Submitted:

31 August 2023

Posted:

05 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

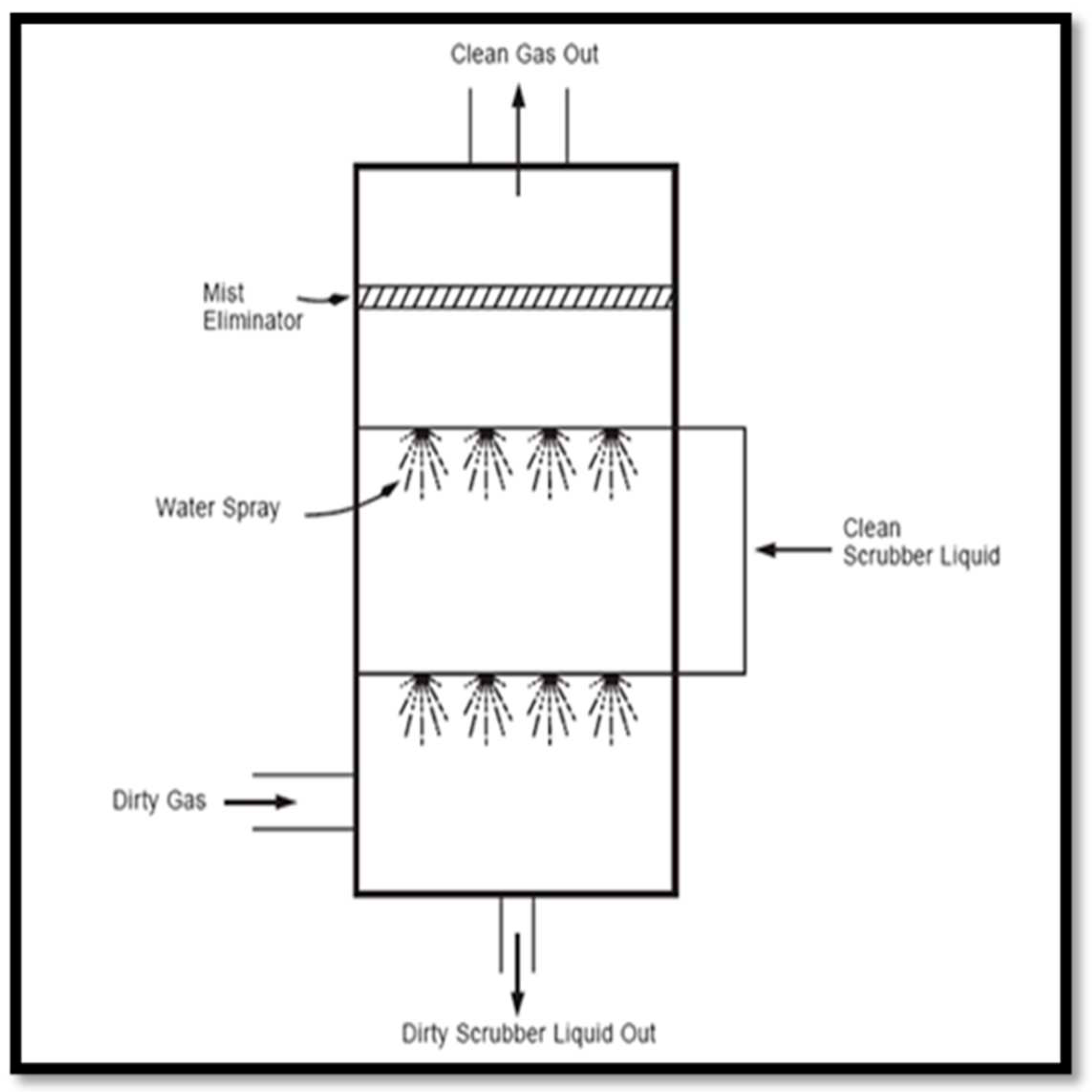

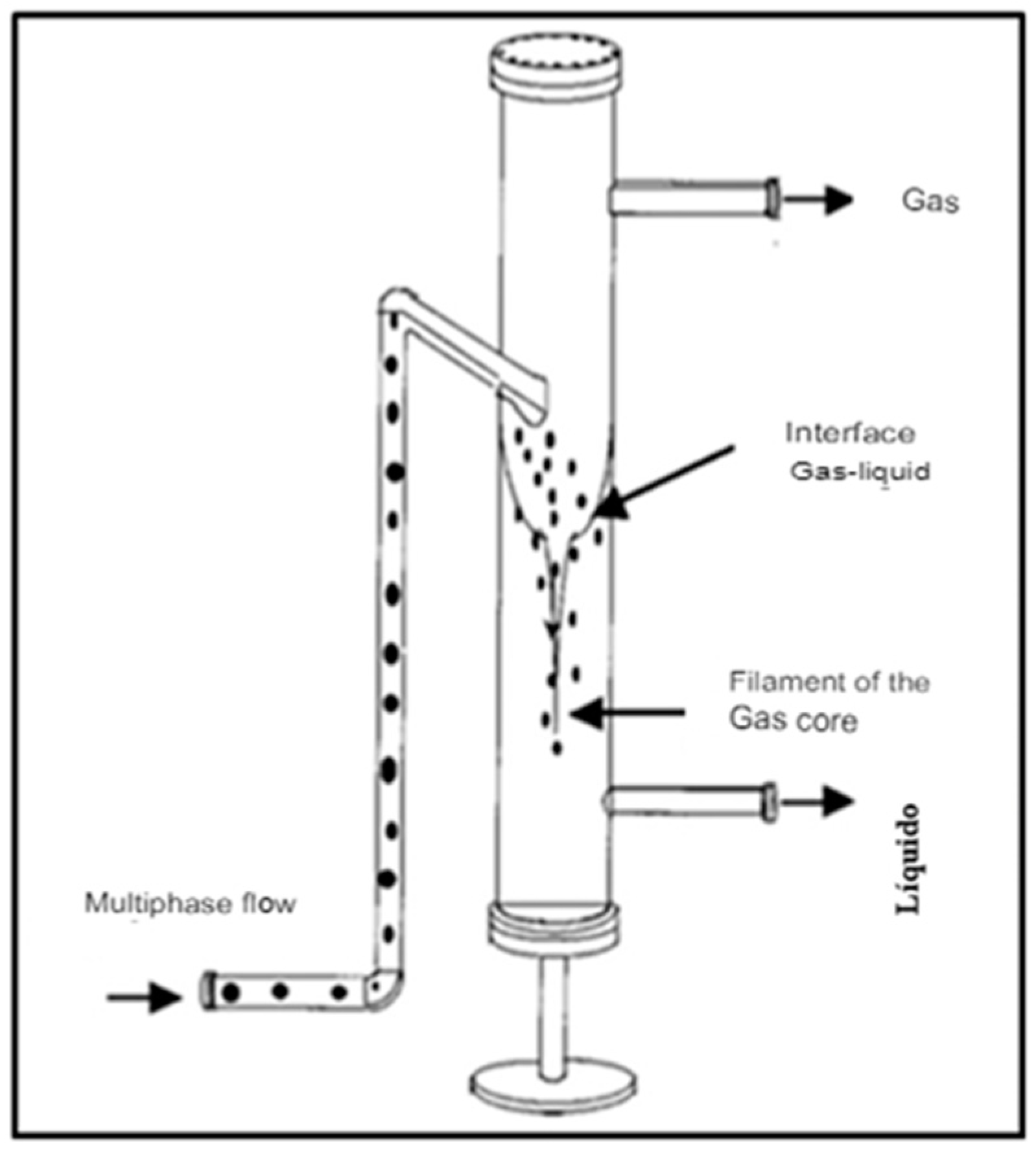

2.1. Spray Towers

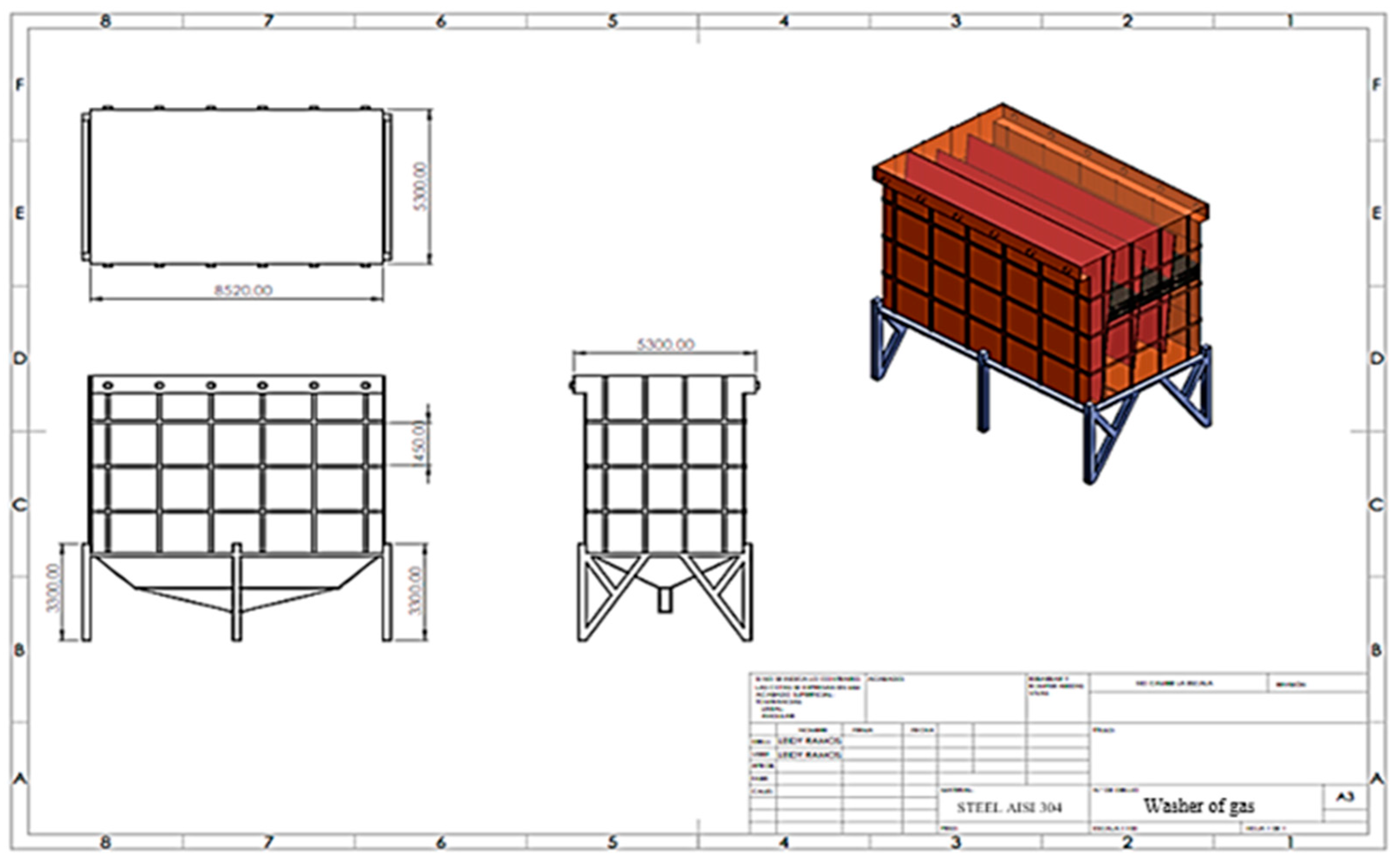

2.2. Gas scrubber

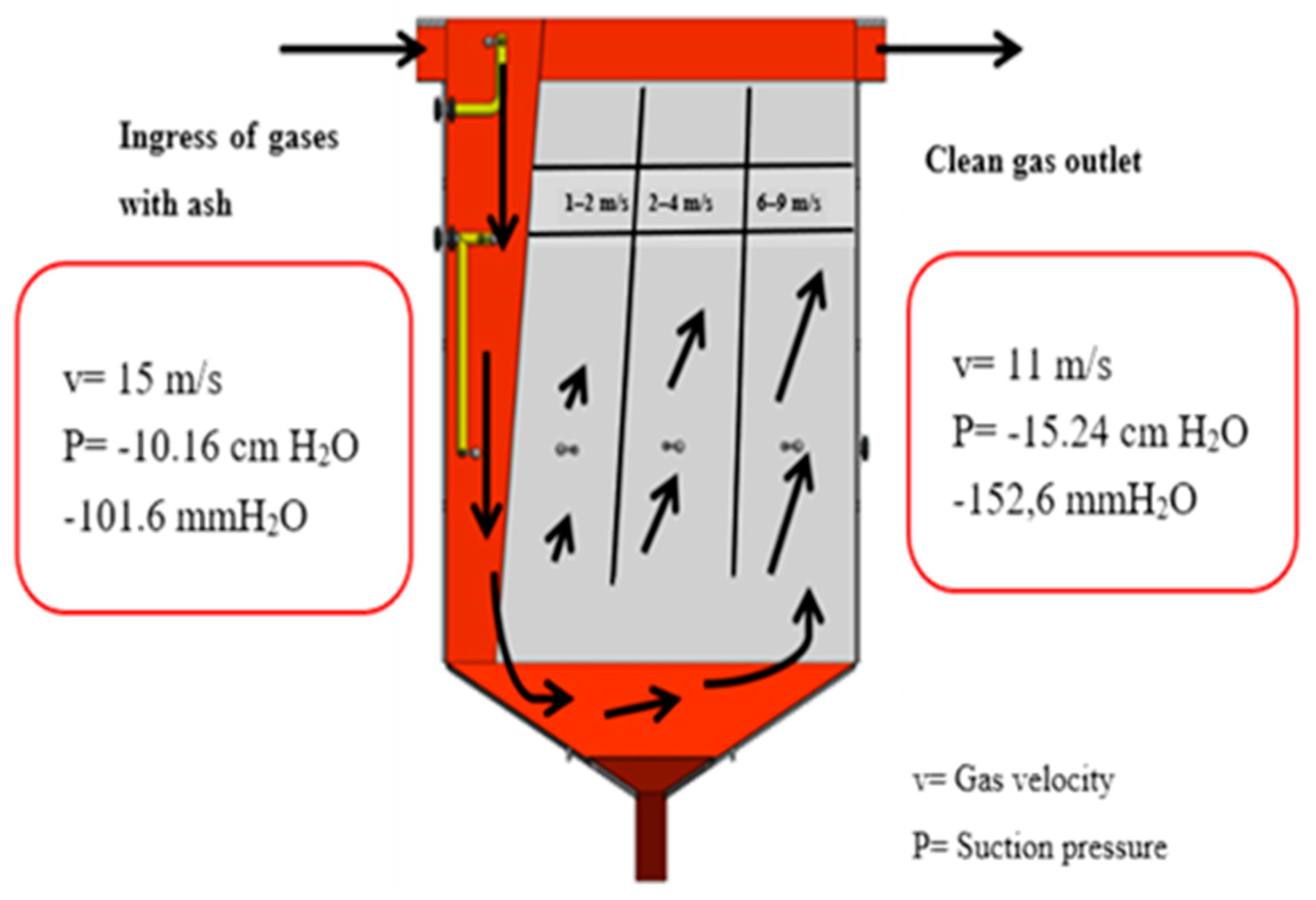

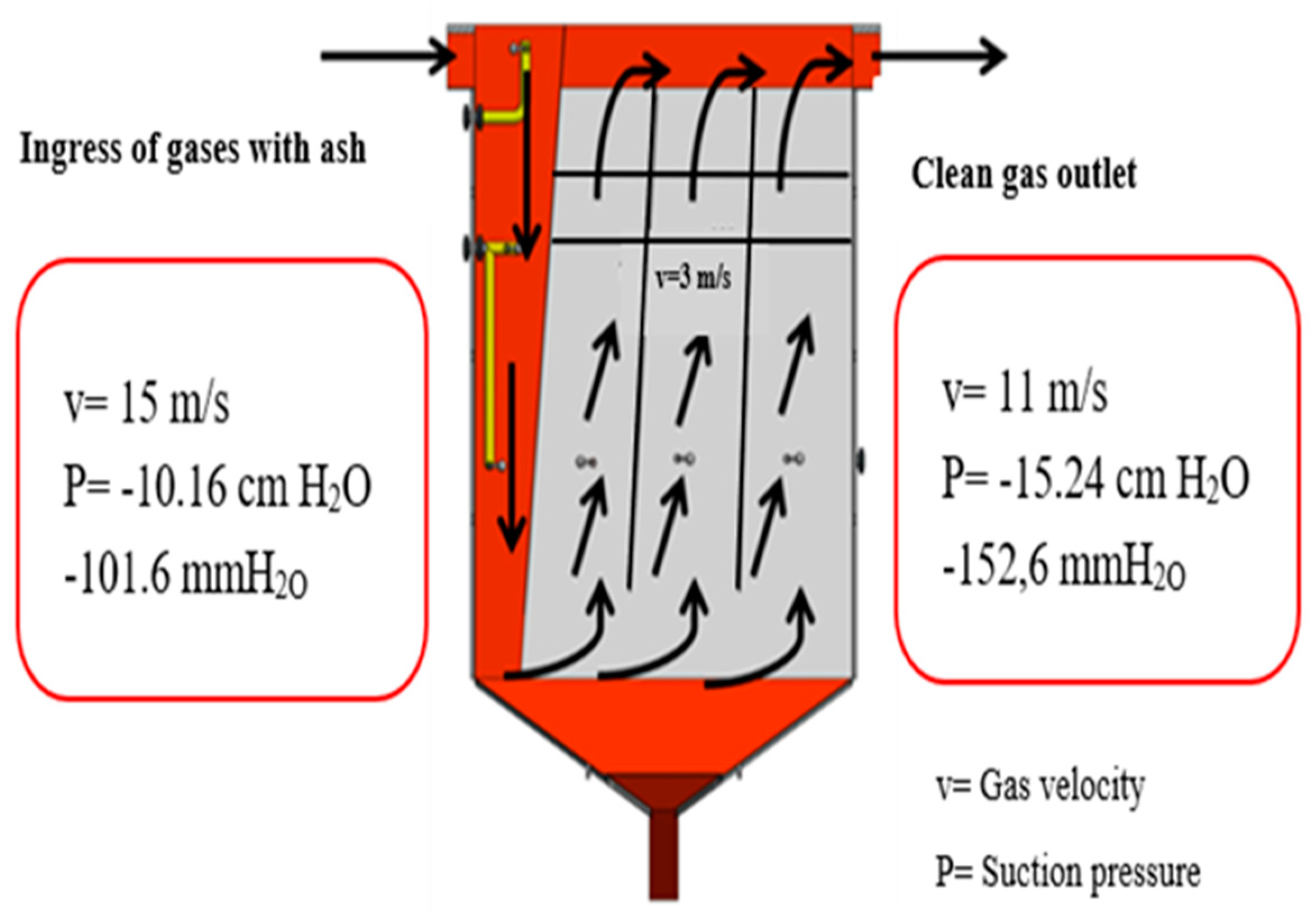

