Max voltage at VCC | 0.3V |

| Operating temperature | From -45 to 80 °C |

| Current consumption | <300 µA |

| Accuracy (0-40 °C) | ±2 ppm |

| Battery | CR2032 (3V coin) |

| Communication interface | I2C |

| PIN * | Description |

|---|---|

| 1 | 32K—oscillator output |

| 2 | SQW—interrupt signal or square-wave output |

| 3 | SCL—serial clock PIN for I2C interface |

| 4 | SDA—serial data PIN for I2C interface |

| 5 | VCC—power supply |

| 6 | GND—ground |

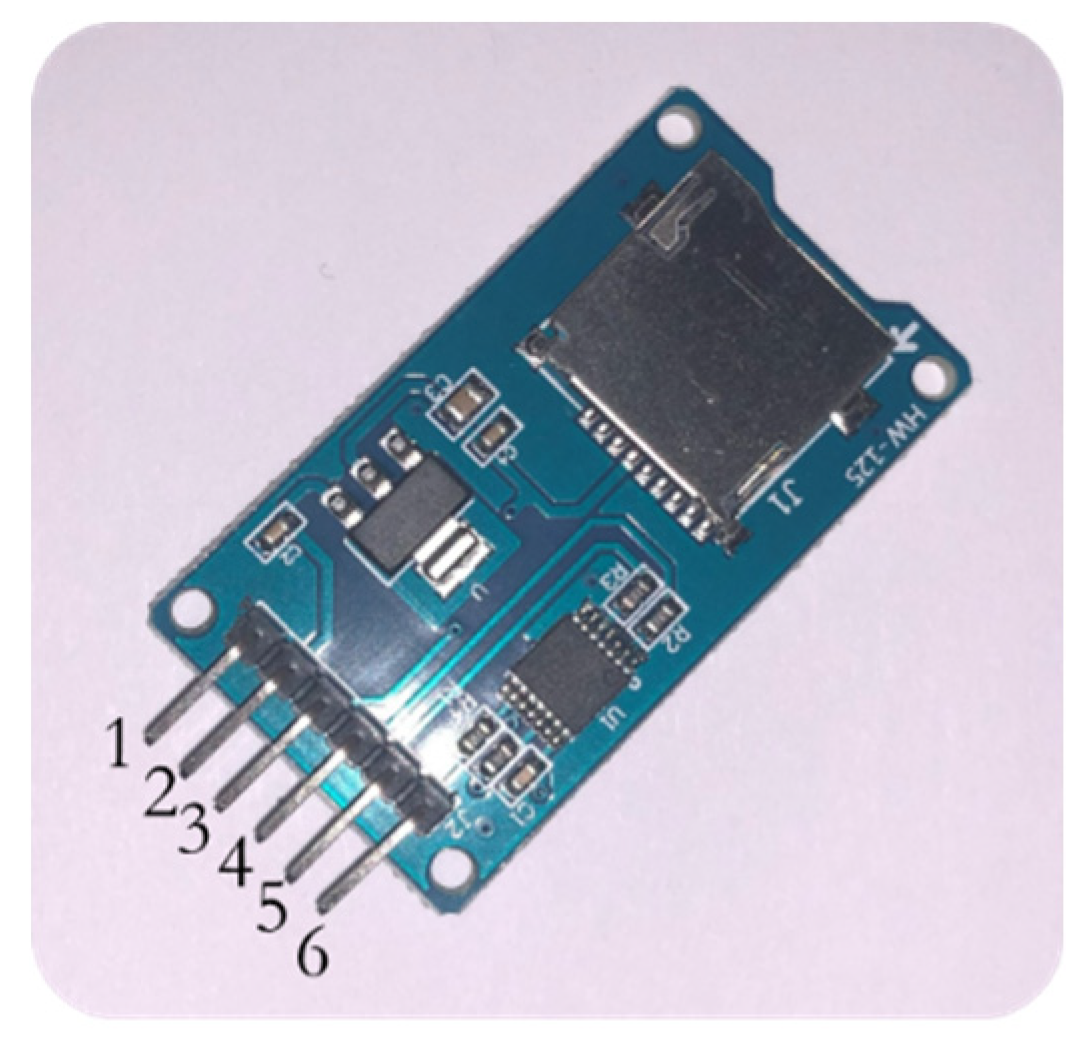

| Parameter | Specification |

|---|---|

| Power Supply | 4.5-5.5V DC |

| Current requirement | 0.2–200 mA |

| File system supported | FAT |

| Card supported | Micro-SD and micro-SDHC |

| Communication interface | SPI |

| PIN * | Description |

|---|---|

| 1 | GND—ground |

| 2 | VCC—power supply |

| 3 | MISO—master input slave output |

| 4 | MOSI—master output slave input |

| 5 | SCK—serial clock |

| 6 | CS—chip select |

| Hardware Components | Where to buy it |

|---|---|

| Arduino UNO-R3 Board | [31] |

| Elegoo UNO-R3 Board | [32] |

| Plantower PMS5003 Sensor | [33] |

| DHT22 Sensor | [34] |

| RTC DS3231 | [35] |

| Micro-SD card adapter | [36] |

| Micro-SD card | [37] |

| Prototype breadboard | [38] |

| Solderable board | [39] |

| USB type C to B converter | [40] |

| USB type C to A cable | [41] |

| Power bank | [42] |

| Elegoo jumper wires | [43] |

| Airtight container | [44] |

| Sensors/Components | PIN linkage |

|---|---|

| Plantower PMS5003 | TX à Digital PIN2 Microcontroller GND à Breadboard – VCC à Breadboard + |

| DHT22 Sensor | GND à Breadboard – DHT22 Out (signal) à Digital PIN4 Microcontroller VCC à Breadboard + |

| RTC DS3231 | GND à Breadboard – VCC à Breadboard + SDA à SDA Microcontroller SCL à SCL Microcontroller |

| Micro-SD card adapter | GND à Breadboard – VCC à Breadboard + MISO à Digital PIN12 Microcontroller MOSI à Digital PIN11 Microcontroller SCK à Digital PIN13 Microcontroller CS à Digital PIN10 Microcontroller |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).