1. Introduction

Lean Six Sigma, a comprehensive management approach, integrates lean and six sigma methodologies to improve performance, enhance customer satisfaction, and increase profits by optimizing processes and reducing waste and variations. It has gained recognition as a powerful strategy for companies seeking a competitive edge and cost reduction (Snee, 2010). With growing research in the field, Lean Six Sigma applications span various disciplines and industries, emphasizing tools and methodologies to drive efficiency and effectiveness (Yadav et al., 2016). In the context of Lean Six Sigma implementation, certain CSFs must be addressed for successful deployment throughout the organization, fostering growth in the industry. Key CSFs include flexible planning and control, employee acknowledgment, adherence to Green and Lean Six Sigma strategies, and effective training (Koppenjan et al., 2011; Pampanelli et al., 2011; Alves and Alves, 2015; Park and Linich, 2008; Antony and Banuelas, 2002; Kwak and Anbari, 2006; Jayaraman and Teo, 2010; Rodriguez and Walters, 2017). Critical Success Factors (CSFs) play a vital role in Lean Six Sigma implementation, requiring special attention for successful adoption. Key CSFs encompass flexible planning and control, employee acknowledgment, adherence to Green and Lean Six Sigma strategies, and effective training. These factors are crucial to successful implementation and long-term organizational success.

This study seeks to investigate the relationship between critical success factors and the success of Lean Six Sigma implementation, focusing on Nigerian manufacturing companies. By exploring a diverse pool of respondents, the research aims to identify CSFs that strongly correlate with effective LSS deployment. Structural equation modeling (SEM) will be employed to model the relationships between CSFs and LSS implementation success, providing valuable insights for organizations seeking optimal process improvement.

Addressing the current knowledge gap, the study's findings will contribute to existing process improvement knowledge and offer practical implications for organizations aspiring to implement Lean Six Sigma successfully. With Lean Six Sigma's objective of optimizing production structures, minimizing waste, enhancing customer satisfaction, and maximizing profitability, understanding its critical success factors becomes imperative. The research will shed light on the effects of these factors on production outcomes and financial performance, assisting companies in maximizing profits and driving continuous improvement. Despite focusing on Nigerian manufacturing companies, the study's insights are likely to hold relevance for organizations across various industries and sectors. The hierarchical structure of success factors will help prioritize and enhance their implementation in different organizational contexts. Though this research aims to provide valuable data on Lean Six Sigma implementation in Nigerian industries, time constraints and the unresponsiveness of some individuals pose limitations in data collection. Nevertheless, the study's outcomes are expected to contribute to further research in the ever-evolving landscape of Lean Six Sigma and its critical success factors.

2. Literature Review

Lean Six Sigma refers to a collaborative team-based process aimed at enhancing performance by systematically eliminating waste and reducing variations (Bhaksar, 2020). The concept is often described as a synergy between lean manufacturing and six sigma methodologies, which jointly focus on flow, value streams, waste reduction, and variation reduction through structured problem-solving and the application of statistical tools (Snee, 2010). Moreover, it is considered a methodology that drives the maximization of shareholder value by improving customer happiness, cost, quality, process speed, and invested capital (Taghizadegan, 2006). In the literature, Lean Six Sigma is commonly defined as both a business strategy and methodology, leading to increased customer satisfaction and higher profitability (Snee, 2010). Furthermore, Lean Six Sigma is recognized as an approach for driving continuous improvement in service businesses, incorporating lean thinking ideals and six sigma's statistical rigor (Assarlind et al., 2013; Heavey and Rowlands, 2014.

2.1. Applications of Lean Six Sigma

Lean Six Sigma has found widespread application across various sectors, leading to improved process performance and reduced organizational costs (Salah et al., 2010). Researchers have increasingly favored the concurrent use of both lean and six sigma techniques, establishing Lean Six Sigma as a tool for operational excellence. Assarlind et al. (2013) studied the adoption of LSS, identifying essential elements for successful future implementations. They emphasized the need for different approaches for major improvement projects and modest ones.

