1. Introduction

Plasma is one of four fundamental states of matter, characterized by the presence of a significant portion of charged particles in any combination of ions or electrons. It is the most abundant form of ordinary matter in the universe, being mostly associated with stars. On Earth, plasma under natural conditions is extremely rare. For technical applications, plasma is produced in devices called plasma reactors [

1]. Plasma cannot be stored, so it is generated during the process conducted with it, directly in the region of its interaction. The predominant method of plasma generation is electrical discharge in a gas. Plasma is used in many technological processes, among which we can mention: cutting [

2], sputtering of coatings [

3], decontamination of gases and surfaces [

4], production of carbon nanotubes [

5], melting of steel [

6]. Each process carried out using plasma requires different plasma parameters.

The possibilities of shaping the plasma parameters in plasma reactors are limited and consist mainly in the choice of the geometry of the electrodes and the material they are made of, the choice of the geometry of the discharge chamber, the choice of the composition of the plasma-generating gas, its pressure and flow rate [

7,

8,

9]. In the main, however, it is the power supply system that determines the plasma parameters. Plasma parameters can be influenced by: (1) selecting the voltage between DC and AC, (2) selecting the frequency of the supply voltage, (4) selecting the value of the voltage, (5) selecting the shape of the voltage, (6) selecting the value of the current, (7) controlling the DC component and higher harmonics in the voltage and current (8) generating magnetic fields [

10,

11,

12].

Due to the wide variety of plasma reactor designs [

13], occurring even within a single type, and the wide variety of plasma processes carried out with their participation, it is difficult to develop a single universal power supply system. In order to achieve high plasma process efficiencies, it is necessary to use specialized power supply systems, individually designed for a specific plasma reactor and a specific technological process [

14].

To perform a well-recognized and reproducible plasma process, one can design a power system that requires no adjustment or requires adjustment of only selected parameters within narrow limits [

15,

16]. Usually, this task is difficult because plasma reactors are rarely subject to full control. Plasma reactors are highly nonlinear receivers with stochastically varying operating parameters, generating strongly electromagnetic interference and significant overvoltages and overcurrents [

17,

18,

19]. Therefore, it is expected that the power system will ensure good cooperation with the power grid, reduce interference with apparatus located in the vicinity of the plasma reactor, and provide a good working environment for people.

An indispensable component of any power supply is a transformer. In some cases, the transformer itself, in a suitable design, is a good source of power for plasma reactors. In order to improve the control characteristics, transformer systems are completed with circuits with semiconductor elements. The use of transistor converters makes it possible to smoothly regulate the current value, voltage value and frequency.

The article [

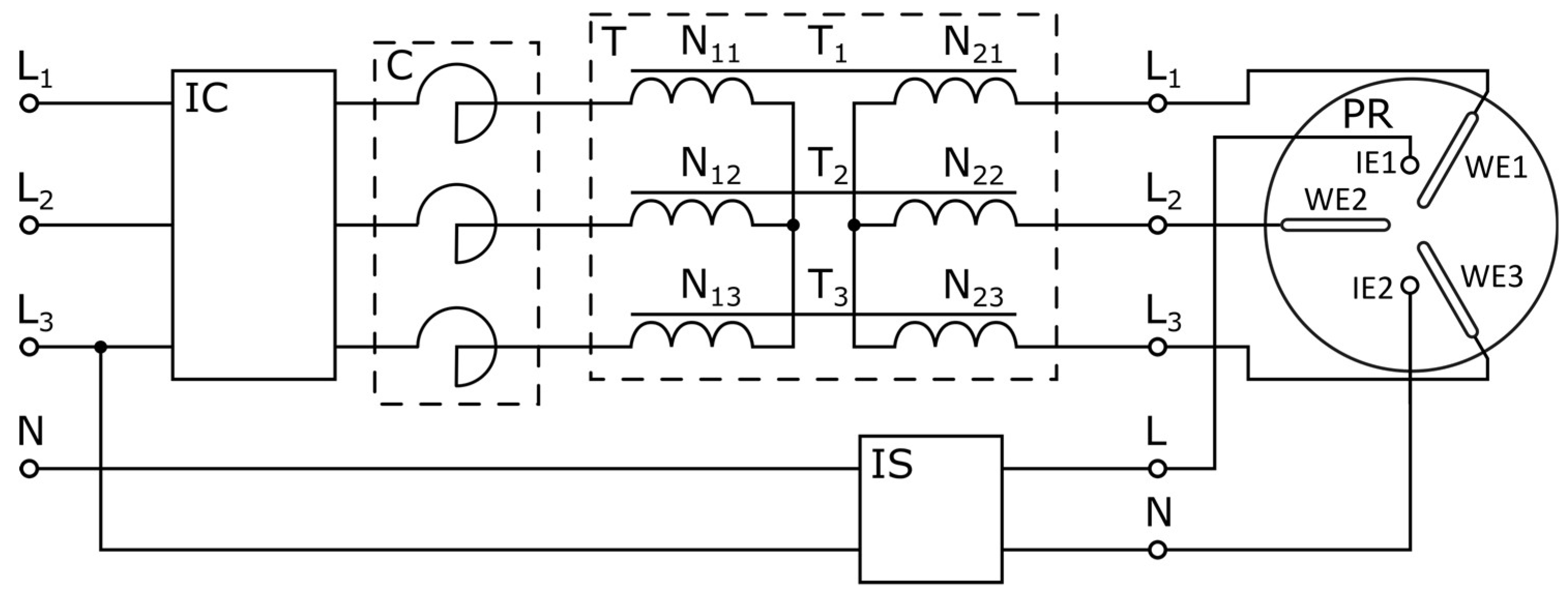

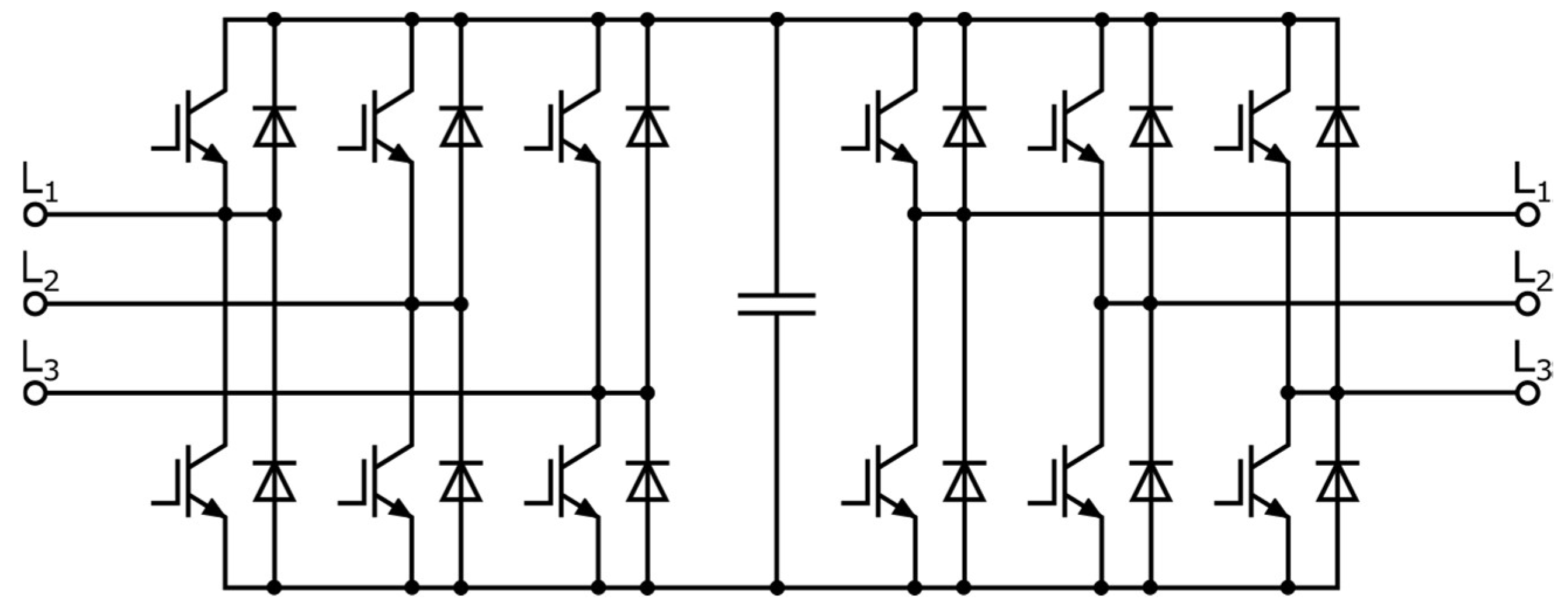

20] presents the problems of construction and operation of several types of power supply systems for a three-phase plasma reactor with gliding arc discharge. Of the power supplies studied, the power converter supply system (PCS), shown in

Figure 1, manifested the most features predisposing it to powering plasma reactors. Despite its relatively poor control characteristics, compared to other power supplies, this power supply guarantees correct burning of the reactor discharge for all plasma gases. A major advantage of the power supply is the ability to shape the plasma parameters by changing the frequency of the supply voltage. In the case of the PCS power supply, the intermediate transformer has a great influence on its cooperation with the plasma reactor. The transformer's gear ratio, the dissipation reactance, the value of the magnetic induction in the core and the material of the core, the ability to carry fast-variable signals are the basic parameters to be taken into account. In the PCS power supply, the big operational problems are generated by the electronic ignition system. This system has a high failure rate and generates large conducted disturbances that interfere with the operation of the converter.