2.3. Particle-separated equipment

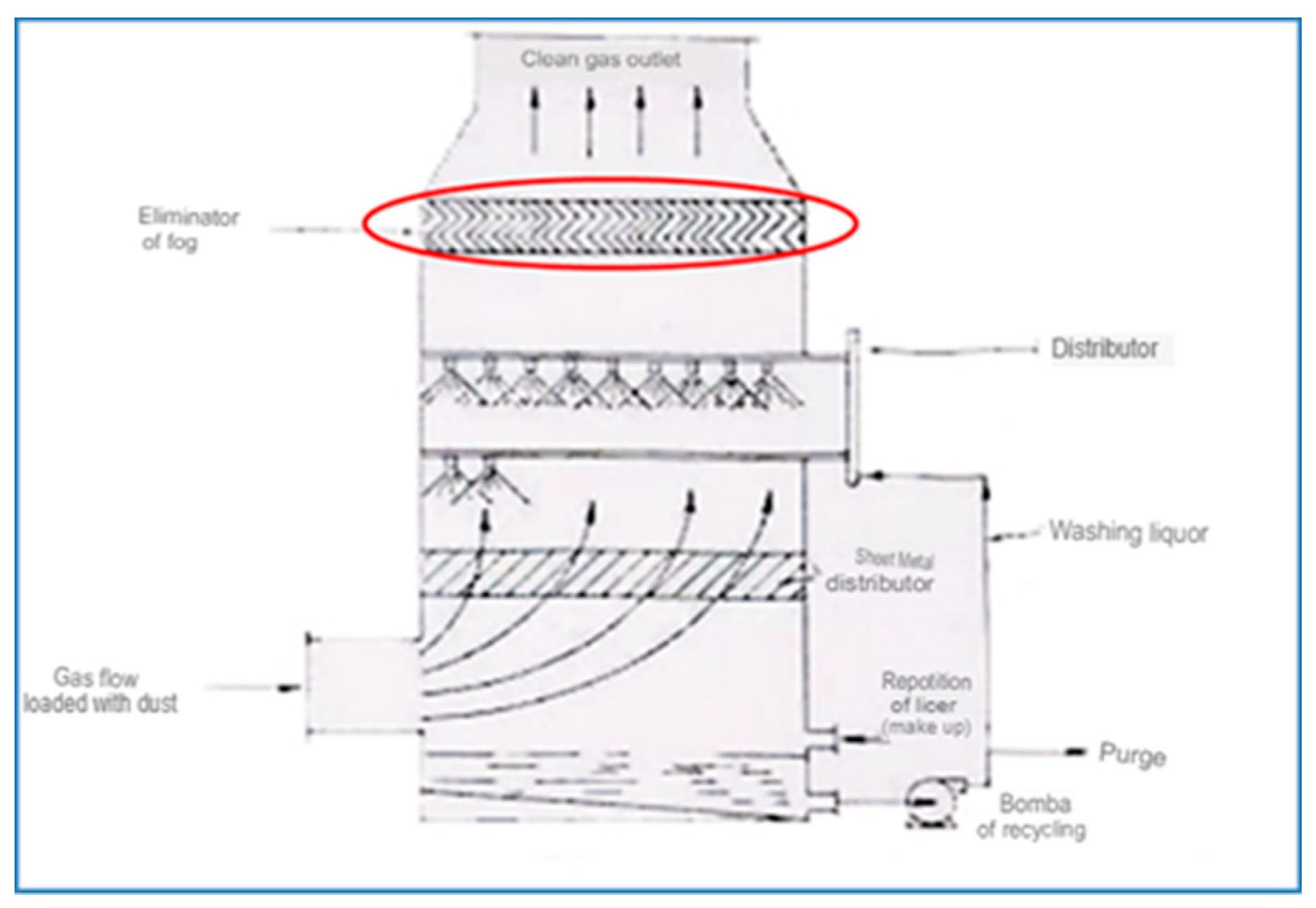

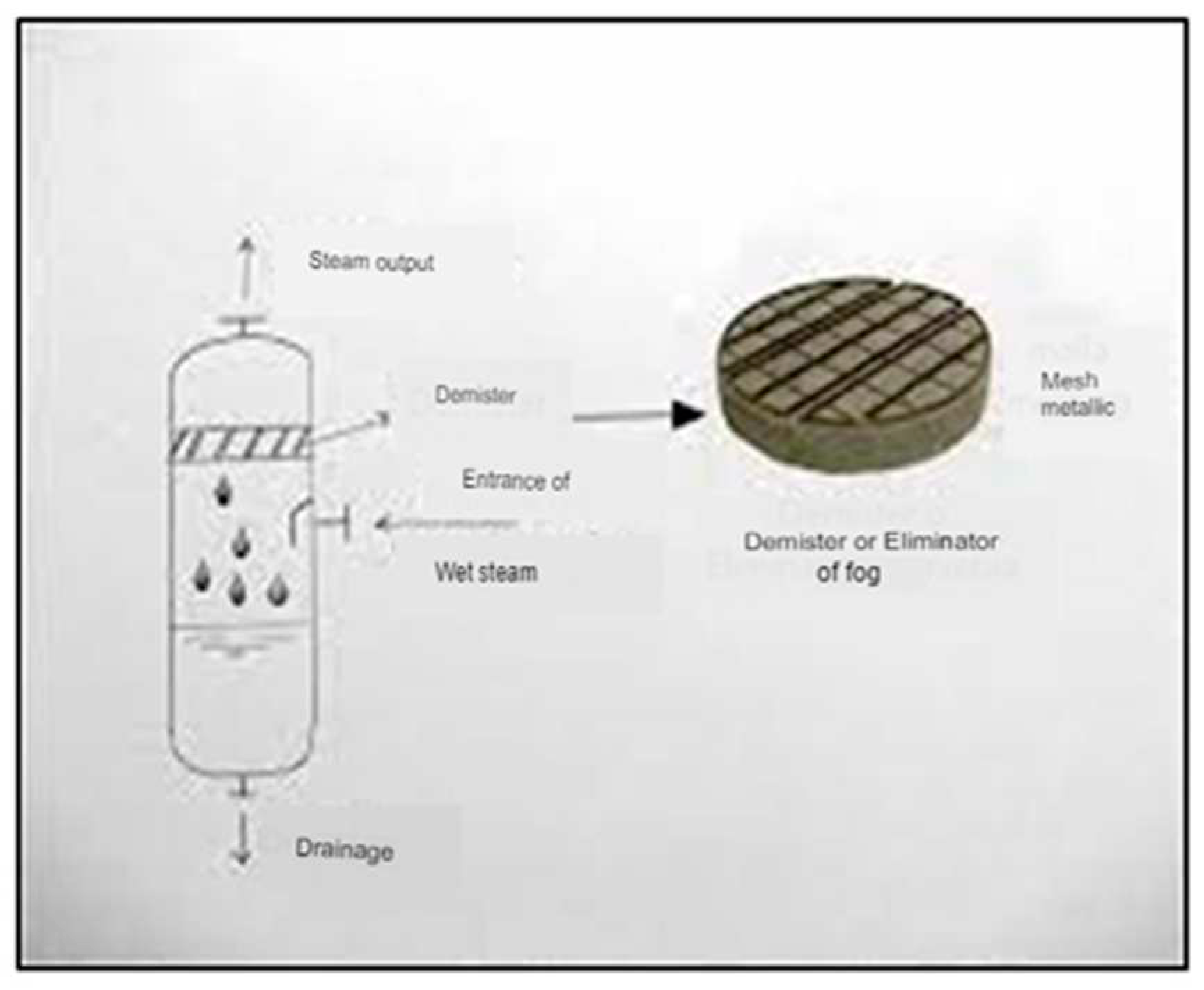

2.4. Mist eliminators

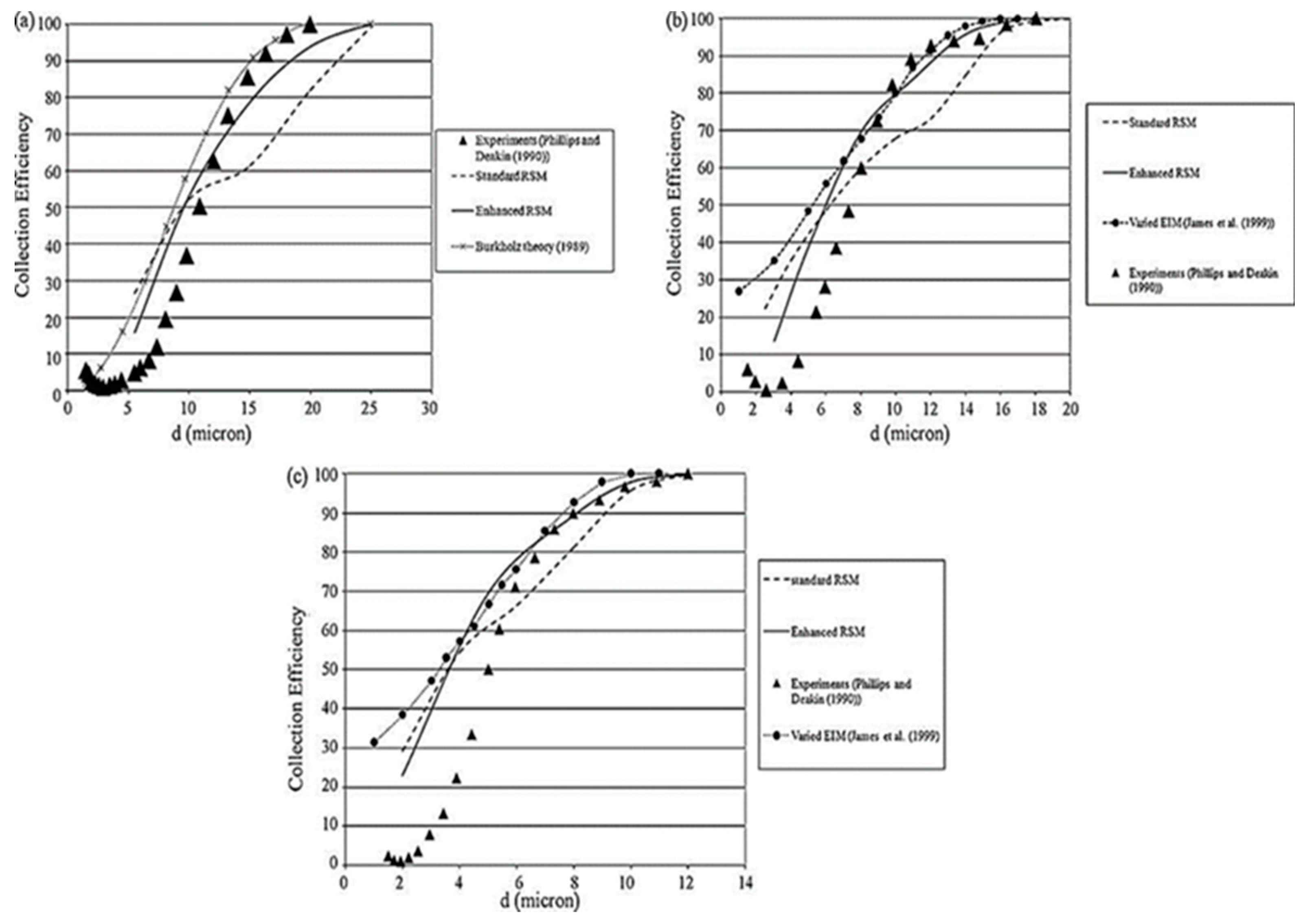

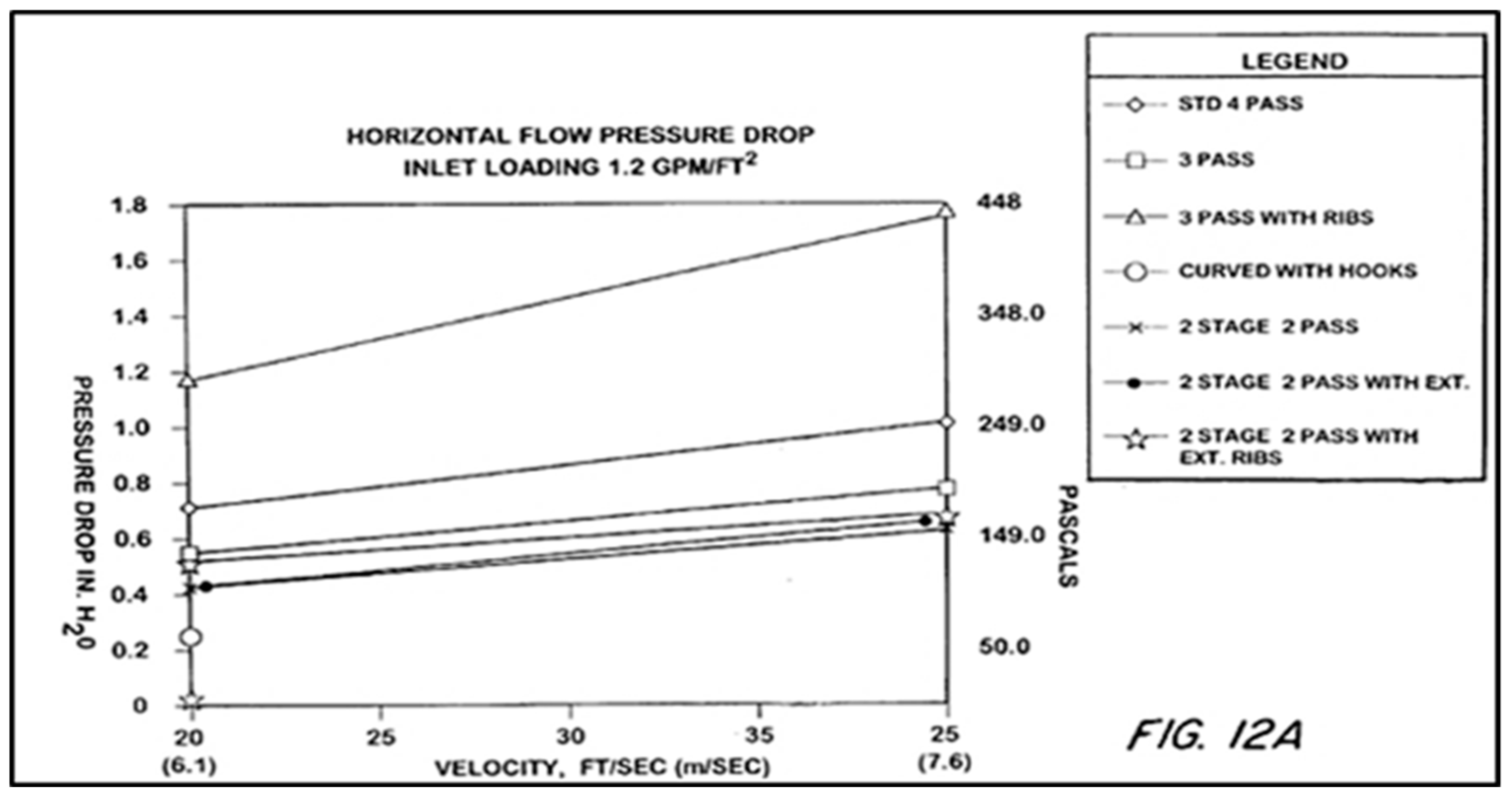

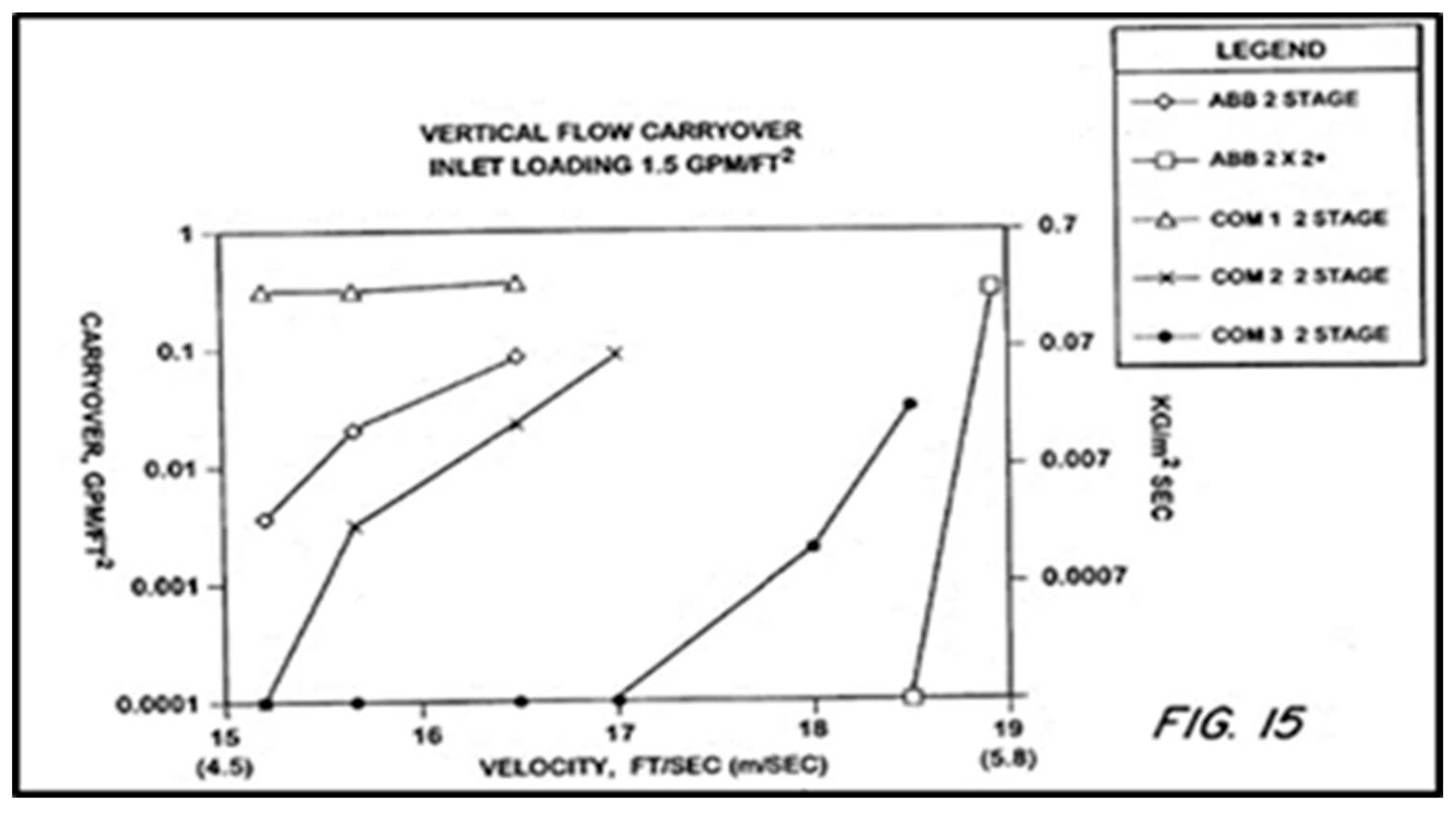

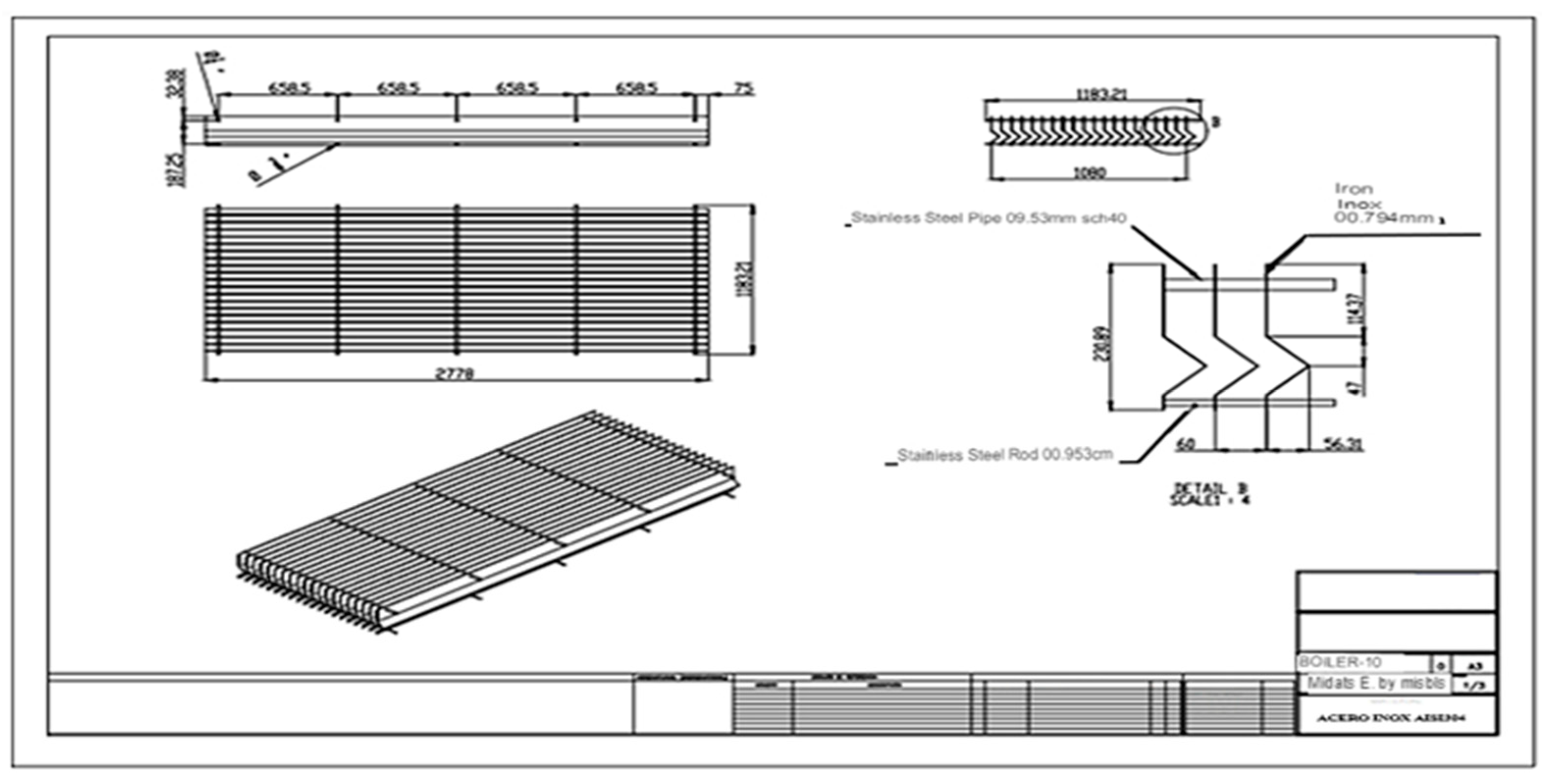

