1. Introduction

The cape gooseberry (Physalis peruviana Linnaeus) is a fruit belonging to the Solanaceae family and genus Physalis. This plant is native to the South American Andes and produces yellow-orange juicy berry-like fruits, with a diameter between 1.25 and 2.50 cm and weight between 4 and 10 g, depending on harvesting conditions (Cardenas-Barboza et al., 2021). It is a climacteric fruit characterized by a bittersweet and fresh flavor, pleasant texture and aroma (Akhtar et al., 2019; González-Locarno et al., 2020), which has a high nutritional value due to the notable presence of compounds such as vitamins (ascorbic acid, thiamine, riboflavin and niacin) and minerals (calcium, phosphorus and iron) (Etzbach et al., 2018). Additionally, it has a high content of carotenes, and other minority compounds that favor its antioxidant capacity and gives it a hepatoprotective, anti-mutagenic, purifying, immune system strengthening and cholesterol and blood sugar lowering effect (Akhtar et al., 2019; Etzbach et al., 2018). All this has led cape gooseberry to be positioned in the market of healthy food products and its application in diverse products such as ice cream, yogurts, jams, sauces, beverages, dehydrated, snacks, desserts and jams. However, its majority form of commercialization is fresh, which makes it a highly perishable food due to its moisture content, sensitivity to ethylene, high respiratory activity, and the incidence of ripening processes that accelerate senescence phenomenon and determine the detriment of its texture, flavor, and aroma conditions. Thus, limiting its shelf life between 10 and 12 days, approximately (Cardenas-Barboza et al., 2021; González-Locarno et al., 2020). Colombia is the main producer and exporter of cape gooseberry, with about 90% of world production. According to the Colombian Ministry of Agriculture and Rural Development, from 2016 to 2020, the cultivation area increased from 1023.1 to 1372.4 hectares. In the same period, there was an increase in production from 15,111.8 to 19,775.7 tons (Ministerio de Agricultura y Desarrollo Rural, 2022). Regarding exportation, according to data provided by National Foreign Trade Association (ANALDEX), during the period 2016-2020, Colombia exported a net amount of 50,865.7 tons, representing an average growth of around 9.1% per year. Therefore, this fruit is also appreciated in the international markets, which makes it a fruit of economic importance for the country.

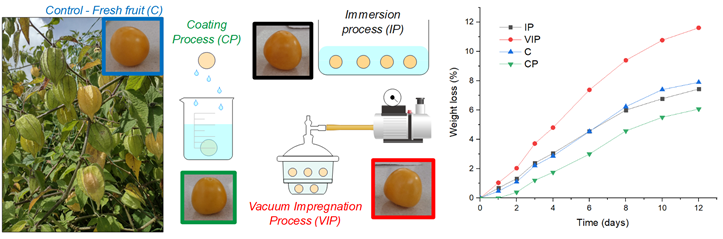

One of the challenges that Colombia faces in the export of cape gooseberry is the demand for fresh quality products, since according to data provided by the National Planning Department (DNP) from the total annual production of fruits and vegetables, about 21% is lost or wasted, which corresponds to between 1,813 and 2,373 tons of cape gooseberry per year, being the main limiting factors weight loss during storage and spoilage by microorganisms, such as Cladosporium, Phomopsis, Pestalotia, Botrytis cinerea and Alternaria spp (Heredia et al., 2017). Among the strategies that have been developed for the conservation of fresh fruits are: high pressures, ultrasound, ionizing radiation, pulsed electric fields, cold plasma, and packaging in modified atmospheres (Bisht et al., 2021; Denoya et al., 2021; Pérez-Martínez et al., 2021). However, the high cost of processing and the acquisition of specialized equipment, limit their use in the Colombian context. Other strategies have used minimal processing methods showing promising results. In the specific case of cape gooseberry, coatings made from beeswax and whey protein (Balaguera-lópez et al., 2014) chitosan and aloe vera (Balaguera-lópez et al., 2014), and chitosan and rosemary essential oil (González-Locarno et al., 2020), have been used. In all of them, a decrease in weight loss of the fruit during storage was achieved, prolonging its shelf life, since the freshness of fruits and vegetables decreases, according to Pinzón et al. (2015), when samples have weight losses of more than 10% (Pinzón et al., 2015). Vacuum impregnation has also been applied for the conservation of cape gooseberry, based on the incorporation of various components such as ethanolic extracts of annatto leaves and seeds (Ciro, 2012), and micronutrients like calcium and vitamins B9, C, D, and E (Puente et al., 2011). Likewise, immersion in technological coadjutants such as citric and ascorbic acids, and calcium chloride have been evaluated for the minimum processing of horticultural and fruit products. Thus, those preservation agents help to prevent browning reactions and provide stability to the matrix against external microbial alterations. In addition, the application of sodium carbonate in fruit products has been proven to inhibit microorganisms such as Botrytis cinerea (Turkkan et al., 2017) and the addition of calcium salts has been used to improve the textural characteristics of horticultural products (Y. Duarte-Correa et al., 2020). However, for the evaluation of the quality characteristics of cape gooseberries, their use in combination with other substances in various postharvest treatments has not been studied before. Therefore, in this study the objective was to evaluate different postharvest processing alternatives: coating process (CP), vacuum impregnation process (VIP), and immersion process (IP), on the conservation of some quality characteristics of cape gooseberry (Physalis peruviana L.), including its sensory analysis. Moreover, different conditions were studied in the selected treatment.

2. Materials and Methods

2.1. Materials

This research used the Colombia ecotype of cape gooseberry (Physalis peruviana L.) with no mechanical affectations and free of damage caused by pathogens and insects. The fruits were category 1 with caliber D and E (20.1–22.0 and > 22.0 mm diameter, respectively) and presented a maturity index between 4 and 6 based on Colombian Technical Standard NTC 4580 (NTC 4580. Frutas Frescas. Uchuva. Especificaciones, 1999) and were harvested in a small village called Mesopotamia (5°53′03″N 75°18′58″O), located east of Medellín city.

2.2. Characterization of fresh and treated fruits.

Moisture content (%) was determined according to the AOAC method (AOAC, 2000). pH was measured using a pH-meter (Hanna Instruments pHmeter, HI3220, Washington, USA). Total acidity was calculated by titration with NaOH (0.1 N) using phenolphthalein as an indicator until reaching the neutralization of all the organic acids present. It was expressed as a percentage of citric acid. The color assessment was determined according to the CIEL*a*b methodology. Finally, the total soluble solids (TSS) were determined through refractometer readings (Brixco Instruments).

