Submitted:

31 August 2023

Posted:

04 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

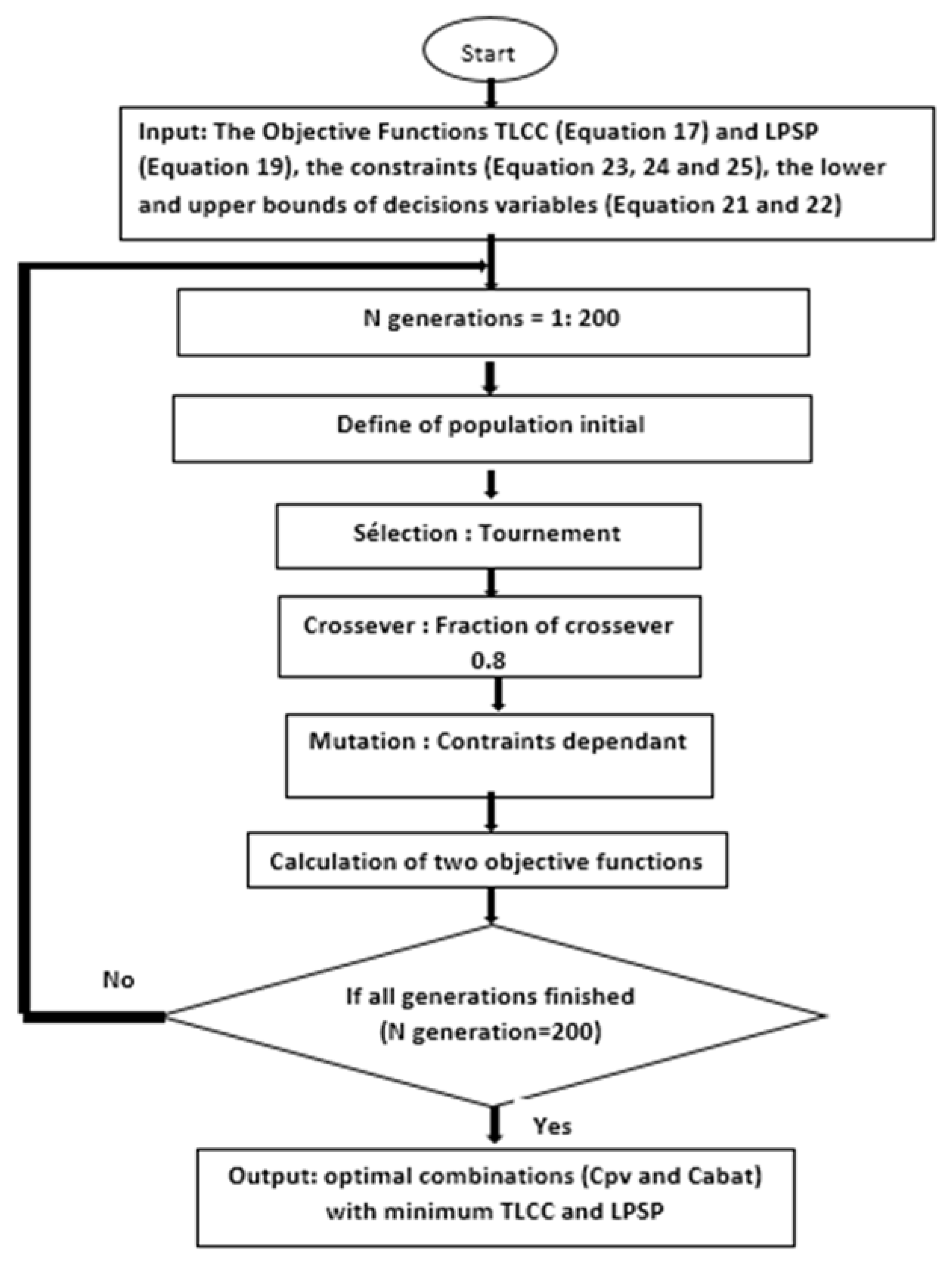

2. The Genetic Algorithm (AG)

- population size: the number recommended for less than five population variables decision is 200, but research has shown that a variation in size from 100 to 3000 has no significant change on the results [13];

- selection and crossing: in most case, the roulette function are considered for the selection with the crossover fraction equal to 0.8[10];

- mutation: GAs use a random mutation procedure to explore new solutions; research has shown that this procedure alters a small percentage of the population except the best individuals; thus a mutation rate between 1% and 20% is often used; for a higher mutation rate too many vouchers parameters can be mutated, then the algorithm stops[8].