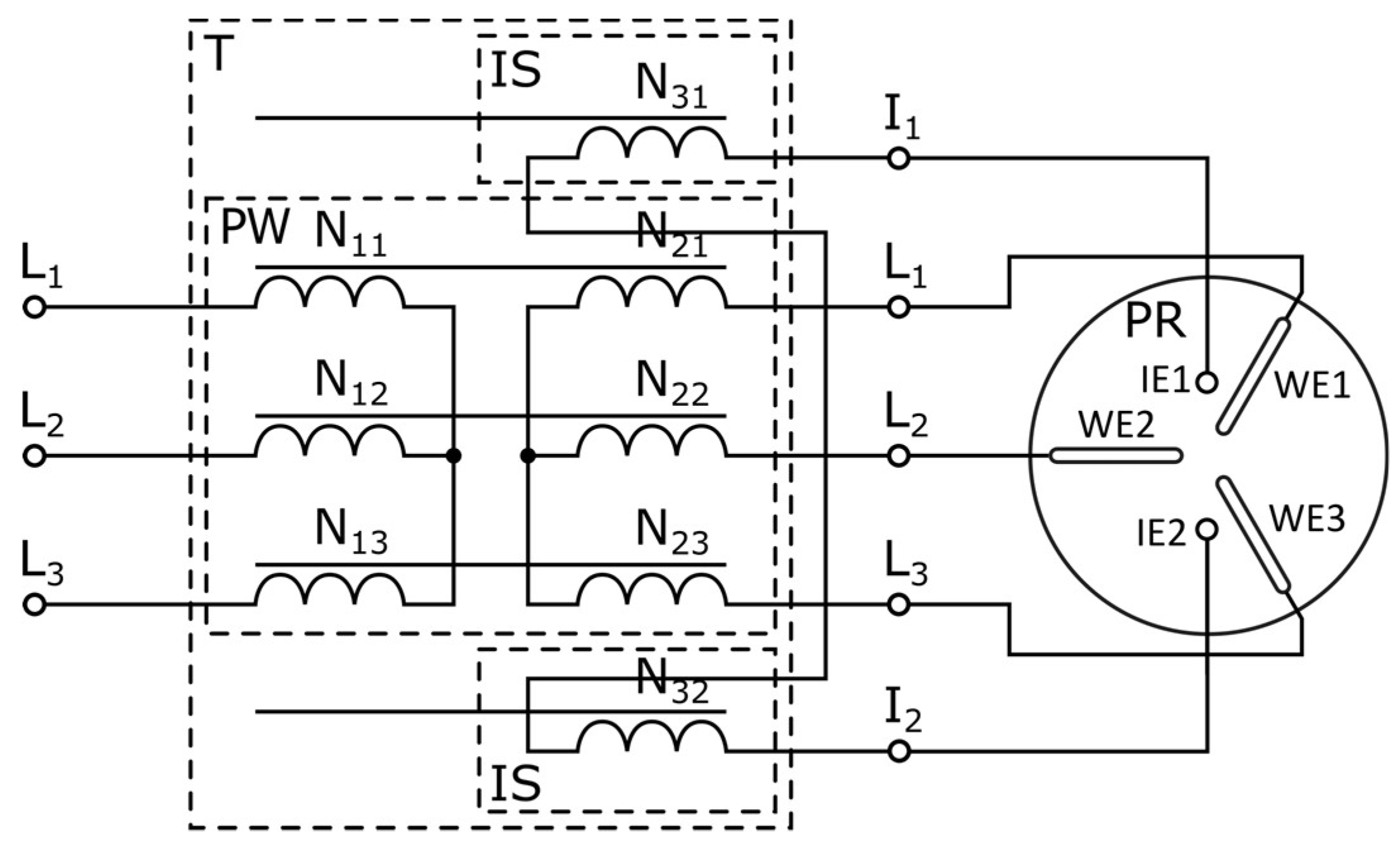

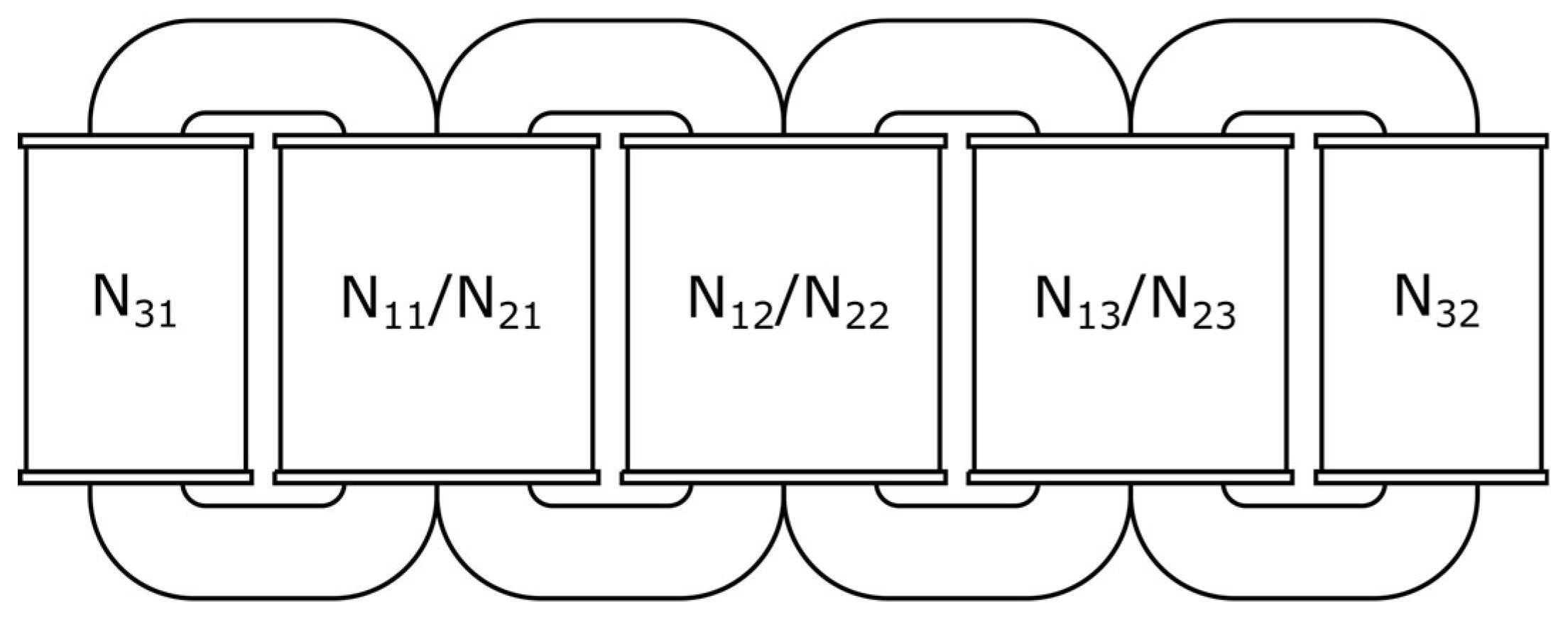

Of the power systems presented in the article [

20] and using only a transformer in its design, the five-limb transformer (IFCTPS) in a special design (

Figure 2) was characterized by good cooperation with the plasma reactor. Using the properties of the five-limb core, this transformer integrates the functions of igniting the discharge in the reactor and sustaining its burning in a single device.

The analyses carried out showed that combining an IFCTPS transformer with a converter derived from a PCS power supply will obtain a power supply system that guarantees optimal cooperation with a plasma reactor. The following part of the article discusses the design of such a power supply and analyzes its cooperation with a three-phase plasma reactor generating a gliding arc discharge.

2. Plasma reactor

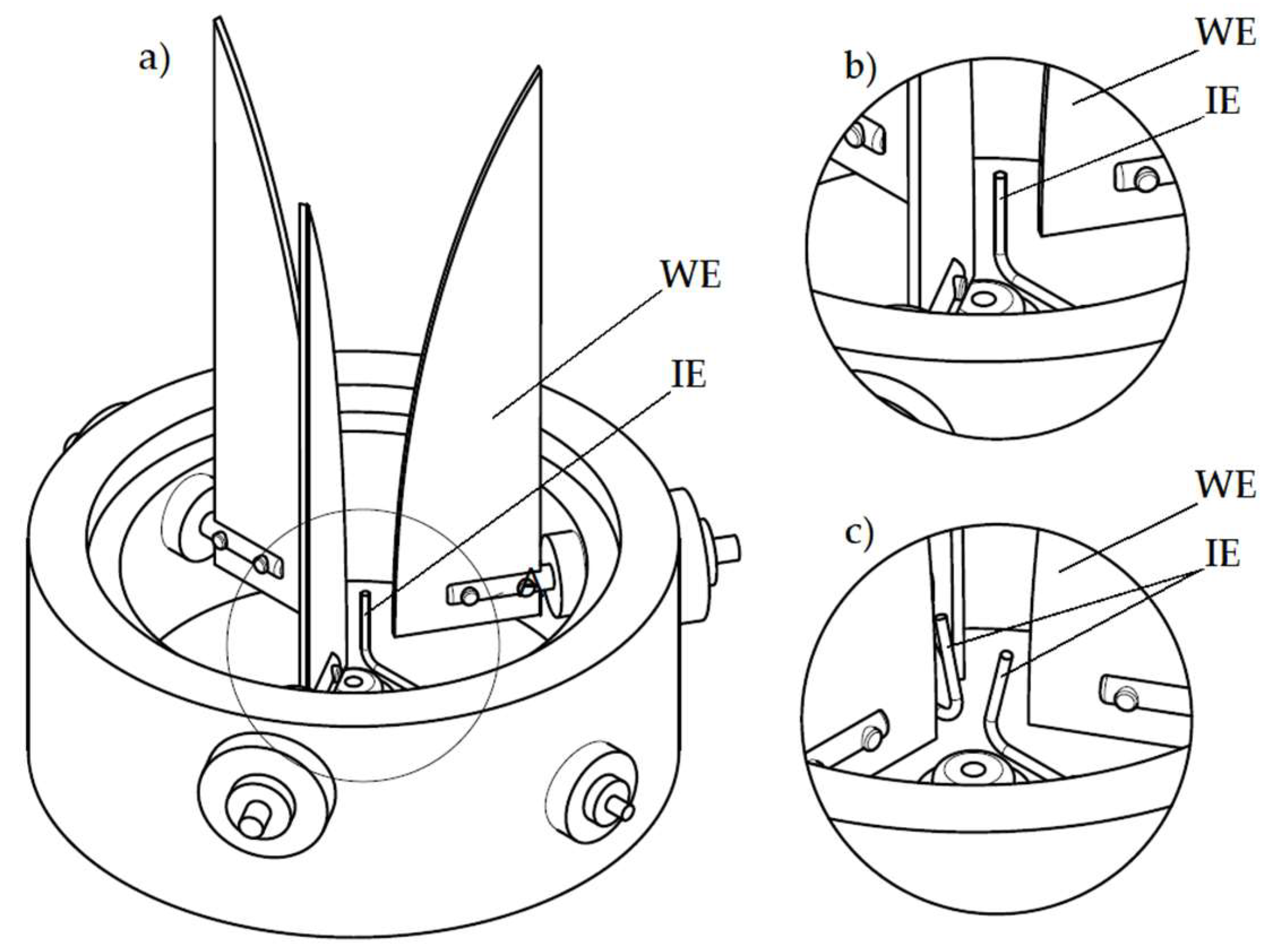

The problems of plasma reactor power supply, presented in the article, focus on ensuring optimal conditions for plasma generation in a three-phase plasma reactor with gliding arc discharge [

21] and its proper cooperation with the power supply system. The design of the plasma reactor is shown in

Figure 3, while its technical parameters are given in

Table 1. The reactor is used in gas decontamination processes.

The reactor is equipped with three knife-shaped metal working electrodes arranged around the axis of the cylindrical discharge chamber every 120°. Each electrode is powered from a separate phase of the three-phase power supply network. It is assumed that in gas decontamination processes the supply voltage of the working electrodes should not exceed 1.5 kV at the mains frequency, while the supply current should be less than 5 A. The specified voltage, with the distances between electrodes used in the reactor, is not sufficient for spontaneous ignition of the arc discharge. For this reason, the reactor is equipped with one or two ignition electrodes. Separating the discharge ignition function from the discharge support function in the reactor allows better control of plasma parameters and significantly reduces the arc voltage.

The task of these electrodes is to reduce the breakdown strength of the gap between the working electrodes by ionizing them. Ignition electrodes are powered by voltages up to 20 kV at mains or elevated frequencies. The value of the current supplying these electrodes usually does not exceed 400 mA. With the given power supply parameters, electric sparks appear between the ignition electrodes. In a situation where there is only one ignition electrode, sparks jump from it to the working electrodes. The sparks initiated at the ignition electrodes ionize the gas, which is introduced into the space between the working electrodes.

The operation of the reactor is a cyclic operation. The arc discharge initiated on the working electrodes, under the influence of gasodynamic forces from the plasma-generating gas flowing into the reactor chamber, moves along the electrodes increasing its length. The discharge is extinguished when the power supplied from the power system is unable to offset the energy losses of the intensively cooled and blown arc column. As soon as the discharge is extinguished, it is rebuilt as a result of the ignition electrodes. The length of the reactor's cycle depends on its design parameters, the parameters of the plasma gas and the parameters of the power supply system [

22,

23,

24]. The cyclic operation of a plasma reactor translates into a variable load on its power supply system. This system operates from a near-short-circuit state, when the electric arc is ignited, to an idle state, when the arc does not burn.