2.3. Determination of vitamin C, carotenoids, total phenolic content, and antioxidant capacity

- -

Vitamin C: Vitamin C was determined following the method used by Contreras-Calderón et al. (2011), based on titration of the analyzed samples with a 2,6-dichlorophenolindophenol standard solution in an acid environment.

- -

Carotenoids: Carotenoids were determined following the methodology described by Rodriguez-Amaya and Kimura (2004) using the absorption coefficient for β-carotene in petroleum ether solvent (A= 25 92). 3 g of homogenized fruit were placed in a falcon tube, and 50 mL of cold acetone were added. Then, they were homogenized in a vortex, and filtered in a Buchner funnel with filter paper. Samples were washed with small amounts of acetone, until colorless. Subsequently, in a decanting funnel of 500 mL, 40 mL of petroleum ether and the acetone extract (obtained previously) was added. Distilled water (~300 mL) was slowly added to avoid the formation of an emulsion. 3 or 4 washes were carried out to eliminate residual acetone. Finally, the petroleum ether was collected in a 50 mL volumetric flask by passing the solution through a funnel containing anhydrous sodium sulfate to remove residual water. The separating funnel was washed with petroleum ether collecting the washings in the volumetric balloon, gauged with petroleum ether, and the absorbance was read at 450 nm (CARY 50 BIO, UV-vis). The analyses were performed in triplicate and the results were expressed as μg/100g.

- -

Total Phenolic Content (TPC): TPC was determined based on the method of Folin– Ciocalteau, following the steps used by Osorio-Arias et al. (2019). Firstly, fruits were dissolved in a methanol/water (50:50) solution and an acetone-water solution (70:30) to make the extracts. Then 20 mL of extract was mixed with 1580 mL of distilled water and 100 mL of Folin–Ciocalteau reagent; after 2 min 300 mL of sodium carbonate (20 g/100 mL) was added and the final mixture was stored in the dark for 1 h. The absorbance of the solution was measured in a spectrophotometer (CARY 50 BIO, UV-vis) at 725 nm and the absorbance was compared with a calibration curve based on gallic acid. The analyses were performed in triplicate and the results were expressed as mg equivalents of gallic acid per 100 grams of fresh sample (mg GAE/100 g).

- -

Antioxidant Capacity: Two different methods were used to evaluate the antioxidant capacity of fresh fruits. FRAP method is based on Single Electron Transfer (SET) mechanism, while ABTS method acts by both SET and Hydrogen Atom Transfer (HAT) reactions. FRAP (Ferric Reducing Ability of Plasma) assay was made under the methodology described by Duarte-Correa et al. (2020). For the first method, 900 μl of FRAP reagent (containing TPTZ, FeCl3, and acetate buffer) was mixed with 90 μl distilled water and 30 μl of the test sample and incubated at 37 °C/30 min. Absorbance was measured at 595 nm after 30 min (UV-3300 Mapada Instruments, Shanghai, China). Trolox was used for the calibration curve. Results were expressed as micromol of Trolox equivalents (TE) per gram (μmol TE/g). Regarding the second method, ABTS ((2,2'-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) assay was made according to Osorio-Arias et al. (2019). Firstly, the radical cation solution (ABTS+) was prepared by mixing 10 ml of an ABTS stock solution (7 mM) with 10 ml of potassium persulfate (2.45 mM). The solution was let stand overnight and subsequently diluted with ethanol until an absorbance reading of 0.7 was achieved (730 nm). Finally, the absorbance of the samples was determined after 30 min of mixing at 30ºC with the radical solution. The reduction in the absorbance was correlated with a Trolox calibration curve. The results were expressed as μM of Trolox equivalent (TE) per gram (μmol TE/g).

2.4. Textural analysis for fresh and treated fruits.

A texture analyzer TPA TexturePro CT V1.6 Build (Brookfield Engineering Labs. Inc, USA) was used to measure the firmness of the fresh and treated fruits, following the methodology described by Olivares-Tenorio et al. (2017). The analysis was carried out with the following specifications: Speed of 0.5mm/s, penetration distance of 5 mm, and a trigger of 4 g. A TA9 stainless steel needle probe with 1.0 mm of diameter was used. In the penetration test, firmness is the maximum force required to break the sample. These measurements were made at room temperature (25 ± 2 ºC) and data were recorded in grams of force (gf). Five samples were used in each treatment.

2.5. Postharvest treatments:

The cape gooseberry fruits were treated under three different postharvest treatments and the methodology used for each one was based on previous studies and slightly modified.

- -

Coating process (CP): The methodology was based on Muley and Singhal (2020). Firstly, the whey protein (WPC) was hydrated: 30g of protein in 188.31 mL of distilled water. Then, the pH was adjusted to 7 by adding NaOH and the solution was heated (55°C, 10 min) with constant stirring. After, 1.59 g of sodium carbonate was added while maintaining the agitation and temperature. 30 g of glycerol was also added. After cooling, the solution was stored under refrigeration (5 ± 1 ºC) until its application. The fruits were submerged twice for 1 minute and then the samples were drained and placed in an oven for 10 minutes at 30ºC to ensure the elimination of the surface liquid.

- -

Vacuum Impregnation Process (VIP): The methodology was based on Ciro (2012). An impregnation solution containing 1% calcium chloride (CaCl2) and 0.05% sodium carbonate (Na2CO3) was prepared over an isotonic aqueous base (sucrose 20 ºBrix). Fruits were placed in a desiccator and the solution ratio was maintained at 1:5 ratio to ensure adequate immersion. A vacuum pump was attached to the desiccator (Welch, Gardner Denver Thomas, Inc. Sheboygan, Wi USA) and the system was subjected to a vacuum pressure: 17 KPa, for 5 min. Subsequently, the atmospheric pressure was restored, and the fruits remained submerged for an additional time (5 min) without stirring. Finally, the impregnated samples were taken out from the desiccator, drained, and they were placed in an oven for 10 minutes at 30 ºC to ensure removal of surface liquid.

- -

Immersion Process (IP): The methodology was based on Pérez-Martínez et al. (2021). The immersion of the fruits was carried out sequentially using technological coadjutants. First, the fruits were immersed in a recipient containing a solution with 500 ppm citric acid and 500 ppm ascorbic acid for 5 minutes. Then, they were taken out from the recipient and immersed in a solution containing Na2CO3 0.05 M for 5 minutes. Finally, they were taken out and submerged in a solution containing 1% CaCl2 for 2 minutes. The immersed samples were drained and placed in the oven for 10 minutes at 30°C to ensure the elimination of the surface liquid.

