1. Introduction

The building sector accounts for 35% global energy consumption[

1]. According to IEA, the building sector is one of the most cost effective sectors for reducing global energy consumption and CO2 emission[

2]. Many countries have been issused building energy policies that are used to achive the reduction of energy consumption and CO2 emission in the building sector[

2,

3,

4]. Building code and regulations have been developed and applied for both new and exiting building. In addition, the development of net zero energy building, energy performance certification, labeling program, ect… also have been paid much attention[

5,

6].

Building materials account for a large part of energy consumption in building construction. Therefore, the amount of energy consumed by materials is essential for developing and evaluating energy-efficient buildings, green buildings, green urban ar-eas, and green construction technologies[

7,

8,

9]. It is clearly that building materials play an important role in setting the energy footprint of a building. To achive energy-saving effect in the building, it is very important to choose a suitable materials right from the design stage. Although most of developing countries have their own building energy policies, the testing, rating and labeling systems to assess the energy performance of building materials are still limited.

In Vietnam, according to the Ministry of Construction, the growth rate of the con-struction industry in the first six months of 2022 increased by about 3.65% compared with the same period in 2021[

10]. The national urbanization rate is about 41%, and the average housing area reached approximately 25.2 m² of floor per person[

10]. Therefore, it has become necessary to find solutions, apply new materials, recycled materials, and utilize sustainable and eco-friendly building materials to minimize the negative im-pacts of the construction industry on the natural environment and people’s lives. As a result of Vietnam’s rapid economic development, lifestyles and residents’ needs are changing, and new building typologies are being implemented with materials, structures, and supply systems not previously common in Vietnam. As comfort demands change, so too does the room climate and the materials are exposed to new indoor conditions, while the outdoor climate is extremely warm and humid. Efforts to save energy and conserve resources are urgently needed as resource shortages, secure energy, pollution and climate change have been identified as pressing issues by policy makers at national and global level. The construction sector with its material flows (eg cement demand in Vietnam will increase by 66% from 2015 to 2020[

11] (GTAI Germany Trade & Invest, 2017) and rising energy demand (eg tripling electricity demand by 2030 compared to 2015 levels[

12] contributes significantly to these problems in Vietnam and most other countries in the world.

In this context, in the Vietnamese construction industry, the use of non-fired bricks and other similar materials as material for walls is currently being introduced in order to reduce the energy and pollution, through the production and consumption of arable land for the production of clay. Masonry blocks made of alternative materials such as aerated concrete blocks and concrete block blocks are advertised as substitutes. However, such new materials require adapted technologies and processing and integration with the building system to be a permanent and sustainable substitute for the technologies established in the marketplace . Especially moisture protection is of great importance in this context[

13]. Failure of such new applications as cracks in plaster or moisture ingress will discredit such sustainable construction practice and is therefore detrimental to sustainable development. However, at present, there is no sufficient knowledge of the building physics properties or capabilities of the Vietnamese construction industry. In fact, the major studies for the development of an infrastructure for the study of new materials, their physical behavior and their technical application, in order to prevent new, more resource-efficient technologies from being discredited in the market by malfunctioning and premature failure, are urgently needed. Although the new building energy code has been introduced, the calculation tools, checklists and other support for architects and engineers are missed. According to building material consumption survey which has been conducted by Vietnam Institute for Building Materials in 2020, around 1200 materials can be used in energy efficient building. However, the values of essential properties for energy saving and other building physical assessments are missing and are not available in Vietnam.

The aim of this research is to build the comprehensive laboratory concept for the installation of instruments, proceduces and test standards for the characterization and reseach of energy efficient building materials and construction products. One focus of empirical research will be the investigation of the legal regulatory framework for energy, resource efficient and sustainable construction. The essential material tests necessary for the effective implementation of the basic energy standards are identified and prioritized. Based on this, all necessary test equipment to implementation energy standards are clarified. Through a strategic implementation plan for research and testing facilities, the determination of the relevant material properties (eg thermal conductivity, moisture absorption) for use in the Vietnamese construction industry has been carried out. Since no stuties have been published worthy. This research has great significance in both pratical and scientific terms. This academic knowledge will greatly contribute to the field of developing new energy-saving materials, energy efficient building, sustainable development to achive the goal of zero emissions by 2050. Based on this research, other developing countries like Vietnam can also improve their systems for testing, rating and labeling building materials for energy performance. Moreover, clear information on energy performance of building materials by testing, rating and labeling systems will support for the development of energy efficent building, sustainable building because it helps the code official easily verify that this material matches the code-compliant design.

2. Methodology

A laboratory for testing building physics properties has been established to determine the basic materials properties required for the application of Vietnamese energy eficiency regulations and are the relevant for the performance, oriented design such as simulation study. All necessary test equipment and test methods are identified precisely with measurement ranges, measurement accuracies, test boundary conditions. In the same vein, a labeling system and catalog of property criteria for energy saving building materials. In addition, a comparative investigations between the German (Fraunhofer Institute for Building Physics – IBP) and Vietnamese laboratories (VIBM) will validate the new measuring equipment in Vietnam. In a feasibility study, the findings from the construction of two building physics laboratories in Vietnam are scaled up to a possible physical infrastructure for further testing and research in Vietnam and the way to implement such a facility is developed.

3. Results and discussion

3.1. Overview on regulations in Vietnam

3.1.1. Current policies related to energy-saving building materials in Vietnam

The implementation of energy saving, greenhouse gas emission reduction and response to climate change is the responsibility of all countries in the world, including Vietnam. For reducing the energy consumption in the building sector, Vietnam government has lunched various policies legal documents related to the requirements of economical and efficient use of energy as follows:

The Law on Economic and efficient use of energy No.50/2010/QH12 requires methodologies for the economical and efficient use of energy in construction activities [

14].

Decision No.1266/QD-TTg was issued in August 2020 about Strategy for the Development of Building Materials in Vietnam for the 2021 - 2030 period, with orientations toward 2050. It is emphasized the importance of the efficient use of natural resources, radically saving energy and raw materials; and minimizing the environmental impact of the mining process for the production of building materials and products[

15]. This aligns with a global response to climate change targeting building materials to reduce greenhouse gas emissions and conserve natural resources.