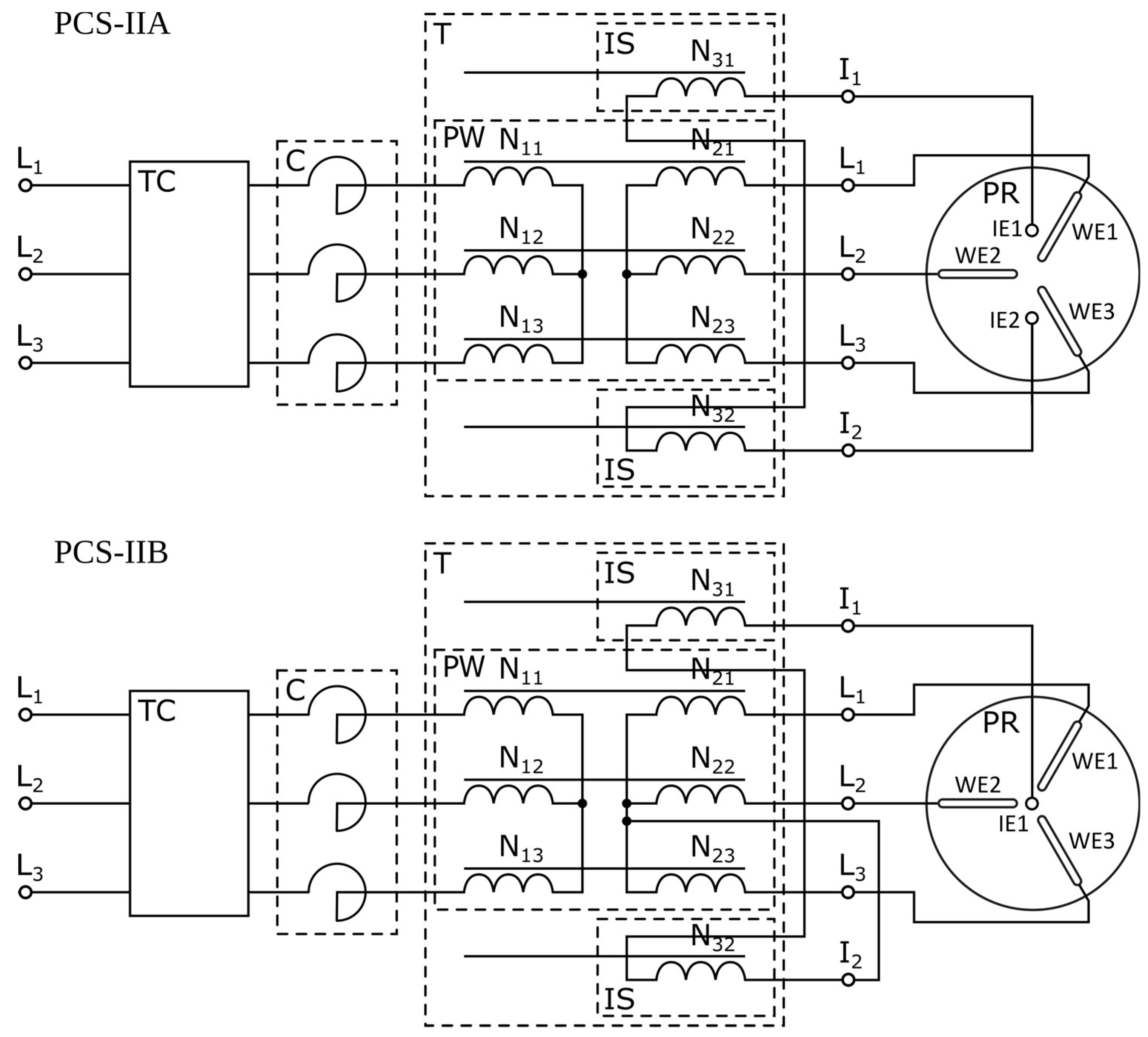

3. Power system of plasma reactor

For the power supply of the presented plasma reactor, a new power supply system was developed, which was given the designation PCS-II. In the PCS-II power supply system (

Figure 4), an AC/DC/AC transistor converter was connected to the transformer supplying the plasma reactor on its primary side. Chokes with inductance of 20 mH were installed between the transformers and the converter. The ratings of the tested transformer design are given in

Table 2.

The converter is built with a three-phase AC/DC transistor rectifier in a 6T+6D arrangement, a DC intermediate circuit, a capacitive filter and a three-phase transistor inverter (

Figure 5). The rectifier circuit is equipped with an additional circuit for power factor improvement. The converter makes it possible to regulate the value of the voltage supplying the transformer, to regulate the frequency in the range from 10 to 200 Hz, and to regulate the discharge current in the reactor.

An important role in the power supply is played by a three-phase transformer, with a five-limb core, in a special design. This transformer matches the output parameters of the converter to those required by the plasma reactor, provides ignition of the discharge in the reactor, galvanically separates the two devices and filters conducted disturbances generated by the plasma reactor.

In three-phase five-limb core transformers, the side limbs of the core are not used to transform energy. The purpose of these limbs is to connect the top yoke of the core to the bottom yoke and create a low reluctance path for the in-phase magnetic fluxes. These fluxes in three-limb cores exit the core and close through oil, air and structural elements of the transformer which increases additional losses.

In the solution in question, the side limbs of the five-limb core were used to transform energy to a specific electricity consumer such as a plasma reactor. For this purpose, additional windings were mounted on the side limbs of the five-limb transformer. The arrangement of the windings on the five-limb core is shown in

Figure 6. The presented solution allows integrating in a single device, which is a five-limb transformer, the functions of ignition of the discharge in the plasma reactor and the functions of sustaining the discharge. The great advantage of the solution is its simple design and high reliability. The division of the voltage required for ignition of the discharge in the reactor into two windings significantly reduces the problems of isolation of high-voltage windings.

The phase windings of the transformer can be made as layer or disk windings. Selecting the number of disks their dimensions and mutual arrangement can influence the value of the transformer's dissipation reactance. The value of this reactance has a significant effect on the operating characteristics of the plasma reactor. These characteristics can also be shaped by including in the current paths between the converter and transformer chokes with inductances selected as needed.

In the power supply design studied, the transformer windings were made with copper wires as layered. The parameters of the windings are given in

Table 3.

Due to the design of the windings, the transformer has additional ratios between the primary windings and the side limbs windings. The values of these additional current and voltage ratios significantly depend on the values of the maximum fluxes present in the side limbs and the dissipation reactance of the side limbs windings. As a result, the current, voltage and winding ratios can have different values. The ratios of the tested transformer design are given in

Table 4.

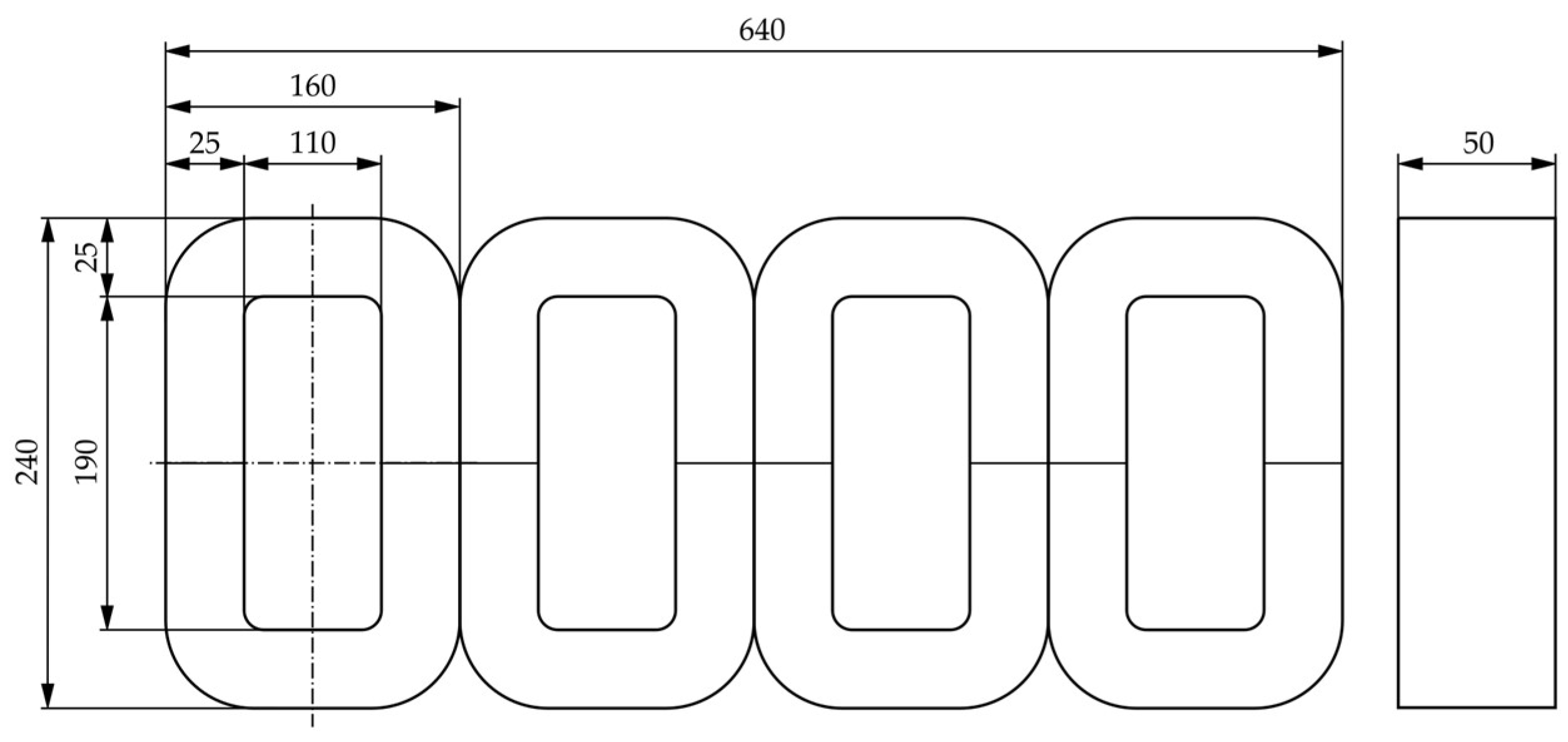

Four wound cores were used to construct the magnetic circuit of the five-limb transformer. The geometry of the core thus obtained is shown in

Figure 7. The choice of such a solution was guided by the high availability of wound cores and the ease of assembly. The effect of using wound cores is that the cross-section of all the yoke parts and side limbs of the transformer core is equal to half the cross-section of the phase limb. In addition, there are vertical air gaps at the junction of two adjacent cores, in the phase limbs. These gaps widen in the yoke sections, causing discontinuity.

The use, instead of wound cores, of a core composed of a package of shapes made of electrical sheets allows at the stage of its design to select the values of fluxes in the side limbs. The distribution of fluxes in the yoke parts of a five-limb transformer depends on the permeance of the sections in which these fluxes occur. In turn, these permeances depend on the lengths, cross sections and magnetic permeabilities of these sections. Assuming that the maximum values of the phase limbs fluxes are equal to each other, the maximum values of the side limb fluxes can vary within the limits:

The case when ϕm4=0 corresponds to a three-limb transformer.

When selecting a transformer core, it is important to pay attention to the material from which it is made. The type of sheet metal used can significantly affect the performance characteristics of the plasma reactor and the parameters of the generated plasma. In this study, cores made of ET 120-27 electrical sheet were used.

The transformer windings can be connected, in two ways (

Figure 4), depending on the design of the plasma reactor ignition system. In both cases, the primary and secondary phase windings are connected in a star without a neutral conductor. The windings from the side limbs are connected in series, keeping the voltages induced in them compatible. The free ends of this connection are connected to the two ignition electrodes of the plasma reactor (

Figure 4 PCS-IIA). Where the plasma reactor is equipped with one ignition electrode, the free end of one winding from the side limb is connected to the ignition electrode and the free end of the other winding to the neutral point of the star-connected secondary phase windings (

Figure 4 PCS-IIB).