The integration of Lean Six Sigma with other approaches has been explored in diverse application areas. Rodgers et al. (2019) demonstrated its integration with quality management systems, energy management systems, environmental sustainability concepts, data science, data mining, agile, artificial intelligence, and more. Bhat et al. (2014) presented a case study of the LSS DMAIC (Define-Measure-Analyze-Control) approach application in the Health Information Department of a Medical College Hospital in India. The results showed significant reductions in patient waiting times, queue length, and staff scheduled for the process. Lean Six Sigma has also been applied to healthcare services, with promising outcomes. Lighter (2014) explored LSS implementation in pediatric healthcare, leading to process improvements, cost savings, and enhanced services for patients. Thomas et al. (2016) deployed the Strategic Lean Six Sigma Framework (SLSSF) in an aerospace manufacturing organization, achieving substantial improvements in construction time, on-time customer deliveries, and value-added time. Although Lean Six Sigma deployment is more prevalent in the private sector, its usage in the public sector, including healthcare, education, government, and law enforcement, has been growing (Rodgers et al., 2019).

2.2. Critical Success Factors of Lean Six Sigma

The Critical Success Factors (CSFs) of Lean Six Sigma encompass a range of key factors that are crucial for its successful implementation. Laureani and Anthony (2012) identified management commitment, cultural transformation, integration with business strategy, and leadership philosophies as important factors for Lean Six Sigma adoption. Middle management engagement in solution development and strategy building by senior management was highlighted as essential for project success (Manville et al., 2012). Research by Forcellini et al. (2017) emphasized the significance of management engagement and leadership as critical variables in LSS implementation. Yadav et al. (2021) identified 20 success variables crucial to the success of LSS, while Aljazzazen et al. (2022) highlighted the selection of competent personnel and top management commitment as primary CSFs. Gastelum-Acosta et al. (2022) identified nine CSFs, finding a substantial relationship between these criteria and the success of LSS programs. Francescatto et al. (2022) identified leadership, management involvement, project management, organizational structure, and effective communication with leaders and managers as key CSFs for successful LSS implementation. Mishra (2022) identified five top CSFs for implementing LSS, including organizational readiness, project selection and priority, resource and skill facilitation, dedicated management and employees, and emphasis on estimation and results. Swarnakar et al. (2022) grouped CSFs into six categories, with economic and managerial factors being the most crucial for sustainable LSS implementation.

2.3. Structural Equation Modelling

Structural Equation Modelling (SEM) is a multivariate statistical approach used to evaluate and estimate multivariate causal linkages (Tarka (2018). It involves evaluating and estimating multivariate causal linkages, encompassing a measurement model (confirmatory factor analysis) and a structural model (Chandra, 2014).

In the context of SEM, multiple latent independent variables are measured by various indicators, and one or more latent dependent variables are assessed using multiple indicators, leading to complex interactions, nonlinearity, measurement errors, and correlated error terms (Adedokun and Egbelakin, 2022). The technique provides several model fit indices, utilizing multiple indices to assess the model's fitness for the data (Adedokun et al., 2022). Structural equation models are formulated based on priori theoretical or logical complex relationships between variables in a linear system of equations. They estimate coefficients representing effects between considered variables and measurement errors. In the behavioral and social sciences, SEM serves as a sophisticated statistical technique, valuable for both basic and applied research, allowing for the evaluation of measurement models, causal hypotheses, and predictive models (Krastevich and Reshetkova, 2021).

2.4. Structural Equation Modeling of the Critical Success Factors of Lean Six Sigma

Several research studies have investigated the critical success factors (CSFs) influencing the implementation of Lean Six Sigma (LSS). For example, Habidin and Yosuf (2013) utilized three Structural Equation Modeling (SEM) techniques to validate the underlying items of LSS's CSFs in the Malaysian automobile industry. Leadership and customer focus were identified as the most important factors for successful LSS implementation. Yadav and Desai (2017) employed fuzzy MICMAC analysis and Interpretive Structural Modeling (ISM) to identify 20 crucial success elements for LSS deployment. Alidrisi (2014) also utilized ISM to examine the relationships between 12 CSFs and create a model for implementing LSS in the automotive services industry. The study confirmed the importance of all CSFs for successful LSS implementation. Raval et al. (2021) used the decision-making trial and evaluation laboratory and DEMATEL to analyze causal linkages between elements impacting LSS implementation in an Indian manufacturing company. They identified ten key success factors for LSS implementation, which were prioritized by top management based on a thorough literature review and professional judgment.

R et al. (2020) collected empirical data from experts implementing LSS and sustainable manufacturing practices to validate a measurement model. Their findings indicated a significant relationship between LSS and sustainable manufacturing components contributing to organizational success. Yazdi et al. (2020) developed 22 customized CSFs using a hybrid model approach combining the Delphi method, SWARA, and genetic algorithm. The resulting prioritization of CSFs helped businesses identify high-priority factors to focus on, saving resources by disregarding less crucial aspects.