In the National Technical Regulation on Energy Efficiency in buildings of Vietnam (QCVN09/2017/BXD), the requirements for (a) Thermal resistance R

0 of the opaque part: exterior walls above the ground surface (opaque parts of the walls) of the air-conditioned spaces shall maintain a minimum overall thermal resistance value R0 not smaller than 0.56 m

2K/W; flat roofs and roofs with a gradient of fewer than 15 degrees placed directly above the air-conditioned spaces shall maintain a minimum overall thermal resistance value R

0min not smaller than 1.00 m

2K/W; (b) for construction and installation products applied in wall structures and building roofs: thermal conductivity coefficient λ of materials must be announced; (c) the requirements for the transparent parts (glazing), maximum SHGC values must comply with the values specified in

Table 1 [

16].

Decision No.280/QĐ-TTg was issued in March 2019 by the Prime Minister, approving the National Program on Economic and efficient use of energy in the period of 2019 – 2030 that clearly defines the target up to 2025 such as: (a) Achieving energy-savings levels from 5.0 to 7.0% of the total national energy consumption in the period from 2019 to 2025; (b) Achieving 80 construction projects (150 construction projects up to 2030) that are certified as green constructions, using economic and efficient energy; (c) Building 01 data warehouse information center for energy and at least two National training centers for using economical and efficient energy; 01 energy-efficient urban model; 05 demonstration models on an investment loan for projects relevant to economical and efficient energy use; 02 energy efficiency-testing laboratories. Up to 2030, implementing energy labels for at least 50% of all types of building materials products having insulation requirements [

17].

Circular 01/2018/TT-BXD relevant to the required criteria for the development of urban green construction was issued in January 2018 [

18].

National standard TCVN 9258:2012 on heat protection for houses – Design guidelines and Standard TCVN 4605–1998 for cladding structures – Design standards for thermal insulation of cover structures for buildings and constructions with microclimate conditions were issued [

19,

20].

3.2.2. Current Situation of Utilization of Energy-saving Materials in Vietnam

In 2019, Vietnam had over 1600 production facilities of unburnt building materials, with a total design capacity of about 10.2 billion standard pellets/year (nearly 30% of the total design capacity of the building materials production line) [

21]. Popular unburnt building materials include concrete bricks, autoclaved aerated concrete bricks, autoclaved aerated concrete slabs, and precast hollow concrete wall panels. Actual production/consumption output reached 4.83 billion standard unburnt bricks [

21].

Regarding the research, production, and use of products and construction materials that are resource-efficient, environmentally friendly, and with energy-saving features, currently, many products and materials are available on the Vietnamese market. The State encourages and supports many projects to produce energy-saving building materials such as Low-E glass and non-burned bricks. Generally, the research, production, testing, and widespread use of products and materials with energy-saving features and environmental friendliness mainly comes from the self-efforts of enterprises producing and distributing products and building materials. However, there is a lack of comprehensive activities of the state and credit institutions to support businesses in this field. In particular, the testing, rating and labeling of these materials has not been focused because of insufficient capacity to test the hygrothermal properties of building materials (eg thermal conductivity, moisture absorption…). Some enterprises need to send products to foreign testing laboratories, which is costly in terms of time and cost. Therefore, it is necessary and urgent work to build a material testing laboratory with sufficient capacity to test, evaluate and label energy-saving building materials and construction products. This is also in line with the development trend of the world.

3.2. Challenges and opportunities

Since 2005 when Decree 102/2003/ND-CP of the Government on economic and efficient use of energy was issued, after nearly 20 years of implementation, although positive results have been achieved, in general, the implementation of the contents of economical and efficient use of energy in the fields of construction, production, and use of building materials with energy-saving features in particular still has a lot of limitations and challenges, namely [

22]:

1. It is not easy to access specific financial incentives for projects that produce energy-saving and environment-friendly building materials and products.

2. It lacks mandatory or recommended regulations for assessment, certification, and energy labeling for products and building materials used in construction.

3. The awareness and interest of stakeholders such as investors, construction contractors, operation management units, and users of the works on economical and efficient energy use are still inadequate.

4. There is no mandatory regulation for new construction or renovation works to meet green building standards.

In addition to the above limitations and challenges, together with the pressure of rising prices of raw material and energy, limited supply and firm commitments of the government on environmental protection, energy saving, and reducing greenhouse gas emissions also create significant opportunities to vigorously develop energy-saving and environment-friendly products, goods, and building materials used in energy-efficient buildings and constructions, green building, and low emission buildings.

With the improvement of people’s living standards and income, the issue of ensuring health and comfort conditions in the building is becoming more concerning. The technical requirements specified in the regulations and standards on indoor air quality, ensuring comfort, limiting the impact of microorganisms, mold, and other qualities have been developed and promulgated, and put into reality application creates an excellent motivation for research, development, production, and use of construction materials with features of energy saving, economical use, resource efficiency, and environmental friendliness to reduce emissions and ensure the health of users. The process of integration and globalization, participation in linkage chains, supply chains, and global value chains put requirements on enterprises producing and distributing products, building materials, and investors. The investment and operation management unit of construction works must comply with and apply criteria and standards and perform the assessment, certification, energy labeling, and eco-label of construction materials used in the building.

3.3. Study on facilities and equipment for testing energy-saving materials in Vietnam

Determining heat transfer, moisture transfer, and durability properties of materials plays a significant role in energy-efficient and economical buildings in all countries worldwide, including Vietnam[

23,

24,

25]. Therefore, it is vital to determine the type of material suitable for the intended use in the project. Furthermore, following the trend of using innovative materials and energy-saving materials, along with the mandatory implementation of QCVN 09:2017/BXD in the near future, the need to research and test the features of heat and moisture transfer as well as the durability of the building materials group for suitable selection to the actual climatic conditions will increase. Therefore, it is urgent to research and improve testing capacity in this field, which will bring long-term effects because it is entirely new in Vietnam.