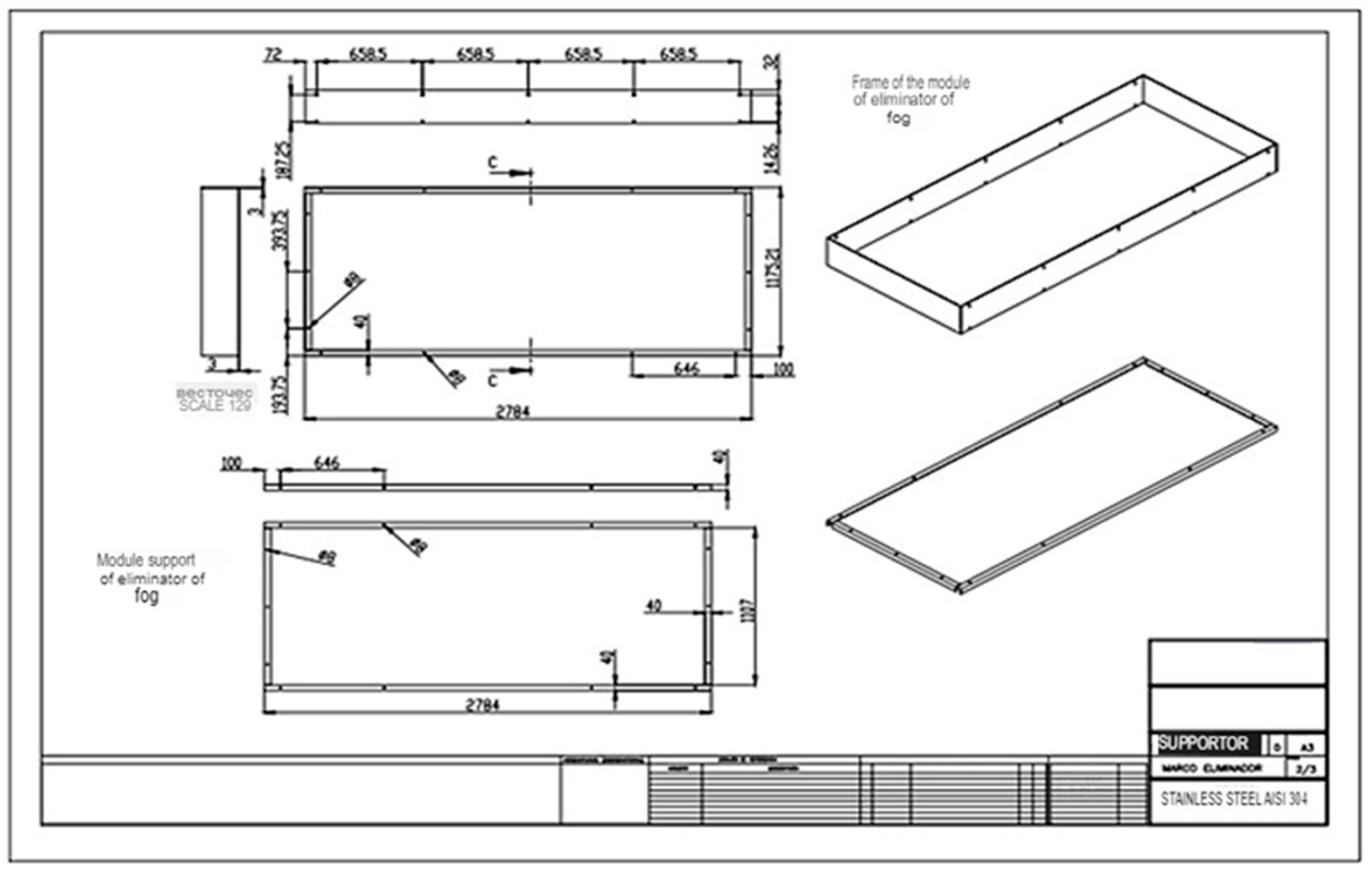

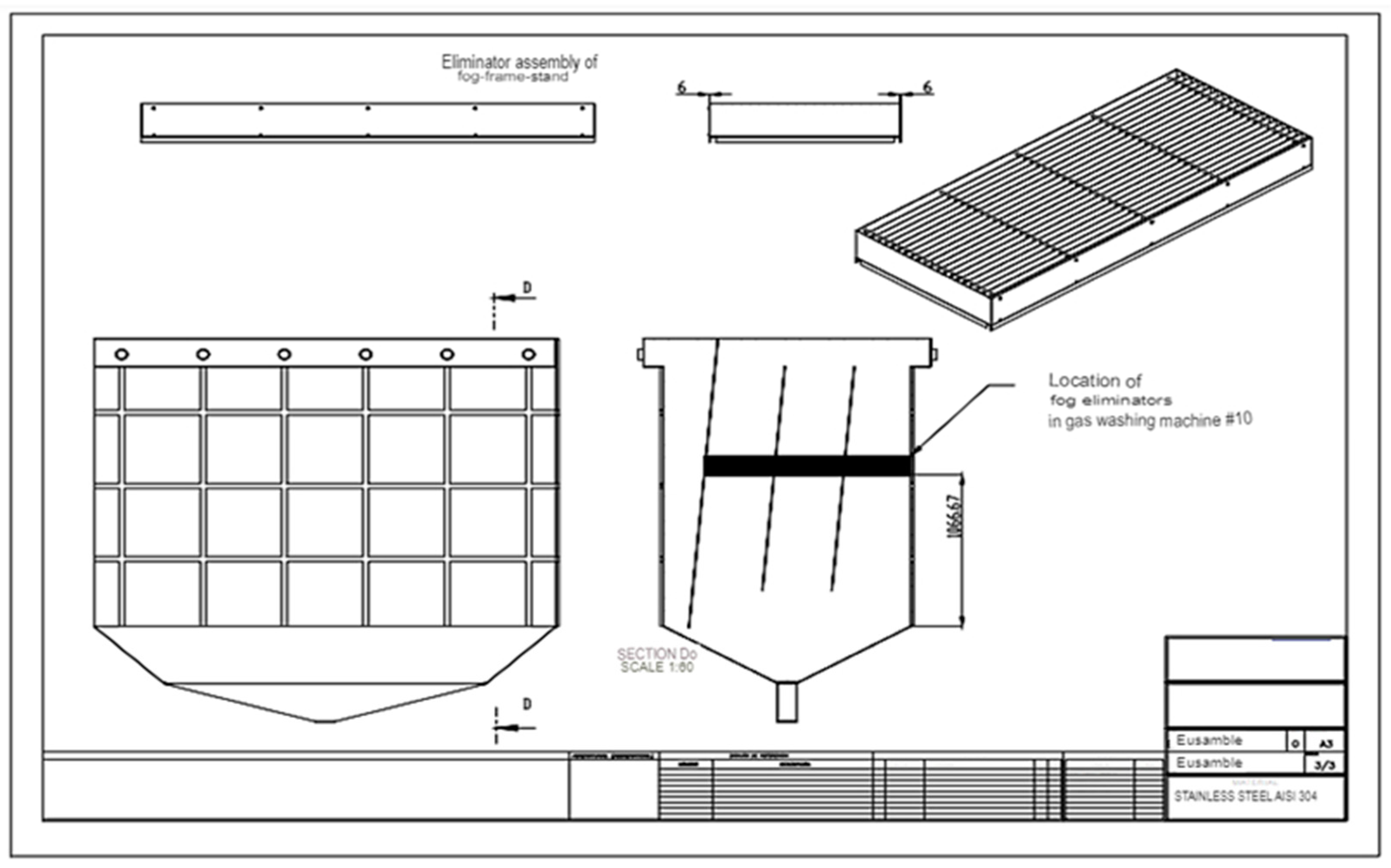

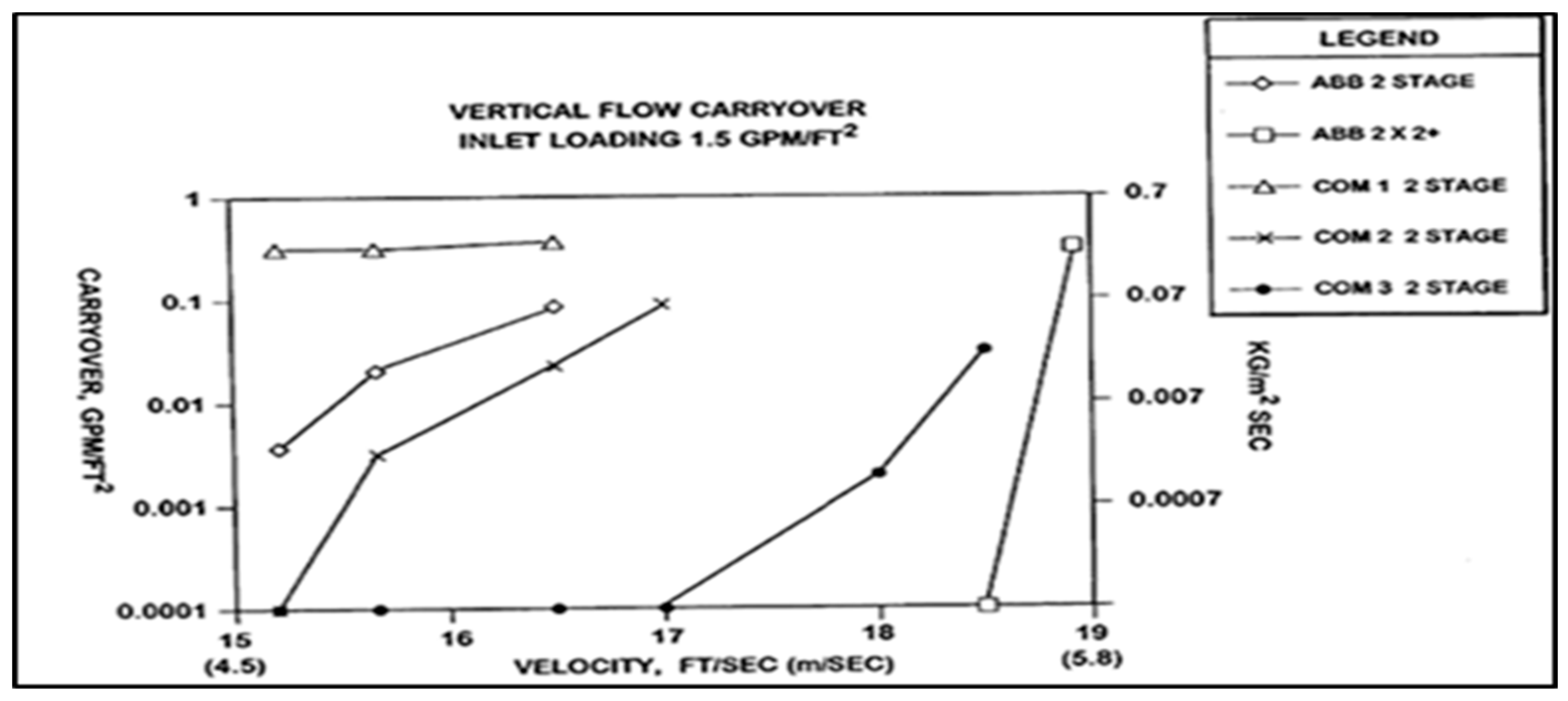

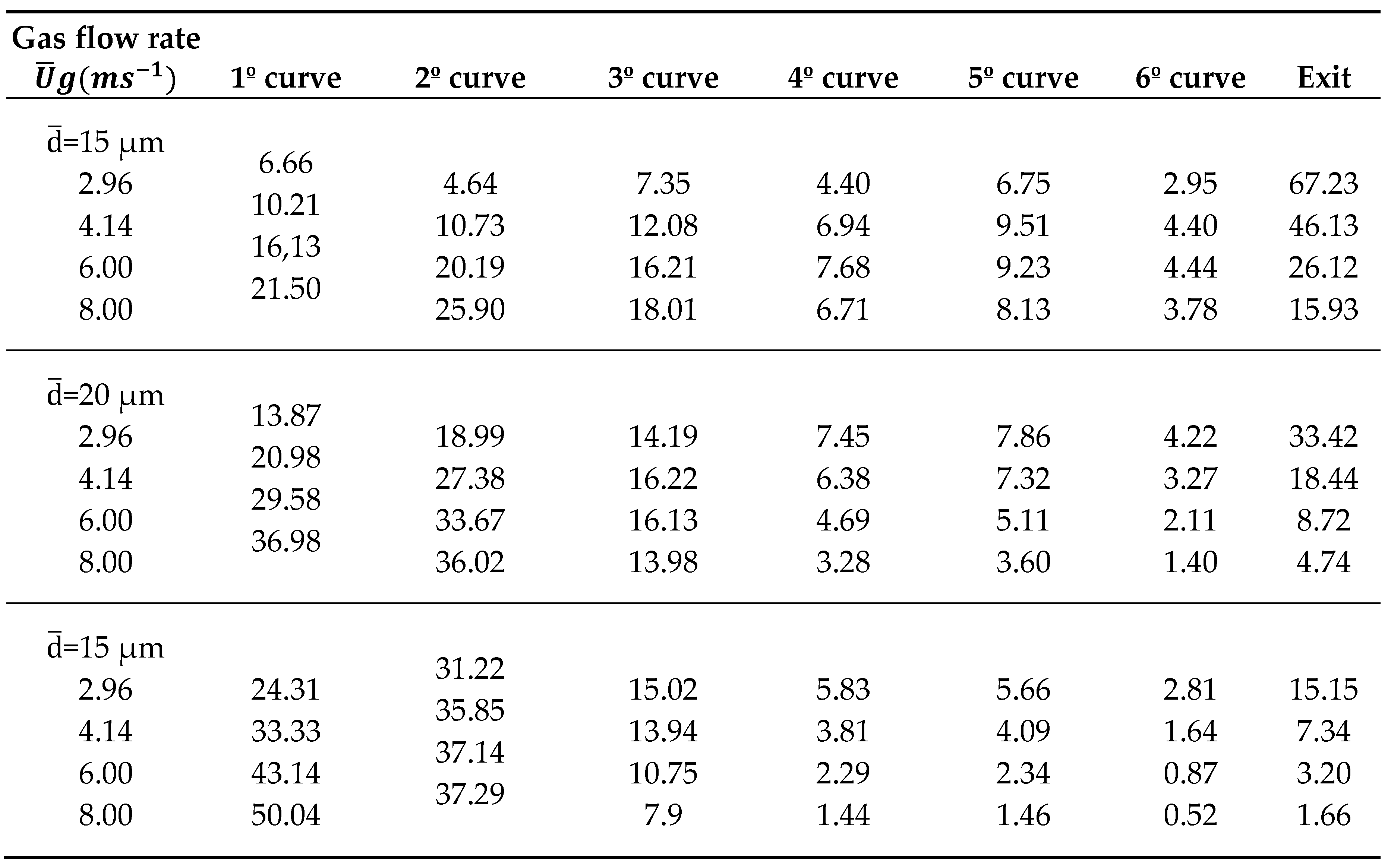

2.5. Justification of the fog eliminator model

2.6. Methodology

2.6.1. Material and procedure

2.6.2. Methods and techniques

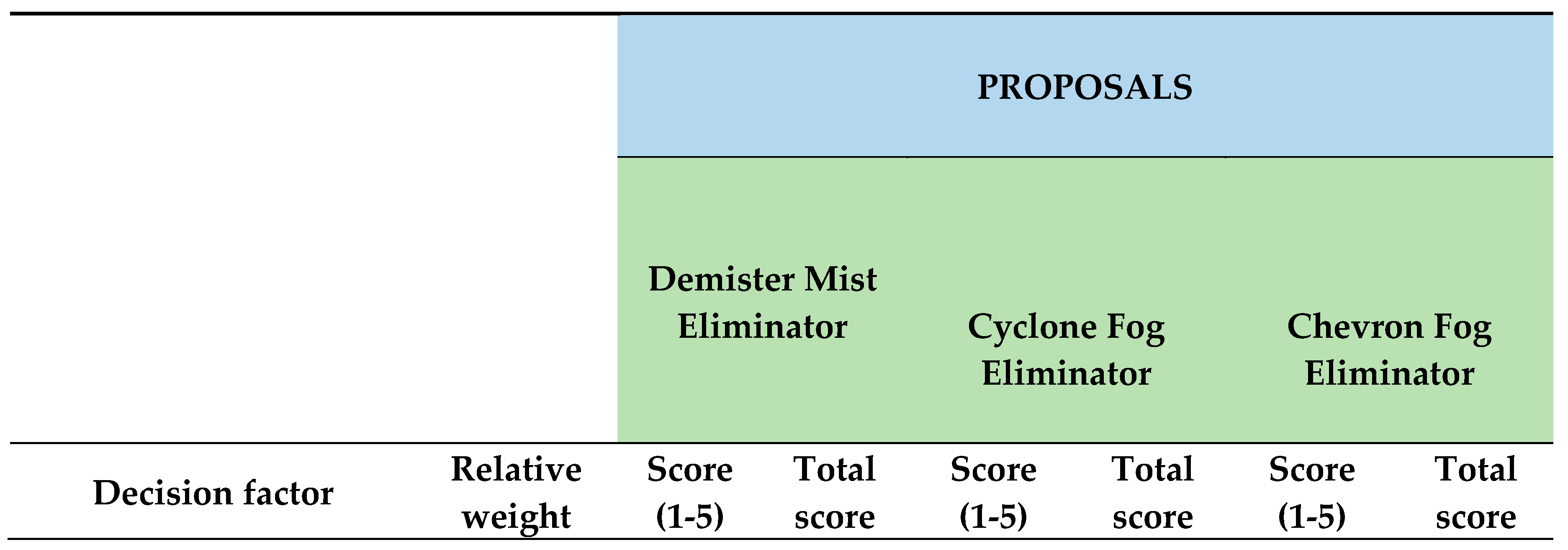