3. Methods

The research process followed nine steps

Step 1: Identification of Relevant CSFs and Creation of a Survey Questionnaire for Data Collection

The first step involved a meticulous analysis of existing literature and expert judgments with substantial support. A convenience sampling strategy was employed to gather data from experts and practitioners who have experience in adopting Lean Six Sigma in their businesses. A survey questionnaire was developed to collect data on crucial Lean Six Sigma success criteria and implementation success metrics. The questionnaire consisted of questions formulated based on the analysis of Lean Six Sigma literature, crucial success criteria, and prior research. A 5-point Likert scale was utilized for responses. The target sample size was 200 participants, randomly drawn from a population of possible respondents to ensure unpredictability and equal selection likelihood. To pilot test the questionnaire, a mixed sample of middle and senior managers, including LSS practitioners, was selected. Minor question format adjustments were made based on pilot survey results.

Step 2: Distribution and Collection of Survey Data

Microsoft Forms links were distributed to all 200 participants through social media platforms like WhatsApp, emails, and LinkedIn. Follow-up reminders were sent to encourage respondents. The questionnaire comprised sections for demographic information, followed by measured items representing latent constructs of interest. Participants rated their agreement or disagreement using the Likert scale. Clear instructions were provided to ensure accurate and thoughtful responses. Validation questions were included to filter out unreliable data. After data filtering, 130 responses were selected for further investigation, resulting in a response rate of 65%. The majority of respondents (69.23%) belonged to the manufacturing, energy, and counseling industries, while the remaining 30.77% represented agriculture, telecommunications, sales, marketing, and other minor sectors.

Step 3: Data Preparation

Before conducting the analysis, the data was carefully reviewed, and any errors, missing values, or anomalies were corrected. Ensuring the data's completeness and accuracy was crucial, as inaccuracies or missing data could impact the results. The Kruskal-Wallis test for K-population samples was used to test for significance.

Step 4: Descriptive Statistics

Descriptive statistics were performed to understand the sample's characteristics. For categorical variables, frequency and percentage were calculated, while mean, median, and standard deviation were calculated for continuous data. Descriptive statistics help in comprehending the data by describing the sample's characteristics (Kaur et al., 2018).

Step 5: Selection of Adequate Measurement Instruments

Appropriate measurement tools were selected to analyze latent variables. These tools could include survey questions, behavioral observations, and other relevant information. It was crucial to ensure the validity and reliability of the measuring instruments, meaning that they effectively measure latent variables and provide consistent results between administrations.

Step 6: Test the Measurement Model using Confirmatory Factor Analysis (CFA)

The measurement model, which outlines the relationships between observed variables and latent variables, was tested using CFA. This statistical method assesses the model's fit to the data and identifies any inaccuracies or anomalies (Distefano and Hess, 2005).