2.6. Determination of weight loss for fresh and treated fruits.

The weight loss was assessed with gravimetric analysis, taking as reference day 0 weight. It was calculated according to Balaguera-lópez et al. (2014), using Eq (1). For each treatment and the control ten separate fruits were placed in two polyethylene containers (with holes), and the weight of each fruit was recorded daily. Samples were stored at 6 ± 2 ºC.

Where P

i is the fruit weight at initial time (day 0) and P

f is the fruit weight at final time (day 12).

2.7. Sensory analysis for fresh and treated fruits.

The sensory analysis of fresh (control) and treated fruits was conducted in the Food Sensory Analysis Laboratory at the University of Antioquia, Colombia using a multidimensional profile approach NTC 3932 (1996) and ISO 11035 (1994) (Norma Tecnica Colombiana NTC 3932. Análisis Sensorial. Identificación y Selección de Descriptores Para Establecer Un Perfil Sensorial Por Una Aproximación Multidimensional., 1996) with an expert panel. The judges were able to identify the set of relevant descriptors for appearance (A), texture (T), flavor (F), odor (O), and somatosensory sensation (S), to provide the maximum amount of information about the samples’ sensorial attributes to establish a sensory profile. The scale used to rank the descriptor´s intensities was from 0 to 5, where 0 is absence, 1 is very weak, 2 is weak, 3 is moderate, 4 is strong, and 5 is intense. The evaluation was carried out in individual cubicles with an ambient temperature of 24.0 ± 0.5 ºC and relative humidity of 64 ± 1%. The overall quality was also evaluated on a scale from 1 to 3, where 1 is low, 2 is medium, and 3 is high quality. The analyses were performed in duplicate following international tenets.

2.8. Statistical analysis

The results of each analysis were expressed as means ± standard deviation from at least three estimations. An analysis of variance (ANOVA) with Fisher’s Least Significant Difference (LSD) test was used to determine significant differences among the means at a significance level of p <0.05 using Statgraphics Centurion XVI software (Statistical Graphics Corporation, Ver. 16.0.07, Rockville, USA). Considering the results obtained with the three postharvest treatments applied to the fruits (CP, VIP, and IP) in terms of physicochemical characterization, weight loss, texture analysis, and sensory analysis, one method was selected to continue with the development of the research. Once a postharvest treatment was selected (IP) a factorial design of experiments was carried out. The independent variables were calcium chloride (1-3%) and immersion time in calcium chloride solution (2-5min). The dependent variables were moisture content (%), TSS, Firmness (gf), and weight loss at 12 days of storage (%).

3. Results

3.1. Characterization of fresh fruit.

Table 1 shows the results for the characterization of the fresh cape gooseberry fruit. The values obtained for moisture content and pH agreed with those reported previously by Balaguera-lópez et al. (2014) for the same ecotype The total acidity was also between the values reported by Bravo et al. (2015) and Pinzón et al. (2015) who found values between 1.49 - 1.90 %. Regarding TSS, they were expressed as °Brix, which is an estimate of sugar content in addition to organic acids, amino acids and soluble pectins, an average of 15.20 was found, similar to those reported by Bravo et al. (2015), who also stated that TSS is strongly affected by cultivar, harvest month and maturity. For the cape gooseberry color, the CIEL*a*b* system was applied. This system uses brightness (L*), red (a*), and yellow (b*) parameters. The positive values of a* and b*, allow us to establish that the fruits present tonalities between red and yellow (Rodriguez-Amaya & Kimura, 2004). These colors are characteristic in fruits with a high content of carotenoids, substances responsible for this coloration. On the other hand, the value of L is related to light (white) luminosities.

Table 2 shows the total phenolic content (TPC), carotenoids, vitamin C and antioxidant capacity (FRAP and ABTS) for the fresh cape gooseberry. The TPC for fresh fruit was similar to that reported by Puente et al. (2011) using a modified Folin-Ciocalteu method. They found values between 33.72 – 44.58 mg GAE/100 g. It has been established that the main phenolic compounds present in cape gooseberries are quercetin, myricetin and kaempferol (Ramadan, 2011). Regarding the carotenoids content, they are responsible for the orange color in the fruit (Puente et al., 2011). The value was found to be in the range reported by Graça Dias et al. (2017) 388.8 - 1460 μg/100g for a similar maturity stage. 22 carotenoid compounds were identified, the main one the all-trans- β-carotene (76.8%), followed by 9-cis- β-carotene (3.6%) and all-trans-α-criptoxantina (3.4%) (Ramadan, 2011). Concerning vitamin C content, the obtained value is similar than reported by Valente et al. (2011) who found 33.1 ± 0.4 mg/100g edible portion. This vitamin is particularly high in cape gooseberry in contrast with other fruits, but there is great variation (Bravo et al., 2015), reaching 68 mg/100g (Valente et al., 2011). Regarding antioxidant capacity, ABTS value was higher than reported Céron, Higuita, and Cardona (2011) who stated an antioxidant capacity of 0.426 µmol ET/g. FRAP value was also higher than those reported by Céron et al. (2011) and Vega et al. (2019), who found a range between 0.055 - 2.661 μmol TE/100 g. The variations are may be due to the edaphoclimatic differences of each variety, and these, in turn, induce variable contents of natural phytochemicals, such as phenolic compounds, anthocyanins, carotenoids, and vitamins, that are related to antioxidant capacities (Bravo et al., 2015; Yudy Duarte-Correa et al., 2021) These differences may be also associated with the fact that the antioxidant capacity shows increasing values with increasing ripening of the cape gooseberry fruit, and there is no information regarding the state of maturity of the fruit used for the cited studies.

