1. Introduction

In recent years, due to the increasing requirements for miniaturization and lightweight of industrial products, power arrays are developing towards high-density, high-power and intelligent direction [

1]. Temperature rise is a critical factor affecting the reliability of power modules.With the increase of temperature, the failure efficiency of electronic components shows an exponential growth trend, which seriously affects the normal operation of supply load [

2]. With the increase of working hours, some cooling measures must be taken to limit the temperature rise of the clustered power modules.

Frequently-used thermal design methods mainly include physical structure heat dissipation and modeling optimization heat dissipation. Physical structure heat dissipation can be divided into natural air cooling, conduction cooling, forced air cooling, circulating water cooling and so on. Natural air cooling mainly transfers heat from the power module shell to the air through natural convection or conducts it to the PCB through pins. The conductive heat dissipation includes a layer of heat-conducting silicone sheet and resin between the shell and the module so that the shell and the module are closely combined.Forced air cooling includes the use of fans to increase air flow to remove accumulated heat.Circulating water cooling involves placing water-filled conduits on top of the heat module to dissipate heat through flow liquor. Software modeling mainly uses computers to carry out thermal simulation calculations with environmental parameter, including structural heat dissipation characteristics and heat source layout, and guides relevant thermal design after establishing thermal simulation models.

In order to solve the problem of heat dissipation of power arrays, various researchers adopt single or combined physical methods based on general thermal design measures and use software analysis. They fails to solve the problem of heat dissipation fundamentally, comprehensively, systematically and completely, and may be accompanied by new problems or risks when it is solved. The paper [

3] combines methods (natural air cooling, thermal conduction, forced air cooling) are used for heat dissipation. The optimized structure can meet the heat dissipation requirements, but the selected test power supply has low power and has not yet met the design requirements of high power and high density. In addition, the numerical simulation method does not consider the influence of materials on conduction heat.The paper [

4] adopts a forced air cooling method and eatablishes a three-dimensional simulation model. The heat dissipation conditions are improved by optimizing the air intake channel. However, all the simulation data only remain in the theoretical calculation stage, and the actual heat dissipation effect lacks full test verification. The paper [

5] designs A air-liquid water-cooling cabinet and optimizes the structural size design. The heat dissipation effect is improved due to optimization of design of structure, but the heat exchange improves the power consumption of the whole system. If the cold plate is subjected to severe impact, vibration and extrusion, it may lead to the leakage of coolant, threatening the safety of the whole system. It can be seen that the current thermal design scheme has more or less the following problems: Firstly, only from the perspective of heat dissipation channel, heat dissipation layout, software modeling, the heat dissipation environment is optimized to improve the heat dissipation effect, the efficiency of heat source, the use of conductive materials and other factors are not considered. Secondly, The effectiveness of thermal design measures cannot be verified without high load test on the basis of miniaturization, high-power and high-density design. Thirdly, the software modeling environment is ideal and the simulation parameters are simple. There is a lack of test data support, resulting in a certain deviation between the simulation environment and the real environment with load, which is not enough to further guide the thermal design. Fourthly, Improving the heat dissipation performance resulting in reliability degradation of system; Fifthly, The lack of logic for the monitoring of temperature, current and voltage related operation data of heat source devices and the formation of feedback regulation may lead to excessive thermal design. For example, forced air cooling can cause the improvement of static power consumption, resulting in unnecessary operation noise.

In this paper, we design an extremely miniaturized high-power and high-density power array. We select high efficiency DC/DC module as the heating source. In the way of heat dissipation, we adopt magnesium and aluminum alloy to the main structural materials, and use graphene as the conduction material between the heat source and the cold plate. They can ensure that the power array case has high thermal conductivity while taking into account the characteristics of high strength, lightweight and anti-electromagnetic interference. And we combine natural air cooling and conduction heat dissipation, forced air cooling as a supplement. In addition, MCU chip, multi-point temperature and voltage and current sensors, A/D acquisition chip, relay and other automation modules, can intelligently monitor the temperature rise of each point of the power module and then control the power array and forced air cooling starting time. Finally, we place the electronic case in a closed thermal environment for dynamic loading to test. The results show that the heat dissipation system can effectively improve the heat dissipation condition and reduce the working temperature of the whole system without sacrificing the performance and meet the requirements of fast response and continuous and efficient output power of the power array.

The paper structure is as follows.

Section 2 presents the thermal design methods of heat dissipation of physical structure and heat dissipation optimization by modeling.

Section 3 presents the design of automatic cooling case based on high-power power supply array, including conduction cooling design, forced air cooling design, high power density power supply array design, automatic control module design. In

Section 4, the test results are analyzed and compared with related performance parameters. In

Section 5, the experimental conclusions and future research are discussed.

2. Related Works

In recent years, various research teams have proposed solutions to the heat dissipation problem of closed power supply cases (modules) with high power density and small volume from different perspectives, which can be roughly divided into two categories as

Table 1: physical structure heat dissipation and modeling optimization heat dissipation.

The heat dissipation of physical structure is usually improved or optimized by the combination of natural air cooling, conduction cooling, forced air cooling and circulating water cooling. Li [

3] analyzes the heat dissipation path of a high power density closed power supply, and proposed a design method to strengthen heat dissipation by using the shell extension surface structure of rectangular fin, so as to increase the area of conduction refrigeration. Yu [

6] adoptes heat pipe cooling technology in cold plate to improve the heat transfer capacity of cold plate. Fu [

7] designs the structure and method of ventilation and heat dissipation of a new energy storage power supply, which realized uniform heat dissipation inside the energy storage power supply through such structures and methods as air inlet and air guide plate at the bottom of the energy storage power supply, switchable cooling mode and independent air duct air outlet. Tan [

4], aiming at the heat dissipation problem of the power cabinet of an airborne equipment, adoptes the method of forced air cooling to reasonably improve the air intake pipe to reduce the pressure loss in the pipe, so as to achieve better air cooling heat dissipation effect. Ben [

6] adopts the distributed forced air cooling for heat dissipation of the modular DC power cabinet in the substation, which effectively controls the temperature difference between the power module and the radiator. However, these solutions based on physical heat dissipation of the selected power module combination power density is low, and only from the heat dissipation structure to optimize adjustment. Without the closed extreme environment for a long time with load output test, cooling effect is unknown, so there is no fundamental solution to the problem of heat dissipation. In addition, structural adjustment may bring low reliability of the whole system.

Thermodynamic analysis software is usually used to establish the simulation model of the power supply, which is used to verify the technical requirements and optimize the product structure and selection design, so as to provide effective and rigorous design scheme guidance for the air-cooled or water-cooled cabinets used in the industrial field. Yang [

5] conducts a three-dimensional simulation analysis from the whole machine to the local cooling air path design, the gas-liquid heat exchange device and the corresponding cold plate for the ship-borne water-cooled cabinet, and conducted heat simulation to check the cooling effect and optimize the structural design. Zhang [

8] calculates the influence of the outlet pressure of the switching power supply on the wind speed of the fan inside the switching power supply and the influence of the inlet wind speed of the power supply on the temperature of the heat source inside the power supply by theoretical calculation and numerical simulation, verified the rationality of the heat dissipation characteristics and structural design of the model, and provided valuable data for the design, simulation, optimization and application of related equipment. Huang [

9] uses mathematical modeling and finite element analysis methods. ANSYS simulation analysis software is used to analyze the heat dissipation structure of high-power microwave power supply, and proposed structural optimization measures for cooling water flow, cooling fan inlet flow and fin thickness. Niu [

10] establishes the thermal resistance model of the power module. By analyzing the coupling relationship between the main heat sources, the temperature rise was calculated, and the thermal simulation model was established by Flothem software to verify the correctness of the thermal resistance model. In view of the thermal stress concentration point, the thermal performance optimization design scheme was proposed. However, these software-based modeling solutions only stay in the ideal simulation stage, the thermal conductivity of heat dissipation materials, power module characteristics, room temperature changes and other factors are not included in the simulation model, resulting in a large gap between the model and the real application scenario. The ultimate purpose of simulation is only to improve the heat dissipation structure, but still not fundamentally solve the heat dissipation problem. Secondly, the simulation model of thermal resistance is also verified by other thermal simulation models, therefore, there are no support and verification of actual data for the validity of the model.

3. Design of automatic cooling case

The automatic heat dissipation case mainly follows the principle of heat source suppression and heat dissipation environment improvement. Firstly, reduce thermal power from the selection and design of heat source. Secondly, improvement of the heat dissipation environment optimize the conduction heat dissipation, air cooling heat dissipation as a supplement. Design of automatic cooling case includes: conduction heat dissipation design, forced air cooling design, high power density power supply array design, automatic control module design.

3.1. Conduction heat dissipation design

3.1.1. Selection of conductive heat dissipation materials

In conductive heat dissipation, the methods to reduce thermal resistance include replacing high thermal conductivity materials and increasing the area of heat dissipation structure [

11]. Metals are commonly used as heat dissipating materials in industrial products. Magnesium aluminum alloy is an aluminum alloy with Mg as the main added element. Magnesium metal is the smallest density of widely used metal metal, magnesium(

) alloy is 20% lighter than plastic, 30% lighter than aluminum. The strength and quality of magnesium alloy are high, and it has a certain bearing capacity. Its heat conductivity is 100 times that of PP material. Related studies have shown that cooling speed is related to parameters(p and c)of heat capacity of materials and cooling time. Material heat capacity parameters(p and c) at the beginning of the cooling had a great influence on the cooling speed. Magnesium alloy AZ91D, for example, compared with the aluminum alloy, its values of p and c are low, so it has faster speed of reduction of temperature in the air [

12]. Therefore, magnesium aluminum alloy has high thermal conductivity with the characteristics of lightweight, high strength, which is the best choice for cold plate and chassis materials. Furthermore, in non-metallic materials, graphene has recently been advocated for high power thermal management enhancement, such as heat dissipation in high-density integrated circuits, due to its high thermal conductivity of 5300w/MK. Packaging composites with high thermal conductivity can be prepared by filling graphene into the polymer matrix, which is much better than other fillers [

13].