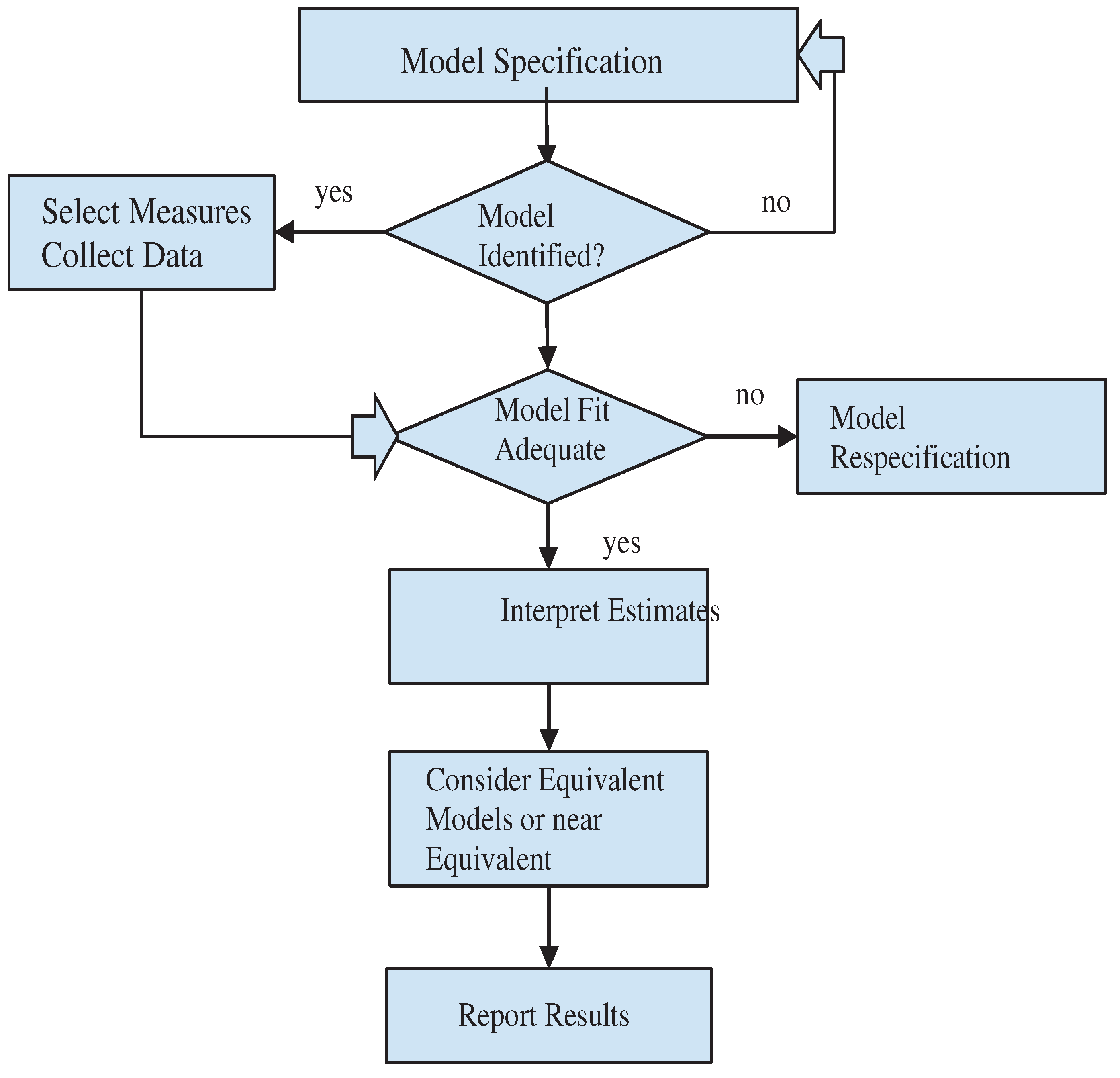

Step 7: Model Estimation using PLS SEM

SmartPLS 4.0 was used to conduct Partial Least Squares Structural Equation Modeling (PLS SEM) to analyze and estimate the relationships between latent variables and validate the model's fit to the data (Sarstedt et al., 2014). This involved describing model parameters, such as path coefficients, and estimating these parameters using maximum likelihood estimation.

Step 8: Evaluate the Model's Fitness

The model's fit was assessed by examining a series of fit indices that reflect how well the model represents the data. Examples of fit indices include the chi-square statistic and the root mean square error of approximation (RMSEA). If the model's fit is inadequate, researchers may need to revise it.

Step 9: Interpretation of Results

After estimating the model and evaluating its fit to the data, the results were interpreted, and conclusions were drawn regarding the relationships between the variables. This involved examining the magnitude and significance of path coefficients and assessing the overall fit of the model to the data.

Figure 1.

Flow Chart of the PLS-SEM Process.

Figure 1.

Flow Chart of the PLS-SEM Process.

Table 1 above summarizes the demographic information of the 130 respondents to the questionnaire categorized into gender, employee size, years of experience and industry. Each Category has subcategories with their percentages out of the population of respondents.

Table 2 contains the selected CSFs that were used in the creation of the questionnaire, categorized into three Subscales.

4. Results

4.1. Validation of Measurement Model

The Cronbach’s Alpha and composite reliability (

Table 3) of the subscales of CSFs in the measurement model was observed to be over 0.7 which indicated that the measurement model's constructs are reliable, consistent, and valid. This enhances the overall quality and robustness of the research findings and supports the accuracy of the structural relationships among the constructs and latent variable which in this case are the CSFs and Successful Lean Six Sigma Implementation

The findings from the convergent validity analysis of the constructs in this study, as indicated by the Average Variance Extracted (AVE) statistics, all exceeded the recommended threshold of 0.5 as shown in

Table 4. This supports the reliability and validity of the measurement model developed. The results demonstrate that the observed variables are reliable and valid indicators of the underlying Critical Success Factors (CSFs), providing valuable insights into their nature and ensuring consistency in measuring the constructs with minimal influence from measurement errors or random variability. Additionally, the Composite Reliability (CR) values were greater than 0.7, indicating that convergent validity is not a concern in this study.