3.2. Postharvest treatments

3.2.1. Physicochemical and texture characteristics

Table 3 shows the moisture content, TSS, pH, total acidity, vitamin C, TPC, and firmness for the cape gooseberry fruit after the different postharvest treatments and the control (fresh fruit). Results showed that there were no significant differences (p>0.05) in moisture content between the treatments. Regarding TSS, the highest TSS value (p<0.05) was that of the fruit subjected to the coating process, this may be due to the addition of sodium carbonate (soluble salt) that increases the total soluble solids content of the fruit and the plasticizing effect of glycerol. For the other treatments, it was possible to maintain the concentration of soluble solids lower, due to the contact with water solutions, which indicates that these have an impact on the slower ripening of the fruit (López et al., 2016). As for total acidity, significant differences were observed between treatments, the immersion process presented the highest acidity (p<0.05), it is because of the addition of citric and ascorbic acids in the immersion solutions. This agrees with the results for the pH, in which the immersion process had the lowest value. Regarding vitamin C content, coating, and immersion treatments led to higher vitamin C values than the control fruit. In the case of coating treatment, it is a protective barrier against permeability to O

2 and CO

2, thus decreasing vitamin autooxidation (Sogvar et al., 2016). In the case of immersion treatment, it is worth mentioning that ascorbic acid was added to the immersion solution, thus, resulting in significantly higher content (p<0.05) compared to the control. In the total phenolic content (TPC), there are significant differences between treatments (p<0.05). On one side, it can be related to the measurement technique, since the Folin–Ciocalteu method measures the reduction of the reagent with the formation of a blue complex (Contreras-Calderón et al., 2011) but it has low specificity, being able to react with any oxidizable hydroxyl, such as those present in the structure of vitamin C, and we stated before that vitamin C were higher for the treated fruits. However, some studies indicate that those higher values can be also attributed to the greater extraction of compounds from within the matrix during the treatments (Barba et al., 2013). Concerning fruit firmness, it was directly affected by the different postharvest treatments. Although calcium has been used in fruit pretreatments and it is generally associated with increased firmness (Y. Duarte-Correa et al., 2020), in this case, the effect of the process itself was superior. In the case of vacuum impregnation, it presented the lowest firmness values, this may be related to the pressure received by the fruit during the vacuum pressure stage, which could have affected the surface of the cape gooseberry and broken its original structure, thus, generating a general softening of the fruit. In fact, this tissue damage was visually perceived in some fruits. Sharma and Dash (2019) describe that the vacuum expels intracellular air forming a high degree of intercellular partitions and voids causing significant changes in the structure and decomposition of the fruit tissue. Concerning the immersion treatment, CaCl

2 was added to the immersion solution, so it could be the reason for the firmness improvement as has been stated before for other food matrices (Radziejewska-kubzdela & Kido, 2014). In this context, it has been reported that Ca

2+ establishes bonds with pectins, forming calcium pectates that increase the firmness of the cell wall (Y. Duarte-Correa et al., 2020). It is stated that with calcium pretreatment, two ways of calcium are identified:

1. bound to carboxyl groups and

2. free or remaining unbound in the plant tissue (Rodríguez-ramírez et al., 2023). In addition, according to Pérez-Martínez et al. (2021), the application of antioxidant agents such as ascorbic acid minimizes and prevents enzymatic reactions, texture changes, and the development of unpleasant flavors and aromas, because it has a high affinity for fruit carbohydrates, thus providing acid and reducing properties that sequester oxygen and act as chelating agents that retard the deterioration processes caused by enzymes and accelerated by the lesions caused in the plant tissue, which directly influences the firmness of the fruit. Therefore, the addition of this acid would also be contributing indirectly to improving the firmness of the fruit treated by immersion.