3.3.1. Necessary material parameters for the energy code

R0-value/ heat conductivity λ

The total thermal resistance describes the resistance of a building construction to the heat flow when a temperature difference is present at the component boundaries. The R

0-value is the reciprocal of the U

0-value and is calculated from the thermal conductivities of the individual component layers and the transition resistances at the surfaces. To determine the R

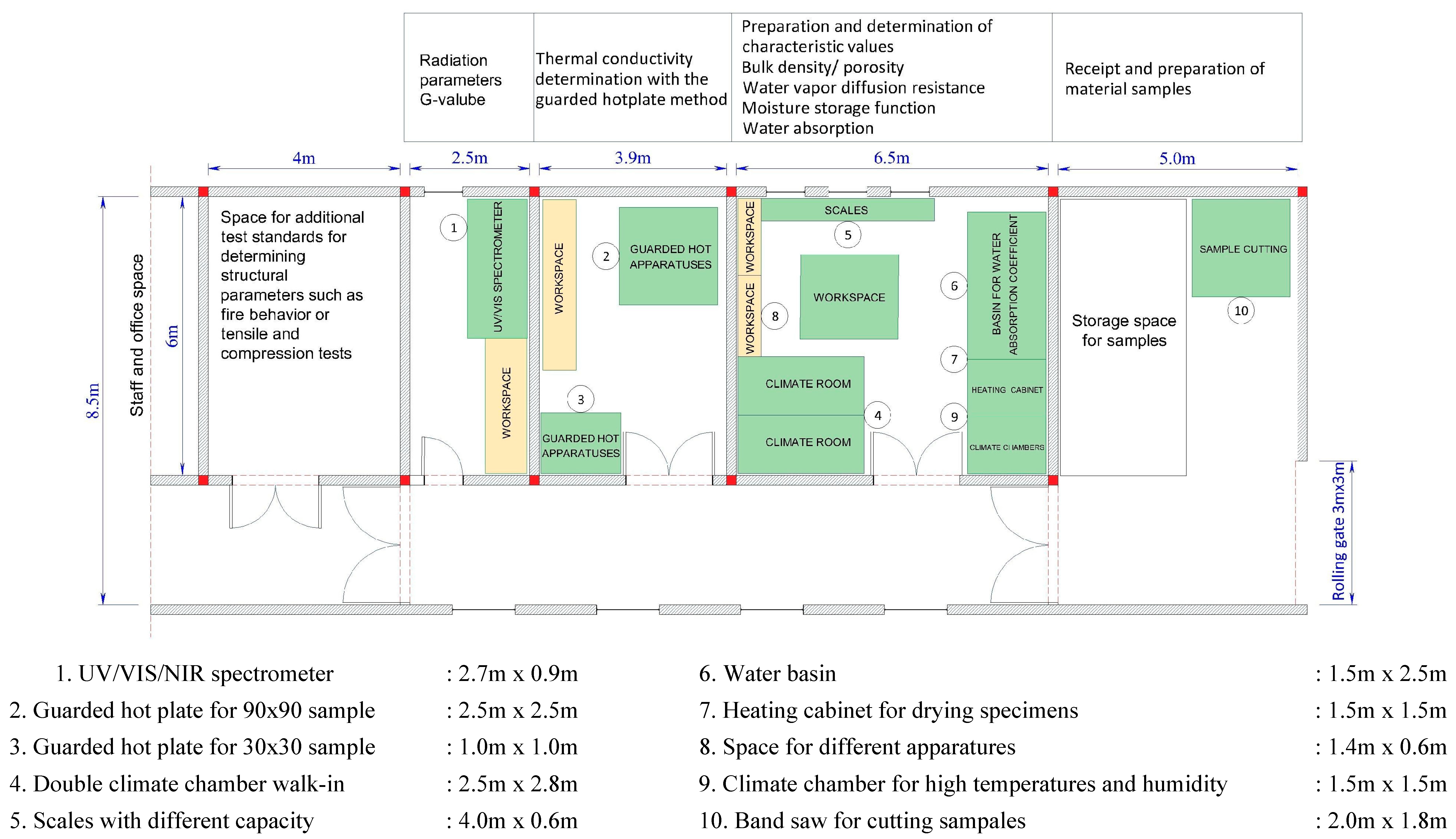

0-value, knowledge of the installation situation is necessary to determine the surface resistances. Independent of the installation situation, the thermal conductivity of the building materials used in the component must be determined. The thermal conductivity is a material parameter that indicates the heat flow at 1 K temperature difference of a 1 m thick sample. The determination of the thermal conductivity by means of a plate device is described in national and international standards, which will be indicated later in this research. For the measurement of the characteristic value, measuring equipment for determining the material thickness must be available. Likewise, both a heating cabinet and a climatic cabinet are necessary for preconditioning. Depending on the plate equipment used, material specimens with dimensions of 0.3 m x 0.3 m to 1.0 m x 1.0 m must be prepared. Depending on the material, a band saw may be useful for cutting the material specimens. To prevent the influence of strong temperature and air humidity fluctuations in the laboratory room, the room in which the measurement with the plate instrument takes place should be air-conditioned. The thermal conductivity of a material depends on the temperature and the moisture content and can also be determined as a function depending on these influences during measurements. The thermal conductivity can be determined in the laboratory A1 (see

Figure 1) as well as in the extended laboratory A2 (see

Figure 2) with the devices No. 2 and No. 3 Guarded hot plate apparatures.

U0-value

The thermal transmittance (U

0-value) is a measure of the heat transfer through a building component and is used to determine the transmission heat loss/gain of a building component. The value can either be calculated from the thermal resistance of the individual materials and the surface resistance or determined directly by a hotbox method.

The hotbox method is usually used to determine the U-value of inhomogeneous structures such as windows and doors. The test setup requires two separate air-conditioned rooms with an opening in the partition wall for the installation of a test specimen. The thermal transmittance is determined in two steps: In the first step, the test stand-related surface resistances are determined using a calibration plate with known thermal properties. In the second step, the thermal transmittance of the test specimen is determined. The size of the test rig depends on the size of the test specimen to be measured. Test stands for windows and doors should have a base area of approx. 5.0 m x 5.0 m.