3.1.2. structure design of conduction heat dissipation

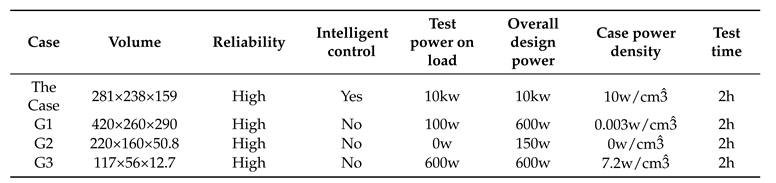

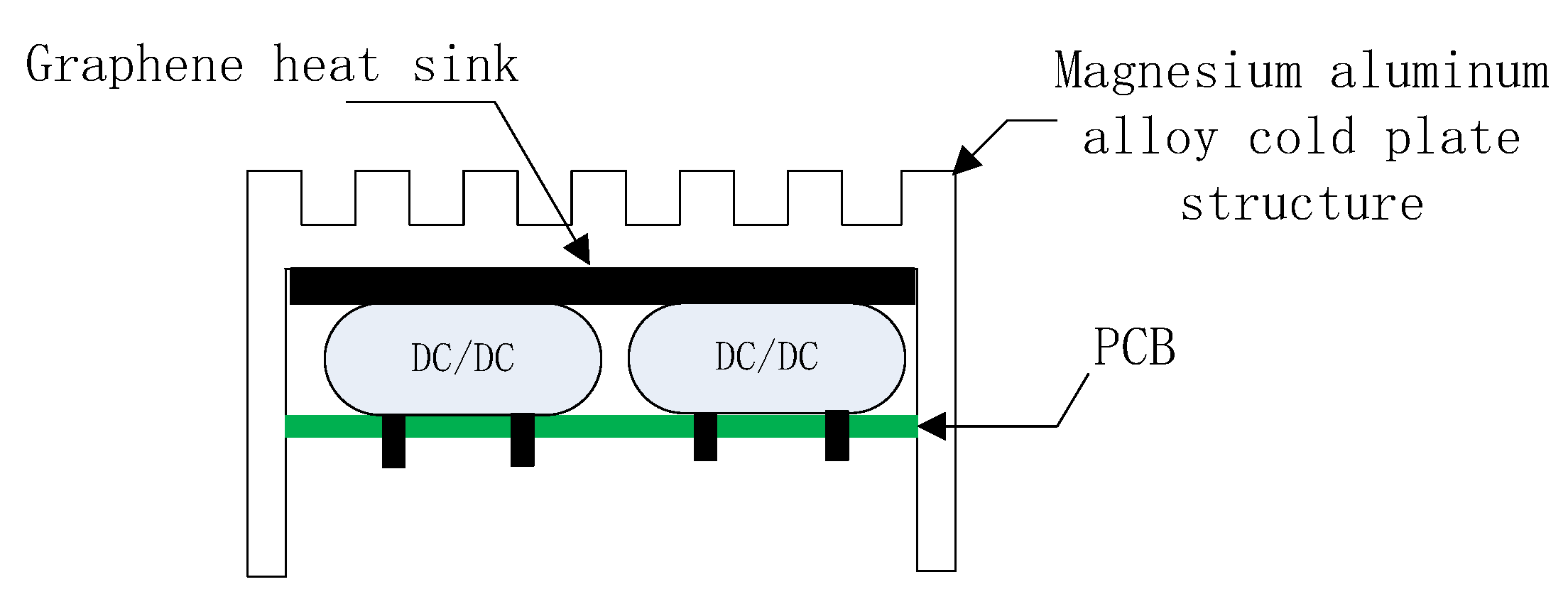

In order to increase the heat dissipation area, the finned AZ91D magnesium aluminum alloy cold plate structure is used in this paper. Graphene is used as the heat conduction material between the cold plate and DC/DC module.

Figure 1 shows Side view of Conduction heat dissipation structure.

Figure 2 shows Top view of Conduction heat dissipation structure. From the

Figure 2, gray is the covered part of the cold plate and red is the DC/DC power supply. white is the cold plate opening, and the dotted black part is the graphene heat sink area. The heat conduction and heat dissipation channel is: DC/DC module interior → module shell → graphene → magnesium aluminum alloy cold plate surface → fin structure → internal case environment.