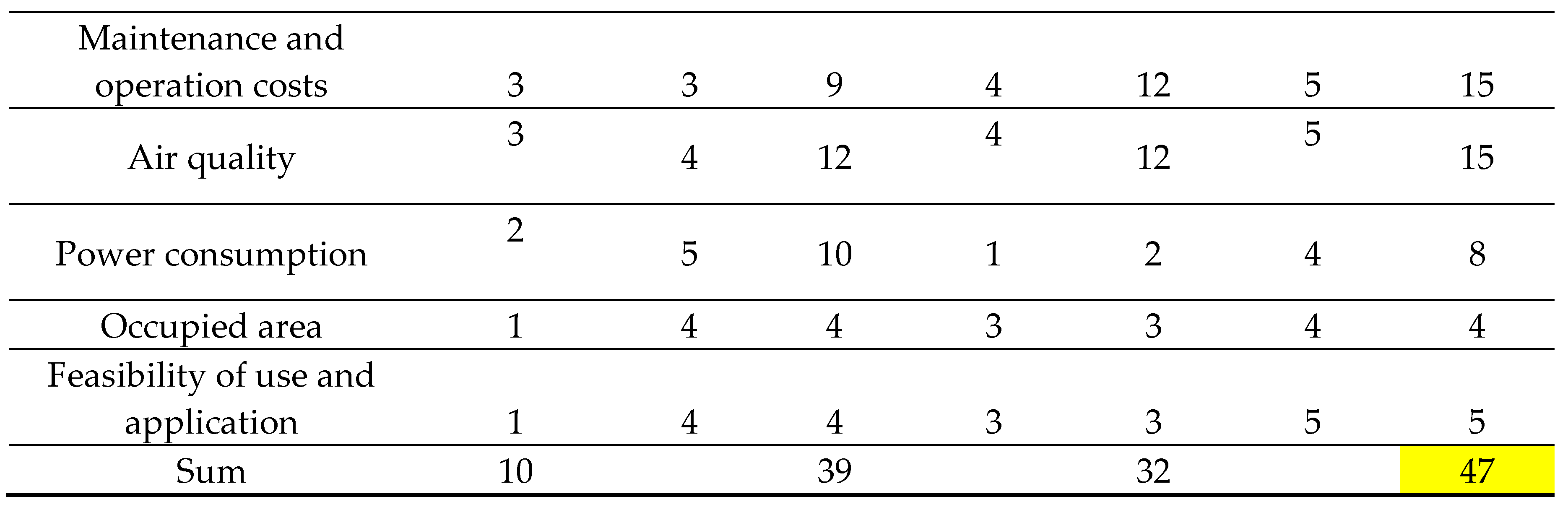

2.7. Multiple Criteria Decision Analysis Method (MCDAM)

2.8. Matching card technique

3. Results

3.1. Fog Eliminator Design

3.2. Characterization of gas scrubbing nozzles

3.2.1. Types of technologies evaluated

3.2.2. Decision Factors

3.2.3. Evaluation Matrix

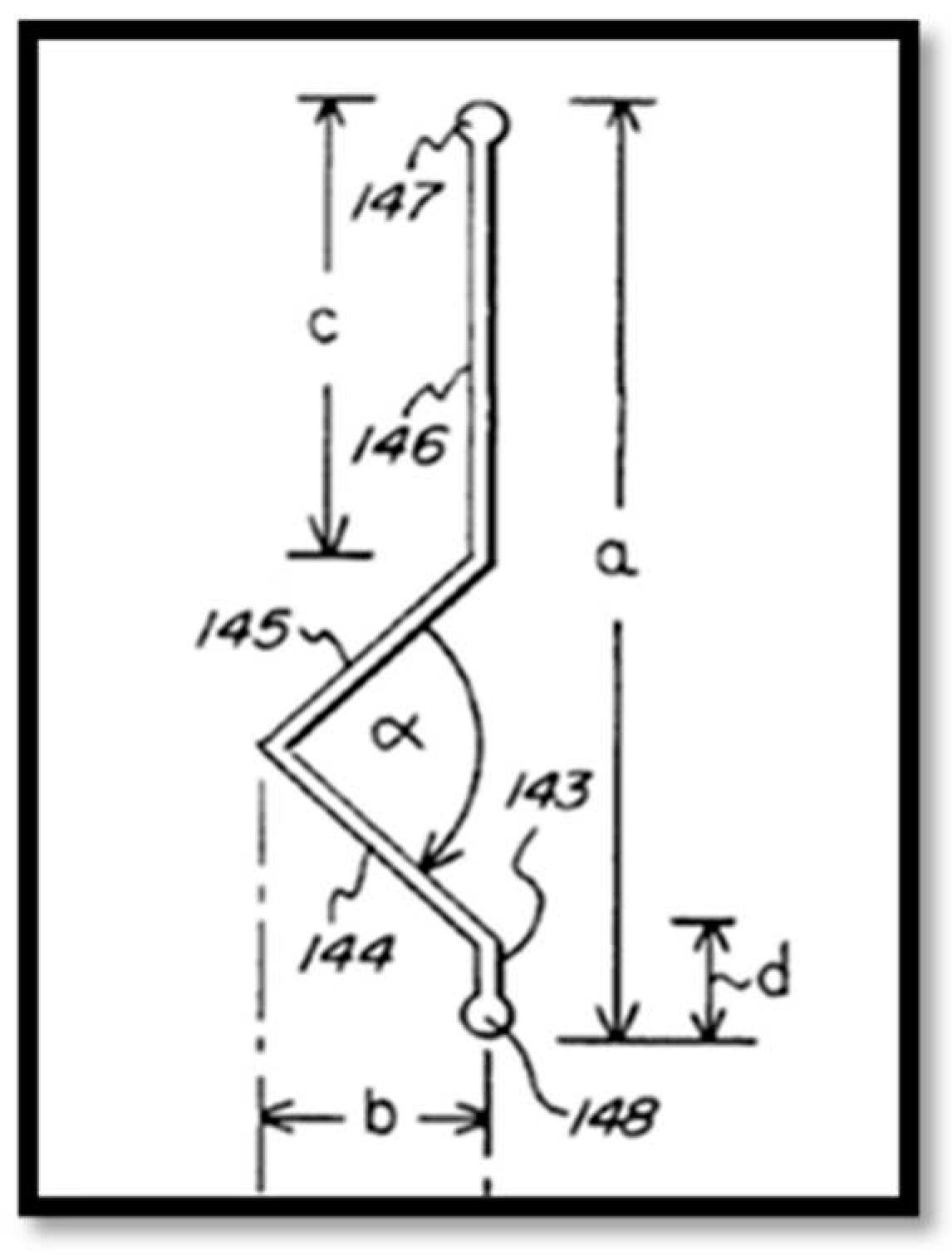

3.2.4. Design and construction of the fog eliminator

3.2.5. Implementation costs

3.2.6. Analysis of NPV and TIR, and finally the ROI for the CAVSA.

3.2.7. ROI analysis or payback period

3.2.8. Discussion of results

4. Conclusions

- The environmental pollution generated by the water-tube cauldrons of the CAVSA, affects approximately 5000 people who live within the Chirijos-Milagro neighborhood, located 500 meters from the chimneys, despite having gas scrubbers that have an ash collection efficiency of the order of 95%, they are not enough to mitigate the permanent particulate matter during the harvest seasons towards the atmosphere.