Our results show in

Table 5 below that for each CSF, the square root of the AVE was indeed greater than its correlation with other constructs; hence, discriminant validity is established. This indicates that in this study, the constructs (CSFs) are conceptually different and represent distinct aspects of the research, thereby enhancing the reliability and accuracy of the findings and interpretations in the research study. For the Fornell and Larcker criterion, discriminant validity is established when the square root of the AVE for a construct is greater than its correlation with all other constructs.

4.1.1. Path Analysis/Second Order Test

Table 6 and

Table 7 summarizes the resulting Critical Success Factors (CSFs) along with their three subscales, Path Coefficients, and Variance Inflation Factors (VIF) concerning the success of Lean Six Sigma (LSS) implementation. The VIF values presented in

Table 7 range between 1 and 5, indicating that the predictor variables exhibit low correlation with each other. This implies that the individual effects of these predictors on the outcome variable can be reliably estimated, thereby enhancing the reliability and interpretability of the regression results.

In

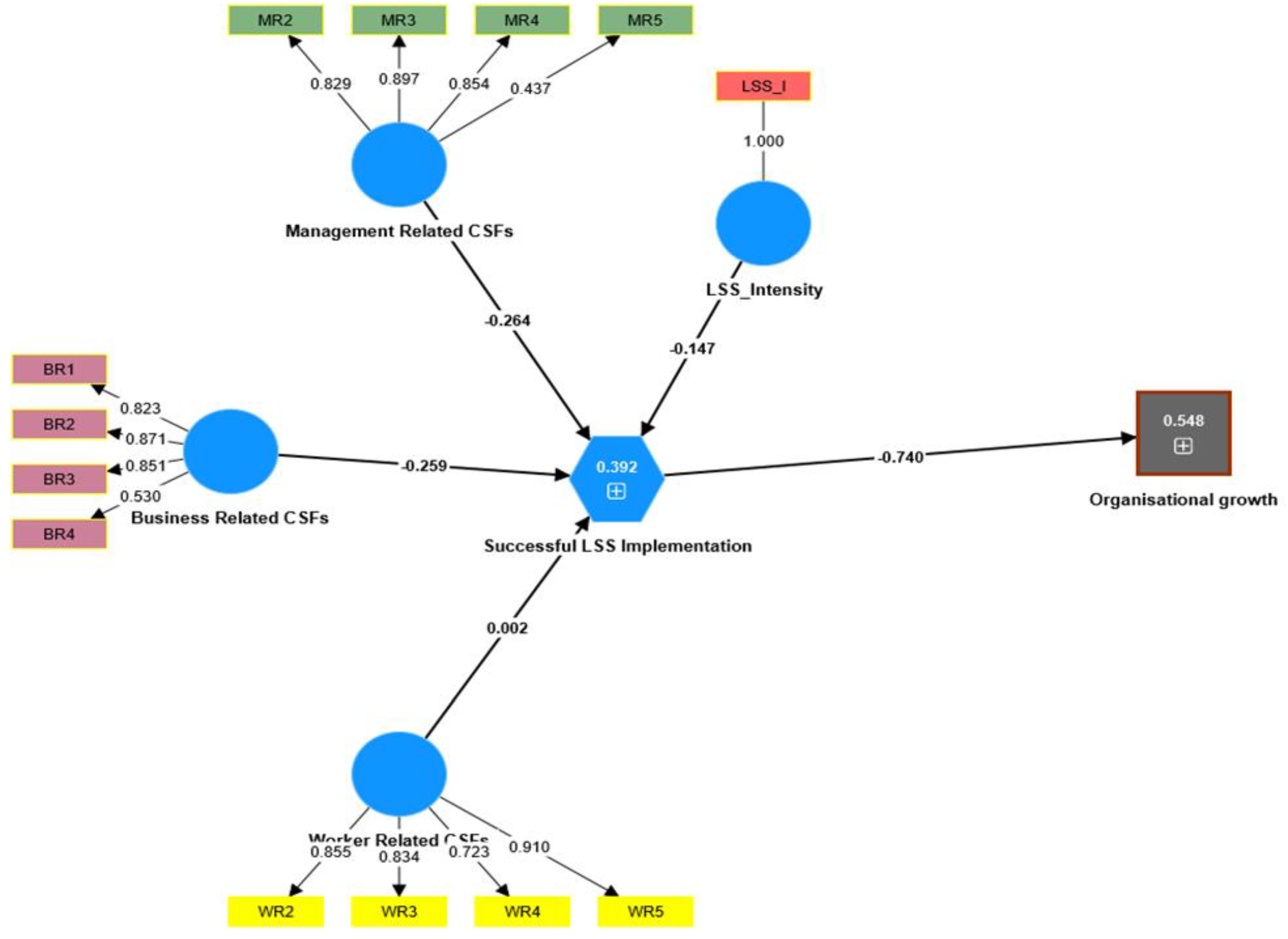

Table 6, all path coefficients are positive, signifying a statistically significant relationship between the two constructs involved in each path. These results support the hypothesis that a focus on the independent construct (CSF) leads to a corresponding increase in the dependent construct (Successful LSS Implementation). The observed path coefficients suggest that a one-unit increase in Business Related CSFs, Management Related CSFs, Worker Related CSFs, and LSS Intensity results in a 0.259, 0.147, 0.264, and 0.002 unit increase in Successful LSS Implementation, respectively. Additionally, a one-unit increase in Successful LSS Implementation is associated with a 0.74 unit increase in Organizational growth. These findings highlight the significant impact of the accepted second-order findings of the three subscales on the successful implementation of Lean Six Sigma.

Figure 2 displays the R2 outcomes for successful Lean Six Sigma (LSS) implementations in the current study model. For Management Related CSFs and Business-Related CSFs, three individual CSFs' factor loadings surpass the recommended value of 0.70, indicating a high correlation between the items and the construct. However, the other two factor loadings indicate a moderate correlation as they are below the recommended value. Similarly, for Worker Related CSFs, the individual CSFs' factor loadings are above the recommended value of 0.70, indicating a high correlation.

The path coefficients obtained illustrate the strength of influence of the subscales on successful LSS implementation and its impact on organizational growth. These coefficients represent the effect size of each relationship in the structural model. Furthermore, the R2 value for successful LSS Implementation is 0.392, suggesting that Lean Six Sigma CSFs contribute to 39.2% of the effectiveness of Lean Six Sigma implementations. Additionally, successful LSS implementations are projected to lead to a 54.8% boost in organizational growth.