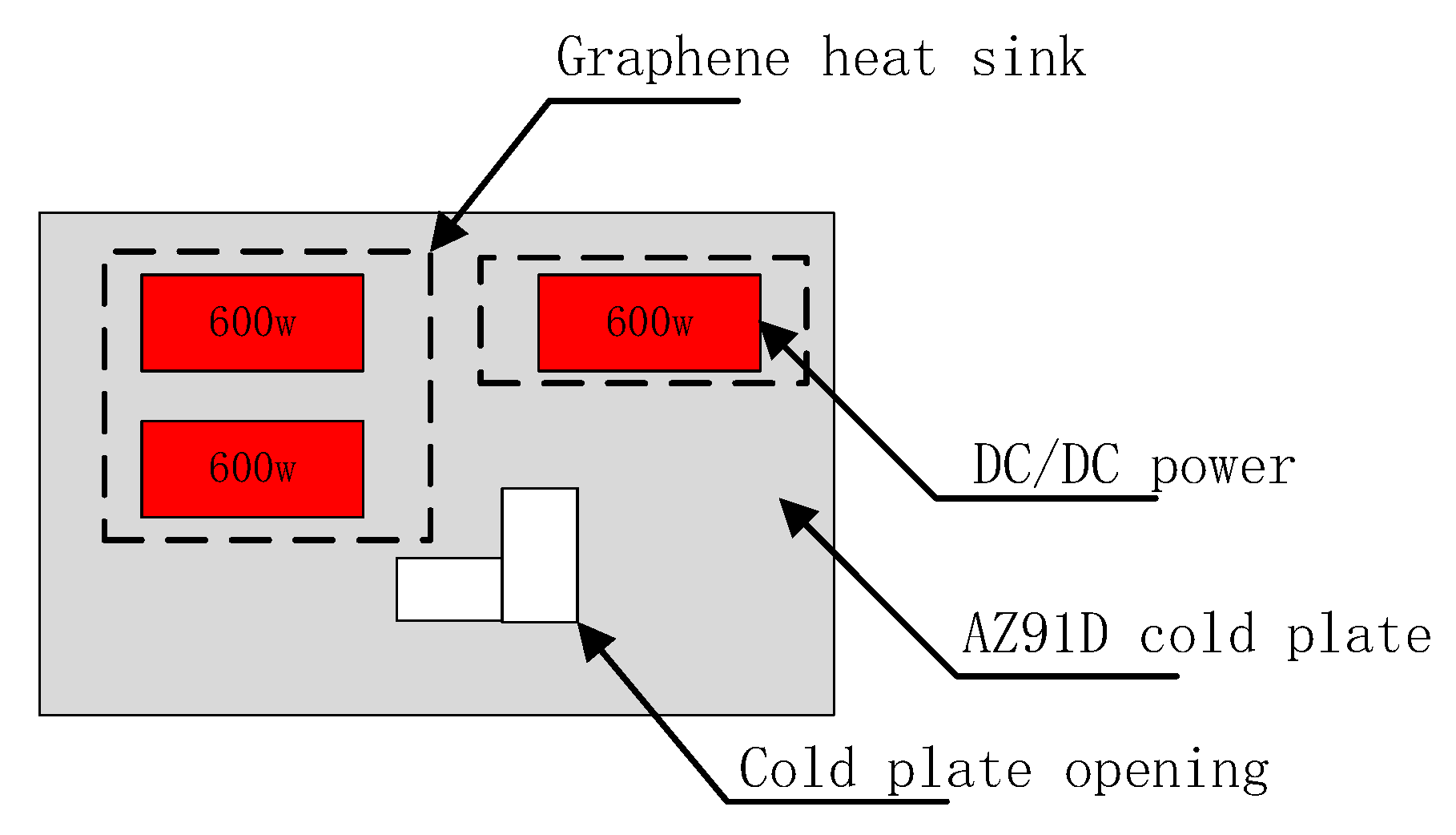

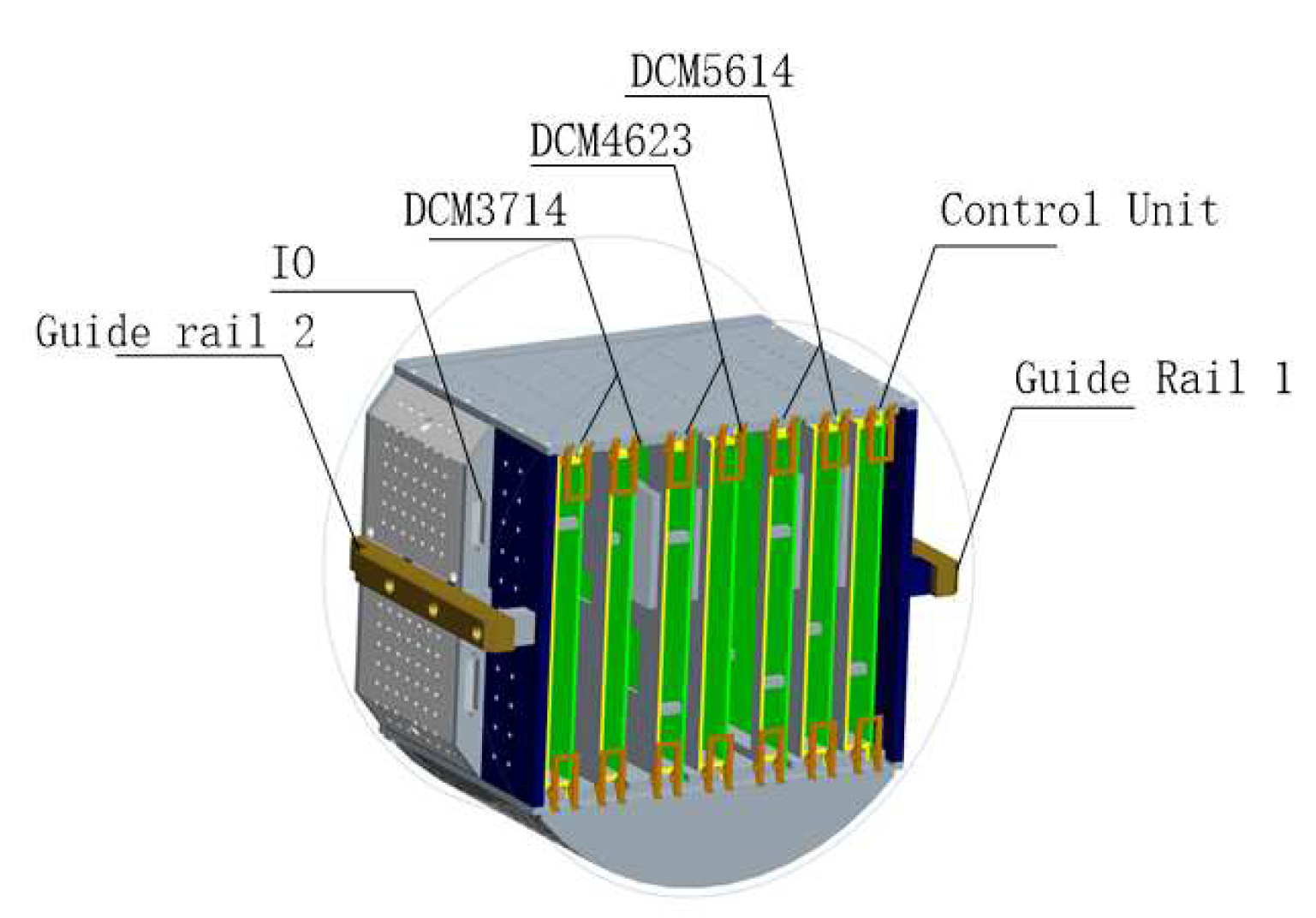

Each series of power supply is loaded by two PCB boards. Taking DCM3714 series as an example, the three-dimensional structure diagram of one board is shown in

Figure 3. The power array consists of six power array PCBs and a control PCB, and the final schematic diagram of the heat dissipation structure of the electronic case is shown in

Figure 4. The container size is about 28.1×23.8×15.9mm, which meets the requirements of miniaturization design [

14]. As shown in

Figure 4, the guide rail design on both sides not only serves to install the structure of the electronic chassis mechanically, but also acts to transfer the heat from the surface of the case to the external mounting structure. As shown in

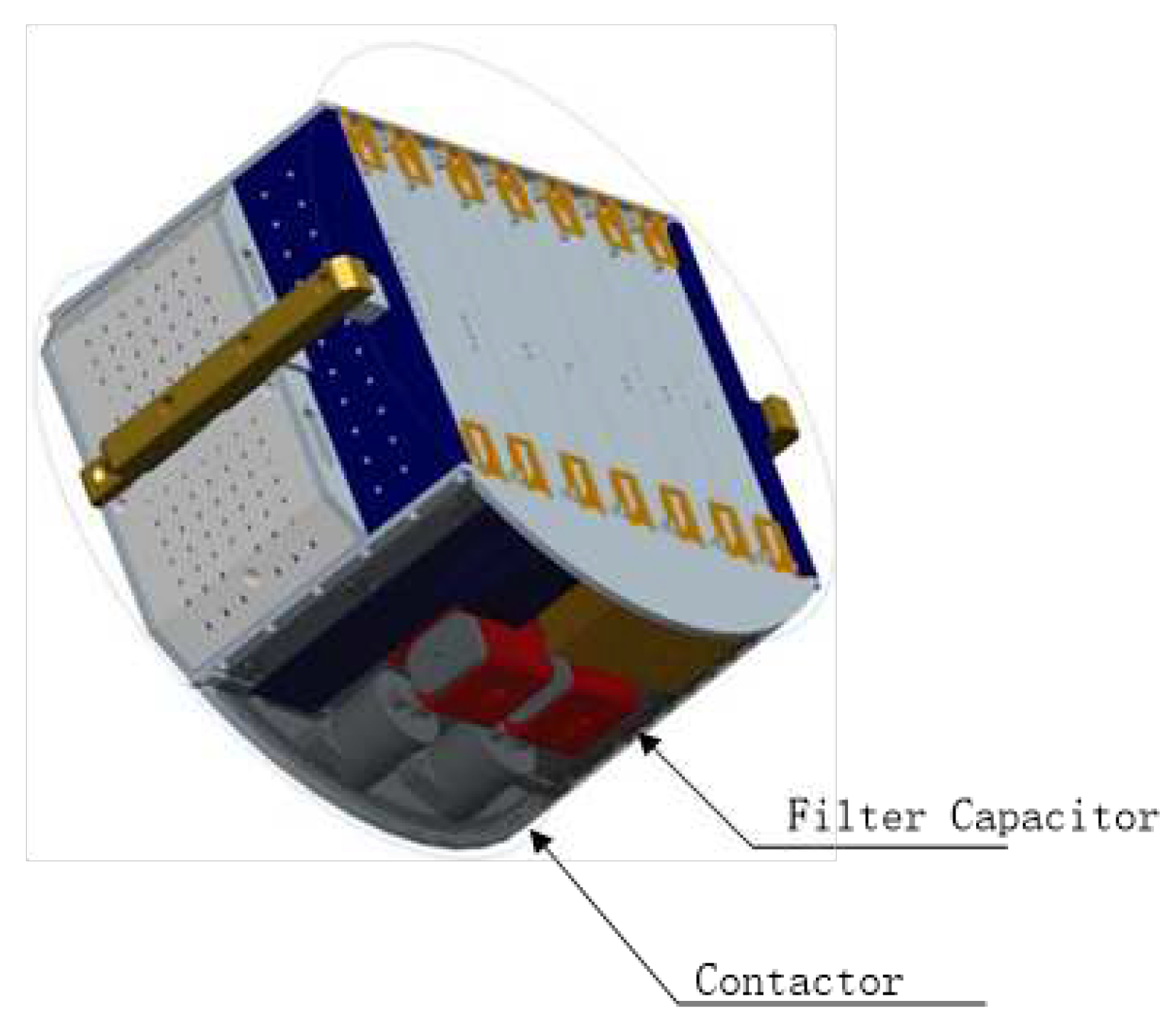

Figure 5, the contactor and filter capacitor are installed at the bottom of case. 300V high-voltage input power is controlled by the contactor and the filter capacitor is used to filter the ripple of high-voltage input.

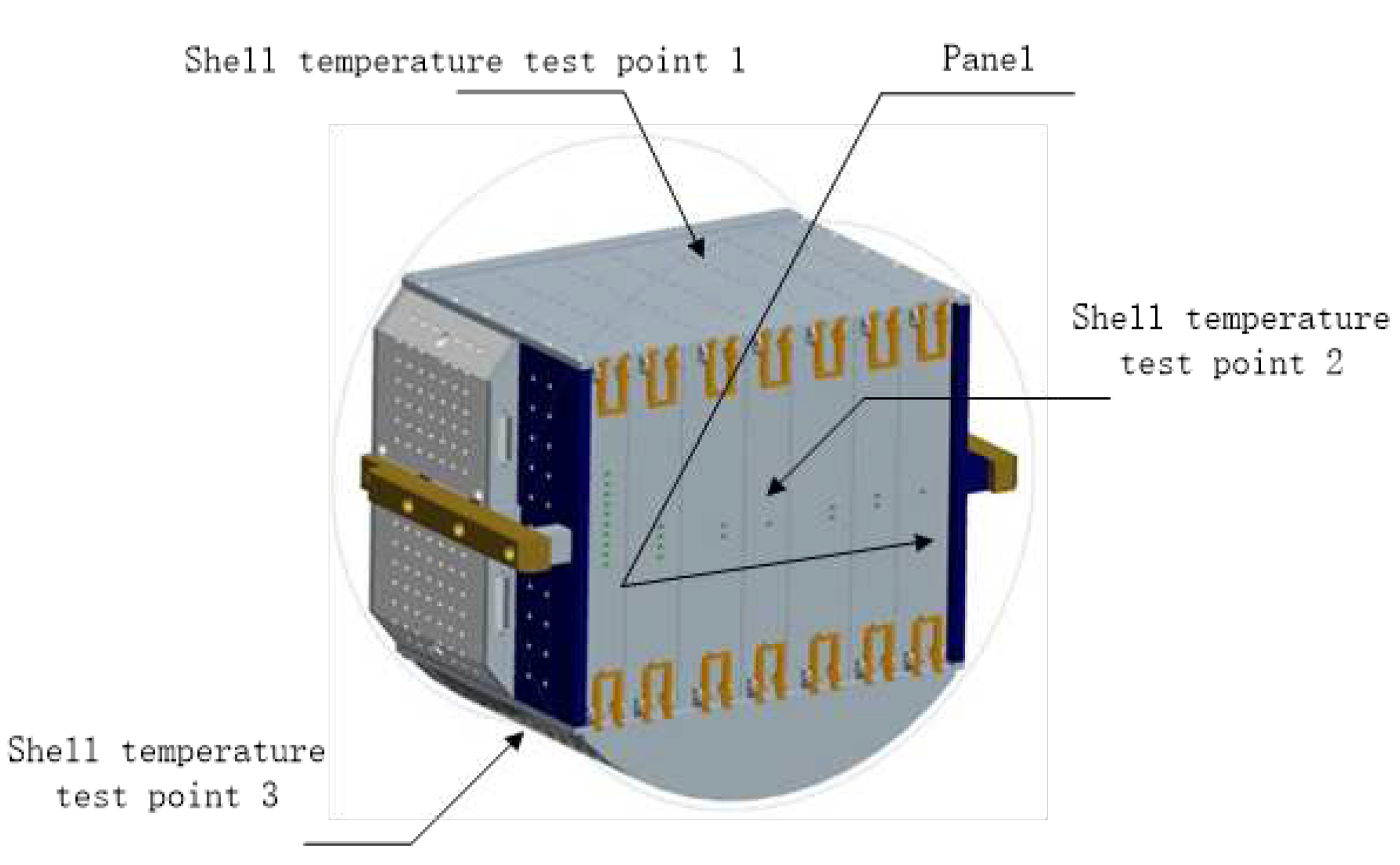

Figure 6 shows the schematic diagram of the overall heat dissipation structure after the assembled panel are finished on case.