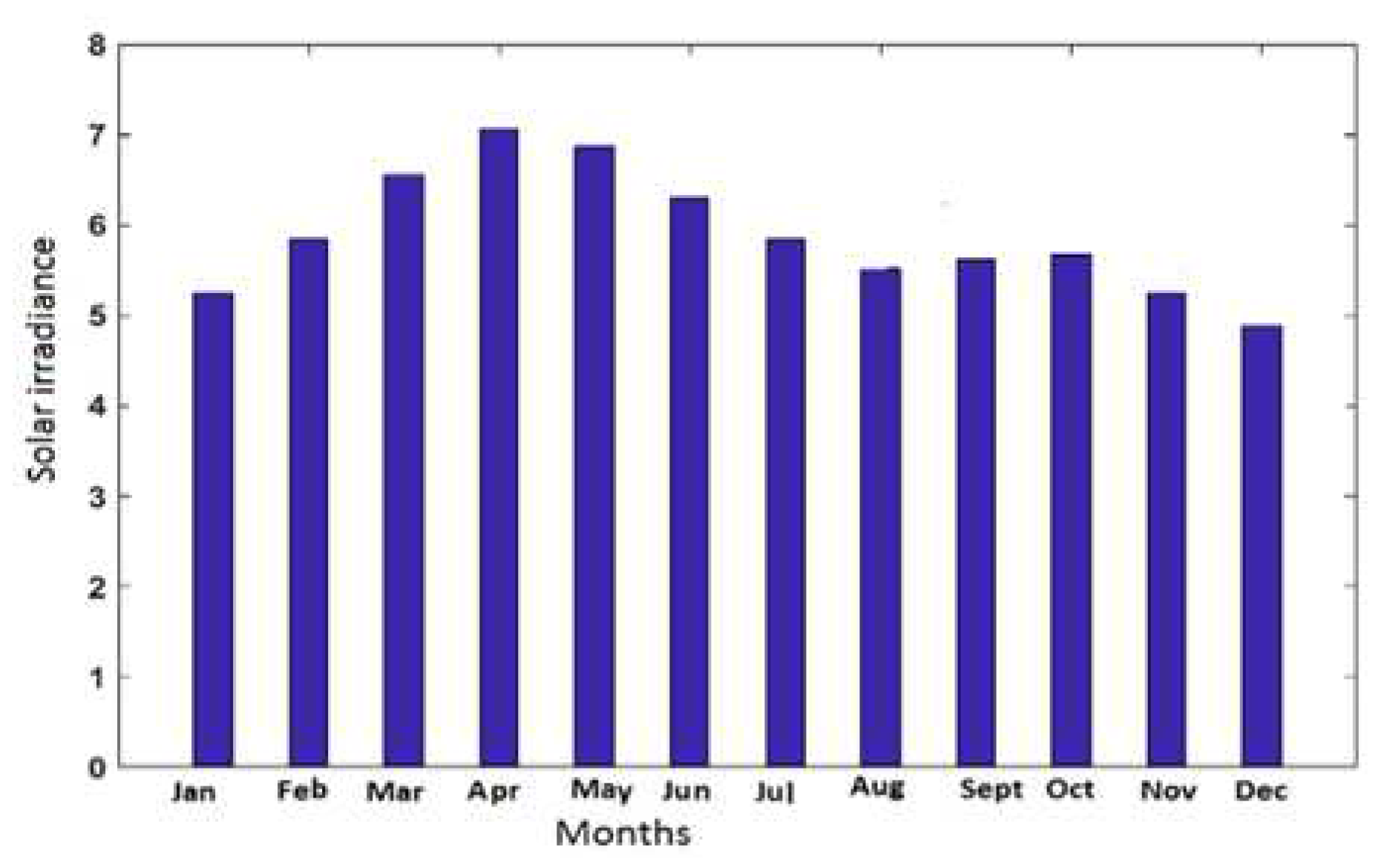

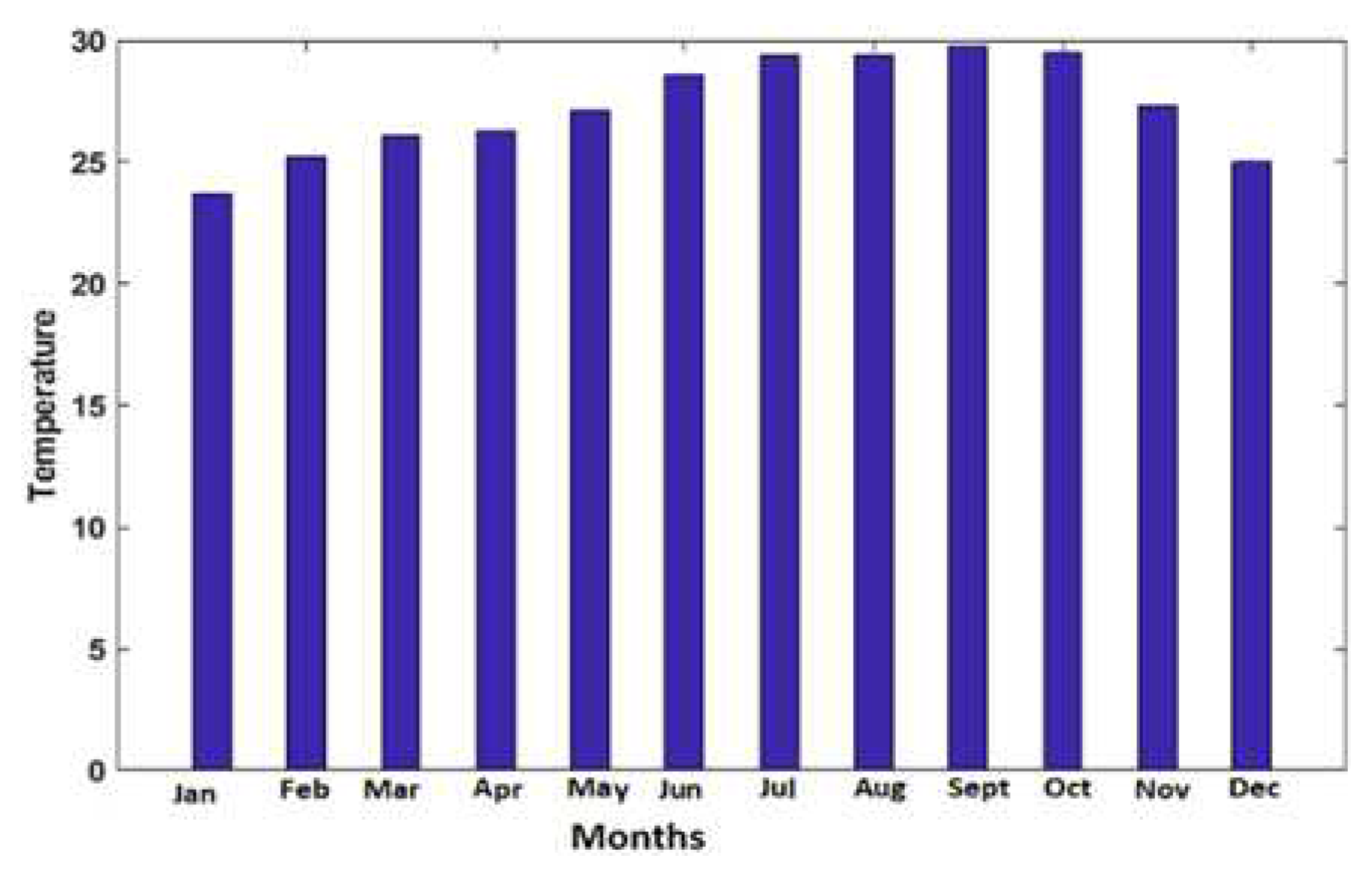

3. Input parameters description Results

4. Sizing method proposed

4.1. Formulation of the optimization problem

4.2. Delimitation of the research space with the intuitive method

4.3. Definition of the constraints

- the average energy produced by the PV array must be able to supply the load of the building-block while recharging the storage system. This is governed by Equation (23):