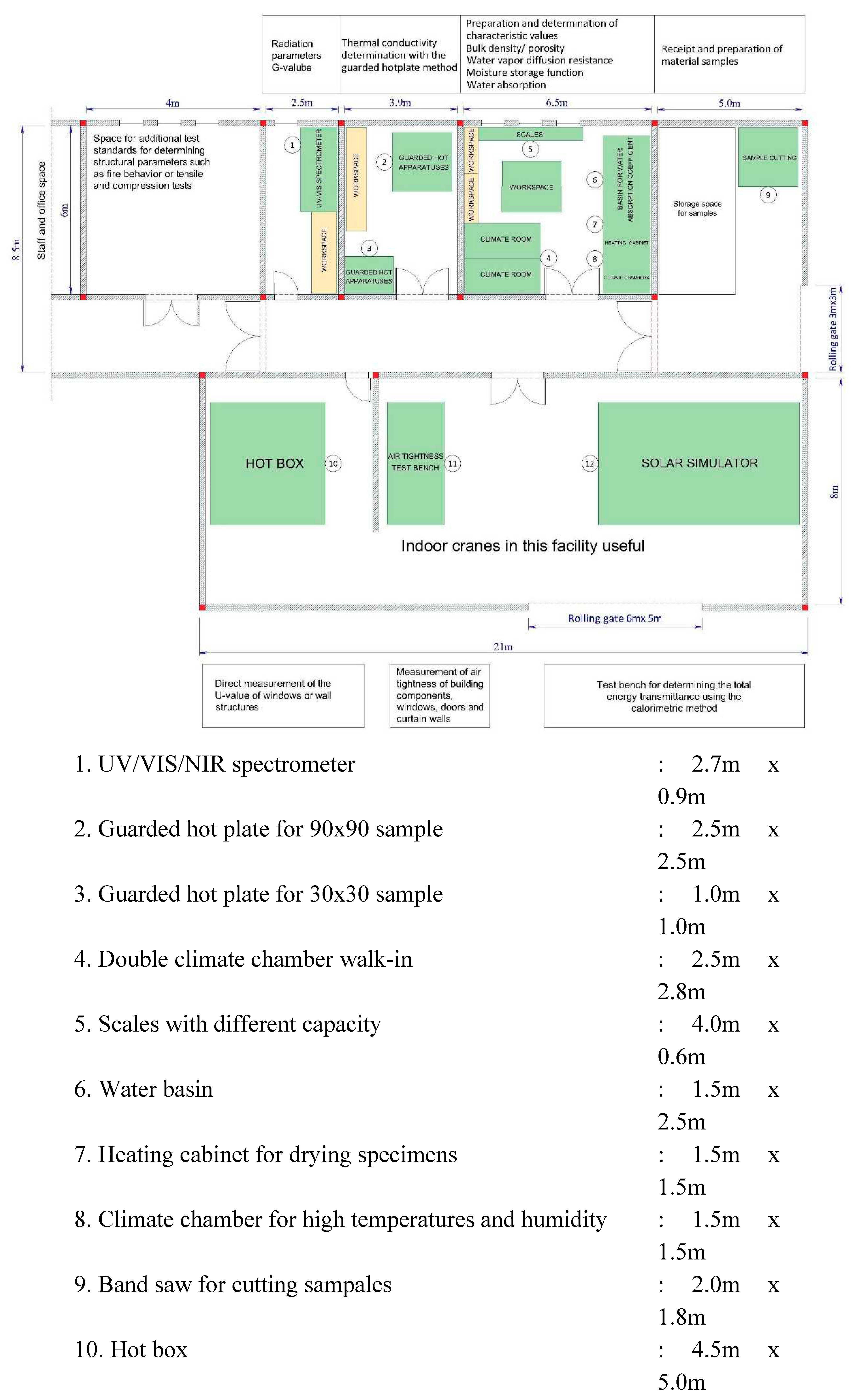

Figure 2 shows a test rig with a floor space of 25 m². The U

0-value using the hotbox-method can only be determined in the extended laboratory A2 No.10 (see

Figure 2).

The total energy transmittance g is the sum of the direct radiation transmittance τ and the secondary heat loss rate qi of the glazing to the inside. The latter is caused by heat transfer due to convection and long-wave IR radiation of the portion of incident radiation absorbed by the glazing [DIN EN 410:201104]. The g-value can be determined for simple glass samples using a spectrometer. Here, radiation properties such as the direct radiation transmittance, direct radiation reflectance and direct radiation absorptance are determined. From these characteristics, both the primary and secondary energy input for single and multiple glazing can be determined. For special components, such as glazing with integrated solar shading or curved components, the g-value can be determined using the calorimetric method. For this method, the test specimen is exposed to artificial solar radiation in the range 300 to 900 W/m² and an energy balance is carried out for the measuring space behind the specimen for defined ambient conditions.

The total energy transmission g-value of smaller samples (600 mm x 600 mm) can be determined in the simple laboratory A1 with the device No.1 UV/VIS/NIR spectrometer. Larger samples can be determined in the extended laboratory A2 with the solar simulator No.12 (see

Figure 2).

3.3.2. Characteristic values for energy optimization

An airtight building envelope can prevent energy input/loss through convective heat flows in the area of leakages. Particularly in the case of openings such as windows and doors, but also in the case of structural connections of different building components, the connection of joints should be designed to ensure the lowest possible air permeability. The air permeability of building components is defined by the air volume flow rate that passes through the leakages of a building component per time at an existing pressure difference. Depending on the standard, this value can refer to the length of a connection joint or the area of a component. To determine the air permeability, an airtight test stand is required in which an opening is provided for the test specimen. A fan is used to generate positive or negative pressure on the test specimen. The air permeability as a function of the applied pressure difference is determined from the measured values of a flow meter and a pressure gauge. Independent of the laboratory measurement, mobile devices can also be used to determine the air permeability of entire buildings. This is advantageous after completion of the airtight building envelope in the shell state, as it allows the execution of the connections to be checked and possibly improved. For air permeability, an air exchange rate of 1/h of the building volume at a pressure difference of 50 Pascal is often determined. An air permeability test of components can be performed in the extended laboratory A2 in the leak test stand No.11 (see

Figure 2).