The thermal conductivity in the PCB thickness direction (i.e.vertical direction) is much smaller than that in the plane direction. In order to improve the thermal conductivity in the thickness direction, the heat dissipation hole can be designed directly below the bottom of the heating source. According to the optimization theory of heat dissipation hole [

15], 0.45mm diameter of the inner hole of the heat dissipation hole is the optimal diameter, and the thermal conductivity can be increased by about 6.5%. Filling with a material with high thermal conductivity such as solder can increase thermal conductivity by about 35%.

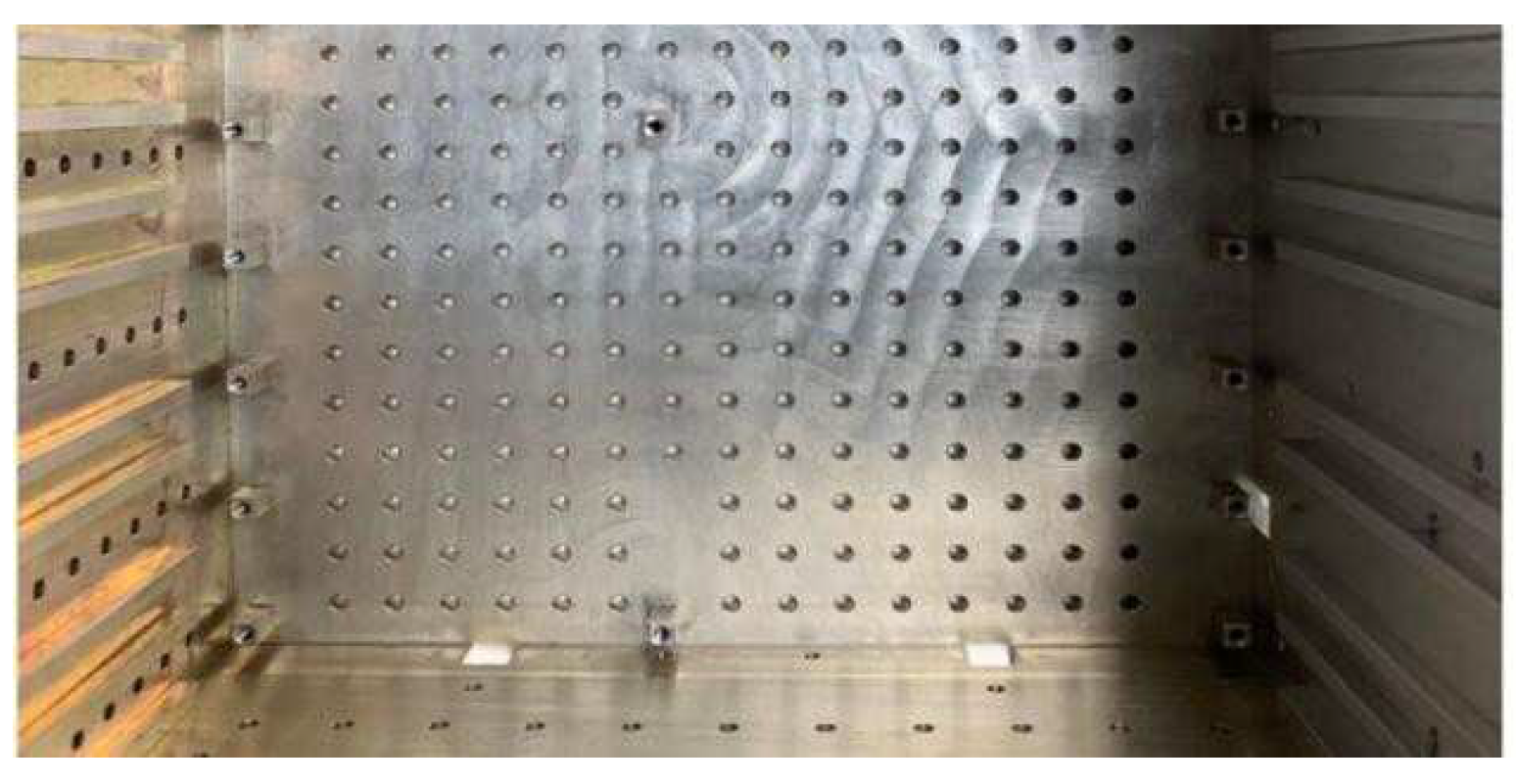

As shown in

Figure 7, the aperture of PCB in this paper is set to 0.45mm. The treatment method of hole of covered oil is adopted, and the hole spacing is kept 1mm. In order to further increase the heat dissipation effect, all the places through holes are covered with copper (the red part in

Figure 7) to increase the heat dissipation area.

According to the convection heat transfer formula [

16]:

is convective heat transfer coefficient and its unit is w/(

·℃).

A is the heat transfer area (

);

is the surface temperature (℃);

is the temperature of cooling gas (℃). In order to change the heat dissipation performance of the case, the convective heat transfer coefficient or the heat transfer area can be changed, and the heat transfer area is directly represented by the area of the heat dissipation hole. Therefore, the layout of the heat dissipation hole and the opening rate of the heat dissipation hole become an important factor of the heat dissipation efficiency. In order to enhance the heat dissipation effect of natural and forced air cooling, the heat inside the electronic case is transferred to the outside in a timely manner, while taking into account electromagnetic compatibility and aesthetic design principles. Mechanical circular holes are designed around the case(at the bottom and at the top) to expand the heat dissipation channels. The diameter of the circular holes is set to 2mm and the gap between the holes is set to 5mm, as shown in

Figure 8.

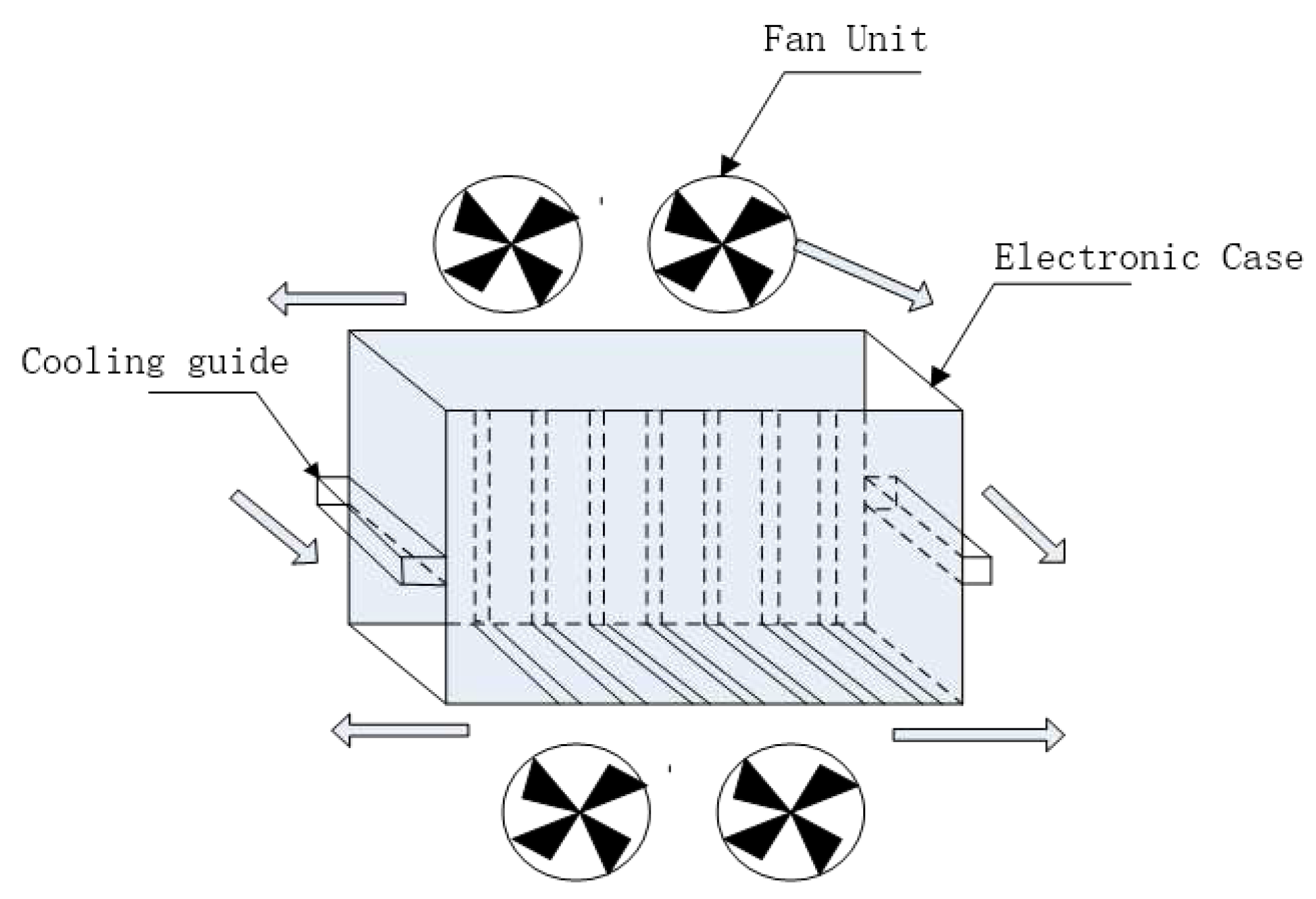

3.2. The design of forced air cooling

Forced air cooling is usually more effective than thermal conduction, and the commonly used forced air cooling method is mainly the use of fans. Under the condition of satisfying the air volume, fans with high air pressure should be selected as far as possible. The structure of the cooling air duct should avoid 90° bending Angle to ensure that the heat generated by the switching power supply can be dissipated in time [

9]. The fan designed in this paper is independent of the electronic case, and is placed at the top and bottom of the case at a distance of about 5cm. The Angle of the cooling air duct is designed to be 0°. The heat trend diagram is roughly shown as the arrow in

Figure 9. The installation inside the case takes up large space, which helps to reduce the size of the electronic case. The introduction of fans will inevitably increase the power consumption and noise of the system, and the reliability will be reduced to varying degrees. Therefore, under the condition that the normal operating temperature is not higher than the preset shell temperature, only conduction heat dissipation is used in this paper. The heat transfer and heat dissipation channels of forced air cooling are as follows: DC/DC module interior → module shell → graphene → surface of MG-Al alloy cold plate → fin structure → internal environment of the chassis → MG-Al alloy surface of the case → external environment of the case. From the direction of heat dissipation, it can be seen that forced air cooling is only conducive to speeding up the effect of conduction heat dissipation, therefore overall cooling effect mainly depends on thermal conduction.