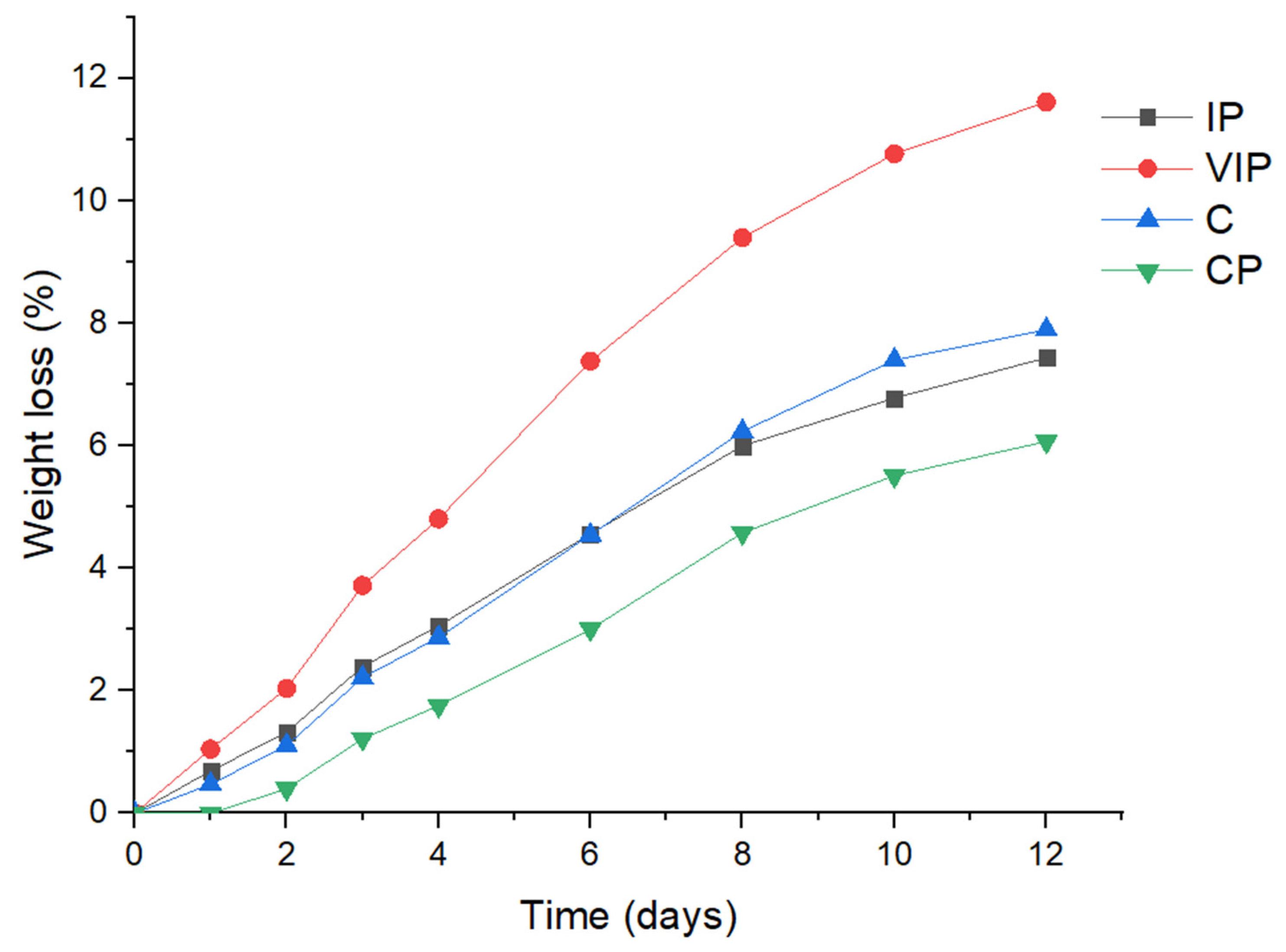

3.2.2. Weight loss

Figure 1 shows the weight loss for CP, VIP, and IP during 12 days of storage. It can be seen that at the end of the study (day 12) the weight loss percentage for Vacuum Impregnation Process (VIP) was significantly higher (11.6%) when compared to the control (7.9%) and the other treatments (CP: 6.1% and IP: 7.4%). For its part, the Immersion Process (IP) led to obtain similar values with the control (C) during all days of the study. Finally, with the Coating Process (CP) the fruits had the lowest weight loss percentage, going from 0.4% on day 2 to 6.1% on day 12. It has been reported that coating process on fruits led to reduce weight loss. López et al. (2016) reported a significant weight loss reduction from 23% to 15% in cape gooseberry samples stored during 15 days at 17 ºC, with the use of a whey and beeswax-based coating. Muñoz et al. (2017) were able to prolong cape gooseberries stored from 9 to 11 days while maintaining a weight loss of less than 10% with the use of a chitosan and aloe vera based coating. According to what was reported by Pinzón et al. (2015), when the samples exceed losses greater than 10% of the weight, the freshness of fruits and vegetables disappears. The large weight loss of fruits subjected to the vacuum impregnation process can be explained by the product deformations promoted by the pressure changes due to the viscoelastic properties of the fruit solid matrix. VIP has been described as a fast mass transfer phenomenon which occurs when porous structures are immersed in a liquid phase and pressure gradients are generated. This causes the external solution to move towards inside the food structure (Yudy Duarte-Correa et al., 2019). Thus, the cape gooseberries subjected to VIP have a higher weight than untreated fruits, related to external liquid gain. However, in some cases, deformations can lead to the size and shape of the pores being changed (Yudy Duarte-Correa et al., 2019), resulting even in tissue injury that may subsequently promote fluid leakage. Regarding the immersion process, at the end of the study it obtained a weight loss of less than 10%, keeping the freshness in similar way to the control. Pauro-Flóres (2016) reached 10% weight loss after 18 days of refrigerated storage (3ºC) and 13 days at room temperature (13ºC) when using immersion in solution with 3% calcium chloride and also found higher values when using coated fruits: 15 and 21 for room temperature and refrigeration, respectively.