4. Cooperation of the power supply with the plasma reactor

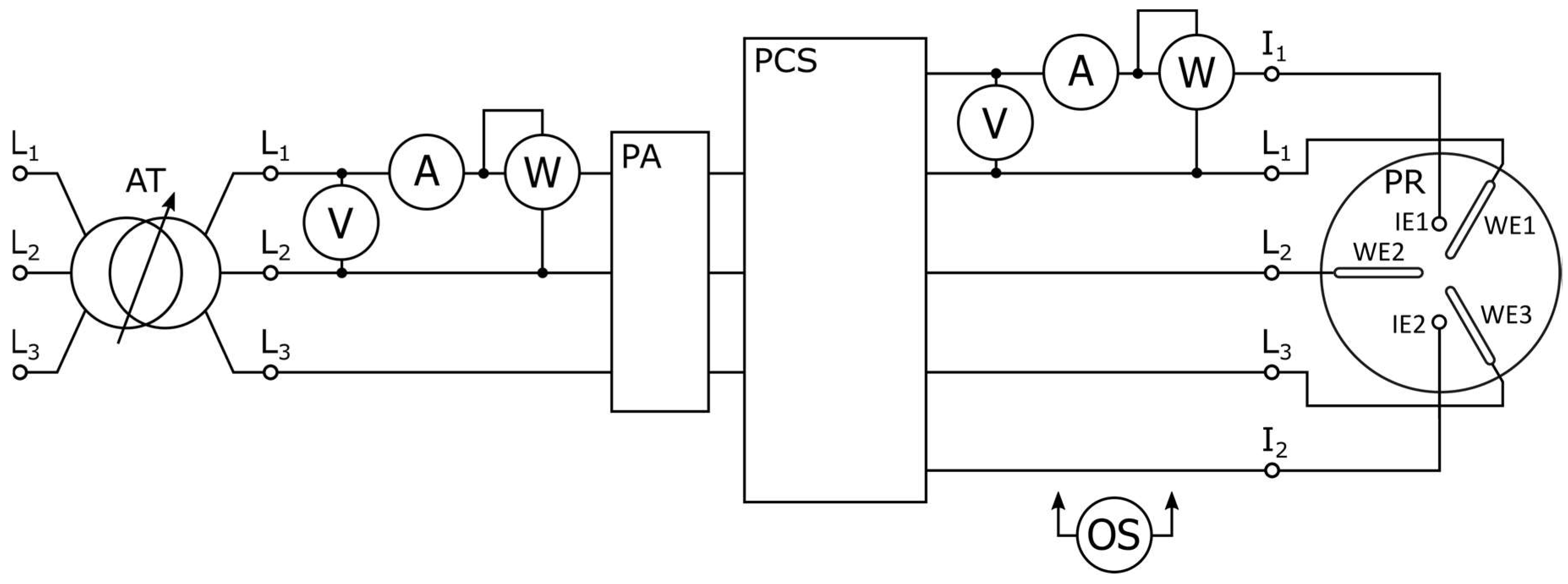

The power system was connected to the power grid and the plasma reactor according to the schematic shown in

Figure 8. The system was powered from a three-phase 400V grid through an ATS-FAZ3-23 autotransformer with a power of 23.4 kVA.

In order to measure magnetic fluxes, additional measuring windings were wound in the core of the transformer on the yokes and limbs. These windings were wound with 20 turns of copper wire. Fluxes were measured indirectly by recording the voltage on the measuring windings using a Tektronix TDS2024B oscilloscope.

Merazet LM-3 voltmeters, Mezaret LE-3 ammeters, Mezaret LW-1 wattmeters, Tektronix DPO3054 oscilloscope, Fluke Norma 5000 power analyzer, and Tektronix P6015A high-voltage and Tektronix TCP0030 current probes were used for the measurements.

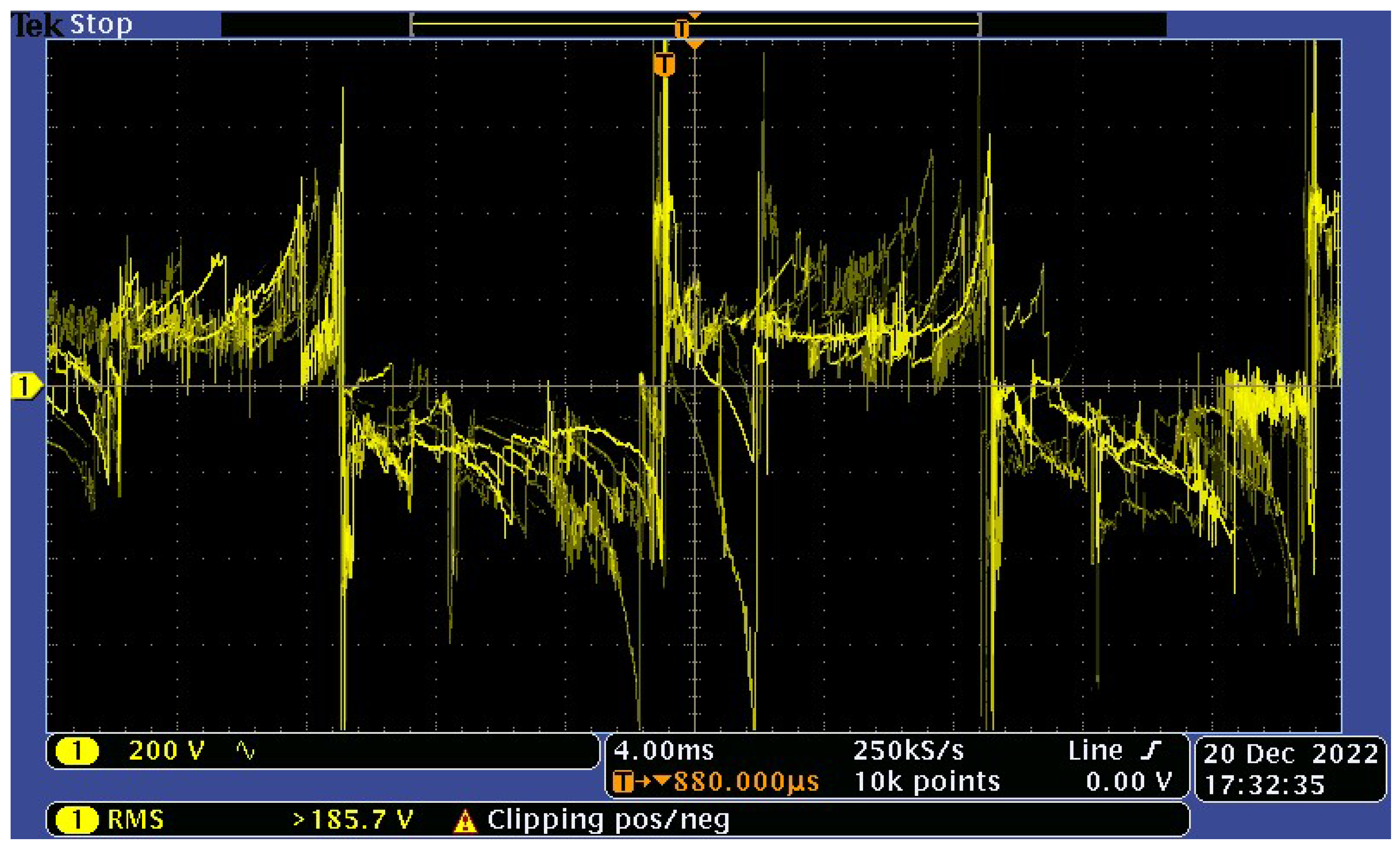

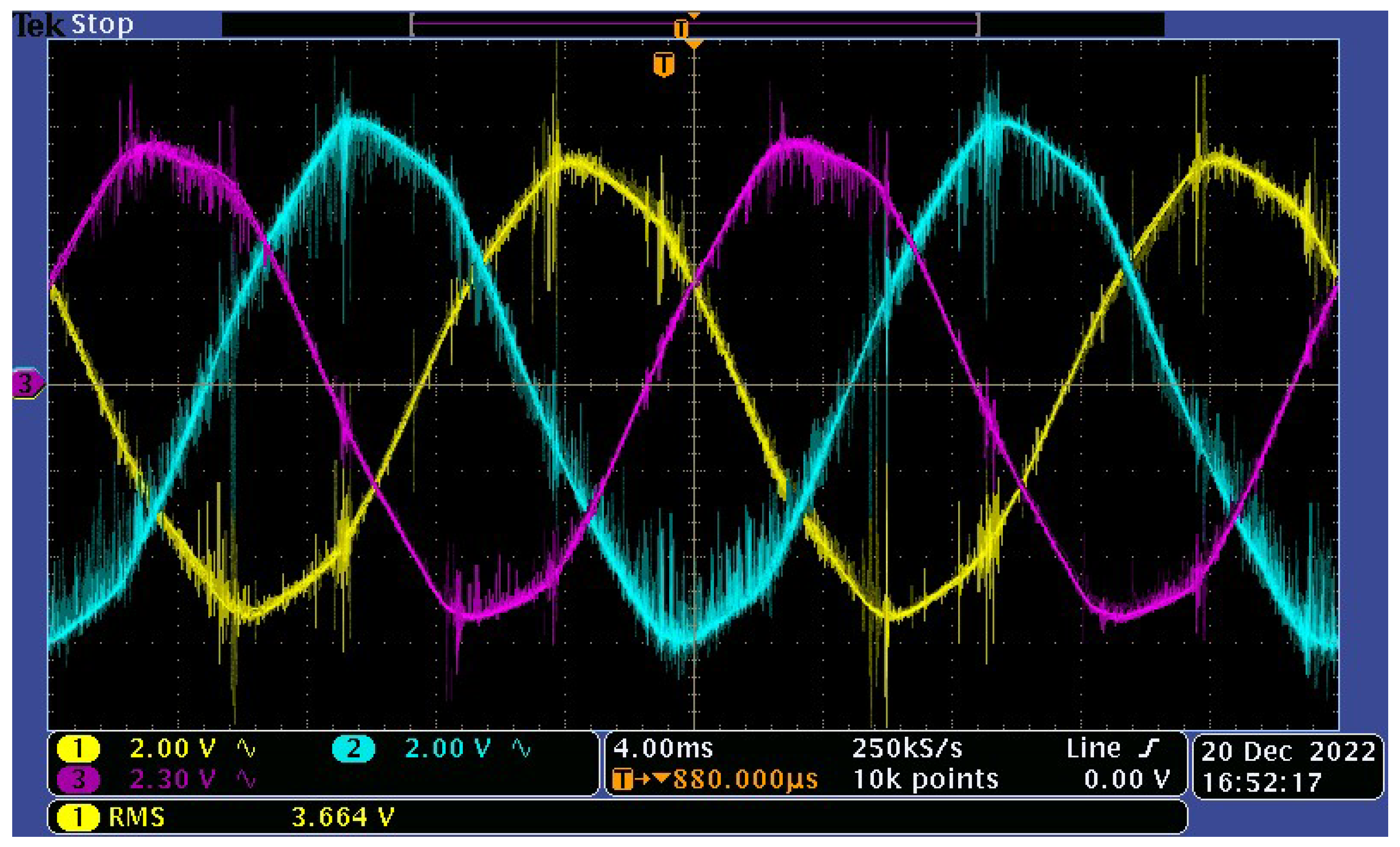

From the point of view of power supply operation, the most important is their operation at the load of the plasma reactor, in which the electrical discharge is burning. The waveform of the phase voltage supplying one of the working electrodes of the reactor is shown in

Figure 9.