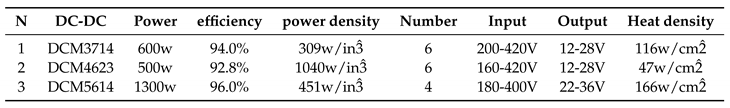

3.3. The design of high-power density power array

The efficiency of DC/DC determines the thermal power consumption, and the thermal power consumption determines the operating temperature [

5], therefore, the selection of high-efficient DC/DC is helpful to significantly reduce the caloric value from the heat source. The theoretical formula of thermal power consumption is shown as follows:

P is the thermal power. is the inherent output power of DC/DC module. Y is the efficiency of DC/DC output at full load. is the thermal power coefficient. When the inherent output power is unchanged, the heating power is mainly determined by the thermal power coefficient. Table 1 shows the corresponding relationship between DC/DC full-load output efficiency and thermal power consumption coefficient. It can be seen from the table that the higher the efficiency, the lower the thermal power consumption coefficient. Every 1% increase in efficiency, the temperature rise per unit time can be reduced by at least 5%. When the efficiency is increased by about 10%, the thermal power consumption can be significantly reduced by about 69% compared with the initial state. Therefore, the improvement of efficiency is more effective than simply optimizing the heat dissipation channel or heat dissipation structure.

Therefore, according to the "Relationship between DC/DC efficiency and thermal power consumption coefficient" (as shown in

Table 2), DCM Chip series power supply of VICOR Company is mainly selected to form the power array (as shown in

Table 3). It is an isolated DC-DC converter with stabilized voltage, which can run in a wide range of unstabilized voltage input to generate isolated output. Efficiency can be up to 96%(output power greater than 90% of the design power) and power density can be up to

, with the characteristics of input under-voltage protection, output over-voltage, over-current, short circuit protection, over-temperature protection.

DC/DC power density [

16] is defined as:

represents DC/DC power density.

indicates the maximum output power of DC/DC.

represents the surface area or volume (

or

) of the DC/DC orthographic projection. However, the current definition of power density in the design of small electronic case only depends on the evaluation of a single DC/DC module. When several DC/DC are used to form a power array to form a systematic design, the power density of a single module cannot represent the power density of the whole system. In addition, the actual output power is far from the maximum output power, resulting in the higher power density. In this paper, a three-dimensional case power density is defined, which can reflect the thermal design index of electronic case in a more comprehensive way:

indicates the power density of the electronic case (

).

indicates the maximum output power (w) of all DC/DC modules in the case.

N indicates the actual power output percentage (%).

stands for the volume of the design case cavity (not including the thickness of the case)(

). For large electrical equipment, the power may be more than 3-5kw. If the overall design and packaging of a high power supply, the application of the device stress will be very large. The corresponding volume and cost will be multiplied. If multiple low-power power sources are used in parallel to achieve high power output (such as 3 power sources(1kw) in parallel to achieve 3kw output power), the difficulty of design will be reduced obviously. Meanwhile, from the perspective of the system, it is beneficial to save costs and improve reliability. In order to realize the parallel output of power modules, parallel current sharing technology is usually adopted [

17]. In this paper, each DC/DC series adopts the design of parallel current sharing(as shown in

Figure 10). The input end is added with a fuse tube, several 3714/4623/5614 DC/DC are connected in parallel, and each output end is connected with a diode (to prevent the load voltage recoil-back to protect the power module), and then connected with electronic load 1-3. Finally, the maximum power output is increased to 3.6kw. When any DC/DC fails at high temperature or needs to be cooled temporarily, the current of this module decreases. However, the current of other DC/DC modules increases to compensate for the power loss and ensure the normal operation of back-end loads. By using parallel current sharing technology, the power array designed in this paper contains 16 DC/DC modules, and the total power can reach 10kw under 90% load test. The average power density of DC/DC is higher than

, and the average power density of the electronic case is up to

.

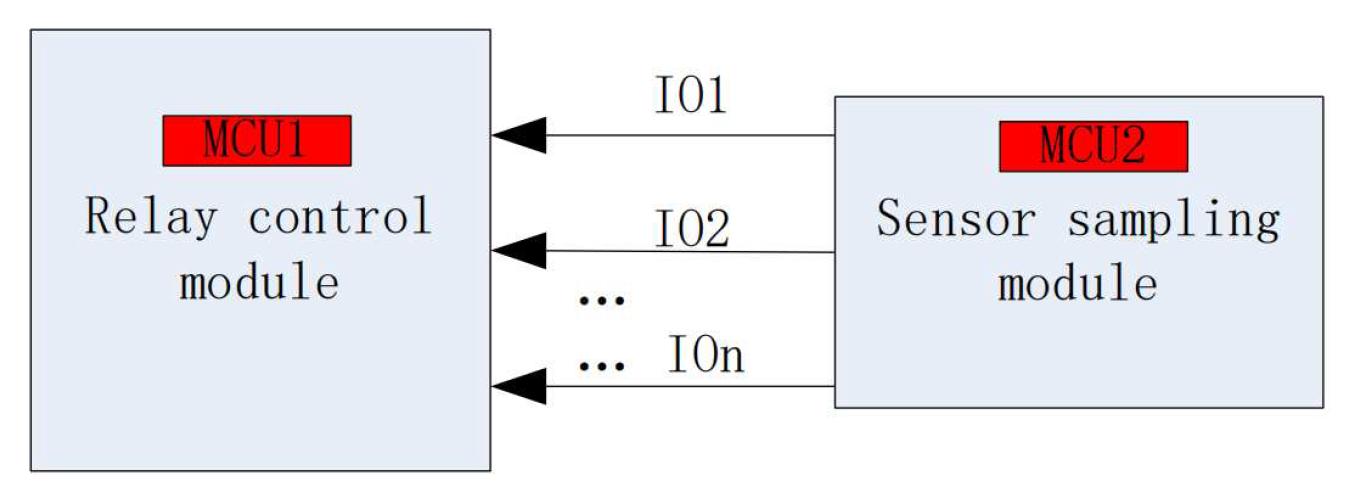

3.4. Design of automatic control components

3.4.1. The design of Automatic control module

The automatic control system mainly includes sensor sampling module and relay control module. The relationship between the two is shown in

Figure 11. Each IO corresponds to a DC/DC shell temperature test point or shell temperature test point on the surface of the case. In fact, an MCU communication link is built between the two modules. When the relay control module detects a high-level signal sent by the sensor sampling module, the MCU1 control mechanism located in the relay control module will be triggered.

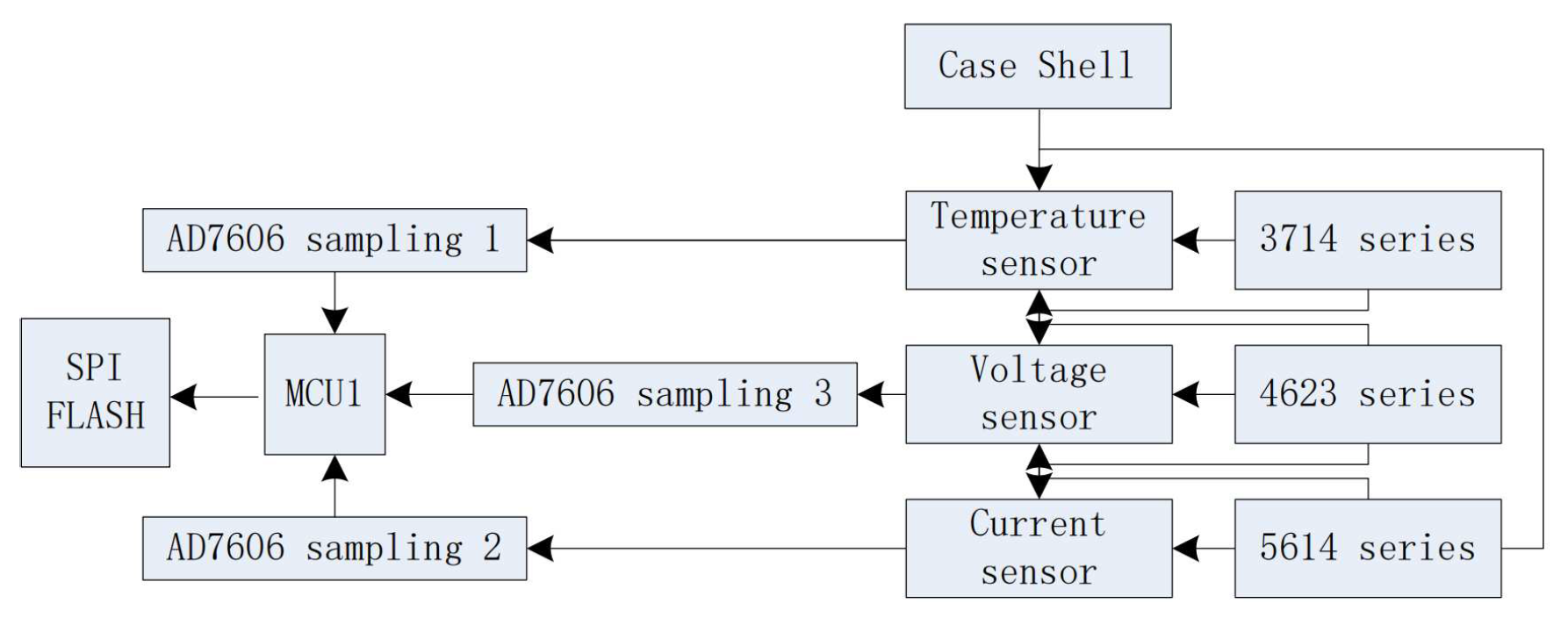

The sensor sampling module is shown in

Figure 12. The sensor module mainly adopts several temperature, voltage and current sensors to collect the three analog quantities of the single DC/DC module in each series. The temperature sensor is DS18B20, which is a single bus digital temperature sensor from Dallas, USA. The temperature measurement range is -55-125 ℃, and the temperature value of the analog can be converted and expressed with the resolution of 9, 10, 11 and 12 bits. The unit temperature values corresponding to the above 4 resolutions are 0.5, 0.25, 0.125 and 0.0625 degrees Celsius [

18]. It can overcome the shortcoming of traditional control mode and realize accurate, fast and reliable temperature acquisition and control. In this paper, 9-bit resolution (corresponding temperature value is 0.5°) is used for temperature sampling, and Analog quantity is converted into digital quantity through AD7606 sampling chip to access MCU. Sampling chip is A/D conversion chip called AD7606, which is launched by American Analog Device Company. The high performance ADC has the characteristics of high resolution, low power consumption and synchronous sampling. Among them, two CONVST pins enable the chip to have the advantage of eight-channel synchronous sampling. Meanwhile, the chip integrates anti-aliasing filter, high-speed serial parallel interface and other modules, making the design of the data acquisition system easier [

19]. Each group of sampling chips includes two AD7606 chips. The final sampling and detection results are stored in SPI FLASH for easy viewing.