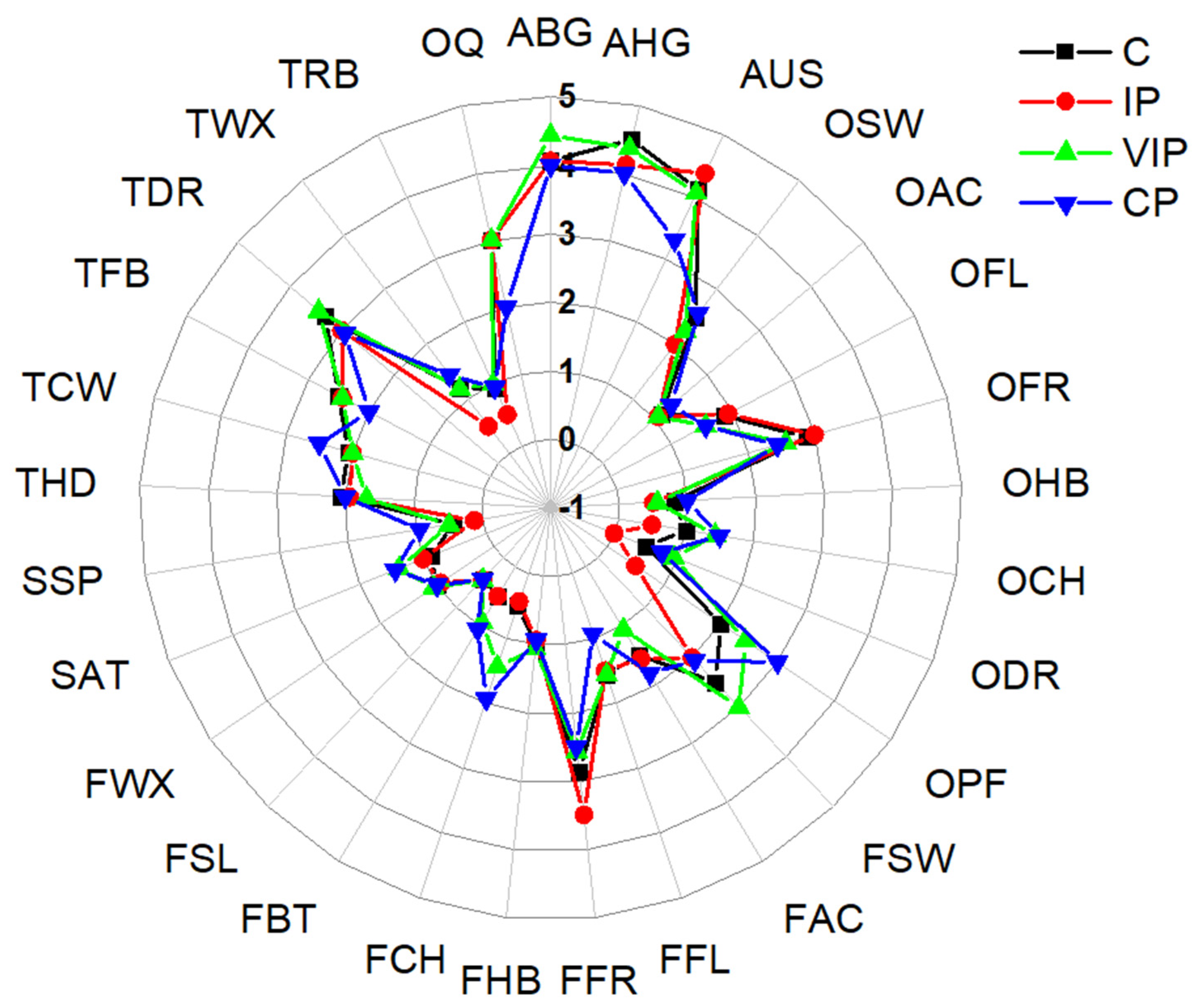

3.2.3. Sensory analysis

Figure 2 shows the descriptors found for appearance (A): brightness (ABG), homogeneous color (AHG), and uniform surface (AUS); for texture (T): hard (THD), chewable (TCW), fibrous (TFB), dry (TDR), waxy (TWX), and rubbery (TRB); for flavor (F): sweet (FSW), acid (FAC), floral (FFL), fruity (FFR), herbal (FHB), chemical (FCH), bitter (FBT), saline (FSL), and waxy (FWX); for odor (O): sweet (OSW), acid (OAC), ), floral (OFL), fruity (OFR), herbal (OHB), chemical (OCH), dairy (ODR), and perfume (OPF); for somatosensory sensation (S): astringent (SAT), and spicy (SSP), of fresh and treated cape gooseberry. The figure also shows the overall quality (OQ) of the fresh and treated fruits. The panelists highlighted some aspects of each of the treatments, including the control fruit. The sensory characteristics of the control present different types of notes associated with sweet, fruity, and herbal flavors, which are predominant for this type of fruit product as they indicate their final quality (Rodríguez et al., 2015). The fresh cape gooseberry presents a waxy surface attributed to the fruit's own natural wax and which constitutes an important point in its long-term preservation since it prevents moisture loss and delays the phenomena associated with senescence. In the fruits subjected to VIP, panelists found the presence of spicy and chemical notes that gave an uncharacteristic residual to the fruit. It could be attributed to the addition of substances such as sodium carbonate and calcium chloride, since with the use of VIP the porous structure of the matrix is filled with the substances present in the impregnation solution, due to the pressure differences (Radziejewska-kubzdela & Kido, 2014). Regarding the IP, it was characterized by the sensory panel as a balanced treatment in relation to flavor and odor and presented texture characteristics similar to the control, being ideal for a fresh fruit product. This balance is because of the presence of ascorbic and citric acids, together, counteracting the presence of sodium carbonate and calcium chloride, thus, helping to maintain the balance and opaquing the chemical notes. For the fruits subjected to CP, their overall quality was the lowest among all treatments, with an overall rating of 2, evidencing that this process had a negative impact on sensory attributes. This low quality is associated with the presence of chemical, astringent, and unpleasant notes, which affect appearance parameters such as brightness and sweet taste, as well as flavor and odor descriptors.

Descriptors for appearance (A): brightness (ABG), homogeneous color (AHG), and uniform surface (AUS); for texture (T): hard (THD), chewable (TCW), fibrous (TFB), dry (TDR), waxy (TWX), and rubbery (TRB); for flavor (F): sweet (FSW), acid (FAC), floral (FFL), fruity (FFR), herbal (FHB), chemical (FCH), bitter (FBT), saline (FSL), and waxy (FWX); for odor (O): sweet (OSW), acid (OAC), ), floral (OFL), fruity (OFR), herbal (OHB), chemical (OCH), dairy (ODR), and perfume (OPF); for somatosensory sensation (S): astringent (SAT), and spicy (SSP).

3.2.4. Postharvest treatment selection

Considering the results obtained with the three postharvest treatments applied to the fruits (CP, VIP, and IP) in terms of physicochemical characterization, weight loss, texture analysis, and sensory analysis, the immersion treatment (IP) was selected to continue with the development of the research.

3.3. Immersion Process (IP) under different conditions

The evaluation of the IP was carried out using a factorial experimental design (

Table 4). Twelve runs were carried out for the treated samples. The value obtained for the moisture of the treated fruits ranged between 81.78% and 84.45%. The value obtained for TSS was in the range of 12.60 and 14.50. The firmness of the fruits was between 22.40 and 34.00 gf. Regarding weight loss after 12 days of storage, the values were between 6.51 and 10.91%. Results showed that there were no significant differences (p>0.05) between any response variables including firmness by the effect of calcium concentration (1-3%). Although higher firmness might be expected with higher calcium concentration used, this behavior could be attributed to the calcium that can precipitate at the entrance of the pores blocking the entrance of more compounds, as has been stated before (Castagnini, 2015). However, comparing the values of firmness for the treated fruits and the control it is noticeable that treated fruits showed higher values. Since the use of different concentrations of calcium chloride used, led to indistinct firmness values, low concentrations can be used to obtain good results at a lower economic cost. On the other hand, there were significant differences (p<0.05) between the firmness values because of the immersion time in CaCl

2 factor. It is, the longer the immersion time, the lower the firmness of the product. It may be due to the relaxation of the fruit tissue that favored the calcium loss, especially those free or not strongly bound to pectins within the tissue (Rodríguez-ramírez et al., 2023). In addition, after reaching the equilibrium, an osmotic effect may occur. Barrera et al. (2009) reported a reduction in calcium content after osmosis due to the concentration gradient and Martínez-Sánchez et al. (2022) observed a leaching effect in banana tissue at higher concentration and temperature of the osmotic solution. Finally, a correlation analysis of Person showed a significant (p<0.05) negative correlation (-0.6397) between moisture content and total soluble solids. This is compositionally related, since the variable TSS is inversely proportional to the moisture content, thus, the higher the humidity, the lower the solids, and vice versa.

4. Conclusion

Of the three treatments evaluated (CP, VIP, and IP), the lowest weight loss was recorded with the use of coating (CP) and immersion (IP). However, the immersion process resulted in the product with the highest overall quality according to the sensory analysis, being comparable with the fresh fruit. Regarding firmness, one of the most important quality attributes for the commercialization and export of fruits, the IP also presented the firmest products. The texture is related to several parameters such as water loss. In that sense, considering 10% as a commercial standard limit for weight loss, the fruit treated under immersion and coating processes can be stored for at least 12 days. However, the CP had the lowest overall sensory quality. Therefore, the immersion process is highlighted since this treatment helps to maintain the fruit quality, so it is presented as a promising alternative for the postharvest treatment of cape gooseberries that it is necessary to continue exploring. For future studies, it will be interesting to incorporate different temperatures for the immersion solutions for IP and to include the use of agitation during the time the fruit is submerged. As a general conclusion, it is important to mention that the quality characteristics of cape gooseberry cannot be determined by a single variable but must be a set of attributes where it is important to include sensory analysis, as it will determine the consumer's acceptance of the product.

Author Contributions

Sara Agudelo-Sánchez: Conceptualization; formal analysis; investigation; methodology; validation; writing - original draft. Yadiela Mosquera-Palacios: Conceptualization; formal analysis; investigation; methodology; validation; writing - original draft. Dairon David-Úsuga: Conceptualization; data curation; formal analysis; investigation; methodology; validation; writing - original draft. Susana Cartagena-Montoya: Formal analysis; methodology; validation; writing - original draft. Yudy Duarte-Correa: Supervision; project administration; resources; writing - original draft; writing-review & editing. All authors have read and agreed to the published version of the manuscript.