4.2. Discussions

The study's results indicate that Lean Six Sigma (LSS) Critical Success Factors (CSFs) play a crucial role in the successful implementation of LSS, leading to significant benefits for Nigerian organizations. Adopting LSS enables organizations to enhance productivity, eliminate waste, and expand operations, resulting in improved overall performance and economic sustainability across various industries. By addressing areas of improvement, LSS implementation leads to waste reduction, financial gains, and better employee relations.

Creating a conducive environment that aligns LSS tools with Lean Six Sigma implementation is vital for Nigerian organizations to maximize the impact of LSS CSFs. The study highlights a strong association between LSS CSFs and successful LSS deployments, with selected CSFs contributing up to 39.2 percent to the overall success of Lean Six Sigma implementations. These findings offer valuable insights into the effective deployment of Lean Six Sigma practices in Nigerian organizations. However, it is essential to consider the moderate correlation observed in some factor loadings and the limitations of the study when interpreting and applying the results to real-world scenarios.

5. Conclusion

5.1. Recommendation

To ensure a successful deployment of Lean Six Sigma (LSS), organizations should focus on implementing the identified LSS Critical Success Factors (CSFs). Creating a supportive environment for change, providing comprehensive training, and continuously improving processes are crucial. The study reveals a strong correlation between LSS CSFs and successful implementations, with these factors contributing significantly (up to 39.2 percent) to the success of LSS deployments. Future research could explore longitudinal studies to assess long-term impacts, sector-specific analyses for targeted recommendations, and qualitative research to understand factors influencing successful deployment and employee well-being during LSS implementation in Nigerian organizations.

5.2. Conclusion

Despite challenges in infrastructure, training, and environmental conditions, Lean Six Sigma (LSS) offers Nigerian organizations the potential to increase productivity, competitive advantage, and achieve long-term production systems by reducing waste and implementing continuous improvement. This study identified 12 critical LSS CSFs categorized as workers, business, and management, using partial least squares structural equation modeling (PLS-SEM). LSS adoption can be beneficial for Nigerian firms to achieve strategic goals, and future research should gather more data and replicate the study in various industries to gain a deeper understanding of the elements leading to LSS success.

By addressing these 12 LSS CSFs, Nigerian organizations can enhance their chances of successful LSS implementation and reap the benefits of Lean Six Sigma.

Funding

This research received no funding.