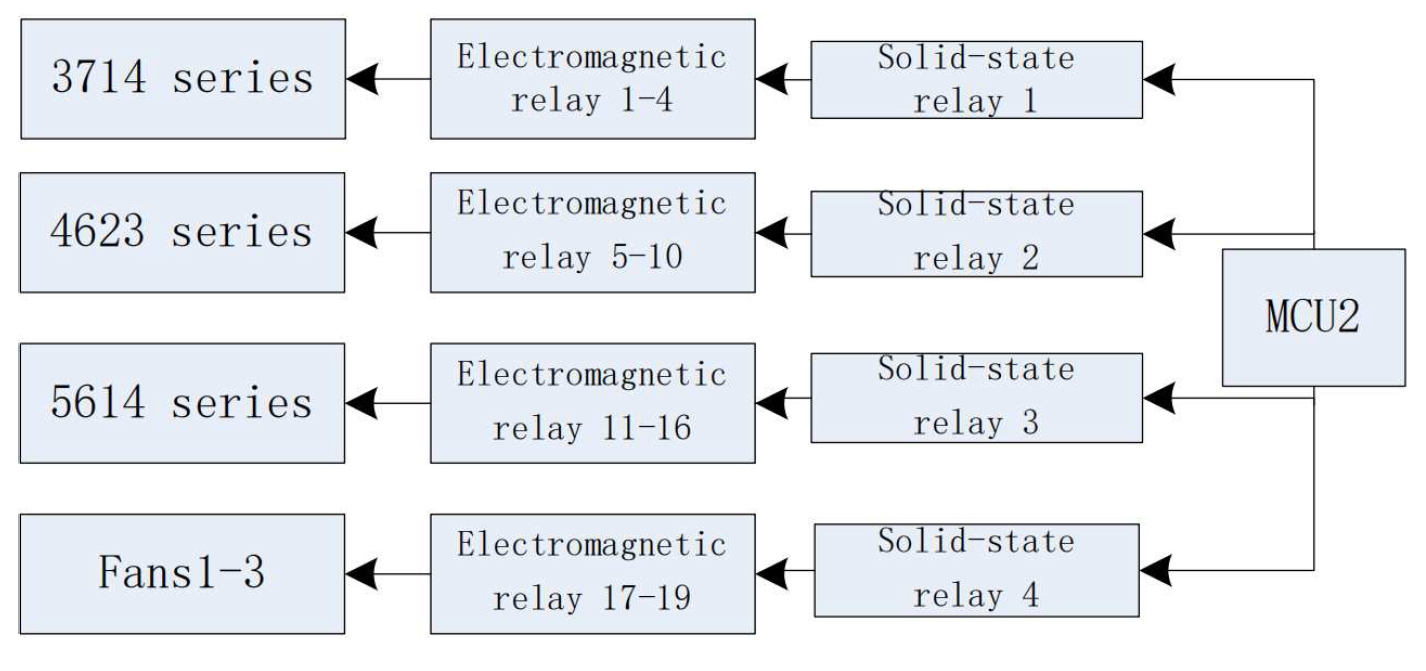

The application of relay plays am important role in the era of automation. It mainly plays a similar role as a switch, so as to achieve the purpose of protecting the operation of electrical appliances and the safety of the line. According to the classification standard of relay, it can be divided into solid state relay, electromagnetic relay and thermal relay. When the temperature of the relay is too high, the metal sheet will be heated and appear bending, resulting in low reliability [

20]. In view of the fact that the relay in this paper is mainly used in high temperature confined space, the combination control mode of single-point solid-state relay and multi-point electromagnetic relay is adopted as shown in

Figure 13. The specific control process is as follows: MCU gives a high level-signal of IO port to drive the solid-state relay, which then triggers the electromagnetic relay, and then enables and controls a DC/DC or fan of the power module to finish startup and shutdown.

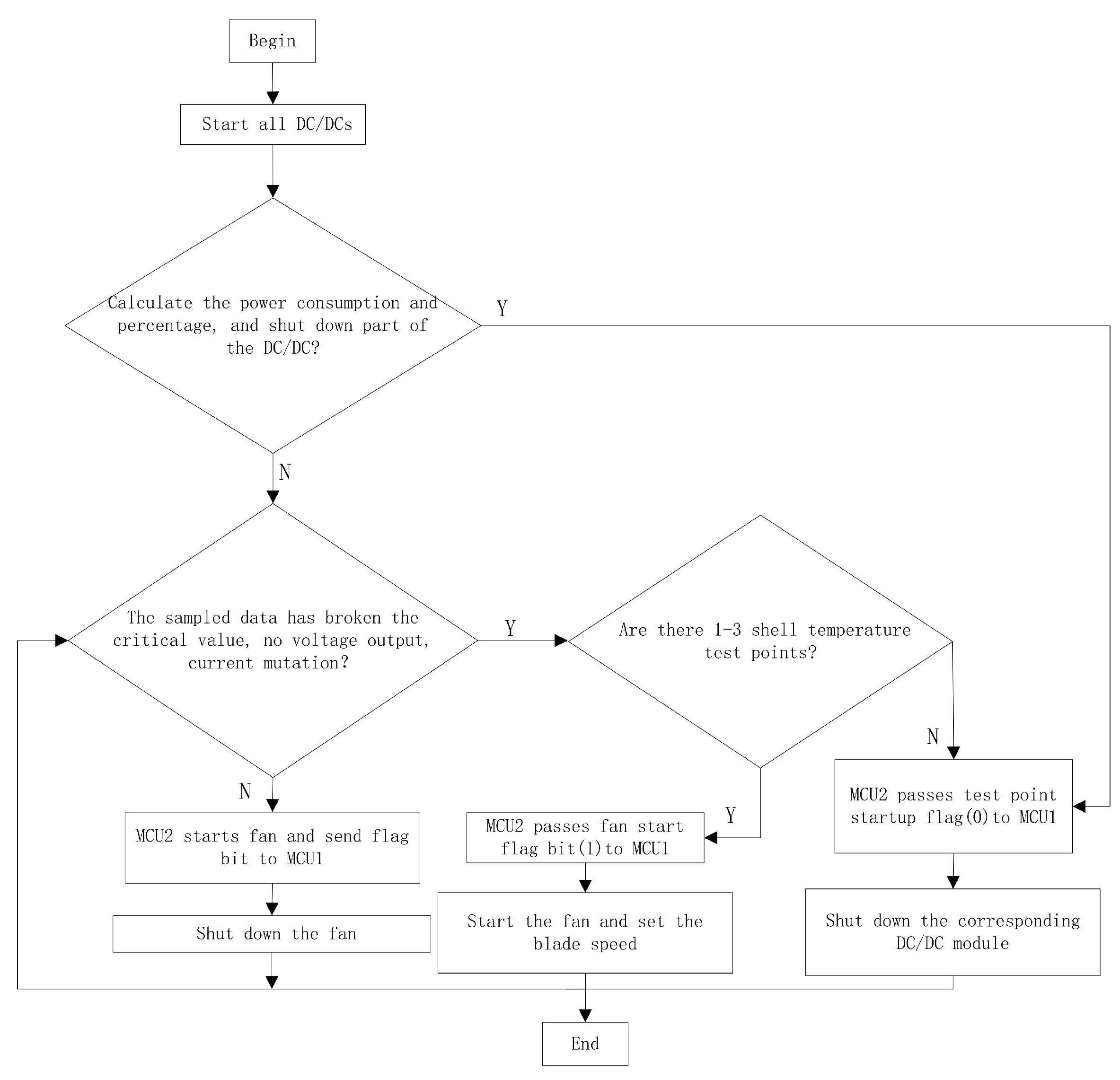

3.4.2. Design of automatic control software

In general, it is recommended that the shell temperature of a power module be 10-15° lower than the highest shell temperature, and the highest shell temperature of a DC/DC module is 100°. Therefore, the recommended operating temperature of a single DC/DC module should be controlled within the range of 90°. The temperature test point of a 1-3 shell should be controlled within 85°, and the maximum temperature value should not exceed 90°. In the design of forced air cooling cooling mode, the heat dissipation capacity of the fan is often positively correlated with the speed of the blade. while the speed cannot be connected with the heat dissipation demand, resulting in the fan set and heat dissipation demand being two unrelated systems, they can not achieve synchronization [

21]. Therefore, in this paper, the speed of the fan bank is set according to the temperature of the test shell. Meanwhile, in order to avoid energy waste, the speed is set as three levels(low, medium and high). Low, medium and high correspond to 0-30%, 30%-60% and 60%-100% load power consumption respectively. According to the sampled data (temperature, voltage, and current of the monitoring point are obtained every 500ms and stored in the SPI FLASH), the MCU1 determines the critical value. According to the critical value, the MCU1 controls the start and close of the DC/DC module or fan group. The critical value of single DC/DC startup/shutdown is shell temperature 90° and power feedback flag bit 1 (if the load power consumption is lower than 30%, MCU enables one-third of the DC/DC output. When the load power consumption is 30% to 60%, MCU enables two-third of the DC/DC output. When the load power consumption is greater than 60%, MCU enables all DC/DCs output), no voltage output, abrupt current. The critical value of shell temperature test point 1-3 is 85°. Startup flag bit 1 indicates that the DC/DC module is enabled, and 0 indicates that the DC/DC module is disabled. Detailed control logic is shown in

Figure 14 below.