In addition to the total energy transmittance, radiation-related characteristic values can be determined for transparent as well as opaque components, which are helpful for energy optimization.

From the spectral data, which are also determined by means of a spectrometer when determining the g-value, the light transmittance for standard light D65 can be calculated. This value can be used in living and working spaces to optimize the use of daylight and thus reduce energy consumption when using artificial light. The light transmittance can also be determined with the UV/VIS/NIR spectrometer No.1 in the laboratory A1 and extended laboratory A2 (see

Figure 2).

The emissivity is a wavelength-dependent quantity and a measure of the radiation exchange of a material with its environment. In building physics, the thermal long-wave radiation range is of particular importance. This characteristic value can be used, for example, to calculate the long-wave radiation of facade and roof surfaces. In the interior, the thermal emissivity is a parameter that is necessary for assessing the operative temperature and thus a factor for evaluating comfort. The thermal emissivity can be determined with emissiometer No. 2 in both laboratories A1 and A2 (see

Figure 1 and

Figure 2).

3.3.3. Additional hygrothermal parameters for research and development of damage-free buildings

As already described, thermal conductivity is a parameter that describes the heat transport through a material. This parameter is strongly dependent on the water content, but also on the prevailing temperature. Simulation programs make it possible to take into account the thermal conductivities dependent on the ambient conditions when evaluating a component. The specific thermal conductivities can also be determined with the aid of plate instruments. Like the simple thermal conductivity, temperature and humidity dependent thermal conductivity can also be determined in the A1 and A2 laboratories (see

Figure 1 and

Figure 2). A plate instrument No.2 No.3 is required for this purpose.

The heat capacity is a quantity that reflects the heat storage capacity of a material. In the laboratory, this value is determined by dynamic differential calorimetry. In simulation programs, the heat capacity is included in the calculations of heat transfer and is a factor responsible for the phase shift of heat transfer under transient boundary conditions. When calculating the energy consumption of a building, this parameter can be used to determine an effective heat storage capacity, which is a building-specific variable and describes the amount of heat that can be absorbed by the interior building components. The heat capacity could be determined in both laboratories A1 and A2 with the necessary measuring device (see

Figure 1 and

Figure 2). Space for such a measuring device is provided under No.8.

The bulk density is the ratio of the mass of a specimen to its total volume. It is a basic characteristic value that is necessary for a number of calculations. Many other characteristic values refer to the bulk density of a material. In simulation calculations, for example, it is used to convert the mass-specific heat capacity into the volume-specific heat capacity or to display water contents in mass percent. The bulk density is determined after drying with the aid of vacuum water absorption and weighing of an impregnated specimen. For the determination of the bulk density, space is provided in both laboratories A1 and A2 for the necessary measuring equipment, such as balances, under No. 5 (see

Figure 1 and

Figure 2).

Porosity is the ratio of the volume of a specimen to the volume of the pores in [m³/m³]. In a porous material, pores can be in contact with the ambient air, but they can also be cavities closed off on all sides. Accordingly, they are usually described by the "open" or "closed" porosity. The open porosity is determined by vacuum water absorption in the same procedure as the bulk density. By crushing and weighing a sample, it is possible to infer the pure density and thus also the total porosity. The open porosity can be used to infer the maximum water content of a material. However, since most simulation calculations are not very sensitive to the maximum water content, the value is of little importance. For the determination of porosity, areas No.5 and No.8 are provided in both laboratories A1 and A2, respectively (see

Figure 1 and

Figure 2).

The µ-value indicates the factor by which the diffusion resistance in the material is higher than in still air. This characteristic value is necessary to determine the moisture penetration via diffusion processes when a partial pressure difference is present and is therefore an essential characteristic value for assessing the freedom from damage of a building structure. In the laboratory, this value is determined by means of the dry/wet cup method. The specimen is exposed to a water vapor partial pressure difference by placing it in an airtight container with a desiccant or an aqueous saturated solution and storing it in a constant climate. The amount of diffused water vapor can be determined by weighing the test setup at regular intervals. The water vapor diffusion resistance can be determined in both laboratories A1 and A2 with the help of the climatic chambers No.4 (see

Figure 1 and

Figure 2).

A porous hygroscopic substance binds water molecules on the inner surfaces of its polymer system until it reaches an equilibrium water content corresponding to the humidity state of the surrounding air. This relationship between the relative humidity and the water content can be represented in a so-called sorption isotherm (moisture storage function), which can be divided into two areas: (i) Sorption range, hygroscopic range: part of the water molecules in the pore air is bound to the pore walls by adsorption and accumulates there with increasing air humidity, first as single molecules, then as molecular groups, then as monomolecular layers and finally as multimolecular layers consisting of several molecular layers, so that the equilibrium water content increases approximately in proportion to the air humidity; (ii) Capillary water area, overhygroscopic area: from a relative humidity of approx. 0.6 to 0.8, additional condensation phenomena occur due to the reduction of the saturation vapor pressure in the fine capillaries, resulting in a significant increase in the equilibrium humidity. The pores then contain not only adsorptively bound but also unbound liquid water.

In simulations, the moisture storage function helps to make statements about the water content and thus also about the thermal conductivity of a material. In the sorption range (up to ≈ 0.9 RH), the function is determined by storing material samples in a climatic chamber at constant temperature and relative humidity and determining the water content gravimetrically. In the capillary water range (above 0.95 RH), a suction stress measurement is carried out with a suction stress apparatus. Characteristic values of the moisture storage function can also be determined using climate chambers No. 4 and No. 9 (see

Figure 1 and

Figure 2).

The water absorption coefficient of a material is defined by the water absorption per area and time. Depending on where a building material is used, the water absorption can be determined according to different standards.

- -

Determination of the water absorption coefficient during partial immersion (capillary water absorption)

- -

Water absorption during long-term immersion

- -

Water absorption by diffusion

The determination of water absorption can be helpful in various areas. Among other things, the water absorption coefficient can be used to evaluate the rain protection effect of a facade or to classify building materials for use in components in contact with the ground. The water absorption can be determined in both laboratories A1 and A2 with the help of trolley No.5 and the dip tanks under No.6 (see

Figure 1 and

Figure 2).