References

- Alves, J.R.X. and Alves, J.M. (2015), “Production management model integrating the principles of lean manufacturing and sustainability supported by the cultural transformation of a company”, International Journal of Production Research, Vol. 53 No. 17, pp. 5320-5333. [CrossRef]

- Adedokun, O., & Egbelakin, T. (2022). Structural equation modelling of risk factors influencing the success of building projects. Journal of Facilities Management. [CrossRef]

- Alidrisi, H. (2014). Prioritizing Critical Success Factors for Six Sigma Implementation Using Interpretive Structural Modeling. American Journal of Industrial and Business Management, 04(12), 697–708. [CrossRef]

- Aljazzazen, S., Schmuck, R. (2022). Critical Success Factors for Successful Lean Six Sigma Implementation in the Service Organizations. (2022). Quality - Access to Success, 23(188). [CrossRef]

- Antony, J. and Banuelas, R. (2002), “Key ingredients for the effective implementation of six sigma program”, Measuring Business Excellence, Vol. 6 No. 4, pp. 20-27. [CrossRef]

- Assarlind, M., Gremyr, I., & Bäckman, K. (2013). Multi-faceted views on a Lean Six Sigma application. International Journal of Quality & Reliability Management, 30(4), 387–402. [CrossRef]

- Bhat, S., Gijo, E. V., & Jnanesh, N. A. (2014). Application of Lean Six Sigma methodology in the registration process of a hospital. International Journal of Productivity and Performance Management, 63(5), 613–643. [CrossRef]

- DiStefano, C., & Hess, B. (2005). Using Confirmatory Factor Analysis for Construct Validation: An Empirical Review. Journal of Psychoeducational Assessment, 23(3), 225–241. [CrossRef]

- Fadly Habidin, N., & Mohd Yusof, S. (2013). Critical success factors of Lean Six Sigma for the Malaysian automotive industry. International Journal of Lean Six Sigma, 4(1), 60–82. [CrossRef]

- Forcellini, F., Pereira, M., Ferenhof, H. A., & Boeing Ribeiro, A. (2017). A Lean Six Sigma implementation model based on Critical Success Factors. Procceedings of the 24th ABCM International Congress of Mechanicl Engineering. 24th ABCM International Congress of Mechanical Engineering. [CrossRef]

- Francescatto, M., Neuenfeldt Júnior, A., Kubota, F. I., Guimarães, G., & de Oliveira, B. (2022). Lean Six Sigma case studies literature overview: Critical success factors and difficulties. International Journal of Productivity and Performance Management. [CrossRef]

- Gastelum-Acosta, C., Limon-Romero, J., Tlapa, D., Baez-Lopez, Y., Tortorella, G., Rodriguez Borbon, M. I., & Navarro-Cota, C. X. (2022). Assessing the adoption of critical success factors for lean six sigma implementation. Journal of Manufacturing Technology Management, 33(1), 124–145. [CrossRef]

- Heavey, C., & Rowlands, D. (2014). Lean six sigma for service: How to use lean speed and six sigma quality to improve services and transactions (2nd ed.). Hoboken, NJ: John Wiley & Sons.

- Jeyaraman, K., & Kee Teo, L. (2010). A conceptual framework for critical success factors of lean Six Sigma: Implementation on the performance of electronic manufacturing service industry. International Journal of Lean Six Sigma, 1(3), 191–215. [CrossRef]

- Kaur, P., Stoltzfus, J., & Yellapu, V. (2018). Descriptive statistics. International Journal of Academic Medicine, 4(1), 60. [CrossRef]

- Koppenjan, J., Veeneman, W., van der Voort, H., ten Heuvelhof, E., & Leijten, M. (2011). Competing management approaches in large engineering projects: The Dutch RandstadRail project. International Journal of Project Management, 29(6), 740–750. [CrossRef]

- Krastevich, T., & Reshetkova, A. (2021). Structural equation modelling in sustainable development research. In I. Olejnik (Ed.), Qualitative and quantitative methods in sustainable development (1st ed., pp. 117–178). Wydawnictwo Uniwersytetu Ekonomicznego w Poznaniu. [CrossRef]

- Kwak, Y.H. and Anbari, F.T. (2006), “Benefits, obstacles, and future of six sigma approach”, Technovation, Vol. 26 Nos 5/6, pp. 708-715. [CrossRef]

- Lal Bhaskar, H. (2020). Lean Six Sigma in Manufacturing: A Comprehensive Review. In F. Pedro García Márquez, I. Segovia Ramirez, T. Bányai, & P. Tamás (Eds.), Lean Manufacturing and Six Sigma—Behind the Mask. IntechOpen. [CrossRef]

- Laureani, A., & Antony, J. (2012). Critical success factors for the effective implementation of Lean Sigma: Results from an empirical study and agenda for future research. International Journal of Lean Six Sigma, 3(4), 274–283. [CrossRef]