4. Analysis of test results and comparison of related performance parameters

The test equipment is shown as

Table 4.

4.1. Analysis of test results

The electronic load is placed at the output end of DCM3714, 4623 and 5614 series power supply respectively for on-load test of power array. In addition to the DC/DC surface, the detection points of the shell temperature sensor are also placed at the center, top and bottom of the end cover of the panel of the electronic case, as shown in

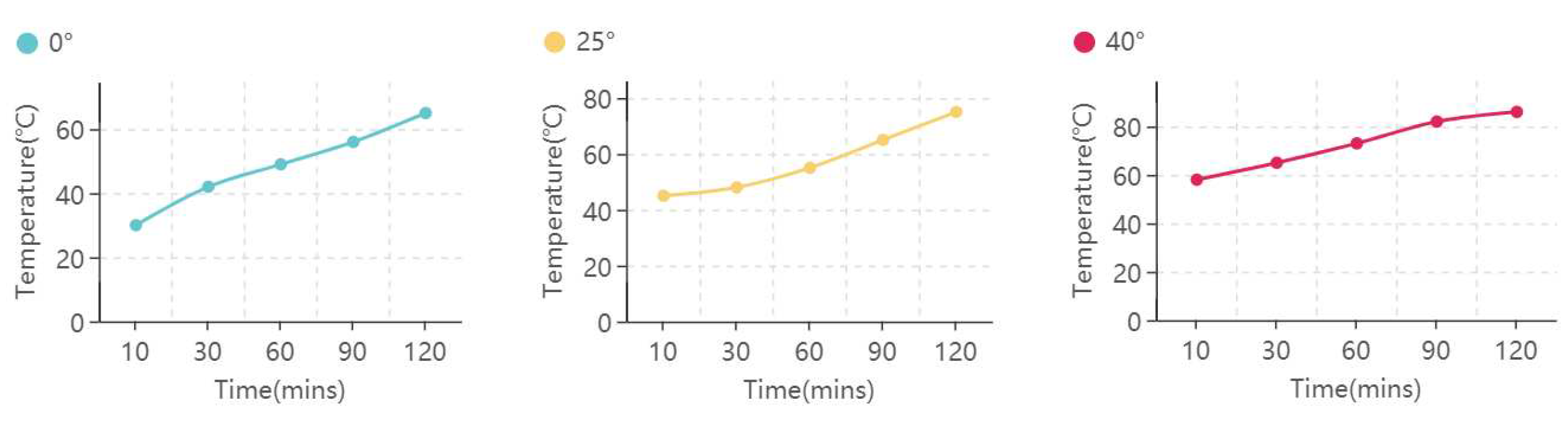

Figure 15, which are defined as shell temperature test points 1-3. The environmental temperature of the test was 0°, 25°, 40°, and the test altitude was 2000m. The absorbed power of the electronic load was set as 30%, 60%, and 90% according to the combined output power of each series of power supply DCM. Since No.2 shell temperature test point is located at the end cover of the panel and is close to DC/DC, it can be closer to the shell temperature during DC/DC operation. Therefore, the sensor reads the No.2 shell temperature test point (the integral part of temperature is taken for convenience of analysis) as the average temperature point of the electronic case so that indexes are analysed and line diagrams can be drawn.

We can see the change trend of temperature with time from

Figure 16: under different ambient temperature conditions, the temperature of each curve increases with time. After 120 minutes of load test, the temperature of No.2 shell temperature test point was effectively controlled within the safe range of 85°. By reading the data monitored by the voltage and current sensors in SPI FLASH, the DC/DC shell temperature briefly exceeds the recommended working temperature when the load is 90%, but the whole power array does not have over-temperature protection. When the time increased to about 90 minutes, the temperature growth rate of No.2 shell temperature test point gradually slowed down and gradually stabilized after 120 minutes. The main reason is that part of the DC/DC surface shell temperature exceeds the safe value range. MCU starts the fan to accelerate the speed of natural heat dissipation and conduction heat dissipation of the case surface. It can be seen that the effect of conduction heat dissipation is limited in a certain period of time. To optimize conduction heat dissipation, forced air cooling can be used to reduce the ambient temperature of the case. Through high temperature and high load limit test, the whole temperature of the electronic case is within the safe range. The structure and design of the closed automatic cooling case are reasonable and feasible.

From

Table 5, No.2 shell maximum temperature for 2h test reduce by from 4.6%-9.2% at different environmental temperature. If environmental temperature continue increasing, the cooling effect will weaken but the shell temperature is still controlled within the safe limits.

4.2. Analysis of test results

In order to comprehensively evaluate the automatic cooling case of high-density power arrays designed in this paper, the relevant performance parameters will be compared with the existing representative small mature cooling case and power modules. The small signal processing case designed by Peng [

22,

23] as the control group 1. The electronic case designed by Yu [

6] served as the control group 2. The electronic case designed by Li [

3] serves as the control group 3.

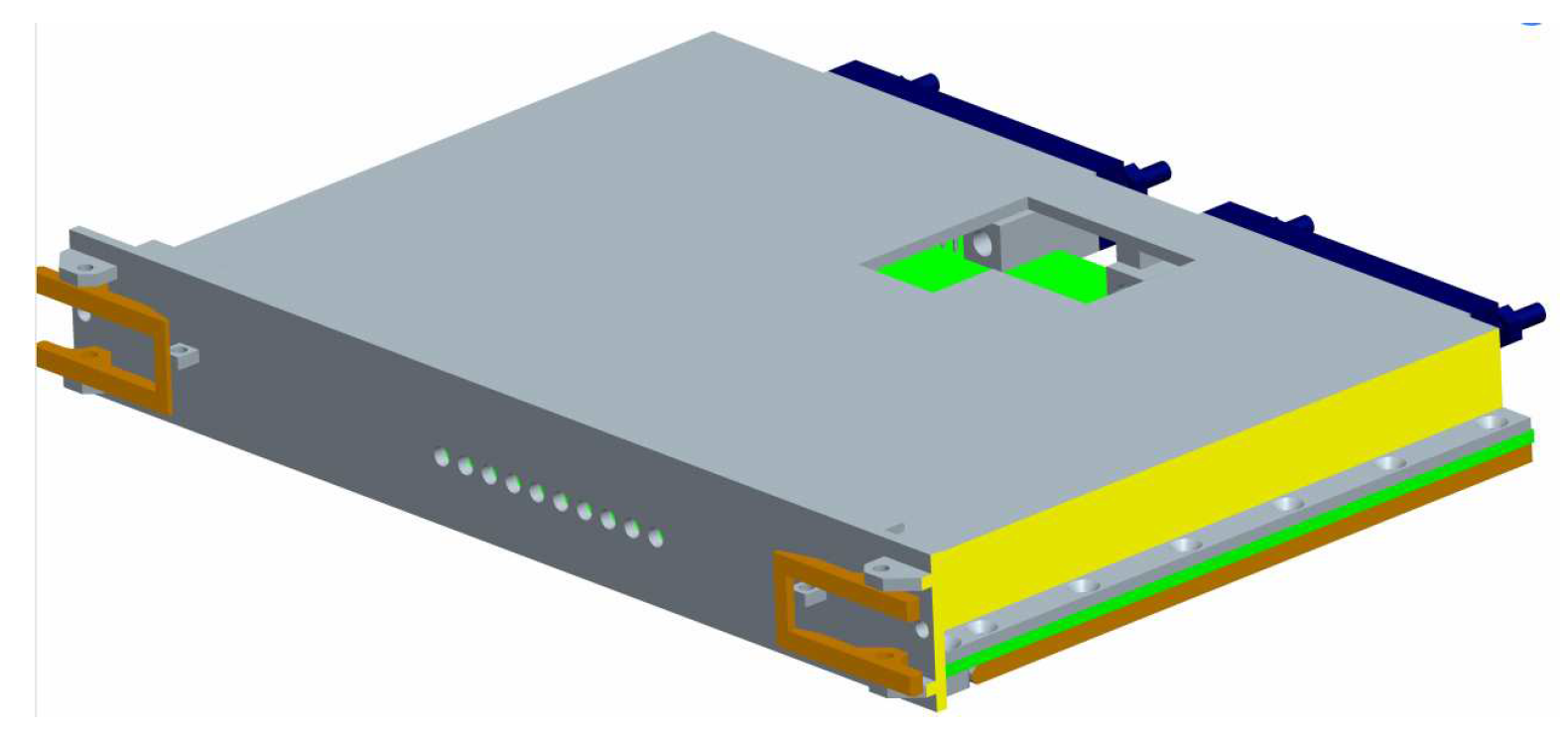

Table 4 lists the performance parameters of the electronic cooling case.

Table 6.

DC/DC series power supply information.

Table 6.

DC/DC series power supply information.

Firstly, it can be seen from

Table 4 in control G1-G3, water cooling is not used in existing mature, miniaturization case (modules) design. Secondly, Temperature monitoring and control design are not adopted. if there is over-temperature, power module may be destroyed. Thirdly, The design power of the whole system is limited below kilowatt level, and the real high power design is not realized, and the efficiency maximization test under the condition of high load output is not carried out. In addition, the volume of the electronic case (module) has been miniaturized, but the power density is far from the high power density design requirements. Because of relatively low thermal power consumption, heat dissipation cannot be fully reflected. For example, control G3 did not actually use the case and only used a single module as a power source for testing and design. It only stayed in the test stage with poor applicability. Finally, Compared with control G1-G3, the electronic case with intelligent temperature control function, high reliability designed in this paper has passed 90% load test and the heat dissipation effect is obvious. The output power of the whole system reaches 10kw level and the load test power is 16 times of control G3. Power density of the case with load is about 10 times higher than control G1 and increase 38% compared with power density of the G3 with load.