For the calculation of heating and cooling loads of a building, the boundary conditions of the adjacent temperatures and weather conditions are decisive in addition to the characteristic values of the building physics. For the climate inside the building, relevant standards such as DIN 4108, EN 15026, ISO 13788 and ASH-RAE 160 specify characteristic values for the indoor climate as a function of the respective outdoor climate. The outdoor climate is taken from the measured data for the test reference year in simulation programs for calculating building energy consumption. In order to obtain reliable weather data for a region under consideration, several weather stations are necessary. Depending on the configuration of the weather station, the following weather data can be recorded:

- -

Direct and diffuse solar radiation in W/m²

- -

Temperature in °C

- -

Relative humidity in %

- -

Wind direction and speed in m/s

- -

Wind direction

- -

Air pressure hPa

- -

Rainfall l/m²h

For a simple energy consumption calculation, the parameters temperature and solar radiation are important. The outside temperature in connection with the thermal conductivity or the U-value of a building component is decisive for the calculation of the transmission heat loss and is thus directly included in the calculation of the heating energy demand. The solar radiation, on the other hand, is used in combination with the g-value to determine the energy input via glass surfaces and thus the necessary cooling load of a building. The other weather data are especially necessary for the evaluation of damage-free constructions. For example, simulations using the amount of rain and the wind direction as well as the water absorption coefficient can be used to make a statement about the water absorption on a facade surface and thus also about the resulting change in thermal conductivity. The relevance of the weather data is to be judged depending on the focus of the observation. Thus, maximum values can also be estimated and determined for the assessment of a worst-case scenario.

3.3.4. Proposal for a simple (A1) and advanced (A2) laboratory

In this study, for the determination of the necessary characteristic values which are required for the calculations of the QCVN 09:2017/BXD National Technical Regulation on Energy Efficient Buildings in Vietnam, two proposals for a smaller (A1) and an advanced laboratory (A2) with the appropriate equipment are being developed. Version A1 shows a smaller laboratory with a floor space of 190 m², with all the necessary measuring equipment to determine the basic building physics parameters. Costs of approximately 500.000 € must be calculated for the laboratory’s equipment. All rooms where measurements are carried out must have an air-conditioning system to maintain stable climatic conditions. In addition to the laboratory floor plan, office equipment space must be planned. The laboratory proposal A1 is intended for measurements on smaller material samples. Therefore an average room height of 3 - 4 m is sufficient for the laboratory rooms. Possible characteristic value determination with the simple laboratory setup is proposed, as shown in

Table 2 and the floor plan in

Figure 1.

In the second version A2, the small laboratory is extended by a larger hall with 170 m² in which additional characteristic values can be determined. The facilities in laboratory A2 also allow larger material samples and components to be measured and their characteristic values to be determined (see

Table 3 and

Figure 2). The additional hall should have a minimum height of 7 m and preferably be equipped with an overhead crane to install heavy components. In addition to the costs of the simple laboratory, a further 850.000 € should be calculated for the equipment of the extended laboratory. All cost estimates are only for the technical equipment and not for the buildings.

3.4. Implementation results

Following the current trend and assisted by many government policies and regulations, energy-saving building materials and products have great potential for further development and nationwide uptake. The government- supports include tax exemptions and reductions for listed eco-friendly products, green credit policy, preferential loans from international organizations, and others. The trend is driven by the general population’s awareness that energy-saving and eco-friendly building products and the recycling of building materials save natural resources and supports the development of sustainable construction. As a result, the trend of using these kinds of materials is increasing among architects, contractors, and investors; but it is also promoted by the State and the Ministry of Construction, and so has a growing interest among consumers.

The VIBM researchers and laboratory staffs were trained in Germany at the locations of the Fraunhofer IBP (Stuttgart and Holzkirchen), and laboratory personnel from Germany visited the locations in Vietnam to exchange experience and further education. Following the implementation and calibration of the laboratory measurement equipment, several relevant materials and material systems were selected for comparative testing. The selected materials are tested in Vietnam and then sent to the Fraunhofer IBP, where the tests are repeated non-destructively on the same samples. Potential problems were identified and resolved through bilateral discussions by comparing the results. This ensures that standard quality standards are adhered to, and the results are internationally comparable. At the moment, this new laboratory is the only one in Vietnam.