- the loss of power supply probability varies from 0 to 1.This is expressed by the following inequalities 24 and 25:

| Specifications | Values |

| Population size | 200 |

| Initial Population | Random |

| Selection | Tournement |

| Crossever | Fraction of crossever 0.8 |

| Mutation | Contraints dependant |

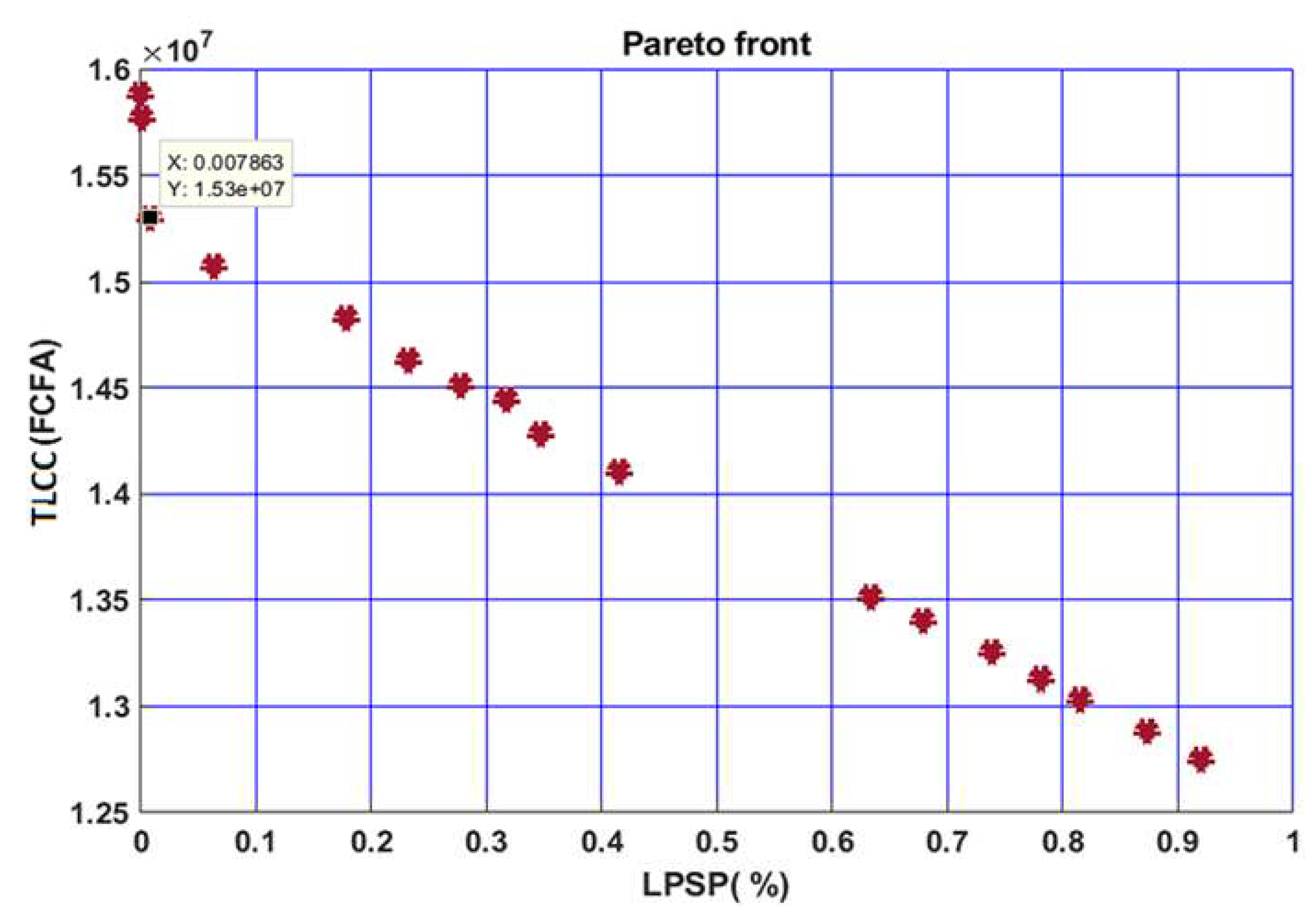

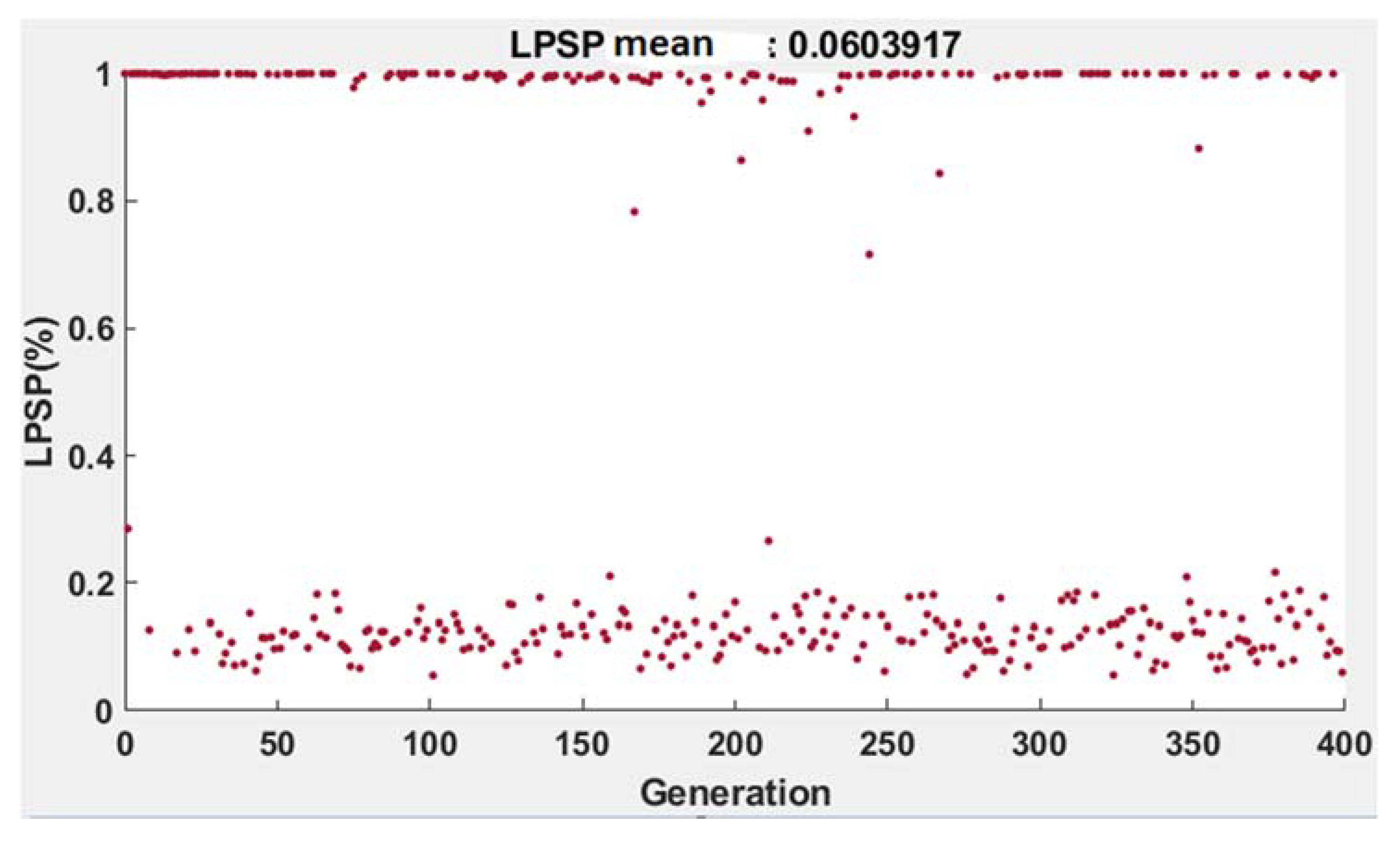

5. Results and discussion

6. Conclusions

Funding

Conflicts of Interest

References

- Jakhrani AQ, Othman AK, Rigit ARH, Samo SR, Kamboh SA. A novel analytical model for optimal sizing of standalone photovoltaic systems. Energy. 2012, 46, 675–682. [Google Scholar] [CrossRef]

- Luque RL, Reca J, Martinez J. Optimal design of a standalone direct pumping photovoltaic system for deficit irrigation of olive orchards. Applied Energie. 2015, 149, 13–23. [Google Scholar] [CrossRef]

- Said A, Busaidi A, Kazem HA, Al-badi AH. A review of optimum sizing of hybrid PV–Wind renewable energy systems in Oman. Renewable and Sustainable Energy Reviews 2016, 53, 185–193. [Google Scholar] [CrossRef]