5. Conclusion and future work

With the wide application of miniaturized multi-board case with high-power and high-density thermal design has become an essential step. However, most of the existing solutions stay in the thermal simulation stage, the optimization of heat dissipation structure or way. There are no real high density design and load high power test. In addition, intelligent monitoring and temperature regulation measures are also not adopted. In this paper, a miniaturized and high-power density electronic case is designed. The power array is composed of DC/DC modules with high efficiency and the technology of parallel current equalization. In order to take into account the surface strength and electromagnetic compatibility of the electronic case, magnesium and aluminum alloy materials are used to enhance the thermal conductivity. Heat dissipation mode accelerates conduction heat dissipation on the basis of optimizing heat dissipation holes, adding fan groups to enhance heat exchange on the surface and inside of conduction case. Designing automatic control module are designed to form monitoring and feedback control mechanism. The heat dissipation design of the miniaturized electronic case is proved to be able to guarantee its normal operation after high temperature and high load environment test. Compared with the existing mature miniaturized electronic case, the load power test is 16 times of the existing load power. When the heat dissipation effect is the same, the power density is about 10 times higher and the performance is better.

The electronic case designed in this paper is installed in a fixed and closed environment on land for testing. If it is used in high altitude or deep water high-speed moving environment, some DC/DC modules may fail to work due to changes caused by shock, vibration and pressure, and temperature between internal and external heat dissipation channels, resulting in decline of output power. The next step is to simulate high altitude or deep water dynamic operating environment and test electronic case with load to verify the effectiveness and reliability of the thermal design.

Author Contributions

Conceptualization, Z.C. and H.F.; methodology, Z.C. and C.Y.; software and data curation, Z.C.; validation and writing—original draft preparation, Z.C.; writing—review and editing, Z.C., H.F. and C.Y.; supervision, F.H. and G.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

We would like to express our gratitude to Guoguang Zhang and Chong Yang for their meaningful support for this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- lV, Y. Research and design of a two-channel high-side intelligent power switching circuit. MA thesis, University of Electronic Science and Technology of China, ChengDu, 2022.

- Ben, A.; Xie, P.; Huang, F. Yu, H. Analysis and Design of Heat Dissipation of Modular DC Power Cabinet in Substation. Machinery Design and Manufacturing Engineering 2020, 49, 57–61. [Google Scholar]

- Li, Y.; Li, Z.; Gao, L. Structural Thermal Design of a High Power Density Closed Power Supply. Electro-mechanical Engineering 2012, 28, 15–36. [Google Scholar]

- Tan, H. Optimization Design and Simulation Analysis of Heat Dissipation of an Airborne Equipment Power Cabinet. South China Agricultural Machinery 2015, 52, 138–140. [Google Scholar]

- Yang, T. Structure and Heat Dissipation Analysis of Shipborne Water-cooled Cabinet. Ship Electronic Countermeasures 2022, 45, 106–110. [Google Scholar]

- Yu, Q.; Ge, X. Heat dissipation Optimization of High Power Supply Module. Electronic World 2021, 08, 170–171. [Google Scholar]

- Fu, P.; Wen, W.; Li, Y. Research on Ventilation and Heat Dissipation Structure and Method of a New Energy Storage Power Supply. Technology and Market 2020, 27, 33–34. [Google Scholar]

- Zhang, G.; Gao, Z.; Yang, L.; Zhang, C. Design and Simulation Analysis of Heat Dissipation in Dense Arrangement of Multi-Switch Power Supply. Road Machinery and Construction Mechanization 2020, 37, 85–89. [Google Scholar]

- Huang, X.; Li, D.; Wei, H.; Hou, S. Optimization design of Heat Dissipation for High Power Microwave Power Supply. Automation and Information Engineering 2023, 44, 39–45. [Google Scholar]

- Niu, Y.; Gan, F.; Gao, M.; Shi, J. Thermal resistance Model Establishment and Heat dissipation Design of DC/DC Power Module. Power Electronics Technology 2021, 55, 137–140. [Google Scholar]

- Zhou, Z.; Tang, H.; Yang, C.; Liu, L. Research on Improving the Working Life of Power Module. Shanghai Electric Technology 2014, 07, 14–17. [Google Scholar]

- Li, X.; Cao, W.; Pei, Q. Thermal properties of AZ91D. Journal of Henan Polytechnic University 2010, 29, 685–688. [Google Scholar]

- Xing, Y.; Xu, K.; Liu, Y.; Zhang, L.; Qi, C. Research progress of graphene’s high thermal conductivity Mechanism and Heat Transfer Enhancement. Chemical Engineer 2015, 29, 54–60. [Google Scholar]

- Yan, L.; Huang, H.; Li, S.; Qu, G. Research on the Standard and Application of Aviation Miniaturized Chassis. Measurement and Control Technology Magazine 2021, 01, 484–487. [Google Scholar]

- Li, Z. Calculation Method and Optimization of Thermal Conductivity of Heat dissipation Hole in Printed Circuit Board. Modern Electronics Technique 2014, 37, 143–147. [Google Scholar]

- Yu, G.; Li, F.; Tian, H. Design of ultra-thin Switching Power Supply with High Power Density. Application of Electronic Technique 2021, 01, 484–487. [Google Scholar]

- Shuai, W. Design of output Parallel Current Sharing Circuit. Electronic Products World 2023, 30, 95–97. [Google Scholar]

- Yang, Y. Design of temperature monitoring system based on single chip microcomputer and DS18B20. Journal of Nonferrous Metal Design 2022, 49, 66–69. [Google Scholar]

- Jiang, S.; Wang, B.; Yu, L.; Yu, T. Design and implementation of Multi-channel Data Sampling System Based on FPGA+AD7606. Electronic Design Engineering 2022, 30, 103–107. [Google Scholar]

- Yang, L. Analysis of Application Strategy of Relay in Automation Engineering. Industrial Innovation Research 2023, 02, 154–156. [Google Scholar]

- Xu, Yan. An Intelligent Cooling System for Hydraulic Fan Motor. Hydraulics Pneumatics and Seals 2023, 43, 63–65. [Google Scholar]

- Yang, A.; Yang, J.; Sun, B.; Yao, C. Modeling Design of Heat Dissipation Hole in Special Case Based on Icepak Analysis. Journal of Machine Design 2022, 39, 143–147. [Google Scholar]

- Peng, H.; Hu, J.; Tao, G. Design of Heat Dissipation in Portable Miniaturized Signal Processing Case. Electro-mechanical Engineering 2020, 36, 18–21. [Google Scholar]

Figure 1.

Side view of Conduction heat dissipation structure.

Figure 1.

Side view of Conduction heat dissipation structure.

Figure 2.

Top view of Conduction heat dissipation structure.

Figure 2.

Top view of Conduction heat dissipation structure.

Figure 3.

Three-dimensional diagram of PCB.

Figure 3.

Three-dimensional diagram of PCB.

Figure 4.

Cutaway view of dissipation structure of electronic .

Figure 4.

Cutaway view of dissipation structure of electronic .

Figure 5.

Schematic diagram of the bottom of the electronic case.

Figure 5.

Schematic diagram of the bottom of the electronic case.

Figure 6.

Schematic diagram of the overall heat dissipation.

Figure 6.

Schematic diagram of the overall heat dissipation.

Figure 7.

PCB Copper-covered heat sink.

Figure 7.

PCB Copper-covered heat sink.

Figure 8.

heat emission hole of electronic case.

Figure 8.

heat emission hole of electronic case.

Figure 9.

Schematic diagram of forced air cooling of electronic case.

Figure 9.

Schematic diagram of forced air cooling of electronic case.

Figure 10.

Parallel current equalizing output mode.

Figure 10.

Parallel current equalizing output mode.

Figure 11.

automatic control system.

Figure 11.

automatic control system.

Figure 12.

sensor sampling module.

Figure 12.

sensor sampling module.

Figure 13.

relay control module.

Figure 13.

relay control module.

Figure 14.

Control logic flow chart.

Figure 14.

Control logic flow chart.

Figure 15.

Temperature curve of No.2 shell temperature test point. (a) 30% Load. (b) 60% Load. (c) 90% Load.

Figure 15.

Temperature curve of No.2 shell temperature test point. (a) 30% Load. (b) 60% Load. (c) 90% Load.

Figure 16.

Shell temperature test point temperature curve of DCM3714 with 90% load.

Figure 16.

Shell temperature test point temperature curve of DCM3714 with 90% load.

Table 1.

Heat dissipation solution.

Table 1.

Heat dissipation solution.

| Classification |

Solutions |

Reference |

physical structure

heat dissipation |

natural air cooling |

[3] |

| conduction cooling |

[3]

|

| forced air cooling |

[4] |

| circulating water cooling |

[5] |

modeling optimization

heat dissipation |

Thermodynamic

analysis software |

[5]

|

Table 2.

DC/DC efficiency and thermal power consumption coefficient.

Table 2.

DC/DC efficiency and thermal power consumption coefficient.

| DC/DC efficiency at full load output |

Thermal consumption coefficient |

| 86% |

0.16 |

| 89% |

0.12 |

| 90% |

0.11 |

| 92% |

0.09 |

| 95% |

0.05 |

Table 3.

DC/DC series power supply information.

Table 3.

DC/DC series power supply information.

Table 4.

Related test equipment and functions.

Table 4.

Related test equipment and functions.

| Equipment |

Function |

| Power Array |

Test source |

| Several 300V high voltage power supplies |

Supply Array power |

| Electronic loads |

Test the performance of the power arrays |

| Temperature, voltage, current sensors |

Monitor running data of the power array |

| Several multimeters |

Monitor DC/DC abnormal data |

| Automatic control module |

Control DC/DC startup and shutdown |

Table 5.

No.2 shell highest temperature comparison diagram for 2h test.

Table 5.

No.2 shell highest temperature comparison diagram for 2h test.

| Environmental Temperature |

Before cooling |

After cooling |

Percentage of cooling |

| 0° |

72° |

65° |

9.2% |

| 25° |

81° |

75° |

8.0% |

| 40° |

90° |

86° |

4.6% |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).