- Lighter, D. E. (2014). The application of Lean Six Sigma to provide high-quality, reliable pediatric care. International Journal of Pediatrics and Adolescent Medicine, 1(1), 8–10. [CrossRef]

- Manville, G., Greatbanks, R., Krishnasamy, R., & Parker, D. W. (2012). Critical success factors for Lean Six Sigma programmes: A view from middle management. International Journal of Quality & Reliability Management, 29(1), 7–20. [CrossRef]

- Mishra, M. N. (2022). Identify critical success factors to implement integrated green and Lean Six Sigma. International Journal of Lean Six Sigma, 13(4), 765–777. [CrossRef]

- Pampanelli, A.B., Found, P. and Bernardes, A.M. (2011), “A Lean and green Kaizen model”, POMS Annual Conference, Nevada, April 29-May 2, 2011.

- Park, C. and Linich, D. (2008), “Green Lean Six Sigma: using Lean to help drive results in the wholly sustainable enterprise”, Deloitte Consulting.

- R., B. R., Vinodh, S., & P., A. (2020). Development of structural equation model for Lean Six Sigma system incorporated with sustainability considerations. International Journal of Lean Six Sigma, 11(4), 687–710. [CrossRef]

- Raval, S. J., Kant, R., & Shankar, R. (2021). Analyzing the critical success factors influencing Lean Six Sigma implementation: Fuzzy DEMATEL approach. Journal of Modelling in Management, 16(2), 728–764. [CrossRef]

- Rodgers, B. A., Antony, J., He, Z., Cudney, E. A., & Laux, C. (2019). A directed content analysis of viewpoints on the changing patterns of Lean Six Sigma research. The TQM Journal, 31(4), 641–654. [CrossRef]

- Rodriguez, J and Walters, K (2017). "The Importance of Training and Development in Employee Performance and Evaluation", World Wide Journal of Multidisciplinary Research and Development, https://wwjmrd.com/upload/1509114292.pdf.

- Salah, S., Rahim, A., & Carretero, J. A. (2010). The integration of Six Sigma and lean management. International Journal of Lean Six Sigma, 1(3), 249–274. [CrossRef]

- Sarstedt, M., Ringle, C. M., Smith, D., Reams, R., & Hair, J. F. (2014). Partial least squares structural equation modeling (PLS-SEM): A useful tool for family business researchers. Journal of Family Business Strategy, 5(1), 105–115. [CrossRef]

- Snee, R. D. (2010). Lean Six Sigma – getting better all the time. International Journal of Lean Six Sigma, 1(1), 9–29. [CrossRef]

- Swarnakar, V., Bagherian, A., & Singh, A. R. (2022). Prioritization of critical success factors for sustainable Lean Six Sigma implementation in Indian healthcare organizations using best-worst-method. The TQM Journal, ahead-of-print(ahead-of-print). [CrossRef]

- Taghizadegan S. (2006). Essentials of Lean Six Sigma. Amsterdam: Elsevier. Wong Y.C., Wong K.Y., Ali A.W. (2009) “A Study on Lean Manufacturing Implementation in the Malaysian Electrical and Electronics Industry”, European Journal of Scientific Research, 38(4): 521-535.

- Tarka, P. (2018). An overview of structural equation modeling: Its beginnings, historical development, usefulness and controversies in the social sciences. Quality & Quantity, 52(1), 313–354. [CrossRef]

- Thomas, A. J., Francis, M., Fisher, R., & Byard, P. (2016). Implementing Lean Six Sigma to overcome the production challenges in an aerospace company. Production Planning & Control, 1–13. [CrossRef]

- Yadav, G., & Desai, T. N. (2016). Lean Six Sigma: A categorized review of the literature. International Journal of Lean Six Sigma, 7(1), 2–24. [CrossRef]

- Yadav, G., & Desai, T. N. (2017). Analyzing Lean Six Sigma enablers: A hybrid ISM-fuzzy MICMAC approach. The TQM Journal, 29(3), 488–511. [CrossRef]

- Yadav, N., Shankar, R., & Singh, S. P. (2021). Critical success factors for lean six sigma in quality 4.0. International Journal of Quality and Service Sciences, 13(1), 123–156. [CrossRef]

- Yazdi, A. K., Hanne, T., & Osorio Gómez, J. C. (2021). A hybrid model for ranking critical successful factors of Lean Six Sigma in the oil and gas industry. The TQM Journal, 33(8), 1825–1844. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).