- To optimize the current wet gas scrubber system, it was essential to know the incidence of the variables that were part of the system such as; Type and amount of pollutant that is produced and emitted into the environment.

- The design of the Chevron type mist eliminator type (ABB 2 STAGE), incorporated into the original gas scrubber of the cauldron, aims to optimize the collection of ash increased by 4.39% with respect to the original efficiency, achieving the capture of 23487000 kilograms of additional ash during the harvest period.

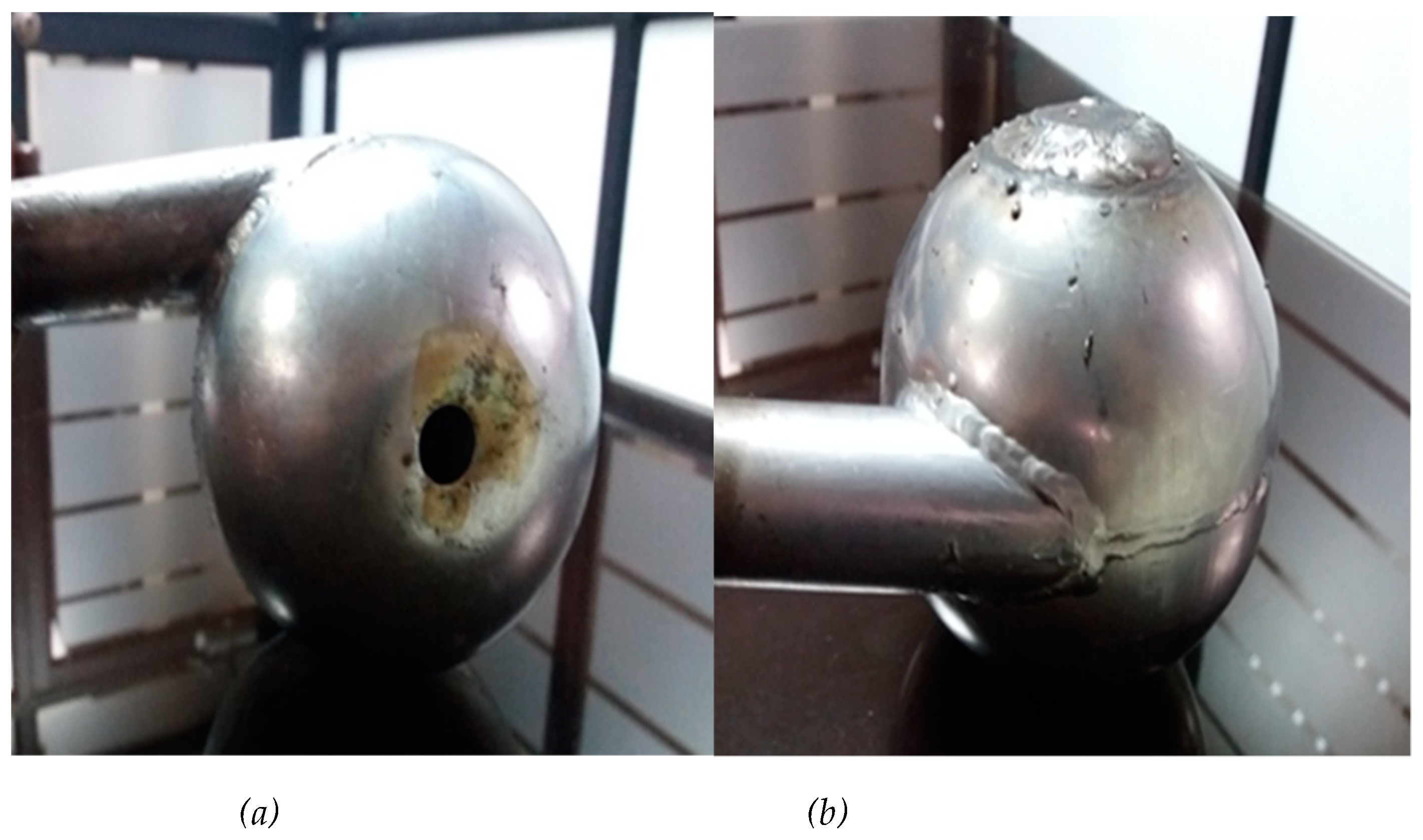

- The nozzles that are in abrasive contact with the ash and, subjected to wear of the external surface causing cracks and damage, to avoid this, the researcher suggests making an epoxy coating, ceramic or with one or two sheets of stainless steel 304 of 0.0794 cm thickness as sacrificial sheet to preserve them.

- In Ecuador there are sufficient laws, standards and environmental regulations, but it does not have a regime or legal audits, which control and regulate the operation of industrial processes, which cause polluting emissions and can be observed or punished.

- The design, construction and installation of devices for the control of emissions do not have direct economic benefits, their economic evaluation is carried out through the non-payment of environmental fines or industrial stoppages, which may be caused by insurgent uprisings of those affected, noticing in the short term the economic benefits indirectly.

- The operating costs per harvest of a proposed system are low, due to the consumption of water and energy ($2000) compared to the design, construction and assembly of equipment such as Chevron type fog eliminator (ABB 2 STAGE) ($10000 approx.).

5. Limitations

6. Implications

References

- Tapia Núñez, Lorena. Air emission standards from stationary sources.2015 Nov. Available online: https://maeorellana.files.wordpress.com/2015/11/anexo-3aire-fuentes-fijas.pdf.

- [EPA air pollution control cost manual [Book]. (D. C. Mussatti, Ed.) Research Triangle Park, NC 27711, North Carolina, Estados Unidos: Air Quality Strategies and Standards Division of the Office of Air Quality Planning and Standards, U.S. 2002. Available online: https://www3.epa.gov/ttncatc1/cica/files/c_allchs-s.pdf.

- China Chevron Vane Type Mist Eliminator Suppliers, Manufacturers—Wholesale price—YUANFENG. (n.d.). Wuxi Anaya Environmental Protection Technology Co., Ltd. (2001). [Internet]. Available online: https://es.yfenvironment.com/mist-eliminator/chevron-vane-type-mist eliminator.html.

- Ramos Núñez and Mendoza Haro. Environmental sustainability, optimization of the gas scrubber for water-tube boilers in Compañía Azucarera Valdez S.A. [Thesis]. Milagro: Unemi Repository, Milagro State University "UNEMI"; 2021 May; (13-56). Available online: https://repositorio.unemi.edu.ec/bitstream/123456789/5583/1/Ramos%20Nu%C3%B1ez%20Leidy%20Jocelyne.pdf.

- Lobato Freire GE, Castillo Castillo ÁF. Design and construction of a cyclonic separator with tangential input and axial discharge for particulate matter smaller than 40 um [Internet]. dspace.espoch.edu.ec. 2015. Available online: http://dspace.espoch.edu.ec/handle/123456789/4852 (accessed on 23 June 2023).

- Rahimi R, Abbaspour D. Determination of pressure drop in wire mesh mist eliminator by CFD. Chemical Engineering and Processing: Process Intensification. 2008 Sep;47(9-10):1504–8. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0255270107002206.

- Narimani E, Shahhoseini S. Optimization of vane mist eliminators. Applied Thermal Engineering. 2011 Feb;31(2-3):188–93. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1359431110003741.

- Galletti C, Brunazzi E, Tognotti L. A numerical model for gas flow and droplet motion in wave-plate mist eliminators with drainage channels. Chemical Engineering Science. 2008 Dec;63(23):5639–52. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0009250908004314.

- Rafeea R, Rahimzadeh H, Ahmadi G. Numerical simulations of airflow and droplet transport in a wave-plate mist eliminator. Chemical Engineering Research and Design. 2010 Oct;88(10):1393–404. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0263876210000912.

- Hernández SAmpieri, R; Fernandez &. Baptist. Research methodology. 6 ed. Mexico City: McGRAW-HILL / INTERAMERICANA EDITORES, S.A. DE C.V. 2010. [Digital book]. Available online: https://www.uca.ac.cr/wp-content/uploads/2017/10/Investigacion.pdf.

- Tashakkori A, Creswell JW. Editorial: Exploring the Nature of Research Questions in Mixed Methods Research. Journal of Mixed Methods Research. 2007 Jul;1(3):207–11. Available online: https://journals.sagepub.com/doi/pdf/10.1177/1558689807302814.

- Castiñeiras S. How to calculate a droplet separator [Internet]. Collaborative Engineering. Available online: https://ingenieriacolaborativa.com/separador-de-gotas/ (accessed on 23 June 2023).

- Cao X, Bian J. Supersonic separation technology for natural gas processing: A review. Chemical Engineering and Processing - Process Intensification. 2019 Feb; 136:138–51. [CrossRef]

- Wang S, Li H, Wang R, Wang X, Tian R, Sun Q. Effect of the inlet angle on the performance of a cyclone separator using CFD-DEM. Advanced Powder Technology [Internet]. 2019 Feb 1 [cited 2022 May 10];30(2):227–39. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0921883118308173.

- Wasilewski M, Brar LS. Effect of the inlet duct angle on the performance of cyclone separators. Separation and Purification Technology. 2019 Apr;213:19–33. [CrossRef]

- Bahadori A. Natural Gas Processing: Technology and Engineering Design [Internet]. Google Books. Gulf Professional Publishing; 2014. Available online: https://books.google.com.ec/books/about/Natural_Gas_Processing.html?id=-cffoQEACAAJ&redir_esc=y (accessed on 23 June 2023).