- Mellit, A. Sizing of photovoltaic systems: a review. Renewable Energy Review. 2007, 10, 463–472. [Google Scholar]

- Khatib T, Ibrahim IA, Mohamed A. A review on sizing methodologies of photovoltaic array and storage battery in a standalone photovoltaic system. Energy Convers Manag. 2016, 120, 430–448. [Google Scholar] [CrossRef]

- Abbes D, Martinez A, Champenois G. Life cycle cost, embodied energy and loss of power supply probability for the optimal design of hybrid power systems. Math. Comput. Simul. 4014, 98, 46–62. [Google Scholar]

- Abdelkader A, Rabeh A, Mohamed Ali D, Mohamed J. Multi-objective genetic algorithm based sizing optimization of a stand-alone wind/PV power supply system with enhanced battery/supercapacitor hybrid energy storage. Energy. 2018, 163, 351–363. [Google Scholar] [CrossRef]

- Zagrouba M, Sellami A, Bouaïcha M, Ksouri M. Identification of PV solar cells and modules parameters using the genetic algorithms: Application to maximum power extraction.Sol. Energy. 2010, 84, 860–866.

- 9. Sadio A, Mbodji S, Fall I, Sow PLT. A comparative study based on the Genetic Algorithm (GA) method for the optimal sizing of the standalone photovoltaic system in the Ngoundiane site. EAI Indorsed Transactions on Energy Web and Information Technology. 2022.

- Ismail MS, Moghavvemi M, Mahlia TMI, Genetic algorithm based optimization on modeling and design of hybrid renewable energy systems. Energy Convers Manag. 2014, 85, 120–130. [CrossRef]

- Muhsen DH, Ghazali AB, Khatib T, Abed IA, Natsheh EM. Sizing of a standalone photovoltaic water pumping system using a multi-objective evolutionary algorithm. Energy. 2016, 109, 961–973. [Google Scholar] [CrossRef]

- Javed MS, Song A, Ma T. Techno-economic assessment of a stand-alone hybrid solar-wind-battery system for a remote island using genetic algorithm. Energy. 2019, 176, 704–717. [Google Scholar] [CrossRef]

- Starke AR, Cardemil JM, Escobar R, Colle S. Multi-objective optimization of hybrid CSP+PV system using genetic algorithm. Energy. 2018, 147, 490–503. [Google Scholar] [CrossRef]

- Ayop R, Isa NM, Tan CW. Components sizing of photovoltaic stand-alone system based on loss of power supply probability. Renewable and Sustainable Energy Reviews. 2018, 81, 2731–2743. [Google Scholar] [CrossRef]

- Nogueira CEC, Vidotto ML, Niedzialkoski RK. Sizing and simulation of a photovoltaic-wind energy system using batteries, applied for a small rural property located in the south of Brazil. Renewable and Sustainable Energy Reviews. 2014, 29, 151–157. [Google Scholar] [CrossRef]

- Kazem, H.A.; Khatib, T. Sopian, K. Sizing of a standalone photovoltaic/battery system at minimum cost for remote housing electrification in Sohar, Oman. Energy Build. 2013, 61, 108–115. [Google Scholar] [CrossRef]

| Blocs | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EL(Wh) | 244734 | 118687 | 51846 | 31010 | 67205 | 47680 | 122010 | 109207 | 101956 | 181339 | 46998 | 14227 |