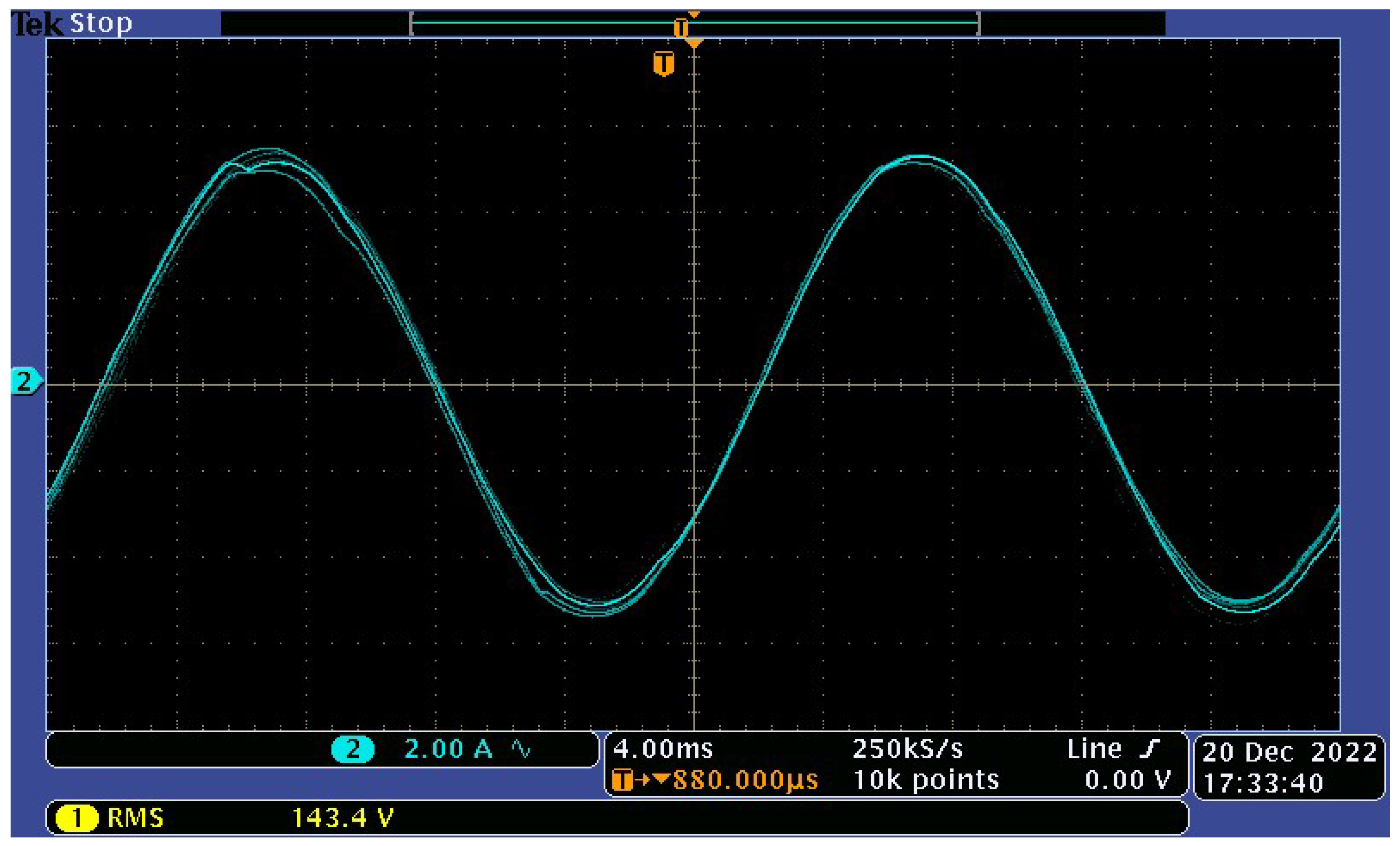

Figure 10 shows the current supplying this electrode. The waveforms were obtained for a discharge burning in argon, whose volumetric flow rate through the plasmotron nozzle was 2.8 m3/h. Sinusoidal current waveforms with strong voltage distortion, in the course of which distinct peaks associated with ignition and quenching of the discharge are visible, are characteristic of intensively cooled electric arcs [

25,

26]. Such arc current and voltage waveforms, which are well documented and described in the literature, allow relatively easy control of the discharge parameters and control of the plasma process. It is also possible to carry out calculations and simulations of the plasma process using generally known mathematical models of the electric arc.

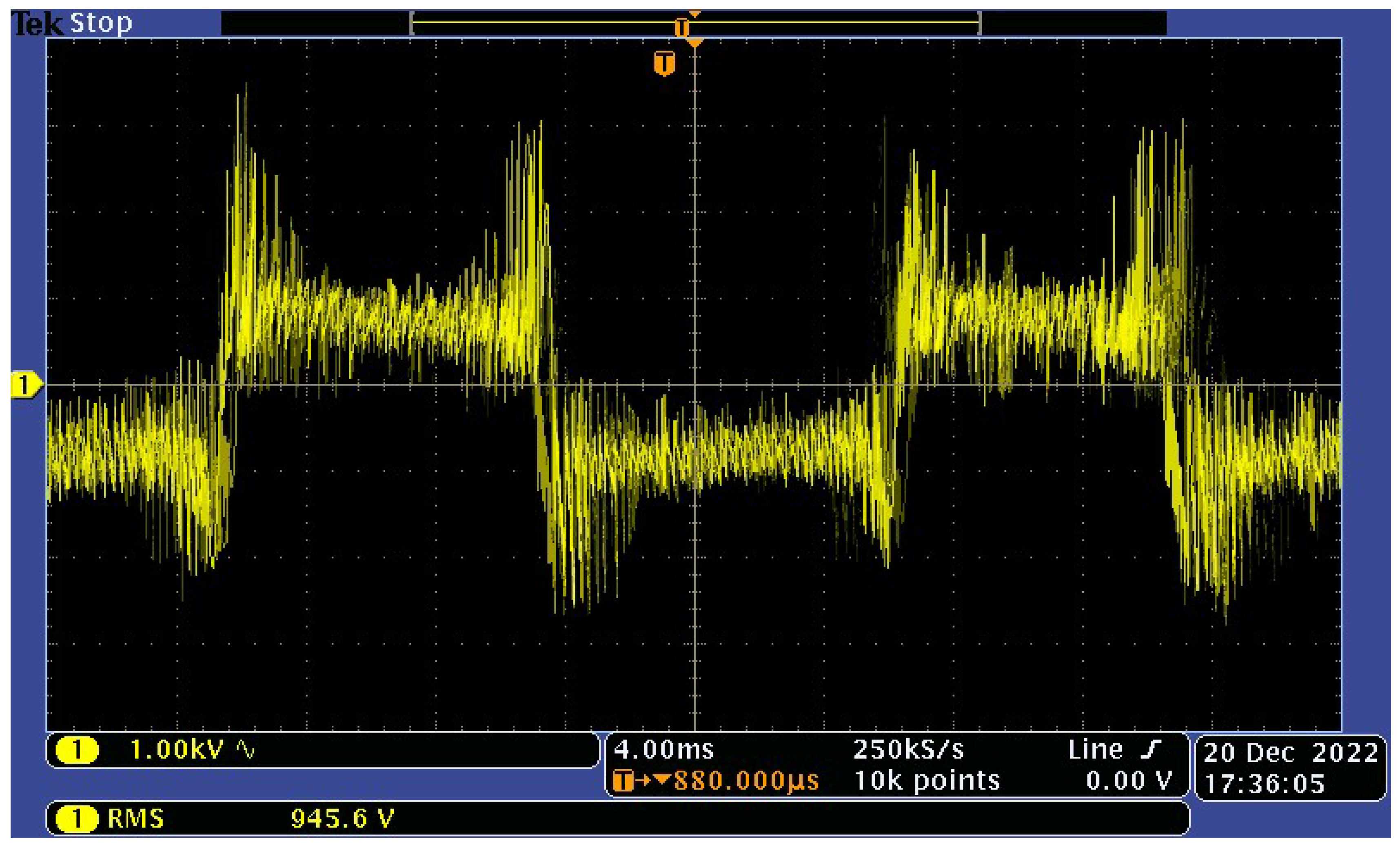

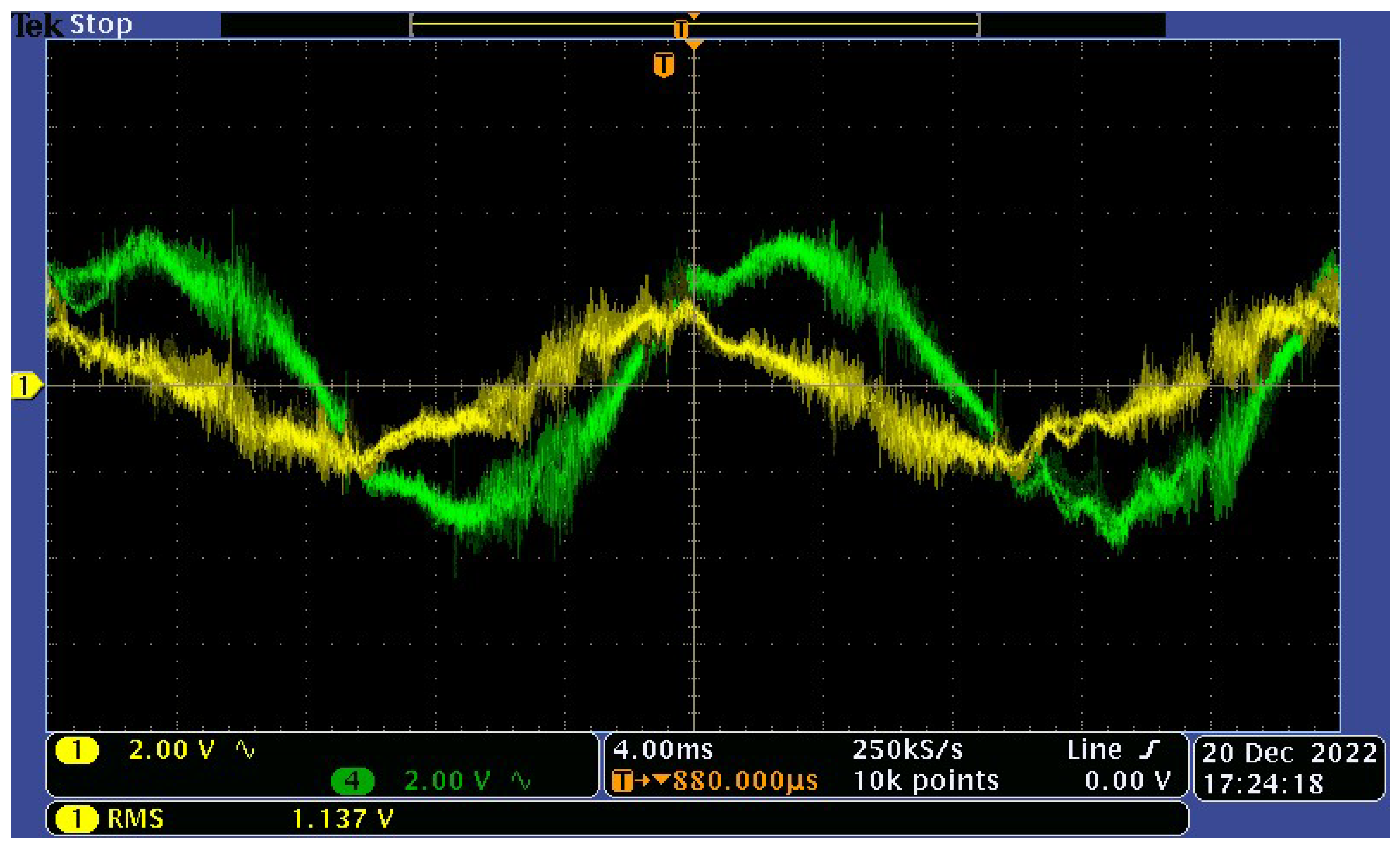

The voltage waveform between the ignition electrodes is shown in

Figure 11, while

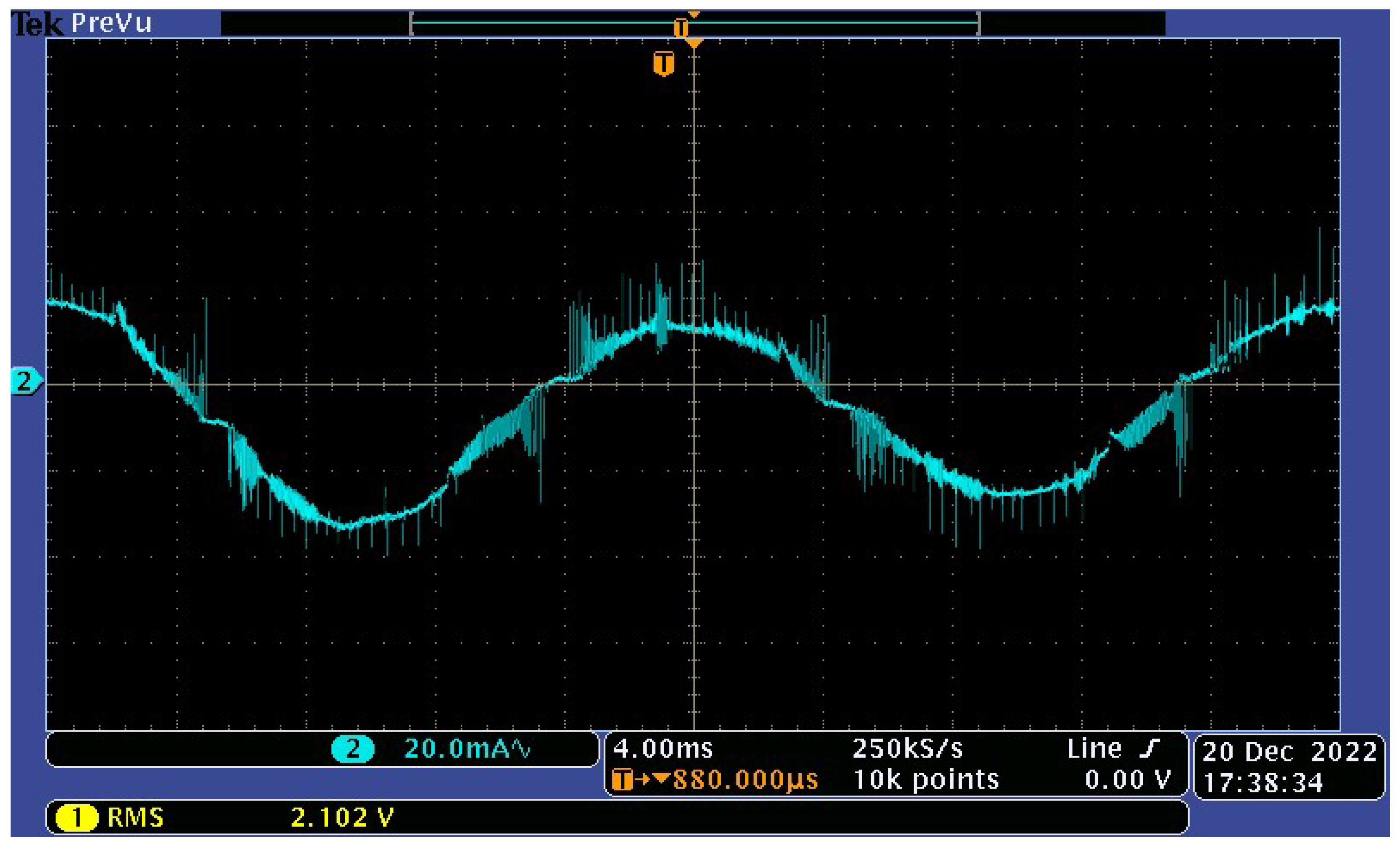

Figure 12 shows the current supplied to the ignition electrodes. A large number of short-lived overvoltages is characteristic of spark discharges [