Funding Information

This work was supported by Faculty of Pharmaceutical and Food Sciences, Universidad de Antioquia. Medellín, Colombia [Project CIFAL-336, 2022]. The role of the funding source was limited to providing resources to develop the research.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

This work was financial supported by resources from Universidad de Antioquia (Medellín, Antioquia, Colombia), through the project CIFAL-336, for the Small Projects for undergraduate students call for proposals 2022.

Declaration of Interest

None.

References

- Akhtar, N., Chaudhari, S. K., Arshad, S., Fatima, H., Amjad, M. S., & Saboon. (2019). Biological activities and nutritional value of physalis peruviana L. Natural Bio-Active Compounds: Volume 1: Production and Applications, 587–598. [CrossRef]

- AOAC. (2000). Oficial Methods of Analysis of AOAC International. In D. G. W. Latimer (Ed.), Association of Analytical Communities. (17th ed). Association of Offical Analytical Chemists.

- Balaguera-lópez, H. E., Martínez, C. A., & Herrera-Arévalo, A. (2014). The role of the calyx in the postharvest behavior of cape gooseberry fruits ecotype Colombia. Revista Colombiana de Ciencias Hortícolas, 8(2), 181–191. [CrossRef]

- Barba, F. J., Esteve, M. J., & Frigola, A. (2013). Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Research International, 50(2), 545–549. [CrossRef]

- Barrera, C., Betoret, N., Corell, P., & Fito, P. (2009). Effect of osmotic dehydration on the stabilization of calcium-fortified apple slices (var. Granny Smith): Influence of operating variables on process kinetics and compositional changes. Journal of Food Engineering, 92(4), 416–424. [CrossRef]

- Bisht, B., Bhatnagar, P., Gururani, P., Kumar, V., Tomar, M. S., Sinhmar, R., Rathi, N., & Kumar, S. (2021). Food irradiation: Effect of ionizing and non-ionizing radiations on preservation of fruits and vegetables– a review. Trends in Food Science and Technology, 114(February), 372–385. [CrossRef]

- Bravo, K., Sepulveda-Ortega, S., Lara-Guzman, O., Navas-Arboleda, A. A., & Osorio, E. (2015). Influence of cultivar and ripening time on bioactive compounds and antioxidant properties in Cape gooseberry (Physalis peruviana L.). Journal of the Science of Food and Agriculture, 95(7), 1562–1569. [CrossRef]

- Cardenas-Barboza, L. C., Paredes-Cordoba, A. C., Serna-Cock, L., Guancha-Chalapud, M., & Torres-Leon, C. (2021). Quality of Physalis peruviana fruits coated with pectin and pectin reinforced with nanocellulose from P. peruviana calyces. Heliyon, 7(9). [CrossRef]

- Castagnini, J. M. (2015). Estudio del proceso de obtención de zumo de arándanos y su utilización como ingrediente para la obtención de un alimento funcional por impregnación a vacío. Universidad Politécnica de Valencia.

- Céron, I., Higuita, J., & Cardona, C. (2011). Capacidad antioxidante y contenido fenólico total de tres frutas cultivadas en la región andina. Vector, 18(1), 2–10.

- Ciro, G. (2012). Conservación de uchuva basada en la impregnación a vacío de extractos de plantas con actividad antimicrobiana y antioxidante. Universidad de Antioquia.

- Contreras-Calderón, J., Calderón-Jaimes, L., Guerra-Hernández, E., & García-Villanova, B. (2011). Antioxidant capacity , phenolic content and vitamin C in pulp , peel and seed from 24 exotic fruits from Colombia. Food Research International, 44(7), 2047–2053. http://dx.doi.org/10.1016/j.foodres.2010.11.003.

- Denoya, G. I., Colletti, A. C., Vaudagna, S. R., & Polenta, G. A. (2021). Application of non-thermal technologies as a stress factor to increase the content of health-promoting compounds of minimally processed fruits and vegetables. Current Opinion in Food Science, 42(Table 1), 224–236. [CrossRef]

- Duarte-Correa, Y., Díaz-Osorio, A., Osorio-Arias, J., Sobral, P. J. A., & Vega-Castro, O. (2020). Development of fortified low-fat potato chips through Vacuum Impregnation and Microwave Vacuum Drying. Innovative Food Science and Emerging Technologies, 102437. [CrossRef]

- Duarte-Correa, Yudy, Granda-Restrepo, D., Cortés, M., & Vega-Castro, O. (2019). Potato snacks added with active components : effects of the vacuum impregnation and drying processes. J Food Sci Technol, 06(52). [CrossRef]

- Duarte-Correa, Yudy, Vargas-Carmona, M. I., Vásquez-Restrepo, A., Ruiz Rosas, I. D., & Pérez Martínez, N. (2021). Native potato (Solanum phureja) powder by Refractance Window Drying: A promising way for potato processing. Journal of Food Process Engineering, 44(10). [CrossRef]

- Etzbach, L., Pfeiffer, A., Weber, F., & Schieber, A. (2018). Characterization of carotenoid profiles in goldenberry (Physalis peruviana L.) fruits at various ripening stages and in different plant tissues by HPLC-DAD-APCI-MSn. Food Chemistry, 245(August 2017), 508–517. [CrossRef]

- González-Locarno, M., Pautt, Y. M., Albis, A., López, E. F., & Tovar, C. D. G. (2020). Assessment of chitosan-rue (Ruta graveolens l.) essential oil-based coatings on refrigerated cape gooseberry (Physalis peruviana L.) quality. Applied Sciences (Switzerland), 10(8). [CrossRef]

- Graça Dias, M., Olmedilla-Alonso, B., Hornero-Méndez, D., Mercadante, A. Z., Osorio, C., Vargas, L., & Meléndez-Martínez, A. (2017). Tabla de contenido en carotenoides de alimentos iberoamericanos. Carotenoides En Agroalimentación y Salud.

- Heredia, A. M., Quiroga, R. J., & Kirschbaum, D. S. (2017). Primer reporte de Géneros Fúngicos causando decaimiento poscosecha en Goldenberry (Physalis peruviana L.) en Argentina. April, 2. https://inta.gob.ar/sites/default/files/inta-poster-primer_reporte_de_generos_fungicos_causando_decaimiento_poscosecha_en_goldenberry_physalis_peruviana_l._en_argentina.pdf.