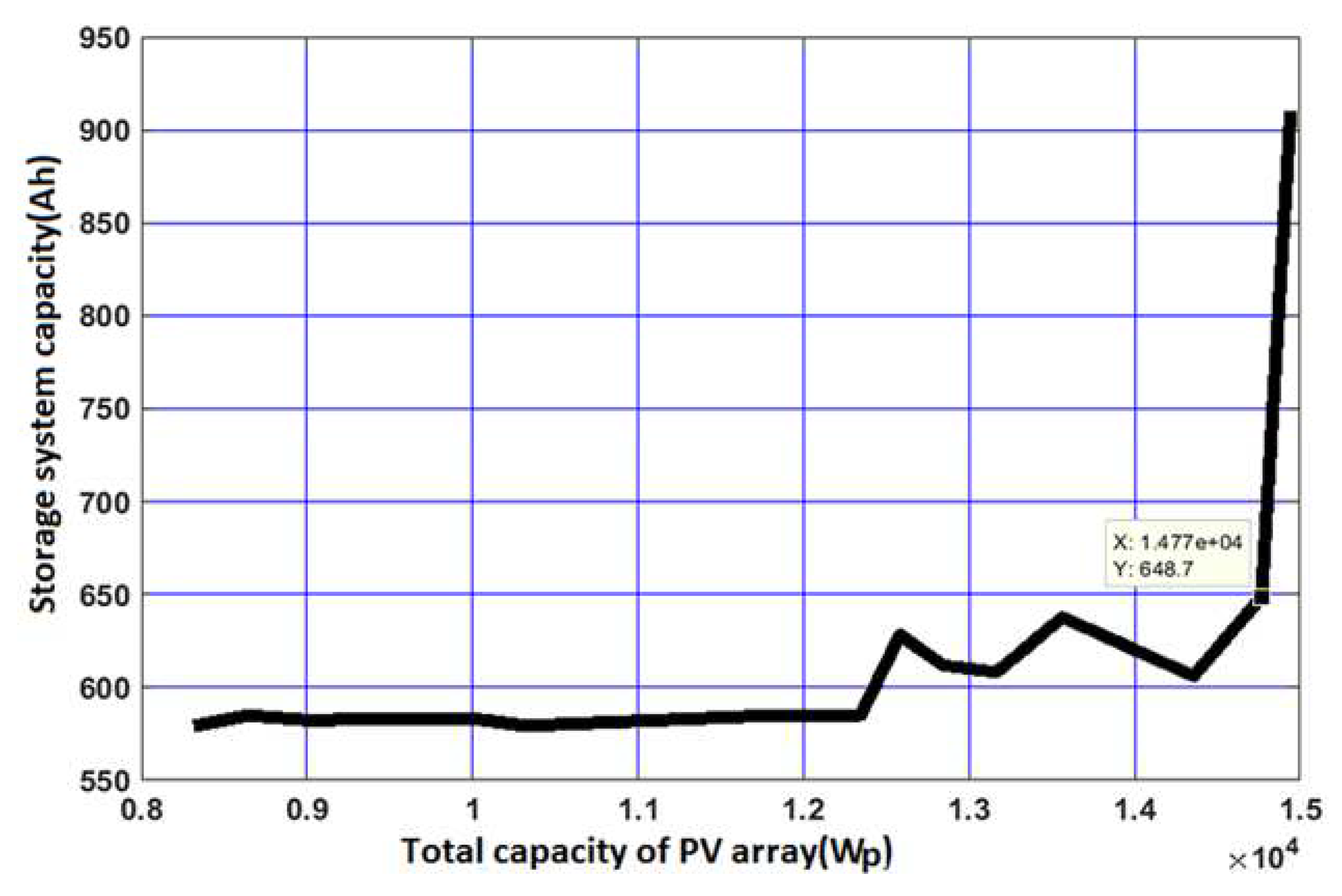

| Index | X1 (Wp) | X2(Ah) | Y (%) | X(FCFA) |

| 1 | 14941.65 | 910.33 | 0.001 | 15 774271.29 |

| 2 | 14766.33 | 648.49 | 0.007 | 15 303151.43 |

| 3 | 14354.85 | 606.07 | 0.06 | 15 081720.69 |

| 4 | 13563.34 | 637.71 | 0.17 | 14 831706.10 |

| 5 | 13164.87 | 608.10 | 0.23 | 14 635226.57 |

| 6 | 12582.45 | 628.27 | 0.31 | 14 446375.46 |

| 7 | 12343.98 | 585.04 | 0.34 | 14 446375.46 |

| 8 | 11869.93 | 585.09 | 0.41 | 14 110327.77 |

| 9 | 10322.86 | 579.35 | 0.63 | 13 516892.63 |

| 10 | 10005.46 | 583.13 | 0.67 | 13 402 810.15 |

| 11 | 9590.56 | 591.06 | 0.73 | 13 258314.70 |

| 12 | 9047.481 | 582.03 | 0.81 | 13 039145.76 |

| 13 | 8642.18 | 584.87 | 0.87 | 12890387.24 |

| Designation | Intuitive method | Genetic algorithm method |

| Total capacity of storage system (A h) | 2153.47 | 648.49 |

| Total capacity of PV array (Wp) | 16240 | 14766.33 |

| ALSP (%) | 0.007 | |

| TLCC (FCFA) | 29 998737.52 | 15 303151.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).