27,

28]. In the current, in turn, a large number of short-lived overvoltages are manifested. These deformations are the result of the strong dynamic interaction of the plasma-forming gas, flowing into the reactor discharge chamber, with the burning discharge between the ignition electrodes. As a result of this interaction, the initiated discharge channels are rapidly cooled and broken.

The use of two ignition electrodes in the plasma reactor (

Figure 4) instead of one significantly improves the operating conditions of the AC/DC/AC converter. In the case of a single ignition electrode, the discharges that initiate arc ignition in the reactor occur to the working electrodes. In this situation, the overvoltages visible in the voltage in

Figure 11 are superimposed on the phase voltages and transferred to the output side of the converter through the transformer.

Analyzing the course of magnetic fluxes in the core of a five-limb transformer, it is found that they are slightly deformed in the phase columns (

Figure 13). The waveforms of these fluxes show numerous peaks and dips of small value and short duration. More distortion is observed in the fluxes in the side limb of the five-limb transformer (

Figure 14). In these streams, in addition to distortion from the sinusoidal waveform, a very large number of peaks and dips similar in character to noise are observed.

A certain limitation in the use of the power supply is the relatively low current values that can be obtained for the discharge in the plasma reactor. The limitation of the upper range of current regulation takes place in the transformer as a result of the use of a core made of ET 120-27 electrical sheet. A core made of such material has a limited ability to carry high-speed signals from the converter. Experience with other power supplies indicates that a core made of amorphous material allows better power transfer from the converter to the plasma reactor.

In the power supply under study, the transformer windings were made as layered windings. Disc windings seem to be a better solution. The alternating arrangement of the primary and secondary winding discs makes it possible to achieve the desired dissipation reactance of the intermediate transformer. With proper design of the windings, it seems possible to eliminate chokes from the output circuits of the AC/DC/AC converter.

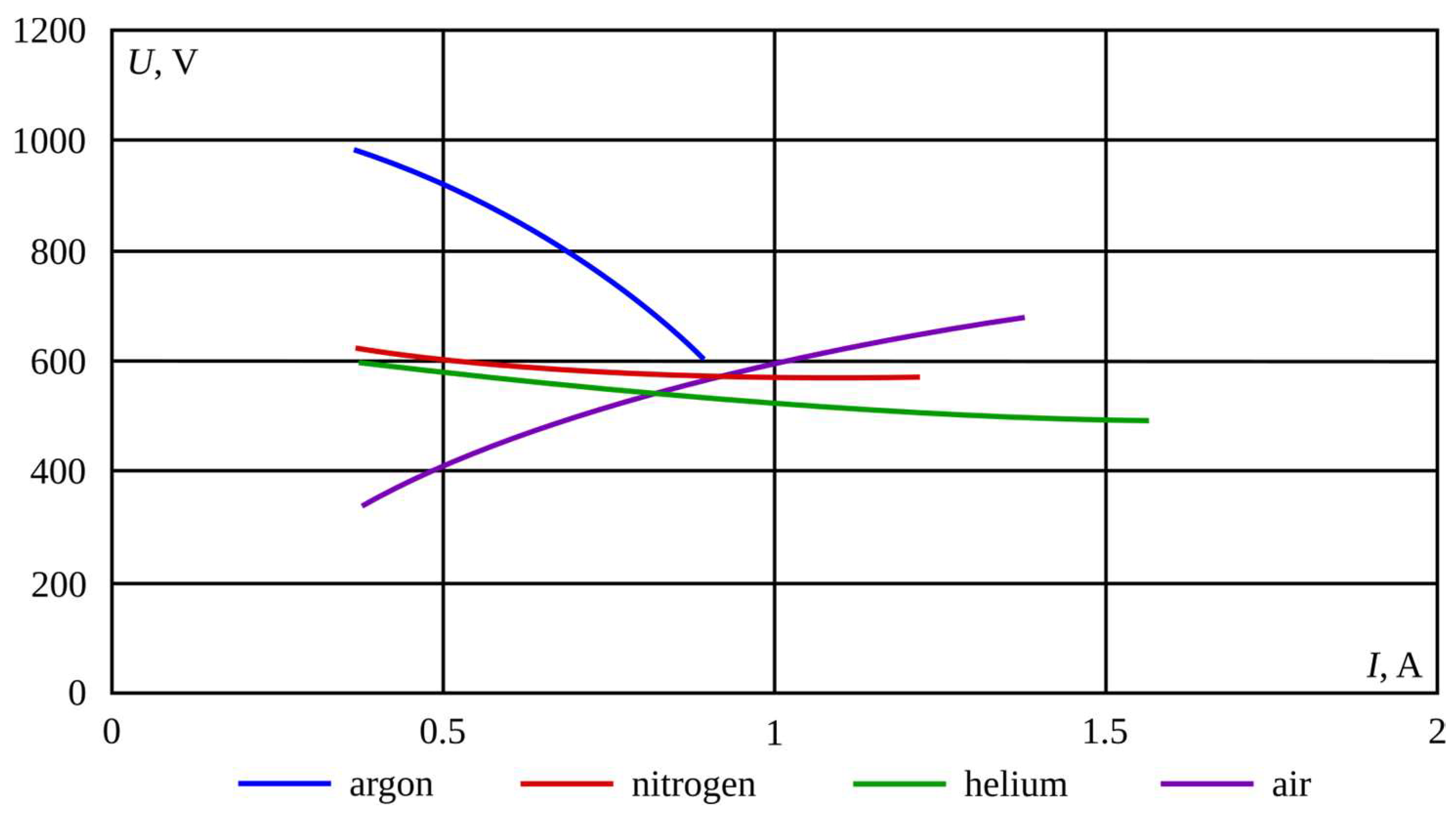

The voltage-current characteristics of the discharge burning in argon, helium, nitrogen and air are presented in

Figure 15. The measurements were carried out at a volume flow of these gases of 1.6 m

3/h.

The characteristics shown in

Figure 15 strongly depend on the type of plasma-forming gas. The influence of the gas composition is particularly evident when comparing the characteristics obtained for a discharge burning in nitrogen and air. When the arc discharge burns in nitrogen with an increase in the current supplied to it, the arc voltage decreases slightly. Adding to nitrogen the admixtures of gases found in air, in the quantities in which they are found in air, causes that with an increase in the current of the arc its voltage increases significantly. By selecting the chemical composition of the plasma-generating gas, it is possible to influence not only the parameters of the generated plasma, but also the operating characteristics of the plasma reactor and its power supply system. It should be borne in mind that uncontrolled changes in the chemical composition of the gas in the reactor discharge chamber can significantly affect the operation of the reactor as well as its electrical power supply system.

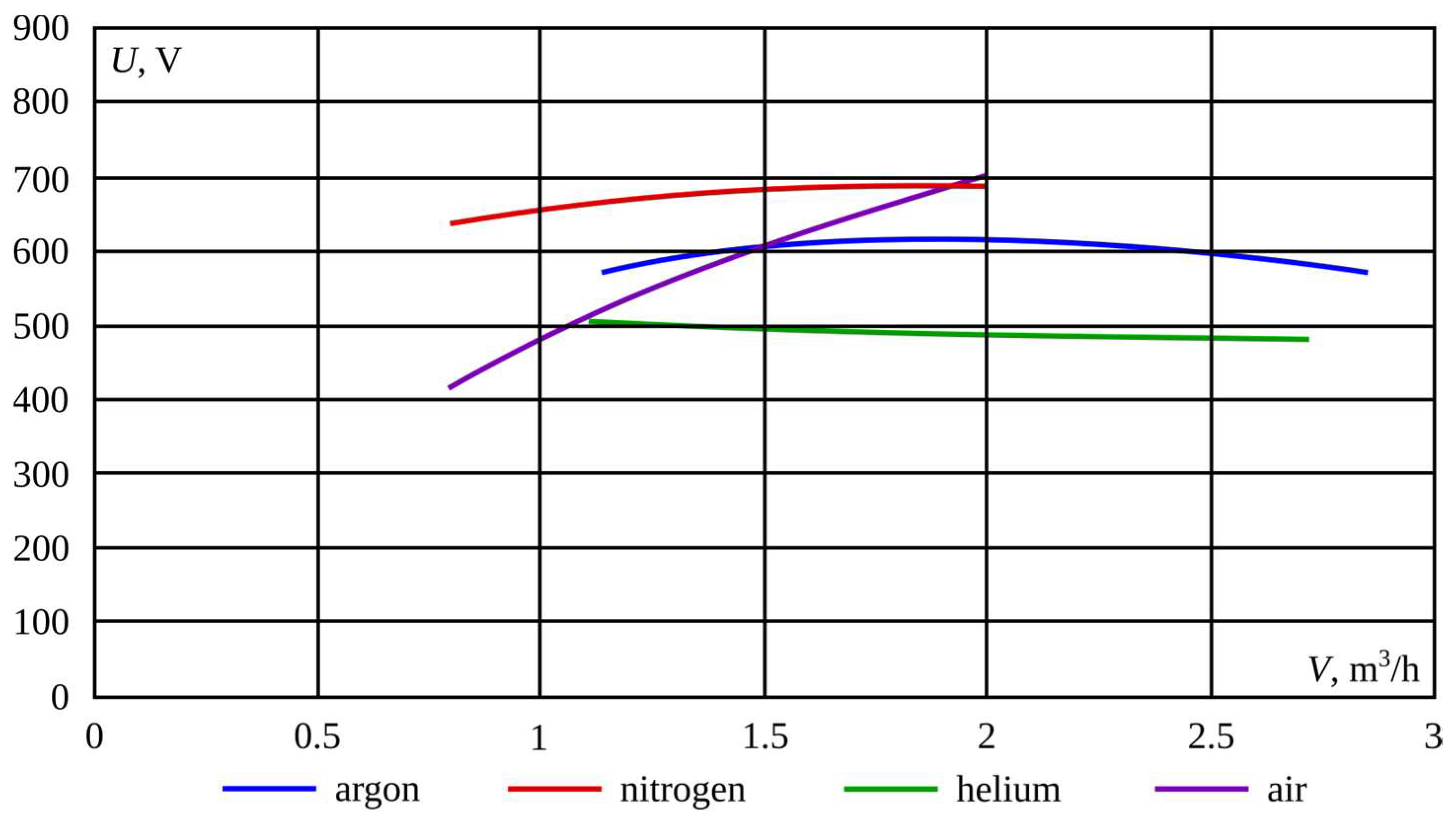

The physical parameters of the plasma-generating gas have a significant effect on the performance characteristics of the plasma reactor.