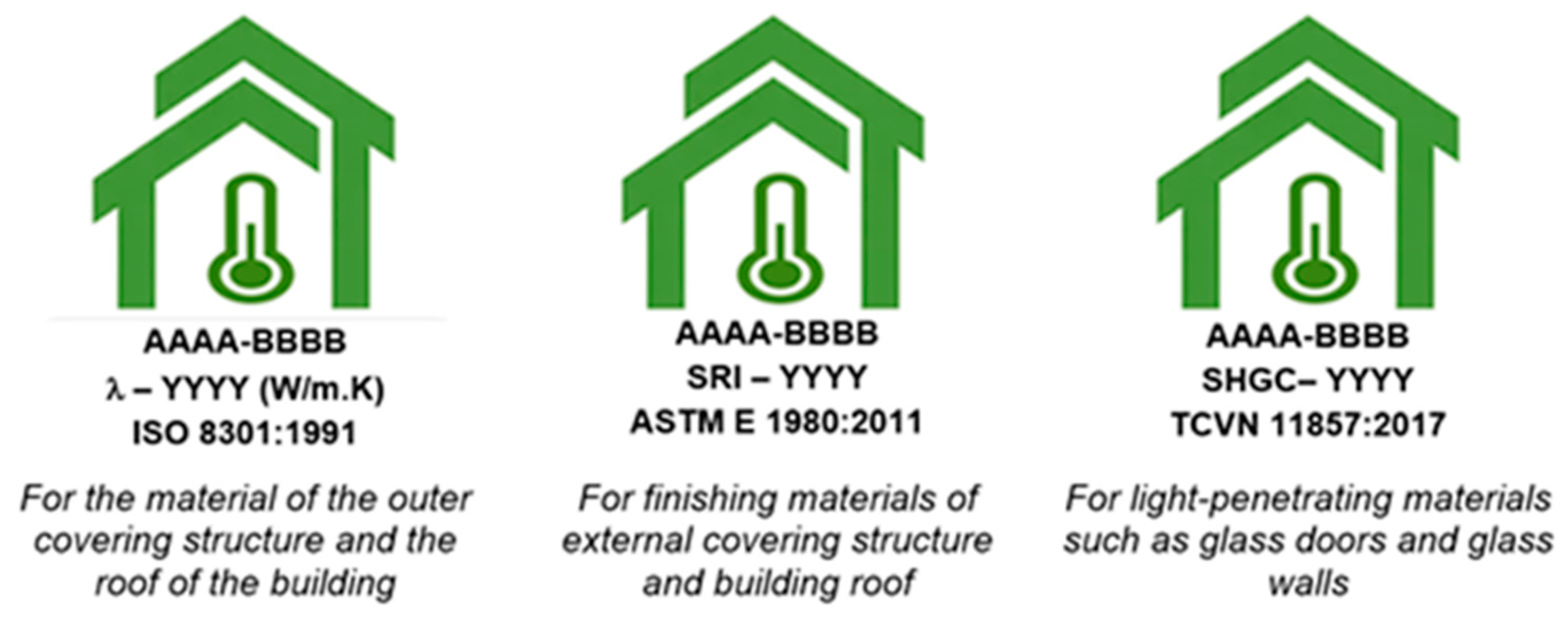

The Vietnam government released a series of policies and regulations to build-up a labeling system for building material. As result, a labeling programs for energy-saving building materials have been developed in 2021 by Vietnam Institute for Building Material. The draft version of the Circular on Energy Labelling for Building Materials has been submitted to the Ministry of Construction and is now under consideration for nationwide implementation

At the institute level, the VIBM has developed a set of criteria for evaluating and labeling energy-saving building materials to help customers to choose suitable products for their responsibility to the environment and society. The energy label for construction materials was announced and managed by VIBM under Decision No. 201/VLXD dated September 29th 2022, with code NNVLXD 01:2022 – Energy Label for Construction Materials [

12]. This labels for construction materials are applied for external covering and roof structures such as wall panels, wall structures, glazing, windows, and doors. The labels includes two mains aspects: basic information of materials/ or products (product name, company…) and its information on energy saving property.

Figure 3 shows the image of VIBM’s label for building materials. Criteria for determining thermal characteristics are presented in the label as following information:

For building materials or construction products used as external covering structure (including wall and rooftop), the thermal conductivity of materials λ (W/m.K) must be declared, except paint for wall;

For the building materials or construction products applying for external enclosure and the roof of the building including the finish coating must provide information on the Solar Reflectance Index – SRI of materials or construction structure;

For building materials and construction products that are light-permeable parts of the work such as glass doors or glass walls, information on the Solar heat gain coefficient - SHGC index of the product of glass doors or glass walls must be announced;

Because there is no benchmark energy consumption data for similar materials are available for comparative evaluation. Therefor, these labels are implemented as a type of informative lables which provide information for investors, designers, consultants, construction contractors, and consumers to choose suitable materials for energy efficiency purposes according to QCVN09:2017/BXD – National technical regulation on energy efficiency in buildings. This is also to accelerate development of energy efficiency technology in the building.

4. Conclusion and policy implications

This research presents the Government of Vietnam with an opportunity to build a system from bottom up and learing from international. In this study, the governance framework on energy efficiency building materials in Vietnam was introduced, including government decrees and technical standards. Then, the research and testing facilities for energy-saving building materials have been conducted and implemented at the VIBM in Hanoi which is the only one in Vietnam at the moment. The laboratory equipment has been installed and commissioned, as well as laboratory staff has been trained. In order to communicate the material properties to the market and enable informed decision-making by the stakeholders, the labeling system was developed. Such a comprehensive framework between governance and the details of technical applications - here demonstrated for energy-efficient construction including the hygrothermal material properties – can serve as a template for the effective implementation in other fields of sustainable construction, such as life-cycle impact assessment of building materials, testing of acoustic properties and fire protection. This study is also a valuable reference for other countries that aim to improve energy efficiency in the building.

Several policy implications can be derivered from our results. First, from the results of the overview regulations, policy makers will know which policies and regulations are missing in order to develop, supplement and complete the regulation framework for the implementaion of saving energy in the building. Secondly, the research on development of laboratory concept with all necessary equipment is a very good tool for implementing energy efficiency regulations in the building such as energy efficiency standards, regulations, labeling programs. Thirdly, this research has proposed a labeling program for enery-saving building material in Vietnam and this result has been submitted to Ministry of Construction of Vietnam. Based on this submission, a Circular on energy labeling for building material is under consideration for promulgation, which is expected to take effect from 2024. Finally, our results are a very good reference for policy makers from developing countries like Vietnam to learn how to develop the field of energy saving in buildings, sustainable development, step by step towards the goal of zero emission by 2025.

Author Contributions

T.S.L: Conceptualization, methodology, writing—original draft preparation, A.Z.: data collection and supervision, H.K: supervision, D.S: writing—review and editing and project leader, C.C.L, T.H.L and T.T.L and T.T.N: Project administration. All authors have read and agreed to published version of the manuscript.

Funding

The CAMaRSEC project is funded within the CLIENT II program "CLIENT II – International Partnerships for Sustainable Innovations" by the German Ministry of Education and Research (BMBF) under funding code 01LZ1804.

Acknowledgments

The research presented in this publication was supported by the Vietnamese Ministry of Construction and the CAMaRSEC project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Transition to Sustainable Buildings – Analysis. Available online: https://www.iea.org/reports/transition-to-sustainable-buildings (accessed on 7 August 2023).