- Norma Tecnica Colombiana NTC 3932. Análisis Sensorial. Identificación y selección de descriptores para establecer un perfil sensorial por una aproximación multidimensional., (1996).

- NTC 4580. Frutas frescas. Uchuva. Especificaciones, (1999).

- López, D., Cuatin, L., Andrade, J., & Osorio, O. (2016). Evaluation of an edible coating based whey protein and beeswax on the physical and chemical quality of gooseberry (Physalis peruviana L.). Acta Agronomica, 65(4), 326–333. [CrossRef]

- Martínez-Sánchez, C., Solis-Ramos, A., Rodríguez-Miranda, J., Juárez-Barrientos, J., Ramírez-Rivera, E., Ruíz-López, I., Gómez-Aldapa, C., & Herman-Lara, E. (2022). Evaluation of ascorbic acid impregnation by ultrasound-assisted osmotic dehydration in plantain. Journal OfFood Processing and Preservation, 46(10).

- Ministerio de Agricultura y Desarrollo Rural. (2022). AGRONET- Rendimiento Nacional por Cultivo. Uchuva. https://www.agronet.gov.co/estadistica/Paginas/home.aspx?cod=1.

- Muley, A. B., & Singhal, R. S. (2020). Extension of postharvest shelf life of strawberries (Fragaria ananassa) using a coating of chitosan-whey protein isolate conjugate. Food Chemistry, 329(January), 127213. [CrossRef]

- Muñoz, A., Barbosa, A., Bustos, D., Ramírez, Y., Vásquez, Y., García, J., & Guancha, M. (2017). Conservation of Uchuva (Physalis Peruviana) by applying a coating based on chitosan and aloe vera, using the spray method. Informador Técnico (Colombia), 81(1), 86–94. [CrossRef]

- Olivares-Tenorio, M. L., Dekker, M., van Boekel, M. A. J. S., & Verkerk, R. (2017). Evaluating the effect of storage conditions on the shelf life of cape gooseberry (Physalis peruviana L.). Lwt, 80, 523–530. [CrossRef]

- Osorio-Arias, J., Delgado-Arias, S., Cano, L., Zapata, S., Quintero, M., Nuñez, H., Ramírez, C., Simpson, R., & Vega-Castro, O. (2019). Sustainable Management and Valorization of Spent Coffee Grounds Through the Optimization of Thin Layer Hot Air - Drying Process. Waste and Biomass Valorization. [CrossRef]

- Pauro-Flóres, V. (2016). Aplicación de dos métodos (encerado o inmersión en cloruro de calcio) para la conservación poscosecha del aguaymanto (Physalis peruviana) sin cáliz [Universidad Nacional del Altiplano]. In Tesis. http://repositorio.unap.edu.pe/bitstream/handle/UNAP/7104/Molleapaza_Mamani_Joel_Neftali.pdf?sequence=1&isAllowed=y.

- Pérez-Martínez, B. S., Ramos-Dubón, E. J., Ramos-Cortez, S., & Munguía, H. E. (2021). Evaluación de dos combinaciones de conservantes y su efecto sobre un producto hortícola de IV Gama. Revista Agrociencia-Revista de Contenido Científico de La Facultad de Ciencias Agronómicas de La Universidad de El Salvador, 4(18), 38–49.

- Pinzón, E. H., Reyes, A. J., Álvarez-Herrera, J. G., Leguizamo, M. F., & Joya, J. G. (2015). Comportamiento del fruto de uchuva Physalis peruviana L., bajo diferentes temperaturas de almacenamiento. Revista de Ciencias Agrícolas, 32(2), 26–35. [CrossRef]

- Puente, L. A., Pinto-Muñoz, C. A., Castro, E. S., & Cortés, M. (2011). Physalis peruviana Linnaeus, the multiple properties of a highly functional fruit: A review. Food Research International, 44(7), 1733–1740. [CrossRef]

- Radziejewska-kubzdela, E., & Kido, M. (2014). Applicability of Vacuum Impregnation to Modify Physico-Chemical , Sensory and Nutritive Characteristics of Plant Origin Products — A Review. International Journal of Molecular Sciences, 15, 16577–16610.

- Ramadan, M. F. (2011). Bioactive phytochemicals, nutritional value, and functional properties of cape gooseberry (Physalis peruviana): An overview. Food Research International, 44(7), 1830–1836. [CrossRef]

- Rodriguez-Amaya, D. ., & Kimura, M. (2004). Handbook for Carotenoid Analysis. HarvestPlus Technical Monographs, 59.

- Rodríguez-ramírez, J., Barragán-iglesias, J., Ramírez-palma, A. J., & Méndez-lagunas, L. L. (2023). Effect of Calcium and Osmotic Pretreatments on Mass Transfer and Texture Parameters during Processing of Chilacayote ( Cucurbita ficifolia Bouché ). 2023.

- Rodríguez, S. del C., Generoso, S., Gutiérrez, D., & Questa, A. (2015). Application of sensory analysis in the evaluation of quality fresh-cut vegetables. Simiente, 85(3–4), 1–27.

- Sharma, M., & Dash, K. K. (2019). Effect of ultrasonic vacuum pretreatment on mass transfer kinetics during osmotic dehydration of black jamun fruit. Ultrasonics Sonochemistry, 58(April), 104693. [CrossRef]

- Sogvar, O. B., Koushesh Saba, M., & Emamifar, A. (2016). Aloe vera and ascorbic acid coatings maintain postharvest quality and reduce microbial load of strawberry fruit. Postharvest Biology and Technology, 114, 29–35. [CrossRef]

- Turkkan, M., Ozcan, M., & Erper, İ. (2017). Antifungal effect of carbonate and bicarbonate salts against Botrytis cinerea, the casual agent of grey mould of kiwifruit. Akademik Ziraat Dergisi, 6(2), 107–114. [CrossRef]

- Valente, A., Albuquerque, T. G., Sanches-Silva, A., & Costa, H. S. (2011). Ascorbic acid content in exotic fruits: A contribution to produce quality data for food composition databases. Food Research International, 44(7), 2237–2242. [CrossRef]

- Vega, J. C. D. la, Cañarejo, M. A., Cabascango, O. N., & Lara, M. V. (2019). Deshidratado de Physalis peruviana L. en dos Estados de Madurez y su Efecto sobre el Contenido de Polifenoles Totales, Capacidad Antioxidante, Carotenos, Color y Ácido Ascórbico. Información Tecnológica, 30(5), 91–100. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).