- Erdal FM, Shirazi SA. Local Velocity Measurements and Computational Fluid Dynamics (CFD) Simulations of Swirling Flow in a Cylindrical Cyclone Separator. Journal of Energy Resources Technology. 2004 Dec 1;126(4):326–33. [CrossRef]

- China Chevron Vane Type Mist Eliminator Suppliers, Manufacturers - Wholesale Price - YUANFENG [Internet]. Wuxi Yuanfeng Environmental Protection Technology Co., Ltd. Available online: https://es.yfenvironment.com/mist-eliminator/chevron-vane-type-mist-eliminator.html (accessed on 24 June 2023).

- ames PW, Azzopardi BJ, Wang Y, Hughes JP. A Model for Liquid Film Flow and Separation in a Wave-Plate Mist Eliminator. Chemical Engineering Research and Design. 2005 May;83(5):469–77. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0263876205727246.

- Bauver IWP, Anderson DK, Kingston WH. Mist eliminator for wet gas scrubbing [Internet]. Estados Unidos Patente nº 6,083,302. Available online: https://patents.google.com/patent/US6083302A/en (accessed on 23 June 2023).

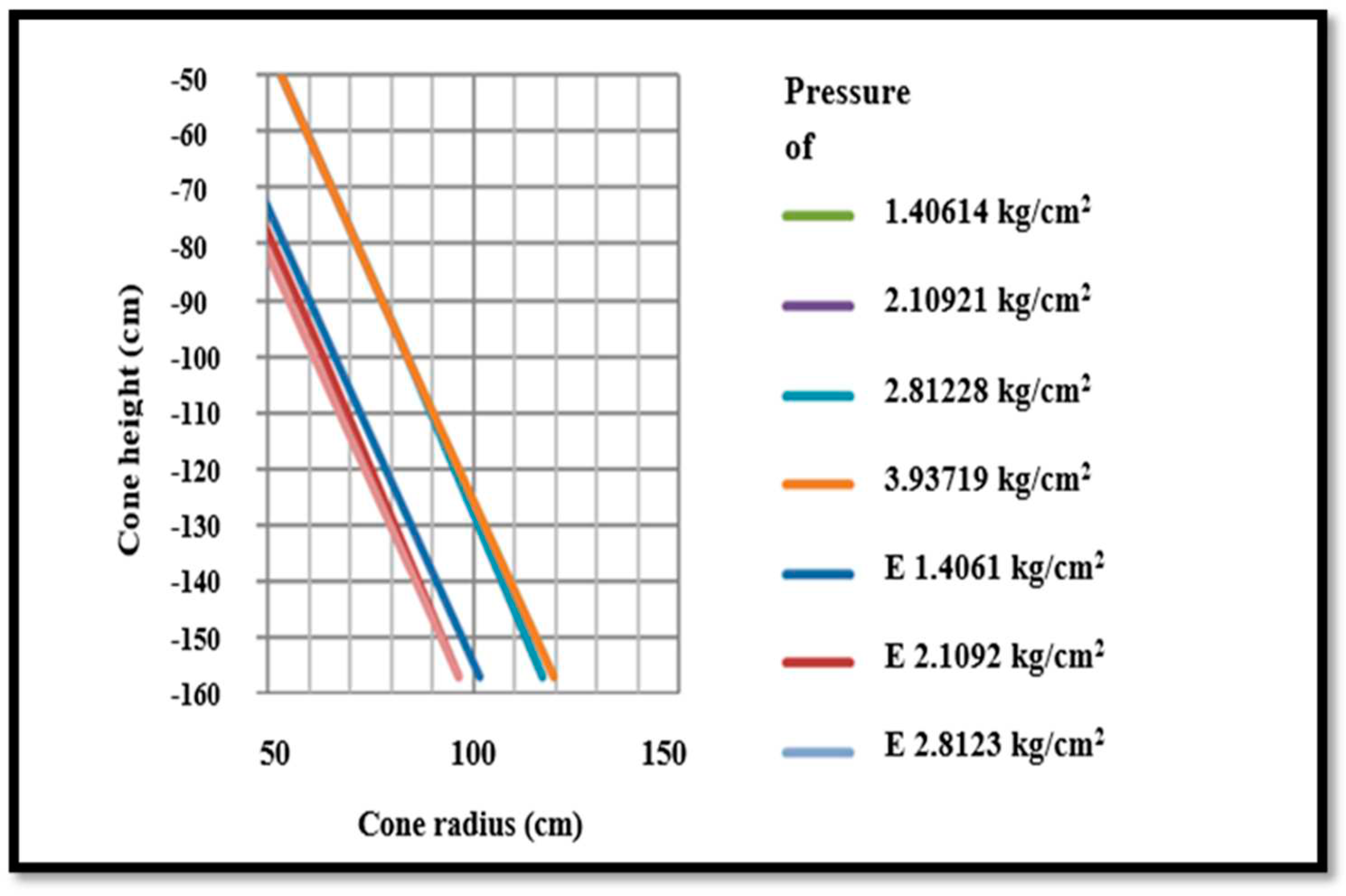

| Pressure [Kg/cm2] | Cono radius [cm] | Height [cm] | Cone thickness [cm] |

|---|---|---|---|

| 1,4062 | 53.34 83.82 119.38 |

50 100 157 |

17.78 17.78 17.78 |

| 2,1092 | 53.34 83.82 116.84 |

50 100 157 |

20.32 20.32 20.32 |

| 2,8123 | 53.34 83.82 116.84 |

50 100 157 |

20.32 20.32 20.32 |

| 3,9372 | 53.34 83.82 119.38 |

50 100 157 |

22.86 22.86 22.86 |

| Nomenclature | Dimensions [mm] |

|---|---|

| a b c d |

230.89 56.31 101.36 22.52 |

| Nomenclature | Dimensions [mm] |

| N.- | Technologies |

|---|---|

| 1 2 3 |

Demister Mist Eliminator Cyclone fog eliminator Chevron type fog eliminator |

| Decision factor | Relative weight |

|---|---|

| Maintenance and operation costs | 3 |

| Air quality | 3 |

| Power consumption | 2 |

| Occupied area | 1 |

| Ease of use and deployment | 1 |

| Workmanship for two-step fog eliminator | |||||

|---|---|---|---|---|---|

| Description | Unit | Unit weight (kg) | Total weight (kg) | Average cost ($) | Total cost ($) |

| Layout and assembly of fog eliminator blades of 0.0794cm x 0.305 m x 2.779 | 180 | 5.29 | 952.20 | 0.80 | 761.76 |

| Folding of blades to form a profile of 0.0794cm (according to plane) | 540 | 5.29 | 2856.60 | 0.25 | 714.15 |

| Drilling holes for pipe of Ø0.953cm in blades (according to drawing) | 855 | 1.00 | 855.00 | 0.25 | 213.75 |

| Drilling of holes for rod of Ø0.953cm in blades (according to drawing) | 855 | 1.00 | 855.00 | 0.25 | 213.75 |

| Layout and assembly of stainless steel support pipes for fog eliminator blades of Ø0.953cm cedula 40 x 1.169 m | 9 | 4.90 | 44.10 | 1.60 | 70.56 |

| Layout and assembly of stainless steel support rod for fog eliminator blades of Ø0.953 cm x 1.169 m | 9 | 2.19 | 19.71 | 1.60 | 31.54 |

| Layout and assembly of fog eliminator support frame 0.231 m x 2,785 m x 1,179 m | 9 | 65.18 | 586.60 | 0.80 | 469.28 |

| Layout and assembly of fog eliminator support with 40 mm Stainless steel angle. | 9 | 14.64 | 131.79 | 0.80 | 105.43 |

| Total | 6301 | Total ($) | 2580 | ||

| Materials for the two-step mist eliminator | |||||

|---|---|---|---|---|---|

| Description | Quantity | Price ($ c/u) | Total | Average cost of ordering ($) | Total Cost ($) |

| Planchas Inox AISI 304 121.92 cm x 243.84 cm por 0.079375 cm | 180 kg | 5.29 | 952.20 | 3.05 | 2901.35 |

| Planchas Inox AISI 304 of 0.3175 cm | 9 kg | 65.18 | 586.60 | 3.17 | 1858.94 |

| Stainless steel pipe AISI 304 of 0.9525 cm cedula 40 | 9 kg | 5.85 | 52.61 | 6.73 | 354.03 |

| Varilla Stainless steel AISI 304 0.635 cm | 9 kg | 2.19 | 19.71 | 0.99 | 19.51 |

| 40 x 40 x 4 mm angle | 9 m | 7.91 | 71.17 | 10.17 | 723.82 |

| Total ($) | 5858 | ||||

| Team | Total(kg) | Unit cost ($) | Total cost ($) |

|---|---|---|---|

| Workmanship for two-step mist eliminator with ext. | 6301 | $ 0.41 | $ 2580 |

| Materials for the two-step mist eliminator with ext. | 1.00 | $ 5857.66 | $5858 |

| Subtotal | 6.301,00 | $8438 | |

| 10% | $844 | ||

| Total | $9282 |

| Data | |

|---|---|

| Initial investment | 9 282 |

| Discount rate | 12% |

| Revenue | 160000 |

| Expenses | 104000 |

| Period | Revenue | Expenses | Net cash flows | Present value of cash flow |

|---|---|---|---|---|

| 0 | -9282 | -9282 | ||

| 1 | 32000 | 20800 | 11200 | 10000 |

| 2 | 32000 | 20800 | 11200 | 8928.57 |

| 3 | 32000 | 20800 | 11200 | 7971.94 |

| 4 | 32000 | 20800 | 11200 | 7117.80 |

| 5 | 32000 | 20800 | 11200 | 6355.18 |

| Net Present Profit (BPU) | 40373.49 | |||

| Net present value (NPV) | $1091.49 | |||

| Internal rate of return (IRR) | 95% | |||

| Period | Present value of cash flow | Accumulated |

|---|---|---|

| 0 | -9282 | |

| 1 | 10000 | 18928.57 |

| 2 | 8928.57 | 18928.57 |

| 3 | 7971.94 | 26900.51 |

| 4 | 7117.80 | 34018.31 |

| 5 | 6355.18 | 40373.49 |

| Recovery period | 0.92 years | |

| Input charging (Kg/s*m²) | Inlet load (l/min*m2) | Efficiency (Kg/s*m²) | Efficiency (l/min*m2) | Accumulated |

|---|---|---|---|---|

| U.S. Study | ||||

| 1.5 | 61.1 | 0,005 | 0,204 | 99,96 |

| Expected results in the proposal | ||||

| 1,12 | 67,2 | 0.008 | 0,407 | 99,39 |

| Particulate emission (kg/h) | Efficiency % | Emission of particles into the atmosphere (kg/h) | Harvest hours | Particulate emission in the harvest period (kg) |

|---|---|---|---|---|

| Without the fog eliminator | ||||

| 891 | 95 | 44.6 | 4320 | 192519 |

| With the fog eliminator | ||||

| 891 | 99.4 | 5.4 | 4320 | 23487 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).