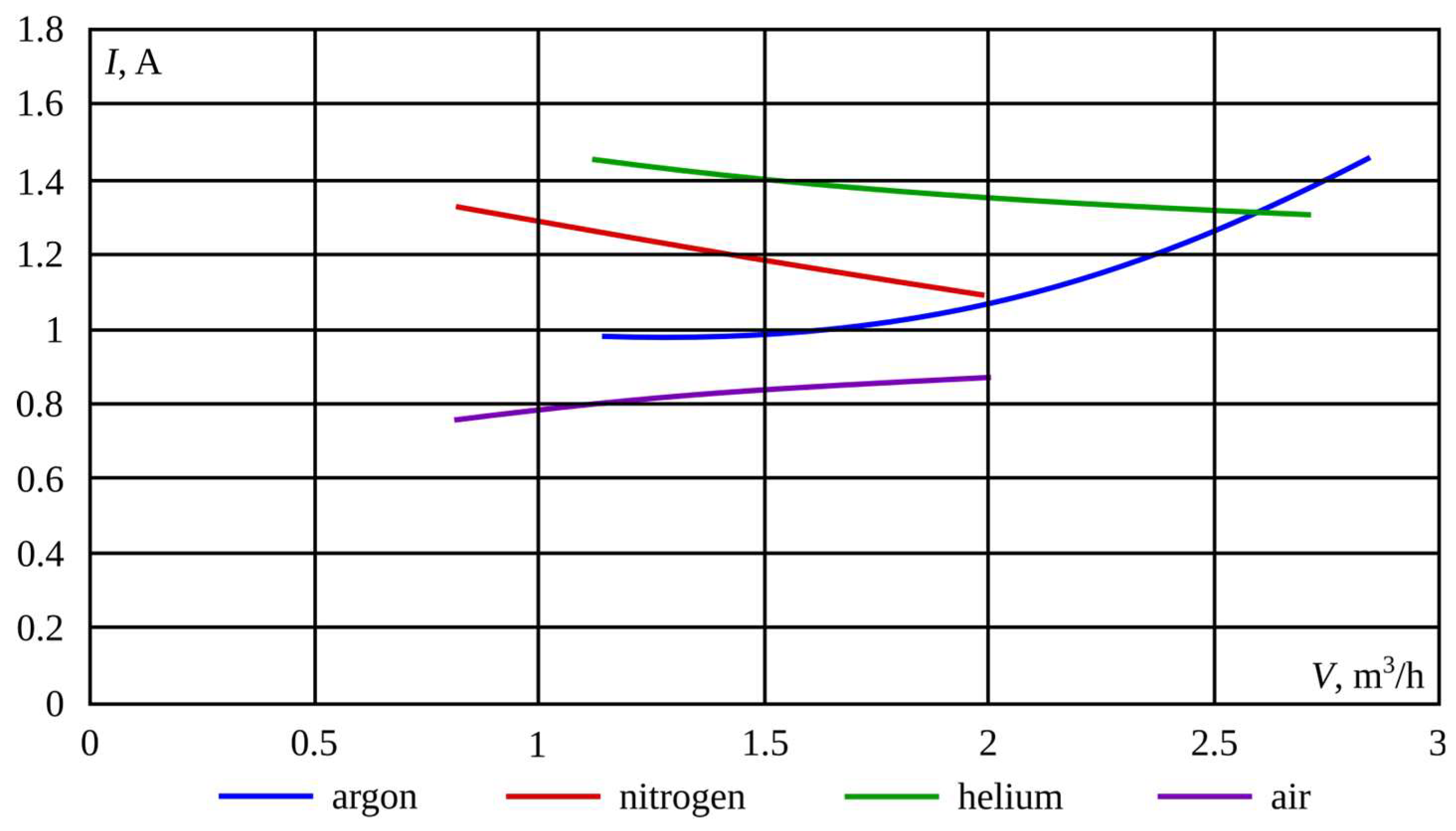

Figure 16 and

Figure 17 show the effect of the value of the volumetric flow of gases through the plasmotron nozzle on the variation of the discharge voltage and current. The characteristics plotted in

Figure 16 and

Figure 17 start from the value of the volume flow of gases at which the discharge in the reactor changes its character. For lower flow values, the discharge has the character of a typical electric arc. In the operation of the reactor, a slow movement of the arc is observed along the working electrodes with long periods of burning at their ends. This arc causes strong erosion of the electrodes, significantly heats up the structural components of the reactor and its plasma has a limited area of influence. In the ranges of gas flows for which the characteristics are plotted, the discharge in the plasma reactor is strongly blown. The discharge does not have a distinct arc column, it resembles a glow discharge in its nature, on the working electrodes there are many points of its attachment rapidly changing their position. The plasma of the discharge is intensively cooled and covers with its area a considerable volume of the reactor discharge chamber. The upper limit of the characteristics shown in

Figure 16 and

Figure 17 is associated with the quenching of the discharge in the reactor. Above this limit, the effect of gas on the interelectrode space is so intense that it does not allow ignition of the discharge in the reactor. The obtained characteristics can be extended to higher values of gas flow by changing the output parameters of the reactor power supply system.

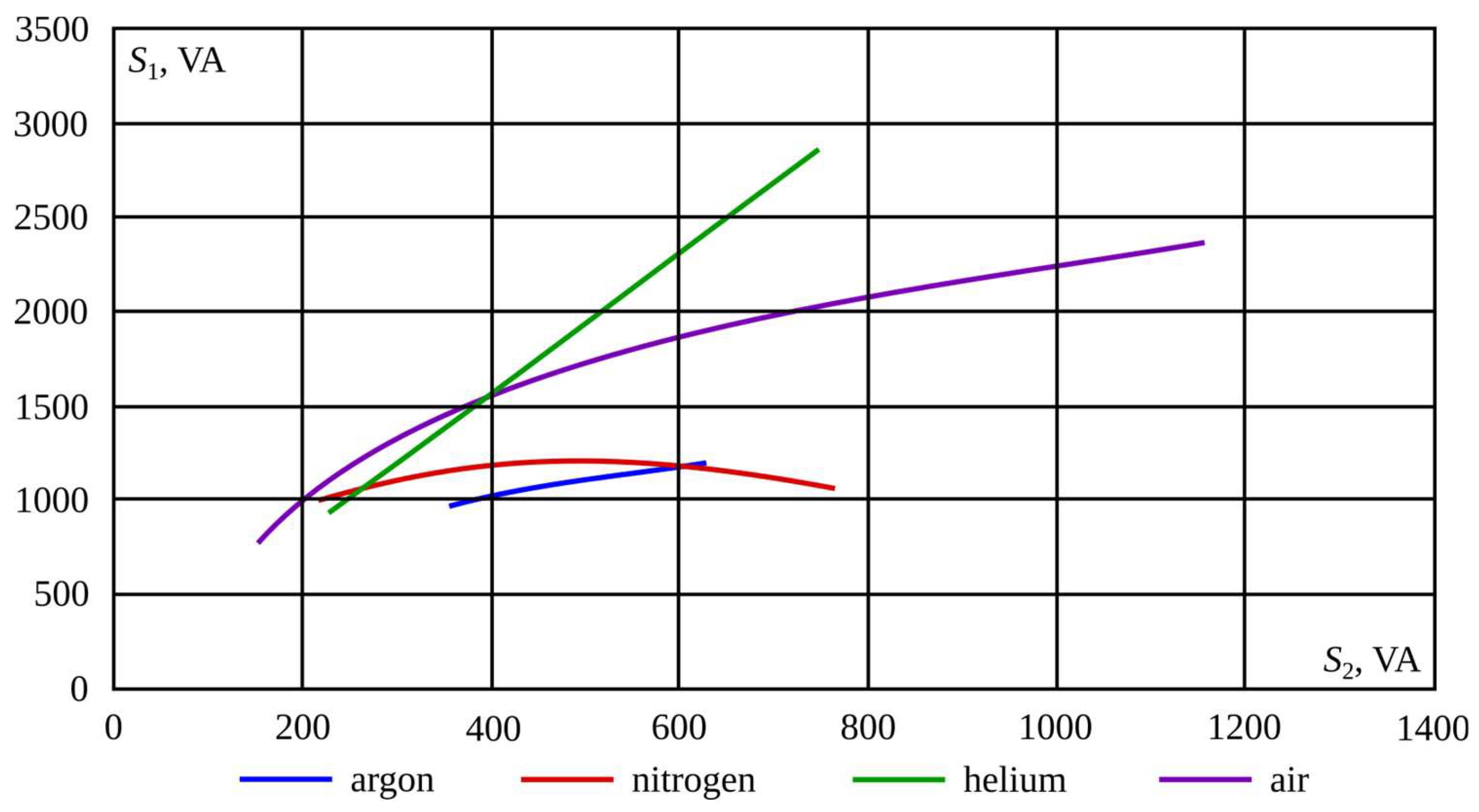

Analysing the apparent powers at the input and output of the power supply, it can be seen that the power supply draws many times more power from the power grid than the power given off to the electrical discharge (

Figure 18 ). Analysis of the cosϕ power factor shows that over the entire range of control of the power supplied to the plasma reactor, these factors, for all the plasma gases tested, range from 0.83 to 1. The measurements show that the powers of the converter system used, as well as the intermediate transformer, are significantly overestimated in relation to the maximum power of the discharge burning in the reactor. As a result, the calculated efficiency with which the power supply operates ranges from 15 % in the lower range of control characteristics to 65 % in the upper range of control characteristics. The type of plasma gas has a strong influence on the efficiency of the power pack. The power pack achieves the highest efficiencies when the plasma-generating gas is nitrogen, while the lowest efficiencies are achieved when the discharge burns in helium.