- Jollands, N.; Waide, P.; Ellis, M.; Onoda, T.; Laustsen, J.; Tanaka, K.; de T’Serclaes, P.; Barnsley, I.; Bradley, R.; Meier, A. The 25 IEA Energy Efficiency Policy Recommendations to the G8 Gleneagles Plan of Action. Energy Policy 2010, 38, 6409–6418. [Google Scholar] [CrossRef]

- Nearly Zero-Energy Buildings. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-buildings_en (accessed on 7 August 2023).

- Kaya, D.; Çanka Kılıç, F.; Öztürk, H.H. Energy Performance Certificate. In Energy Management and Energy Efficiency in Industry: Practical Examples; Kaya, D., Çanka Kılıç, F., Öztürk, H.H., Eds.; Green Energy and Technology; Springer International Publishing: Cham, 2021; pp. 73–79. ISBN 978-3-030-25995-2. [Google Scholar]

- Jaysawal, R.K.; Chakraborty, S.; Elangovan, D.; Padmanaban, S. Concept of Net Zero Energy Buildings (NZEB) - A Literature Review. Cleaner Engineering and Technology 2022, 11, 100582. [Google Scholar] [CrossRef]

- Union, P.O. of the E. 2000/532/EC: Commission Decision of 3 May 2000 Replacing Decision 94/3/EC Establishing a List of Wastes Pursuant to Article 1(a) of Council Directive 75/442/EEC on Waste and Council Decision 94/904/EC Establishing a List of Hazardous Waste Pursuant to Article 1(4) of Council Directive 91/689/EEC on Hazardous Waste (Notified under Document Number C(2000) 1147) (Text with EEA Relevance), CELEX1. Available online: http://op.europa.eu/en/publication-detail/-/publication/239a2785-9115-4e06-adae-66c8e08a5a42 (accessed on 6 December 2021).

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Martínez, M.; Fernández, A.I.; Urge-Vorsatz, D. Affordable Construction towards Sustainable Buildings: Review on Embodied Energy in Building Materials. Current Opinion in Environmental Sustainability 2013, 5, 229–236. [Google Scholar] [CrossRef]

- Usta, P.; Zengin, B. The Energy Impact of Building Materials in Residential Buildings in Turkey. Materials (Basel) 2021, 14, 2793. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Cheng, J.; You, S.; Ye, T.; Zhang, H.; Fan, M.; Wei, S.; Liu, S. Effect of Implementing Building Energy Efficiency Labeling in China: A Case Study in Shanghai. Energy Policy 2019, 133, 110898. [Google Scholar] [CrossRef]

- Ministry of Finance Vietnam. Available online: https://mof.gov.vn/webcenter/portal/btcvn/pages_r/l/tin-bo-tai-chinh?dDocName=MOFUCM222793 (accessed on 7 June 2023).

- GTAI Germany Trade & Invest. Industry Analysis: Construction Industry in Vietnam. Report 2017 ( online , accessed 17.11.2017).

- Asian Development Bank and Asian Development Bank Institute of Viet Nam, Energy sector assessment, strategy, and road map. Asian Development Bank 2016 ( online , accessed 18.11.2017).

- Möller. Thermo-hygric shape changes and residual stresses of natural and artificial bricks. University of Stuttgart 1993. [Google Scholar]

- Law on Economical and Efficient Use of Energy (50/2010/QH12). | UNEP Law and Environment Assistance Platform. Available online: https://leap.unep.org/countries/vn/national-legislation/law-economical-and-efficient-use-energy-502010qh12 (accessed on 6 June 2023).

- Decision, No. 1266/QD-TTg 2020 Strategy for Development of Building Materials in 2021-2030. Available online: https://english.luatvietnam.vn/decision-no-1266-qd-ttg-approving-the-strategy-for-development-of-vietnams-building-materials-for-the-20-189217-doc1.html (accessed on 5 June 2023).

- National Technical Regulation on Energy Efficiency Buildings | ESCAP Policy Documents Managment. Available online: https://policy.asiapacificenergy.org/node/1107 (accessed on 6 June 2023).

- Decision No. 280/QD-TTg Dated March 13, 2019 on Approval for National Program for Thrifty and Efficient Use of Energy for the Period of 2019 -2030 280/QD-TTg, 2019. Available online: https://lawnet.vn/en/vb/Decision-280-QD-TTg-2019-approval-for-national-program-for-thrifty-and-efficient-use-of-energy-6E098.html (accessed on 6 June 2023).

- Circular No. 01/2018/TT-BXD Dated January 05, 2018 on Urban Green Growth Indicators, 2018. Available online: https://lawnet.vn/en/vb/Circular-01-2018-TT-BXD-on-urban-green-growth-indicators-5B69A.html (accessed on 6 June 2023).

- National standard TCVN 9258:2012. Available online: https://vanbanphapluat.co/tcvn-9258-2012-chong-nong-cho-nha-o-chi-dan-thiet-ke (accessed on 6 June 2023).

- National standard TCVN 4605:1988. Available online: https://vanbanphapluat.co/tcvn-4605-1988-ky-thuat-nhiet-ket-cau-ngan-che-tieu-chuan-thiet-ke (accessed on 6 June 2023).

- Vietnam Insitute for Building Materials. Survey the current status of building materials consumption, Annual report, 2021.

- Decree 102/2003/ND-CP of the Government on economic and efficient use of energy. Available online: https://thuvienphapluat.vn/van-ban/Tai-nguyen-Moi-truong/Nghi-dinh-102-2003-ND-CP-su-dung-nang-luong-tiet-kiem-hieu-qua-51315.aspx (accessed on 6 June 2023).

- Liu, F.; Jia, B.; Chen, B.; Geng, W. Moisture Transfer in Building Envelope and Influence on Heat Transfer. Procedia Engineering 2017, 205, 3654–3661. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, Y.; Zhao, Z.; Wang, D.; Liu, Y.; Liu, J. Effect of Moisture Transfer on Heat Transfer through Exterior Corners of Cooled Buildings in Hot and Humid Areas. Journal of Building Engineering 2021, 43, 103160. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, C.; Liu, Y.; Wang, D.; Liu, J. Effect of Moisture Migration and Phase Change on Effective Thermal Conductivity of Porous Building Materials. International Journal of Heat and Mass Transfer 2018, 125, 330–342. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).