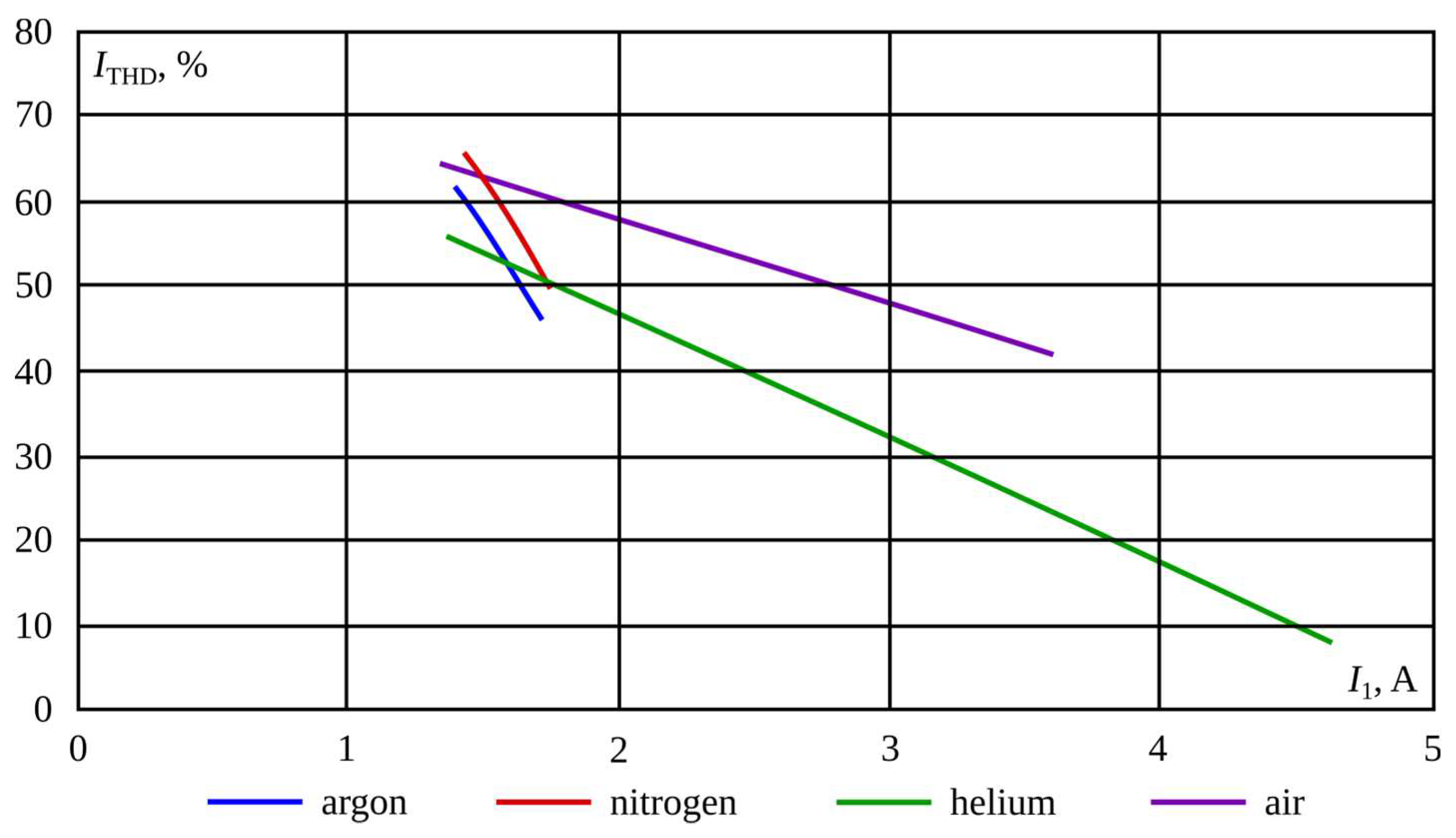

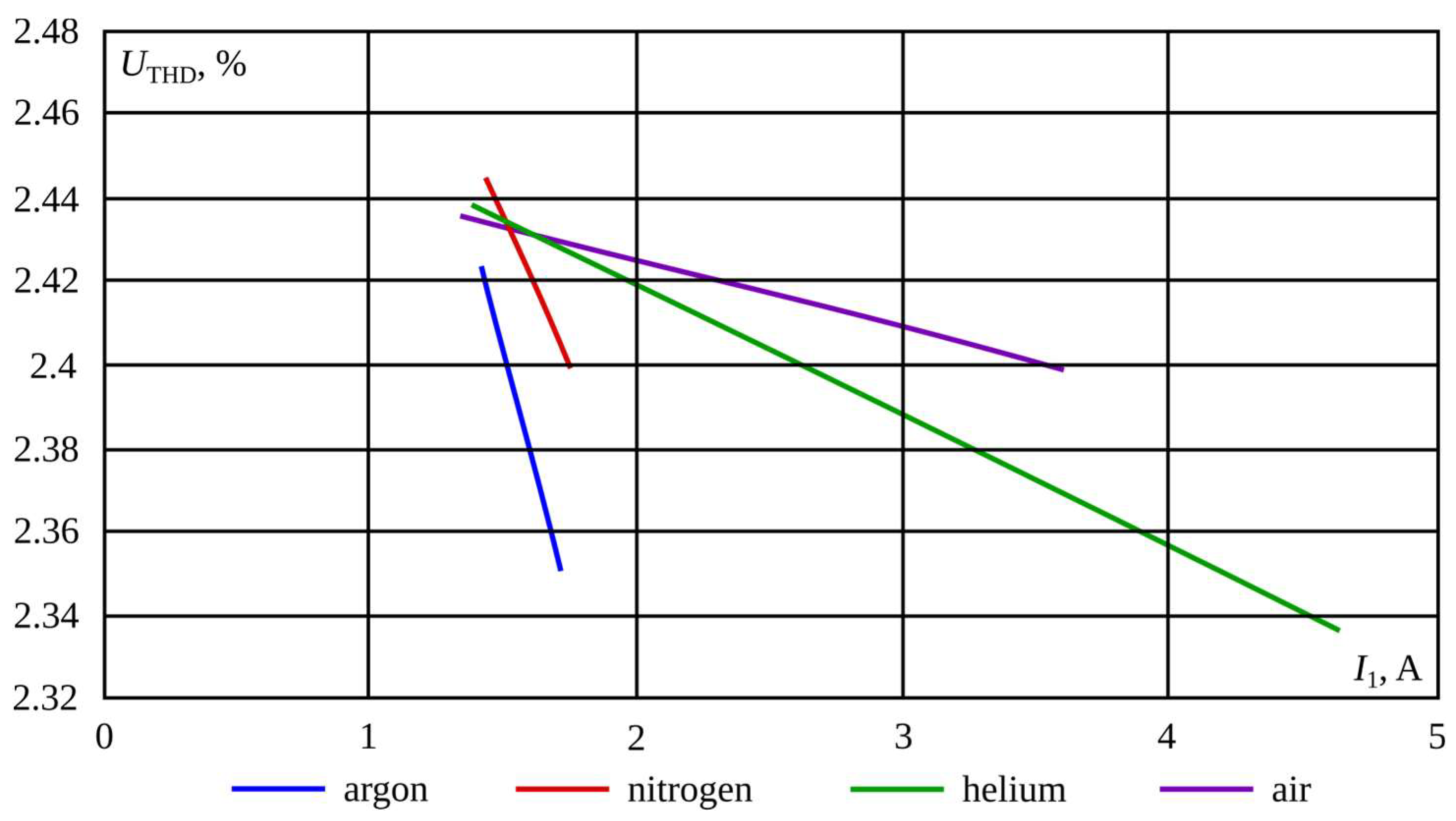

Analysis of the interaction of the power supply, loaded with the plasma reactor, with the power grid in terms of harmonic content showed a high value of the harmonic content coefficients in the current drawn from the grid (

Figure 19) and a relatively small value of this coefficient for the grid voltage (

Figure 20). In both cases, increasing the power supplied to the discharge reduces the value of the harmonic content factor. The type of plasma gas has a large influence on the value of this coefficient.

Figure 1.

Converter power system PCS, PR - plasma reactor, T1, T2, T3 – transformers, reactor working electrodes power circuit, C – chokes, IS – ignition electrodes power circuit, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 1.

Converter power system PCS, PR - plasma reactor, T1, T2, T3 – transformers, reactor working electrodes power circuit, C – chokes, IS – ignition electrodes power circuit, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 2.

Transformer power system IFCTPS, PR – plasma reactor, T – transformer, PW – reactor working electrodes power circuit, IS – ignition electrodes power circuit, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 2.

Transformer power system IFCTPS, PR – plasma reactor, T – transformer, PW – reactor working electrodes power circuit, IS – ignition electrodes power circuit, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 3.

Three-phase plasma reactor with gliding arc discharge, (a) overview drawing, (b) one ignition electrode system, (c) two ignition electrode system, WE - working electrodes, IE - ignition electrodes.

Figure 3.

Three-phase plasma reactor with gliding arc discharge, (a) overview drawing, (b) one ignition electrode system, (c) two ignition electrode system, WE - working electrodes, IE - ignition electrodes.

Figure 4.

Converter power system PCS-II, PR – plasma reactor, T – transformer, PW – reactor working electrodes power circuit, IS – ignition electrodes power circuit, C – chokes, TC – AC/DC/AC transistor converter, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 4.

Converter power system PCS-II, PR – plasma reactor, T – transformer, PW – reactor working electrodes power circuit, IS – ignition electrodes power circuit, C – chokes, TC – AC/DC/AC transistor converter, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings, WE1, WE2, WE3 – plasma reactor working electrodes, IE1, IE2 – reactor ignition electrodes.

Figure 5.

Construction of the AC/DC/AC converter.

Figure 5.

Construction of the AC/DC/AC converter.

Figure 6.

Location of windings on a five-limb core, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings.

Figure 6.

Location of windings on a five-limb core, N11, N12, N13 – primary windings, N21, N22, N23 – secondary windings, N31, N32, – additional secondary windings.

Figure 7.

Geometry of the five-limb core.

Figure 7.

Geometry of the five-limb core.

Figure 8.

Measuring system, AT – autotransformer, V – voltmeter, A – ammeter, W – wattmeter, OS – oscilloscope, PA – power analyser, PCS – power system of plasma reactor, PR – plasma reactor.

Figure 8.

Measuring system, AT – autotransformer, V – voltmeter, A – ammeter, W – wattmeter, OS – oscilloscope, PA – power analyser, PCS – power system of plasma reactor, PR – plasma reactor.

Figure 9.

Voltage between the working electrodes.

Figure 9.

Voltage between the working electrodes.

Figure 10.

Current supplying the working electrode.

Figure 10.

Current supplying the working electrode.

Figure 11.

Voltage between the ignition electrodes.

Figure 11.

Voltage between the ignition electrodes.

Figure 12.

Current supplying the ignition electrode.

Figure 12.

Current supplying the ignition electrode.

Figure 13.

Voltages corresponding to fluxes occurring in the phase columns of a five-limb transformer.

Figure 13.

Voltages corresponding to fluxes occurring in the phase columns of a five-limb transformer.

Figure 14.

Voltages corresponding to fluxes occurring in the side limbs of a five-limb transformer.

Figure 14.

Voltages corresponding to fluxes occurring in the side limbs of a five-limb transformer.

Figure 15.

Voltage-current characteristics of the reactor discharge.

Figure 15.

Voltage-current characteristics of the reactor discharge.

Figure 16.

Characterisation of the variation of arc voltage as a function of changes in the volume flow of plasma-generating gases.

Figure 16.

Characterisation of the variation of arc voltage as a function of changes in the volume flow of plasma-generating gases.

Figure 17.

Characterisation of the variation of arc current as a function of changes in the volume flow of plasma-generating gases.

Figure 17.

Characterisation of the variation of arc current as a function of changes in the volume flow of plasma-generating gases.

Figure 18.

Variation characteristics of the power taken from the grid by the power supply as a function of arc power changes.

Figure 18.

Variation characteristics of the power taken from the grid by the power supply as a function of arc power changes.

Figure 19.

Harmonic content factor of the current drawn by the power supply as a function of changes in this current.

Figure 19.

Harmonic content factor of the current drawn by the power supply as a function of changes in this current.

Figure 20.

Coefficient of harmonic content in the voltage the power supply is supplied with as a function of variations in the current drawn from the grid.

Figure 20.

Coefficient of harmonic content in the voltage the power supply is supplied with as a function of variations in the current drawn from the grid.

Table 1.

Technical parameters of the plasma reactor.

Table 1.

Technical parameters of the plasma reactor.

| Number of working electrodes |

3 |

| Number of ignition electrodes |

1 or 2 |

| Height/width/thickness of working electrodes |

140 mm/30 mm/2 mm |

| Working electrode spacing, bottom/top |

5 mm/50 mm |

| Working electrode material |

steel 0H18N9 |

| Material of ignition electrodes |

tungsten, wire ∅1 mm |

| Height of the discharge chamber |

500 mm |

| Discharge chamber diameter |

114 mm |

| Material of the discharge chamber |

quartz glass |

| Material of the electrode mounting ring |

aluminum PA6 (2017A) |

| Current passes of electrode holders |

copper DIN CuCrZr |

| Insulation of electrode holders |

ceramic AL- 70 |

| Gas inlet nozzle |

∅5 mm |

Table 2.

Power supply ratings.

Table 2.

Power supply ratings.

| Primary voltage, U1 |

V |

230 |

| Secondary voltage, U2

|

kV |

1.5 |

| Secondary voltage of side limb winding, U3

|

kV |

1.9 |

| Primary current, I1

|

A |

15.8 |

| Secondary current, I2

|

A |

2.4 |

| Secondary current of side limb winding, I3

|

mA |

350 |

Table 3.

Parameters of transformer windings.

Table 3.

Parameters of transformer windings.

| Number of windings of the primary winding, N1

|

|

550 |

| Number of windings of the phase secondary winding, N2

|

|

3600 |

| Number of windings of the secondary winding of side limb, N3

|

|

25000 |

| Wire cross section of the primary winding |

mm2

|

6 |

| Wire cross section of the secondary winding |

mm2

|

0.78 |

| Wire cross section of the secondary winding of side limb |

mm2

|

0.12 |

Table 4.

Transformer ratios.

Table 4.

Transformer ratios.

| Ratios between primary and secondary windings |

Ratios between the primary and secondary windings of side limbs |

| Turns |

Voltage |

Current |

Turns |

Voltage |

Current |

|

|

|

|

|

|

| 6,5 |

6,5 |

6,5 |

45.5 |

8.2 |

45.5 |